#boiler components

Explore tagged Tumblr posts

Text

Economiser Coil: Enhancing Boiler Efficiency in Industrial Applications

Introduction

The economiser coil is a crucial component in modern industrial boiler systems. Its primary role is to recover waste heat from exhaust gases and transfer it to the feedwater, improving the overall efficiency of the boiler system. By preheating the feedwater, the economiser reduces fuel consumption, helping industries save on operational costs and reduce their environmental footprint. This blog explores the importance of economiser coils, their function within the broader system of boiler components, and how they integrate into boiler manufacturing processes. We'll also discuss why choosing the right boiler manufacturers in Chennai is essential for maximizing the benefits of these systems.

Understanding the Economiser Coil and Its Role in Boiler Systems

The economiser coil in boiler is a heat exchanger designed to capture waste heat from the flue gases produced during combustion. The coil works by transferring this heat to the feedwater before it enters the boiler. This preheating process makes the boiler more energy-efficient by reducing the amount of fuel required to heat the water. In many industrial settings, where boilers are used for generating steam or hot water, energy conservation is critical, making the economiser coil an indispensable part of the system.

Unlike other boiler components, the economiser plays a specialized role in enhancing thermal performance. It is typically made from durable materials capable of withstanding high pressure and temperature fluctuations, ensuring long-term efficiency. As a key part of boiler pressure parts, the economiser coil helps extend the life of the boiler by reducing thermal stress and preventing the system from overworking.

The Importance of Economiser Coils in Boiler Manufacturing

In boiler manufacturing, the integration of an economiser coil is a standard practice, especially in high-performance systems that require maximum fuel efficiency. When boiler manufacturers design a new system, they focus on incorporating components like the economiser to ensure optimal energy recovery.

An efficient economiser system is essential not only for improving energy efficiency but also for meeting regulatory requirements regarding emissions and energy consumption. Many industries are under pressure to minimize their carbon footprint, and using economiser coils is one of the most effective ways to achieve this goal. By installing an economiser coil, companies can reduce both fuel costs and environmental impact.

When selecting boiler manufacturers in Chennai, it is crucial to choose one with experience in integrating high-efficiency systems like economiser coils. The right manufacturer can customize the design of the economiser to suit specific operational needs, ensuring optimal performance and maximum fuel savings.

Economiser Coils in Boiler

Key Boiler Components and the Role of the Economiser Coil

To understand how the economiser coil fits into a larger boiler system, it is important to explore some of the other key boiler components. Boilers are complex systems composed of various pressure parts, heat exchangers, and safety mechanisms, all working together to produce steam or hot water for industrial use.

Boiler Coil

The boiler coil is another essential component of the boiler system, designed to absorb and transfer heat from the combustion process. Unlike the economiser coil, which preheats the feedwater, the boiler coil maintains the heat exchange process during combustion. Both the economiser coil and boiler coil work together to ensure the system is efficient, with the economiser handling energy recovery and the boiler coil focusing on heat distribution.

Boiler Pressure Parts

Boiler pressure parts are components that must withstand high-pressure conditions during boiler operation. These include the economiser coil, steam drum, superheaters, and more. Each part is designed with specific materials and engineering considerations to ensure that the boiler can operate safely and efficiently under demanding conditions. The economiser coil, as a key boiler pressure part, is designed to handle extreme temperatures and pressures, ensuring reliable performance over the life of the system.

Combustion System

The combustion system plays a central role in generating the heat needed to operate the boiler. It burns fuel to create high-temperature gases that transfer heat to the water in the boiler system. The economiser coil recovers some of the heat from the exhaust gases before they are released, making the system more energy-efficient. By doing so, the economiser reduces the need for additional fuel input, optimizing the combustion process and reducing overall fuel consumption.

Advantages of Economiser Coils in Industrial Boilers

Incorporating an economiser coil into a boiler system offers numerous advantages for industrial applications. Here are some of the key benefits of using economisers:

Energy Efficiency: The primary benefit of an economiser coil is improved energy efficiency. By recovering waste heat from the flue gases, the economiser reduces the amount of energy needed to heat the feedwater, lowering fuel consumption.

Cost Savings: With reduced fuel consumption, industries can significantly lower their operating costs. This is especially important in industries that rely heavily on boilers for energy production, such as power plants, chemical factories, and manufacturing units.

Environmental Benefits: The reduction in fuel consumption also leads to a decrease in harmful emissions. Economiser coils help companies meet regulatory standards for emissions by improving the overall efficiency of the system.

Extended Boiler Life: By preheating the feedwater and reducing thermal stress on the boiler components, the economiser coil helps extend the life of the boiler. This leads to reduced maintenance costs and fewer system breakdowns.

Improved System Performance: The integration of an economiser coil ensures that the boiler operates at peak performance, providing consistent heat output with minimal fuel consumption.

Choosing the Right Boiler Manufacturers in Chennai

When selecting boiler manufacturers in Chennai, it is essential to choose a company with a proven track record in designing and manufacturing high-efficiency boiler systems. Leading boiler manufacturers understand the importance of components like the economiser coil and integrate them into their designs to ensure optimal energy recovery.

Reputable manufacturers can customize the economiser coil and other boiler pressure parts to meet specific client needs, ensuring that the system delivers the highest performance and efficiency. Choosing a trusted manufacturer ensures that the economiser coil and other components are built to the highest quality standards, providing reliability and durability over the long term.

Conclusion: Ribo Industries – A Leading Name in Boiler Manufacturing

At Ribo Industries, we specialize in the design and manufacture of high-quality boilers, including the integration of advanced economiser coils to maximize fuel efficiency and reduce operational costs. With years of experience in boiler manufacturing and a commitment to excellence, Ribo Industries is one of the leading boiler manufacturers in Chennai.

Choose Ribo Industries for your boiler needs and benefit from our extensive expertise, high-quality boiler components, and state-of-the-art technology. Let us help you optimize your energy consumption and reduce your environmental footprint with our top-of-the-line boiler systems.

0 notes

Text

https://www.kbgboilers.in/

#Steam Boilers#Boiler Components#Industrial Boilers#Boiler Manufacturing#Boiler Suppliers#Boiler Technology

0 notes

Text

IBR Flanges: Ensuring Safety and Reliability with Tubefit Industries

IBR Flanges: A Comprehensive Guide by Tubefit Industries

IBR flanges are necessary element used in industries requiring high-pressure applications, such as power plants, refineries, and chemical plants. The term "IBR" stands for Indian Boiler Regulations, a set of standards established to ensure the safety, reliability, and efficiency of boiler systems. These flanges are designed and manufactured to meet stringent specifications set by IBR, ensuring they can withstand the most demanding environments.

At Tubefit Industries, we specialize in producing high-quality IBR flanges that cater to various industrial needs. Our IBR flanges are manufactured from superior-grade materials, offering exceptional durability, corrosion resistance, and long-term performance. Whether you're working with steam, water, or other high-pressure fluids, Tubefit Industries provides flanges that comply with IBR standards, ensuring the safety and operational integrity of your system.

Key Features of IBR Flanges by Tubefit Industries:

Compliance with IBR Standards: All flanges are manufactured in strict adherence to the Indian Boiler Regulations, ensuring high safety and quality standards.

Wide Range of Materials: Available in materials like carbon steel, stainless steel, and alloy steel, suitable for various industrial applications.

Precision Engineering: Our flanges are crafted using advanced technology, ensuring precise dimensions and a perfect fit for reliable and leak-proof connections.

Corrosion Resistance: Tubefit Industries' IBR flanges are designed to resist corrosion and maintain their strength even in harsh environments.

Customizable Options: We offer customized IBR flanges based on client specifications, ensuring compatibility with specific system requirements.

If you need top-notch IBR flanges for your high-pressure systems, Tubefit Industries is your trusted partner. Our Dictionary to quality, reliability, and customer contentment ensures that you get the best product for your industrial applications.

Contact us at:

Phone: 9999622266, 9999010233

Email: [email protected]

Website: https://www.tubefitindustries.in/ibr-flanges/

Add: Kila Number 20-21 Pali Nekpur Road Pali Faridabad-121004

#IBR Flanges#IBR Tees#IBR Elbow#IBR Syphon#IBR Reducers#IBR Pipe Fittings Manufacturer in India#IBR Fittings#IBR Pipe Spools#IBR Forgings#IBR Steam Headers Manufacturer#Indian Manufacturers#Industrial Pipe Fittings#IBR Fittings India#Precision Pipe Fittings#Tube Fit Industries#Flanges Manufacturers#Pipe Fittings India#Industria lPipe Components#IBR Standards#Quality Pipe Fittings#Pipe Fitting Solutions#Boiler Components#Flanges#Industrial Flanges#Steel Flanges#Manufacturing#Boiler Manufacturing

0 notes

Text

What is Dataflow?

This post is inspired by another post about the Crowd Strike IT disaster and a bunch of people being interested in what I mean by Dataflow. Dataflow is my absolute jam and I'm happy to answer as many questions as you like on it. I even put referential pictures in like I'm writing an article, what fun!

I'll probably split this into multiple parts because it'll be a huge post otherwise but here we go!

A Brief History

Our world is dependent on the flow of data. It exists in almost every aspect of our lives and has done so arguably for hundreds if not thousands of years.

At the end of the day, the flow of data is the flow of knowledge and information. Normally most of us refer to data in the context of computing technology (our phones, PCs, tablets etc) but, if we want to get historical about it, the invention of writing and the invention of the Printing Press were great leaps forward in how we increased the flow of information.

Modern Day IT exists for one reason - To support the flow of data.

Whether it's buying something at a shop, sitting staring at an excel sheet at work, or watching Netflix - All of the technology you interact with is to support the flow of data.

Understanding and managing the flow of data is as important to getting us to where we are right now as when we first learned to control and manage water to provide irrigation for early farming and settlement.

Engineering Rigor

When the majority of us turn on the tap to have a drink or take a shower, we expect water to come out. We trust that the water is clean, and we trust that our homes can receive a steady supply of water.

Most of us trust our central heating (insert boiler joke here) and the plugs/sockets in our homes to provide gas and electricity. The reason we trust all of these flows is because there's been rigorous engineering standards built up over decades and centuries.

For example, Scottish Water will understand every component part that makes up their water pipelines. Those pipes, valves, fitting etc will comply with a national, or in some cases international, standard. These companies have diagrams that clearly map all of this out, mostly because they have to legally but also because it also vital for disaster recovery and other compliance issues.

Modern IT

And this is where modern day IT has problems. I'm not saying that modern day tech is a pile of shit. We all have great phones, our PCs can play good games, but it's one thing to craft well-designed products and another thing entirely to think about they all work together.

Because that is what's happened over the past few decades of IT. Organisations have piled on the latest plug-and-play technology (Software or Hardware) and they've built up complex legacy systems that no one really knows how they all work together. They've lost track of how data flows across their organisation which makes the work of cybersecurity, disaster recovery, compliance and general business transformation teams a nightmare.

Some of these systems are entirely dependent on other systems to operate. But that dependency isn't documented. The vast majority of digital transformation projects fail because they get halfway through and realise they hadn't factored in a system that they thought was nothing but was vital to the organisation running.

And this isn't just for-profit organisations, this is the health services, this is national infrastructure, it's everyone.

There's not yet a single standard that says "This is how organisations should control, manage and govern their flows of data."

Why is that relevant to the companies that were affected by Crowd Strike? Would it have stopped it?

Maybe, maybe not. But considering the global impact, it doesn't look like many organisations were prepared for the possibility of a huge chunk of their IT infrastructure going down.

Understanding dataflows help with the preparation for events like this, so organisations can move to mitigate them, and also the recovery side when they do happen. Organisations need to understand which systems are a priority to get back operational and which can be left.

The problem I'm seeing from a lot of organisations at the moment is that they don't know which systems to recover first, and are losing money and reputation while they fight to get things back online. A lot of them are just winging it.

Conclusion of Part 1

Next time I can totally go into diagramming if any of you are interested in that.

How can any organisation actually map their dataflow and what things need to be considered to do so. It'll come across like common sense, but that's why an actual standard is so desperately needed!

845 notes

·

View notes

Text

Sweet things

@bucktommyfluffebruary - day two prompt ‘cooking together’

Notes: established relationship, domestic fluff, Tommy is too busy staring at his boyfriend to be an effective sous chef | Rating: G | Words: 700

[Read on A03]

——-

“Sorry I’m late!” Tommy calls through the house, “there was an accident, traffic was a nightmare.”

“That’s okay,” a familiar voice calls back. “I had to start without you.” Tommy comes into the kitchen to find Evan whisking a bowl of egg whites. “Need to keep on schedule so it has to bake and cool before we put it together.”

Tommy half remembers the 20 minute run down of why you have to let a meringue cool slowly, something to do with sudden temperature change causing cracks? In his defence he had been half asleep at the time, laid out on the sofa with Evan’s fingers carding through his hair.

Ever since Athena had assigned them the dessert portion of the menu for their barbecue this evening Evan had been spending every spare minute searching for the perfect thing to make. Several internet deep dives, three new recipe books and countless conversations later he had come to the conclusion that a pavlova would be perfect for the job.

“It’s the best of all things.” He had explained one evening, plastered against Tommy’s back while he did the washing up. “It’s crunchy and chewy, sweet but if you choose the right flavour crème, I was thinking passion fruit, then it’s not too sweet. Plus it’s light enough for after a big meal, perfect for a summer barbecue.”

Tommy comes around the kitchen island, rests his hand on Evan’s hip and presses a quick kiss to the back of his neck.

“Hope you didn’t do all of my jobs for me. I want to look Hen in the eye and tell her I helped make this thing, I’m pretty sure it’s high on her list of things she doesn’t believe are possible.”

Evan laughs,

“I need you to separate some more eggs, 3 yolks should do and then they need to go on a double boiler-” he shifts out of Tommy grasp, pulling the scales out of a nearby cupboard and measuring sugar into a bowl.

“I thought we were making meringue.”

“We’re making a pavlova, three key components; meringue, crème and fruit.”

“Oh yes of course, how could I forget the three key components.”

Evan pulls a face of mock shock at Tommy’s sarcastic tone.

“How indeed” he reaches up and taps the recipe card taped to the cupboard. “All the instructions are there if you need them.”

Tommy separates the eggs carefully, and puts them in a double boiler on the stove. He is stirring them gently when he feels Evan’s gaze boring into the side of him.

“Can I help you with something?”

Evan waggles his hand in the direction of the drawer Tommy is stood in front of.

“Can you pass me a spoon?”

“Sure.”

He digs one out and gives it to Evan, their fingers brushing over the handle. His gaze lingers on Evan for a moment too long.

“You know you have to stir those constantly right?”

“Mmm?” Truth be told, Tommy is a little less focused on the steaming bowl and more on his gorgeous boyfriend. He feels a bit lost with the way the afternoon sun is catching the lighter tones in Evan’s hair, lifting the golden tones of his skin.

Evan reaches over with the hand not currently occupied whisking egg whites and closes it over Tommy’s wrist, forcing him to stir the mixture.

“If you don’t they will scramble.”

“We can’t have that.” Tommy murmurs softly, still entranced by the way the light makes Evan’s eyes shine, picking up the different shades of blue in his eyes and making them sparkle.

Evan catches Tommy’s eyes and stops for a moment, his trademark frantic cooking energy slowing down as he looks at Tommy. He knows realistically that 24 hours is not a hugely long time to go without seeing someone but the way he feels immediately lighter under Tommy’s gaze makes him realise how much he misses him when he’s at work.

“Sorry,” he mumbles “I didn’t even say hello.”

“That’s okay baby, I know how important the structural integrity of meringues is to you.”

“You’re important to me too.”

Tommy smiles and Evan thinks he may never get tired of seeing it.

Tagging some beloveds (as always let me know if you want to be added/removed);

@leashybebes @livelaughlou @loucifersbitch @dark-alice-lilith @mmso-notlikethat @laundryandtaxesworld @bucksaiga @littlepaws9 @sad-girl-hours23 @evansbuck-ley @jamieroyjamieroy @typicalopposite

@moonydanny @teenmaximoff @bucksboobs @ohithankyou @bi-bi-buckleys @rubydaiquiri @hellion-child @aringofsalt @sweaters-and-silly @theotherbuckley @comfortingevanbuckley @epiphainie @wikiangela @bidisasterevankinard

@sunnywithachanceofbi @desert--moonchild @blitzynatural @actuallyitsellie @big-urchin-energy @fyrehose @buckleyskinards @owlgirl495 @honeyloulou @setmeatopthepyre @salty-autistic-writer @thecarrott

#bucktommy fluffebruary#my writing#bucktommy#911#Evan Buckley#tommy kinard#cooking together#fluff#domestic fluff#fanfic

144 notes

·

View notes

Text

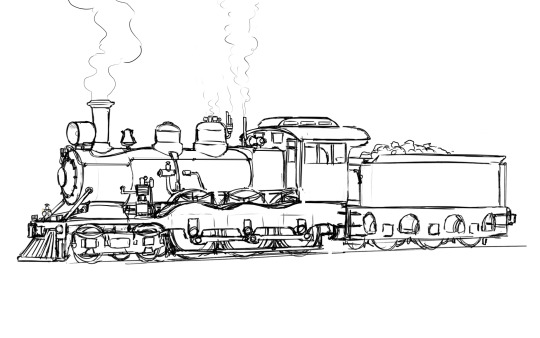

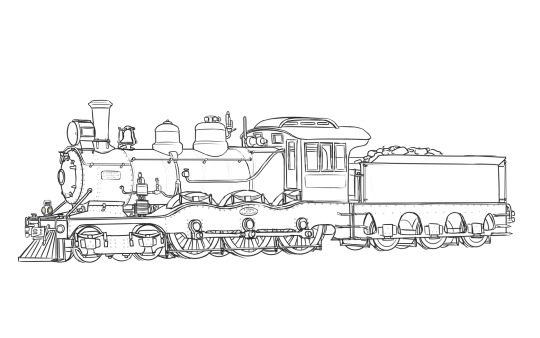

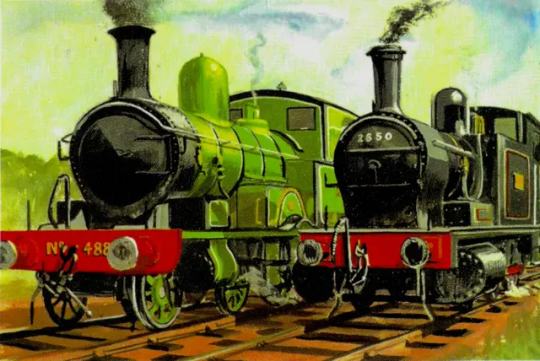

Commission for @pikablob of the steam locomotive Featherfoot from her Underrail fantasy setting (which can be found here)

Finally, on the nearest occupied track, close enough that she could hear some component within chunking back and forth with quiet mechanical regularity, was an engine painted in brilliant scarlet. Its boiler seemed to be in the dominant Freehold-style, with a tall funnel, two great domes, and exposed pipework, backing into a large cab topped with a little clerestory bump; but its wheels and mechanics were mostly hidden by heavy frame-plates, save for exposed cranks between the three driving axles.

Featherfoot is sapient, with a "Coal Heart" in her firebox which acts as the mind and main power source for the loco (though she still consumes coal). She is a one-off 4-6-0 Constitution-type built by E. Towan & Co. Jushi Works, using a boiler built by Cortopassi Locomotive Works.

More background and alternate image versions below the cut:

Featherfoot is based on a Illinois Central Railroad ten wheeler of the type that was involved in Casey Jones' infamous train collision, but below the frames it more resembles an outside-frame inside-cylinder Great Western Railway 4-4-0--a City or a Duke class. Its tender is based on a GNR tender similar to what the Stirling Single carried.

There are four holders for marker lamps or flags--three along the pilot beam and one on the smokebox, intended to be used with UK-style headcodes but with US-style marker lamps.

The livery is based on the fictionalized GWR Duke class seen in Assasin's Creed Syndicate.

Here's some WIP images: 1:25 PM to 2:37 PM

While waiting for the client to get back to me on some questions, I doodled this:

Eaurp Guz! What are you doing on a miniaturized fantasy train!? Ah who am I kidding this is super in-character for her.

After a break and a little back and forth with the client (moved and replaced the whistle, replaced the oil headlamp with an electric one, added a dynamo), I completed the sketch.

I also tweaked some of the proportions a little. Note that when I am doing a "sketch" commission as opposed to "clean line art" i usually clean the sketch up a little more than I did here.

I then moved on to line art, which also gave me a chance to get the proportions on the wheels and frames right. I also totally re-thought the appliances and piping visible on the boiler.

By 10:31, the line art was complete. It had taken about an hour and thirty minutes, i don't have an exact timestamp.

Various other details were also added here--rivets, brake pipe, detailed coupler, detailed air compressor, snifters, wheel spokes, cut levers, the two builder's plates.

Here's the loco with full color. This is more or less how I left the loco off at the end of last night, at around 11:30 PM.

This morning at about 10:30 AM, I started working on rendering--and at 12:30 PM I finished the drawing.

The rest of these alt. versions are not chronological, and were created by removing certain layers:

The engine, cold.

The engine, solid color (but finished).

Solid color, but brightened to look better in a white background.

Transparent version with and without full rendering, steam, and lights.

I was shocked to find that with the line art removed, it didn't look half bad. It does look way messier, but I really need to go and try to tackle a fully lineless drawing in this style some time.

#Underrail#Featherfoot#Fantasy train#fantasy art#D&D art#train#steam train#steam engine#steam locomotive#locomotive#commission#art#digital art#digital painting#painting#underground#red train#steampunk#railway#railroad#original character art#oc art

59 notes

·

View notes

Text

this got long lol

so for hugo's bike, with it being steam-powered (look at him and his kingdom, theres no way it isnt), there's likely an alternative to coal he uses. the boiler would use some sort of concoction instead of coal as a heat source (side note, we're working with this with the prerequisite that this is a fantastical world, so the boiler fucking exploding isnt as big of a risk- and eco-friendly and relatively safe alternatives to coal exist)

enter varian and his creation of Flynnolium right. the stuff he made to heat up the boilers under corona which eventually lead it to be the first kingdom with a running hot water system (beating the industrial kingdom, apparently). the stuff is POTENT. so the idea here is, after giving the bike some excitable and genuine praise, for varian to suggest adding it to hugo's steam cycle- to which hugo vehemently refuses. why would he use something that could blow up his bike AND named after flynn rider of all things (its mostly the latter, lets be real)

(btw this is all in hugo's kingdom, i think hugo keeps his bike around that area and never too far outside of it)

so fast forward later. lets say theres a chase happening in his kingdom. lots of fun shots with hugo zipping around expertly through the twisted streets (and even rooftops) of his kingdom. but whatever is chasing them is keeping a steady pace so varian, again and again, is telling hugo we have GOT to use the flynnolium. they argue a little, mostly hugo refusing more and more stubbornly. but finally he literally has to give in bc theyre getting dangerously close to getting caught so after another yell from varian, he just lets out a dramatic groan and leans over and whispers to his bike something like "im sorry" and tells varian to do it. and naturally this makes the bike go fucking fast. it helps them get out of there AND ! it doesnt explode. isnt that fun. after that hugo has to swallow his stubborn pride and admit its a really, really good component for the steam cycle (but, yknow, maybe consider renaming it)

#also /maybe/ having varian hold onto him tight AND helping with his bike was nice. but you didnt hear that from me#vat7k#varigo#posting

62 notes

·

View notes

Text

STEX APPRECIATION MONTH DAY 2: PEARL

Favorite Actor(s): Stephanie Lawrence, Reva Rice, Lovette George

Favorite Song/Scenes: OLC He Whistled At Me i love you and miss you every day. Also love the versions of the love ballads where Pearl has a solo first where she reflects on her relationship with Rusty <3

Favorite Costume(s): OLC PEARL FOREVER AND EVER. She was so poofy and princessy and I will always love the pink white and silver combo!! However the big curly wigs of late london and 2010s bochum will always slay

Favorite Ships/Friendships: Fav romantic ship is ofc prusty I LOVE them. As for friendships I always love to see her with any of the other coaches. I can't really see her being super close with any of the freight or even components tbh. I see her keeping her circle of close friends pretty small post-canon

Headcanons: While Pearl IS the youngest of the coaches she isn't brand new to the yard she's been there for a bit. She is the newest and most well-kept of the coaches though. I think she's cold all the time because she's air conditioned (which makes Rusty the perfect cuddle partner, he's always hot due to his boiler)

Unpopular Opinion: The OLC had the clearest and most fleshed out (and my favorite) characterization of Pearl. Scenes like Hitching and Switching and He Whistled at Me (+ the prior argument with Rusty) do a lot to flesh her out imo

#my art#fanart#starlight express#stex#pearl the observation car#stex appreciation month#stex appreciation month 2024#im sorry in advance for how often im going to gush about how much i love the olc in these coming days. its not my fault im like this.

59 notes

·

View notes

Text

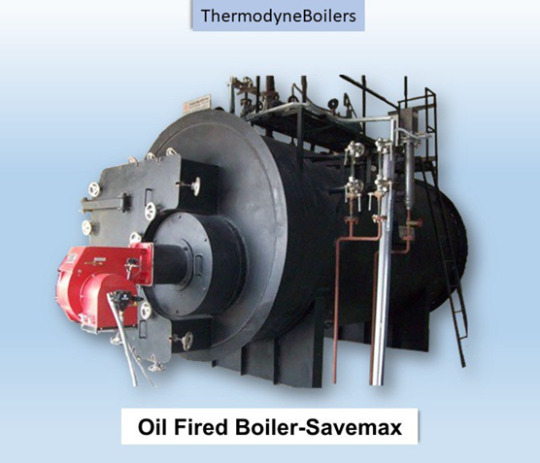

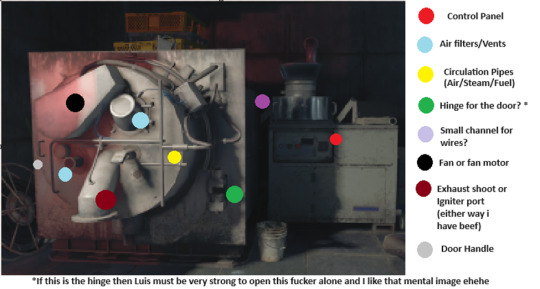

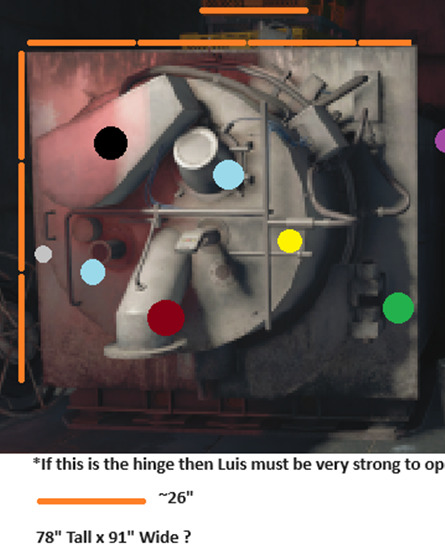

Long-ass post about what the fuck this machine might be:

Screenshot by @geddy-leesbian and sent to me for research by @courtofparrots

So, what the /fuck/ is this damn thing? (And it’s side-quest: This fucking /shoot/):

At first I thought the machine was some form of Vacuum Furnace since the shape and the possible intake shoot (which will give me hell this entire research process) looks like an incinerator and something to suck things into the incinerator:

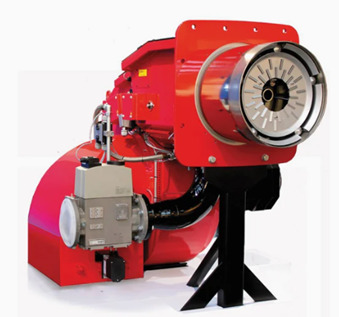

(Source.)

But the shape isn’t 100% right, and as CAPCOM need something to do a 1:1-ish model for the game, I scrapped it and moved on.

The next candidate made my heart hurt since it’s a Marine Waste Incinerator:

The shape is similar, it has a box-like connection that I wasn’t able to find almost anywhere else, but no fucking shoot.

/However/, I think I’m onto something here’s a couple other models I found:

Why is this heartbreaking? Because Luis is not only on a shoe-string budget in the middle of noplace, but he’s also having to use whatever the cult can scrounge up for him. I’m convinced he brought his little autoclave from a mainland somewhere, but he needed an incinerator.

They’re off the ocean.

Where there’s a will there’s a way, and Lord Saddler is demanding he makes a way using this hulking machine that isn’t even meant for use on land.

However, the one in Luis’ lab doesn’t look like it’s meant for use on a ship, and there isn’t that fucking spout.

Next, I followed the little tubes on the sides:

And it looks a lot like they’re meant to be on a locomotive or a boiler:.

Why would he need a boiler? I have no idea, ask a scientist. But, visually we’re getting closer.

I looked up what that black piece is for, since I initially thought the piece on Luis’ machine was for some sort of vault technology, housing a locking mechanism for keeping a vacuum seal in the case of the vacuum furnace.

^This thing.

In boilers however, it tends to contain an exhaust fan/motor (iirc). Again, having a fan could work for some sort of incinerator and there’s no real point in having a vent/air filter right below it (the cylindrical thing) unless it’s dealing with something that needs a lot of air.

Now, on boilers and incinerators there tends to be some sort of (usually red) component on the front that /could/ be something that damn shoot connects to. Ex:

That is a burner/igniter.

^This is what it looks like on the inside.

Could the shoot be a hookup? I have no idea. I don’t /think/ so though, since the shoot looks more like a place to expell something (think coal from a coaling tower on a railroad). (In fact, this thought momentarily brought me down a rabbit hole of ‘what if it’s for some sort of coal refinement’? But I rejected that idea because then it would be more of a grinding machine and this is more boiler-incinerator-type-deal.)

My friend brought up a good point that maybe the shoot is for sucking up waste material.

Using my own knowledge of trades, I’m not sure that’s the case? Usually, if something has to go down then the spout will be tilted up so that it’s not fighting gravity. However, I am a city kid with a business degree, so we can safely shelve that idea since it’s outside my wheelhouse.

It was at this point that I realized the box next to Luis’ machine could be part of the whole device:

The only times I’ve seen something like this with an attached cube it was on an electric steam boiler:

And on the vacuum furnace, marine waste incinerator (already mentioned), and this medical waste incinerator:

Which brings us right back around to incinerators.

So while I can’t find anything that has the damn shoot, here’s what I /think/ all the pieces of the machine are. (Again, I am not in sciences or in trade, so this is all I could find after a three-hour research stint that ended when I got too frustrated.)

AND COMPLETELY EYEBALLING THIS NEXT PART:

The items on top of it are these little crates that I’ve only seen in workshops but the ones I’ve seen are roughly 26” across. Which makes this mystery machine ~78” Tall and ~91” Wide (not accounting for the angle it seems to be at).

In closing, I think this is some sort of incinerator (wow, three hours of research just to be back at square one? First of all, rude. Second of all, I now know more than when I started so that’s fun for me!) and for storytelling purposes I want it to be a marine waste incinerator, built for burning waste onboard a ship or for getting rid of oil waste. This way it illustrates just how resourceful and flexible Luis had to be in order to /try and get his fucking tools to do what they’re supposed to/. His autoclave isn’t a true autoclave and it’s /tiny/. He’s working with an old acrylic glove box. He’s been given an oil waste incinerator off a boat and he has to make it /work/.

In short, this is what I do for fun and now I have to get back to work. 😊

Sources:

https://www.marineinsight.com/tech/9-tips-to-maintain-high-efficiency-of-marine-incinerators/

https://addfield.com/case-studies/waste-oil-incinerator/

https://xuyemachinery.en.made-in-china.com/product/FdRTyotOfHUY/China-Industrial-Incinerator-Waste-Oil-Burner-Available.html

https://zaobt.ru/en/news/marine-incinerator-for-vostochnaya-verf-jsc-shipped-from-the-site-of-st-inc

https://www.indiamart.com/proddetail/incinerators-3550461212.html

https://trends.medicalexpo.com/inciner8-ltd/project-115640-426969.html

https://www.google.com/imgres?q=steam%20boiler&imgurl=https%3A%2F%2Fwww.3diequipment.com%2Fwp-content%2Fuploads%2F2023%2F01%2Fcocran-steam-boiler-model-thermax-pic2371b-1-600x377.jpg&imgrefurl=https%3A%2F%2Fwww.3diequipment.com%2Fproduct%2Fcochran-steam-boiler-model-thermax%2F&docid=xunMT1CJ-fei2M&tbnid=zBjSfu1BNa7HiM&vet=12ahUKEwif7dG8hYSIAxURAzQIHazPMW44KBAzegQIUBAA..i&w=600&h=377&hcb=2&ved=2ahUKEwif7dG8hYSIAxURAzQIHazPMW44KBAzegQIUBAA

https://www.google.com/imgres?q=steam%20boiler&imgurl=https%3A%2F%2Fwww.hvacinformed.com%2Fimg%2Fproducts%2F400%2Fu-nd-400_1628544986.jpg&imgrefurl=https%3A%2F%2Fwww.hvacinformed.com%2Fbosch-thermotechnology-u-hd-boiler-technical-details.html&docid=8M3mwXLLyvCvNM&tbnid=qs-8ZiQlRet2ZM&vet=12ahUKEwif7dG8hYSIAxURAzQIHazPMW44KBAzegQIUhAA..i&w=400&h=400&hcb=2&ved=2ahUKEwif7dG8hYSIAxURAzQIHazPMW44KBAzegQIUhAA

https://easywater.com/commercial/applications/steam-boilers/

https://www.thermodyneboilers.com/3-ton-steam-boiler-price/

https://www.thermodyneboilers.com/oil-fired-boilers/

https://www.parat.no/products/marine/parat-mel/

https://betterbricks.com/resources/boilers

https://powerhouse-combustion.com/components-of-a-boiler/

https://cs.wikipedia.org/wiki/Lokomotivn%C3%AD_parn%C3%AD_kotel

#luis serra navarro#resident evil meta#what do i even tag this as#research with me? lol#re4r meta#research with me

40 notes

·

View notes

Text

High Pressure Boiler Components: An In-Depth Analysis

In the realm of industrial applications, high pressure boilers play a crucial role in generating steam and power. Understanding the high pressure boiler boiler components is essential for ensuring efficiency, safety, and longevity. In this guide, we will delve into the critical components that make up a high pressure boiler system.

What is a High Pressure Boiler?

A high pressure boiler is a type of boiler that operates at a pressure exceeding 15 psi (pounds per square inch). These boilers are commonly used in power plants, industrial facilities, and manufacturing processes where steam generation is required for various operations. The higher pressure allows for increased energy transfer, leading to higher efficiency and productivity.

High pressure boilers are designed to handle extreme conditions and are built with robust materials to withstand high temperatures and pressures. They are often used in applications such as electricity generation, chemical processing, and heating systems for large buildings.

Key High Pressure Boiler Boiler Components

1. Boiler Shell

The boiler shell is the outermost structure that contains the water and steam. It provides structural support and withstands the internal pressure generated during the operation of the high pressure boiler. The shell is typically made of high-strength steel to handle the intense pressure and temperature conditions.

The design of the boiler shell is critical for ensuring safety and efficiency. It must be able to resist corrosion and thermal stress while providing a stable environment for steam generation.

2. Furnace

The furnace is the combustion chamber where fuel is burned to generate heat. The heat produced in the furnace is transferred to the water to create steam. The design and efficiency of the furnace play a critical role in the overall performance of the high pressure boiler.

Furnaces can use various types of fuel, including coal, natural gas, oil, or biomass. The choice of fuel depends on the specific application and environmental considerations. Proper airflow and temperature control are essential for efficient combustion and reduced emissions.

3. Tubes

Boiler tubes are essential components that allow heat transfer from the combustion gases to the water. These tubes are typically made of high-strength materials that can withstand high temperatures and pressures.

There are two main types of boiler tubes: water tubes and fire tubes. Water tubes carry water that is heated by the combustion gases, while fire tubes allow hot gases to pass through the tubes, heating the surrounding water. The choice of tube design depends on the application and desired efficiency.

4. Superheater

The superheater is responsible for further heating the steam produced in the boiler. By increasing the temperature of the steam, the superheater improves the efficiency and power output of the high pressure boiler.

Superheated steam is essential for applications like turbines and engines, where dry steam is required for optimal performance. The superheater also helps reduce the risk of condensation and corrosion in the steam lines.

5. Economizer

The economizer is a heat exchanger that preheats the feedwater using the residual heat from the flue gases. This process improves the overall efficiency of the high pressure boiler by reducing fuel consumption.

By recovering waste heat from the exhaust gases, the economizer helps lower energy costs and reduces the environmental impact of the boiler system. It is a critical component for achieving higher thermal efficiency.

6. Safety Valves

Safety valves are critical components that prevent excessive pressure buildup within the boiler. These valves automatically release steam when the pressure exceeds a predetermined limit, ensuring the safety of the system.

Safety valves are designed to protect the boiler and associated equipment from catastrophic failure due to overpressure. Regular testing and maintenance of safety valves are essential to ensure proper operation and compliance with safety regulations.

7. Water Level Indicator

The water level indicator provides real-time information about the water level inside the boiler. Maintaining the correct water level is essential to prevent overheating and damage to the boiler components.

Low water levels can lead to overheating and tube failure, while high water levels can cause carryover of water into the steam lines. Accurate monitoring and control of the water level are crucial for safe and efficient boiler operation.

8. Steam Drum

The steam drum is a reservoir that collects and stores steam generated in the boiler. It also separates steam from water, ensuring that only dry steam is delivered to the steam turbine or other applications.

The steam drum plays a vital role in maintaining the balance between water and steam within the boiler system. Proper circulation and separation are essential for efficient heat transfer and preventing water droplets from entering the steam lines.

9. Feedwater Pump

The feedwater pump supplies water to the boiler at the required pressure. It is a vital component that ensures a continuous supply of water for steam generation.

Feedwater pumps are designed to handle high-pressure conditions and must be able to deliver water consistently and efficiently. Proper pump operation is essential for maintaining the water level and preventing damage to the boiler.

10. Air Preheater

The air preheater warms the incoming air before it enters the furnace. This component improves combustion efficiency and reduces fuel consumption.

By preheating the air, the air preheater helps achieve complete combustion and reduces the formation of pollutants. It also enhances the overall efficiency of the high pressure boiler system.

Importance of High Pressure Boiler Boiler Components

Each component in a high pressure boiler system plays a crucial role in ensuring efficient operation and safety. Proper maintenance and regular inspections of these components are essential to prevent breakdowns, reduce energy consumption, and extend the lifespan of the boiler.

Neglecting any component can lead to reduced efficiency, increased fuel consumption, and safety hazards. For example, a malfunctioning safety valve can result in overpressure and potential explosions, while a clogged economizer can reduce heat recovery and increase operating costs.

Conclusion

High pressure boiler boiler components are integral to the performance and safety of industrial steam generation systems. From the boiler shell to the safety valves, each component contributes to the overall efficiency and reliability of the system. By understanding these components and their functions, industries can optimize their operations and reduce downtime.

Regular maintenance, proper monitoring, and adherence to safety standards are essential for maximizing the performance and lifespan of high pressure boilers. For top-quality high pressure boiler components manufacturers, trust Ribo Industries, a leader in the field of industrial boiler manufacturing and services.

#boiler components#industrial#HighPressureBoiler#BoilerManufacturing#RiboIndustries#PowerPlantSolutions

1 note

·

View note

Text

Thermic Fluid Heater Manufacturer in India

KBG Boilers Pvt. Ltd. stands as a prominent name in the field of thermal energy solutions, offering state-of-the-art products designed to meet the diverse heating requirements of industries worldwide. As a trusted Thermic Fluid Heater Manufacturer, we specialize in delivering high-performance solutions that ensure efficiency, reliability, and safety in operations. Our products are engineered with precision, making us a preferred choice among industries such as chemical processing, textiles, pharmaceuticals, food production, and more.

Our thermic fluid heaters are designed to provide consistent and efficient heat transfer without direct contact between the heat source and the end-use equipment. These systems are ideal for applications requiring uniform heating across various industrial processes. As a reputed Thermic Fluid Heater Manufacturer in India, we offer a comprehensive range of models, including cutting-edge electric thermic fluid heaters that cater to eco-friendly and energy-efficient requirements. Our solutions integrate advanced technology and premium-grade materials to ensure maximum durability and optimal performance, even under demanding conditions.

At KBG Boilers Pvt. Ltd., we not only excel in manufacturing but also pride ourselves as leading Thermic Fluid Heater Exporters in India, supplying top-quality products to clients across global markets.

Our focus on innovation and adherence to international standards has helped us establish a robust reputation among our domestic and international clientele. From robust design to low maintenance and high energy efficiency, our thermic fluid heaters are tailored to enhance operational productivity. Whether it's steam boilers, electric boilers, or high-capacity industrial systems, We ensure each product meets rigorous quality and safety standards.

In addition to thermic fluid heaters, KBG Boilers Pvt. Ltd. is a trusted partner for boiler solutions. As one of the leading Boiler Manufacturers in India, we offer a wide array of boilers designed to meet specific industrial needs. Partnering with KBG Boilers Pvt. Ltd. means choosing a company committed to delivering excellence. Our customer-centric approach, backed by a team of skilled engineers and state-of-the-art manufacturing facilities, ensures every client receives solutions tailored to their unique requirements. With a focus on sustainability, efficiency, and long-term reliability, we strive to empower industries with advanced thermal heating systems. Trust KBG Boilers Pvt. Ltd., your dependable Thermic Fluid Heater Manufacturer, for innovative products that redefine industrial heating standards.

1 note

·

View note

Text

HEART PIRATES WEEK 2025 - Part 3 of 9

It's Heart Pirate season!

Day Three: Penguin - Insomnia

686 words; also just quickly looked-over so sorry if something reads a bit off; can read as slightly PenLaw now that I’m looking at it but I don’t ship it so if you do get your goggles ready

-_-_-_-_-_-_-

It wasn’t his shift to be up, and yet Penguin tossed and turned in his bunk, attempting to get comfortable to no avail as everyone else in the bunkroom snored and farted in their sleep. Next month was supposed to be when he switched to nights, making his inability to get rest all the more frustrating.

Eventually, he rolled out of bed and made his way towards the cafeteria. It was quiet in the ship—the thrumming of the engine in low-power mode, the lack of crew chatter, the subtle movement of the water all around the ship… there was so little noise it was deafening. At least if he went into the kitchen he’d hear other noises… could keep himself out of his own head.

Ah, yes; peace at last. Penguin busied himself with making some tea, the motions familiar and relaxing. He made Bepo some tea the first night they were together and, since then, the Mink was very good at providing him and Shachi and the Captain (and eventually, the rest of the crew) with herbal tea whenever they couldn’t sleep. It was… comforting, in its own way, and the familiarity of it felt natural in a way he could never describe.

As his tea steeped, Penguin went over to the small shelving unit set into the wall that held some of the crew’s shared books and plucked one off without even thinking about it. After tossing it on one of the tables, he grabbed the teapot and a mug and sat down to flip through the book while he continued letting his drink brew. Great—he ended up grabbing one of the beaten old technical manuals for the ship. The drier and more boring the text, the better his chances were at falling asleep mid-page, and any sleep was good sleep at this point. He began to read, eventually pouring himself a steaming mug of tea…

…except, instead of getting tired, he was simply getting bored. He kept trying to read, only to find that his attention span was growing shorter and shorter by the minute. Another cuppa once his first was drained and he kept trying, only to grow increasingly frustrated.

“Can’t sleep either?” Penguin glanced towards the doorway and saw the Captain, standing there as though he’d come in for the exact same reason—he looked like hell, as though the crew’s suspicions were correct and he really hadn’t slept in two whole days. Then again, he sounded awful too. The Captain saw the teapot and stared almost longingly. “Is that chamomile?”

“Lemon ginger—you’ll smell it once you come over here and pour yourself some.”

“Fair.” The Captain acquired a mug and indeed poured out some tea for himself. “You’ll never fall asleep reading that.”

“I’m trying,” Penguin groused. “This is probably one of the most snooze-worthy books on the entire ship.”

“Close,” his captain agreed, “but I doubt it’ll do anything but annoy you since it’s all stuff we’ve altered already.”

“Wanna bet?”

“Considering Ikkaku scrapped that component to make the espresso machine the second week she was here, yeah.” The Captain tapped his pointer finger on the page closest to him and pointed out a gyro that was indeed sitting on the kitchen counter. He drank some of his tea and gave his old friend an unbothered look—he had him there.

“Plenty in here’s still relevant,” Penguin frowned as he began to flip through the manual. “This got moved to the secondary engine, but it’s still fully operational. This got upgraded but it still is functional, this was tossed but looks very similar in setup to the new boiler dongle that we rigged up last week, and…”

Noticing that the Captain was very quiet, Penguin glanced over and saw that he was slumped against the table, eyes closed as he pillowed his head against folded arms. Penguin leaned in and confirmed the other man’s soft snores—at least one of them was out. He poured himself the last of the tea and continued reading.

Maybe, if he was lucky, they’d both get some sleep before breakfast.

#Heart Pirates Week#HeartPiratesWeek#HeartPiratesWeek2025#Heart Pirates Week 2025#One Piece#One Piece fan fiction#Penguin One Piece

15 notes

·

View notes

Text

What are Infused Oils?

What are they?

Infused oils are herbal components or spices placed in a jar of carrier oil like Olive Oil, Grapeseed Oil, Avacado Oil, Jojoba Oil, Coconut Oil, etc. Can be used in cooking, herbal ailments and skincare.

Are they essential oils?

No. Short answer, no. Long answer? I'll give you an explanation. Essential oils are distilled using Steam Distillation, Solvent Extraction, CO2 Extraction, Maceration, Enfleurage, Cold Press Extraction, and or Water Distillation. Lotta words huh? It takes a lot of work to make essential oils. Unfortunately, it also takes quite a bit of that plant to make even those tiny 10ml bottles you purchase. Of course, each plant varies. However, it still can lead to a larger environmental impact.

For instance, one pound of essential oil can be extracted from approximately 250 pounds of rosemary leaves, or from 150 pounds of lavender buds, or say 50 pounds of eucalyptus leaves. This is why you see some as more expensive than others. Unfortunately, you can see where the problem lies in plants that are more threatened or endangered. If you must use essential oils, source responsibly (and not from a Pyramid scheme but I'm not opening that can of worms)

Can I use infused oils in my practice?

Yes! Absolutely! All these oil recipes you see for spell oils are exactly that. You can even use the elemental correspondences of the carrier oils you use for spell oils. As an example Olive Oil is traditionally known for the fire element and Coconut Oil is water. The possibilities for your personal correspondence are endless!

Now I'll stop rambling. Here are a few methods I learned to infuse oils in my courses and through self-herbalist study.

Method One:

The Folk Method - The most common

Directions

Place DRIED herbs in a clean, dry jar. Leave at least 1 to 3 inches of open space above your herbs to cover with oil.

Fill the remaining space in the jar with the oil of your choice, making sure to cover herbs by at least 1 inch or more. If the herbs emerge above the surface of the oil at any point while infusing, pour more oil on top to ensure the herbs remain covered.

Cap the jar tightly and shake well.

Place the jar in a sunny, warm windowsill and shake once or more per day.

After 2 to 3 weeks, strain the herbs out of the oil using cheesecloth or a mesh strainer. Or you can leave it in but straining is recommended if you are using dropper bottles as it clogs the caps.

Pour into clean glass bottles.

Remember to label your jars with the date, type of oil, and herbs used! You WILL forget! Trust me.

Store in a cool, dark place. The oil may keep for up to a year.

Method Two:

The Heat Infused Method - Quick Infusion

Directions

Place herbs in the crock pot or double boiler. Cover with extra virgin olive oil (or other carrier oil of choice), leaving at least an inch or two of oil above the herbs.

Gently heat the herbs over very low heat (preferably between 100° and 140° F for 1 to 5 hours, until the oil takes on the colour and scent of the herb. Some recommend heating the oil for 48 to 72 hours at a controlled temperature of 100° F. Turn off the heat and allow it to cool. I personally prefer letting it sit in a crock pot for 72 hours as I feel like I get all of the benefits out of the herb.

Once oil is cooled, strain using cheesecloth.

Bottle in dry, sterilized glass bottles. LABEL your bottles with the date and contents before storing them.

Store in a cool, dark, dry place for up to six months.

Best herbs to infuse in oil

There are a countless number of herbs, spices and resins that can be infused into the oil. Please make sure these herbs are free from pesticides and chemicals (not found on the roadside). Dried herbs work best as you don't want your mixture spoiling sooner. Here are some great examples of herbs to use.

Pine needles

Calendula flowers

Chamomile flowers

Lavender

Lemon balm

Peppermint leaf

Rosemary leaf

Thyme leaf

There you have it! Now have fun and source responsibility.

Happy witching!

Want to read more?

On sustainability and impact:

Links:

Dangers of essential oils and pets:

Link:

Want to check out my other post? Look at my Masterpost

#witchcraft#witch#infused oils#spell oils#essential oils#aromatherapy#kitchen witchcraft#herbal magic#herbalism#herbalist#herbal medicine#witchblr

115 notes

·

View notes

Text

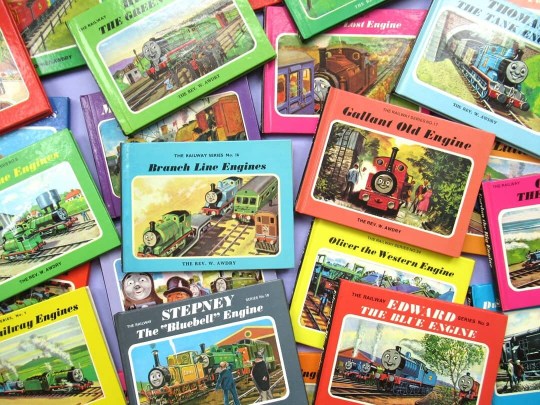

Traintober 2023: Day 1 - Free Day

Preservation on Sodor:

Sodor must be one of the most interesting places to look at when it comes to railway preservation, if not also road, sea and air preservation. For starters, the island’s railways are all still primarily run by vintage steam traction – but there’s also Harold, who is in his 60s or 70s at this point, Bertie the bus (who is nearing 100), Trevor and Terrence and George – not to mention the fact that the island seems to continue to have antique ships within its waters, including steam ships and fishing trawlers.

But of course, I want to focus on the railways – and in particular how Sodor must be the British hub for heritage railways, museums and other attractions. For starters, Sodor has by far the largest heritage railway system in the world for its size, with over 80 miles of mainline, several branchlines, a narrow-gauge railway, a mountain railway and a miniature gauge railway. It also has a massive fleet of engines – 80 by the Reverend’s count on the NWR alone – making it possibly the single largest working heritage railway in the UK, if not Europe. This would instantly attract many preservationists wishing to run their locomotives, meaning that mainline excursions and visitors would be a frequent sight on the island. This in turn would bring in tourists, who would make money for the NWR and the railway the engines belong to, as well as helping the Fat Controller if one of his enignes is unable to work. It would also give us as railfans the chance to see unique motive power on a variety of trains - like a Coronation Class pulling a slow goods, or a Hughes Crab on a China Clay train - things we don't get to see anymore.

Furthermore, Sodor is home to Crovan’s Gate Works, the largest steamworks of its kind in Britain. For its influence, I am going to turn to 60163 Tornado. When Tornado was built, her boiler had to be manufactured in Germany because there was just no one in the UK able to produce a boiler of the type, while the superheater header needed to be attempted by three foundries before it was assembled correctly. Crovan’s Gate Works, which is able to maintain a full fleet of engines including Gordon – who is also an A1 with many similarities – would have been able to do both in a far timelier manner. The same would go for all locomotive repair programs in the UK. Crovan’s Gate would either host locomotives or manufacture parts for them, becoming a hub for preservation across the country. Engines like Stepney or Green Arrow would be able to be overhauled at the Works, rather than be taken out of service. This would effect how many steam engines are in working order in Britain, if not Europe, as the refurbishment time would be significantly shortened - something that is compounded if said locomotive shares any components with a Sodor engine - like Talyllyn, Dolgoch, Flying Scotsman or any of the Black 5s, Panniers or Autotanks in preservation.

This brings me on to the last point: International Tourism. Sodor must be one of the most visited locations in Britain in this universe. For starters, there’s all the fans of the book and TV series (which are both canon and referenced in the books). This means that Sodor would have tens of thousands of families coming to the island from around the world annually to see the ‘Eight Famous Engines’ or the ‘Steam Team’, bringing in a massive amount of revenue for hotels, local businesses and the railways themselves. But there would also be the railfans who come with the aforementioned railtours, as well as international railfans who want to see steam in action in a mainline setting – something nearly impossible anywhere on the planet. Sodor has at least one airport (and probably two, considering in real life there is an airport on Walney Island near the real-life Vickerstown), six ports connected to the NWR, and a rail and road link to the UK. The island has the infrastructure to handle the flocks of tourists, and this would in turn benefit much of the rest of Northern England. This would majorly benefit the preservation world by bringing in funding for Sodor, which is in turn able to fund things like track upgrades, or overhauls for engines beyond their own railway. It also gives other railways a good place to promote themselves, as Sodor has a guaranteed market for tourists who may travel to these other railways.

You cannot understate how much these books have done for Sodor, and for railway preservation as a whole.

So, Sodor is at the very least a centre for preservation in the UK, with railtours, overhauls and masses of international tourists – but it’s also where a lot of engines were likely rescued from. We see it in Oliver and Douglas, but engines know of Sodor and its safety. I can imagine an alternate universe in which engines keep turning up throughout the 1960s, being brought to safety on Sodor and then sold to heritage railways, being overhauled at Crovan’s Gate before moving to their new homes. Sodor would act as an intermediate in this era, being able to do the paperwork to preserve engines due to its position in the national network while also being aligned with the cause of the heritage railways. Sodor is a safe haven for steam, and this would have a significant impact on its position as a preservation hub for the UK.

Back to the Master Post

#railway series#weirdowithaquill#thomas the tank engine#railways#traintober 2023#railway preservation#rambles

109 notes

·

View notes

Note

Wild and Engineer. Technology.

The Engineer looked intently at the remains of a Guardian. She giggled like a mad scientist as she picked up some of the metal parts. ...man Purah would love this kid.

Glider sat down next to her and looked at the pieces as well. He signed, "Enjoying yourself?"

She nodded enthusiastically. "Some of these pieces would be fascinating to implement in a vehicle. I think trains would still be superior to any "walking" mode of transport but these-" the Engineer grabbed the leg of the Guardian and moved it, watching the pieces slide smoothly together, "Could make beautiful connection points between cars so a train could turn more easily. It could even make it harder to knock over during sharp turns!"

Glider grinned, snickering, "I think that'd be less creepy than what they're for."

Engie nodded, then turned to delve further into the components of the guardian. She took out pieces Glider wasn't aware they had. "What are they powered by? I can't find a boiler or anything."

Glider grinned and grabbed some pieces of the metal. He arranged the pieces together in a rather hodgepodge fashion, held together with pieces of wrapped wire and springs. The Engineer watched intently, confused and curious. Glider supposed it wasn't very obvious for what it was when it stood still. So he grabbed an Ancient Core from the slate, nestled it into the center, and the hodgepodge creation of gears and springs lept into action.

"A FROG!" Engie cheered, laughing and practically pouncing to grab it. She nearly ate grass in the first attempt. The mechanical creature lept around her, and she fell back to capture it in her hands. She giggled and inspected the Core as she held it up. "This is so COOL! Where did you learn to make that?"

Glider shrugged, "I just watch Purah sometimes. That one's easy."

"And this is the power source?" Engineer said as she poked it lightly.

"Be careful. It explodes sometimes.... No. Usually explodes. Not very stable."

Engineer's eyes widened, but made no move to put it down. "Ohh. How do you think it works?"

Glider hummed and flipped through the slate. He pulled out an electric keese wing and a topaz.

"Ew," She said with a giggle, "I don't think that is part of this."

Glider snorted and shook their head, taking the frog contraption and removing the core. He placed the stone inside, adjusting some of the wire pieces to secure it better. Then, they smacked it with the wing. An electric charge that made the hairs of his arm stand on end and brought a slight tingling taste to his tounge made the mechanism leap up dramatically.

"Woah! Electric charge! Fascinating."

The charge petered out quickly, but the Engineer quickly made grabby hands for the wing. Glider laughed, handing it off.

17 notes

·

View notes

Text

traintober - day 12/13 - something borrowed, something new

"In 1921, the Corris acquired a fourth locomotive from Kerr Stuart and No.2 became a standby. No. 1 had received a new boiler in 1913, which had seen little use, and in 1922 the railway began the process of creating one working locomotive from components of the other two Hughes locos. Evidence suggests that the resulting locomotive had: frames made up of plates from Nos. 1 and 3; the boiler and saddle tank of No. 1; the cab and bunker of No. 3; and possibly motion parts from No. 2." (wikipedia)

#ttte#ttte sir handel#ttte peter sam#been busy so today's one is simple#anyway. i love the story of how sir haydn was built from the three Corris Hughes locomotives#sir handel was built *for* MSR. but perhaps his parts werent made just for him#capy's graffiti#capy posting#traintober 2023

66 notes

·

View notes