#Pcb Assembly Cable

Explore tagged Tumblr posts

Text

Unveiling PCB Assembly Cables: Bridging the Gap in Electronic Design

In the world of electronics, the assembly of Printed Circuit Boards (PCBs) is a complex process that requires precise attention to detail. One crucial aspect often overlooked in the PCB assembly process is the role of PCB assembly cables. These cables are vital for connecting and integrating different electronic components and systems, ensuring that your devices operate efficiently and reliably. If you’re curious about PCB assembly cables and their significance, this blog post will provide a comprehensive overview, including their types, applications, and considerations for choosing the right cables for your project.

What are PCB Assembly Cables?

PCB assembly cables, often referred to as cable assemblies or wire harnesses, are integral to the interconnection of various components within an electronic device. These cables facilitate communication and power transfer between PCBs and other system elements, such as sensors, connectors, and displays. They are designed to ensure that electronic systems function as intended by providing reliable and efficient connections.

Key Functions of PCB Assembly Cables:

Signal Transmission: PCB assembly cable carry electrical signals between different parts of a system, ensuring accurate data transfer and communication.

Power Distribution: These cables deliver power from the power supply to various components, maintaining the required voltage and current levels.

Mechanical Support: By securing connections and reducing stress on PCB connectors, assembly cables help prevent damage and ensure durability.

Types of PCB Assembly Cables

There are several types of PCB assembly cables, each suited to different applications and requirements. Here’s a look at some common types:

Flat Ribbon Cables:

Description: These cables consist of multiple wires arranged parallel to each other and encased in a flat, flexible insulation.

Applications: Often used in applications where space is limited and a large number of connections are needed, such as in computer motherboards and internal devices.

Round Cables:

Description: These cables feature a round cross-section and can include multiple wires insulated individually or as a bundle.

Applications: Common in power distribution and general-purpose connections where flexibility and durability are required.

Flexible Flat Cables (FFC):

Description: FFCs are thin, flexible cables that consist of flat conductors and are ideal for space-constrained applications.

Applications: Frequently used in compact electronic devices such as smartphones, cameras, and portable electronics.

Coaxial Cables:

Description: Coaxial cables have a central conductor surrounded by an insulating layer and an outer conductive shield.

Applications: Used for high-frequency signal transmission, such as in RF applications, video signals, and data communication.

Custom Cable Assemblies:

Description: Custom cables are designed and manufactured according to specific requirements and specifications provided by the client.

Applications: Ideal for specialized applications where off-the-shelf solutions are not suitable.

Applications of PCB Assembly Cables

PCB assembly cables find applications across a wide range of industries and devices. Some common areas include:

Consumer Electronics:

Devices: Smartphones, tablets, laptops, and gaming consoles.

Role: Connect internal components like displays, processors, and batteries.

Automotive Industry:

Devices: In-vehicle infotainment systems, engine control units, and sensors.

Role: Facilitate communication and power distribution within vehicle electronics.

Medical Devices:

Devices: Diagnostic equipment, patient monitoring systems, and imaging devices.

Role: Ensure reliable connections for data transfer and power supply in critical medical applications.

Industrial Equipment:

Devices: Manufacturing machinery, robotics, and control systems.

Role: Provide robust and durable connections to withstand harsh operating conditions.

Telecommunications:

Devices: Networking equipment, routers, and signal processors.

Role: Enable high-speed data transmission and connectivity.

Choosing the Right PCB Assembly Cable

Selecting the appropriate PCB assembly cable is essential for ensuring the reliability and performance of your electronic devices. Here are some factors to consider:

Application Requirements:

Considerations: Determine the specific requirements of your application, such as signal type, power needs, and environmental conditions.

Cable Specifications:

Factors: Evaluate cable specifications including gauge, insulation type, shielding, and flexibility based on your design requirements.

Durability and Reliability:

Assessment: Ensure the cables are durable and reliable, particularly in harsh environments or critical applications.

Custom vs. Standard Solutions:

Decision: Decide whether off-the-shelf cables are sufficient or if custom solutions are needed to meet specific design constraints.

Quality and Compliance:

Standards: Choose cables that meet industry standards and certifications to ensure MT PCB Assembly quality and compliance.

PCB assembly cables are crucial components in the electronic design and assembly process, playing a vital role in connecting various parts of a system and ensuring seamless operation. Understanding the different types of cables, their applications, and the factors to consider when selecting them can significantly impact the performance and reliability of your electronic devices.

By focusing on quality and choosing the right cables for your specific needs, you can ensure that your PCB assemblies operate efficiently and effectively, paving the way for successful and reliable electronic products.Pcb Assembly Cable

#Pcb Assembly Cable#4 Cores Power Cable#4pin Connector Cable#5pin Connector Cable#MT PCB Assembly#printed circuit assembly#pcba circuit board

0 notes

Text

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

We sell —CCTV security systems video Balun from China —-email : [email protected]

#cctv camera#cctvinstallation#china#electronic#video#powersupply#hdmi cable#BNC connector#pcb assembly#audio cable#electronic components#PoE switch#RCA pin jack#RF coaxial connector

0 notes

Text

Services at inYantra Technologies Pune, India

0 notes

Text

https://www.futureelectronics.com/p/interconnect--connector-tools-contacts-accessories/0462-005-20141-te-connectivity-3076065

What is a cable assembly, crimping tool, electrical connector, Crimp tools,

16-18 AWG Size 20 Nickel Plated Crimp Automotive Terminal Contact Socket

#Connectors#Tooling and Accessories#0462-005-20141#TE Connectivity#What is a cable assembly#crimping tool#electrical#circular#USB#PCB#rectangular industrial#SMA RF#Barrier strip#data connector#transmitting power#Wire crimp#socket

1 note

·

View note

Text

#smart watch assembly#smart watch factory#smart wearable tws assembly#cable wiring harness factory#quality Smart Watch Assembly#affordable Smart Watch Assembly#best Smart Watch Factory#electronics pcba factory#printed circuit board assembly#electronics#smt pcb jobwork#electronics manufacturer

0 notes

Text

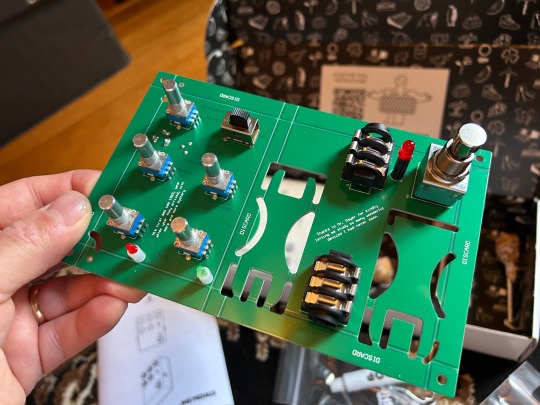

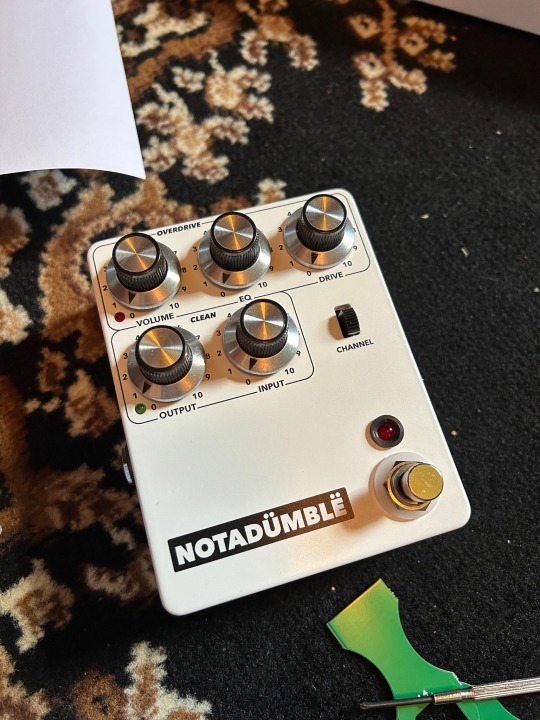

Today I assembled the device

A disappointing lack of soldering and a disappointingly threadbare looking PCB

All that reduces down to this

There wasn’t much to photograph of the actual assembly. You tighten a total of: eight nuts, five knob set screws, and four back plate screws. You also connect the two PCBs with a ribbon cable.

It is kind of a pleasing looking thing tho

5 notes

·

View notes

Text

I bought an 8bitdo NGC controller mod-kit!

Bought me an 8bitdo Gamecube conversion kit and used a for-parts indigo controller off of eBay for the donor parts and ABXYLRZ/Start buttons. What do I think of it, Tumblr?

Marketed as completely solderless, not really true; soldering together the rumble motor to the supplied connector is the best way to go about it. You could PROBABLY do it solderless if you were really patient and had needlenose pliers or thick tweezers? What they do is give you a slide-in-LEGO connector with its wires exposed so you can yank the original motor out of the back of the controller, twist-tie the corresponding wires together, and then heat-shrink wrap your connections for insulation. Soldering the wires together is way less frustrating and much faster. Technically solderless, not practically solderless or perfectly solderless

The hall effect analog sticks are really really really good. They feel borderline identical to original Gamecube sticks and come with replacement caps that are virtually identical to the OEM originals

The Z button feels more tactile than an original, which is actually a good thing

The analog shoulders do work and use an identical mechanism to what was on the original Gamecube, but it's a bit of a bugger to get them working without the Retro Receiver (sold separately) and a Gamecube controller port. The controller only supports d-input and Switch input, the latter of which mimics a Pro Controller and so doesn't have analog input. D-input meanwhile has working analogs over wireless but not the way they're detected by Windows by default. Dolphin picks up the analog-capable controller input as "WGInput" and cannot find a rumble motor

In keeping with the Pro Controller mimic there are a couple button binds on that mode so you don't lose Home button functionality. It lists a combo for the "Back" button but I'm assuming they mean the screenshot button

The barrel jack replacing the original wire is a very clever combination of the wireless receiver and filling that space originally occupied. My kingdom for a USB-C port, but a barrel jack is the next best thing and they give you a USB-to-barrel cable for charging

No real input lag that I can feel

I like the touch that the PCB and associated bits come in an oversized anti-static bag, the intention is you dump the old PCB and cable into this bag so you can revert the controller back to an original if you want. The mod is fully reversible

Considering that rumble doesn't fucking work over d-input anyways, you can buy the 8bitdo mod kit and an Extremerate Gamecube controller shell off of Amazon and have a completely functional, fully assembled Gamecube controller for around $45, or you could buy an XYAB Gamecube controller for its shell and buttons to knock a few bucks off and (I assume?) keep the rumble motor

I think if you're fully aware of the caveats of this conversion kit (no X-input and no support will come, a few quirks, need a sold-separately wireless receiver to use it on original hardware, also need a Mayflash adapter or other PC-Gamecube adapter for out-of-the-box rumble and analogs with the receiver on PC) it's hard to beat $25 for breathing new life into your dead or for-parts Gamecube controller without changing how it feels. Adding an Extremerate shell or XYAB controller on top of it for $15-$20, in the event you don't have a donor controller, makes a $40-$45, authentic Gamecube controller in 2024 a pretty attractive proposition. Just be sure you're setting it to WGInput if you're going to use it for Dolphin.

4 notes

·

View notes

Text

not only I can't find half of my Game Boy cartridges, all three of my GBs are busted one way or another and I can't really play any of my old games that I've managed to locate.

Green chunky one has a blank row in the top half of the screen aka the reason why I got the purple Game Boy Color way back in... 1999? I think? (Probably fixable if I bring out my soldering iron and take a deep breath before poking around a 25yo dot matrix screen with a hot piece of metal.)

But now the GBC reads games maybe once every three times and the buttons don't work. (Probably fixable if it's just an oxidation issue.)

The most busted of all however is the GBA SP, which I bought already used in 2007. The ribbon cable for the screen is corroded and that means the whole screen assembly needs to be tossed out. Which is a shame because it was the most comfortable one for playing games, I really don't know how Nintendo kept the 'absolutely no backlight' policy well into the GBA era. (Repairing this one could be an interesting project since there's a big modding scene for these and upgrading the screen is relatively cheap. But I don't know if the corrosion on the ribbon cable means the connector on the main pcb is also corroded which could mean spending money purchasing a new screen for a console that's potentially unsalvageable.)

4 notes

·

View notes

Text

Avalon Technologies Limited Is a Top EMS Industries In India

We Provide Services and Solutions Like:

Design

Engineering

NPI

Volume Production

Life Cycle Management

System Integration

PCB Assembly

Cable & Wire Harness

Sheet Metal

Aerospace Metal

Machining

Magnetics

Plastics

Supply Chain & Logistics

2 notes

·

View notes

Text

Why Should You Rely on Connector Wrenches for Precision and Safety?

Introduction to Connector Wrenches

Connector wrenches are essential tools engineered to simplify the tightening and loosening of connectors in a wide variety of electrical, electronic, and mechanical assemblies. Unlike generic wrenches, connector wrenches are specially designed to provide optimal torque control, ensuring secure connections without damaging delicate components. Their role is increasingly important in precision-driven industries, from telecommunications and aerospace to electronics manufacturing and data centers. The compact design and compatibility with hard-to-reach spaces make these tools a must-have for technicians and engineers working with connectors, sensors, cables, microcontrollers, and other sensitive components.

Why Are Connector Wrenches So Important?

Connector wrenches serve as the interface between quality installation and long-lasting performance. Whether assembling fiber optic cables or tightening RF connectors in communication equipment, these wrenches ensure a perfect fit and torque consistency, reducing the risk of signal loss or component failure.

Their significance extends across multiple fields:

In electronics, they provide careful application of pressure, preserving internal components.

In safety-critical environments, they prevent under-tightening or over-tightening, which can compromise functionality.

In thermal and high-frequency environments, they help maintain signal integrity and reduce potential system malfunctions.

With the rise in automated systems, robotics, and microelectronic devices, connector wrenches have become more refined, precise, and essential.

What Are the Key Features of a Connector Wrench?

Connector wrenches are built with attention to detail, functionality, and durability. The best models are manufactured using high-grade materials like stainless steel or anodized aluminum, and are compatible with various connector types and industry standards.

Key features include:

Ergonomic handles that provide a comfortable, anti-slip grip during repetitive tasks

Torque-limiting designs to prevent damage to sensitive terminals or threaded connectors

Slim or angled profiles to access connectors in tight or obstructed areas

Interchangeable heads to work with different connector sizes or standards

Non-magnetic materials to ensure safety in environments with magnetic-sensitive components like capacitors, sensors, and microprocessors

These design features make connector wrenches versatile for professionals working with thermal pads, controllers, contactors, and other high-performance equipment.

How Are Connector Wrenches Used in Industry?

Connector wrenches are utilized across several technical sectors where precise connectivity is essential. In telecommunications, for example, connector wrenches are commonly used to install coaxial or fiber connectors. In the aviation and aerospace industry, they’re instrumental in ensuring vibration-resistant terminations. In electronics, especially during PCB assembly or repair, connector wrenches help technicians maintain uniform pressure on connector housings, cable grips, and solderless terminals.

They are also integral in:

Automotive electronics installation and diagnostics

Sensor placement in industrial automation systems

Power connector setup in energy distribution equipment

Secure mounting of thermal systems involving heatsinks or fans

Connector wrenches not only streamline workflows but also improve the longevity and safety of complex systems.

What Types of Connector Wrenches Are Available?

There is a wide range of connector wrenches, each tailored for specific applications or connector types. Selecting the right wrench ensures compatibility and precision.

Common types include:

Fixed-head connector wrenches for specific connector sizes and types

Adjustable connector wrenches for handling multiple dimensions with one tool

Torque-limiting connector wrenches with calibrated mechanisms for consistent tightness

T-handle and L-handle styles that enhance torque application in confined spaces

Ratcheting connector wrenches for high-efficiency repetitive tasks

Insulated connector wrenches designed for working with electrical connectors in live circuits

Selecting the correct type ensures compatibility with connectors in tools, switches, safety modules, microcontrollers, and more.

Where Are Connector Wrenches Most Commonly Applied?

Connector wrenches are ubiquitous in various high-tech and industrial environments. Their ability to handle components without risking deformation makes them especially useful in sensitive electrical and data systems.

Typical applications include:

Networking installations involving coaxial, SMA, or fiber connectors

Aerospace electronic equipment where vibration-resistant assembly is vital

Medical devices requiring delicate yet firm connection fittings

Industrial automation systems incorporating sensors, thermal components, and fuses

Consumer electronics involving microprocessors, LEDs, and compact controllers

Renewable energy systems for secure connection of high-power terminals and capacitors

These tools are ideal for use during both installation and maintenance phases.

What Are the Benefits of Using the Right Connector Wrench?

Using the right connector wrench can enhance performance, increase safety, and reduce rework. As systems become increasingly compact and complex, the precision offered by connector wrenches becomes even more valuable.

Key benefits include:

Enhanced reliability of electrical and mechanical connections

Minimization of torque-related connector damage

Efficient installation and maintenance of components such as switches, thermal pads, and cables

Reduction in installation time and human error

Compliance with technical standards in regulated industries

The result is a cleaner, more stable connection with increased system performance and reduced maintenance costs.

How to Choose the Ideal Connector Wrench?

Choosing the right connector wrench depends on various factors such as the type of connector, environment, access space, and required torque.

Consider the following criteria:

Material durability and resistance to wear

Ergonomic design suited for extended use

Compatibility with specific connector types (e.g., SMA, N-Type, DIN)

Availability of torque control if precision is critical

Magnetic safety when working near microelectronics

Size and weight for ease of transport in fieldwork

Investing in a quality wrench tailored to your workflow can make all the difference in precision and efficiency.

Final Thoughts

Connector wrenches play a vital role in ensuring reliable, secure, and professional-grade connectivity across electronics, automation, communications, and industrial applications. As the demand for high-performance systems increases, the importance of using precise tools like connector wrenches becomes evident. These tools enhance system performance, improve safety, and prolong the lifespan of critical components.

Whether you're an electronics technician working with sensors and microcontrollers or an engineer installing power connectors and thermal solutions, connector wrenches are your trusted companion for clean, secure, and efficient assembly. Explore quality options from trusted brands and elevate your toolkit for modern-day applications.

0 notes

Text

Top 10 PCB Manufacturers in the World: A Comprehensive Guide

Introduction

In today's technologically advanced world, printed circuit boards (PCBs) play a crucial role in powering various electronic devices. From smartphones and laptops to medical equipment and automotive systems, PCBs serve as the backbone of modern technology. With the increasing demand for high-quality PCBs, it's essential to know about the top manufacturers in the world. This comprehensive guide will explore the top 10 PCB manufacturers globally, shedding light on their expertise, capabilities, and contributions to the industry.

PCB Manufacturing Industry: An Overview

Before delving into the top 10 PCB manufacturers, let's first understand the PCB manufacturing industry as a whole. PCBs are vital components that provide electrical connections and mechanical support for various electronic components. They are made by laminating thin layers of copper onto a non-conductive substrate, usually made of fiberglass or composite epoxy materials.

PCBs can have multiple layers, each serving a specific purpose. The manufacturing process involves intricate steps such as designing the PCB layout, etching the copper layers, drilling holes, and applying solder mask and silkscreen for labeling.

The PCB manufacturing industry is highly competitive and driven by innovation. With advancements in technology, manufacturers are constantly pushing the boundaries to produce PCBs that are smaller, more efficient, and capable of supporting complex electronic designs.

Now, let's dive into the top 10 PCB manufacturers in the world and explore their unique strengths and contributions.

ACME Circuits — We are the best-printed circuit board manufacturer and services providers. We provide high-quality PCB assembly, PCB design, PCB fabrication, PCB layout, PCB programming, testing, etc.

2. Foxconn Technology Group

3. TTM Technologies

4. Tripod Technology Corporation

5. Unimicron Technology Corporation

6. Zhen Ding Technology Holding

7. Nippon Mektron

8. Sumitomo Electric Industries

9. Young Poong Electronics

10. Samsung Electro-Mechanics

Conclusion

Choosing the right PCB manufacturer is paramount to the success of any electronic product. The top 10 PCB manufacturers in the world mentioned in this article have demonstrated their expertise, reliability, and commitment to delivering high-quality PCB solutions. Whether you prioritize innovation, customization, sustainability, or scalability, these manufacturers offer a diverse range of options to suit your specific requirements. By partnering with a reputable and trusted PCB manufacturer, you can ensure the seamless integration of PCBs into your electronic devices, ultimately enhancing their performance and reliability.

#Printed Circuit Board Manufacturers#pcb manufacturing#printed circuit board assembly#circuit board manufacturing#pcb board manufacturer#high frequency pcb manufacturing#printed circuit board manufacturers near me#pcb manufacturer#pcb supplier#pcb assembly services#pcb assembly manufacturer#electronic cable assembly#electronic contract services#pcb exporters#printed circuit board manufacturer in india#pcb manufacturing companies in india

1 note

·

View note

Text

Top 10 Electronics Manufacturing Companies in India You Should Know About

India is rapidly becoming a global hotspot for electronics manufacturing, and it’s no accident. Thanks to government initiatives like Make in India and PLI (Production Linked Incentive), along with a skilled workforce and cost-competitive production, electronics manufacturing companies in India are shaping the future of global tech.

If you’re in the electronics industry or simply curious about the powerhouses driving India’s growth, here’s a curated list of the Top 10 Electronics Manufacturing Companies in India you should have on your radar.

Let’s dive in.

Why India for Electronics Manufacturing?

✅ Skilled Workforce: Thousands of engineers entering the industry every year.

✅ Policy Support: Incentives through Make in India & PLI schemes.

✅ Global Demand: Supplying top brands worldwide.

✅ Innovation Focus: Companies invest heavily in R&D for future technologies.

⚙️ Top 10 Electronics Manufacturing Companies in India

1️⃣ Dixon Technologies

Noida-based Dixon Technologies leads the way in contract manufacturing for electronics. They work with major global brands producing everything from smartphones to LED TVs.

Specialties:

Consumer Electronics

Mobile Phones

Lighting & Security Devices

Why Dixon? Trusted by names like Samsung, Xiaomi & Panasonic.

2️⃣ Bharat Electronics Limited (BEL)

A government-owned giant, BEL is best known for defense electronics but also manufactures products for telecom, civilian, and broadcast sectors.

Specialties:

Defense Electronics

Communication Equipment

Radar Systems

Why BEL? Top choice for mission-critical and defense-grade tech.

3️⃣ Elin Electronics

Based in Ghaziabad, Elin Electronics provides EMS solutions across LED lighting, appliances, and medical devices.

Specialties:

PCBA

Small Appliances

Automotive Electronics

Why Elin? Known for quality and reliable partnerships.

4️⃣ Syrma SGS Technology

Catering to IoT, automotive, and healthcare industries, Syrma SGS stands out for both manufacturing and design services.

Specialties:

Electronics Manufacturing

RFID

Custom Magnetics

Why Syrma? Global clientele and versatile capabilities.

5️⃣ Avalon Technologies

With a focus on high-complexity assemblies, Avalon is ideal for companies needing precision engineering and system integration.

Specialties:

PCB Assembly

System Integration

Cable Assemblies

Why Avalon? Perfect for custom, small-batch production.

6️⃣ SFO Technologies (NeST Group)

A key player for companies in aerospace, healthcare, and industrial automation, SFO Technologies delivers more than just manufacturing—they build complete systems.

Specialties:

EMS

Embedded Systems

Software Development

Why SFO? Seamless integration of software and hardware expertise.

7️⃣ Kaynes Technology

If you’re in the IoT game, Kaynes Technology is a name to remember. They offer end-to-end EMS services, especially for IoT, automotive, and defense.

Specialties:

IoT Product Development

Embedded Systems

Automotive Electronics

Why Kaynes? Known for cutting-edge innovation in connected tech.

8️⃣ Optiemus Electronics Limited (OEL)

A major contributor to India’s smartphone manufacturing revolution, OEL partners with global brands to build mobile devices and accessories.

Specialties:

Mobile Phones

Wearables

Accessories

Why Optiemus? Trusted by telecom giants for device manufacturing.

9️⃣ VVDN Technologies

What sets VVDN apart is their design-led manufacturing approach, especially for IoT, telecom, and networking solutions.

Specialties:

IoT Product Design

Embedded Software

Cloud & App Integration

Why VVDN? Full-stack development plus manufacturing.

🔟 Centum Electronics

For high-reliability electronics in critical sectors like space and defense, Centum Electronics is a leader, supplying even ISRO and DRDO.

Specialties:

Aerospace Electronics

Microelectronics

Defense Tech

Why Centum? Precision-built for mission-critical applications.

🏆 How to Choose Your Manufacturing Partner?

Here’s what you should focus on when selecting an electronics manufacturing company:

✔ Industry Expertise

✔ Certifications (ISO, IATF, etc.)

✔ Capacity for Production Scale

✔ Design & R&D Capabilities

✔ Location and Logistics

Pro Tip: Use platforms like FindingMFG to connect with verified manufacturers across India. It’s faster, safer, and saves a lot of hassle.

🌐 Ready to Start?

The electronics manufacturing company in India is growing stronger every year—and these companies are leading the charge. Whether you’re launching a startup, scaling your supply chain, or just exploring opportunities in tech manufacturing, India’s EMS ecosystem has the solutions you need.

👉 Explore more at FindingMFG.com

#electronics manufacturing#electronics manufacturing companies#top 10 electronics manufacturing companies in India#manufacturing directory#business directory

0 notes

Text

"Why Wire-to-Board Connectors Matter in Today's Tech Landscape"

In the ever-evolving landscape of electronics and electrical engineering, wire-to-board (WTB) connectors are fundamental components that provide a secure, efficient link between a set of discrete wires and a printed circuit board (PCB). Despite their small size, these connectors are indispensable in a wide range of applications—from consumer electronics and automotive systems to industrial machinery and telecommunications.Get more news about Wire-to-board Connector,you can vist our website!

What Are Wire-to-Board Connectors? Wire-to-board connectors are used to route electrical signals or power from individual wires onto a printed circuit board. Unlike board-to-board connectors that facilitate connections between PCBs or wire-to-wire connectors that link individual wire sets, WTB connectors interface directly between a cable harness and the board, typically through soldering or press-fit terminals. This facilitates modular design, ease of maintenance, and scalable manufacturing.

They consist of two primary components: the plug (housing the wires) and the receptacle or header (mounted on the PCB). These connectors are available in various pitches (the center-to-center spacing between pins) and configurations (vertical or right-angle orientations), making them adaptable for a variety of design constraints and spatial limitations.

Key Features and Considerations Designers and engineers often evaluate several critical factors when selecting WTB connectors:

Current and Voltage Ratings: Depending on the application, connectors must meet safety and performance thresholds.

Pitch Size: Fine-pitch connectors (≤1 mm) allow for compact design, while larger pitches offer greater robustness.

Locking Mechanisms: Latch or friction locks ensure secure connections that resist vibration or accidental disconnection.

Material and Plating: Contact materials, often copper alloys with gold or tin plating, influence conductivity and longevity.

Environmental Resilience: Some WTB connectors are designed for harsh environments with resistance to moisture, dust, or high temperature.

Applications Across Industries The versatility of wire-to-board connectors is reflected in their widespread use across diverse industries:

Consumer Electronics: Used in smartphones, laptops, and wearable devices for internal signal and power connections.

Automotive: Essential for infotainment systems, sensors, and electronic control units (ECUs), where compact, vibration-resistant connectors are critical.

Medical Equipment: Connectors must meet stringent reliability and safety standards in devices like diagnostic equipment and patient monitors.

Industrial Automation: WTB connectors facilitate modular assembly and simplify maintenance for sensors, controllers, and interface devices.

Trends and Innovations Modern trends push the boundaries of connector miniaturization and performance. As electronic devices become more compact and sophisticated, the demand for high-density connectors with increased signal integrity and EMI shielding continues to grow. Additionally, some manufacturers are integrating features like surface-mount technology (SMT) compatibility and automated cable termination to streamline production and assembly.

Another key trend is the development of eco-friendly, RoHS-compliant connectors to meet global environmental standards while ensuring high performance. With the rise of Industry 4.0 and the Internet of Things (IoT), wire-to-board connectors are playing an increasingly strategic role in enabling smart, connected systems.

Conclusion Although often overlooked compared to high-profile semiconductors or processors, wire-to-board connectors are vital enablers of modern electronic innovation. Their reliability, precision, and adaptability allow designers to build smaller, more powerful, and more efficient systems. As technology continues to advance, the humble WTB connector will remain a quiet but essential hero in the background—connecting ideas to reality, one circuit at a time.

0 notes

Text

Marck Industries: Trusted Manufacturer of Premium Elevator Spare Parts

Why Reliable Spare Parts Matter in Elevator Systems

Elevators are essential in modern buildings—transporting people and goods swiftly and safely. Downtime due to broken or worn-out parts isn’t just inconvenient—it can impact safety, building efficiency, and tenant satisfaction. That’s why having a dependable source of high-quality spare parts is vital.

What Sets Marck Industries Apart

1. Decades of Expertise

With years of experience in manufacturing elevator components, Marck Industries understands the stringent requirements of vertical transportation—ensuring every part is engineered for precision, durability, and compliance with international safety standards.

2. Comprehensive Product Portfolio

From mechanical to electrical systems, we supply a full range of elevator parts, including:

Controller boards & PCBs

Inverter and VFD units

Proximity switches & sensors

Door lock and safety gear

Brake assemblies & drums

Buffers, rollers, and pulleys

Cabin fixtures: buttons, display panels, handrails

3. Precision Manufacturing

Utilizing CNC machining, injection molding, and automated PCB assembly, each component is produced to exact tolerances—ensuring fit and function with OEM performance or better. Strict quality checks, including EN 81, ASME A17.1, and ISO audits, guarantee consistency.

4. Certified Quality & Safety

Marck operates with certifications to:

ISO 9001 Quality Management

CE marking and compliance

Adherence to EN (Europe) and ASME (North America) elevator safety codes

These credentials ensure safe, global-grade parts.

5. Custom Solutions & Adaptability

Recognizing that every elevator system is unique, Marck Industries excels in custom engineering—from tailored connectors and cables to complete PCB re-engineering—while maintaining cost and lead-time efficiency.

Benefits of Partnering with Marck Industries

Advantage

Impact

High Uptime & Quick Delivery

Minimize downtime with rapid part replacement and fast shipping

Competitive Pricing

Optimized production lowers costs without compromising quality

Global Support Infrastructure

Sales and technical teams available round-the-clock across regions

Extended Product Warranty

Confidence via long-term warranty and support packages

Serving Diverse Market Segments

Residential Buildings: Reliable replacements for passenger-lift maintenance.

Commercial Complexes: Durable components suited for high-traffic usage.

Industrial Facilities: Heavy-duty parts designed for freight and goods lifts.

OEM Collaborations: Contract manufacturing aligned with global elevator brands.

Quality Control & Testing Procedures

Each batch undergoes:

Incoming Material Inspection (IQC)

In-Process Monitoring (IPC)

Performance Testing: Load, endurance, vibration, and electrical tests

Final Audits & Certification

Partnering with Marck: How It Works

Initial Consultation Understand your system specs, OEM models, and usage patterns.

Quotation & Sample Approval We provide detailed proposals and offer test samples for validation.

Order & Production Ranging from small spare lots to mass production, with regular updates.

Technical & After-Sales Support Including troubleshooting, field assistance, and prompt RMA processes.

Ongoing Relationship We offer lifecycle support—even for legacy elevators requiring obsolete part replacements.

Elevate Your Operations with Marck Industries

Your elevator fleet deserves nothing less than reliable, certified parts that stand the test of time. Choose Marck Industries for precision, safety, and peace of mind—backed by technical excellence and global service reach.

Ready to discuss your parts needs? Contact our sales team or request a quote through the Marck Industries website today.

0 notes