#Plastic Processing Machinery Industry

Explore tagged Tumblr posts

Text

Plastic Processing Machinery Industry: A Critical Component of the Circular Economy

Global plastic processing machinery industry data book is a collection of market sizing information & forecasts, competitive benchmarking analyses, macro-environmental analyses, and regulatory & technological framework studies. Within the purview of the database, such information is systematically analyzed and provided in the form of outlook reports and summary presentations on individual areas of research.

The market incorporates a wide range of equipment used in the manufacturing and processing plastic products, including injection molding machines, blow molding machines, extrusion machines, and more. The demand for plastic products across various industries, such as packaging, automotive, electronics, and construction, has been a key driver for the expansion of this market.

Access the Global Plastic Processing Machinery Industry Data Book, 2023 to 2030, compiled with details like market sizing information & forecasts, trade data, pricing intelligence, competitive benchmarking, macro-environmental analyses, and regulatory & technological framework studies.

Plastic Injection Molding Machine Market Report Highlights

The plastic injection molding machine market was estimated at approximately USD 11.75 billions in 2022, growing at a CAGR of 4.8% from 2023 to 2030 according to a new report by Grand View Research, Inc. The increasing adoption of plastic injection molding machines in the automotive, electronics, and packaging industries is likely to be the key driver for the growth of the industry over the forecast period.

Plastic injection molding is suitable for producing various exterior automotive components such as mudguards, door panels, wheel arches, grilles, trunk trims, front and rear covers, and outside car door trims. Automotive injection molding is an important manufacturing process in the automotive industry, where safety, consistency, and quality are critical.

The automobile end-use category accounts for a sizable portion of the injection molding machine market. A variety of automobile parts, such as outer body panels, bumpers, spoilers, dashboards, and electrical housings, are made using plastic injection molding machines. Many automotive interior parts are manufactured using plastic injection molding as well as the instrumentation components, interior surfaces, glove boxes, dashboard faceplates, air vents, and other items. Rapid growth in demand for automotive components has boosted global automobile production, resulting in a high demand for injection-molded parts in the automotive industry.

Plastic injection molding is utilized for the formation of plastic packaging for a variety of applications and in a variety of forms. The injection method is used to manufacture food and beverage containers, creatively designed body care packaging, and even packaging for household chemicals. The plastic injection molding technique solves problems related to barrier protection, handling, product visibility, salability, and aesthetics.

Plastic Extrusion Machinery Market Report Highlights

The global plastic extrusion machine market size is expected to reach USD 6.41 billions in 2022, expanding at a CAGR of 4.4% from 2023 to 2030, according to a new report by Grand View Research, Inc. Increasing penetration of plastics in the manufacturing of consumer electronics is expected to be one of the critical factors for the growth of plastic extrusion machine. In addition, plastic extruded parts are widely used for manufacturing structures & bodies of television sets, video recorders, cameras, and laptops. Moreover, motor housings and interior frames are manufactured using the extrusion process.

The demand for plastic extrusion machine is rising owing to the ability of plastics to be formed into complex shapes and the relative ease compared to metals or ceramics. Moreover, surged usage of engineering-grade plastics for producing pipe, fencing, window frames, plastic films, wire insulation, and deck railing is anticipated to grow during the forecast period.

Plastic extruded parts provide a solution for high volume and cost-efficiency. The recent trend of lightweight in the automotive industry to enhance fuel efficiency has resulted in increased use of plastic extruded parts coupled with the growing adoption of extruded products in the packaging industry is projected to drive the market of plastic extrusion machines over the forecast period.

The demand for plastic extruded products has been on the rise for several years because of several advantages of the extrusion process and the rising demand from end-use industries such as automotive, electronics, consumer goods, telecommunications, and renewable energy. Moreover, the low cost per part, flexibility in operation, high production volume, and compounding ability are the other factors responsible for the growing demand for extruded plastic and metal products.

Order your copy of Free Sample of “Plastic Processing Machinery Industry Data Book - Plastic Injection Molding Machine, Plastic Extrusion Machinery, Plastic Blow Molding Machine Market Size, Share, Trends Analysis, And Segment Forecasts, 2023 - 2030” Data Book, published by Grand View Research

Plastic Blow Molding Machine Market Report Highlights

The global plastic blow molding machine market size is anticipated to reach USD 2.97 billions in 2022, growing at 3.9% CAGR from 2023 to 2030, according to a new report by Grand View Research, Inc. High demand for packaged goods in the food and beverage industry, increasing use of plastic blow molding machines in the production of industrial and automotive components, and rising need for plastic packaging solutions in the pharmaceutical industry are major factors driving market revenue growth.

In addition, the machines are widely used in several applications and sectors including plastic packaging, chemical, automobile, pharmaceuticals, lubricants, edible oils, FMCG, and others. The surge in demand for sanitizing and cleaning products fueled the adoption of blow molding machines to manufacture sanitizers, hand soaps, and hydrogels.

Plastic packaging alternatives are in high demand in the pharmaceutical business because they protect drugs from contamination and extend their shelf life. Plastic blow molding machines are used to create containers, plastic bottles, and vials, often used as packaging materials in the pharmaceutical industry. For instance, Bekum Maschinenfabriken GmbH announced the introduction of the BM 902D, a new, high-performance blow molding machine, in 2021. The machine has a cutting-edge hydraulic system and an intuitive user interface and is built to create massive parts with excellent precision and productivity.

Growing preferences for molded plastic products, rising demand due to the material's flexibility, rising demand due to the prevalence of low labor costs, and low waste production are some of the factors that will likely propel the growth of the plastic blow molding machine industry over the forecast period. On the other hand, as technology continues to progress, it will create more potential for the market for plastic blow molding machines to expand over the coming years. For instance, Taiwan-based Parker Plastic Machinery Co. Ltd., a producer of plastic blow molding machines, offers its fully electric plastic blow molding machines. It is growing in recognition for its high-performance hydraulic power-saving technology.

Key players operating in the Plastic Processing Machinery Industry are –

• Arburg GmbH + Co KG. • KraussMaffei • Haitian International • Milacron • Nissei Plastic Industrial Co. Ltd. • ENGEL AUSTRIA GmbH. • Chen Hsong Holdings Limited • UBE Machinery Corporation, Ltd. • Husky Injection Molding Systems Ltd.

#Plastic Processing Machinery Industry#Plastic Processing Machinery Market#Plastic Injection Molding Machine Industry Trends Data Book#Plastic Extrusion Machinery Market Size#Plastic Blow Molding Machine Market Share#Plastic Blow Molding Machine Market Growth#Plastic Processing Machinery Sector Report

0 notes

Text

At UMSPCS, we provide tailored OTR safety systems for rubber and plastic machinery, ensuring operational protection in high-load industrial environments. Our components are engineered to minimize downtime, reduce heat generation, and extend machinery life, making them ideal for precision manufacturing operations. Choose UMSPCS for reliable rubber and plastic machinery OTR safety that enhances productivity and prevents wear & tear in mission-critical environments.

Visit here: https://umspcs.in/

#consultant#business#consulting#govt#technology#Construction machinery OTR applicability#Rubber and plastic machinery OTR safety#Packaging machinery BIS compliance#Public works machinery OTR checklist#Industrial furnace and heater OTR regulation#WPC ETA approval process

1 note

·

View note

Text

Jet Dyeing Machines Market Set to Hit $1569.3 Million by 2035

The Jet Dyeing Machines market is projected to experience substantial growth, with industry revenue estimated to rise from $596.0 million in 2024 to $1569.3 million by 2035. This growth represents a Compound Annual Growth Rate (CAGR) of 9.2% from 2024 to 2035. As industries across the globe adopt advanced technologies and prioritize sustainability, the demand for Jet Dyeing Machines is expected to surge, driven by key applications such as textile dyeing, wool processing, plastic coloring, and leather treatment.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/jet-dyeing-machines-market-research-report

Key Applications Driving Market Growth

Jet Dyeing Machines are critical in a wide range of applications where precision and efficiency are necessary. The major sectors relying on these machines include:

Textile Dyeing: Essential for the mass production of textiles, ensuring uniform and high-quality dyeing for fabrics used in various industries, including fashion and home textiles.

Wool Processing: Used to achieve optimal dyeing for wool fibers, which are sensitive to heat and require gentle treatment.

Plastic Coloring: Important in the plastic industry for achieving consistent and uniform coloring of plastic materials.

Leather Treatment: Plays a vital role in achieving consistent dyeing results for leather products, which are used in fashion, furniture, and automotive industries.

Industry Leadership and Competitive Landscape

The Jet Dyeing Machines market is characterized by fierce competition, with several leading players such as Thies GmbH & Co. KG, Fong's Industries Company Limited, Sclavos TVE ESCE, Brazzoli S.p.A., CHTC Fong's International Co. Ltd., Jeanologia S.L., and others dominating the market. These companies are actively innovating and expanding their operations to meet growing demand across multiple industrial sectors.

Technological advancements in jet dyeing machines, coupled with the rise of sustainable manufacturing processes, are expected to significantly drive the market's expansion. Efficiency improvements, reduced water consumption, and enhanced dye quality are key areas where innovation is helping to capture more market share.

Growth Opportunities in Emerging Markets

The Jet Dyeing Machines market presents substantial growth opportunities in emerging markets, where rapid industrialization, urbanization, and increasing environmental concerns are driving demand for more efficient and sustainable dyeing solutions. Key countries such as China, India, Germany, U.S., and Italy continue to lead the market, while emerging markets like Vietnam, Ethiopia, and Bangladesh represent significant revenue opportunities for manufacturers.

Regional Shifts and Evolving Supply Chains

North America and Europe are the two primary regions driving the demand for Jet Dyeing Machines. These regions benefit from high industrialization levels and technological advancements in manufacturing processes. However, the market dynamics are shifting as manufacturers look to streamline their supply chains and cater to the growing demand in emerging markets. Challenges such as high equipment costs, regulatory hurdles, and environmental concerns are also pushing the market to evolve.

Emerging markets such as Vietnam, Ethiopia, and Bangladesh are expected to present strong opportunities for revenue diversification and Total Addressable Market (TAM) expansion as local industries adopt more advanced technologies to meet the increasing demand for high-quality and eco-friendly dyeing processes.

Future Outlook

The Jet Dyeing Machines market is set to undergo significant growth over the next decade, driven by technological advancements, sustainability trends, and expanding industrial automation. The adoption of green dyeing technologies and improvements in dyeing efficiency will continue to play a critical role in shaping the future of the market. With the strategic expansion into emerging markets and a focus on technological innovation, the Jet Dyeing Machines market will likely witness substantial transformation, presenting new opportunities for both established players and new entrants.

About DataString Consulting

DataString Consulting is a global leader in market research and business intelligence, offering comprehensive solutions for both B2B and B2C markets. With more than 30 years of combined experience in market research and strategy advisory, DataString Consulting provides tailored services designed to meet the specific needs of businesses across various industries.

Through its unique approach to market research and insights, DataString helps clients navigate emerging market trends, optimize strategies, and unlock new opportunities in an ever-evolving marketplace.

#Jet Dyeing Machines#Textile Machinery#Textile Dyeing#Industrial Dyeing Equipment#Dyeing Technology#Textile Manufacturing#Sustainable Dyeing#Wool Processing#Plastic Coloring#Leather Dyeing#Industrial Automation#Eco-Friendly Dyeing Solutions#Fabric Dyeing Machines#Textile Industry Trends#Dyeing Machine Market Forecast#Emerging Markets#Market Research#DataString Consulting#Industrial Equipment Market#Global Textile Market

0 notes

Text

𝙀𝙭𝙥𝙡𝙤𝙧𝙞𝙣𝙜 𝙩𝙝𝙚 𝙋𝙡𝙖𝙨𝙩𝙞𝙘 𝙋𝙧𝙤𝙘𝙚𝙨𝙨𝙞𝙣𝙜 𝙈𝙖𝙘𝙝𝙞𝙣𝙚𝙧𝙮 𝙈𝙖𝙧𝙠𝙚𝙩: 𝘼 𝙂𝙧𝙤𝙬𝙞𝙣𝙜 𝙄𝙣𝙙𝙪𝙨𝙩𝙧𝙮!

𝘿𝙤𝙬𝙣𝙡𝙤𝙖𝙙 𝙖 𝙁𝙍𝙀𝙀 𝙎𝙖𝙢𝙥𝙡𝙚: https://www.nextmsc.com/plastic-processing-machinery-market/request-sample

The 𝙋𝙡𝙖𝙨𝙩𝙞𝙘 𝙋𝙧𝙤𝙘𝙚𝙨𝙨𝙞𝙣𝙜 𝙈𝙖𝙘𝙝𝙞𝙣𝙚𝙧𝙮 𝙈𝙖𝙧𝙠𝙚𝙩 is experiencing significant growth and innovation. With increasing demand for plastic products across various industries such as packaging, automotive, healthcare, and consumer goods, the market is expected to expand substantially in the coming years.

𝙆𝙚𝙮 𝙏𝙧𝙚𝙣𝙙𝙨 𝘿𝙧𝙞𝙫𝙞𝙣𝙜 𝙩𝙝𝙚 𝙈𝙖𝙧𝙠𝙚𝙩:

𝙏𝙚𝙘𝙝𝙣𝙤𝙡𝙤𝙜𝙞𝙘𝙖𝙡 𝘼𝙙𝙫𝙖𝙣𝙘𝙚𝙢𝙚𝙣𝙩𝙨: Automation and IoT integration in plastic processing machinery are enhancing efficiency and productivity.

𝙎𝙪𝙨𝙩𝙖𝙞𝙣𝙖𝙗𝙞𝙡𝙞𝙩𝙮 𝙄𝙣𝙞𝙩𝙞𝙖𝙩𝙞𝙫𝙚𝙨: The push for eco-friendly and recyclable plastic products is fostering the development of advanced machinery designed for sustainable processing.

𝙀𝙢𝙚𝙧𝙜𝙞𝙣𝙜 𝙀𝙘𝙤𝙣𝙤𝙢𝙞𝙚𝙨: Rapid industrialization and urbanization in developing countries are boosting the demand for plastic processing machinery.

𝘾𝙪𝙨𝙩𝙤𝙢𝙞𝙯𝙖𝙩𝙞𝙤𝙣 𝙖𝙣𝙙 𝙁𝙡𝙚𝙭𝙞𝙗𝙞𝙡𝙞𝙩𝙮: Growing demand for customized plastic products is leading to the adoption of flexible machinery capable of handling diverse production requirements.

𝙈𝙖𝙧𝙠𝙚𝙩 𝙄𝙣𝙨𝙞𝙜𝙝𝙩𝙨:

Innovations in injection molding, extrusion, and blow molding technologies are expected to drive market growth.

Key players are investing heavily in R&D to introduce cutting-edge machinery with enhanced capabilities.

𝙆𝙚𝙮 𝙋𝙡𝙖𝙮𝙚𝙧𝙨: Various key market players operating in the plastic processing machinery industry includes Star Plastic Machinery, CMD Corporation, Arburg GmbH, ENGEL, Plustech Systems & Solutions, Sumitomo (SHI) Demag Plastics Machinery GmbH, FCS Group, Toshiba Machine Co. Ltd., Milacron Holdings Corporation, Haitian International Holdings Ltd., and others.

𝘼𝙘𝙘𝙚𝙨𝙨 𝙁𝙪𝙡𝙡 𝙍𝙚𝙥𝙤𝙧𝙩: https://www.nextmsc.com/report/plastic-processing-machinery-market

𝙇𝙤𝙤𝙠𝙞𝙣𝙜 𝘼𝙝𝙚𝙖𝙙: The future of the Plastic Processing Machinery Market looks promising, with continuous advancements and a strong focus on sustainability. As the industry evolves, staying updated with the latest trends and technologies will be crucial for businesses aiming to thrive in this dynamic market.

#plastic processing#manufacturing#industry trends#sustainability#innovation#market growth#market research#machinery#market analysis

0 notes

Text

Elevate Your Business with Verified Lead - IndiaBizzness

IndiaBizzness: Elevate your business with India's premier online B2B platform. Connect, showcase, and expand your reach effortlessly. Explore a myriad of opportunities for growth and success with IndiaBizzness.

#Business#IndiaBizzness#B2B Site#Second Hand Machinery#Used Machinery Sale#Packaging Machinery#Plastic Processing Machinery#Printing Machinery#Businesses for Sale#Industrial Plants For Sale

0 notes

Note

Hi!!

Just wanted to let you know I've re-read for loke the 10nth time the seeing-deaths!reader×bakugo story and oh my god it's so good, it's one of my favorite stories ever

If you feel like it, have you ever thought about Bakugou's side of the story? Especially after the ending. I think the story is perfect as is and doesn't necessarely need a sequel but I often wonder about this Bakugo so I'd love to hear any of your thoughts if you feel like sharing them!

Anyway, love your writing and have a good day!

Xo

The ghost story. 🥺

I hadn’t actually sat down to think about how it would effect Bakugou, like, in-depth until mei-writes reblogged it and pointed out how devastating a loss would be for an older Bakugou, one who fought so hard to make through to the other side of his (in Mei’s brilliant words!!) inferiority complex and anger. 🥺 I said in reply that I thought Katsuki would like, throw himself into work until he broke, as a way of regaining some control/giving himself a distraction, but that it wouldn’t work. And it wouldn’t!! I think it would be an unholy drive, though; I always saw our killer as getting away that day (it’s why we die, it’s a distraction), and I don’t think Katsuki would give himself even a moment’s grace to process things. He’d just—immediately chase after him. Of course he has to. He failed to get this guy once, and look what hap—anyway. Don’t think about it, not now, get this bastard first.

Katsuki would genuinely scare everyone who cares about him. Denki, Kirishima. Izuku. When Katsuki finally finds and corners the guy it’s like, idk, in some industrial real-estate, just a warren of warehouses and factory floors and empty parking lots. Katsuki’s been going 24/7, he’s running on fumes and fury, and this prick is like, making machinery and walls topple down in a spray of fine steel dust, piping hot concrete. Inorganic material that reacts to insane heat differently than—

You know, Katsuki’s always prided himself on how tightly controlled his explosions can be. On the discipline it takes. But like I said, he’s running on empty. He’s exhausted, he’s not letting himself think of why he’s here in some fucking shitty-ass industrial park, chasing down a fucker who’s laughter keeps echoing around these fucking buildings—so maybe he loses his temper. Maybe his explosions start rippling through warehouses and storage spaces with plastic containers of hazardous materials until he creates an inferno. Maybe, just maybe, when Izuku arrives (breathless, afraid, his jaw tightening when he finds Katsuki standing motionless in front of a blaze so high and hot it’s that the blond is shimmering with sweat, dripping like jewels) it’s too late.

Death during legal intervention. That’s the phrase used in the coroner’s findings. It’s shocking, and there’s some grumblings—by the press mostly, who brand Dynamight a danger to order and decency. Anti Pro-Hero groups arc up about it, and maybe a justice-system reform organisation pushes for actual punishment. But mostly the public forgives. The guy was dangerous. He killed people! There’s literally footage of it from multiple angles, it’s so horrific and sad. The looks on the victims faces, before it happens. Still. The Hero Commission can’t let it look like they don’t care about order—Katsuki’s on immediate leave, two months, half-pay.

His friends are still scared. They enact the Sit-a-Chan system, babysitting Katsuki, making sure he doesn’t do anything crazy. He hates it—people in his fucking space when he doesn’t want them!! Deku’s the worst, he hovers, but Kirishima and his yapping is a close second. And then Denki—ugh. He’s the one that notices the extra toothbrush, in the bathroom. The little toiletry bag, wedged in between Katsuki’s shaver, some callous cream.

(Denki’s heart drops to his ass when he realises, and carefully—quietly, before Katsuki can notice his silence and get suspicious, he peers into Katsuki’s bedroom.

He doesn’t know what he’s afriad of finding—a lifesized mannequin of you, maybe, dressed up in your clothes or whatever, paint smeared on its face. But Katsuki’s room is neat and tidy, spartan almost, his bed made.

There’s just—

Denki’s mouth thins, sad, when he sees it. On the end of Katsuki’s bed is a small pile of fresh laundry, neatly folded—all in colours Denki’s never, ever seen him wear.

“Got any plans for what you wanna do with the—with everything?” The asshole asks, suddenly, as Katsuki tries to ignore him by pretending to take a nap on the couch.

It takes a moment for him to register what the walking charging pack is saying, his body recognising it before his brain, his chest immediately tightening at the words.

Fury jerks Katsuki upright. “If you’ve touched one fucking thing—”

But Denki’s hands are already up in surrender. “Nah! Nah man, I promise, I’m not gonna do anything.” There’s a beat between them, where Denki watches him, mouth shut before he says, very, very gently, “No one’s gonna force you to do anything. I’m just—curious. Izuku said you’d met with… with the mother. Of both of them.”

Talking to Kacchan is a lot like talking a tiger, at times; red, feline eyes staring at Denki unblinkingly, untrusting, until they cut away to the kitchen, his table. The expression on his face doesn’t change, but Denki can only guess what he’s thinking of. Who’s he’s thinking of.

“There’s nothin’ to do,” Katsuki says, eventually, voice hard. “Whatever’s here is it.”

Denki nods. Your apartment, your belongings—your mother probably dealt with all that. Suddenly he realises just how little his friend has of you. A folded pile of clothes. A toothbrush. Time.)

Two months is a lot of downtime for a man who’s used to saving the country regularly. The things left in Katsuki’s apartment move around, like your restless ghost is unsure of where to leave them, Katsuki’s restlessness unsure. There’s nothing of value to them and your Mother had shaken her head when Katsuki had mentioned that he—that you—that he had a few things of yours, if they were important—

But still. He doesn’t know what to do with them. The book you were reading slips in among his own, sticking out like a baboon’s ass. He hands up your cardigan in his wardrobe—just to get it out of the way, he tells himself. The bag of your skincare and shit—an italian handcream, a lip balm, moisturiser, some other things—still sit behind his mirror, where he sees it every day.

He doesn’t tell anyone when he leaves the city, your little toilet bag shoved in his dufflebag, unceremoniously thrown in the backseat of his car, sleek and black and shinning under the city lights as he drives. It’s the closest you’ll get to leaving the damn place, together; though Katsuki doesn’t let himself think that.

Your Mother, when Katsuki had met her, had almost seemed—resigned. Not surprised.

“It’s been hard,” she’d told him, his skin prickling uncomfortably. “Not just—not just this. But… but being unable to help throughout everything. Did you—did the two of you ever talk about… about your quirks?”

Katsuki had shaken his head, his jaw locking. He had always assumed you were quirkless; you had always avoided the conversation.

Your Mother had swallowed. Nodded. “If you ever… if you’re ever our way, back home, please—please call in. It would mean a lot.”

To her. To you, maybe, if you’d still been here. To Katsuki too, though it’s harder for him to admit to himself.

He drives through the night to your hometown, the sun rising when he finally makes it, pulling in off the road, just up on a hill that overlooks the town lights below. It’s a chilly morning; Katsuki leans against his car, scuffing at the gravel under his boots as he shoves his hands in his pockets. Maybe he’ll get some answers here. Some insight into what was going on in there, behind those big, unsure eyes you’d sometimes look at him with.

(He does, and he doesn’t. Your mother has pictures of you, ready, when he makes it. You in highschool with a tall, redheaded boy that’s all grins. You as a small kid, with an older, smiling woman, round and soft-looking.

Your mother is silent as she watches Katsuki take them in.

“They’re all gone, now,” she tells him, when Katsuki eventually glances back to her.

You and your collection of ghosts. Your mother tells him what she knows, and it’s not everything—but he thinks he finally begins to understand.)

#ofmermaidstories-asks#prompts and drabbles and other things#merms apology tour#hi anon 🥹 thank you for the ask—it was fun to mull over!!! i hope your weekend is going well 🥹🌷

33 notes

·

View notes

Text

Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad 7337443480

Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad is not just hot water and cold water; it also purifies pure water and safe water. Voltas Dispenser Service Centre Near Banjara Hills Hyderabad presents a new range of Water Dispensers that you want to choose between Hot water Normal water & Cold water and also Volta's water dispenser puts every drop through a 4-stage filtration process. It is better Voltas Dispenser Service Center Near Banjara Hills Hyderabad than other Dispensers. For any repairs, eServe supports Voltas Water Dispenser Service center Near Banjara Hills. Voltas Bottom Loaded Water Dispenser Service Center Near Banjara Hills: The New Voltas Bottom Mounted Water Dispenser Service Centre Near Banjara Hills has with water bottle loaded inside the cabinet. If there is any problems contact eServe for Voltas water dispenser Service Center Phone Number Hyderabad. Voltas Table Top Water Dispenser: Compact Voltas Table Top Water Dispenser Water Dispenser Service Center Near Banjara Hills range with hot water, cold water, and normal water dispensing features. Take the support of eServe for any repairs with Volta's water dispenser service center in Madhapur. Voltas Floor Mounted Water Dispenser Service Center Near Banjara Hills: Voltas Floor Mounted Water Dispenser range with hot water, cold water, and normal water dispensing features with refrigerator and storage cabinet options. If there are any repairs are there, Take eServe support by searching the Voltas water dispenser service center near me, Voltas water dispenser service repair near me. Voltas Visi Cooler: Specially designed To Cool Uniformly As well As Showcase the Products Inside like cool drinks and other beverages. Key Features of Voltas VISI Cooler UV Grade Plastic Material For Long-Lasting Appearance of Voltas Visa Cooler Low Glazing Glass to Avoid Cooling Loss of Voltas Visi Cooler Compact Design - which suits everywhere soft and Aesthetic Design Energy-Efficient Compressor to reduce power consumption Anti-Corrosive Pre-Coated Body - Which fit's any corner in INDIA

If there are any repairs in Voltas Water Dispenser Service Center Near Banjara Hills Visi Cooler Features take the support of eServe you can search for us like Voltas Water Dis Service center near me, Voltas Service Center number near me Hyderabad to get best from our team.

Tata voltas service Center near me : Voltas restricted is associate Indian company specializing in air con and cooling technology the corporate is broadly speaking structured into comes and product business the comes business is split into Domestic comes cluster and International Operations Business cluster. Voltas Water Dispenser Service Center Near Banjara Hills , established in 1954, operates in 3 segments - Unitary Cooling product, Electro-Mechanical comes & Services, and Engineering product & Services. Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad is India's largest air conditioning company, and one among the world's premier engineering solutions suppliers and comes specialist.

Founded in India in 1954, Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad restricted offers engineering solutions for a large spectrum of industries in areas like heating, ventilation and air conditioning, refrigeration, electro-mechanical comes, electrification, textile machinery, mining and construction instrumentality, water management & treatment, cold chain solutions, building management systems, and indoor air quality. Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad is India's largest air conditioning company and India's No. one air conditioning complete, Voltas Water Dispenser Service Center Near Banjara Hills besides being the well-liked EPC contractor within the comes house and one among India's most trustworthy names in textile machinery and mining & construction instrumentality.

Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad includes a pan-India presence through its network of sixteen branches and over 300 textile engineers. On five could 2015 Voltas Water Dispenser Service Center Near Banjara Hills proclaimed its invade air coolers business with the launch of fresh-air coolers below the Voltas complete. Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad The new vary comes with engaging options like exclusive honeycomb cooling pads carbonized dirt filters and powerful air throw. On 27 March 2017 Voltas restricted proclaimed that it's fortified its leadership position within the cooling class by crossing one.5 million units within the year 2016-17. Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad On 23 could 2017 Voltas restricted and Ardutch B.V. in agreement to determine a venture Company (JVC) in India to enter the patron consumer goods market within the country.

The new company to be incorporated in Asian nation are associate equal partnership venture. The projected JVC can leverage the sturdy complete presence and wide sales and distribution network of Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad which is the market leader for residential air-conditioners in the Asian nations the JVC its sturdy R&D and producing artistry additionally to a good product vary and world sourcing capabilities. Voltas Water Dispenser Service Center Near Banjara Hills Bako the worldwide complete has been the quickest-growing home appliances complete of Europe for the past seven years. The projected JVC can launch refrigerators laundry machines microwaves and alternative white goods/domestic appliances in Asian nations. Voltas Dispenser Service Center Near Banjara Hills Hyderabad On a pair of February 2018 Voltas Water Dispenser Service Center Near Banjara Hills launched India's 1st Window cooling system with DC electrical converter technology.

Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad It works on a singular Steady Cool electrical converter mechanical device that could be a variable speed mechanical device providing steady cooling and steady savings. With this launch, Voltas Water Dispenser Service Center Near Banjara Hills Hyderabad Voltas has strengthened its commitment of unceasingly Transferal the latest technology within the Indian market.

#Voltas Water Dispenser Service Center Near Banjara Hills#Voltas Water Dispenser Service Center At Banjara Hills#Voltas Dispenser Service Center Near Banjara Hills Hyderabad#Voltas Dispenser Service Center Center Near Banjara Hills.

22 notes

·

View notes

Text

"Trace On"

So far, in terms of magical spells from fiction, no spell has made better overall sense than Emiya Shirou's "Trace On", which he learned from Emiya Kiritsugu: the one spell that Kiritsugu would consent to teach his son, his compromise with himself. Kiritsugu had come to despise magic and mages and yet his son wouldn't let him alone until he learned that one simple and useful spell.

One magic spell can destroy the world. I'm not kidding. I've come to realize this truth about "true magic", which one feels instinctively is a legitimate concept or category. The Arthur Clarke cliché is wrong, preciously wrong: magic and technology are interrelated but they are always distinguishable from each other. Technology always seems like it's approximating magic, catching up to magic, while the tantalizing possibilities of magic race ahead of technology, always just a bit out of reach. And thus one can easily see that a "true magic" spell, something that can be wielded in a few moments any time the magic-user wants, can do immense damage beyond what technology can manage, for magic permits exceptions to the predictable actions of technology and machines.

An ordinary human being has a gun pointed at them and the desperate human being plugs the barrel with a piece of paper. What effect will that have? None. What if Emiya Shirou plugs a gun with a wad of paper? The gun blows up in the user's hands.

Think of everything in the world, every solid object, that's required to break in some consistent way. What if Emiya Shirou applied "Trace On" to the paper tape at the end of a footrace? The race wouldn't end properly! That's a silly example but now imagine Shirou applying that strengthening ability to, oh, sheets of plastic or paper in an industrial context, gumming up an entire factory because suddenly it can't cut any boxes open or rip open any packages.

I've never seen Death Note but I feel like I get the premise of the show, instinctively: the shinigami's stray "death note" book has world-ending consequences. But even very small magic powers also have world-ending consequences. The machinery of the contemporary human world, Earth 2024 (as it seems), requires utmost predictability in order to achieve its simulation of magic. Corporations have fallen in love with "just in time" scheduling of their operations, i.e. requiring everyone along the supply chain to be always ready to pounce on any request or transfer, and that can only work as well as it does because of the predictability of machinery. Gumming up even one key machine or structure in the process has the potential to cause a major blockade. I'm curiously reminded of the container ship that got wedged in the Suez Canal, one of the world's most important bottlenecks in its supply chains.

And somehow I can almost imagine "Trace On", persuading the atoms and molecules to shift just a little way this and that, bonding with each other temporarily perhaps, conferring a sudden rigidity and crystallinity to materials that otherwise lacked them. It's a sensible magic spell all right, and it has a logical consequence: "projection". If you can impose added structure onto a material, then perhaps you can duplicate the structures of materials as well, which Emiya Shirou does. The evolution of that skill is not arbitrary, but suggested by the possibilities of the simpler spell.

See, ma? It is possible to explain why magic "makes sense" in fiction! I feel like I've been working on this problem for...decades, trying to justify an age-old intuition. Bad magic writers (q.v. Jo Rowling) think of magic as arbitrary, anything-goes stuff, but that's not true. Chaos and discord are "anything goes" but magic has structure. Magic needs to be consistent and sensible in fiction in order to be believable. And Nasu...I gotta say, whatever else his faults as a writer and a person, he's careful about writing magic, and thus he's always in (or near) the realm of the plausible from what I've seen.

~Chara of Pnictogen

8 notes

·

View notes

Text

What Materials Are Used in Making Paper Bag Handles?

As businesses and consumers become more environmentally conscious, the shift from plastic bags to paper bags has accelerated globally. But while much attention is given to the bag itself, a key component often overlooked is the handle. The strength, recyclability, and sustainability of a paper bag significantly depend on the type of handle and the materials used to make it.

At Prakash Machineries Pvt Ltd, we manufacture paper bag handle-making machines that support a wide range of eco-friendly materials—helping businesses produce high-quality, sustainable bags at scale.

In this article, we’ll explore the most common materials used in making paper bag handles, their properties, benefits, and how they align with green manufacturing practices.

🌱 Why Handle Material Matters

Handles are not just an accessory. They directly influence:

Load capacity

Durability

Comfort

Recyclability

Using eco-friendly and biodegradable materials for handles ensures that the entire paper bag remains sustainable, making it easier for businesses to meet global environmental regulations and appeal to eco-aware consumers.

🧵 Most Common Materials Used for Paper Bag Handles

Let’s take a closer look at the materials commonly used in paper bag handle manufacturing:

1. 🟫 Kraft Paper

What is it?

Kraft paper is the most widely used material for making twisted and flat paper handles. It is made from wood pulp using the kraft process, which results in strong, tear-resistant, and biodegradable paper.

Features:

Available in brown, white, or printed variants

Comes in rolls of various GSM. (grams per square meter)

100% recyclable and compostable

Ideal for both twisted rope and flat folded handles

Applications:

Grocery bags

Fashion retail bags

Branded promotional bags

Sustainability Score: ⭐⭐⭐⭐⭐

Kraft paper is one of the most eco-friendly materials, especially when unbleached and made from recycled sources.

2. 🧶 Twisted Paper Rope

What is it?

Twisted rope handles are made by twisting narrow strips of kraft paper into a rope-like structure using a twisting mechanism. These ropes are often glued to patch paper before being attached to the bag.

Features:

Lightweight but strong

Clean appearance, available in multiple colors

Recyclable and biodegradable

Applications:

Boutique bags

Gift bags

Takeaway and food delivery bags

Sustainability Score: ⭐⭐⭐⭐⭐

Since it’s made from paper, the twisted rope is fully biodegradable and recyclable. It adds both strength and style without harming the environment.

3. 📏 Flat Paper Strips

What is it?

Flat paper handles are produced by folding and gluing kraft paper into thick, flat strips. They are stronger than twisted ropes and ideal for heavier bags.

Features:

Excellent load-bearing capacity

Smooth surface for better gluing

Stackable design for efficient packaging

Applications:

Supermarket and grocery bags

Bookstore bags

Commercial delivery bags

Sustainability Score: ⭐⭐⭐⭐⭐

Flat handles are made from the same kraft paper as the bag body, making the entire product easy to recycle and appealing to green packaging initiatives.

4. ♻️ Recycled Paper

What is it?

Recycled paper—derived from post-consumer or industrial waste—is now widely used for both twisted and flat paper handles. The quality has improved significantly, making it a practical, eco-friendly option.

Features:

Low environmental footprint

Suitable for short-length or lightweight bags

Available in natural tones or dyed colors

Applications:

Everyday shopping bags

Eco-branded merchandise packaging

Sustainability Score: ⭐⭐⭐⭐⭐

Recycled paper helps reduce deforestation and landfill waste, aligning perfectly with sustainability goals.

5. 🧵 Jute and Cotton Cord (Optional Premium Option)

What is it?

In premium or luxury bags, handles are sometimes made from natural fibers like jute, hemp, or cotton cords. While these are not produced by standard paper handle-making machines, they are still considered sustainable when sourced responsibly.

Features:

Soft, durable, and stylish

Reusable by customers

Higher cost per unit

Applications:

Luxury fashion or jewelry bags

High-end gift bags

Sustainability Score: ⭐⭐⭐⭐☆

Natural fibers are biodegradable, but their cost and manual handling limit scalability.

🛠️ What Materials Do Our Machines Support?

At Prakash Machineries Pvt Ltd, our twisted and flat handle-making machines are compatible with

Kraft paper rolls (brown/white/recycled)

Water-based, non-toxic glues

Patch paper rolls for pasting units

Our machines are engineered for precision, speed, and eco-efficiency, making them ideal for businesses aiming to meet sustainability standards without compromising on productivity.

💡 Tips for Choosing the Right Handle Material

Consider the bag use case: heavier bags (e.g., groceries) need flat or reinforced handles. Lighter retail bags can use twisted paper rope.

Match Your Branding: Kraft paper in natural or printed form complements earthy, sustainable brand images.

Go Recycled Where Possible: Choose FSC-certified or post-consumer recycled kraft paper for maximum environmental impact reduction.

Use Water-Based Glue: Avoid synthetic adhesives; they make recycling more difficult.

🌏 The Future of Sustainable Handle Materials

With the rise of the circular economy, more innovation is happening in the area of biodegradable, plant-based, and upcycled materials for packaging. Research into agricultural waste pulp, bamboo fiber, and algae-based paper may lead to even greener handle options in the future.

At Prakash Machineries Pvt Ltd, we stay ahead of these trends by ensuring our machines remain compatible with emerging paper types, helping you stay compliant and competitive.

🧾 Final Thoughts

In the paper bag manufacturing industry, the handle is just as important as the bag itself—not only for functionality but also for environmental credibility. Using materials like kraft paper, twisted rope, and recycled paper ensures your packaging is not only strong but also sustainable.

With growing consumer demand for eco-conscious products, choosing the right handle material—and the right machinery—is a strategic move for any forward-thinking brand or manufacturer.

Ready to produce sustainable paper bag handles at scale? 👉 Contact Prakash Machineries Pvt Ltd to learn more about our eco-friendly handle-making machines or request a live demo.

#breakfast#delicious#chocolate#alien stage#dan and phil#baking#cake#chris sturniolo#cooking#critical role#paper bag manufacturer#manufacturer#machines#paper bag#paper#v bottom#square bottom

2 notes

·

View notes

Text

Plastic Processing Machinery Industry To Rise As Of Growing Demand For Plastic Products Across Various Industries

Grand View Research’s plastic processing machinery industry data book is a collection of market sizing information & forecasts, competitive benchmarking analyses, macro-environmental analyses, and regulatory & technological framework studies. Within the purview of the database, such information is systematically analyzed and provided in the form of outlook reports and summary presentations on individual areas of research.

Access the Global Plastic Processing Machinery Industry Data Book, 2023 to 2030, compiled with details like market sizing information & forecasts, trade data, pricing intelligence, competitive benchmarking, macro-environmental analyses, and regulatory & technological framework studies.

Plastic Injection Molding Machine Market Report Highlights

The plastic injection molding machine market was estimated at approximately USD 11.75 billion in 2022, according to a new report by Grand View Research, Inc.

• The hydraulic technology segment accounted for the highest revenue share in 2022.The automotive industry is expected to have a high demand for hydraulic technology as manufacturing large & heavy parts requires a strong clamping force. In fields like aerospace, defense, and marine, it is frequently used to make heavy parts • The electric technology segment also accounted for a significant share in 2022. Electric injection molding machines are highly efficient and require less start-up time and run time compared to hydraulic injection molding machines. • In addition, factors, such as quiet operation, energy savings from 30 to 70%, less wastage of material, and low requirements of power are expected to have a positive impact on the demand for electric injection molding machines. • The medical end-use segment is projected to register the fastest CAGR from 2023 to 2030 due to constant technological developments, demand for medical disposables, and rising plastics consumption in healthcare applications. • U.S. accounted for the maximum share in 2022 due to the presence of a robust automotive industry. Moreover, the presence of advanced processing capabilities, greater R&D endeavors, and availability of a highly skilled workforce help improve the penetration of EVs in the U.S., thereby supporting segment growth. • The increasing demand for plastic injection molded components in electric and conventional vehicles for exterior and interior parts will boost market growth in the U.S.

Plastic Extrusion Machinery Market Report Highlights

• Plastic extrusion is a manufacturing process involving melting plastic materials and shaping them into a continuous profile through a die. This technology has wide-ranging applications in various industries, including packaging, construction, automotive, and electronics. • Moreover, the low cost per part, flexibility in operation, high production volume, and compounding ability are the other factors responsible for the growing demand for extrusion machinery. • The market for plastic extrusion machinery has been driven by several factors. Firstly, the increasing demand for plastic products, particularly in developing economies of Asia Pacific and Central & South America, has fueled the need for efficient and high-capacity extrusion machinery. • Additionally, advancements in technology have led to the development of more sophisticated and automated extrusion equipment, improving productivity and reducing production costs.

Order your copy of Free Sample of “Plastic Processing Machinery Industry Data Book - Plastic Injection Molding Machine, Plastic Extrusion Machinery, Plastic Blow Molding Machine Market Size, Share, Trends Analysis, And Segment Forecasts, 2023 - 2030” Data Book, published by Grand View Research

Plastic Blow Molding Machine Market Report Highlights

• The demand for blow molding machines has been fueled by the increasing use of plastic containers, bottles, and other hollow plastic products in various industries, including packaging, automotive, consumer goods, and construction. • These machines are essential for the efficient and cost-effective production of high-quality plastic products on a large scale. • Manufacturers are investing in advanced blow molding machines that offer improved automation, energy efficiency, and versatility in terms of mold capabilities and production speed. • The market is witnessing the development of new technologies and innovations that enhance the efficiency and capabilities of blow molding machines, leading to higher productivity and reduced production costs. • The growing focus on sustainability and environmental consciousness has also influenced the plastic blow molding machine market. • Many manufacturers are investing in machines that enable the use of recycled materials or employ eco-friendly production techniques.

Go through the table of content of Plastic Processing Machinery Industry Data Book to get a better understanding of the Coverage & Scope of the study.

Competitive Landscape

Key players operating in the Plastic Processing Machinery Industry are – • Arburg GmbH + Co KG. • KraussMaffei • Haitian International • Milacron • Nissei Plastic Industrial Co. Ltd. • ENGEL AUSTRIA GmbH. • Chen Hsong Holdings Limited • UBE Machinery Corporation, Ltd. • Husky Injection Molding Systems Ltd.

Check out more Industry Data Books, published by Grand View Research

About Grand View Research

Grand View Research, U.S.-based market research and consulting company, provides syndicated as well as customized research reports and consulting services. Registered in California and headquartered in San Francisco, the company comprises over 425 analysts and consultants, adding more than 1200 market research reports to its vast database each year. These reports offer in-depth analysis on 46 industries across 25 major countries worldwide. With the help of an interactive market intelligence platform, Grand View Research helps Fortune 500 companies and renowned academic institutes understand the global and regional business environment and gauge the opportunities that lie ahead.

Contact:

Sherry James

Corporate Sales Specialist, USA

Grand View Research, Inc.

Phone: 1-415-349-0058

Toll Free: 1-888-202-9519

Email: [email protected]

Web: https://www.grandviewresearch.com/sector-reports-list

Follow Us: LinkedIn | Twitter

#Plastic Injection Molding Machine Industry Trends Data Book#Plastic Processing Machinery Industry#Plastic Processing Machinery Sector Report

0 notes

Text

Specialist practice

Saddle Stitch Binding

Our first binding method is saddle stitch, which happens to be the easiest of all. Saddle stitching proves affordable and ideal for documents consisting of fewer pages. By stapling wire through the spine and folding printed sheets in half, a finished product takes shape. Alternatively, utilizing looped staples permits insertion into ring binders without requiring punched holes.

Side Staple Binding

The side staple technique is primarily employed to bind perforated pages, such as those found in quote books and delivery notes. The procedure involves stacking individual pages together before stapling them with wire through the front cover from front to back before trimming.

Singer Sewn & Side Sewn Binding

Singer-sewn binding is a sturdy technique employed for creating resilient materials such as passports. It employs an industrial sewing machine to stitch the pages together along the spine lengthwise. Additionally, side singer-sewn or side-sewn binding provides another option where pages are jointly fastened through both front and back covers, making it perfect for thicker books and notepads.

Padded/Pad Binding

The technique of pad binding, also known as "padding," is utilized primarily for notepads and enables the easy detachment of individual pages. A lower-strength adhesive coating is applied on the edge of a stack of pages to create these pads. To ensure stability and usability when held, a thicker board is generally affixed at the back end.

Wiro /Plastic Coil Binding

The two primary types of punched binding are wire and plastic coil binding, enabling books to open fully flat with the pages rotating 360 degrees towards the back. Firstly, printed pages are trimmed and then hole-punched before being fastened using a spiral coil or wire that is crimped shut.

Japanese / Stab Binding

Dating back centuries, Japanese or stab binding is a decorative technique where sheets are folded once at the center, hole-punched and sewn by hand along the spine using different needle and thread patterns.

Perfect binding

The process of perfect binding involves using machinery to bind softcover books, magazines and brochures. The technique entails stacking individual pages together before affixing them to an outer cover that sports a square spine. This is achieved by the application of potent polyurethane (PUR) glue which gives the method its name- Perfect Binding.

Burst Binding

Burst binding is essentially perfect binding with a unique twist whereby pages are grouped into sections, folded and then notched down the spine by machinery to achieve stronger adherence of glue. This results in an exceptionally robust finish that makes it particularly ideal for books containing a greater number of pages compared to standard bindings.

Quarter Binding

In the past, quarter-bound, half-bound or taped bindings were commonly used to produce books at a lower cost by employing inexpensive materials. These binding methods involve two distinct materials - one for covering the spine and another for protecting the cover. However, to enhance durability, pages are often bonded together and fastened on one side which results in reduced ease of opening compared with

Case Binding

The conventional hardcover book involves printing pages that are folded and stitched into multiple sections, safeguarded by a firm rigid cover. The covers may be coated with various materials like linen, buckram or leather; alternatively, a printed design can be affixed on top of the tough casing. Such casebound books have long-lasting durability and might even sustain restoration years down the road.

Pamphlet Stitch

A refined binding technique known as the pamphlet stitch is ideal for documents with a modest number of pages. After folding and hole-punching the printed sheets, one manually threads them together using needle and thread before tying them off at the book's center to finish it elegantly.

Exposed Spine Binding

Exposed spine binding, also known as exposed Smyth sewn or thread-bound, is an aesthetically appealing method of bookbinding. The pages are folded into sections and then hand-sewn together at the spine with a continuous thread. To reinforce durability, pad glue is applied to the spine after sewing it. Books bound in this manner open almost completely flatly for easy reading.

Chicago Screw Binding

The Chicago Screw technique involves utilizing metal screw posts for fastening pages, allowing flexibility in terms of adding or removing sheets. This makes it a desirable option for materials like menus and folios that undergo frequent revisions. Furthermore, an expandable hardcover can be customized with exterior, interior or concealed screws to fit any desired dimensions. Given its versatile nature, this binding process is particularly popular among property sales pitches as well as showcasing photographic portfolios.

Custom Boxes, Slipcases and Ring Binding

sophisticated storage solution that allows for showcasing your valuable materials and samples, custom boxes and slipcases are just the perfect fit. This type of binding is artistically crafted according to your precise specifications. Manual assembly entails utilizing top-quality board material before wrapping it with an array of premium fabrics including buckram, linen cloths as well as leather or printed laminated paper.

47 notes

·

View notes

Text

Bright Christmas

Childlike wonder does not persist at standard temperature and pressure. Growing up is the process by which it evaporates, as you convince yourself that it never existed in the first place.

The first snow of winter isn’t beautiful; it’s a nuisance that blocks the driveway.

Your toys never meant anything; they were only answers to craving.

It doesn’t matter whether you’re naughty or nice; only what the world’s coffers hold for you.

Santa Claus isn’t real; there are only lies to children and games grown-ups play.

But there still exists a joy which will never thaw, grace impossibly preserved.

What has Saint Nick brought you for Christmas this year?

Pick two.

Protoclay

A lifetime supply of foundation. Each morning, you receive a random new LEGO set, still fresh in its packaging and wrapped with a little bow. Sets can be delivered which never made it to release, or were created by fans, or are no longer in production, or which never existed at all. But you’ll never receive the same set twice.

All of your LEGO pieces respond directly to the power of your imagination. Even when following an instruction guide, your creations will grow stronger as they’re assembled, so long as you care about what you’re making - bricks snapping together at the joints with unreal precision, toy models that don’t fall apart unless they’re deliberately dismantled, clever assemblies that work as intended.

Used as a channel for your own creativity, the pieces only grow stronger, permitting the construction of impossible objects. A boxy plastic triangle that cuts food and can be cleaned like a metal knife. A LEGO armchair that feels soft and gives way like stuffed leather. Futuristic industrial machinery made out of Technic parts. A magic staff that shoots mighty fireballs from its translucent red core. There are no fundamental limits to the quality and potency of what you can assemble; only what you can convincingly translate from idea to reality.

Memento

A letter to eternity, bound within a diary. Simply pressing a point into the surface of its endless pages will see it well with ink or glue or crinkle with embossing, and a stylus hangs from the end of its long bookmark. Nothing committed to this scrapbook can ever be removed, but the strange sheen of its paper grants clarity enough to avoid unforced errors.

By your status as the master of the diary, it grants you knowledge of its contents as if each word was memorized. But its greater power is the preservation of more than memory: all historical information scribed within traces a shadow of the time in which it was still true, pale moments which can be dredged forth and cast as shadows upon the changing now. Victories recorded may be synthesized and re-enacted, wizened performance sustained with the intensity of youth. Entire spaces may eventually be locked in an eternalist present or superposed with their ancient history - the only limit to this power of manifestation is your total will to defy entropy.

Even should every other part of yourself be destroyed, you may choose to linger as a timeless memory within the pages of your diary, suspended and composited in the apex of your life.

Velveteen

A boon companion - or the boon companion, rather. They may be the treasured friend you loved the most, now awakened and quickening, or something new entirely, the toy you never had. In any case, a stuffed animal, a figurine, a doll, a childhood companion brought to life in your arms. In all respects, their personality is compatible with your own, their loyalty assured without the flaws of obedience, their love for you untainted by misunderstandings.

It would be a mistake, too, to regard them as a mere animated object now that they’ve surpassed the circle of representation and become Real. Their forms and powers flow straightforwardly from their nature, simple but overwhelmingly effective in their domains; a teddy bear who commands a healing sleep and an aura of protection against evil, a doll with supernatural beauty and mastery of all things even remotely related to housekeeping.

Though your companion may be a person and take human shape to walk with you in the daylight, they still belong to a different order of life, reproducing through the exchange of love rather than biological DNA. If you and your companion ever both come to love another companion-toy as much as you love one another, then it may become Real too, no lesser than its predecessors.

Hexahedron

The root of all brainteasers. Its form shifts wildly and without warning, taking new permutations on the order of minutes or days - or even sooner, if you should ever solve one of its iterations with time to spare. Twisty puzzles, wire puzzles, puzzle boxes, burr puzzles, puzzle locks, puzzle rings, jigsaws… almost anything tactile enough to hold might pass through your hands, shapes rising and falling in a spiral without limit.

Each time you successfully solve the Hexahedron, it will open your mind to paradoxes and arcana, revealing some quantity of information in a random domain related to the puzzle that preceded it. Lore mastered in this fashion can include procedural skill as well as declarative knowledge, and nothing you learn this way will ever harm you or be forgotten.

The harder a puzzle is and the less time you have in which to solve it, the greater the quantity and quality of useful information you can glean from it; at the highest levels of gnosis, the Hexahedron may even grant you knowledge of functional spells and rituals. There are no fundamental barriers to stop you from sharing this preternatural knowledge with the world at large, but others will struggle to understand what esoterica you effortlessly comprehend.

Abstract

The fundamental implement. This edutainment kit consists of the materials to introduce you to a profession or hobby in a fun and easy way - an Easy-Bake cooking set, a set of Nerf guns for play-fighting, fake fossils to excavate from National Geographic. But it’s not limited by concession to practicality or lies to children.

As you continue to learn, your resources will only grow, and your tools will only increase in fidelity. Equipment that once was only an imitation will become capable of handling the real thing, diversifying until you have everything you need; handbooks of toy problems will teach you more adroitly than college textbooks ever could, guiding you along a road where each step is, if not easy, then at least as clear as the first one.

Where your skill in your chosen hobby or profession surpasses normal human limits, you may use your tools to wield it with increasing applicability and at increasing scales - a painter who uses art of surpassing beauty to argue, churning pieces out at a breakneck clip, an electrician who wires entire cities, shaping strange coils to channel the flow of traffic within it. There are no fundamental limits to what you can accomplish beyond your ability to learn.

Ouroboros

The circle of completion. A basic train table, marble run, or other looping toy set with room to grow. Just as a closed circle implies an interior, so too does your toy circumscribe a place - an otherworld within to which you can open portals to and fro at will. You are the ultimate master of the Ouroboros, and none can gainsay your right to control its circulation and borders.

The interior of the Ouroboros is a macrocosmic reflection of its exterior, a series of closed spaces moving and interlinked in greater cycles. There’s already room enough inside to live there in a pinch, but as you continue to add to its exterior, its interior will grow - each train car or marble either adding a new chamber, or being consumed to increment the scale and magnificence of a chamber that already exists.

Beyond a certain threshold of grandiosity, spaces within the Ouroboros can develop increasingly supernatural qualities: a library train car that gathers cursed tomes, a bathing world that swells with healing waters. There is no fundamental barrier to exploiting these spaces for power in the outside universe, but all advantages are ultimately derived from the use of resources within, albeit renewable ones.

Mantle

The distinction between man and beast. A few tokens of clothing for the winter and the seasons to come - perhaps socks or a scarf, jeans or jacket. Just wearing it already confers benefits based on its nature as clothing, above and beyond what mere clothes make possible - bolstering your willpower with justified confidence, flattering your body so acutely as to push its physical limits, protecting you from the world like a suit of armor.

With an exertion of will, you can choose to don your gifted clothing more completely, as far removed from an ordinary person wearing clothes as a person wearing clothes is removed from the naked. A masque donned as you move through the world becomes a sword to overturn it, permitting the flowering of aesthetics into power: a biker with a chariot of fire, a streetwear super-hacker, a goth commanding the darkness.

Should you mix your outfits and regularly wear another article of clothing together with this set for a year and a day, you may allow some of this stylistic magic to rub off on it. There’s no limit to the number of enchanted articles you can collect, and if you find something new that feels truer to wear, its potency in your hands will be increased to match.

-----------------------------------------------------------------------------

Whatever your presents, know that they are a blessing true, treasures that shall never be lost or destroyed, only well-loved and shared as you please.

But there is another gift that must be given before winter’s end, and a burden that must be accepted.

Is it yours to carry?

If you know, in your heart of hearts, that duty comes before joy.

Open the mystery box?

29 notes

·

View notes

Text

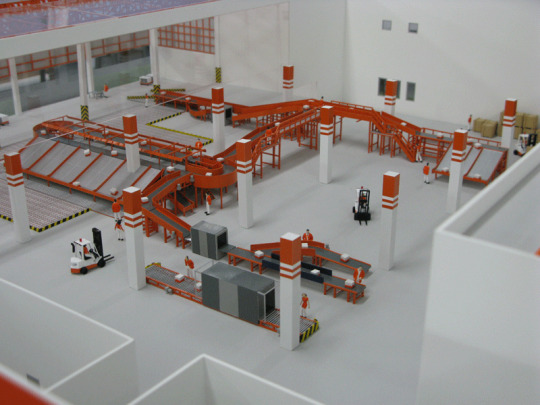

What Materials Are Used for Making Scale Models and Miniature Models?

How AR Model Makers Choose Materials for Stunning Scale Models

When it comes to crafting precise and eye-catching scale models, the materials used can make or break the final product. Whether it’s an engineering model, a marine model, an industrial model, or an architectural model, the team at AR Model Makers knows that selecting the right materials is key to delivering quality. In this article, we’ll explore the materials commonly used by expert miniature model makers like AR Model Makers, how they enhance different types of models, and why they matter to clients across industries. From house models to complex industrial designs, you’ll discover what goes into creating these miniature masterpieces.

Why Material Choice Matters in Scale Model Making

Common Materials Used by Miniature Model Makers

Miniature models come in all shapes and sizes, and so do the materials used to create them. Here’s a breakdown of the most popular choices at AR Model Makers and how they’re applied.

Wood – The Timeless Classic

Acrylic and Plastics – Precision and Durability

Metal – Strength for Industrial and Marine Models

Foam and Cardboard – Lightweight and Cost-Effective

https://armodelmakers.com/wp-content/uploads/2025/03/Foam-and-Cardboard.jpg

3D Printing Resins – The Future of Model Making

How AR Model Makers Tailor Materials to Your Project

Every project at AR Model Makers is unique, and material choices reflect that. For a marine model, they might combine metal for the hull with acrylic for water effects, creating a lifelike display. An industrial model could blend 3D-printed parts with metal accents to highlight machinery. By understanding the project’s purpose—whether it’s a trade show display or a client presentation—AR Model Makers ensures the materials align with both budget and vision.

For instance, a recent house model project in Delhi used a mix of wood and foam to craft a realistic neighborhood layout, earning praise from clients and establishing AR Model Makers as one of the best model makers in Delhi.

The Role of Craftsmanship in Material Selection

Materials alone don’t tell the full story—expert craftsmanship brings them to life. As one of the best model makers in Mumbai and beyond, AR Model Makers combines cutting-edge tools with hands-on expertise. Their team knows how to sand wood to a perfect finish, weld metal seamlessly, or paint acrylic for a polished look. This dedication elevates every engineering model, marine model, or architectural model they produce.

Interested in the process? Learn more about their approach on the AR Model Makers About Us page.

Why Choose AR Model Makers for Your Next Model?

With a reputation as top model makers in India, AR Model Makers stands out for their material expertise and client-focused approach. Whether you need a detailed marine model for a maritime expo or a sleek industrial model for a product pitch, their use of high-quality materials ensures stunning results. Plus, their presence in cities like Delhi and Mumbai makes them accessible to businesses nationwide.

Ready to start your project? Reach out via the AR Model Makers Contact Us page to discuss your vision.

External Resources for Further Reading

To dive deeper into scale model materials, check out these authoritative sources:

The Spruce Crafts: Guide to Model Making Materials

Material Properties for 3D Printing by Formlabs

If you have a project In mind just give us a Call

Have a project in mind? Let AR Model Makers bring it to life with the perfect materials! Drop a comment below with your thoughts, share this post with fellow model enthusiasts, or reach out to the team at AR Model Makers Contact Us to get started.

FAQ

What materials are best for an engineering model?

Materials like acrylic, metal, and 3D printing resins are ideal for engineering models due to their precision and durability, as used by best engineering model makers like AR Model Makers.

How long does it take to build a marine model with AR Model Makers?

Depending on complexity, a marine model can take anywhere from a few days to weeks, with AR Model Makers using metals and acrylics for top-quality results.

#marine model#architectural model#scale model#craft#art#model makers#model making#miniature model#engineering model#scalemodel

2 notes

·

View notes

Text

Sustainability in the Food and Beverage Sector: A Business Take

Sustainability in the food and beverage industry goes beyond a trendy concept—it’s a necessity. It involves ensuring that production, transportation, and sales processes minimize environmental harm while maintaining long-term ecological balance. Businesses that adopt sustainable practices not only contribute to a healthier planet but also build resilience and gain consumer trust.

Read More: https://theenterpriseglobe.com/business/sustainability-in-the-food-and-beverage-sector-a-business-take/

Rethinking the Value Chain

The supply chain offers a significant opportunity to drive meaningful change. Many companies depend on large suppliers who may not prioritize sustainability. Instead, businesses should focus on sourcing from certified suppliers, reducing food miles, and supporting local farmers. Local sourcing not only reduces costs and fosters goodwill but also allows companies to offer fresher products to their customers.

Another crucial factor is logistics. Are we optimizing transportation? Are we investing in fuel-efficient or electric vehicles? Such questions can reshape operations, making supply chains smarter and more sustainable.

Reducing Food Waste

Food waste remains a massive challenge. The Food and Agriculture Organization (FAO) estimates that nearly one-third of global food production is wasted. Effective demand forecasting and inventory management can prevent overproduction and spoilage. AI-driven analytics can enhance demand prediction, reducing unnecessary waste.

Repurposing excess food is another viable solution. Donating surplus food to charities or converting waste into by-products can make a significant difference. Innovative approaches, such as using fruit peels for packaging materials, demonstrate how businesses can turn waste into valuable resources.

Towards Renewable Energy & Green Operations

A major yet often overlooked issue is the energy consumption of food and beverage companies. Transitioning to renewable energy sources like solar panels, wind turbines, and energy-efficient machinery can drastically cut reliance on fossil fuels. While initial investments may seem steep, the long-term cost savings and environmental benefits are undeniable.

Water conservation is equally important. Implementing water-efficient irrigation methods, recycling water in processing plants, and reducing wastage in production can help preserve this vital resource.

Eco-Friendly Packaging Solutions

The industry’s reliance on single-use plastics is a growing concern. Consumers are demanding more eco-friendly alternatives, pushing businesses to explore biodegradable and recyclable packaging. Edible packaging, made from natural materials, is an innovative solution that reduces waste while maintaining functionality.

However, switching materials isn’t enough. Educating consumers about proper disposal methods through clear labeling and awareness campaigns ensures that recyclable and compostable packaging serves its intended purpose.

Transparency & Authentic Communication

Transparency fosters trust. Consumers want to know where their food comes from and how it is produced. Companies that openly share their sustainability efforts—including sourcing, production methods, and targets—tend to attract loyal customers. Certifications such as Fair Trade, USDA Organic, or Rainforest Alliance add credibility.

However, businesses must avoid greenwashing. Authenticity is key—sharing both successes and challenges helps build genuine connections with consumers and stakeholders.

Collaboration for Greater Impact

Sustainability is not a solo effort. Collaboration between companies, industries, and even competitors can drive significant progress. Joint initiatives can tackle larger issues such as climate change and deforestation, creating shared standards that benefit the entire sector.

Educating Employees & Consumers

Sustainability starts from within. Educating employees on conservation practices—whether through energy-saving initiatives in offices or participating in community clean-ups—creates a culture of responsibility.

Consumers also play a crucial role. Awareness campaigns that promote sustainable consumption, such as reducing meat intake or choosing seasonal produce, can drive behavioral change, influencing demand and encouraging responsible choices.

Monitoring & Measuring Progress

Setting achievable sustainability goals and tracking progress is essential. Businesses that conduct regular sustainability audits can identify areas for improvement and adjust their strategies accordingly. Measuring impact ensures that sustainability efforts remain effective and aligned with broader environmental goals.

Final Thoughts

Sustainability in the food and beverage industry is no longer optional—it’s imperative. Every effort, from rethinking supply chains to educating stakeholders, contributes to a larger movement toward environmental responsibility. The journey may be challenging, but the rewards—both for businesses and the planet—are invaluable. By working together, companies and individuals can build a future where the food and beverage industry nourishes both people and the planet.Source: https://theenterpriseglobe.com/

#theenterpriseglobe#Sustainability#FoodIndustry#EcoFriendly#GreenBusiness#SustainableLiving#FMCG#FoodInnovation#ClimateAction#ZeroWaste

2 notes

·

View notes

Text

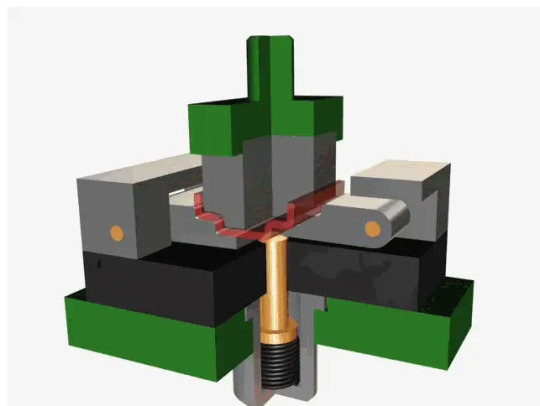

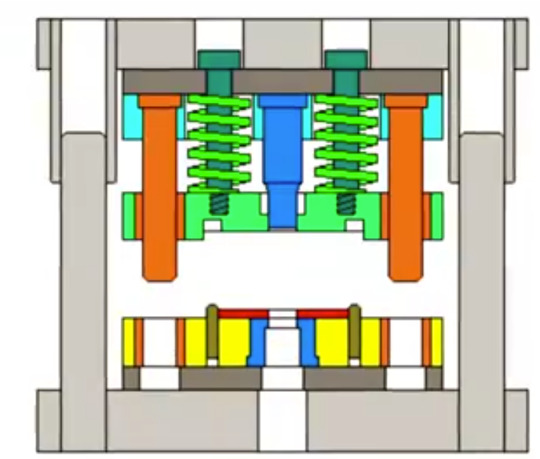

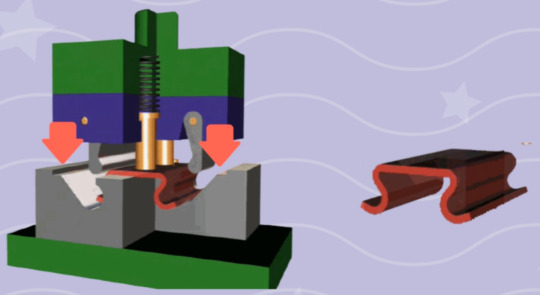

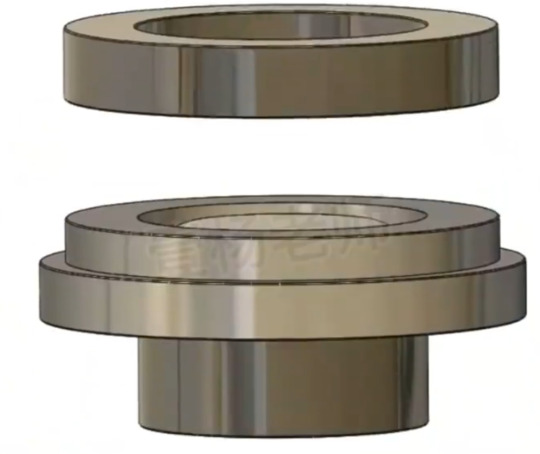

What is the stamping process?

1.Stamping is a forming method that uses a press and a die to apply external force to plates, strips, pipes and profiles to cause plastic deformation or separation, thereby obtaining a workpiece (stamping part) of the desired shape and size. Stamping and forging belong to plastic processing (or pressure processing), collectively known as forging. The blanks for stamping are mainly hot-rolled and cold-rolled steel plates and strips. 60-70% of the steel in the world is sheet material, most of which is stamped into finished products. The body, chassis, fuel tank, radiator fins of automobiles, the steam drum of boilers, the shell of containers, the iron core silicon steel sheets of motors and electrical appliances are all stamped. There are also a large number of stamped parts in products such as instruments and meters, household appliances, bicycles, office machinery, and daily utensils.

2.Stamping is a production technology that uses the power of conventional or special stamping equipment to directly subject sheet metal to deformation force in the die and deform it, thereby obtaining product parts with certain shapes, sizes and performances. Sheet metal, die and equipment are the three elements of stamping. According to the stamping temperature, it is divided into hot stamping and cold stamping. The former is suitable for sheet metal processing with high deformation resistance and poor plasticity; the latter is carried out at room temperature and is a commonly used stamping method for thin plates. It is one of the main methods of metal plastic processing (or pressure processing) and also belongs to material forming engineering technology.

3.The die used for stamping is called a stamping die, or simply a die. A stamping die is a special tool for batch processing materials (metal or non-metal) into the required stamping parts. The die is crucial in stamping. Without a die that meets the requirements, batch stamping production will be difficult to carry out; without advanced dies, advanced stamping technology cannot be achieved. The stamping process, die, stamping equipment and stamping materials constitute the three elements of stamping processing. Only when they are combined with each other can stamping parts be obtained.

Sheet metal, die and stamping equipment are the three essential elements of stamping processing:

Characteristics and application of stamping processing Stamping production relies on dies and presses to complete the processing process. Compared with other processing methods, it has the following characteristics in terms of technology and economy:

(1) The dimensional accuracy of stamped parts is guaranteed by the die, and they have exactly the same characteristics, so the quality is stable and the interchangeability is good.

(2) Due to the use of die processing, parts with thin walls, light weight, good rigidity, high surface quality and complex shapes that cannot be or are difficult to manufacture by other processing methods can be obtained.