#Powder Packing Machine Manufacturer in India

Explore tagged Tumblr posts

Text

Eco-Friendly Agrochemical Packaging: How India’s Manufacturers Can Stay Ahead of Global Sustainability Trends

The rising agricultural demand and growing awareness of modern farming practices have led to the flourishing of the Indian agrochemical sector and increased export opportunities. However, this growth has come at a time when environmental sustainability is under strict global scrutiny. As agrochemical usage increases, so does the volume of packaging waste, prompting regulatory bodies and environmentally conscious consumers to challenge traditional packaging materials.

#agrochemical#agrochemical packaging#intelligent packaging lines#agrochemical manufacturers#packaging machine manufacturer#Vertical Form Fill Seal (VFFS) Machines#liquid packaging machines#End-of-line Automation#agrochemical packaging solutions#end-to-end packaging solutions#track-and-trace technology innovations#powder filling machine#bulk bag filling machine#automatic carton box packing machine#powder bottle filling machine#case packer manufacturers india#automatic case erector#carton box packing machine#carton packing machine#automatic bottle filling machine#horizontal flow wrap machine#bottle filling machine

0 notes

Text

Top Packaging Machines for All Industries | Munky Packaging Machine

Looking for a High-Quality Packaging Machine to Streamline Your Business? Munky Packaging Machine Offers Durable, Efficient, and Versatile Solutions for a Wide Range of Industries Including Food, Agriculture, Chemicals, and Fmcg. Our Machines Are Designed for Precision, Speed, and Hygiene, Ensuring Your Product Is Packed Perfectly Every Time. Whether You're Packaging Powders, Granules, or Liquids, We Have the Right Equipment to Meet Your Needs. with Advanced Technology and a Strong Support System, Munky Ensures Minimal Downtime and Maximum Productivity. Choose a Packaging Machine That Boosts Efficiency and Reduces Labor Costs. Visit Our Website or Call to Get Started Today.

Call Now:- 9599919442

#Packaging Machine#Packing Machinery#Automatic Packing Machine#Chips Packing Machine#Filling Machine#Best packaging machine for small businesses#Industrial packaging machine manufacturers in India#High-speed packing machinery for FMCG industry#Packing machinery for spices and powders#Automatic packing machine for granules and powders#Affordable automatic packing machine in India#Fully automatic chips packing machine in India#Chips packing machine for small scale industry#Auger filler filling machine for masala and flour#Liquid filling machine with automatic capping

0 notes

Text

How Nichrome’s End of Line Machines benefits businesses with efficiency

In today’s fast-paced industrial environment, efficiency is key to staying ahead of the competition. Businesses are constantly on the lookout for innovative solutions that can streamline their operations, reduce costs, and enhance productivity. As a leading name in packaging solutions, we offer a range of end of line machines designed to meet these needs. Let's explore how our end of line machines can benefit your business with unparalleled efficiency.

#tin filling machine#Jar filling machine manufacturers#auto case erector#bulk bag filling machine#case packer manufacturers india#tin can filling and sealing machine#automatic case erector#ghee jar filling machine#tin packing machine#oil tin filling machine#powder jar filling machine#automatic carton box packing machine#carton packing machine#carton box packing machine#Bottle Filling Line#horizontal flow wrap machine#powder filling machine#box packing machine#automatic bottle filling machine#cartoning machine#flow wrap machine#secondary packaging#bottle filling machine#powder bottle filling machine#shrink wrapping machine manufacturer#bottle capping machine#shrink wrapping machine for bottles#can seamer machine

0 notes

Text

Selecting the appropriate industrial filling machine is crucial. It comes regardless of your just upgrading or launching a new production line. Filling machinery must be installed for every product to ensure correct packing. It includes liquids and powders and creams. You can rely on them to assist you in more precisely and accurately putting your possessions into containers.

#fillingmachine#pillowfillingmachine#cushionfillingmachine#industrialfillingmachine#fillingmachinemanufacturer

0 notes

Text

How Vibro Motors Improve Efficiency in Industrial Automation

How Vibro Motors Improve Efficiency in Industrial Automation

The manufacturing and industrial sectors are continuously evolving, driven by technological advancements that enhance productivity, reduce downtime, and optimize costs. One such innovation that has significantly contributed to industrial automation is the vibro motor. These powerful, precision-engineered motors play a crucial role in various industrial applications, offering efficiency, reliability, and cost-effectiveness.

In this comprehensive guide, we will explore how vibro motors work, their key applications, benefits, and why JK Industries, a leader among Vibro Motor Manufacturers in India, is at the forefront of this revolution.

Understanding Vibro Motors and Their Mechanism

A Vibro Motor, also known as a vibratory motor, is an electric motor designed to generate mechanical vibrations. It achieves this by rotating eccentric weights attached to both ends of the motor shaft, creating centrifugal force. This force induces vibrations, which can be harnessed for various industrial applications.

Key Features of Vibratory Motors:

Compact and robust design for heavy-duty applications

Low maintenance with high durability

Variable frequency and amplitude settings

Energy-efficient operation

Customizable options for specific industrial needs

Applications of Vibro Motors in Industrial Automation

The adaptability of vibratory motors makes them indispensable across numerous industries. Here are some of the primary applications:

1. Material Handling and Conveying

Industries such as mining, construction, and agriculture rely on Vibro motors to power vibratory feeders and screens. These motors facilitate the efficient movement of bulk materials, preventing blockages and enhancing throughput.

Mining Industry: Vibratory screens separate minerals based on size, improving sorting efficiency.

Construction: Vibrating conveyors transport cement, sand, and other materials efficiently.

Agriculture: Used in grain processing plants for sorting and grading.

2. Food Processing Industry

In food production, vibratory motors enable precise movement and handling of food products without causing damage.

Ensures uniform distribution of food particles in processing lines

Helps in quality control by removing unwanted elements

Used in vibrating sieves for separating contaminants from food products

3. Pharmaceutical & Chemical Industries

Precision and contamination-free processing are critical in the pharmaceutical and chemical sectors. Vibratory motors help maintain stringent quality control standards.

Used in tablet coating machines for uniform application

Facilitates precise powder mixing and sieving

Enhances drying processes by evenly distributing chemicals

4. Packaging Industry

In automated packaging systems, vibro motors help streamline the movement of goods on conveyor belts, ensuring accurate positioning, filling, and sorting.

Ensures even distribution of products in containers

Reduces spillage and packaging errors

Speeds up automated sorting and packing lines

5. Concrete Compaction

Construction sites extensively use vibratory motors in concrete compactors, which help remove air voids and improve the density of concrete structures.

Enhances the structural integrity of concrete

Reduces the likelihood of cracks and defects

Improves the longevity of buildings and infrastructure

Benefits of Incorporating Vibro Motors in Industrial Automation

1. Enhanced Operational Efficiency

By integrating vibratory motors into automation systems, industries can achieve faster and more precise operations. These motors facilitate consistent movement and sorting, significantly reducing manual intervention and labor costs.

2. Energy Efficiency and Cost Savings

Modern vibro motors consume less energy while delivering optimal performance. Their efficient design reduces power wastage, leading to lower operational costs and sustainable manufacturing.

3. Improved Precision and Quality Control

The ability to control vibration frequency and amplitude allows for precise handling of materials, ensuring uniform quality and reducing defects.

4. Reduced Downtime and Maintenance Costs

Designed for continuous operation under tough conditions, vibratory motors require minimal maintenance. Their durable construction ensures long service life, reducing unplanned downtime.

5. Versatility Across Industries

From mining to food processing and pharmaceuticals, vibratory motors can be adapted for a wide range of industrial applications, making them a valuable investment for businesses.

JK Industries: Leading the Vibro Motor Revolution in India

When it comes to sourcing high-quality vibratory motors, JK Industries is a trusted name among Vibrator Motor Manufacturers in India. With decades of experience, JK Industries has established itself as a leader in providing reliable and innovative vibration solutions.

Why Choose JK Industries?

Cutting-Edge Technology: Implements the latest advancements in vibration engineering to develop high-performance motors.

Custom Solutions: Offers tailored vibro motors to meet specific industrial requirements.

Superior Durability: Designs motors with high-grade materials for extended lifespan.

Energy-Efficient Designs: Focuses on reducing power consumption without compromising performance.

Exceptional Customer Support: Provides expert guidance for selecting the right motor for your application.

How to Select the Right Vibro Motor for Your Industrial Needs

Choosing the right vibratory motor depends on several factors, including:

1. Application Type

For bulk material handling: High-capacity vibratory motors with adjustable speed.

For food or pharmaceutical use: Hygienic, stainless steel motors with precise control.

For concrete compaction: Heavy-duty motors with high-frequency vibration.

2. Vibration Intensity & Frequency

Low-frequency motors are ideal for coarse materials.

High-frequency motors work best for fine materials and precision applications.

3. Power and Load Capacity

Ensure the motor has adequate power to handle the required load without excessive wear.

4. Environmental Conditions

Consider factors like temperature, humidity, and exposure to chemicals when selecting a motor.

5. Mounting and Installation Requirements

Choose motors that align with your existing system for easy installation and minimal modifications.

Future Trends in Vibro Motor Technology

The field of vibratory motors continues to evolve, with innovations focused on enhancing efficiency and performance. Some key trends include:

Smart Vibration Technology: Integration of IoT-enabled sensors for real-time monitoring and predictive maintenance.

Eco-Friendly Motors: Development of energy-efficient motors with reduced carbon footprint.

Advanced Material Engineering: Use of lightweight, high-durability materials to enhance motor lifespan.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Cafe Desire coffee latte premix is a low sugar premix and comes in a 500g pack, designed to give you more cups per pack as the usage of the premix powder required for a cup is less. If you prefer a sweeter coffee, check out our 1kg instant coffee premix. USE IT MANUALLY : For a perfect cup, mix 2 tea spoons (7gm Approximately) of premix with 65ml ( 3/4 cup )of boiling water. Stir well, and adjust to your taste. With a bit of practice, you’ll find your ideal mix. USING A VENDING MACHINE :Just pour the premix into the Cafe Desire or any other brand's vending machine canister, press the button, and your delicious, unsweetened, coffee is ready. We use the finest milk powder, sourced from the leading manufacturer in India, and a premium blend of coffee powder. It’s the best, so your coffee tastes the best. Check our other products in our Latte / unsweetened range. [ad_2]

0 notes

Text

Pharma Machine Manufacturer & Supplier in India | IRM Enterprise Pvt. Ltd – Trusted Pharma Machine

IRM Enterprise Pvt. Ltd stands as a prominent Pharma Machine Manufacturer in India, offering a comprehensive range of pharmaceutical machines that meet stringent industry standards and cater to the needs of pharmaceutical producers across the globe.

Leading the Way in Pharmaceutical Machines

IRM Enterprise Pvt. Ltd has carved a niche in the Indian pharmaceutical machinery industry through its innovative approach, superior engineering, and commitment to quality. As one of the most reputed Pharma Machine Suppliers, the company offers equipment that serves the full spectrum of pharma production – from formulation and granulation to tablet compression, capsule filling, liquid processing, and packaging.

The pharmaceutical industry demands precision machinery capable of handling complex formulations and high production volumes without compromising on hygiene and efficiency. IRM Enterprise delivers on all fronts, offering tailored solutions to both small-scale manufacturers and large-scale pharmaceutical corporations.

Wide Range of Pharma Machines Offered

IRM Enterprise Pvt. Ltd specializes in a vast portfolio of pharmaceutical machines engineered to optimize production, minimize downtime, and ensure regulatory compliance. Key offerings include:

Tablet Compression Machines: These machines are essential in compressing granulated powders into tablets of uniform size and weight. IRM’s tablet press machines are known for their robustness, user-friendly interface, and high output efficiency.

Capsule Filling Machines: Designed to accurately fill powder, granules, or pellets into capsules, these machines ensure dose consistency. Available in both semi-automatic and fully automatic variants, they serve diverse production needs.

Liquid Filling and Sealing Machines: Perfect for filling oral and injectable liquids, these machines guarantee precise fill volumes and sterile sealing – critical in maintaining drug efficacy.

Granulation Equipment: Including high shear mixers, fluid bed dryers, and oscillating granulators, these machines prepare the base material for tablet or capsule formation.

Powder Processing Machines: From blenders to mills and sifters, IRM Enterprise manufactures a full range of equipment that ensures uniform mixing and size reduction of pharmaceutical powders.

Packaging Solutions: IRM offers a variety of machines for blister packing, strip packing, labeling, and cartoning. These machines help maintain product integrity and extend shelf life.

Why Choose IRM Enterprise Pvt. Ltd as Your Pharma Machine Partner?

As a trusted Pharma Machine Manufacturer in India, IRM Enterprise Pvt. Ltd brings several advantages that set them apart:

✅ Unmatched Engineering Expertise

Backed by years of experience and a skilled R&D team, IRM Enterprise incorporates the latest technological advancements into every machine they produce.

✅ Compliance with International Standards

All machines are designed to comply with GMP (Good Manufacturing Practices), WHO, and other international standards, ensuring acceptance in global markets.

✅ Customization for Diverse Requirements

Every pharmaceutical production unit has unique needs. IRM provides customized machinery solutions that align perfectly with specific production goals and space constraints.

✅ Durability and Reliability

The machines are built with high-grade stainless steel and precision components to ensure long-lasting performance with minimal maintenance.

✅ After-Sales Support and Training

IRM Enterprise is not just a machine supplier but a long-term partner. They offer complete installation support, operator training, and prompt after-sales service to ensure smooth operation.

Serving the Indian and Global Market

IRM Enterprise Pvt. Ltd is not just a Pharma Machine Manufacturer for the Indian market but has extended its reach across international borders. With exports to Asia, Africa, the Middle East, and parts of Europe, the company has become a reliable name worldwide. Their commitment to delivering technologically advanced and cost-effective solutions makes them a preferred Pharma Machine Supplier in competitive international markets.

Future-Ready Manufacturing Solutions

The pharmaceutical sector is constantly evolving with the integration of automation, data tracking, and smart controls. IRM Enterprise is well-prepared to meet these future demands by offering machines embedded with Industry 4.0 features. With innovations like PLC-based automation, touchscreen interfaces, real-time data monitoring, and remote diagnostics, their pharmaceutical machines are designed for the future of smart manufacturing.

Industries Served

IRM Enterprise caters to a diverse clientele, including:

Pharmaceutical manufacturers

Nutraceutical companies

Biotech firms

Ayurvedic and herbal medicine producers

Research laboratories

Veterinary medicine manufacturers

Each sector requires high levels of hygiene, accuracy, and scalability—features IRM’s machines are specifically designed to deliver.

Commitment to Sustainability and Clean Manufacturing

IRM Enterprise is equally focused on sustainability, integrating energy-efficient designs and reducing waste in the manufacturing process. Their pharma machines are designed to reduce power consumption, optimize material usage, and promote eco-friendly operations—ensuring a greener footprint for your manufacturing unit.

Quality Assurance and Certifications

Every machine undergoes rigorous quality checks at every stage of production. IRM Enterprise is ISO-certified and adheres to strict QA/QC protocols. Their machines meet national and international compliance standards, giving clients peace of mind and assurance of consistent performance.

In a competitive and quality-driven industry like pharmaceuticals, the importance of reliable, high-performance machinery cannot be overstated. IRM Enterprise Pvt. Ltd, as a trusted Pharma Machine Manufacturer in India, stands as a beacon of quality, innovation, and customer satisfaction. Their comprehensive range of pharmaceutical machines is a testament to their dedication to excellence and their deep understanding of the industry's evolving needs.

Whether you're looking to set up a new pharmaceutical manufacturing unit or upgrade existing equipment, IRM Enterprise Pvt. Ltd is your ideal partner for world-class machinery and ongoing support.

Ready to Upgrade Your Pharmaceutical Production?

Get in touch with IRM Enterprise Pvt. Ltd, your trusted Pharma Machine Manufacturer and Supplier in India, for top-of-the-line pharmaceutical machines tailored to your needs.

Let’s build the future of pharmaceutical manufacturing—together.

For more info: https://www.karnavatiengineering.com/

Call Now: 7567876473

Email id: [email protected]

Location: S. No. 342, Nani Kadi, Taluka - Kadi, Dist - Mehsana, Gujarat - 382715, India

#Pharmaceutical Machines#Pharma Machine#Pharma Machine Manufacturer#Pharma Machine Manufacturer in India#Pharma Machine Suppliers

0 notes

Text

Eco-Friendly Agrochemical Packaging: How India’s Manufacturers Can Stay Ahead of Global Sustainability Trends

The rising agricultural demand and growing awareness of modern farming practices have led to the flourishing of the Indian agrochemical sector and increased export opportunities. However, this growth has come at a time when environmental sustainability is under strict global scrutiny. As agrochemical usage increases, so does the volume of packaging waste, prompting regulatory bodies and…

View On WordPress

#agrochemical#agrochemical manufacturers#agrochemical packaging#agrochemical packaging solutions#Automatic Bottle Filling Machine#automatic carton box packing machine#automatic case erector#bottle filling machine#bulk bag filling machine#carton box packing machine#carton packing machine#cartoning machine#case packer manufacturers india#End-of-line Automation#end-to-end packaging solutions#horizontal flow wrap machine#intelligent packaging lines#Liquid packaging machines#packaging machine manufacturer#powder bottle filling machine#Powder filling machine#Secondary Packaging#track-and-trace technology innovations#Vertical Form Fill Seal (VFFS) Machines

0 notes

Text

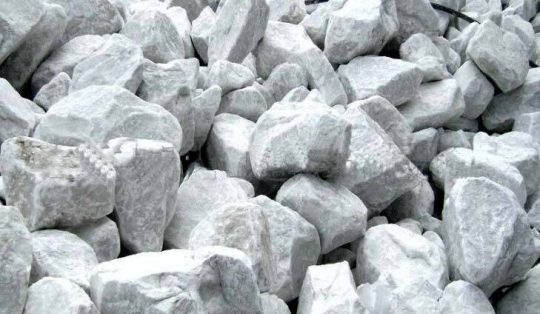

How Calcium Carbonate Is Extracted and Processed

Calcium carbonate is one of the most widely used minerals across the globe. It is a crucial raw material in industries such as construction, paper, plastics, paints, pharmaceuticals, and agriculture. Found naturally in limestone, chalk, and marble, calcium carbonate (CaCO₃) is prized for its whiteness, purity, and versatility. But how does it go from natural deposits to a fine, industrial-grade powder?

This article provides a comprehensive look into how calcium carbonate is extracted and processed—from quarry to final product. We’ll also highlight why working with a trusted Calcium Carbonate Manufacturer in India can ensure superior quality, cost efficiency, and supply chain reliability.

What Is Calcium Carbonate?

Calcium carbonate is a chemical compound made up of calcium, carbon, and oxygen. It naturally occurs in rocks such as limestone, marble, and chalk, and is also found in the shells of marine organisms and eggs. It is available in two primary forms:

Ground Calcium Carbonate (GCC): Produced by mechanical grinding of natural limestone or marble.

Precipitated Calcium Carbonate (PCC): Produced through a chemical precipitation process involving carbon dioxide and lime.

This article focuses on the extraction and processing of Ground Calcium Carbonate (GCC).

Step-by-Step: How Calcium Carbonate Is Extracted and Processed

1. Mining and Quarrying

The process begins with the identification of high-purity limestone or marble deposits. In India, states like Rajasthan, Gujarat, and Himachal Pradesh are known for their vast reserves of quality limestone.

The mining process includes:

Surveying and Mapping: Geologists assess the quality, thickness, and distribution of the deposit.

Overburden Removal: The top layer of soil and rock is removed to access the limestone.

Extraction: Limestone is extracted using drills, explosives, or mechanized equipment like excavators and bulldozers.

The extracted rocks are then transported to the processing plant for further refinement.

2. Primary Crushing

At the plant, the raw limestone is passed through crushers (usually jaw or cone crushers) that reduce large chunks into smaller, manageable pieces. This step is essential to prepare the material for grinding.

3. Grinding and Pulverization

The crushed limestone is fed into grinding machines such as ball mills, vertical roller mills, or Raymond mills. The goal here is to reduce the limestone into a fine powder.

The degree of fineness depends on the intended application:

Coarse particles (100-200 mesh) for agriculture and construction

Fine particles (300-500 mesh) for plastics, paints, and coatings

Ultra-fine particles (800 mesh or more) for specialty industries like cosmetics or pharmaceuticals

4. Air Classification

Once ground, the powder is passed through classifiers or sieves that separate particles based on size. Air classifiers are often used to ensure a uniform particle distribution. Finer grades may go through multiple stages of classification.

5. Surface Treatment (Optional)

In some industries—particularly plastics, rubber, and coatings—the calcium carbonate may undergo surface modification. This involves coating the particles with fatty acids like stearic acid to enhance compatibility with organic compounds and improve dispersion.

6. Quality Control and Testing

Before packaging, calcium carbonate undergoes stringent quality control tests, including:

Whiteness and brightness index

Particle size distribution (PSD)

Moisture content

Chemical purity (CaCO₃ content)

Specific gravity and oil absorption

These parameters ensure that the product meets industry-specific requirements.

7. Packaging and Distribution

Once the product passes quality checks, it is packed in moisture-proof bags or bulk containers (such as jumbo bags or tankers) depending on the client's requirements. It is then shipped locally or exported to global markets.

Applications of Calcium Carbonate

The versatility of calcium carbonate makes it essential in various industries:

Construction

Used as a key ingredient in cement, concrete, and mortar. It also serves as a base material in roads and as a filler in asphalt.

Paper and Pulp

Calcium carbonate is used as a filler and coating agent to enhance paper brightness, smoothness, and printability.

Plastic and Rubber

Acts as a functional filler to improve mechanical strength, reduce material costs, and increase thermal conductivity.

Paints and Coatings

Used as an extender and pigment, it improves opacity, brightness, and weather resistance.

Agriculture

Used to neutralize acidic soils and provide essential nutrients like calcium and magnesium.

Pharmaceuticals and Food

High-purity grades are used as dietary calcium supplements and food additives (E170).

Why Choose a Calcium Carbonate Manufacturer in India?

India is one of the largest producers of calcium carbonate in the world. Partnering with a reliable Calcium Carbonate Manufacturer in India offers several advantages:

1. Abundant and High-Quality Resources

India has vast limestone deposits known for their high purity, making it easier to produce premium-grade calcium carbonate at scale.

2. Cost-Efficient Production

Lower labor and production costs allow Indian manufacturers to offer highly competitive pricing without compromising on quality.

3. Technological Expertise

Modern Indian manufacturers use advanced machinery and quality control systems, ensuring consistent product specifications across batches.

4. Export Capabilities

Many Indian suppliers are well-established exporters, capable of meeting international demand with proper documentation, timely delivery, and global logistics support.

5. Customization and Technical Support

Top-tier manufacturers offer tailored solutions such as custom particle sizes, surface-treated grades, and technical consultations for specific industrial applications.

Conclusion

The production of calcium carbonate—from natural limestone to industrial-grade powder—is a well-defined, precision-driven process involving extraction, grinding, classification, and testing. Its widespread use across diverse industries makes it one of the most important industrial minerals today.

Choosing the right Calcium Carbonate Manufacturer in India is key to ensuring consistent quality, cost savings, and reliable supply. Whether you're in construction, plastics, pharmaceuticals, or agriculture, sourcing calcium carbonate from a trusted Indian manufacturer can significantly enhance your product performance and operational efficiency.

0 notes

Text

In today’s fast-paced industrial environment, efficiency is key to staying ahead of the competition. Businesses are constantly on the lookout for innovative solutions that can streamline their operations, reduce costs, and enhance productivity. As a leading name in packaging solutions, we offer a range of end of line machines designed to meet these needs. Let's explore how our end of line machines can benefit your business with unparalleled efficiency.

#tin filling machine#Jar filling machine manufacturers#auto case erector#bulk bag filling machine#case packer manufacturers india#tin can filling and sealing machine#automatic case erector#ghee jar filling machine#tin packing machine#oil tin filling machine#powder jar filling machine#automatic carton box packing machine#carton packing machine#carton box packing machine#Bottle Filling Line#horizontal flow wrap machine#powder filling machine#box packing machine#automatic bottle filling machine#cartoning machine#flow wrap machine#secondary packaging#bottle filling machine#powder bottle filling machine#shrink wrapping machine manufacturer#bottle capping machine#shrink wrapping machine for bottles#can seamer machine

0 notes

Text

Yogurt Packaging Machine Africa I Yogurt Packaging Machine Reliable, low-maintenance multitrack machines for milk powder in small SKUs; bottle filling lines, tin filling lines and cup filling lines for yogurt & dairy products, and fast milk pouch packaging machines. Indias pioneering milk pouch packing machine manufacturer, Nichrome offers a gamut of dairy packaging solutions, including complete mini-dairy plants

#milk packaging machine#yogurt packaging machine#diary product packaging machine#packaging machine in kenya#nichrome africa packaging machine#mini diary plant africa#bottle filling line#tine filling line#cup filling line#multitrack machines

0 notes

Text

Automatic Packing Machine – Boost Your Production Line

Streamline Your Packaging Process with an Advanced Automatic Packing Machine Built for Speed, Accuracy, and Durability. Ideal for Packaging Powders, Granules, or Liquids, It Ensures Minimal Human Intervention and Maximum Productivity. With easy-to-use Controls and Customizable Settings, This Machine Fits Perfectly into Any Production Line. Whether in Food, Pharma, or Consumer Goods, Achieve Consistent Sealing and High Output with Ease. Save Time, Reduce Labor, and Scale Up Efflessly with Our Efficient Automation Technology.

Learn More:-

Call Now:- 9599919442

0 notes

Text

How to Start a Profitable Dhoop Stick Making Business from Home in India

Starting a dhoop stick making business in India is a promising opportunity for aspiring entrepreneurs, especially those seeking a low-investment, high-demand venture. Dhoop sticks, widely used in religious rituals and for their aromatic properties, have a consistent market across the country. This blog provides a comprehensive guide to help you embark on this business journey.

Why Choose Dhoop Stick Making Business?

The dhoop stick industry in India is thriving due to the country's rich cultural and religious practices. With the increasing demand for incense products, starting a dhoop stick manufacturing unit can be both profitable and fulfilling.

Step-by-Step Guide to Starting Your Dhoop Stick Business

1. Conduct Market Research

Before diving in, understand the market dynamics:

Demand Analysis: Identify regions with high consumption.

Competitor Study: Analyze existing brands and their offerings.

Customer Preferences: Determine popular fragrances and stick sizes.

This research will help tailor your products to meet market needs.

2. Create a Business Plan

A well-structured business plan should include:

Investment Details: Initial capital, operational costs, and projected profits.

Production Capacity: Daily output targets.

Marketing Strategy: Channels for product promotion and distribution.

A clear plan will guide your business decisions and attract potential investors.

3. Legal Formalities and Registrations

Ensure your business complies with legal requirements:

Business Registration: Register as a sole proprietorship, partnership, or company.

GST Registration: Mandatory for tax purposes.

Trade License: Obtain from local authorities.

MSME Registration: Avail benefits for small enterprises.

Pollution Control Certificate: Required for manufacturing units.

Proper documentation ensures smooth operations and eligibility for government schemes.

4. Set Up Your Manufacturing Unit

Choose a location with adequate space (around 500-1000 sq. ft.) and essential utilities. Ensure proper ventilation and storage facilities for raw materials and finished products.

5. Procure Raw Materials and Machinery

Essential raw materials include:

Wood Powder: Base material for sticks.

Charcoal Powder: Enhances burning quality.

Jigat Powder: Acts as a binder.

Essential Oils: For fragrance.

Packaging Materials: Boxes, labels, and wrappers.

Invest in a reliable dhoop stick making machine to ensure consistent quality and efficiency.

6. Production Process

The manufacturing process involves:

Mixing: Combine wood powder, charcoal, and jigat powder in appropriate ratios.

Fragrance Addition: Incorporate essential oils into the mixture.

Molding: Use the machine to shape the mixture into sticks.

Drying: Allow the sticks to dry naturally or use drying chambers.

Packaging: Pack the dried sticks into boxes, ready for sale.

7. Marketing and Distribution

Promote your products through:

Local Retailers: Supply to nearby shops and markets.

Online Platforms: List products on e-commerce websites.

Social Media: Create pages to showcase products and engage with customers.

Trade Fairs: Participate in exhibitions to reach a broader audience.

Building a strong brand identity and customer trust is crucial for long-term success.

Investment and Profitability

Starting a dhoop stick business requires a modest investment, primarily for machinery, raw materials, and initial marketing. With efficient operations and effective marketing, entrepreneurs can expect a good return on investment, making it a viable small-scale business option.

Challenges and Solutions

Quality Control: Ensure consistent product quality through regular checks.

Market Competition: Differentiate your products with unique fragrances and packaging.

Supply Chain Management: Establish reliable sources for raw materials to avoid disruptions.

Addressing these challenges proactively will pave the way for a sustainable business.

Conclusion

The dhoop stick-making business offers a blend of cultural significance and economic opportunity. With careful planning, dedication, and quality products, entrepreneurs can establish a successful venture in this domain.

Looking to kickstart your dhoop stick manufacturing journey? Pragati Gruh Udyog offers top-quality dhoop stick making machines and comprehensive support to help you succeed.

Contact Us:

Phone: +91 93562 53975

Email: [email protected]

Join hands with us and turn your entrepreneurial dreams into reality!

0 notes

Text

From Quarry to Industry: Hydrated Lime Production by Top Manufacturers in Jodhpur

Introduction: Jodhpur’s Lime Legacy

Jodhpur, known for its architectural beauty and mineral wealth, is also a major hub for lime production. With vast limestone reserves and industrial expertise, the city houses some of the best Lime powder suppliers in Jodhpur, making it a cornerstone of India’s lime industry.

This blog will take you inside the complete production process of hydrated lime, revealing how raw material from quarries transforms into a refined product used across industries like steel, construction, water treatment, and chemicals. We also highlight how hydrated lime manufacturers in Jodhpur and quick lime manufacturers in India ensure top-quality outputs with cutting-edge technology.

1. What Is Hydrated Lime?

Hydrated lime, also called calcium hydroxide, is produced by adding water to quick lime (calcium oxide). This reaction, called "slaking," results in a white, dry powder used in multiple industries. Its purity, reactivity, and particle size determine its industrial value.

Before understanding hydrated lime's manufacturing, we must first understand how its precursor—quick lime—is produced.

2. Stage One: Quarrying of Limestone

The production journey begins at limestone quarries scattered across the Jodhpur region. Here, high-grade limestone, rich in calcium carbonate (CaCO₃), is extracted using advanced mining techniques.

Steps:

Drilling and blasting: Controlled explosions break the limestone into manageable sizes.

Crushing and sorting: The raw stone is crushed and segregated by size and purity.

Transport: Crushed limestone is transported to the calcination facility.

Jodhpur’s geological profile gives manufacturers access to superior raw material—one of the reasons why hydrated lime manufacturers in Jodhpur lead the national market.

3. Stage Two: Calcination—Creating Quick Lime

Once the limestone reaches the plant, it undergoes calcination—a high-temperature process in rotary or shaft kilns.

Process:

Heating at 900–1100°C: This drives off carbon dioxide, converting calcium carbonate into calcium oxide (quick lime). Reaction: CaCO₃ → CaO + CO₂↑

Quality checks: The resulting quick lime is tested for purity and reactivity.

Quick lime manufacturers in India, especially in Rajasthan, have invested heavily in modern kiln technologies, ensuring consistent and high-quality CaO production.

4. Stage Three: Hydration—Forming Hydrated Lime

The next step is slaking—where quicklime reacts with water to form hydrated lime.

Hydration Process:

Controlled addition of water to quick lime in a hydrator machine.

Exothermic reaction produces heat and results in fine calcium hydroxide powder. Reaction: CaO + H₂O → Ca(OH)₂ + Heat

Cooling and drying: The powder is cooled to ambient temperature.

Grinding and classification: Final product is ground and sieved to desired fineness.

The process requires precision, as both under-hydration and over-hydration can result in sub-standard product. That’s why the best Lime powder suppliers in Jodhpur use automated systems and real-time sensors.

5. Stage Four: Quality Control and Packaging

Once produced, the hydrated lime is subjected to rigorous quality checks:

Purity Tests

Moisture Content

Reactivity Index

Fineness and Particle Size Analysis

After approval, it is packed in moisture-proof bags (HDPE or paper) ranging from 25kg to 50kg or bulk bags for industrial buyers.

Leading hydrated lime manufacturers in Jodhpur comply with BIS (Bureau of Indian Standards) and international quality benchmarks to meet diverse client needs.

6. Applications Across Industries

Hydrated lime is not just a construction material—it plays a critical role across numerous sectors:

Industry

Application

Steel & Metallurgy

Flux for refining and removing impurities

Water Treatment

pH adjustment and removal of heavy metals

Construction

Soil stabilization, whitewash, and mortars

Chemicals

As a precursor for calcium-based compounds

Paper & Pulp

Bleaching and chemical recovery processes

Sugar Industry

Purification of sugarcane juice

This wide applicability keeps quick lime manufacturers in India and their hydrated lime divisions in continuous demand.

7. Why Jodhpur is the Ideal Manufacturing Base

Several factors make Jodhpur the preferred location for lime manufacturing:

Rich limestone reserves with high calcium content

Skilled labor force with generations of experience

Proximity to industrial hubs in Gujarat, Punjab, and Delhi

Government support and infrastructure for mineral processing

These advantages have led to the emergence of trusted names among the best Lime powder suppliers in Jodhpur, known for quality, service, and delivery efficiency.

8. Sustainability in Lime Production

Modern manufacturers in Jodhpur are adopting greener practices:

Use of alternative fuels like biomass in kilns

Waste heat recovery systems

Water recycling systems in the hydration process

Dust control and emission filtration technologies

These efforts are helping hydrated lime manufacturers in Jodhpur reduce environmental impact and meet ESG (Environmental, Social, Governance) goals.

9. Choosing the Right Manufacturer: Key Criteria

When selecting a lime supplier, consider the following:

Product purity and reactivity

Customization and particle size options

Delivery timelines and logistics

Certifications and client reviews

After-sales support

Reputed quick lime manufacturers in India often have in-house hydration units, ensuring consistency and traceability across the product line.

10. Conclusion: Precision from Stone to Solution

From the rugged quarries of Rajasthan to the precision-engineered plants of Jodhpur, the journey of hydrated lime is a remarkable transformation. The process reflects not only industrial prowess but also a commitment to quality, sustainability, and service.

Whether you're in construction, metallurgy, or water treatment, choosing one of the best Lime powder suppliers in Jodhpur ensures you're using a product that meets stringent industry standards and delivers performance.

#hydrated lime manufacturers in jodhpur#limestone suppliers in india#calcined lime powder manufacturers in india

1 note

·

View note

Text

Eco-Friendly Agrochemical Packaging: How India’s Manufacturers Can Stay Ahead of Global Sustainability Trends

The rising agricultural demand and growing awareness of modern farming practices have led to the flourishing of the Indian agrochemical sector and increased export opportunities. However, this growth has come at a time when environmental sustainability is under strict global scrutiny. As agrochemical usage increases, so does the volume of packaging waste, prompting regulatory bodies and environmentally conscious consumers to challenge traditional packaging materials.

This paradigm shift is more than just reducing waste; it is about transforming the fundamental way in which agrochemicals are being packed, transported, and consumed. And the true essence of this evolution is Eco-friendly packaging, which has now become a necessity rather than a trend. Understanding this, the Indian manufacturers are also now being called upon to reimagine their packaging strategies and align themselves with the global sustainability benchmarks and standards.

Nichrome, a leading player in packaging innovation, stands at the forefront of this green revolution. Through our cutting-edge technology and intelligent design, we at Nichrome offer sustainable, future-oriented options for agrochemical packaging that don’t compromise on performance, safety, or cost-efficiency.

Impact of Agrochemical Packaging

Agrochemical packaging serves multiple vital functions, like ensuring safe storage and transport of chemicals, maintaining product integrity and facilitating proper dosage, all the while preventing environmental contamination. From pesticides to herbicides and insecticides to fertilisers, the right packaging can ensure that the chemical packed inside does its job without posing any risk to the handler, consumer, or the ecosystem.

However, many times the very material used for these purposes can often contradict the true sustainability goal. Single-use plastics, metal cans, and non-recyclable laminates dominate the market. While being effective in containment, these materials are difficult to dispose of responsibly. They contribute to landfills, leach toxins into soil and water, and in many cases are incinerated, releasing harmful emissions.

Challenges of traditional agrochemical packaging

Let’s delve into the most common challenges that come with it:

Environmental Damage: Plastics are not biodegradable and remain in the environment for centuries. Chemical container residues can leach into the soil, degrading soil fertility and polluting groundwater resources.

Health Hazards: Inadequate disposal of packaging and containers can expose humans and animals to harmful chemicals. Rural areas, with minimal awareness of safe disposal, are most vulnerable.

Logistical Issues: Conventional agrochemical packaging formats are often bulky, fragile, and not quite optimised for the diverse transportation conditions in India. It comes with issues like spillage, leakage, and breakage.

Regulation Compliance: As international pressure mounts, countries are strictly regulating the packaging of agrochemicals. Non-compliance may stall export prospects and lead to fines.

All these challenges highlight the need to rethink the materials we use and the machines we trust. And for forward-thinking manufacturers, it’s a chance to lead with conscience, competitiveness, and care.

The emergence of eco-friendly packaging solutions

As the world is shifting towards greener and cleaner practices, the agrochemical industry has found itself at a crossroads, where innovation has to meet intention. The shift to eco-friendly agrochemical packaging isn’t just a trend; it’s a transformation. From stricter regulations to growing consumer consciousness, the demand for eco-friendly packaging materials that don’t compromise on performance is higher than ever.

Let’s quickly explore some of the frontrunning solutions that are involved in shaping the Indian and global future of agrochemical packaging:

Biodegradable and Compostable Materials: Materials that are made from natural fibres or plant-based polymers decompose naturally and pose no long-term threat to the environment. Since they help in reducing carbon footprint, they are ideal for single-use formats.

Recyclable Laminated Films: High-barrier laminated films are designed to provide superior moisture, UV, and chemical resistance, ensuring product safety while being recyclable and reducing environmental impact.

Smart and Intelligent Packaging: By incorporating features like QR codes, tamper-evident seals, and temperature/moisture indicators, this type of packaging can enhance product traceability and transparency. This is crucial for regulatory compliance and quality assurance.

Flexible Packaging Formats: Formats like pouches, sachets, and bag-in-box reduce material usage, as they are easy to transport, enable exact dosing and generate less waste.

Sustainability in agrochemical packaging isn’t a one-size-fits-all solution; it is a layered journey of material innovation, smart systems, and forward-thinking design. Whether it is through compostable sachets, intelligent packaging lines, or high-barrier recyclable films, the future is being shaped today. And with eco-conscious consumers, strict global norms, and the Indian agricultural vision driving the push, there’s no better time for the agrochemical manufacturers to make the sustainable switch.

Nichrome’s role in sustainable agrochemical packaging

Eco-consciousness has now become a necessity, more than a trend. The Indian agrochemical manufacturers are also being called on to reinvent how they package, store and deliver. In this move to better and greener growth, Nichrome has also stepped in, and not just as a packaging machine manufacturer but also as a transformative partner.

With our over 40+ years of innovation and expertise, we are creating one big cohesive ecosystem tailored to the agrochemical industry that brings automation, precision, and sustainability together.

Our packaging machines and systems are designed to help you reduce waste, cut energy costs, and embrace environmentally friendly practices, whether you are packaging a small batch of liquid insecticide or high-volume fertiliser bottles. All of this is done without compromising on performance, quality or compliance.

Here is how our offerings are empowering agrochemical players in India to grow stronger while going green:

Vertical Form Fill Seal (VFFS) Machines: These systems are engineered for high-speed and high-precision packaging of granular and powdered fertilisers. With advanced sealing technology and minimal wastage, they reduce the environmental footprint of every batch.

Liquid Packaging Machines: We offer servo-driven liquid packaging machines that ensure accurate dosing, spill-proof filling, and minimal contamination risk for packaging pesticides and liquid fertilisers.

Secondary and End-of-line Automation: Our primary packaging effortlessly blends with secondary solutions like case packers, bundlers, and palletisers. These not only help in optimising storage and transport but also incorporate recyclable and biodegradable materials.

Sustainable Machine Design: We seamlessly integrate energy-efficient components, low-waste technology, and compact footprints in our machines and systems. Modular designs can cater to both large-scale operations and smaller agrochemical units in tier 2 and 3 markets.

From local fields to global exports, we at Nichrome are enabling a cleaner, smarter and greener packaging future for Indian agrochemicals. By integrating automation with sustainability, we ensure that the packaging process doesn’t just protect the product but also protects the planet.

Business benefits of sustainable packaging

For Indian agrochemical manufacturers, embracing eco-friendly packaging goes beyond environmental responsibility. It is about making a smart business move that ripples across operations, branding, and global outreach.

Here’s why going green makes strategic sense:

Regulatory Alignment: Sustainable packaging ensures compliance with both Indian and global regulations by minimising legal risks and opening export doors.

Cost Efficiency: Even though sustainable solutions come with higher investment options, reduced material usage, lower transport costs, and minimised waste disposal expenses emerge as the long-term saving benefits.

Brand Value: Brands that showcase eco-conscious practices earn greater trust and loyalty, in turn becoming a market differentiator.

Operational Resilience: Smart packaging solutions help in increasing shelf life, minimise damage, and ensure consistent performance, even in diverse climates.

Sustainable packaging is about a competitive edge for agrochemical brands that are ready to lead. It builds a future-ready brand image, opens new markets, and strengthens operational foundations. In this dynamic industry, change is the only constant. This has made green packaging an investment in resilience, reputation, and readiness. As regulatory landscapes evolve and consumers demand greater accountability, businesses that embrace sustainable packaging today will lead the agrochemical industry tomorrow.

Ideal audience for sustainable transformation

Now that we have spoken so much about sustainability no longer being just a “buzzword” in India’s agrochemical sector, you may start to wonder whether it is the right move for you. What can you stand to gain by adopting eco-friendly agrochemical packaging solutions?

So, let’s take a closer look at the key stakeholders who are best positioned for this sustainable shift:

Large-Scale Agrochemical Manufacturers

Global giants are no newbies to international criticism. As ESG (Environmental, Social, and Governance) standards become the norm for international trade and investor trust, transitioning to sustainable packaging is not just a compliance measure—it's a brand strategy. Our end-to-end packaging solutions, which are specifically tailored to address agrochemical packaging regulations, enable these producers to enhance traceability, decrease environmental footprint, and grow into environmentally sensitive markets with confidence.

Startups and MSMEs with Growth Aspirations

Small does not necessarily mean slow. Market leaders of the future are today's flexible mid-sized companies and agile startups. Our modular and scalable packaging machines are built for flexibility, allowing new players to adopt green practices from day one. From packaging pesticides to packaging fertilisers and liquid insecticides, green becomes a strength, not a liability.

Rural and Local Agrochemical Suppliers

India's tier 2 and tier 3 towns are fertile ground for demand for agrochemicals, and these suppliers require low-maintenance, robust, and easy-to-use packaging systems. Our robust machinery is capable of withstanding the rigours of rural supply chains, with consistent operating performance in the event of power supply fluctuations or the absence of infrastructure. It's sustainable transformation, made affordable.

Therefore, whether you are an MNC eyeing global exports, a homegrown startup building your green legacy, or a regional supplier ensuring that every drop counts, eco-friendly agrochemical packaging is your common road to future readiness.

Future of India’s green packaging revolution

India is positioning itself as a global agricultural powerhouse, and the way you package agrochemicals is going to be crucial in defining your sustainability narrative. Agrochemical packaging in the rural areas that often go overlooked must now evolve to ensure both user safety and environmental protection.

We at Nichrome are helping write this future by:

Designing cost-effective packaging machines specifically for fertilisers, pesticides, and micronutrients

Developing track-and-trace technology innovations to promote transparency and counter counterfeiting

Assisting local producers with training, technical services, and material advice to make a smooth shift to environmentally friendly practices.

Conclusion

Agrochemical packaging for sustainability is not a choice – it's a strategic necessity. From regulatory pressures to consumer expectations, the message is unequivocal: packaging needs to change. We respond to this challenge with smart, future-proof solutions that don't just deliver today's requirements but innovate for tomorrow's demands.By making a commitment to green packaging today, India's agrochemical players can ensure a cleaner, safer, and more profitable tomorrow. We are not only a machinery ally, but a forward-thinking mentor in your quest for green packaging excellence.

#agrochemical#agrochemical packaging#intelligent packaging lines#agrochemical manufacturers#packaging machine manufacturer#Vertical Form Fill Seal (VFFS) Machines#liquid packaging machines#End-of-line Automation#agrochemical packaging solutions#end-to-end packaging solutions#track-and-trace technology innovations#powder filling machine#bulk bag filling machine#automatic carton box packing machine#powder bottle filling machine#case packer manufacturers india#automatic case erector#carton box packing machine#carton packing machine#automatic bottle filling machine#horizontal flow wrap machine#bottle filling machine#secondary packaging#cartoning machine

0 notes

Text

Why Top IT Firms Choose Our Fresh Milk Coffee & Tea Vending Machines

In most IT offices, coffee and tea aren’t just drinks—they fuel long hours, tight deadlines, and quick meetings. That’s why top IT firms are turning to Pradeep iBrew. Our fresh milk coffee and tea vending machines keep teams energized and focused, without skipping on taste or quality.

Fresh Milk. Real Taste. Every Time.

Most vending machines use powder or premix. But not ours. Pradeep iBrew uses fresh milk in every cup. That means better flavor, smoother texture, and a more satisfying break. Our machines serve coffee and tea that taste like they were brewed at home.

Why IT Firms Prefer Us

IT companies need things to work fast and without fuss. Our automatic tea coffee machine for offices do just that. With the push of a button, staff can get their favorite brew—hot and ready in seconds.

We also offer options. From strong filter coffee to spiced karak chai, our menu fits all tastes. Whether your team likes light tea or bold brews, our machines deliver.

Smart Machines Built for Office Life

Pradeep iBrew machines are made for high-use areas. They’re easy to clean, fast to refill, and built to last. And they don’t need a barista. Our automatic tea coffee vending machines do all the work.

Built with smart tech, they keep track of drink counts and even alert when supplies run low. That means fewer surprises—and more uptime.

Made in India, Trusted Nationwide

We’re proud to be a top tea machine manufacturer in India. Every machine is designed and made here. That means better service, faster support, and parts always in stock.

We’ve worked with big names in tech, and we know what offices need: quick service, clear pricing, and no delays. We deliver on time, every time.

Best Filter Coffee, Just a Button Away

There’s nothing like South Indian filter coffee. Our best filter coffee maker machine in India brings that classic taste to your office. Fresh ground, hot brewed, and full of flavor—without needing a full kitchen setup.

Love Chai? Try Our Karak Tea Chai Machine

Chai lovers aren’t left out. Our karak tea chai machine makes bold, spiced tea that packs a punch. It’s rich, hot, and made with real ingredients—not instant mix. Perfect for that mid-day break or post-lunch recharge.

Reliable. Easy. Loved by Teams.

Happy teams are more productive. A simple coffee break can lift moods and spark ideas. With our chai machines and coffee makers, you give your staff something small that makes a big difference.

Ready to Upgrade Your Office?

If you’re looking for a fresh milk automatic tea coffee vending machine that delivers taste, speed, and ease—choose Pradeep iBrew. We help IT firms serve better coffee and tea, without the hassle.

#automatic tea coffee machine for office#automatic tea coffee vending machine#best filter coffee maker machine in India#chai machine#karak tea chai machine#tea machine manufacturer

0 notes