#Plastic Processing Machinery Sector Report

Explore tagged Tumblr posts

Text

Plastic Processing Machinery Industry: A Critical Component of the Circular Economy

Global plastic processing machinery industry data book is a collection of market sizing information & forecasts, competitive benchmarking analyses, macro-environmental analyses, and regulatory & technological framework studies. Within the purview of the database, such information is systematically analyzed and provided in the form of outlook reports and summary presentations on individual areas of research.

The market incorporates a wide range of equipment used in the manufacturing and processing plastic products, including injection molding machines, blow molding machines, extrusion machines, and more. The demand for plastic products across various industries, such as packaging, automotive, electronics, and construction, has been a key driver for the expansion of this market.

Access the Global Plastic Processing Machinery Industry Data Book, 2023 to 2030, compiled with details like market sizing information & forecasts, trade data, pricing intelligence, competitive benchmarking, macro-environmental analyses, and regulatory & technological framework studies.

Plastic Injection Molding Machine Market Report Highlights

The plastic injection molding machine market was estimated at approximately USD 11.75 billions in 2022, growing at a CAGR of 4.8% from 2023 to 2030 according to a new report by Grand View Research, Inc. The increasing adoption of plastic injection molding machines in the automotive, electronics, and packaging industries is likely to be the key driver for the growth of the industry over the forecast period.

Plastic injection molding is suitable for producing various exterior automotive components such as mudguards, door panels, wheel arches, grilles, trunk trims, front and rear covers, and outside car door trims. Automotive injection molding is an important manufacturing process in the automotive industry, where safety, consistency, and quality are critical.

The automobile end-use category accounts for a sizable portion of the injection molding machine market. A variety of automobile parts, such as outer body panels, bumpers, spoilers, dashboards, and electrical housings, are made using plastic injection molding machines. Many automotive interior parts are manufactured using plastic injection molding as well as the instrumentation components, interior surfaces, glove boxes, dashboard faceplates, air vents, and other items. Rapid growth in demand for automotive components has boosted global automobile production, resulting in a high demand for injection-molded parts in the automotive industry.

Plastic injection molding is utilized for the formation of plastic packaging for a variety of applications and in a variety of forms. The injection method is used to manufacture food and beverage containers, creatively designed body care packaging, and even packaging for household chemicals. The plastic injection molding technique solves problems related to barrier protection, handling, product visibility, salability, and aesthetics.

Plastic Extrusion Machinery Market Report Highlights

The global plastic extrusion machine market size is expected to reach USD 6.41 billions in 2022, expanding at a CAGR of 4.4% from 2023 to 2030, according to a new report by Grand View Research, Inc. Increasing penetration of plastics in the manufacturing of consumer electronics is expected to be one of the critical factors for the growth of plastic extrusion machine. In addition, plastic extruded parts are widely used for manufacturing structures & bodies of television sets, video recorders, cameras, and laptops. Moreover, motor housings and interior frames are manufactured using the extrusion process.

The demand for plastic extrusion machine is rising owing to the ability of plastics to be formed into complex shapes and the relative ease compared to metals or ceramics. Moreover, surged usage of engineering-grade plastics for producing pipe, fencing, window frames, plastic films, wire insulation, and deck railing is anticipated to grow during the forecast period.

Plastic extruded parts provide a solution for high volume and cost-efficiency. The recent trend of lightweight in the automotive industry to enhance fuel efficiency has resulted in increased use of plastic extruded parts coupled with the growing adoption of extruded products in the packaging industry is projected to drive the market of plastic extrusion machines over the forecast period.

The demand for plastic extruded products has been on the rise for several years because of several advantages of the extrusion process and the rising demand from end-use industries such as automotive, electronics, consumer goods, telecommunications, and renewable energy. Moreover, the low cost per part, flexibility in operation, high production volume, and compounding ability are the other factors responsible for the growing demand for extruded plastic and metal products.

Order your copy of Free Sample of “Plastic Processing Machinery Industry Data Book - Plastic Injection Molding Machine, Plastic Extrusion Machinery, Plastic Blow Molding Machine Market Size, Share, Trends Analysis, And Segment Forecasts, 2023 - 2030” Data Book, published by Grand View Research

Plastic Blow Molding Machine Market Report Highlights

The global plastic blow molding machine market size is anticipated to reach USD 2.97 billions in 2022, growing at 3.9% CAGR from 2023 to 2030, according to a new report by Grand View Research, Inc. High demand for packaged goods in the food and beverage industry, increasing use of plastic blow molding machines in the production of industrial and automotive components, and rising need for plastic packaging solutions in the pharmaceutical industry are major factors driving market revenue growth.

In addition, the machines are widely used in several applications and sectors including plastic packaging, chemical, automobile, pharmaceuticals, lubricants, edible oils, FMCG, and others. The surge in demand for sanitizing and cleaning products fueled the adoption of blow molding machines to manufacture sanitizers, hand soaps, and hydrogels.

Plastic packaging alternatives are in high demand in the pharmaceutical business because they protect drugs from contamination and extend their shelf life. Plastic blow molding machines are used to create containers, plastic bottles, and vials, often used as packaging materials in the pharmaceutical industry. For instance, Bekum Maschinenfabriken GmbH announced the introduction of the BM 902D, a new, high-performance blow molding machine, in 2021. The machine has a cutting-edge hydraulic system and an intuitive user interface and is built to create massive parts with excellent precision and productivity.

Growing preferences for molded plastic products, rising demand due to the material's flexibility, rising demand due to the prevalence of low labor costs, and low waste production are some of the factors that will likely propel the growth of the plastic blow molding machine industry over the forecast period. On the other hand, as technology continues to progress, it will create more potential for the market for plastic blow molding machines to expand over the coming years. For instance, Taiwan-based Parker Plastic Machinery Co. Ltd., a producer of plastic blow molding machines, offers its fully electric plastic blow molding machines. It is growing in recognition for its high-performance hydraulic power-saving technology.

Key players operating in the Plastic Processing Machinery Industry are –

• Arburg GmbH + Co KG. • KraussMaffei • Haitian International • Milacron • Nissei Plastic Industrial Co. Ltd. • ENGEL AUSTRIA GmbH. • Chen Hsong Holdings Limited • UBE Machinery Corporation, Ltd. • Husky Injection Molding Systems Ltd.

#Plastic Processing Machinery Industry#Plastic Processing Machinery Market#Plastic Injection Molding Machine Industry Trends Data Book#Plastic Extrusion Machinery Market Size#Plastic Blow Molding Machine Market Share#Plastic Blow Molding Machine Market Growth#Plastic Processing Machinery Sector Report

0 notes

Text

Resin Dryers Market Revenue, Size, Segment by Type, Application, Key Companies 2033

The global resin dryers market is expected to reach a valuation of US$ 16.65 billion in 2023, with projections indicating it will grow to US$ 24.65 billion by 2033. The industry is anticipated to expand at a compound annual growth rate (CAGR) of 4% during the forecast period.

Key Takeaways:

The resin dryers market is expected to experience a strong compound annual growth rate (CAGR) from 2023 to 2033.

The manufacturing sector is projected to lead the global market, capturing the largest share by 2033.

North America is anticipated to maintain dominance in the global market, securing a significant share throughout the forecast period.

For more insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=8602

Which Countries Influence the Global Market and Why?

Several countries play a significant role in shaping the global resin dryers market, influenced by various factors. These countries include:

China: China is expected to capture the largest share of the global market during the forecast period. The growing demand across industries such as consumer goods, automotive, packaging, and electronics is driving the market in China. The expanding manufacturing sector is boosting the adoption of resin dryers, ensuring safety, enhanced performance, and high-quality drying processes.

United States: The United States is projected to hold a significant market share due to the increasing demand from end-user industries like aerospace, consumer goods, and automotive. U.S. manufacturers focus on producing high-standard, consistent, and quality products to meet consumer needs.

Germany: The growing manufacturing sectors in chemicals, machinery, and automotive are driving demand for resin dryers in Germany. The country is committed to sustainability, focusing on developing high-quality resin dryers that reduce environmental impacts.

Japan: Japan is contributing to rising demand for moisture-removal solutions across industries such as electronics, chemicals, and automotive. Manufacturers in Japan are adopting advanced technologies, such as artificial intelligence, to create innovative, high-quality, and efficient resin dryers.

India: The expanding manufacturing, packaging, construction, and automotive industries are fueling the Indian market for resin dryers. The growing demand for plastic products is significantly contributing to the market's revenue potential.

South Korea: South Korea has a strong presence in the global market, driven by the rise of end-user industries, innovation, and the development of high-quality products, securing a better market share in the country.

Common Reasons Behind the Demand for Resin Dryers are:

Expansion of manufacturing and industrialization.

Emphasis on product consistency and maintaining high-quality standards.

Focus on sustainability, innovation, and technological advancements.

Strict regulations aimed at minimizing environmental impacts.

Rising demand for plastic products across various industries.

How Are Key Players Adding Values in the Global Market?

Key players in the market are driving innovation by investing heavily in research and development to create unique and improved products. These companies focus on understanding consumer needs and delivering advanced solutions to attract customers. To further elevate their position in the global market, they are employing various marketing strategies, including mergers, collaborations, acquisitions, product launches, and agreements.

Recent Developments in the Global Market are:

Motan Colortronic introduced its latest product, MOTANCONNECT, which enables remote monitoring, material handling, and control of resin drying processes.

Wittmann Battenfeld launched its new product, Wittmann 4.0, designed to enhance communication during resin drying, ensure seamless integration, and improve connectivity.

Matsui America unveiled its advanced resin dryer, the MDW-2000. Specifically developed for large enterprises, this model is engineered to provide high-quality moisture-removal solutions.

Key Companies Profiled

Novatec, Inc.

Conair Group

Motan Colortronic

Wittmann Battenfeld

Matsui America

Una-Dyn (Maguire Products)

AEC, Inc. (Auxiliary Equipment Company)

Moretto S.p.A.

Shini Plastics Technologies, Inc.

Piovan S.p.A.

Koch-Technik

Summit Systems

Bry-Air (Asia) Pvt. Ltd.

Tummers Group

Sterling

Maguire Products, Inc.

Dri-Air Industries, Inc.

Comet Plastic Equipment, LLC

Labotek A/S

Shini Group

Key Segmentation in the Global Resin Dryers Market are

By Type:

Desiccant Dryers

Hot Air Dryers

Vacuum Dryers

Compressed Air

By Technology:

Dehumidifying Dryers

Convection Dryers

Infrared Dryers

Centrifugal Dryers

By Application:

Automotive

Packaging

Construction

Consumer Goods

By Capacity:

Small Capacity Dryers

Medium Capacity Dryers

Large Capacity Dryers

By End-user Industry:

Plastics Manufacturing

Chemical Industry

Food & Beverages

Pharmaceuticals

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

🧴 Bottle Filling Machine Market to Reach $6.31 Billion by 2032 – Driven by Food, Pharma & Cosmetics Boom! 🚀

📊 The global bottle filling machine market was valued at USD 3.81 billion in 2018 and is projected to climb to USD 6.31 billion by 2032, growing at a steady CAGR of 3.4%.

🌏 Asia Pacific led the global market with a 35.17% share in 2018, attributed to the region’s expanding food & beverage and pharmaceutical industries, along with growing automation in manufacturing.

🏭 Market Overview:

Bottle filling machines are extensively used across:

🥤 Food & Beverages

💊 Chemicals & Pharmaceuticals

💄 Cosmetics

They enable high-speed, contamination-free filling of PET, glass, and other bottle types, addressing industry demands for efficiency, hygiene, and customization.

🧩 By Bottle Type:

PET Bottles

Glass Bottles

Others

🧪 By Application:

Food Products

Beverages

Chemicals & Pharmaceuticals

Cosmetics

🏢 Key Companies Profiled:

Syntegon Technology GmbH (Bosch Packaging Technology)

GEA Group Aktiengesellschaft

JBT Corporation

Tetra Laval

KHS GmbH

Krone Group AG

Coesia Group SpA

Ave Technologies

E-PAK Machinery

Pacific Packaging Machinery Inc.

ProMatch

KB Associates

🔧 Key Industry Developments:

✅ Bosch Packaging Technology won the German Packaging Award for its ALF 5000 Series, a high-tech solution for filling ampoules and vials, especially in the pharma sector.

✅ JBT Corporation acquired Proseal UK Limited for USD 280 million, enhancing its sealing solutions in the food packaging segment.

✅ Ave Technologies launched a versatile bottling machine at PPMA Total Show, capable of handling multiple bottle substrates and customizable capping options—enhancing adaptability across sectors.

💡 Growth Drivers:

🌍 Rising demand for processed food and beverages

🏭 Surge in automated and hygienic production lines

💉 Expansion of pharma manufacturing

🌿 Shift towards eco-friendly and non-plastic packaging

With a global push for automation, hygiene, and speed, the bottle filling machine market is set to play a vital role in modern production ecosystems.

📎 Explore Full Report Here: 👉 https://www.fortunebusinessinsights.com/bottle-filling-machine-market-10264

#BottleFillingMachines#PackagingAutomation#FillingTechnology#PETandGlassBottles#FoodProcessing#PharmaPackaging#PackagingInnovation#MachineryMarket#ManufacturingAutomation#CAGR2032#BoschPackaging#JBTCorporation#AveTechnologies#IndustrialMachineryGrowth

0 notes

Text

2-Ethylhexanoic Acid Price Trend: Insights Into Market Dynamics and Procurement Strategy

2-Ethylhexanoic Acid (2-EHA) is a vital specialty chemical used in a broad range of industrial applications such as paints, coatings, plasticizers, lubricants, and automotive coolants. Given its wide applicability and petrochemical origin, the 2-Ethylhexanoic Acid price trend is significantly influenced by raw material availability, demand patterns, and global trade dynamics.

Understanding the price fluctuations of 2-EHA is crucial for procurement professionals, manufacturers, and industry stakeholders looking to ensure cost-efficiency and supply chain stability.

What is 2-Ethylhexanoic Acid?

2-Ethylhexanoic Acid (C₈H₁₆O₂) is a branched-chain carboxylic acid primarily derived from 2-ethylhexanol. It is a clear, colorless, slightly viscous liquid with a mild odor and is soluble in organic solvents. It is known for forming metal salts (carboxylates) that serve as catalysts and stabilizers in various processes.

Key Applications

2-Ethylhexanoic Acid is widely used across industries, including:

Paints & Coatings Used to produce metal driers like cobalt, manganese, and zirconium salts in alkyd-based paints and inks.

Plasticizers and PVC Stabilizers Acts as a raw material for additives in plastic production.

Synthetic Lubricants Enhances performance in lubricants and greases used in automotive and industrial machinery.

Automotive Coolants Serves as a corrosion inhibitor in engine coolants and radiator fluids.

Cosmetic and Pharma Intermediates Used in formulating esters and emollients in cosmetics and as intermediates in pharmaceuticals.

Production Process

The production of 2-Ethylhexanoic Acid generally involves:

Aldol condensation of butyraldehyde to form 2-ethylhexanal.

Hydrogenation to produce 2-ethylhexanol.

Oxidation of 2-ethylhexanol to yield 2-ethylhexanoic acid.

The price and availability of butyraldehyde and 2-ethylhexanol directly affect the cost of 2-EHA production.

2-Ethylhexanoic Acid Price Trend Overview

The price trend of 2-Ethylhexanoic Acid is affected by several key market factors:

Raw Material Costs Feedstock volatility—especially in n-butyraldehyde and 2-ethylhexanol, which are derived from crude oil—directly influences pricing.

Crude Oil and Energy Prices Rising global energy prices increase production and transportation costs, affecting the overall 2-EHA price.

Demand from End-Use Industries High demand from the paints, plastics, and automotive sectors increases market pressure on pricing.

Supply Chain Constraints Logistic disruptions, shipping delays, and capacity limitations in Asia and Europe can lead to short-term price spikes.

Environmental Regulations Stricter chemical production standards in the EU and China can cause plant shutdowns or reduced output, impacting supply and pushing prices up.

In recent quarters, 2-EHA prices have experienced moderate upward trends, particularly in Asia-Pacific and Europe, due to raw material shortages and increasing industrial demand post-pandemic.

Procurement Insights

For procurement managers, staying informed on the 2-Ethylhexanoic Acid price trend is essential for:

Accurate cost forecasting

Identifying optimal purchase windows

Managing supplier risks

ProcurementResource.com provides valuable tools such as:

Real-time price trend analysis

Cost structure breakdowns

Regional market outlooks

Supplier benchmarking reports

0 notes

Text

How to Maximize Efficiency with Mine Recycling in Perth: Pro Tips

Introduction: Why Mine Recycling Matters

Mining is one of the most resource-intensive industries in Western Australia, especially in and around Perth. While this sector plays a vital role in the economy, it also produces significant volumes of industrial waste—from metal offcuts and plastic piping to discarded machinery and electronics. Left unmanaged, this waste can severely impact the environment and incur high disposal costs.

That’s where mine recycling in Perth becomes essential. Recycling isn’t just an eco-friendly practice—it’s a smart operational strategy. With the right approach, mining companies can reduce waste, recover valuable materials, lower environmental risks, and save money.

This article explores pro tips to help you maximize efficiency with mine recycling in Perth, whether you’re running a large-scale operation or managing a localized site.

What Is Mine Recycling?

Mine recycling refers to the recovery, processing, and repurposing of waste generated during mining operations. This includes materials like:

Scrap metals (iron, steel, aluminum, copper)

HDPE plastics (pipes, containers, liners)

Rubber (tires, conveyor belts)

Electrical and electronic waste

Timber, concrete, and packaging materials

Instead of sending these to landfills, they can be collected, sorted, and either reused on-site or processed by local recycling facilities in Perth.

Tip #1: Conduct a Waste Audit Before You Start

Before setting up a recycling process, you need to understand what materials your site is generating. Conducting a waste audit helps you categorize waste, identify recyclables, and estimate volume.

What to Include in a Waste Audit:

Types of waste (metal, plastic, e-waste, etc.)

Amount of each material generated per month

Contamination levels (e.g., oil-soaked parts)

Current disposal methods and costs

Use this data to design an efficient recycling strategy tailored to your operation’s needs.

Tip #2: Separate Waste at the Source

One of the most effective ways to boost recycling efficiency is to segregate materials on-site. Sorting waste early prevents cross-contamination and improves the quality of recycled material.

Set Up a Segregation System:

Use clearly labeled bins for different waste types

Train staff on proper disposal practices

Keep hazardous and recyclable materials in separate areas

Place collection stations near work zones for convenience

Efficient sorting saves time at the recycling center and increases the value of the recycled output.

Tip #3: Focus on High-Value Recyclables

Not all waste is created equal. Some materials—like metals and HDPE plastics—offer higher returns when recycled. These materials are commonly found on minesites and can be easily processed in Perth’s specialized recycling centers.

High-Value Materials:

Steel and iron: Used in construction and equipment

Aluminum and copper: Found in cables and electronics

HDPE plastic: Common in mining pipes and drums

E-waste: Often contains valuable components like gold, silver, and rare earth elements

Prioritizing these items can improve both the environmental and economic impact of your recycling program.

Tip #4: Partner with Local Recycling Experts in Perth

Not all recycling services can handle heavy-duty mining waste. That’s why it’s important to partner with experienced recyclers in Perth who understand the specific needs of the mining industry.

Benefits of Working with Local Providers:

Reduced transport costs and lower carbon footprint

Compliance with Western Australia’s recycling regulations

Access to industry-grade processing equipment

Timely pickups and reliable service

Ask your recycler if they provide reports, on-site collection, or bulk material handling—features that can greatly improve recycling efficiency.

Tip #5: Schedule Regular Pickups to Avoid Clutter

Letting waste build up on-site can create safety hazards, slow down operations, and attract fines. Establishing a regular pickup schedule helps keep your site clean and ensures that recyclable materials are moved promptly to processing facilities.

Scheduling Tips:

Base pickup frequency on waste generation volume

Use compactors or balers to save space for plastic and metal

Communicate clearly with your recycling partner about preferred times and locations

Keeping the flow of waste consistent makes the recycling process more efficient from collection to processing.

Tip #6: Invest in On-Site Recycling Solutions

For high-volume operations, consider investing in on-site recycling equipment like shredders, balers, or compactors. This is especially useful for materials like HDPE plastic and scrap metal, which can be processed before transportation.

On-Site Equipment Can Help You:

Reduce hauling costs

Minimize storage needs

Improve material quality

Control contamination

While there is an upfront investment, the long-term savings and improved efficiency can make it worthwhile for large-scale mine operations.

Tip #7: Train Your Workforce for Long-Term Success

Your recycling program is only as good as the people running it. Training your team in proper recycling practices ensures better participation and fewer mistakes.

What to Include in Training:

How to identify recyclable materials

Where and how to dispose of different types of waste

Importance of minimizing contamination

Who to contact for questions or issues

Make recycling part of your safety and environmental compliance training. Consider posting guides or signage near recycling stations to reinforce practices.

Tip #8: Use Recycling Data to Track Progress

Tracking your recycling efforts helps you measure impact, identify bottlenecks, and set sustainability goals. Many recyclers in Perth offer detailed reports, including:

Total volume of waste recycled

Breakdown by material type

Environmental impact statistics (e.g., emissions saved)

Cost savings or revenue earned from recyclable materials

Use this data in ESG reports, audits, and stakeholder communications to show your commitment to sustainable practices.

Tip #9: Align Recycling Goals with Local Regulations

Western Australia has implemented sustainability goals through initiatives like the Waste Avoidance and Resource Recovery Strategy 2030, which encourages commercial waste reduction and resource reuse. By aligning your mine recycling efforts with these goals, you can stay compliant and potentially access local incentives.

Make sure to:

Stay updated on recycling laws and guidelines

Register with certified recyclers or waste handlers

Retain documentation for environmental audits

This ensures you meet both legal requirements and environmental responsibilities.

Conclusion: Turn Waste into Opportunity with Efficient Mine Recycling

Mine recycling in Perth isn’t just about managing waste—it’s about improving efficiency, reducing costs, and contributing to a cleaner future. Whether you’re dealing with scrap metal, HDPE plastics, or e-waste, applying the pro tips in this article will help you streamline your recycling processes and increase your environmental performance.

With local recycling expertise, smart sorting systems, and trained staff, your operation can transform waste into opportunity—supporting both your business goals and Western Australia’s sustainability efforts.

0 notes

Text

Everything You Need to Know About Calibration Services Manufacturers in Ahmedabad

Why Calibration Is Essential for Precision and Safety in Industrial Equipment

In any industrial environment, calibration is more than just a routine check-up—it’s the foundation of precision, efficiency, and safety. Calibration ensures that tools, machines, and measurement instruments provide accurate results within defined tolerances. Over time, even the most reliable equipment can drift from its original specification due to regular usage, environmental changes, or mechanical wear and tear. When this happens, the accuracy of the entire production process is compromised.

By regularly calibrating their equipment, industries avoid costly errors, prevent machine downtime, and maintain compliance with regulatory standards. More importantly, calibration ensures the safety of workers, especially when machinery or high-pressure equipment is involved. This is why manufacturers and industries in Ahmedabad prioritize working with certified and experienced Calibration Services Manufacturers in Ahmedabad to meet their routine and critical calibration needs.

Key Industries in Ahmedabad That Depend on Professional Calibration Services

Ahmedabad has emerged as one of India’s leading industrial hubs. With a strong presence of textile, pharmaceutical, chemical, plastic, and engineering industries, the demand for accurate measuring instruments has never been higher.

Here are some of the major sectors relying on professional calibration services:

Pharmaceuticals: For dosage accuracy, environmental monitoring, and compliance with FDA/WHO standards.

Automotive and Engineering: For machine tool calibration, torque wrenches, and alignment equipment.

Textiles: For monitoring temperature, pressure, and flow in dyeing and finishing operations.

Food & Beverage: For temperature and humidity monitoring in food safety compliance.

Electrical & Electronics: For calibration of voltmeters, ammeters, oscilloscopes, and other sensitive instruments.

These industries require repeatable and dependable results, which makes partnering with certified calibration service providers essential to operational success.

Top Features to Look for in Calibration Services Manufacturers in Ahmedabad

When choosing a calibration partner, industries must evaluate multiple aspects beyond just pricing. Here are the top features that define a reliable calibration manufacturer:

Accreditation & Certification Ensure that the company holds NABL (National Accreditation Board for Testing and Calibration Laboratories) accreditation. This confirms that their calibration processes meet global standards.

Range of Equipment Support From pressure gauges to digital thermometers and from flow meters to high-end CMM machines, the wider the range, the more value they can offer.

On-Site Calibration Services Many manufacturers offer on-site services that reduce equipment downtime and logistics hassles.

Quick Turnaround Time Time-sensitive industries benefit from manufacturers who offer fast and reliable services without compromising quality.

Data Traceability and Documentation Proper calibration reports with traceable references are crucial for audits and quality certifications.

These qualities help companies maintain operational accuracy while building trust in the quality of their measurements.

Types of Instruments Commonly Calibrated by Experts in Ahmedabad

Calibration services in Ahmedabad are known for handling a broad spectrum of instruments across multiple domains. Some of the most frequently calibrated devices include:

Temperature and Humidity Instruments: Digital thermometers, RTDs, data loggers, and hygrometers

Pressure Equipment: Pressure gauges, transmitters, and barometers

Flow and Volume Meters: Turbine meters, rotameters, and ultrasonic flow meters

Electrical Instruments: Multimeters, insulation testers, current clamps, and oscilloscopes

Dimensional Instruments: Vernier calipers, micrometers, dial indicators, and CMMs

Mass and Weight Instruments: Balances and weighing machines

The right calibration services provider will have the infrastructure and trained technicians to deliver highly accurate, traceable results for these instruments.

How to Choose a Reliable Calibration Partner for Long-Term Success

With numerous service providers in Ahmedabad, selecting the right calibration partner can be a challenge. Here are a few pointers to consider:

Experience and Market Reputation: A long-standing presence in the calibration field indicates reliability and deep domain knowledge.

Technology and Equipment Used: Modern labs equipped with automated calibration benches and software-driven analysis offer better accuracy and repeatability.

Client Portfolio: Serving well-known industries adds credibility to a calibration service provider.

Customer Support and Service Contracts: Look for companies offering annual maintenance contracts (AMCs) and real-time technical support.

One such trusted name in the region is Machinery Clinic, known for its state-of-the-art calibration services and prompt support for industries across Gujarat.

Bonus Insight: The Role of Automation and Robotics in Calibration

As automation spreads across manufacturing lines, calibration processes too are becoming smarter and faster. The integration of sensors, AI-based monitoring, and IoT-enabled devices is streamlining calibration workflows. Some advanced facilities are even employing robotic arms for precise instrument alignment and testing. This evolving synergy reflects the growing importance of Industrial Robots Manufacturers in Ahmedabad, who are now working in tandem with calibration service providers to build integrated, automated quality systems.

Final Thoughts

From enhancing operational precision to ensuring industry compliance, calibration services play a vital role in modern manufacturing. Ahmedabad’s industrial ecosystem benefits immensely from its pool of skilled Calibration Services Manufacturers in India, who offer dependable, accredited, and industry-specific solutions.

Choosing a trusted partner like CNC Mall can help you maintain consistent performance, meet audit requirements, and reduce costly downtime. In a competitive industrial landscape, precision isn't just a goal—it's a standard.

0 notes

Text

Food Tray Sealer Market Growth Analysis, Market Dynamics, Key Players and Innovations, Outlook and Forecast 2025-2032

According to a new market analysis, the global Food Tray Sealer market was valued at USD 515 million in 2024 and is projected to reach USD 614 million by 2032, growing at a Compound Annual Growth Rate (CAGR) of 2.6% during the forecast period (2025-2032). The growth is driven by increasing demand for packaged convenience foods, technological advancements in packaging machinery, and stringent food safety regulations worldwide.

Download FREE Sample Report: Food Tray Sealer Market - Detailed Research Report

What is a Food Tray Sealer?

A Food Tray Sealer is an industrial packaging machine that uses heat-sealing technology to securely package food products in trays. These machines play a crucial role in maintaining product freshness and extending shelf life for various food categories including ready-to-eat meals, fresh produce, and frozen foods. Modern tray sealers can operate at speeds of up to 60 cycles per minute, making them essential for high-volume food production lines.

Key Market Drivers

1. Growth of Packaged Food Industry

The global packaged food sector's expansion, particularly in ready-to-eat meals (projected at 4.3% CAGR through 2030), has directly increased demand for efficient packaging solutions. Urbanization and changing consumer lifestyles have made tray-sealed convenience foods increasingly popular, with 42% of consumers prioritizing convenience in food purchases. Major food processors are investing heavily in automated tray sealing lines to meet this demand while reducing production costs.

2. Technological Advancements in Packaging

Recent innovations in tray sealing technology include ultrasonic sealing systems that reduce energy consumption by 30%, and IoT-enabled machines with real-time monitoring capabilities. The integration of Industry 4.0 technologies has improved production efficiency by 15-20% for manufacturers adopting these advanced systems. Leading companies like Multivac and Ishida have recently launched models featuring robotic loading and integrated quality inspection systems.

Market Challenges

High capital investment requirements (ranging from $50,000 to $500,000 per machine) and shortage of skilled operators remain significant barriers to adoption, particularly for small-to-medium enterprises. Additionally, increasing environmental regulations on packaging materials, such as the EU's Single-Use Plastics Directive, are forcing manufacturers to develop new sealing solutions compatible with sustainable materials while maintaining performance standards.

Opportunities Ahead

Emerging markets in Asia-Pacific and Latin America present significant growth potential due to rising middle-class populations and expanding food processing industries. The development of compostable mono-material films and energy-efficient sealing technologies creates new application opportunities. Key players are also focusing on smart packaging solutions with RFID and QR code integration to enhance supply chain traceability and consumer engagement.

Regional Market Insights

Europe dominates with 35% market share, driven by strict food safety regulations and high automation adoption in countries like Germany and France.

North America follows closely, with the U.S. food processing industry investing heavily in high-speed automated sealing systems to meet FDA requirements.

Asia-Pacific is the fastest-growing region, projected at 4.1% CAGR, with China and India modernizing their food packaging infrastructure.

Latin America and MEA show emerging potential, although adoption rates vary significantly based on local industrial development.

Competitive Landscape

Multivac leads with 20% market share, offering the most comprehensive range of tray sealing solutions globally.

Proseal UK and Ishida specialize in high-speed automated systems with gas flushing capabilities.

In 2024, SEALPAC introduced a breakthrough in sustainable packaging with its fully recyclable mono-material tray sealing system.

Market Segmentation

By Type:

Manual Tray Sealers

Semi-Automatic

Fully Automatic

By Application:

Fresh Food

Ready Meals

Processed Food

Pharmaceutical

By Technology:

Heat Sealing

Ultrasonic

Modified Atmosphere Packaging (MAP)

Report Scope & Offerings

This comprehensive report provides:

2025-2032 market forecasts with COVID-19 impact analysis

Competitive intelligence on 15+ key players including Multivac, Ishida, and Proseal

Emerging technology analysis covering IoT integration and sustainable packaging solutions

Download FREE Sample Report: Food Tray Sealer Market - Detailed Research Report

View Full Report: Comprehensive Food Tray Sealer Market Analysis

Visit more reports :

About Intel Market Research

Intel Market Research delivers actionable insights in technology and infrastructure markets. Our data-driven analysis leverages:

Real-time infrastructure monitoring

Techno-economic feasibility studies

Competitive intelligence across 100+ countries Trusted by Fortune 500 firms, we empower strategic decisions with precision.

International: +1(332) 2424 294 | Asia: +91 9169164321

Website: https://www.intelmarketresearch.com

Follow us on LinkedIn: https://www.linkedin.com/company/intel-market-research

0 notes

Text

Cleaning with Chemistry: A Forecast Report on Industrial Solvent Demand

The global industrial cleaning solvents market was valued at USD 49.34 billion in 2024 and is anticipated to reach USD 65.78 billion by 2030, expanding at a compound annual growth rate (CAGR) of 4.9% from 2025 to 2030. This growth reflects the increasing demand across a broad spectrum of industries that rely heavily on cleaning solvents for maintaining hygiene, equipment performance, and compliance with safety standards.

Industrial cleaning solvents are extensively utilized in a wide array of sectors, including but not limited to manufacturing, automotive, aerospace, electronics, pharmaceuticals, and metal fabrication. These industries depend on specialized solvents to meet diverse cleaning requirements, ranging from general maintenance to precision cleaning tasks.

Solvents play a crucial role in various cleaning applications such as degreasing of metal parts, cleaning of electronic components, removal of flux residues, surface preparation for coatings or painting, routine equipment maintenance, and cleaning of precision instruments. The selection of an appropriate solvent is determined by several factors, including the type of contaminant, compatibility with the materials being cleaned, regulatory compliance, worker safety protocols, and the complexity of the cleaning process involved.

The growing scale of industrial production and automotive manufacturing is a major driver for the increased consumption of industrial cleaning solvents. These solvents are essential for the regular cleaning of machinery, tools, and components, which helps to optimize operational efficiency and prolong equipment lifespan.

In response to heightened environmental concerns and stringent regulatory frameworks, there is a noticeable shift toward the adoption of biodegradable and non-toxic cleaning solvents. These eco-friendly alternatives are designed to minimize environmental impact and reduce dependence on conventional petroleum-based chemical solvents, thus supporting sustainable industrial practices.

Industrial cleaning solvents can either be pure chemical compounds or custom-formulated mixtures developed to meet specific cleaning needs. They are selected based on various parameters such as solvency power, evaporation rate, toxicity level, and material compatibility. Their primary function is to remove unwanted substances such as contaminants, dirt, oils, greases, and other residues from industrial surfaces, parts, and equipment.

Key Market Trends & Insights

The Asia Pacific region led the global industrial cleaning solvents market, accounting for the highest revenue share of 50.7% in 2024. This dominance can be attributed to the region's robust industrial base, particularly in countries like China, India, and Southeast Asian nations.

Based on product type, hydrocarbon solvents emerged as the leading segment, capturing a revenue share of 35.5% in 2024. Their widespread use in degreasing and cleaning applications across multiple industries has solidified their market position.

By end-use industry, the healthcare sector held the largest market share, contributing 2% of the total revenue in 2024. This can be linked to the growing emphasis on sanitation, hygiene, and sterilization in medical environments, which rely heavily on effective cleaning solvents.

Order a free sample PDF of the Industrial Cleaning Solvents Market Intelligence Study, published by Grand View Research.

Market Size & Forecast

2024 Market Size: USD 49.34 Billion

2030 Projected Market Size: USD 65.78 Billion

CAGR (2025-2030): 4.9%

Asia Pacific: Largest market in 2024

Key Companies & Market Share Insights

Some of the key players operating in the market include Dow and AkzoNobel N.V.

Dow manufactures chemicals, agrochemicals, rubber, specialty chemicals, and plastic materials. The company serves its products globally to several industries, including agriculture, infrastructure, packaging, and consumer care. It has a presence in all regions, including North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Its major markets include North America and Asia Pacific. The company had 106 manufacturing sites, 19 manufacturing sites in 10 Asia Pacific countries, 37 sites in 15 Europe, Middle East, Africa, and India (EMEAI) countries, 15 sites in 4 Latin America countries, and 35 manufacturing sites in the U.S. and Canada.

Akzo Nobel N.V. is a producer of paints, coatings, and specialty chemicals for industry and consumers across the globe. The company has a presence in over 80 countries. The well-known brands of the company are Dulux, Sikkens, Interpon, and Eka. The company serves its products to diverse end-use industries such as building & construction, industrial manufacturing, transportation, packaging, and consumer durables.

Key Players

The following are the leading companies in the industrial cleaning solvents market.

Dow

Ashland

Evonik Industries

Eastman Chemical Company

Shell Plc

The Lubrizol Corporation

Arkema

ExxonMobil Corporation

Solvay SA

AkzoNobel N.V.

LyondellBasell Industries Holdings B.V.

Browse Horizon Databook on Global Industrial Cleaning Solvents Market Size & Outlook

Conclusion

The global industrial cleaning solvents market was valued at USD 49.34 billion in 2024 and is anticipated to reach USD 65.78 billion by 2030, expanding at a compound annual growth rate (CAGR) of 4.9% from 2025 to 2030. This growth reflects the increasing demand across a broad spectrum of industries that rely heavily on cleaning solvents for maintaining hygiene, equipment performance, and compliance with safety standards. Industrial cleaning solvents are extensively utilized in a wide array of sectors, including but not limited to manufacturing, automotive, aerospace, electronics, pharmaceuticals, and metal fabrication. These industries depend on specialized solvents to meet diverse cleaning requirements, ranging from general maintenance to precision cleaning tasks.

0 notes

Text

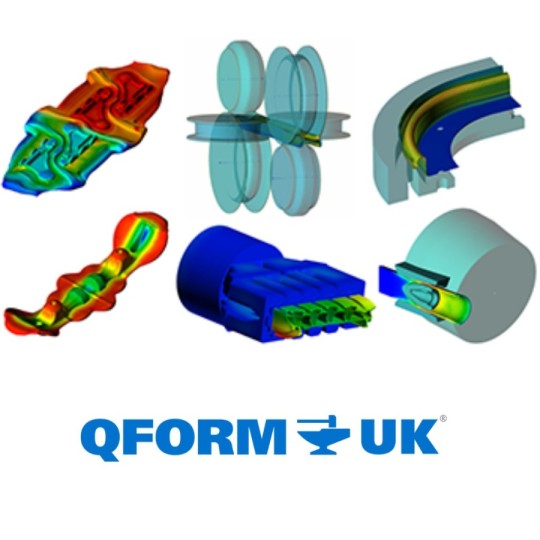

Unlock Manufacturing Excellence with Q Form Software: Your Ideal Partner for Metal Forming Simulation

In today’s competitive manufacturing landscape, optimizing processes and ensuring product quality are paramount. For industries dealing with metal forming, the right simulation software can make all the difference. Enter Q Form Software, a world leader in simulating, analyzing, and optimizing metal forming processes. Its robust capabilities and user-friendly design make it the ideal choice for businesses aiming for precision, efficiency, and innovation.

Introduction

Q Form Software is a professional engineering tool renowned for its reliability in metal forming process simulation. From large forging companies to research institutions, it serves a diverse clientele across critical sectors like aerospace, defense, automotive, energy, and aluminum extrusion. Its reputation as a global leader in extrusion, forming, and rolling simulations, along with aluminum extrusion die design, is built on its intuitive interface, advanced algorithms, and dedicated technical support.

Comprehensive Project Planning

Q Form empowers engineers with the tools needed for meticulous project planning. Its ability to simulate complex tools and handle multiple instruments and workpieces within a single simulation model allows for a holistic view of the manufacturing process. This comprehensive approach ensures that every variable is accounted for, leading to well-informed decisions and optimized outcomes from the outset.

Robust Task Management

The software’s powerful capabilities extend to robust task management through its advanced simulation features. Whether it’s simulating the forming of multiple workpieces of different materials, or incorporating spring-loaded tools and load holders, Q Form provides the flexibility and precision required. This allows for detailed analysis and refinement of individual tasks within the larger project, ensuring each step contributes to overall success.

Resource Allocation and Management

Q Form facilitates efficient resource allocation and management by providing in-depth insights into material behavior and tool interactions. Its coupled thermo-mechanical problem simulation in the Workpiece-Tool system helps predict material flow and temperature distribution, enabling better utilization of resources. The support for both implicit and explicit integration methods further enhances its versatility in handling various forming scenarios, ensuring optimal use of materials and machinery.

Real-Time Collaboration and Communication

While not explicitly a communication platform, Q Form’s precise and reliable simulation results foster better collaboration. By providing a clear and accurate digital representation of the forming process, it minimizes ambiguity and facilitates effective communication among design, engineering, and production teams. User-defined functions (UDF) and special boundary conditions also allow for custom inputs, catering to specific project requirements and ensuring all stakeholders are aligned.

Performance Tracking and Reporting

Q Form excels in performance tracking by allowing users to simulate visco-plastic, elastic-plastic, and thermo-elastic-plastic deformation. This detailed analysis helps in understanding and predicting material response, enabling performance optimization. The software’s powerful capabilities for modifying simulation parameters and finite element mesh further aid in fine-tuning processes and generating comprehensive reports on simulated performance, allowing for continuous improvement.

Why DDSPLM?

DDSPLM Private Limited, with over 25 years of experience, is a trusted engineering solution vendor and Siemens Expert Partner. Their extensive expertise and commitment to customer success, demonstrated by advising over 700 clients across various industries, make them a reliable partner for implementing and supporting advanced engineering solutions like Q Form.

Conclusion

In summary, Q Form Software empowers industries to achieve higher levels of precision and efficiency in metal forming. Its advanced simulation capabilities, coupled with the reliable support from experienced partners like DDSPLM, make it the ultimate choice for companies looking to innovate and excel in their manufacturing endeavors. Invest in Q Form and transform your metal forming processes for a future of unparalleled quality and performance.

0 notes

Text

Plastic Processing Machinery Industry To Rise As Of Growing Demand For Plastic Products Across Various Industries

Grand View Research’s plastic processing machinery industry data book is a collection of market sizing information & forecasts, competitive benchmarking analyses, macro-environmental analyses, and regulatory & technological framework studies. Within the purview of the database, such information is systematically analyzed and provided in the form of outlook reports and summary presentations on individual areas of research.

Access the Global Plastic Processing Machinery Industry Data Book, 2023 to 2030, compiled with details like market sizing information & forecasts, trade data, pricing intelligence, competitive benchmarking, macro-environmental analyses, and regulatory & technological framework studies.

Plastic Injection Molding Machine Market Report Highlights

The plastic injection molding machine market was estimated at approximately USD 11.75 billion in 2022, according to a new report by Grand View Research, Inc.

• The hydraulic technology segment accounted for the highest revenue share in 2022.The automotive industry is expected to have a high demand for hydraulic technology as manufacturing large & heavy parts requires a strong clamping force. In fields like aerospace, defense, and marine, it is frequently used to make heavy parts • The electric technology segment also accounted for a significant share in 2022. Electric injection molding machines are highly efficient and require less start-up time and run time compared to hydraulic injection molding machines. • In addition, factors, such as quiet operation, energy savings from 30 to 70%, less wastage of material, and low requirements of power are expected to have a positive impact on the demand for electric injection molding machines. • The medical end-use segment is projected to register the fastest CAGR from 2023 to 2030 due to constant technological developments, demand for medical disposables, and rising plastics consumption in healthcare applications. • U.S. accounted for the maximum share in 2022 due to the presence of a robust automotive industry. Moreover, the presence of advanced processing capabilities, greater R&D endeavors, and availability of a highly skilled workforce help improve the penetration of EVs in the U.S., thereby supporting segment growth. • The increasing demand for plastic injection molded components in electric and conventional vehicles for exterior and interior parts will boost market growth in the U.S.

Plastic Extrusion Machinery Market Report Highlights

• Plastic extrusion is a manufacturing process involving melting plastic materials and shaping them into a continuous profile through a die. This technology has wide-ranging applications in various industries, including packaging, construction, automotive, and electronics. • Moreover, the low cost per part, flexibility in operation, high production volume, and compounding ability are the other factors responsible for the growing demand for extrusion machinery. • The market for plastic extrusion machinery has been driven by several factors. Firstly, the increasing demand for plastic products, particularly in developing economies of Asia Pacific and Central & South America, has fueled the need for efficient and high-capacity extrusion machinery. • Additionally, advancements in technology have led to the development of more sophisticated and automated extrusion equipment, improving productivity and reducing production costs.

Order your copy of Free Sample of “Plastic Processing Machinery Industry Data Book - Plastic Injection Molding Machine, Plastic Extrusion Machinery, Plastic Blow Molding Machine Market Size, Share, Trends Analysis, And Segment Forecasts, 2023 - 2030” Data Book, published by Grand View Research

Plastic Blow Molding Machine Market Report Highlights

• The demand for blow molding machines has been fueled by the increasing use of plastic containers, bottles, and other hollow plastic products in various industries, including packaging, automotive, consumer goods, and construction. • These machines are essential for the efficient and cost-effective production of high-quality plastic products on a large scale. • Manufacturers are investing in advanced blow molding machines that offer improved automation, energy efficiency, and versatility in terms of mold capabilities and production speed. • The market is witnessing the development of new technologies and innovations that enhance the efficiency and capabilities of blow molding machines, leading to higher productivity and reduced production costs. • The growing focus on sustainability and environmental consciousness has also influenced the plastic blow molding machine market. • Many manufacturers are investing in machines that enable the use of recycled materials or employ eco-friendly production techniques.

Go through the table of content of Plastic Processing Machinery Industry Data Book to get a better understanding of the Coverage & Scope of the study.

Competitive Landscape

Key players operating in the Plastic Processing Machinery Industry are – • Arburg GmbH + Co KG. • KraussMaffei • Haitian International • Milacron • Nissei Plastic Industrial Co. Ltd. • ENGEL AUSTRIA GmbH. • Chen Hsong Holdings Limited • UBE Machinery Corporation, Ltd. • Husky Injection Molding Systems Ltd.

Check out more Industry Data Books, published by Grand View Research

About Grand View Research

Grand View Research, U.S.-based market research and consulting company, provides syndicated as well as customized research reports and consulting services. Registered in California and headquartered in San Francisco, the company comprises over 425 analysts and consultants, adding more than 1200 market research reports to its vast database each year. These reports offer in-depth analysis on 46 industries across 25 major countries worldwide. With the help of an interactive market intelligence platform, Grand View Research helps Fortune 500 companies and renowned academic institutes understand the global and regional business environment and gauge the opportunities that lie ahead.

Contact:

Sherry James

Corporate Sales Specialist, USA

Grand View Research, Inc.

Phone: 1-415-349-0058

Toll Free: 1-888-202-9519

Email: [email protected]

Web: https://www.grandviewresearch.com/sector-reports-list

Follow Us: LinkedIn | Twitter

#Plastic Injection Molding Machine Industry Trends Data Book#Plastic Processing Machinery Industry#Plastic Processing Machinery Sector Report

0 notes

Text

Plastic Formworks: Revolutionizing Modern Construction with Nova Formworksblr

In the ever-evolving construction industry, the need for durable, efficient, and cost-effective materials has led to significant innovations. Among these, Plastic Formworks have emerged as a transformative solution for modern building practices. Nova Formworksblr, a trusted name in the sector, has been at the forefront of this revolution, offering top-quality Plastic Formworks that address traditional challenges while enhancing overall productivity and sustainability in construction.

What Are Plastic Formworks?

Plastic Formworks are modular construction systems made from high-quality plastic materials that serve as molds for pouring concrete. Unlike conventional wooden or metal shuttering systems, Plastic Formworks are reusable, lightweight, and resistant to water and chemical corrosion. These qualities make them ideal for various applications, from residential buildings to large-scale commercial and infrastructure projects.

Nova Formworksblr manufactures Plastic Formworks designed to meet the rigorous demands of construction sites while ensuring precision, efficiency, and long-term cost savings. Their formwork systems are engineered to deliver excellent surface finish and structural strength with minimal maintenance.

Advantages of Using Plastic Formworks

Durability and Longevity

Plastic Formworks are designed for multiple reuse cycles, significantly outlasting traditional wooden or plywood systems. Nova Formworksblr offers formwork systems made from tough and resilient plastic materials that do not warp, swell, or degrade with exposure to moisture, ensuring consistent performance throughout their lifecycle.

Ease of Handling and Installation

One of the standout features of Plastic Formworks is their lightweight nature. They are easy to transport, assemble, and dismantle without requiring heavy machinery or extensive labor. This ease of use reduces construction time and labor costs, making the overall process more efficient. Nova Formworksblr’s systems come with user-friendly locking mechanisms and modular panels that ensure seamless operation on-site.

Superior Finish and Accuracy

Plastic Formworks provide smooth and uniform concrete finishes, reducing the need for extensive plastering or surface treatment. The high precision of Nova Formworksblr’s formwork panels ensures accurate dimensions and a high-quality finish, which is particularly beneficial in exposed concrete applications.

Environmentally Friendly

With growing concerns about environmental sustainability, Plastic Formworks offer a greener alternative to timber-based shuttering. Since they can be reused many times and do not contribute to deforestation, they are a more eco-friendly option. Nova Formworksblr emphasizes sustainability by manufacturing recyclable and reusable Plastic Formworks that reduce construction waste.

Cost-Effective Over Time

While the initial investment in Plastic Formworks may be higher than traditional options, their long-term cost benefits are substantial. The high reuse factor, reduced labor costs, and minimal maintenance make them a cost-effective solution. Nova Formworksblr’s clients have reported significant savings across multiple construction cycles.

Applications of Plastic Formworks

Plastic Formworks are suitable for a wide range of applications, including:

Residential Construction: Ideal for slab casting, beams, columns, and walls in housing projects.

Commercial Projects: Used in office buildings, malls, and industrial complexes where fast-paced construction is crucial.

Infrastructure: Applied in the construction of bridges, culverts, water tanks, and other public utilities.

Precast Structures: Useful in the manufacturing of precast panels, blocks, and decorative concrete products.

Nova Formworksblr provides versatile solutions that cater to all these applications, ensuring that every project benefits from efficiency, precision, and reduced operational hurdles.

Why Choose Nova Formworksblr?

Nova Formworksblr stands out in the Indian market for its commitment to innovation, quality, and customer satisfaction. Here are a few reasons why they are a preferred partner for Plastic Formworks:

Customized Solutions: Every construction project has unique requirements. Nova Formworksblr offers tailor-made formwork designs that align perfectly with client needs.

Comprehensive Support: From consultation and design to delivery and post-sale service, they provide end-to-end support.

Proven Track Record: With successful installations across residential, commercial, and infrastructure sectors, Nova Formworksblr has earned a reputation for excellence.

In-house Manufacturing: Their in-house manufacturing facilities ensure strict quality control and faster turnaround times.

Maintenance and Storage

Maintaining Plastic Formworks is remarkably easy. Unlike wooden formworks that are prone to rotting or warping, plastic systems require only basic cleaning after each use. Nova Formworksblr recommends simple washing with water to remove residual concrete. Their products are designed for quick storage, and the stackable design of the panels minimizes storage space requirements on-site.

The Future of Formworks

As construction demands grow and evolve, so does the need for smarter and more sustainable building materials. Plastic Formworks are quickly gaining traction as the go-to solution for projects that demand high performance and efficiency. With increasing emphasis on green building practices and cost control, the adoption of reusable formwork systems will continue to rise.

Nova Formworksblr is not just keeping pace with this change—they are leading it. Their continuous focus on research, innovation, and client-centric solutions positions them as a pioneer in the Plastic Formworks industry.

Conclusion

Plastic Formworks are redefining the construction landscape by providing a smarter, safer, and more sustainable approach to concrete forming. From durability and ease of use to superior finish and long-term savings, the advantages are clear. Nova Formworksblr’s commitment to quality and innovation makes them the ideal partner for construction firms looking to elevate their building practices.

Whether you're planning a small-scale housing project or a large infrastructure development, Nova Formworksblr offers the Plastic Formworks solutions you need to build faster, better, and more efficiently.

0 notes

Text

🤖 Europe Industrial Robots Market Poised for Explosive Growth – $18.27 Billion by 2032! 🚀

📊 The Europe industrial robots market, second only to Asia-Pacific, is set for a massive surge – from USD 5.84 billion in 2024 to USD 18.27 billion by 2032, growing at the highest CAGR of 15.7% globally! 🌍💼

Europe’s automation revolution is driven by booming industries: automotive 🚗, food & beverages 🍽️, chemicals ⚗️, and a rapidly evolving e-commerce ecosystem 📦. Countries like Germany and Italy are leading the robotic charge, thanks to robust manufacturing infrastructures and high industrial automation demand.

💥 Market Growth Catalysts:

📈 Automotive sector dominance in Germany (38% of Europe’s robot usage)

📦 13% YoY growth in Europe’s e-commerce (2021–2022)

🏭 Need for precision, speed & cost-efficiency in industrial operations

⚙️ By Robot Type:

Articulated

SCARA

Cylindrical

Cartesian/Linear

Parallel

Others

🔧 By Application:

Pick & Place

Welding & Soldering

Material Handling

Assembling

Cutting & Processing

Others

🏭 By Industry:

Automotive

Electrical & Electronics

Healthcare & Pharmaceutical

Food & Beverages

Rubber & Plastic

Metals & Machinery

Others

🏆 Top Companies in Europe:

KUKA AG (Germany)

ABB (Switzerland)

Universal Robots (Japan)

Rethink Robotics GmbH (Germany)

Schunk GmbH & Co. KG (Germany)

Staubli Intl. AG (Japan)

Compau SpA (Italy)

TM Robotics (U.K.)

Fanuc Corporation (Japan)

Artiminds Robotics GmbH (Germany)

🔍 Key Industry Developments:

Nov 2022: KUKA AG launched KR 3 D1200 for food, electronics & medical industries.

Oct 2022: ABB introduced IRB 1010, a small robot with 20% energy savings.

🟢 Europe is rapidly becoming the innovation hub for industrial robotics adoption.

📌 Don’t Miss the Full Report: 🔗 https://www.fortunebusinessinsights.com/europe-industrial-robots-market-108628

#IndustrialRobots#EuropeRobotics#AutomationEurope#RoboticAutomation#SmartManufacturing#EcommerceGrowth#Industry40#RobotTech#CAGR#ABB#KUKA#Fanuc#ManufacturingFuture#RoboticsIndustry#AIinManufacturing#FutureOfWork

0 notes

Text

Polyoxymethylene (POM) Production Cost Analysis Report by Procurement Resource

Procurement Resource, a leader in procurement intelligence and market research, presents its latest Polyoxymethylene (POM) Production Cost Report - a crucial tool for businesses, investors, and industry players aiming to understand the cost dynamics, operational requirements, and profitability factors of producing this engineering thermoplastic.

This detailed report delivers a cost-centric perspective into POM production, incorporating raw material market behavior, utility and infrastructure needs, labor and regulatory frameworks, and financial projections. It is an invaluable asset for anyone seeking to assess feasibility, optimize operations, or expand within the specialty plastics sector.

Polyoxymethylene: A High-Performance Engineering Plastic

Polyoxymethylene (POM), also known as acetal or polyacetal, is a high-strength, low-friction, wear-resistant thermoplastic. Known for its superior mechanical properties and dimensional stability, POM is widely used in the automotive, electronics, industrial, and consumer goods sectors.

Its applications span a variety of components such as gears, fasteners, fuel system parts, bearings, and housings. The compound's ability to replace metal in precision parts has significantly boosted its global demand.

The growing shift toward lightweight, high-durability materials in automotive and electronics manufacturing positions POM as a critical material in the future of engineering plastics.

Request your free sample report now: https://www.procurementresource.com/production-cost-report-store/polyoxymethylene/request-sample

Market Overview and Global Trends

Key Demand Drivers

Automotive Sector: Lightweighting efforts drive demand for POM in fuel systems, door locks, and window lift systems.

Electronics and Electrical: High dielectric strength makes POM ideal for connectors, switches, and components.

Industrial Machinery: Used in gear wheels, rollers, and moving parts that require reduced friction.

Consumer Goods: Increasing use in kitchen appliances, zippers, and sporting goods.

Regional Highlights

Asia-Pacific (China, Japan, South Korea): Largest production and consumption region, driven by domestic manufacturing.

Europe: Home to specialty compounders and automotive component manufacturers.

North America: Technological innovation and R&D in engineering polymers sustain steady demand.

The report details demand patterns, import/export balances, and trade flows impacting regional pricing and plant viability.

Raw Material and Feedstock Cost Analysis

The core feedstock for POM production includes formaldehyde and methanol, both derived from petrochemical sources. This makes POM cost structures closely tied to the oil and natural gas markets.

Key Raw Material Inputs

Formaldehyde: Major component contributing to polymer chain formation.

Methanol: Used upstream in formaldehyde production.

Catalysts and stabilizers: Required for polymer stability, often included in minor but essential quantities.

Market Volatility and Price Dynamics

Price fluctuations in natural gas and crude oil impact methanol and formaldehyde pricing.

Seasonal and regional variations in supply influence short-term procurement strategies.

The report provides updated cost indices and historical pricing curves for raw materials in key production hubs.

Infrastructure and Utility Requirements

POM production facilities require robust utility access and specialized infrastructure to maintain operational stability and product quality. The report assesses:

Plant site and zoning: Industrial zoning requirements, environmental clearances, and safety buffers.

Utilities: High energy demand for polymerization and drying stages; water and gas for process needs.

Waste treatment: By-products and effluents require dedicated treatment systems for compliance.

The infrastructure needs outlined in the report help businesses estimate upfront setup costs and plan location-specific investments.

Equipment and Capital Investment Insights

Although not detailing the production process, the report provides a thorough assessment of the capital expenditure required for POM facility setup, including:

Reactor systems and storage units

Cooling and ventilation systems

Pelletizing and drying equipment

Quality control and lab testing infrastructure

Packaging and warehousing facilities

Cost estimates are tiered based on scale—covering small batch operations to high-capacity industrial plants. Each model includes construction, installation, and commissioning projections.

Labor and Workforce Considerations

Running a POM production plant involves highly skilled technicians and process engineers due to the material's precision use cases and environmental sensitivities.

Workforce Breakdown

Process Operators

Chemical Engineers and Polymer Technologists

Maintenance and Safety Personnel

Quality Assurance Staff

The report outlines average wage rates across key production regions, labor availability, required certifications, and training standards. Labor productivity benchmarks are also provided to gauge efficiency and optimization potential.

Regulatory and Environmental Compliance

Producing POM involves handling volatile chemicals and maintaining high emission control standards. The report covers:

Regulatory requirements for emissions, waste management, and storage under REACH, EPA, and other global frameworks.

Occupational health and safety protocols associated with chemical exposure.

Product quality certifications, including ISO and ASTM standards, to ensure acceptability in automotive and electronics supply chains.

The cost of compliance is factored into the operating cost model, enabling a realistic view of expenses tied to global operations.

Operating Cost Breakdown

Recurring production expenses are detailed in the report across categories such as:

Raw material procurement

Energy consumption

Labor and supervision

Maintenance and calibration

Waste disposal and environmental management

Insurance, logistics, and packaging

This breakdown provides clarity on total cost-per-ton of POM produced and helps identify cost reduction opportunities through improved sourcing or process efficiency.

Profitability Outlook and ROI Projections

The POM market has demonstrated steady margins, especially for producers with downstream integration or specialty grades.

ROI analysis based on typical selling prices across automotive and electronic applications.

Margin estimates for general-purpose vs. high-performance POM.

Payback period projections under various market demand scenarios.

Break-even point calculations including variable and fixed cost assumptions.

The report also explores long-term profitability scenarios, especially under sustainability initiatives and circular economy shifts.

Sustainability and Future Market Drivers

As industries adopt greener manufacturing goals, the POM sector is seeing innovation in recycling and bio-based alternatives.

Emerging Trends

Recycled POM and closed-loop systems gaining traction in electronics and auto sectors.

Bio-based methanol and formaldehyde offering cleaner feedstock routes.

Downstream integration with additive manufacturers and 3D printing technologies.

Smart factory investments using AI/IoT to reduce downtime and optimize energy use.

The report evaluates these emerging technologies and their potential impact on production costs and market competitiveness.

Why Choose Procurement Resource?

Procurement Resource brings unmatched accuracy, granularity, and foresight to production cost analysis. Our deep domain knowledge in chemicals and polymers makes us the partner of choice for decision-makers in procurement, investment, and operations.

We offer:

Region-specific cost benchmarking

Customized feasibility and cost modeling

Real-time market intelligence

Strategic procurement consulting

Whether you're establishing a new facility, evaluating suppliers, or conducting due diligence, our actionable insights enhance your cost-efficiency and operational success.

Request Your Free Sample Report

Looking to invest in Polyoxymethylene production or optimize existing operations? Procurement Resource’s latest POM Production Cost Report delivers the insights you need to make smart, scalable, and strategic decisions.

Request your free sample report now: https://www.procurementresource.com/production-cost-report-store/polyoxymethylene/request-sample

Contact Information

Company Name: Procurement Resource Contact Person: Ashish Sharma (Sales Representative) Email: [email protected] Location: 30 North Gould Street, Sheridan, WY 82801, USA Phone: UK: +44 7537171117 USA: +1 307 363 1045 APAC: +91 1203185500

#Polyoxymethylene#market research#procurement intelligence#POM production#acetal#polyacetal#electronics#automotive#consumer goods

0 notes

Text

Industrial Rooftop Solar Panels in Raipur: Powering Sustainable Manufacturing and Savings

Industries across India are facing rising electricity costs, stringent sustainability regulations, and pressure to reduce their carbon footprint. In cities like Raipur, Chhattisgarh, where sunlight is abundant and industries are rapidly expanding, industrial rooftop solar panels have become a game-changer. They allow factories, warehouses, and manufacturing units to generate clean electricity right from their rooftops—reducing operational costs while ensuring a reliable power supply.

At Techno Sun Energy, we provide turnkey solutions for industrial rooftop solar panel systems in Raipur, helping businesses harness the sun to fuel growth, efficiency, and sustainability.

Why Solar for Industrial Use?

Industrial operations are energy-intensive. Whether it’s running heavy machinery, motors, or air-conditioning units, factories demand consistent and high volumes of electricity. Conventional grid electricity is not only expensive but also vulnerable to outages and tariff hikes.

This is where industrial rooftop solar systems step in—with benefits that go beyond just saving on bills:

✅ Massive Cost Reduction

Solar drastically reduces electricity bills. Many of our industrial clients have seen savings of ₹5–15 lakhs annually, depending on plant size.

✅ High ROI

With commercial power rates ranging from ₹6 to ₹10/unit, solar offers a payback period of just 3–4 years, followed by decades of free electricity.

✅ Grid Independence & Stability

Solar power reduces reliance on grid supply and diesel generators, especially during peak load hours.

✅ Green Branding & CSR Compliance

Solar adoption supports sustainability goals and improves the brand's public image. It also aids in ESG reporting and carbon credits.

Ideal Industries for Rooftop Solar in Raipur

Steel and fabrication units

Food processing factories

Pharmaceutical industries

Textile manufacturing

Plastic molding and packaging units

Automotive workshops and service centers

Warehouses and cold storage

Brick kilns and cement-based factories

If your facility has an unused rooftop, terrace, or shed, we can turn it into a powerful source of clean energy.

Types of Solar Systems for Industrial Use

At Techno Sun Energy, we offer the following system types based on your requirements:

🔹 On-Grid Industrial Solar System

Connected to the grid with net metering

Surplus energy exported for credits

Ideal for industries with daytime operations

🔹 Hybrid Industrial Solar System

Combines solar, grid, and battery backup

Ensures continuous power supply for critical machinery and IT infrastructure

🔹 Off-Grid Solar System

Best for remote units where grid supply is unreliable

Includes battery bank for full independence

Why Raipur is Ideal for Industrial Solar

Raipur, with over 300 sunny days a year, is perfect for solar energy production. The city is also a major industrial hub, supported by Chhattisgarh State Industrial Development Corporation (CSIDC) and CREDA. These agencies actively promote solar adoption in industrial zones like:

Urla Industrial Area

Siltara Sector

Bhanpuri and Birkoni

Tilda and Borjhara Clusters

Techno Sun Energy has implemented multiple industrial rooftop solar projects in these areas with measurable success.

Our Process at Techno Sun Energy

We offer end-to-end project execution for industrial solar: