#PowerPlantSolutions

Explore tagged Tumblr posts

Text

At one of India’s largest thermal sites, our deployed team of 31 specialists is now empowered with drone-based safety monitoring—trained and supervised in-house. Real people. Real-time insight.

#DroneTechnology#AerialSurveillance#SkilledManpower#PowerPlantSolutions#EnergySectorIndia#WorkforceDevelopment

0 notes

Text

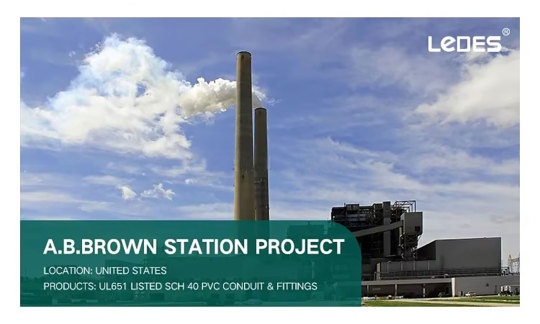

Discover how Ledes® UL Listed Schedule 40 Conduit System is ensuring reliable power distribution at a major US power plant.

Ready to fortify your next project with the gold standard in conduit protection? Click the link to learn more! ➡️

#ULlisted#Schedule40Conduit#Casestudy#PowerPlantSolutions#ElectricalProtection#IndustrialStrength#MadeInTheUSA#LedesConduit

0 notes

Text

High Pressure Boiler Components: An In-Depth Analysis

In the realm of industrial applications, high pressure boilers play a crucial role in generating steam and power. Understanding the high pressure boiler boiler components is essential for ensuring efficiency, safety, and longevity. In this guide, we will delve into the critical components that make up a high pressure boiler system.

What is a High Pressure Boiler?

A high pressure boiler is a type of boiler that operates at a pressure exceeding 15 psi (pounds per square inch). These boilers are commonly used in power plants, industrial facilities, and manufacturing processes where steam generation is required for various operations. The higher pressure allows for increased energy transfer, leading to higher efficiency and productivity.

High pressure boilers are designed to handle extreme conditions and are built with robust materials to withstand high temperatures and pressures. They are often used in applications such as electricity generation, chemical processing, and heating systems for large buildings.

Key High Pressure Boiler Boiler Components

1. Boiler Shell

The boiler shell is the outermost structure that contains the water and steam. It provides structural support and withstands the internal pressure generated during the operation of the high pressure boiler. The shell is typically made of high-strength steel to handle the intense pressure and temperature conditions.

The design of the boiler shell is critical for ensuring safety and efficiency. It must be able to resist corrosion and thermal stress while providing a stable environment for steam generation.

2. Furnace

The furnace is the combustion chamber where fuel is burned to generate heat. The heat produced in the furnace is transferred to the water to create steam. The design and efficiency of the furnace play a critical role in the overall performance of the high pressure boiler.

Furnaces can use various types of fuel, including coal, natural gas, oil, or biomass. The choice of fuel depends on the specific application and environmental considerations. Proper airflow and temperature control are essential for efficient combustion and reduced emissions.

3. Tubes

Boiler tubes are essential components that allow heat transfer from the combustion gases to the water. These tubes are typically made of high-strength materials that can withstand high temperatures and pressures.

There are two main types of boiler tubes: water tubes and fire tubes. Water tubes carry water that is heated by the combustion gases, while fire tubes allow hot gases to pass through the tubes, heating the surrounding water. The choice of tube design depends on the application and desired efficiency.

4. Superheater

The superheater is responsible for further heating the steam produced in the boiler. By increasing the temperature of the steam, the superheater improves the efficiency and power output of the high pressure boiler.

Superheated steam is essential for applications like turbines and engines, where dry steam is required for optimal performance. The superheater also helps reduce the risk of condensation and corrosion in the steam lines.

5. Economizer

The economizer is a heat exchanger that preheats the feedwater using the residual heat from the flue gases. This process improves the overall efficiency of the high pressure boiler by reducing fuel consumption.

By recovering waste heat from the exhaust gases, the economizer helps lower energy costs and reduces the environmental impact of the boiler system. It is a critical component for achieving higher thermal efficiency.

6. Safety Valves

Safety valves are critical components that prevent excessive pressure buildup within the boiler. These valves automatically release steam when the pressure exceeds a predetermined limit, ensuring the safety of the system.

Safety valves are designed to protect the boiler and associated equipment from catastrophic failure due to overpressure. Regular testing and maintenance of safety valves are essential to ensure proper operation and compliance with safety regulations.

7. Water Level Indicator

The water level indicator provides real-time information about the water level inside the boiler. Maintaining the correct water level is essential to prevent overheating and damage to the boiler components.

Low water levels can lead to overheating and tube failure, while high water levels can cause carryover of water into the steam lines. Accurate monitoring and control of the water level are crucial for safe and efficient boiler operation.

8. Steam Drum

The steam drum is a reservoir that collects and stores steam generated in the boiler. It also separates steam from water, ensuring that only dry steam is delivered to the steam turbine or other applications.

The steam drum plays a vital role in maintaining the balance between water and steam within the boiler system. Proper circulation and separation are essential for efficient heat transfer and preventing water droplets from entering the steam lines.

9. Feedwater Pump

The feedwater pump supplies water to the boiler at the required pressure. It is a vital component that ensures a continuous supply of water for steam generation.

Feedwater pumps are designed to handle high-pressure conditions and must be able to deliver water consistently and efficiently. Proper pump operation is essential for maintaining the water level and preventing damage to the boiler.

10. Air Preheater

The air preheater warms the incoming air before it enters the furnace. This component improves combustion efficiency and reduces fuel consumption.

By preheating the air, the air preheater helps achieve complete combustion and reduces the formation of pollutants. It also enhances the overall efficiency of the high pressure boiler system.

Importance of High Pressure Boiler Boiler Components

Each component in a high pressure boiler system plays a crucial role in ensuring efficient operation and safety. Proper maintenance and regular inspections of these components are essential to prevent breakdowns, reduce energy consumption, and extend the lifespan of the boiler.

Neglecting any component can lead to reduced efficiency, increased fuel consumption, and safety hazards. For example, a malfunctioning safety valve can result in overpressure and potential explosions, while a clogged economizer can reduce heat recovery and increase operating costs.

Conclusion

High pressure boiler boiler components are integral to the performance and safety of industrial steam generation systems. From the boiler shell to the safety valves, each component contributes to the overall efficiency and reliability of the system. By understanding these components and their functions, industries can optimize their operations and reduce downtime.

Regular maintenance, proper monitoring, and adherence to safety standards are essential for maximizing the performance and lifespan of high pressure boilers. For top-quality high pressure boiler components manufacturers, trust Ribo Industries, a leader in the field of industrial boiler manufacturing and services.

#boiler components#industrial#HighPressureBoiler#BoilerManufacturing#RiboIndustries#PowerPlantSolutions

1 note

·

View note

Text

We offer state-of-the-art Substation Automation Systems (SCADA), utilizing advanced communication protocols like IEC61850, IEC101, IEC104, and Modbus. Our services include design, engineering, and development of HMI & SCADA solutions for substations, switchyards, and power plants. Our SCADA system integrates computers, networked communications, and GUIs for high-level process management, featuring Siemens RTUs and control panels. We also offer SCADA training sessions, covering essential concepts, applications, and troubleshooting. Contact us at +91 7021624024 or [email protected] to explore our automation solutions.

#substationautomation#SCADASolutions#industrialautomation#PowerSystemControl#RTUConfiguration#IEC61850#EnergyManagement#PowerPlantSolutions#SCADAEngineering#ControlSystems#HMIandSCADA#ProcessAutomation#SiemensSCADA#AutomationTraining#SmartGridTechnology#electricalengineering#smartgrid

0 notes