#filler particle size

Explore tagged Tumblr posts

Text

The Latest Innovations in Dermal Filler Technology

Dermal fillers have become one of the most sought-after non-surgical cosmetic treatments due to their ability to restore volume, smooth wrinkles, and enhance facial contours. Over the past few years, significant innovations in dermal filler technology have emerged, leading to safer, longer-lasting, and more natural-looking results. In this article, we’ll explore the latest advancements in dermal filler technology and how they’re changing the aesthetics industry.

1. Biodegradable Fillers and the Push for Natural Results

One of the most significant trends in dermal filler technology is the move toward biodegradable materials. Fillers like hyaluronic acid (HA), calcium hydroxylapatite (CaHA), and poly-L-lactic acid (PLLA) are all biocompatible, meaning they break down naturally in the body over time.

The shift toward biodegradable fillers allows for safer treatments and more natural results. As these materials break down, they leave behind collagen stimulation and skin rejuvenation. This is in contrast to older filler technologies, which could sometimes feel unnatural or even cause complications in the long term.

The key benefit of biodegradable fillers is that they can provide temporary results, giving patients the option to decide if they want to continue or adjust their treatments. This has led to more personalized care and a focus on natural enhancement rather than drastic changes.

2. The Rise of Combination Fillers

Another exciting development in dermal filler technology is the use of combination fillers that combine multiple active ingredients for enhanced results. For example, Juvéderm Voluma XC combines hyaluronic acid with a unique cross-linking process that improves longevity and creates a firmer texture for deep injections, like in the cheeks.

Combination fillers offer multi-dimensional benefits by addressing various concerns at once. They may include a blend of ingredients that add volume, improve hydration, and stimulate collagen production. This multi-functional approach ensures that the filler performs well across multiple treatment areas, from the cheeks to the jawline, providing a more comprehensive treatment for facial rejuvenation.

3. Fillers Designed for Specific Areas

Innovations in dermal filler technology are also allowing for targeted treatments for specific facial areas. Newer filler formulations are designed to address the unique demands of different regions of the face, providing tailored results.

For example, under-eye fillers are now more refined, specifically designed to fill in hollow areas without causing overfilling. The soft consistency of these fillers ensures a natural look while restoring volume and minimizing dark circles.

In contrast, jawline fillers are formulated with more dense properties to provide structural support. These fillers can be injected deeper into the skin for more substantial lifting and contouring of the jaw area.

By using area-specific formulations, injectors are able to target precise concerns, such as nasolabial folds, temples, and cheeks, resulting in more customized and natural outcomes.

4. Nanotechnology in Dermal Fillers

Nanotechnology is also making waves in the dermal filler industry, particularly in how the filler particles are engineered. Nanoparticles are smaller than traditional filler particles, which means they can better integrate into the skin for a smoother, more uniform appearance.

The use of nanotechnology allows for more controlled release of the filler, providing longer-lasting and more even results. It can also reduce the risk of complications, such as lumps or migration, which are often caused by larger, less refined filler particles.

Nanoparticles can also enhance the body’s natural collagen production by being absorbed more gradually, leading to more subtle and natural improvements over time.

5. Cross-Linked Fillers for Longer Lasting Results

The process of cross-linking has revolutionized dermal filler technology by improving the strength and longevity of fillers. Cross-linking refers to the method of bonding hyaluronic acid molecules together, creating a more stable, cohesive gel that stays in place longer and provides better structural support.

Cross-linked fillers, like Restylane Lyft or Juvéderm Voluma, have a higher degree of stability, making them ideal for areas that need a firmer structure, such as the cheeks, chin, or jawline.

By increasing the degree of cross-linking, fillers become more resistant to breakdown, resulting in longer-lasting results that can persist from 6 months to 2 years depending on the type of filler used.

6. Improved Injection Techniques

Technological innovations aren’t just limited to the fillers themselves. The tools used to administer dermal fillers have also advanced, allowing for more precise and comfortable treatments. For example, micro-cannulas are becoming increasingly popular over traditional needles.

These flexible, blunt-ended tools reduce the risk of bruising and swelling by causing less tissue damage. Micro-cannulas also allow for larger areas to be treated with fewer injection sites, resulting in faster recovery times and more natural results.

7. The Role of Personalized Medicine in Dermal Filler Advancements

With the growing understanding of individual skin types, age-related changes, and genetic factors, dermal filler technology is evolving toward personalized treatments. By analyzing a patient’s unique needs—such as skin elasticity, facial volume loss, and skin texture—injectors can now choose the most appropriate filler for a patient’s specific needs.

This trend in personalized dermal filler technology is leading to tailored treatments that offer more effective results for each patient. The future of fillers may even include the use of genetic testing to predict how individuals will respond to different filler compositions, leading to even more customized solutions.

8. The Future of Dermal Fillers: What’s Next?

Looking ahead, the future of dermal filler technology holds exciting possibilities. Researchers are working on bio-stimulatory fillers that can not only add volume but also actively regenerate tissue and stimulate collagen production over time. These fillers could offer longer-lasting effects and may even reduce the need for frequent treatments.

Additionally, regenerative medicine may play a larger role in dermal filler advancements. By combining stem cell therapy and other regenerative techniques, future dermal fillers could potentially offer permanent results by stimulating the body’s own healing processes.

Conclusion: The Evolution of Dermal Fillers

Innovations in dermal filler technology have made these treatments safer, more effective, and more customizable than ever before. From biodegradable materials to nanotechnology, advancements are leading to longer-lasting results and more natural-looking enhancements. Whether through more refined injection techniques or the use of personalized filler options, the future of dermal fillers is bright and full of possibilities.

For those considering dermal fillers, staying informed about the latest innovations can help you make the best choice for achieving your desired aesthetic outcomes.

#ermal fillers#latest dermal filler technology#biodegradable dermal fillers#hyaluronic acid fillers#calcium hydroxylapatite fillers#poly-L-lactic acid fillers#cross-linked dermal fillers#nanotechnology in fillers#filler longevity#dermal filler brands#soft tissue fillers#facial volume restoration#under-eye fillers#lip enhancement fillers#cheek fillers#jawline fillers#targeted dermal fillers#filler injection techniques#micro-cannula technique#natural-looking fillers#combination dermal fillers#filler particle size#collagen stimulation with fillers#personalized filler treatments#filler safety#non-surgical facial rejuvenation#lifting and contouring fillers#hyaluronic acid vs other fillers#filler for deep wrinkles#filler for facial symmetry

0 notes

Text

I don't plan on doing anything with this because tbh I'm unsure how their personalities would combine to effect a child but-

Had Quentin and Marie-Therese's baby lived here are some name ideas :)

Flint Potterswheel (Calcined flint, crushed then ground to fine particle size. A raw material in various ceramic bodies, used as a filler to attenuate drying shrinkage but it also modifies the fired thermal expansion.)

Matte Potterswheel (Like, Matt, short for Matthew. A dull-surfaced glaze with no gloss. Can also be achieved by sand blasting.)

Craquelle Potterswheel (An intentionally crazed or cracked effect on art pottery, emphasized by rubbing colouring matter into the cracks and re-firing the ware.)

Porsha-Lynn Potterswheel (Porcelain)

6 notes

·

View notes

Text

Understanding The Long-Term PLLA Filler Cost With Devolux

Understanding the long-term PLLA filler cost is a crucial consideration for individuals contemplating injectable treatments, as it relates to their ability to afford the entire course of PLLA filler therapy. This is to avoid the undesirable situation where treatment is interrupted due to insufficient funds, or where the financial burden of purchasing PLLA fillers becomes too great for the patient. To prevent these scenarios, Devolux stands out in the field of medical aesthetics with its durability, effectiveness, and affordability. It is an advanced PLLA filler that combines high-quality materials with cutting-edge manufacturing technology, offering consumers long-lasting results that can persist for two to three years. This significantly lowers the long-term PLLA filler cost for patients, making Devolux the preferred choice for those seeking sustainable beauty enhancements.

Factors Affecting Long-Term PLLA Filler Cost

The long-term PLLA filler cost is influenced by various factors, which play a crucial role in determining the overall affordability and effectiveness of the treatment. Below, we explore these factors in detail.

Initial Purchase Price And Promotions

One of the primary factors affecting the long-term PLLA filler cost is the initial purchase price. Devolux offers competitive pricing, especially through its official brand site, where frequent promotions and discounts are available. These promotional activities can substantially reduce the upfront cost, making Devolux a more affordable option compared to other PLLA fillers on the market.

Adverse Reactions Post-Injection

The occurrence of adverse reactions post-injection can significantly impact the long-term PLLA filler cost. Inferior PLLA fillers often lead to issues such as redness, swelling, and allergic reactions, necessitating additional treatments or even corrective procedures. Devolux's high-quality PLLA minimizes these risks, ensuring that patients do not incur extra costs related to managing side effects, and thus protecting the reputation of beauty institutions. This safety aspect contributes to the overall reduction in long-term PLLA filler cost.

Duration Of Effects

The longevity of the filler’s effects is another critical factor in assessing the long-term PLLA filler cost. Fillers with shorter durations require more frequent re-injections, increasing both the financial burden and the discomfort for patients. Devolux stands out by providing effects that last between 2-3 years, reducing the need for frequent touch-ups and thereby lowering the overall cost over time.

Advantages Of Devolux

Devolux distinguishes itself through a combination of innovative technology, safety certifications, and versatile applications. Here, we delve into the specific advantages that make Devolux an exceptional choice for long-term PLLA filler.

GranCross Technology

Enhanced Safety and Reduced Risk: Devolux leverages GranCross technology, a pioneering approach that ensures 0 water phase, 0 emulsifier, and 0 dispersant during the preparation process. This meticulous production method significantly enhances the safety profile of Devolux, making it superior to other PLLA fillers that might contain potentially irritating additives.

Smaller Particle Size: The GranCross technology also enables Devolux to achieve a remarkably small particle size of 3-5 microns, compared to the typical 10-100 microns in other PLLA fillers. This finer particle size allows Devolux to dissolve and dilute in as little as 5 minutes, whereas other brands may require several hours or even days for preparation. This efficiency not only saves time for practitioners but also minimizes the likelihood of post-injection complications such as nodules and swelling, further reducing the long-term PLLA filler cost.

CE Certification

Devolux's CE certification is a testament to its high safety and quality standards. This certification involves rigorous evaluation of the manufacturing process, product quality, and safety protocols, ensuring that Devolux meets the stringent requirements set by regulatory authorities. From production to transportation, every step is carefully monitored to maintain the integrity and efficacy of the filler, providing assurance to both practitioners and patients.

Prolonged Results

One of the most significant advantages of Devolux is its long-lasting effects. The combination of high-quality PLLA and HA ensures that patients enjoy visible improvements for up to 2-3 years. This extended duration between treatments directly contributes to a lower long-term PLLA filler cost, as fewer sessions are required to maintain the desired aesthetic results.

Natural-Looking Outcomes

Devolux is renowned for its ability to provide natural-looking results. The gradual stimulation of collagen production leads to a subtle and progressive enhancement of facial features, avoiding the overfilled appearance that can sometimes occur with other fillers. This natural aesthetic appeal makes Devolux a preferred choice for those seeking understated yet effective rejuvenation.

Versatility In Application

Devolux’s versatility allows it to be used for a wide range of cosmetic enhancements, addressing various areas of the face and body:

- Forehead and Temples: Devolux effectively fills in hollow temples and smooths forehead lines, restoring a more youthful contour.

- Cheeks: It adds volume to sunken cheeks, enhancing facial symmetry and fullness.

- Marionette Lines: Devolux smooths deep marionette lines, reducing the appearance of sagging around the mouth.

- Hands and Neck: The filler can rejuvenate the hands and neck, areas often neglected but prone to showing signs of aging.

- Breast and Buttocks Augmentation: Devolux can be used for non-surgical enhancement of the breasts and buttocks, providing a natural lift and volume without the need for implants.

This wide range of applications makes Devolux a comprehensive solution for aesthetic improvements, catering to diverse patient needs and further enhancing its value in terms of long-term PLLA filler cost.

Understanding the long-term PLLA filler cost with Devolux reveals its cost-effectiveness and superior performance in the realm of aesthetic treatments. The combination of competitive initial pricing, minimal adverse reactions, and prolonged effects makes Devolux an excellent investment for those seeking reliable and lasting results.

The innovative GranCross technology, CE certification, and versatile application range further solidify Devolux’s position as a leading choice in the market. Patients and practitioners alike can benefit from the high safety standards, natural-looking outcomes, and comprehensive treatment options provided by Devolux.

If you are interested in experiencing the exceptional benefits of Devolux or wish to learn more about how it can meet your aesthetic goals, we invite you click here to contact our professional customer service team.

Source: https://www.devoluxplla.com/blogs/understanding-the-long-term-plla-filler-cost-with-devolux

1 note

·

View note

Note

Fic authors self rec! When you get this, reply with your favorite five fics that you've written, then pass on to at least five other writers. Let’s spread the self-love 🤍

Oooh, hmm. I don't have anything in the Stargate Atlantis fandom posted yet, mostly because I'm… not done writing anything and plot bunnies keep cropping up, but let's see what I rummage through, in no particular order:

Baku-Ra, YGO DM, 2k, Bakura Ryou, Millennium World, Dreameater AU, Peri-Canon

Summary:

The figurines on his shelf had grown dusty. And, frankly, Ryou had plenty to say about that.

Restoring Force, Quantum Leap, 3k, Sam Beckett/Al Calavicci, Sam Beckett Leaps Home, Genderfluid Ziggy, Discussions of Quantum Mechanics, Friends to Lovers, Grief/Mourning, First Kiss

Summary:

"In physics, the restoring force is a force which acts to bring a body to its equilibrium position. The restoring force is a function only of position of the mass or particle, and it is always directed back toward the equilibrium position of the system. The restoring force is often referred to in simple harmonic motion. The force which is responsible to restore original size and shape is called restoring force." "See also: Response amplitude operator"

Hiraeth, Kingsman, 15k, Harry Hart | Galahad/Merlin/Gary "Eggsy" Unwin, Celtic Mythology & Folklore, Resurrection, Canonical Character Death, Butterflies, POV Merlin (Kingsman), Supernatural Elements, Character Turned Into a Ghost, Magical Realism, Time Loop, Welsh Mythology & Folklore, Literary References & Allusions, Not Kingsman: The Golden Circle Compliant, Inspired By Real Places, Morally Ambiguous Character, Character Study

Summary:

May the wings of the butterfly kiss the sun, and find your shoulder to light on.

ešretū of a burglar, The Hobbit (Jackson Movies), 5k, Bilbo Baggins/Thorin Oakenshield, Alternate Universe - Canon Divergence, Alternate Universe - Everyone Lives/Nobody Dies, Fix-It, Dwarf Culture & Customs, Dwarf & Hobbit Cultural Differences, Religious Imagery & Symbolism, Bilbo Baggins Destroys the Arkenstone, Bilbo Baggins Destroys the One Ring, Mentioned Aulë | Mahal - Freeform, Mentions of the Fell Winter, Grief/Mourning

Summary:

The hoard of gold is cursed. Bilbo looks at Thorin and suspects the Arkenstone is, too. This beautiful, thrice-blasted stone weighs heavily in his hands and he would like nothing better than to give it to another’s. Whose hands, he thinks bitterly, could hold the Arkenstone without breaking under its thrall? No mortal being, and that is certainly the truth.

meḥ ȧb menkh, Stargate SG-1, 31k, Jack O'Neill/Teal'c, Jack O'Neill & SG-1 Team, Bra'tac & Jack O'Neill, Alternate Universe - Canon Divergence, Marriage Contest - Must Win in Ritual Combat Against Potential Spouse, Marriage of Convenience - To Extend Legal Rights/Protections To Partner, Wedding Night – Consummation, POV Jack O’Neill, Smart Jack O’Neill, Worldbuilding, Politics, Jaffa culture, Tok’ra Culture, Families of Choice, Team as Family, Family Shenanigans, The Love Is Requited They’re Just Idiots, Yearning, Romance, Love Languages, First Kiss, Declarations Of Love, Foreplay, Sexual Content

Summary:

Egyptian, "perfect filler of the heart, a title".

5 notes

·

View notes

Text

In theory, any material that can be transformed into small granules could be used as a filler for plastics. For example, we can use sand as a filler, and the end result is that in the plastic there will be sand particles. The possibilities for combining resins with other materials are endless, but for successful mixing, the filler needs to melt and disperse well in the resin mix. At higher technical requirements, they must be chemically inert, free of metal impurities to avoid plastic degradation, low hardness to avoid wear of equipment, and most importantly, the cost must be cheap and readily available to be suitable for commercial use.

No plastic is perfect, and no filler is ideal either. The essence of using fillers is a compromise between properties that will be improved and those that will be lost. To get the best trade-off, manufacturers need to understand the properties of fillers, and how they will interact with the plastic. There is something quite special, is that knowing the chemical composition of fillers will not help much to use them. Because in most cases, chemicals have no effect on plastic. The real things of concern for fillers are the physical parameters, including particle size and shape, and their surface area

2 notes

·

View notes

Text

Tablube Magnesium Stearate in High-Speed Compression: Lubrication Without Compromise

Introduction: Keeping Up with the Speed of Innovation

In today’s fast-paced pharmaceutical landscape, the push for increased production efficiency has made high-speed tablet compression a standard across modern manufacturing lines. As output speeds increase, the performance demands placed on excipients—especially lubricants—are higher than ever. Among them, Magnesium Stearate stands out for its critical role in ensuring tablet quality and equipment protection.

This article explores how Tablube Magnesium Stearate, a high-purity, pharma-grade lubricant from Nitika Pharma, is engineered to meet the lubrication challenges of high-speed compression without compromising tablet integrity, dissolution, or downstream processing.

Why Lubrication in High-Speed Compression Is a Science

As tablet presses operate at higher speeds, friction and heat generation become significant concerns. Proper lubrication is essential to:

Minimize die wall friction and reduce ejection force

Prevent sticking and picking

Extend tooling life

Ensure tablet surface smoothness and uniformity

However, excessive or poorly distributed lubricant—especially low-quality Magnesium Stearate—can lead to hydrophobicity, reduced tablet hardness, and delayed dissolution. The formulation challenge is to find a balance: effective lubrication without compromising performance.

What Sets Tablube Magnesium Stearate Apart?

Tablube is Nitika Pharma’s premium Magnesium Stearate solution, optimized for pharmaceutical use. It’s manufactured using controlled precipitation methods to ensure:

High specific surface area Improves distribution at low concentrations, maintaining compact strength and fast disintegration.

Controlled particle size Minimizes variability and ensures reproducibility across production batches.

Low heavy metal content & high purity Compliant with USP/NF, Ph. Eur., and JP pharmacopeias.

Tailored flow characteristics Ideal for blending with both direct compressible and granulated formulations.

These features make Tablube the preferred lubricant for high-speed rotary tablet presses, where consistency and control are paramount.

Addressing the Lubrication-Dissolution Trade-Off

One of the most debated concerns with Magnesium Stearate is its tendency to retard dissolution. This is primarily due to its hydrophobic nature, which forms a water-resistant film around drug particles.

However, Tablube's optimized morphology and reduced surface coating behavior allow for:

Lower usage levels (typically 0.25–1%) without compromising lubrication

Improved blend homogeneity, reducing risk of over-lubrication

Rapid disintegration, especially in fast-acting or immediate-release tablets

This makes Tablube ideal for sensitive APIs and time-critical delivery systems, where fast dissolution is essential.

Tablube in Multi-Lane and Multi-Tip Tooling Systems

Modern pharmaceutical production increasingly uses multi-lane tablet presses to boost throughput. This introduces challenges in powder flow, compression uniformity, and tool wear.

Tablube supports these high-demand systems by:

Providing uniform die wall lubrication, even in long compression runs

Preventing capping and lamination, common issues at higher turret speeds

Protecting punches and dies from abrasion and seizing

Its ability to maintain stable lubrication under dynamic pressure variations ensures consistent tablet output at speeds above 100,000 tablets/hour.

Compatibility with Modern APIs and Fillers

Pharmaceutical companies are increasingly working with low-dose, high-potency APIs, amorphous solid dispersions, and high-load formulations. These pose unique challenges for lubricants.

Tablube is compatible with:

Lactose, MCC, and DCP-based blends

Complex multi-component granules

Modified release and enteric coated systems

Its neutral pH and chemical inertness ensure no unwanted interactions with actives or coating agents.

Supporting QbD and PAT Frameworks

In the era of Quality by Design (QbD) and Process Analytical Technology (PAT), understanding and controlling excipient functionality is essential. Tablube supports QbD initiatives through:

Consistent critical material attributes (CMA) such as particle size, density, and moisture content

Digital documentation and Certificates of Analysis with each batch

Compatibility with in-line monitoring tools for blending and compression

With a reliable excipient like Tablube, manufacturers can more easily meet FDA and EMA expectations for real-time process control.

Sustainability and Regulatory Confidence

Beyond technical performance, sustainability and regulatory alignment are non-negotiable in today’s procurement environment.

Tablube is GMO-free, BSE/TSE compliant, and meets halal and kosher standards

Produced in ISO-certified, GMP-compliant manufacturing facilities

Backed by complete traceability and material origin documentation

This makes it a risk-free option for global regulatory submissions and audits.

Conclusion: High-Speed Doesn't Mean High-Risk—With the Right Lubricant

As compression technologies evolve, the importance of high-performance lubrication grows. Tablube Magnesium Stearate rises to meet the needs of high-speed, high-efficiency, and high-compliance production lines without compromising critical quality attributes like dissolution and uniformity.

Whether you're upgrading your tableting line or formulating a sensitive API, Tablube offers a well-balanced, proven solution trusted by formulation experts worldwide.

Unique Call-to-Action (CTA)

Experience lubrication without compromise. Upgrade your formulation performance with Tablube Magnesium Stearate, engineered for the demands of modern tablet manufacturing.

📞 Let our technical team at Nitika Pharma help you select the right grade for your process. 📧 Email: [email protected] | ☎ +91 7122554812

Magnesium stearate for high-speed compression

Lubricant excipients for tablet manufacturing

Pharma-grade magnesium stearate supplier

Magnesium stearate dissolution effects

Best lubricant for rotary tablet press

#Nitika#Nitika Pharma#Nitika Pharmaceutical#Nitika Pharmaceutical Specialities Pvt Ltd#Excipients#Tablube#Magnesium Stearate#India

0 notes

Text

What Are Core–Shell Nanoparticles? Uses, Benefits & Why They’re Transforming Modern Materials

1. Welcome to the Core–Shell Revolution

Imagine materials so small they're invisible to the naked eye—yet powerful enough to revolutionize everything from clean energy to medical diagnostics. These are core–shell nanoparticles, and they’re quietly powering the next wave of innovation across industries.

At Nanochemazone, we work with a wide range of advanced nanomaterials like PTFE Suspension Resin Powder, Graphene Oxide Powder, and Calcium Carbonate (CaCO₃) Nanoparticles—all of which play a role in composite and hybrid structures like core–shells. In this post, we’ll unpack what core–shell nanoparticles are, how they’re made, where they’re used, and why they’re becoming essential to everything from electronics to biotech.

2. What Are Core–Shell Nanoparticles?

At their core (literally), these nanoparticles are a two-part system: a central core made of one material (metal, ceramic, or polymer), surrounded by a protective or functional shell made of another.

This core–shell structure provides several advantages compared to traditional single-material nanoparticles, including enhanced stability, improved functionality, and the ability to fine-tune surface properties for targeted applications. The shell can enhance properties such as stability, functionality, or reactivity—without changing the identity of the core.

At Nanochemazone, we offer several high-purity, lab-ready core–shell combinations including:

Gold–Palladium (Au/Pd) – for catalysis and biomedical uses

Aluminium/Silica (Al/SiO₂) – for thermal insulation and composite materials

Lanthanum Fluoride doped with Europium (LaF₃/Eu) – for medical imaging and fluorescence applications

3. How Are They Made?

Though they may sound complex, core–shell nanoparticles are synthesized through well-established processes such as:

Sol–gel techniques

Microemulsion synthesis

Chemical precipitation

Each method allows control over particle size, composition, and core-to-shell ratio. For example, with products like Graphene Nanoplatelets Powder or PTFE Suspension Resin Powder, we can fine-tune the shell thickness or disperse them in resins or solvents for enhanced compatibility.

4. Real-World Uses & Applications

4.1 Catalysis & Chemical Industry

Core–shell nanoparticles like Gold–Palladium (Au/Pd) and Gold–Platinum are prized for their high catalytic activity. They’re widely used in:

Catalytic converters

Green hydrogen production

Organic synthesis

Powders such as Calcium Oxide Nanoparticles and Barium Sulfate Nanoparticles are also used in tandem with core–shell structures to enhance catalytic surface area and reusability.

4.2 Electronics & Conductive Inks

In modern electronics, core–shells enable better conductivity, durability, and miniaturization. CdSe/ZnS core–shells are widely utilized in quantum dots and sensor technologies.

Materials like Graphene Powder (Industrial Grade), Reduced Graphene Oxide Powder, Polyetheretherketone (PEEK), and Polyamide 66 (PA66) are frequently embedded in circuits, inks, or casings to boost strength and conductivity.

4.3 Medicine, Biotech & Imaging

Thanks to their biocompatibility and controlled surface properties, core–shells such as Au/Pd and LaF₃/Eu are increasingly used in:

Bioimaging and diagnostics

Drug delivery systems

Photodynamic therapy

Other materials like Cellulose Nanofiber Powder and Calcium Carbonate Nanoparticles are used to develop bioresorbable carriers or as drug-loading matrices.

4.4 Coatings, Composites & Advanced Materials

For engineers, PTFE Suspension Resin Powder and Carbon Fiber Powder are go-to choices for high-performance coatings and composites.

Core–shells incorporated into polymers like PVC, PET, POM, and PS—along with fillers like CaCO₃ or BaSO₄—create materials with superior strength, thermal resistance, and surface finish.

5. Top Benefits of Core–Shell Structures

✅ Tunable Properties – Adjust thermal, optical, and catalytic behavior without changing the core material ✅ Improved Stability – Shells protect against oxidation, moisture, and chemical degradation ✅ Cost Efficiency – Use expensive materials (e.g., palladium) only on the shell, reducing overall material cost ✅ Hybrid Functionality – Combine magnetic + fluorescent or conductive + barrier features in one particle

6. Emerging Trends & Future Potentials

The future of core–shell nanotechnology lies in multifunctional hybrid structures:

Nanowires, MXenes, and graphdiyne are rapidly emerging as promising materials in electronics and energy storage.

Researchers are exploring ZnO–TiO₂ and ZnO–MgO core–shells for dye-sensitized solar cells.

Sustainability is driving demand for green nanomaterials, including biodegradable or plant-based nanoparticle systems.

7. Nanochemazone’s Edge: Why Partner With Us

At Nanochemazone, we offer:

ISO and GMP-certified nanomaterials for industrial and research-grade use

A wide selection of powders and dispersions: PTFE, Graphene Oxide, CaCO₃, BaSO₄, CaO, Cellulose Nanofiber

Global shipping, 24/7 support, and custom synthesis services

Every product is customizable by purity, particle size, solvent type, and more—so you always get exactly what you need.

8. Practical Tips: Choosing the Right Core–Shell

🧪 Match by function:

Catalysis → Au/Pd

Imaging → LaF₃/Eu

Electronics → CdSe/ZnS

📏 Choose the right size: Most core–shell particles are 50–100 nm, but we can scale up/down to your requirements.

🧴 Decide on the form: Choose between dry powder or liquid dispersion depending on your process.

9. FAQ Section

Q: What’s the difference between PTFE Suspension Resin Powder and Graphene Oxide Powder? A: PTFE offers non-stick, thermal resistance ideal for coatings. Graphene Oxide brings conductivity and flexibility, great for electronics or inks.

Q: How do I store core–shell nanoparticles safely? A: Store in airtight containers at room temperature, away from light and moisture. Store dispersions in the refrigerator and shake well before use.

Q: Are core–shells scalable for mass production? A: Absolutely. Our synthesis processes are scalable from grams to kilos while maintaining particle integrity.

Q: Can they be used with polymers like PET, PA66, or PEEK? A: Yes—core–shells are often blended into thermoplastics for high-strength, functional composites.

10. Conclusion

Core–shell nanoparticles aren’t just lab curiosities—they’re real-world game changers. Whether you're creating next-gen electronics, developing smart drug delivery systems, or formulating high-performance coatings, these engineered nanomaterials are unlocking new frontiers.

👉 Explore Nanochemazone’s full catalog today, or contact us for a custom quote tailored to your formulation needs. We’re here to help you innovate—one nanoparticle at a time.

#Core–Shell Nanoparticles#Nanoparticle Applications#Advanced Nanomaterials#Nanomaterial Powder Suppliers#Core–Shell Nanoparticle Uses#Graphene Oxide Nanoparticles#PTFE Suspension Resin Powder#Calcium Carbonate Nanoparticles#Bulk nanomaterials delivery#Nanoparticles Supplier#High Purity Nanopowders#Metal Oxide Nanopowders#Laboratory Grade Nanomaterials#Custom Nanomaterial Synthesis#Carbon Nanotubes Bulk#Graphene Nanoplatelets#Buy MXene Online

1 note

·

View note

Text

0 notes

Link

#market research future#dermal fillers market#dermal fillers market size#dermal fillers market trends#dermal fillers market growth

0 notes

Text

High-Quality Maltodextrin for Sale – Reliable, Consistent, and Bulk Ready

Looking for a trusted source of high-quality maltodextrin? Whether you're in the food, pharmaceutical, supplement, or industrial sector, having a dependable supply of premium maltodextrin can make all the difference in production quality and efficiency.

We offer bulk maltodextrin that meets stringent quality standards and delivers reliable performance across applications—ensuring your business never compromises on quality.

What is Maltodextrin?

Maltodextrin is a fine, white, tasteless or slightly sweet powder made from the partial hydrolysis of starches such as corn, potato, or rice. It’s known for its excellent solubility in water, neutral flavor, and easy digestibility.

Thanks to these properties, maltodextrin is used in a wide variety of applications—from enhancing food texture to acting as a filler in pharmaceutical and nutritional products.

Why Choose Our Maltodextrin?

Our maltodextrin for sale is:

Food-grade and pharma-grade certified

Free from contaminants and additives

Available in multiple DE (dextrose equivalent) values

Supplied in hygienic, moisture-proof packaging (25kg, 50kg, jumbo bags)

Backed by documentation (COA, MSDS, and quality certificates)

With consistent particle size, purity, and easy handling, our maltodextrin is designed to integrate smoothly into your production processes.

Applications of Maltodextrin

Food & Beverage

Adds body and smoothness to sauces, soups, and dressings

Works as a carrier for flavors, colors, and seasonings

Bulking agent in low-calorie products

Enhances mouthfeel in powdered drink mixes

Pharmaceuticals

Used as a binder and stabilizer in tablet and capsule production

Ideal filler for powdered and liquid medicines

Safe and non-reactive with most active ingredients

Nutritional Supplements

Provides quick energy in sports drinks and post-workout mixes

Common in mass gainers, protein powders, and energy gels

Blends well with vitamins, minerals, and other additives

Cosmetics & Personal Care

Helps thicken and stabilize creams, lotions, and powders

Acts as a moisture-retaining agent in skin-care products

Industrial Uses

Functions as a carrier for agrochemicals and industrial blends

Used in fermentation, biodegradable products, and chemical formulations

Why Buy in Bulk?

Purchasing maltodextrin in bulk offers major advantages:

Lower cost per unit

Reliable inventory for continuous production

Uniform product quality across batches

Streamlined logistics and delivery options

Whether you need 25kg bags or tonnage orders, we’re equipped to deliver efficiently and on time.

Let’s Work Together

If your business needs high-quality maltodextrin for sale, we’re here to help. We support bulk orders, custom supply plans, and technical assistance—ensuring you get the right grade for your specific application.

📞 Contact us today for pricing, product samples, or documentation.

#MaltodextrinForSale#BulkMaltodextrin#FoodGradeMaltodextrin#PharmaExcipients#NutritionAdditives#IndustrialIngredients#BuyMaltodextrinInBulk

0 notes

Text

Can Calcium Carbonate Powder Replace Traditional Fillers in Modern Manufacturing?

In the ever-evolving world of manufacturing, companies constantly seek materials that enhance product performance while remaining cost-effective. As industries adapt to environmental concerns and shifting economic factors that influence the use of Calcium Carbonate Powder emerges as a strong contender against traditional fillers. Could this mineral truly redefine how we approach industrial fillers?

Understanding Traditional Fillers in Manufacturing

Traditional fillers like talc, kaolin clay, silica, and carbon black have been extensively used for decades. They serve crucial roles in altering material properties, reducing costs, and enhancing processing capabilities. However, these fillers come with their own limitations—rising costs, limited reserves, and growing environmental concerns, which drive industries to explore alternative solutions.

What is Calcium Carbonate Powder?

At its core, calcium carbonate powder is a naturally occurring mineral composed of calcium, carbon, and oxygen. Found in abundance in limestone, marble, and chalk deposits, it is processed into a fine, white powder that can be incorporated into various manufacturing processes.

Historical Use of Calcium Carbonate

Calcium carbonate isn’t new to the scene. It has long been used in construction (cement, lime), agriculture (soil treatment), and food industries (as a dietary supplement). But its role in modern manufacturing as a primary filler has only recently gained momentum.

How Calcium Carbonate Powder Differs from Traditional Fillers

Unlike many traditional fillers, calcium carbonate powder offers a unique combination of affordability, performance, and versatility. Its low abrasiveness, high whiteness, and excellent dispersion qualities make it ideal for a wide range of applications, setting it apart from its more expensive or environmentally challenging counterparts.

The Growing Demand for Sustainable Alternatives

Today’s manufacturers face mounting pressure to adopt greener, more sustainable practices. Traditional fillers, often requiring energy-intensive mining and processing, contribute significantly to environmental degradation. Calcium carbonate powder, being widely available and requiring relatively lower processing energy, presents an eco-friendlier choice.

Key Industries Using Calcium Carbonate Powder

Plastics Industry

In the plastics sector, calcium carbonate powder is increasingly favored as a filler. It enhances rigidity, improves dimensional stability, and reduces production costs, all while maintaining the desired mechanical properties of the plastic products.

Rubber Industry

Rubber manufacturers benefit from the inclusion of calcium carbonate powder by improving the stiffness and durability of rubber products. Its fine particle size allows for uniform dispersion, leading to superior product consistency.

Paints and Coatings Industry

Calcium carbonate powder acts as a functional extender pigment, contributing to better opacity, surface gloss, and paint durability. It also helps in reducing the reliance on more expensive titanium dioxide.

Paper Industry

One of the oldest applications, calcium carbonate powder, helps improve brightness, opacity, and smoothness of paper, while also enhancing printability and reducing production costs.

Advantages of Using Calcium Carbonate Powder

Cost Efficiency

Perhaps one of the most attractive aspects for manufacturers is its affordability. Calcium carbonate powder reduces the need for more costly raw materials without compromising product performance.

Improved Product Properties

Products filled with calcium carbonate often exhibit improved physical properties—enhanced strength, better processing behavior, and improved thermal stability, making them more desirable in competitive markets.

Environmental Benefits

Compared to some traditional fillers, calcium carbonate powder offers lower carbon footprint production. Its wide availability also means reduced environmental impact from mining operations.

Challenges and Limitations

While calcium carbonate powder offers numerous benefits, it isn’t a perfect solution for every application. Issues like compatibility with certain polymers, moisture sensitivity, and limitations in ultra-high-performance materials still require careful consideration.

Technological Innovations Boosting Its Adoption

Advances in surface modification technology, nano-calcium carbonate production, and enhanced dispersion methods have significantly improved its application range, addressing many of its earlier limitations and making it viable even in more demanding manufacturing processes.

Comparing Performance with Traditional Fillers

When directly compared, calcium carbonate powder often matches or exceeds traditional fillers in applications that prioritize cost, sustainability, and moderate performance requirements. However, in extremely high-performance products where specialized properties are critical, traditional fillers may still hold an edge.

Economic Implications for Manufacturers

For industries battling shrinking profit margins and rising raw material costs, calcium carbonate powder provides a lifeline. Its integration can dramatically cut production costs while maintaining, or even improving, product quality, leading to stronger market competitiveness.

Sudarshan Group’s Role in Supplying High-Quality Calcium Carbonate Powder

As a trusted name in the industry, Sudarshan Group has been at the forefront of delivering premium quality calcium carbonate powder to manufacturers across sectors. With stringent quality control, advanced processing facilities, and a commitment to sustainability, Sudarshan Group ensures that industries receive consistent, high-purity material tailored to their unique manufacturing needs.

Future Trends and Market Predictions

The global demand for calcium carbonate powder is projected to rise steadily as industries worldwide lean into sustainable, cost-effective manufacturing solutions. Innovations in processing and application technology are expected to widen its adoption even further, potentially positioning it as a dominant filler across multiple industries.

Conclusion

The manufacturing landscape is shifting, and calcium carbonate powder stands poised to take center stage. While it may not completely replace every traditional filler, its growing versatility, affordability, and environmental advantages make it a highly attractive option for many industries. Companies like Sudarshan Group are ensuring that this transition is smooth, providing top-quality materials that meet the evolving needs of modern manufacturers.

FAQs

Q1: Is calcium carbonate powder safe for all manufacturing processes? Yes, but manufacturers must consider compatibility with specific materials and processing conditions to optimize performance.

Q2: Can calcium carbonate powder fully replace titanium dioxide in paints? Not entirely. While it can significantly reduce the need for titanium dioxide, certain high-opacity requirements still necessitate some titanium dioxide usage.

Q3: Does calcium carbonate powder affect the recyclability of plastics? Generally, it does not negatively impact recyclability and can sometimes improve certain recycling processes by enhancing thermal properties.

Q4: What are the main environmental benefits of using calcium carbonate powder? Lower energy consumption during processing, abundant natural reserves, and reduced environmental footprint compared to some traditional fillers.

Q5: Why is Sudarshan Group considered a reliable supplier of calcium carbonate powder? Due to their strict quality control, advanced manufacturing techniques, and strong focus on customer-specific solutions, Sudarshan Group ensures high-quality, consistent products for various industries.

0 notes

Text

PMMA Dermal Filler Brands Compared: Expert Recommendations

In the world of long-lasting aesthetic injectables, PMMA filler brands have garnered growing attention for their impressive durability, collagen-stimulating properties, and natural-looking results. Whether you're a medical aesthetics professional or an individual exploring permanent filler brands, it is crucial to understand the different PMMA dermal filler brands available today. Among them, PrimeFill® stands out as a next-generation innovation, combining advanced formulation techniques with clinical performance.

Let's explore together the most recognized PMMA filler brands, examine their compositions and mechanisms, and discover which options align best with your aesthetic goals. For inquiries about our product range, don’t wait to contact us.

Leading PMMA Filler Brands Compared

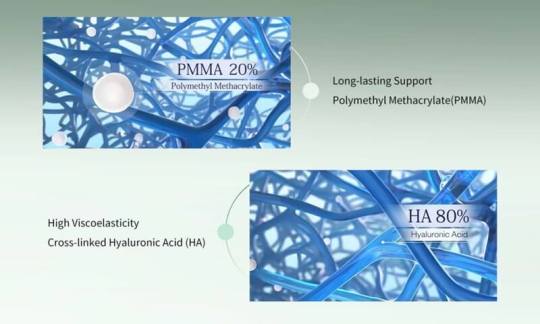

When it comes to PMMA dermal filler brands, understanding their specific characteristics can help aesthetic professionals and patients choose the product that aligns best with individual treatment goals. This section aims to objectively outline the composition, particle size, carrier gel, injection properties, and typical duration of action for PrimeFill®, Bellafill®, and Metacrill®—three of the most commonly used permanent filler brands.

Composition and Microsphere Characteristics

PrimeFill®

Microsphere content: 20% PMMA

Particle size: Uniform, 20-50 μm (achieved via Microfluidic Tech™)

Carrier gel: 80% cross-linked hyaluronic acid

Key features: Smooth, monodispersed microspheres designed for enhanced safety and consistent collagen stimulation

Bellafill®

Microsphere content: \~20% PMMA

Particle size: Approx. 30-50 μm (based on published clinical data)

Carrier gel: Bovine collagen (approximately 3.5%) + lidocaine

Key features: FDA-approved for acne scar and nasolabial fold correction; requires allergy testing due to animal-sourced collagen

Metacrill®

Microsphere content: Varies by batch and region (usually 30-40%)

Particle size: Reported wider distribution, approx. 40-60 μm

Carrier gel: Non-animal synthetic gel, often with unspecified composition

Key features: Available in larger volume options; may be used off-label in some cases

To explore more scientifically advanced PMMA filler brands for your clinic, contact us for technical documents and purchasing options.

Carrier Gel and Handling Properties

PrimeFill®

HA-based gel carrier enhances hydration

High viscosity enables stable tissue support

Suitable for molding and shaping in high-mobility areas

Bellafill®

Collagen gel provides initial volume but is reabsorbed over several months

Lidocaine improves injection comfort

May be less sculptable due to lower viscosity

Metacrill®

Varies depending on formulation batch

Some reports suggest higher injection resistance

Less predictable gel integration in dynamic zones

Duration of Effect and Maintenance

PMMA is known for its long-lasting effect due to its non-degradable structure. However, how the product behaves in the tissue also depends on the carrier gel, microsphere size, and injection technique.

PrimeFill®: Clinical observations suggest effects can last up to 5 years, depending on area treated and patient metabolism.

Bellafill®: FDA-cleared duration up to 5 years for nasolabial folds, with collagen reabsorption occurring within 3-6 months.

Metacrill®: Duration reports range from 2 to 4+ years, depending on injection site and formulation consistency.

While all three belong to the category of permanent filler brands, outcomes are influenced by technique, indication, and patient factors. Consulting with experienced professionals remains essential.

For clinicians seeking long-term PMMA dermal filler brands with transparent performance data, PrimeFill® is available through our global supply channels. Contact us for a sample kit or expert support.

Why PrimeFill® Is a Leader Among PMMA Filler Brands

Superior Composition and Technology

PrimeFill® is uniquely formulated with an 80:20 HA to PMMA ratio, optimizing injectability, safety, and efficacy. The Microfluidic Tech™ ensures each microsphere is uniformly sized, enhancing biocompatibility and reducing complication risks.

Long-Term Satisfaction with Immediate Results

By combining the hydrating power of hyaluronic acid with the longevity of PMMA, PrimeFill® provides immediate enhancement followed by gradual, natural collagen stimulation – the hallmark of top-tier permanent filler brands.

Designed for Versatile Indications

From mid-face contouring to jawline definition, PrimeFill® covers a broad range of aesthetic needs, making it one of the most versatile and well-balanced PMMA filler brands on the market.

About Dermax: The Manufacturer Behind PrimeFill®

With over 20 years of experience in the global aesthetic industry, Dermax is the innovative force behind PrimeFill®. Headquartered in Asia and with manufacturing hubs across Germany, Korea, and China, Dermax delivers high-quality aesthetic solutions to over 80 countries worldwide. Dermax is also known for its range of proprietary products, such as:

Aqua Secret®: Hyaluronic acid filler with multiple particle sizes

Devolux® & Devolux Vital: Biostimulatory PLLA filler for long-term collagen induction

Magik Thread®: PDO thread lifting technology offering non-surgical rejuvenation

These innovations have made Dermax a favorite among dermatologists, plastic surgeons, and medical spa professionals across the globe.

If you're seeking PMMA dermal filler brands from a reputable, experienced manufacturer, contact us today for professional support, pricing, and delivery options tailored to your clinic's needs.

Source: https://www.dermaxmed.com/pmma-dermal-filler-brands-compared-expert-recommendations.html

0 notes

Text

Barium Sulphate Market: A White Gold Mine in Industrial Applications

Barium sulphate (BaSO₄), commonly known by its mineral form barite, is a versatile inorganic compound renowned for its high density, chemical inertness, and exceptional whiteness. These unique properties make it an indispensable material across a wide array of industries, establishing the "Barium Sulphate Market" as a robust and steadily growing sector within the global chemicals industry.

The market's growth is predominantly driven by its extensive use in the oil and gas industry, where it serves as a crucial weighting agent in drilling fluids. This application helps maintain hydrostatic pressure in wells, preventing blowouts and ensuring safer, more efficient drilling operations. With ongoing global exploration and production activities, particularly in unconventional oil and gas, the demand for barium sulphate in this segment remains consistently high.

Beyond drilling, barium sulphate plays a significant role in the paints and coatings industry. Its high opacity and brightness make it an ideal filler and pigment extender, enhancing the quality, durability, and aesthetics of paints, lacquers, and varnishes. The automotive and construction sectors, with their continuous demand for high-performance coatings, are key consumers in this segment.

Furthermore, the medical field relies heavily on barium sulphate as a radiocontrast agent for X-ray imaging, particularly in gastrointestinal diagnostics (often referred to as a "barium meal"). Its ability to absorb X-rays strongly, coupled with its low solubility and non-toxicity when ingested in this form, makes it a safe and effective tool for visualizing internal organs. The rising prevalence of chronic diseases and the increasing number of diagnostic procedures globally are bolstering demand in this specialized medical application.

Market statistics underscore this growth trajectory. The Barium Sulphate Market is expected to register a CAGR of 5% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031. While natural barium sulphate (from barite mining) remains a significant portion, precipitated barium sulphate, which offers higher purity and controlled particle size, is witnessing faster growth due to its increasing adoption in paints, plastics, and medical imaging. The Asia-Pacific region, driven by rapid industrialization and burgeoning construction and automotive sectors in countries like China and India, accounts for a substantial share of the market.

However, the market also faces challenges, including fluctuations in raw material prices (barite ore) and stringent environmental regulations concerning the mining and disposal of barium compounds. Despite these hurdles, ongoing technological advancements in extraction and processing, as well as the development of specialized grades for niche applications like advanced plastics and lightweight materials, present significant opportunities. As industries continue to seek high-performance, cost-effective, and safe materials, the barium sulphate market is poised for sustained expansion.

Author's Bio:

Nilesh Shinde

Senior Market Research expert at The Insight Partners

0 notes

Text

From Paints to Pharma: Why Ceramic Grinding Beads Matter

In the world of ultra-fine grinding and dispersion, the choice of media directly determines the consistency, throughput, and final product quality. Among a variety of options available, 3.0mm ceramic grinding beads stand out for their precision, durability, and versatility across industries. These tiny, spherical components may appear simple, but their unique material properties and dimensional stability make them indispensable in high-performance milling processes.Get more news about 3.0mm ceramic grinding beads,you can vist our website!

Understanding Ceramic Bead Composition

Ceramic grinding beads are typically composed of high-purity zirconium oxide (ZrO₂), yttria-stabilized zirconia (Y-TZP), alumina, or silica-based ceramics. The 3.0mm size refers to the bead’s diameter—a sweet spot for balancing kinetic energy, contact frequency, and product flow. This size is especially suitable for horizontal mills and bead mills that operate under high shear and turbulence.

The hardness, density, and sphericity of ceramic beads contribute to their superior grinding efficiency. They exhibit minimal wear and resist contamination, which is crucial for applications involving sensitive materials like pharmaceuticals, electronic pastes, and advanced ceramics.

Performance Characteristics

The performance of 3.0mm ceramic grinding beads lies in their high bulk density (typically above 6.0 g/cm³ for zirconia types), narrow size distribution, and extremely smooth surface finish. These features allow uniform energy transfer during milling, leading to highly consistent particle size reduction.

Additionally, ceramic beads are chemically inert and thermally stable, which means they retain their performance across a wide range of materials and temperatures. This makes them ideal not only for wet grinding applications but also for processes requiring strict contamination control.

Applications Across Industries

One of the most notable advantages of 3.0mm ceramic beads is their adaptability. In the paint and coatings industry, they enable uniform dispersion of pigments and fillers, ensuring vibrant, consistent color and smooth texture. In the pharmaceutical sector, these beads are employed to grind active pharmaceutical ingredients (APIs) with high precision, often at micron or sub-micron scales, ensuring drug efficacy and uniformity.

Ceramic beads are also widely used in the mining industry for regrinding and fine grinding of ores, as well as in the food and cosmetic sectors where hygiene and consistency are paramount. Their chemical inertness ensures no interference with taste, composition, or safety standards.

Advantages Over Traditional Media

Compared to steel or glass beads, ceramic grinding media exhibit a much longer service life, reduced contamination risk, and improved throughput. This results in lower operational costs over time, despite the higher upfront investment. Their smooth surface and hardness also reduce mill wear, contributing to lower maintenance and downtime.

Looking Forward: Innovation and Sustainability

With ongoing developments in nanomaterials and sustainable manufacturing, the role of precision grinding media like 3.0mm ceramic beads is set to grow. Manufacturers are continually working on improving bead homogeneity, reducing energy consumption, and extending product lifespan, aligning with global pushes for cleaner, more efficient industrial processes.

In conclusion, while small in size, 3.0mm ceramic grinding beads pack a punch in industries that rely on fine dispersions and precision milling. Their unique properties offer an unbeatable combination of efficiency, reliability, and quality—cementing their place in the future of material processing.

0 notes

Text

Unlocking Peak Performance: The Power of Creatine and Whey in Fitness

Many athletes remember the moment they first noticed real muscle gains—the kind that comes not from extra reps, but from smarter recovery and superior nutrition. In the pursuit of fitness goals, what separates consistent progress from frustrating plateaus often lies in the quality of supplements. This article explores two widely acclaimed supplements: micronized creatine monohydrate and supreme Whey Protein, examining their benefits, how they complement training, and their essential role in achieving peak performance.

UNDERSTANDING MICRONIZED CREATINE MONOHYDRATE

Creatine has long been a trusted companion for athletes seeking enhanced power and endurance. Among its various forms, micronized creatine monohydrate stands out due to its smaller particle size, which improves solubility and absorption. It helps increase phosphocreatine stores in muscles, which in turn allows better production of ATP—the energy currency of the body. When consumed regularly, this supplement supports short bursts of high-intensity training, such as lifting or sprinting. The micronized version minimizes bloating and stomach discomfort, making it a preferred choice for daily consumption.

HOW MICRONIZED CREATINE MONOHYDRATE ENHANCES RESULTS

Consistency in performance hinges on recovery, strength, and energy regeneration. Micronized creatine monohydrate enhances recovery between sessions and boosts muscular output over time. This enables athletes to perform more reps and train harder without overtraining. Unlike standard creatine, the micronized form ensures even distribution in liquids, which improves its effectiveness and minimizes waste. As a result, users experience less fatigue and more sustained gains, especially during resistance training or intense athletic cycles. It proves particularly effective when paired with a high-protein diet and a structured exercise regimen.

ROLE OF DIET IN FITNESS PROGRESS

Nutritional discipline is foundational to any transformation. A carefully balanced intake of macronutrients, especially proteins, significantly influences how efficiently the body repairs muscle tissue. After workouts, muscles are in a state of breakdown and require amino acids to rebuild stronger. That is where supplementation becomes critical—not just in quantity, but also in the quality and absorption rate of protein sources. Using a clean and fast-digesting supplement like supreme Whey Protein makes the post-workout window more effective and speeds up the process of muscle protein synthesis, reducing soreness and fatigue.

THE ADVANTAGE OF SUPREME WHEY PROTEIN IN RECOVERY

Athletes often face the dilemma of choosing between countless protein brands that promise muscle growth. Supreme Whey Protein distinguishes itself through its rich amino acid profile, especially branched-chain amino acids (BCAAs), which are vital for muscle repair. With high bioavailability, it absorbs quickly and gets to work immediately after ingestion. Midway through a rigorous training program, the body relies heavily on protein to prevent catabolism. By incorporating supreme Whey Protein, individuals can ensure they're not just maintaining muscle, but actively building new tissue while reducing inflammation and supporting lean muscle mass.

WHY SUPREME WHEY PROTEIN OUTPERFORMS COMMON PROTEINS

The filtration process used in producing supreme Whey Protein preserves important microfractions that contribute to immunity and muscle integrity. Unlike inferior powders loaded with sugars and fillers, this product focuses on purity and function. It blends smoothly, avoids clumping, and is gentle on digestion—critical for athletes who consume protein multiple times a day. Whether used post-workout or between meals, it delivers consistent results. For those aiming for body composition goals or improved athletic output, the protein’s quality is as essential as training intensity or sleep.

0 notes

Text

What Is Coated Calcite? Properties, Processing, and Applications Explained

Calcite is a widely known and used mineral, primarily composed of calcium carbonate (CaCO₃). When calcite is treated with a coating—most often with stearic acid—it is transformed into coated calcite, a value-added product with enhanced functionality in various industrial applications. From plastics to paints and beyond, coated calcite plays a critical role in modern manufacturing. In this article, we’ll explore what coated calcite is, its key properties, how it’s processed, and where it’s commonly used, along with why sourcing from a reliable Coated Calcite Manufacturer in India is essential for industrial success.

What Is Coated Calcite?

Coated calcite is a form of calcium carbonate in which the surface of the particles is treated—typically with fatty acids like stearic acid—to improve dispersion, compatibility with polymers, and performance in specific applications. The coating process reduces the surface energy of calcite particles, making them more hydrophobic (water-repelling) and oleophilic (oil-attracting).

This modification significantly improves the material’s effectiveness in polymer-based systems, where natural calcite may otherwise cause processing difficulties or lead to inconsistent product performance.

Chemical and Physical Properties

Coated calcite retains most of the physical characteristics of natural or precipitated calcite but has enhanced surface properties. Here are the key features:

Chemical Formula:

CaCO₃ (Calcium Carbonate)

Physical Properties:

Particle Size: Typically ranges from 1 to 20 microns (can be customized)

Whiteness: 95% or higher

Specific Gravity: Around 2.7 g/cm³

Moisture Content: Low (typically < 0.2%)

Surface Treatment: Usually 1–3% stearic acid

Modified Properties:

Improved dispersibility in polymers and oils

Hydrophobic surface for better moisture resistance

Reduced agglomeration in composite systems

These enhanced properties make coated calcite highly valuable in thermoplastics, paints, adhesives, and sealants.

How Is Coated Calcite Processed?

The production of coated calcite involves several key steps:

1. Raw Material Selection

High-purity natural calcite or ground calcium carbonate (GCC) is selected. The raw material must be free from impurities like silica, iron oxide, and heavy metals.

2. Grinding and Classification

The calcite is finely ground using advanced grinding mills. The particle size is precisely controlled depending on the target application.

3. Surface Treatment

The ground calcite particles are mixed with stearic acid or another surface modifier. This is done in a coating machine or heated mixer, ensuring even distribution of the coating agent on the particle surfaces.

4. Cooling and Packaging

Once coated, the material is cooled, dried (if needed), and then packaged in moisture-proof bags for storage and shipment.

A leading Coated Calcite Manufacturer in India typically adheres to strict quality control protocols at each step to ensure consistency, purity, and desired performance metrics.

Applications of Coated Calcite

1. Plastic and Polymer Industry

One of the largest consumers of coated calcite is the plastic industry. It is used in:

PVC pipes and cables

Polypropylene (PP) and polyethylene (PE) films

Masterbatches

Automotive plastics

Benefits include improved dimensional stability, better flow characteristics, reduced shrinkage, and cost-effectiveness.

2. Paints and Coatings

In the paints industry, coated calcite acts as a functional filler:

Enhances brightness and opacity

Improves dispersion of pigments

Provides anti-settling properties

Increases durability and scrub resistance

Its hydrophobic nature makes it particularly useful in water-resistant and outdoor coatings.

3. Rubber Industry

Coated calcite serves as a reinforcing agent in rubber compounds. It increases volume, improves hardness, and reduces production costs while maintaining elasticity.

4. Adhesives and Sealants

In formulations like hot-melt adhesives and sealants, coated calcite contributes to viscosity control, improved bonding, and thermal stability.

5. Paper Industry

Though less common than uncoated calcium carbonate, coated variants are used in specialty papers for improved smoothness, brightness, and printability.

Why Choose a Coated Calcite Manufacturer in India?

India has become a global hub for high-quality mineral processing, including coated calcite production. A reputable Coated Calcite Manufacturer in India offers:

Wide range of particle sizes and coatings tailored to industry-specific needs

Consistent product quality, with low moisture and high brightness

Competitive pricing and bulk supply capabilities

Eco-friendly manufacturing practices

Global export support with customized logistics

Indian manufacturers source calcite from rich mineral reserves in Rajasthan and Gujarat, ensuring steady availability and scalability.

Environmental and Safety Considerations

Environmentally Safe:

Coated calcite is non-toxic and environmentally friendly, especially when manufactured with low-VOC and lead-free processing agents. It poses minimal environmental risk in production or application.

Workplace Safety:

While the material is not hazardous, fine powders may cause respiratory irritation if inhaled in large amounts. Proper ventilation and protective gear are recommended during handling.

Choosing the Right Manufacturer

When selecting a Coated Calcite Manufacturer in India, consider the following:

Certifications such as ISO 9001, REACH compliance, and ROHS

Quality control labs with testing for brightness, moisture, and coating efficiency

Experience in your specific industry

Supply chain reliability for both domestic and international markets

Partnering with an experienced and quality-conscious supplier ensures your end product meets both functional and regulatory standards.

Conclusion

Coated calcite is more than just a mineral filler—it is a performance-enhancing material that adds real value across industries such as plastics, paints, rubber, and adhesives. Its hydrophobic nature, fine particle size, and compatibility with polymers make it a must-have for modern manufacturing processes.

As demand continues to rise globally, sourcing from a dependable Coated Calcite Manufacturer in India ensures consistent quality, cost savings, and product innovation. Understanding its properties and applications allows businesses to leverage coated calcite for superior performance and market competitiveness.

0 notes