#PharmaPackaging

Explore tagged Tumblr posts

Text

Global Composite Packaging Market - Industry Trends and Forecast

Composite packaging combines two or more materials—such as paper, aluminum foil, plastic films, or specialized polymers—to deliver high barrier protection, durability, and lightweight performance. It’s widely used in food & beverage cartons (like aseptic packs), pharmaceutical blister packs, flexible pouches, and household products. Composite packaging offers extended shelf life, moisture and oxygen resistance, and customized features like resealable spouts and tamper-indication. As sustainability takes center stage, innovation in mono-material designs, recyclable layers, and smart features (e.g. embedded QR codes, sensors) is accelerating market growth globally.

#CompositePackaging#SmartPackaging#BarrierMaterials#SustainablePackaging#AsepticCartons#FlexiblePouches#PharmaPackaging#RecyclableMaterials#CircularEconomy#FoodPackaging#PackagingInnovation#EcommercePackaging#SmartLogistics#EcoFriendlyPackaging#MaterialsScience

0 notes

Text

Sachet Packaging Machine Market Growth Driven by Demand for Compact Packaging Solutions

The Sachet Packaging Machine Market has emerged as a key player in modern packaging due to the rising demand for compact and efficient packaging solutions. Businesses across industries such as food, beverages, pharmaceuticals, and personal care are rapidly adopting sachet packaging for its affordability and convenience.

Growing Popularity of Sachet Packaging Solutions

Compact packaging formats are highly popular among consumers seeking affordable and single-use products. Sachets cater to these demands by offering cost-effective solutions, particularly in emerging economies where affordability drives purchasing decisions. For manufacturers, sachets reduce material usage and enhance distribution efficiency, making them an appealing option for cost-conscious production.

Factors Driving Market Growth

Several factors contribute to the robust expansion of the sachet packaging machine market:

Affordability and Accessibility: Sachet packaging makes premium products affordable to low-income consumers by offering smaller, pocket-friendly units.

Convenience and Portability: Consumers prefer easy-to-use, single-serve packs for personal care, condiments, and health supplements.

Emerging Markets Growth: Countries in Asia-Pacific and Africa are witnessing exponential sachet adoption due to urbanization and growing disposable incomes.

Rising Demand from Food and Beverage Sector

The food and beverage industry dominates the sachet packaging machine market, driven by high demand for instant food products, sauces, seasonings, and powdered beverages. Brands are leveraging sachet packaging to maintain product freshness while ensuring portion control.

Technological Advancements in Sachet Packaging Machines

Innovation plays a vital role in shaping market dynamics. Modern sachet packaging machines are equipped with advanced automation, enabling faster production, minimal waste, and better sealing technology. Features such as servo-driven operations, real-time monitoring, and error detection enhance efficiency, reduce downtime, and improve product quality.

Sustainability and Environmental Considerations

As environmental concerns rise, manufacturers are exploring eco-friendly packaging materials compatible with sachet machines. The integration of biodegradable and recyclable films aims to address sustainability challenges without compromising packaging efficiency.

Regional Market Trends

Asia-Pacific leads the global sachet packaging machine market, fueled by the region’s large population, expanding middle class, and increasing demand for affordable packaged goods. Latin America and Africa are emerging as promising markets, given their growing retail sectors and consumer preference for cost-effective packaging.

Challenges and Restraints

Despite significant growth, the market faces challenges such as plastic waste concerns, regulatory restrictions on single-use packaging, and fluctuating raw material prices. Manufacturers must invest in R&D to develop sustainable alternatives and comply with global packaging regulations.

Future Outlook

The sachet packaging machine market is projected to continue its upward trajectory, driven by advancements in automation, eco-friendly packaging innovations, and rising demand across industries. With customization and scalability becoming industry priorities, manufacturers offering versatile and sustainable solutions will gain a competitive edge.

#SachetPackaging#PackagingInnovation#CompactPackaging#FoodAndBeverage#PharmaPackaging#EcoFriendlyPackaging#MarketGrowth#Automation#SustainablePackaging#ConsumerGoods

0 notes

Text

Story Behind the Market – Pharmaceutical Packaging

Packaging isn’t just protection—it’s precision, compliance, and innovation. The Pharmaceutical Packaging Market is projected to grow from $149.97B in 2024 to $335.78B by 2032, at a strong CAGR of 10.6%. This growth is driven by the rise of biologics, injectables, and smart packaging technologies that ensure drug safety, traceability, and patient adherence.

🚀 What’s shaping the future?

📦 Smart packaging: RFID tags, sensors, and tamper-evident features

🧪 Biologic-friendly formats: prefilled syringes, vials, and temperature-controlled packs

🌱 Eco-conscious materials: paperboard and biodegradable plastics gaining traction

With North America leading innovation and Asia-Pacific accelerating production, pharmaceutical packaging is evolving into a high-tech, sustainable backbone of global healthcare.

🔗 Read the full report: https://www.skyquestt.com/report/pharmaceutical-packaging-market

0 notes

Text

Maximize efficiency and minimize downtime with Shree Bhagwati’s 120 CPM Cartoning Machine! Designed with overload safeguards and vacuum protection, it ensures safe, reliable, and high-speed packaging for various industries. Perfect for blister packs, bottles, and more! For more details, visit: https://www.bhagwatipharma.com/120-cpm-automatic-cartoning-machine/

#shreebhagwatipharma#CartoningMachine#highspeedpackaging#productionline#packagingmachinery#blisterpackingmachine#bottlespackaging#ManufacturingSolutions#pharmapackaging#SafetyFeatures

0 notes

Text

Sealing the Standard: How Pharmaceutical Zip Lock Bags Safeguard Medical Products

Secure and hygienic storage is essential in healthcare. By choosing Pharmaceutical Zip Lock Bags Wholesale, medical facilities and pharmacies gain access to bulk, cost-effective packaging that ensures product safety and compliance. These durable, resealable bags are ideal for storing medications, offering convenience, organization, and protection in medical environments.

0 notes

Text

Labelling Solutions Tailored for Every Industry – Maharshi Machines

Discover Maharshi’s versatile and innovative range of labelling machines designed to serve multiple industries including pharmaceuticals, cosmetics, food, beverages, and more.

This infographic visually showcases various high-performance labelling solutions such as Automatic Sticker Labelling Machines, Stand-Alone Label Applicators, Rotary Sticker Labellers, Semi-Automatic Labelling Machines, Top & Bottom Labelling Systems, and Tube Labelling Machines. Each machine is engineered for precision, speed, and adaptability—ideal for both small-scale businesses and high-volume production environments. Whether you need wrap-around, flat surface, or top-bottom labelling, Maharshi offers a solution that ensures consistency and compliance in packaging. For more details, visit - www.maharshi.com

#LabellingMachines#PackagingSolutions#Maharshi#AutomaticLabeller#IndustrialMachinery#RotaryLabelling#TubeLabeller#PharmaPackaging#FMCGLabeling#EngineeringSolutions#PackagingTechnology

0 notes

Text

Vaccine Packaging Market Drivers Include Cold Chain Advancements and Global Immunization Campaign Growth

In the evolving landscape of pharmaceutical logistics, the Vaccine Packaging Market stands as a critical component, driven by advancements in cold chain technologies and the global escalation of immunization campaigns. As the world battles both ongoing and emerging infectious diseases, the need for robust packaging solutions that ensure vaccine integrity from production to administration has never been more urgent.

Cold Chain Enhancements: Backbone of Safe Vaccine Delivery

Vaccines are sensitive to temperature fluctuations, requiring continuous cold storage from the point of manufacture to the point of use. Recent technological advancements in cold chain logistics have significantly improved the reliability and efficiency of vaccine distribution. From advanced insulated containers and phase change materials to GPS-enabled temperature tracking, cold chain systems now offer higher transparency and precision. These innovations minimize spoilage and help meet stringent global regulatory standards, boosting trust among stakeholders.

Moreover, the development of last-mile cold delivery systems is extending vaccine access to remote and underserved regions. These include solar-powered refrigerators and mobile cooling units that maintain product efficacy in environments previously deemed logistically challenging.

Global Immunization Drives Fueling Packaging Demand

The expansion of immunization campaigns, both routine and emergency, plays a pivotal role in market acceleration. National vaccination programs, supported by organizations like WHO, UNICEF, and Gavi, have prompted the mass deployment of vaccines to diverse geographies. This surge in volume necessitates scalable, reliable, and compliant packaging infrastructure capable of maintaining product stability during complex distribution.

Additionally, the inclusion of newer vaccines such as HPV, pneumococcal, and malaria inoculations within national immunization schedules requires tailored packaging formats. Each of these vaccines comes with unique handling needs, encouraging the development of highly specialized primary and secondary packaging solutions.

Integration of Data-Driven Packaging Technologies

Another major driver influencing vaccine packaging is the adoption of data-driven innovations like smart labels and RFID-enabled tracking systems. These tools provide real-time visibility into environmental conditions, storage status, and location, ensuring accountability and preventing counterfeit risks. This level of data integration also enhances the ability of health authorities to manage inventories, optimize distribution routes, and respond rapidly to demand spikes.

By merging traditional cold chain technologies with digital intelligence, the vaccine packaging sector is setting new standards in transparency and safety—factors critical to global health governance and pandemic response.

Emerging Economies and Vaccine Infrastructure Investments

Emerging markets are seeing intensified investment in healthcare infrastructure, with vaccine cold chains receiving particular attention. Government health ministries and international funding bodies are working to establish packaging and distribution frameworks that can accommodate a diverse range of vaccines. In countries like India, Brazil, and South Africa, rapid urbanization and growing healthcare budgets are catalyzing the deployment of state-of-the-art vaccine packaging facilities.

Furthermore, pharmaceutical manufacturers are increasingly localizing packaging operations in developing countries to reduce transit times and costs while complying with regional regulatory mandates. These shifts further contribute to overall market growth and resilience.

Packaging Material Evolution Supports Growth

Alongside cold chain and campaign-related developments, material innovations are reshaping packaging formats. The use of high-barrier polymers, shatterproof glass alternatives, and environmentally conscious materials enables vaccine packaging to perform in diverse conditions while reducing waste and minimizing environmental impact. These materials are engineered for strength, durability, and thermal resistance, making them ideal for high-volume vaccine programs across a wide range of climates.

Regulatory Harmonization and Standards Elevate Market Maturity

Global harmonization of vaccine packaging standards by bodies such as the WHO, FDA, and EMA also strengthens market dynamics. These regulations emphasize the use of validated, performance-based packaging that ensures dosage safety, proper labeling, and traceability. As compliance requirements intensify, manufacturers are compelled to invest in superior packaging technologies to maintain market eligibility and reduce recalls or losses.

The Future Outlook: Embracing Digitization and Expansion

As vaccine programs continue to evolve to address both endemic and pandemic threats, packaging needs will become increasingly sophisticated. The integration of real-time data monitoring, biodegradable materials, and modular cold storage units is expected to define the next phase of vaccine packaging innovation.

Moreover, as international immunization efforts target broader age groups and new disease strains, packaging scalability and adaptability will remain a critical focus. Continuous collaboration between pharmaceutical giants, government agencies, and tech companies will ensure the sector remains agile and responsive.

Conclusion: Leading into Smart Packaging Solutions

With cold chain breakthroughs and global immunization drives at the forefront, the Vaccine Packaging Market is undergoing a transformative phase. As we explore the next article, we’ll delve into how sustainable, tamper-proof, and smart labeling technologies are becoming pivotal in shaping future packaging trends across the vaccine sector.

#VaccinePackaging#ColdChainLogistics#ImmunizationCampaigns#SmartLabeling#PharmaPackaging#GlobalHealth#VaccineDistribution#SustainablePackaging#TemperatureSensitivePackaging#HealthcareInnovation

0 notes

Text

How Oxygen Absorbers Protect Pharma Products | O-Sorb Explained

Discover how O-Sorb Oxygen Absorbers safeguard pharmaceutical and healthcare products from oxidative damage. These powerful packets reduce oxygen levels to below 0.01%, preserving the potency, stability, and shelf life of tablets, capsules, diagnostic kits, and more. Learn how oxygen scavengers work, their key applications, and why they’re essential for pharma packaging and compliance with global standards like USFDA and EU regulations.

Explore the science behind oxygen protection and how it ensures product safety from manufacturing to end use.

#OxygenAbsorbers#PharmaPackaging#OSorb#PharmaceuticalProtection#HealthcarePackaging#ShelfLifeExtension#OxidationPrevention#DrugStability#PharmaDesiccants#MedicalLogistics#Pharmaceutical#Nutraceuticals#Diagnostic Products#MedicalDevice#Injectables#Healthcare#Healthcare Products#Biopharmaceutical#Ayurvedicmedicine

1 note

·

View note

Text

Keep an Eye on Everything: The Power of Track & Trace in 2025

In today’s fast-paced, data-driven world, real-time visibility is no longer a luxury—it’s a necessity. Businesses across industries are leveraging the track and trace system to optimize operations, enhance transparency, and gain a competitive edge. From pharmaceutical packaging to nationwide logistics, these systems are revolutionizing how we monitor and manage the journey of products.

In this blog, we’ll explore how the track and trace system works, its growing role in India, and how innovations like barcode scanners and GPS tracking systems are transforming industries—especially the pharma sector.

#TrackAndTrace#PharmaPackaging#FoodTraceability#ManufacturingSolutions#BarcodeScanner#GPSTrackingSystem#TrackAndTraceIndia#SupplyChainTech#DigitalIndia#ProductAuthentication

0 notes

Text

High-Performance ROPP Cap Manufacturing Machine by NPM Machinery

Boost your packaging line with NPM Machinery’s advanced ROPP Cap Manufacturing Machine. Designed for precision, speed & efficiency—ideal for pharma, beverages & more. Explore the power of automation now!

#ROPPCapMachine#CapManufacturing#PackagingMachinery#NPMPackaging#PharmaPackaging#BeveragePackaging#MonoblockCapper#LiquidFillingMachine#NPMMachinery

0 notes

Text

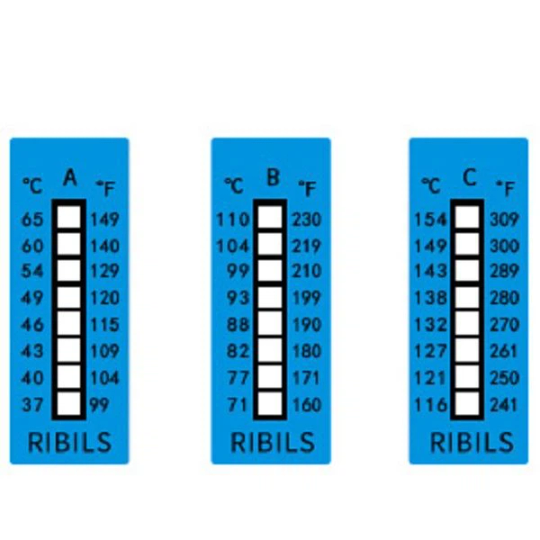

Time Temperature Indicator Labels Market Future Trends Driven by Food Safety and Cold Chain Expansion

The time temperature indicator (TTI) labels market is witnessing transformative growth, fueled by heightened awareness around food safety, pharmaceutical integrity, and cold chain reliability. These smart labeling solutions, designed to monitor and visually communicate exposure to temperature over time, are gaining traction as critical components in ensuring product quality and safety from production to consumption.

With the global movement toward more traceable and accountable supply chains, TTIs are evolving from basic indicators to sophisticated tools integrated with digital platforms. As a result, the market is on the cusp of numerous exciting trends that will redefine its scope, utility, and technological sophistication over the coming years.

Rising Adoption Across Cold Chain Applications

Cold chain logistics—especially for food, beverages, and pharmaceuticals—has emerged as a major driver of TTI label demand. Ensuring that temperature-sensitive products maintain optimal storage conditions from production facilities to end consumers is vital for health, compliance, and brand reputation. TTIs are increasingly being employed across frozen foods, dairy, seafood, vaccines, biologics, and other perishable items to maintain quality assurance throughout the chain.

The future will likely see an increased preference for TTIs with broader temperature sensitivity ranges, multi-threshold indicators, and clear, irreversible visual cues. Businesses are also showing interest in bulk implementation to cover secondary and tertiary packaging layers.

Integration With Smart Packaging Technologies

One of the most prominent future trends is the integration of TTIs with broader smart packaging solutions. As the Internet of Things (IoT) continues to penetrate logistics and retail, TTIs are being embedded with digital sensors and QR codes for real-time data capture and sharing.

Smart TTIs that can communicate directly with mobile apps or centralized monitoring systems are beginning to replace passive indicators. These labels not only show visual color changes but also log data that can be analyzed for inventory management, quality control, and predictive analytics. This integration offers transparency, faster decision-making, and greater control over supply chain variables.

Demand From E-Commerce and Direct-to-Consumer Models

With the rise of online food delivery and direct-to-consumer pharmaceutical services, TTIs are becoming more essential in smaller packaging formats. Consumers are now more aware of freshness indicators and often demand proof of proper handling during transit.

TTI labels are expected to play a bigger role in boosting consumer trust in online food platforms, meal kits, and prescription deliveries. Companies that include these indicators on packaging enhance perceived value and demonstrate their commitment to safety and transparency, creating competitive differentiation in the market.

Innovation in Label Materials and Printing Techniques

As sustainability becomes a growing concern, future TTI development will also focus on eco-friendly materials, non-toxic indicator inks, and recyclable adhesives. Biodegradable substrates and compostable labels are in demand, especially among companies pursuing green certification and reducing packaging waste.

Innovative printing technologies like inkjet and roll-to-roll digital printing are being explored to reduce costs and enhance the scalability of TTI labels. This evolution in production methods also enables greater customization, allowing companies to design TTI labels suited for specific use-cases and branding needs.

Expansion Into Emerging Markets

As cold chain infrastructure improves in emerging economies such as India, Brazil, and Southeast Asia, the demand for TTIs is expected to surge. Governments and regulatory agencies are tightening food and pharma handling laws, encouraging local businesses to adopt TTIs for compliance and export-readiness.

The future will likely see wider adoption across local meat markets, dairy cooperatives, vaccine storage facilities, and agricultural exporters in these regions. Local manufacturing of TTIs in these markets will also help reduce costs and increase penetration.

Regulatory Influence and Compliance Standards

Global food and drug regulatory bodies such as the FDA, EFSA, and WHO are increasingly encouraging or mandating the use of time temperature monitoring tools. TTIs are being viewed as crucial evidence in compliance audits, recalls, and quality assurance practices.

In the coming years, expect TTIs to become standard in packaging across high-risk products. As new legislation emerges focusing on traceability and consumer protection, more companies will proactively integrate TTIs into their packaging processes to stay ahead of regulatory requirements.

Personalized and Customizable Indicator Solutions

As industries diversify, the need for customizable TTI labels will increase. Companies are requesting indicators tuned to specific time-temperature thresholds that reflect the perishability and stability of individual products. For example, the temperature tolerance of a fresh salad kit differs significantly from a vial of insulin.

Label providers that offer personalization options, on-demand printing, and integration with digital platforms will gain a significant edge in the evolving market. This shift towards tailored solutions will define the next wave of innovation in the TTI space.

Enhanced Focus on Consumer Awareness

Consumer education about freshness and safety indicators is expected to grow, further influencing demand for TTIs in retail packaging. Packaging that visibly shows freshness status builds brand trust and enhances product appeal. As shoppers become more informed, TTI-labeled products will increasingly become a deciding factor at the point of sale.

Brands that actively promote their use of TTIs in marketing campaigns are likely to strengthen their value proposition, especially in health-conscious and premium product segments.

Conclusion

The future of the time temperature indicator labels market lies in its adaptability, integration with digital ecosystems, and alignment with global safety standards. As cold chains grow more complex and consumers demand greater transparency, TTIs will evolve into intelligent tools offering insights beyond simple temperature tracking. Players in this space who innovate in technology, sustainability, and user experience are poised to lead the next phase of growth in this essential and rapidly expanding market.

#TimeTemperatureIndicatorsMarket#SmartPackaging#ColdChainLogistics#FoodSafetySolutions#PharmaPackaging

0 notes

Text

Parth Engineers and Consultant’s liquid filling machine delivers exact doses with servo motor control and reduces foaming thanks to its smart diving nozzle. Stainless steel body means it’s built tough for your high-volume, contamination-sensitive needs. Industrial vibes but make it sleek.

For more details, visit- https://www.parthec.com/product/automatic-servo-base-volumetric-liquid-filling-machine

#parthengineersandconsultant#automaticvolumetricliquidfillingmachine#liquidfillingmachine#volumetricliquidfillingmachine#pharmapackaging#automaticmachine

0 notes

Text

Bottle Cap Torque Tester - BCT - 201

The Pharmag Instruments Bottle Cap Torque Tester 201 comes with High Accuracy and High Resolution. It can be used to measure the torque value. It is easy to operate. The force gauge can display the Torque direction. It has the white background light. The Bottle Cap Torque can store 20 Batch values with date and time. It measures the Units Kgf.cm/ Inch.lbs/ daN.cm/ N.cm/ N.m/ KP. Data can transfer from RS232 to PC during every test.

Compatibility: High Resolution, High Accuracy and Easy to operate.

Real-time Data Transfer: It can transmit the data through RS-232 to PC during every test.

Unit selection & Conversion: Units available: Kgf.cm/Inch.lbs/daN.cm/N.cm/N.m/KP.

Parameter Measurements: Very low; low; high; very high, which permit to detect and display messages of quality in relation to the detected torque (visualization on bar-graph).

Memorization of 4 thresholds: The Bottle Cap Torque Tester can set the Upper and Lower limit Deviation value to judge the measured results. It has a buzzer which can alarm automatically with sound and light.

Display: Monochrome Graphical Display.

Results Storage: Measures 20 batch data values with date and time available. visit www.technovalue.in for more info

#PharmaPackaging#QualityControl#PackagingTesting#PharmaceuticalTesting#LabEquipment#BottleSealingTest#TorqueMeasurement#BottleCapTorqueTester#TorqueTester#BCT201#CapTorqueMeasurement#TorqueDirectionDisplay#HighAccuracyTesting#ForceGauge

0 notes

Text

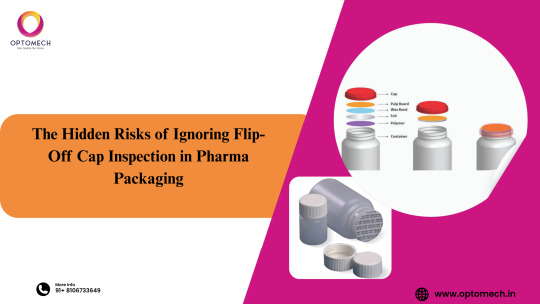

The Hidden Risks of Ignoring Flip-Off Cap Inspection in Pharma Packaging

In pharmaceutical manufacturing, every detail counts — from sterile filling to labeling. But one component often overlooked is the flip-off cap that seals injectable vials. It’s small, yes — but the consequences of not inspecting it are anything but.

Let’s talk about why ignoring flip-off seal inspection is a risk no modern pharma brand should take, and how Optomech’s FOSIS system brings precision, automation, and peace of mind to the process.

🧨 The Problem: Small Defects, Big Consequences

You may think a cap is just a cap. But even minor defects in flip-off seals can cause:

Regulatory failures during batch audits

Sterility breaches in transit or storage

Patient safety risks due to contaminated vials

Brand reputation damage from recalls or customer complaints

Typical issues include:

Black spots

Short filling of the PP button

Cut or dented aluminum shells

Color mismatches

Improper or missing plastic caps

Now imagine these defects slipping through manual or random inspections. That’s a compliance risk pharma companies can no longer afford.

✅ The Solution: Meet FOSIS – Flip-Off Seal Inspection System

FOSIS is Optomech’s high-speed, camera-based vision inspection system — purpose-built to scan, detect, and reject defective flip-off caps with unmatched accuracy.

🎯 Key Features at a Glance:

Speed: Inspects up to 600 caps/min

Vision Accuracy: Detects 20+ types of defects

Automation: No manual checking, no guesswork

Rejection System: Faulty caps are auto-ejected instantly

Compliance: Fully 21 CFR Part 11 compliant

🧠 How It Works:

Caps are fed into the system via a vibratory bowl.

High-speed cameras capture images from multiple angles.

Advanced algorithms compare each cap to a defect-free reference.

Defective caps are rejected, and logs are generated.

Reports can be exported via Excel/network sharing.

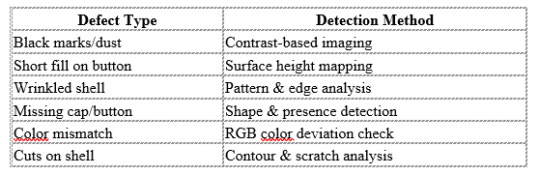

📊 Defects Detected by FOSIS:

🏭 Who Needs FOSIS?

FOSIS is ideal for:

Pharmaceutical manufacturers of injectable drugs

CMOs (Contract Manufacturing Organizations)

Flip-off cap producers

Companies targeting zero-defect packaging

Whether you're building a new packaging line or upgrading your existing setup, FOSIS integrates seamlessly and boosts inspection reliability from day one.

🔒 Why Flip-Off Cap Inspection Can’t Be Optional Anymore

In today’s regulated pharma landscape:

Quality audits are stricter

Sterility concerns are growing

Brand protection is non-negotiable

FOSIS isn't just a machine — it's your frontline quality gate. It helps you catch defects before regulators or customers do.

🏁 Final Takeaway: Inspection Is No Longer Optional — It's Strategic

Flip-off seal inspection may be a “last step” in the process, but with FOSIS, it becomes a first-class safeguard for your production integrity. Speed, accuracy, compliance — all in one automated system.

📞 Want to see FOSIS in action or schedule a demo? 📧 [email protected] 🌐 www.optomech.in/flipoff-inspection-system-2

#flipoffsealinspection#pharmapackaging#capdefectdetection#machinevisionqc#21cfrcompliant#injectablepackaging#optomechinspection#capinspectionmachine#visualinspectionpharma#zeroDefectPackaging

0 notes

Text

Our Blister Packaging Machine offers smooth, noiseless performance with low power consumption and easy operation. Available in Model 150 and 300, it delivers up to 300 packs per minute – perfect for tablets and capsules. Customisable to your needs, it's the ideal choice for efficient pharmaceutical packaging.

For more details, visit - https://www.bhagwatipharma.com/blister-packaging-machinery/

#BhagwatiPharma#BlisterPackagingMachine#PharmaPackaging#TabletCapsulePacking#HighSpeedPackaging#PharmaceuticalMachinery

0 notes

Text

Unlocking Safety and Integrity: The Role of Pharmaceutical Zip Lock Bags in Enhancing Product Protection

Secure and hygienic storage is essential in healthcare. By choosing Pharmaceutical Zip Lock Bags Wholesale, medical facilities and pharmacies gain access to bulk, cost-effective packaging that ensures product safety and compliance. These durable, resealable bags are ideal for storing medications, offering convenience, organization, and protection in medical environments.

0 notes