#Programmable logic controllers

Explore tagged Tumblr posts

Text

Exploring the PLC Industry: Rabwellplc and Schneider Industrial Electric Motors

Hello everyone! I'm excited to share my thoughts on the PLC industry, particularly focusing on the amazing brand Rabwellplc and their collaboration with Schneider Electric.

As we all know, programmable logic controllers (PLCs) have revolutionized the automation industry, and Rabwellplc is at the forefront of this innovation. Their commitment to quality and efficiency has made them a trusted name among engineers and manufacturers alike.

The integration of Schneider Electric products with Rabwellplc products enhances the performance and reliability of automation systems. These products are known for their durability and energy efficiency, making them an excellent choice for various industrial applications.

I recently had the opportunity to work on a project involving Rabwellplc's PLC systems paired with Schneider products, and I was genuinely impressed by how seamlessly they operate together. The ease of integration and the robust functionality allowed us to achieve our project goals ahead of schedule.

In conclusion, the PLC industry continues to thrive, and brands like Rabwellplc, along with Schneider Electric, are leading the way in providing innovative solutions for automation challenges. I'm looking forward to seeing how these technologies evolve in the future!

Thank you for reading, and I hope this information inspires others in the field!

Best regards!

#energy efficiency#innovation#Rabwellplc#programmable logic controllers#automation systems#Schneider Electric#automation

0 notes

Text

Exploring the Future of PLC Industry with Rabwellplc

Hello everyone! I'm excited to share my thoughts on the PLC industry, particularly focusing on the innovative brand Rabwellplc. As we know, PLCs (Programmable Logic Controllers) play a crucial role in automating industrial processes, and Rabwellplc stands out for its commitment to quality and reliability.

One of the key aspects of Rabwellplc is its integration with industrial electric motors. These motors are known for their efficiency and durability, making them an excellent choice for various applications. With the combination of Rabwellplc's advanced PLC technology and robust electric motors, industries can achieve higher productivity and lower operational costs.

If you're in the market for reliable automation solutions, I highly recommend considering Rabwellplc. Their products not only enhance operational efficiency but also contribute to a more sustainable future in the industrial sector. Let's embrace the advancements in technology and work towards a brighter, automated future together!

#operational costs#durability#automation solutions#electric motors#Programmable Logic Controllers#technology advancements#industrial automation#efficiency

0 notes

Text

NX-ERA Xpress PLC For salt spray Chamber Automation

In the industrial domain, corrosion is not just a problem, it’s a stealthy destroyer. From car parts to ocean gear to electronics, the shadow of rust looms over all. That’s where the salt spray chamber comes in useful, enabling us to simulate the most extreme conditions. However, the catch is that manual systems don’t cut it anymore.

Enter the NX-ERA Xpress PLC—a smart, compact PLC for industrial automation that’s changing the game for good.

We at Messung have a strong expertise in programmable logic controllers, and today we’re demonstrating to you why a salt spray chamber needs aSCADA for demanding environments that’s fluent in Industry 4.0.

#plc#micro plc#mini plc#salt spray chamber#compact plc#modular plc#compact plc for industrial automation#programmable logic controllers#and today we’re demonstrating to you why a salt spray chamber n#rugged modular PLC#industry 4.0#PLC (Programmable Logic Controller)#SCADA

0 notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

Programmable Logic Controllers

ROC Automation offers high-quality programmable logic controllers (PLCs) for industrial automation, ensuring precision and efficiency. Designed for seamless integration, these controllers optimize processes, enhance productivity, and reduce downtime. With advanced features and reliable performance, PLCs support various applications, from manufacturing to energy management, providing smart solutions for automation needs. Buy now on https://rocautomation.co/

0 notes

Text

Why Siemens Industrial Automation is the Key to Your Success

These days, competing has become synonymous with the embracing of innovative technology. Siemens Industrial Automation is the solution for all businesses intending to increase productivity, streamline processes, and reduce operational costs. Siemens is deliberately focused on innovativeness; therefore, it features a variety of top-of-the-line automation products for diverse needs of the industry.

Why Choose Siemens Industrial Automation?

Siemens is the finest industrial automation provider. It has a complete range of products for industries of all sizes. Here is what makes Siemens special:

Advanced Technologies: Garden Industrial Solutions by Siemens construct with preventive innovations, that work flawlessly to automate daily tasks.

Applications: From manufacturing to energy grids, all kinds of applications and extreme efficiency are available from Siemens.

Reliability: Decades of accumulated experience make it last with the utmost reliability in products.

Explore Siemens Automation Products

Siemens has indeed a wide variety of products catering to industrial automation applications and among these popular Siemens Automation Products are:

Siemens Programmable Logic Controller (PLC): These sturdy controllers form the backbone of industrial automation, providing precise control over machinery and processes, whether small or large production lines or huge units, through their Siemens PLCs, which are reliable and scalable.

Siemens Controllers: Optimally designed Siemens controllers boost the efficiency of very large industrial systems. Everything from other Siemens solutions would seamlessly be integrated into a streamlined flexible workflow.

Benefits of Siemens Programmable Logic Controller

Siemens Programmable Logic Controllers are a fundamental part of automation today. They have the following functionalities:

Flexibility: Suitable for usage from small to large.

User-Friendly Programming: Simple programming that saves much time and resources.

Improving Efficiency: Less downtime and higher productivity.

Energy Saving: Help for the industries to achieve their sustainability goals.

Siemens PLCs are fitted according to every requirement be it automotive, food processing, or packaging industry.

Industries Benefiting from Siemens Industrial Automation

Siemens products are revolutionizing industries all around the world. Some examples are:

Manufacturing: Higher Efficacy Automation of Assembly Lines.

Energy: Optimize Grid Performance and Ensure Sustainable Energy Solutions.

Pharmaceuticals: Provide Precision in Production Processes.

Logistics: Optimize Warehouse Operations That Save Time in Deliveries.

Future-Proof Your Business with Siemens Controllers

Siemens Controllers play a major role in all industrial automation systems. They allow an industry to get real-time decision-making insights that can be trusted for quick decision making. Choosing Siemens controllers is investing in a future-proof investment and enables adaptation with evolving industrial demands.

Final Thoughts

Siemens Industrial Automation paves the way for businesses to excel in a competitive market. Unlock new avenues of efficiency and productivity with industry-leading Siemens Automation Products, including Siemens Programmable Logic Controllers and reliable Siemens Controllers.

Start your journey with Naksh Technology Solutions LLP towards smarter automation today. Check out the complete offerings of Siemens to see how you can transform your industrial operations.

#Siemens Industrial automation#Siemens Automation Products#Siemens Controllers#Programmable logic controllers

0 notes

Text

How Siemens Controllers Are Revolutionizing Music Production Studios

In the rapidly evolving world of music production, the quest for greater efficiency, precision, and creative control has led to significant advancements in technology. Among the innovations driving these changes are Siemens controllers, which are revolutionizing how music is produced, mixed, and mastered. By integrating Siemens' cutting-edge automation technology into music production studios, professionals are achieving new levels of productivity and sonic quality. Here's how Siemens controllers are making waves in the music industry.

Siemens Controllers: The Backbone of Modern Music Studios

Siemens controllers, including programmable logic controllers (PLCs) and motor controllers, are renowned for their reliability and precision in various industrial applications. However, their impact extends beyond traditional manufacturing environments. In modern music production studios, Siemens controllers are enhancing automation, improving control over studio equipment, and streamlining production processes.

One notable example is the use of Siemens’ SIMATIC PLCs in controlling and automating audio equipment. These advanced controllers manage everything from digital mixing consoles to automated fader adjustments, providing sound engineers and producers with a level of control that was previously unattainable.

Enhancing Efficiency with Siemens Automation Technology

Efficiency is paramount in a music production studio, where time is often as valuable as creativity. Siemens controllers play a crucial role in automating repetitive tasks and optimizing workflows. For instance, automated mixing and mastering processes are facilitated by Siemens controllers, which handle complex signal routing and processing tasks with precision.

By integrating Siemens’ automation technology, studios can reduce the time spent on manual adjustments and focus more on the creative aspects of music production. Automated systems controlled by Siemens controllers ensure that equipment settings are consistent and repeatable, which is essential for achieving high-quality results across multiple sessions and projects.

Precision Control with Siemens Motor and Motion Controllers

In a music studio, precise control over equipment is essential for achieving the desired sound quality. Siemens motor controllers and motion control systems provide unparalleled accuracy in adjusting audio equipment. Whether it’s controlling the movement of a motorized microphone stand or fine-tuning the position of speakers and monitors, Siemens controllers ensure that every adjustment is executed with pinpoint accuracy.

The ability to program and control these adjustments via Siemens’ programmable logic controllers allows sound engineers to create intricate setups and configurations that can be replicated with ease. This level of control enhances the overall quality of recordings and ensures that the production process is smooth and efficient.

Streamlining Production with Advanced Automation and Process Automation

Process automation is transforming music production studios by automating complex workflows and enhancing overall efficiency. Siemens controllers are at the heart of this transformation, offering solutions that streamline various aspects of the production process.

For example, Siemens controllers can automate the setup and calibration of audio equipment, reducing the time needed for manual adjustments. This automation extends to the management of recording sessions, where Siemens controllers handle tasks such as track switching, level adjustments, and signal routing with minimal human intervention.

Additionally, the integration of Siemens controllers into digital audio workstations (DAWs) allows for seamless control of software and hardware components. This integration ensures that all elements of the production process work in harmony, resulting in a more cohesive and efficient workflow.

The Impact of Siemens Controllers on Creative Processes

Beyond improving efficiency and precision, Siemens controllers also have a significant impact on the creative processes within music production studios. By automating routine tasks, these controllers free up time for producers and engineers to focus on creative experimentation and innovation.

The ability to program complex automation sequences and recall them with ease enables sound engineers to explore new creative possibilities. For instance, automated dynamic changes in a mix or the creation of intricate effects can be accomplished effortlessly using Siemens controllers, allowing for greater experimentation and artistic expression.

Implementing Siemens Controllers in Your Music Studio

Integrating Siemens controllers into a music production studio involves several key steps. First, assess your studio’s current setup and identify areas where automation and control improvements can be made. Siemens offers a range of controllers and automation solutions, including the SIMATIC PLCs and motor controllers, that can be customized to meet your specific needs.

Once the appropriate Siemens controllers are selected, the next step is to implement them into your studio’s infrastructure. This process may include configuring the controllers, integrating them with existing equipment, and training staff to utilize the new technology effectively.

Ongoing maintenance and support are essential to ensure that Siemens controllers continue to perform optimally. Siemens provides comprehensive support services, including technical assistance and software updates, to help you maximize the benefits of their controllers and maintain peak performance.

Conclusion

Siemens controllers are revolutionizing music production studios by enhancing efficiency, precision, and creativity. With their advanced automation technology, including programmable logic controllers (PLCs) and motor controllers, Siemens is setting new standards for control and automation in the music industry. By integrating Siemens controllers into your music production setup, you can streamline workflows, improve the quality of your productions, and unlock new creative possibilities. As the music industry continues to evolve, Siemens controllers will remain at the forefront of innovation, driving the future of music production.

#siemens#siemens controller#siemens controllers#industrial automation#programmable logic controllers#motor controllers#motion control#factory automation#automation technology#process automation#simatic#controllers#automation#controller#production#automated

0 notes

Text

Industrial Automation Trends Shaping The Future: Insights-for-electricians-students-and-institutions

Are you an electrician, student, or institution interested in staying ahead in the ever-evolving field of industrial automation? With the rapid advancement of technology and the growing influence of artificial intelligence (AI), it is crucial to be aware of the latest trends shaping the future of industrial automation. This blog will explore some of these trends, such as the use of collaborative robots in manufacturing and the adoption of predictive maintenance through AI, and discuss their implications for electricians, students, and institutions in the field. Know more: https://www.pmv.net.au/industrial-automation-trends-shaping-the-future

0 notes

Text

Why Rugged PLCs Are Essential For Demanding Industrial Environments

Industrial environments are far from the sterile climate of a computer lab. From scorching steel mills to dusty mines, these settings present a harsh reality for electronics: extreme temperatures, relentless vibrations, and omnipresent dust. In such unforgiving conditions, even the most sophisticated equipment can struggle. This is where rugged Programmable Logic Controllers (PLCs) step in, offering a lifeline of reliable automation amidst the industrial chaos.

The Brutal Reality Of Industrial Environments

Imagine a factory floor: molten metal roars from furnaces, robots tirelessly weld and assemble, and heavy machinery vibrates with each operation. This is just one example of the harsh realities electronics face in industrial settings. Here are some key challenges:

Extreme Temperatures

Industrial environments can subject equipment to various temperatures. From the frigid chill of freezers to the searing heat of furnaces, conventional electronics can malfunction or even permanently fail outside their narrow operating range.

Relentless Vibrations

The constant hum of machinery and the movement of heavy equipment create a constant barrage of vibrations. These vibrations can damage delicate electronic components and lead to erratic operation.

Dust And Contaminants

Industrial processes generate a constant barrage of dust, metal shavings, and other airborne contaminants. These contaminants can infiltrate sensitive electronics, causing short circuits, overheating, and premature component failure.

Rugged PLCs: Built To Endure

Standard PLCs, while powerful tools are often not designed for such unforgiving environments. Rugged PLCs, however, are specifically engineered to withstand these harsh conditions. Here's what sets them apart:

Wide Operating Temperature Ranges

Rugged PLCs boast a much wider operating temperature range than their commercial counterparts. This allows them to function reliably in extreme heat or cold, ensuring consistent performance across diverse industrial settings.

Vibration And Shock Resistance

Rugged PLCs are built with robust construction and shock-mounted components to withstand the constant vibrations and occasional bumps common in industrial environments. This ensures reliable operation even under heavy machinery or on mobile platforms.

Conformal Coating

A conformal coating acts as a protective layer on the PLC's circuit board. This coating repels dust, moisture, and other contaminants.

Rugged PLCs in Action: Real-World Benefits

The advantages of rugged PLCs translate into tangible benefits for various industries, particularly heavy manufacturing:

Reliable Automation In Steel Mills

Rugged PLCs ensure the smooth operation of automated processes in scorching steel mills, where temperatures soar and molten metal flows. They control critical functions like furnace temperature regulation, material handling systems, and rolling mill operations, ensuring consistent product quality and production uptime.

Uninterrupted Operation In Mining

Dust and vibrations constantly threaten electronics deep within mines. Rugged PLCs, resistant to both, can reliably control mining equipment, ventilation systems, and conveyor belts, ensuring the safety and efficiency of mining operations.

Enhanced Performance In Chemical Processing Plants

Chemical processing plants often operate in environments with corrosive fumes and extreme temperatures. Rugged PLCs, resistant to these challenges, can control vital processes like mixing, blending, and distillation. This ensures accurate and safe operation, minimising the risk of accidents and production delays.

Final Thoughts

Reliability is paramount in the unforgiving world of industrial automation. Rugged Programmable Logic Controllers, designed to withstand temperature, vibration, and dust extremes, offer a dependable solution for complex automation tasks. Their ability to ensure uninterrupted operation translates to improved production efficiency, enhanced safety, and reduced downtime, making them the cornerstone of robust industrial automation systems.

0 notes

Text

An Introduction to Programmable Logic Controllers

From building phones to assembling cars and producing consumer packaged goods, there is a constant drive to automate every step of the manufacturing process. Machines are capable of producing more, have an increased tolerance level, and have a higher quality level of craftsmanship when it comes to repetitive processes.

Programmable logic controllers (PLCs) were created in the last century to meet the demand for improved automation. At their most basic level, PLCs are specialized computers designed to control machines and processes.

0 notes

Text

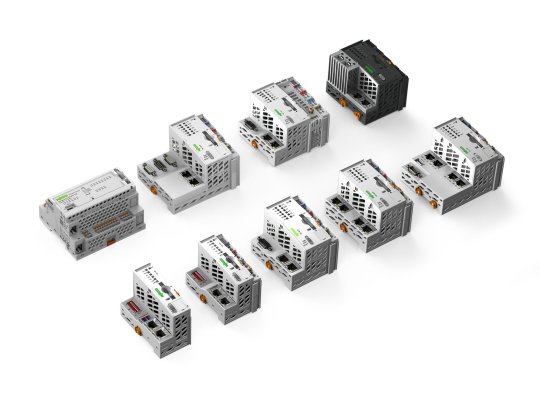

Types of programmable logic controllers?

PLC Types Based on Size Small [PLC] Medium [PLC] Large [PLC]

2.PLC Types Based on Hardware Setup ·Compact PLC ·Modular PLC

3.PLC Types Based on Power Supply

🌐Website :- https://asteamtechno.com

👉Contact us :- +919537840404

📧Email :- [email protected]

#trending#tumblr trends#viralpost#automation#viral#trendingnow#bestdeals#allen bradley#rockwell automation#plc#programmable logic controllers#types

1 note

·

View note

Text

Programmable Logic Controller Market Set to Hit US$ 17.2 Bn with Strong Demand from Smart Industries

The global programmable logic controller (PLC) market, valued at US$ 11.6 Bn in 2022, is forecast to grow at a CAGR of 4.7% between 2023 and 2031, reaching a market value of US$ 17.2 Bn by the end of 2031, according to the latest industry insights. This growth is propelled by a surge in demand for industrial automation, smart manufacturing, and increased integration of the Industrial Internet of Things (IIoT).

Market Overview: A programmable logic controller (PLC) is a digital computer used to automate electromechanical processes, particularly in manufacturing environments. These devices are integral to the efficient operation of assembly lines, robotic devices, and any activity requiring high-reliability control and ease of programming. With increasing adoption across automotive, food & beverage, chemical, energy & utility, and construction industries, the global PLC market continues to expand in scope and application.

Market Drivers & Trends

The rising trend of smart factories and Industry 4.0 is among the most significant growth drivers. Manufacturers are increasingly adopting automation to reduce operational costs, improve productivity, and enhance precision. PLCs play a critical role in this transformation by allowing control over complex industrial processes with minimal human intervention.

Additionally, the growing need for data-driven decision-making, along with advancements in machine learning and artificial intelligence, is leading to deeper integration of PLCs in industrial settings. As automation becomes central to production and operational strategies, the demand for PLCs is expected to surge further.

Latest Market Trends

One of the most notable trends is the shift toward modular PLCs, which accounted for over 68.2% of the market share in 2022. These PLCs are gaining popularity due to their scalability and suitability for large-scale, complex automation tasks. Modular systems offer higher flexibility, can handle thousands of inputs/outputs, and support multitasking environments—making them ideal for high-volume manufacturing operations.

Another trend is the miniaturization of PLCs, which supports their deployment in compact systems and small machinery, especially in consumer electronics and smaller automated units.

Key Players and Industry Leaders

The competitive landscape is fragmented yet dominated by global industrial automation giants. Leading companies in the PLC market include:

Siemens

Rockwell Automation

Mitsubishi Electric Corporation

Schneider Electric

OMRON Corporation

ABB

Panasonic Corporation

Bosch Rexroth Corporation

Delta Electronics, Inc.

Honeywell International Inc.

These companies continue to drive innovation through strategic partnerships, R&D investments, and product expansions to enhance their market share and global footprint.

Recent Developments

Crouzet, in December 2022, launched Millennium Slim, the slimmest PLC in the world, tailored for compact industrial applications.

In July 2022, OMRON Corporation introduced the CP2E Micro PLC, designed for smaller devices and capable of data collection and machine-to-machine communication. This supports low-cost automation solutions for small- and mid-sized enterprises.

Electronics Corporation of India Limited (ECIL) released its own PLC and SCADA software in May 2022, targeting industrial control applications in Indian manufacturing ecosystems.

These product introductions underline the market’s commitment to technological advancement and responsiveness to evolving industrial demands.

Market Opportunities

The expansion of material handling systems, especially in e-commerce logistics, warehousing, and food processing industries, presents substantial growth potential for PLC integration. In material handling, PLCs streamline storage, movement, and tracking—drastically improving throughput and inventory management.

Additionally, the increasing popularity of energy-efficient manufacturing and sustainability initiatives provides ample opportunity for advanced PLC systems that help monitor and reduce energy consumption across production lines.

Gain a preview of important insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=32672

Future Outlook

The future of the programmable logic controller market lies in enhanced interoperability, cloud integration, and edge computing. With greater reliance on smart infrastructure and connected devices, PLCs are expected to evolve into more intelligent, connected controllers.

The incorporation of AI-powered PLCs is expected to revolutionize industrial automation by enabling predictive maintenance, self-diagnosis, and adaptive process control. As PLCs continue to advance, their use will extend beyond industrial sectors into smart cities, transportation systems, and building automation.

Market Segmentation

By Offering:

Hardware: CPU, I/O Modules, Power Supply, Memory System

Software

Services

By Type:

Compact PLC

Modular PLC

Nano, Micro, Small, Medium, and Large PLCs

By Application:

Material Handling

Packaging & Labeling

Process Control

Safety Monitoring

Energy Management

Home & Building Automation

Industrial Equipment Control

By End-use Industry:

Automotive

Energy & Utilities

Food & Beverage

Pharmaceuticals

Construction

Oil & Gas

Semiconductors & Electronics

Regional Insights

Asia Pacific held the largest market share of 36.3% in 2022, led by strong industrial growth in China, Japan, South Korea, and India. The increasing demand for smart manufacturing systems and compact automation solutions in the region is expected to maintain its dominance through 2031.

North America, with a market share of 26.4% in 2022, continues to grow due to early adoption of factory automation and significant investment in smart infrastructure in the U.S. and Canada.

Europe remains a hub for automation technology innovation, with countries like Germany, the U.K., and France focusing on Industry 4.0 implementation across automotive and manufacturing sectors.

Why Buy This Report?

This comprehensive report offers:

Detailed market size, forecast, and growth rate

In-depth competitive landscape and company profiling

Analysis of key market drivers, trends, and opportunities

Region-wise breakdown for strategic decision-making

Porter’s Five Forces, value chain, and trend analysis

Insights into technological developments and their impact

Market segmentation for customized investment strategies

With expert analysis and forward-looking insights, this report serves as a valuable resource for stakeholders, investors, industrial engineers, and policymakers seeking to navigate and capitalize on the fast-evolving programmable logic controller market.

Explore Latest Research Reports by Transparency Market Research: 5G Smart Antenna Market: https://www.transparencymarketresearch.com/5g-smart-antenna-market.html

Solid State Transformer Market: https://www.transparencymarketresearch.com/solid-State-transformer.html

Interactive Display Market: https://www.transparencymarketresearch.com/interactive-display-market.html

GaN Epitaxial Wafers Market: https://www.transparencymarketresearch.com/gan-epitaxial-wafers-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Enhancing Salt Spray Chamber Performance with PLC Automation – Powered by NX-ERA Xpress

In the industrial domain, corrosion is not just a problem, it's a stealthy destroyer. From car parts to ocean gear to electronics, the shadow of rust looms over all. That's where the salt spray chamber comes in useful, enabling us to simulate the most extreme conditions. However, the catch is that manual systems don’t cut it anymore.

Enter the NX-ERA Xpress PLC—a smart, compact PLC for industrial automation that’s changing the game for good.

We at Messung have a strong expertise in programmable logic controllers, and today we're demonstrating to you why a salt spray chamber needs a rugged modular PLC for demanding environments that's fluent in Industry 4.0.

What is a Salt Spray Chamber?

A salt spray chamber is a specialized testing environment that helps industries evaluate the durability of coatings, components, and materials under harsh environments. These rooms are intended to:

● Simulate corrosive environments

● Test the metals, coatings, and components

● Provide accelerated ageing tests in controlled environments

Industries that swear by it:

● Automotive Companies

● Paint and Coating Producers

● Marine Equipment Manufacturers

Electronics OEMS

Why Automate Salt Spray Chambers with a PLC?

Consider switching temperatures, humidity levels, and spray intervals by hand every hour. Time-consuming, prone to error, and a time-waster. A PLC (Programmable Logic Controller) coordinates the whole process—managing logic, control, timing, and communication like a maestro directing a symphony.

Meet the NX-ERA Xpress PLC – your multi-protocol, multi-project, one seamless controller. It never sleeps, never messes up, and always provides you with accurate data. From Messung Industrial Automation, a cost-effective PLC that is MQTT and OPC UA enabled, UL certified, and ready for the most demanding automation tasks.

Key Roles of a PLC in Salt Spray Chambers

Behind each reliable corrosion test is a smart PLC working diligently to maintain consistency, compliance, and control. What it provides to the chamber is:

Precise Temperature Regulation - Dry bulb, wet bulb, ambient—all held constant with surgical accuracy by PID loops. No ups and downs, just stable, calibrated climates.

Humidity Control - Because one droplet too much or too little throws the test off balance. A smart PLC fine-tunes every moisture movement to mimic real-world conditions.

Spray System Management - Controls mist cycles, nozzle diameters, sizes, and flows to ASTM/BIS/ISO specifications. No guessing—only predictable, programmable spray patterns.

Test Cycle Automation - Start, stop, repeat—all done without ever lifting a finger. Install it once, and the PLC takes care of complex test schedules with ease and accuracy.

Alerts & Notifications - Monitors for anomalies, alerts you in real-time, and records deviations for later reference. The watchdog your lab never knew it had.

In short, a robust PLC is not just a controller—it's the brain behind every flawless salt spray test. Accuracy-driven, standards-enabled, and always on the job.

How NX-ERA Xpress PLC Transforms Salt Spray Testing

In the high-pressure world of corrosion testing, consistency and accuracy are not just a good idea, but a necessity. Manual control isn't capable of keeping up with tight industry regulation or sophisticated test cycles. That's where the NX-ERA Xpress PLC comes in—turning laborious processes into error-free, data-driven automation that produces perfect results, every time.

Let's break it down.

Accuracy with PID Control - Control temperature and humidity like an expert, with advanced PID algorithms that make continuous adjustments in both dry and wet bulb parameters. This ensures every salt spray cycle is to your exact specification—no overshoots, no drift—so you achieve flawless repeatability in every test.

Versatile I/O for Complete Control - From compressors and solenoid valves to heating coils and compressors, the modular I/O design lets you mix analogue and digital channels in any combination necessary. You have total control over each chamber component, expanding and contracting as test demands vary or grow.

Communication-Ready - Native support for MQTT, OPC UA, Modbus TCP, PROFINET, and EtherCAT allows for plug-and-play real-time data logging to your SCADA/HMI dashboards. Remote monitoring of vital parameters, automatic export of logs, and integration with your Industry 4.0 configuration become a breeze.

Custom Tests, Custom Logic - Whether ASTM B117, ISO 9227, or your own proprietary cycle, programmable sequences allow you to specify start/stop times, spray cycles, and number of repetitions. Switch to new standards with ease without re-wiring or re-engineering your setup.

Remote Diagnostics - Eliminate extraneous lab trips with integrated troubleshooting capabilities. See live status, detect faults, and edit logic remotely—so you can maintain tests operating smoothly, even from miles away.

With the NX-ERA Xpress PLC, salt spray testing is smarter, faster, and more reliable. Upgrade your chamber control today and see your lab's efficiency—and confidence—take flight.

Industry Applications

From the lab to the great outdoors, salt spray testing holds up over time in any sector. It's the gold standard for corrosion resistance testing, subjecting your products to the ultimate test of the harshest conditions, without breaking a sweat.

Automotive - Rust-proofing bumpers, body panels, and alloy wheels. Because no one wants corrosion writing their brand off.

Paint & Coating - Verify finish quality in tough conditions. Observe how your coat stands up when the weather gets nasty.

Electronics - Ensure devices do not short or fail in high-salt air zones. Because reliability should not vanish with the sea breeze.

Marine & Offshore - Replicate real sea spray on metal parts and composite structures. For wave-riding performance and not rust.

Whether you're creating for highways, oceans, or skies, salt spray testing subjects your innovations to the elements, rain or shine. Test smart. Build bold. Trust durability.

Unique Features of the NX-ERA Xpress PLC

Where ruggedness, connectivity, and accuracy meet, the NX-ERA Xpress PLC is the ideal controller for the industrial automation of the new age. Built to satisfy the tough requirements of the new factory and laboratory, it provides an ideal combination of cutting-edge features designed for accuracy.

Small, and robust structure - Designed to be flexible and space-efficient installation without sacrificing strength.

IoT-based PLC for automation control in real-time - Enables end-to-end data exchange and remote monitoring to enhance Industry 4.0 capabilities.

Supports multiple protocols natively - Enables effortless connection to industrial networks of different types like PROFINET, EtherCAT, and Modbus TCP.

Smoother is used as a mission-critical safety PLC - Designed to ensure fail-safe operation where safety is never an option.

Designed to endure tough conditions with rock-solid dependability - Built to last through the toughest conditions, providing smooth operation under trying conditions.

Together, these capabilities make the NX-ERA Xpress PLC a valuable ally in taking your automation journey with confidence and control.

IoT PLC for Industry 4.0 Labs

In a smart lab, you decide in milliseconds. You need a PLC that can talk with your MES, ERP, cloud dashboards, and even mobile applications.

NX-ERA Xpress is an intelligent programmable controller for intelligent manufacturing systems that connects, communicates, and controls. With MQTT over TLS 1.2, OPC UA, and real-time updates, it's your gateway to Industry 4.0.

Why Messung for Your Salt Spray Automation?

Where passion and precision meet, innovation happens. We combine decades of experience with automation driven by innovation to provide smart salt spray solutions designed for performance, efficiency, and durability.

● 4 Decades of Automation Experience

● Strong R&D Backing and Engineering Support

● Global system integrator network

● Economical and UL-approved PLC alternatives

● Backed by a promise—We don't just automate, we enhance.

Join forces with Messung and go beyond mere automation—into a world where quality, reliability, and intelligent control govern every result.

Final Word: Don’t Let Rust Eat Into Your Reputation

Salt spray testing is the ultimate protection in demonstrating your product's endurance. One mistake—whether it's temperature fluctuation or skipped spray cycle—can cause damage to your brand, expense in recalls, or safety malfunction. Why take the risk?

Let NX-ERA Xpress PLC, an intelligent compact PLC for industrial automation, get behind the wheel. With IoT-capable PLC functionality, multi-protocol capability such as Modbus, PROFINET, EtherCAT, OPC UA, and MQTT, it provides reliable precision you can count on. Supported by our 4 decades of automation expertise, the rugged modular PLC for extreme environments guarantees your salt spray chamber operates like clockwork—every time.

Whether you are replacing or starting from scratch, this budget PLC with MQTT and OPC UA future-proofs your test environment. Salt corrodes. But not with our NX-ERA Xpress PLC. Your performance—and your reputation—are never compromised.

FAQs

Why is NX-ERA Xpress superior to other compact PLCs?

It combines tough construction, multiprotocol support, onboard IoT capabilities, and price efficiency—all within a compact size.

Which laboratories can be served by this Smart PLC?

Any corrosion, materials, or environmental testing laboratory requiring precise, automated, and repeatable results will be significantly helped.

Is NX-ERA Xpress suitable for harsh environments?

Indeed. It's a tough PLC that can withstand heat, humidity, and electrical stress—perfect for industrial-strength test labs.

Does NX-ERA Xpress support SCADA systems?

Yes. With natively supported MQTT, OPC UA, and Modbus TCP, it integrates seamlessly with the majority of contemporary SCADA systems.

#compact PLC#programmable logic controllers#rugged modular PLC#Industry 4.0.#salt spray chamber#PLC (Programmable Logic Controller)#cost-effective PLC#robust PLC#PID Control#smart PLC#Modbus#SCADA#salt spray testing#industrial automation#IoT-based PLC for automation control

0 notes

Text

Programmable Logic Controller Market Anticipated to Grow Owing to Automation Demand

The Global Programmable Logic Controller Market is estimated to be valued at USD 12.40 Bn in 2025 and is expected to exhibit a CAGR of 4.3% over the forecast period 2025 to 2032. Programmable logic controllers (PLCs) represent a critical segment of industrial automation technology, designed to monitor inputs, make logic-based decisions, and control outputs in real time. Functioning as ruggedized computers, PLCs offer unparalleled reliability, scalability, and flexibility across manufacturing, automotive, food & beverage, and oil & gas sectors. In the context of Industry 4.0, where digitalization and connectivity drive operational excellence, Programmable Logic Controller Market Insights serve as the foundational element for implementing smart factories, predictive maintenance practices, and energy management systems. By providing advanced diagnostics, traceability, and easy programming through ladder logic or structured text, these controllers reduce downtime, lower maintenance costs, and enhance business growth by boosting overall equipment effectiveness.

Get more insights on,Programmable Logic Controller Market

#Coherent Market Insights#Programmable Logic Controller#Programmable Logic Controller Market#Programmable Logic Controller Market Insights#Ladder Logic

0 notes

Text

Remote Monitoring with PLC Panels: Managing Your Plant from Anywhere

Introduction

In today’s fast-moving industrial world, being physically present on the shop floor every hour of the day is neither practical nor necessary. Thanks to modern PLC Panels, plant managers and engineers can now monitor and control their operations from virtually anywhere.

This is where remote monitoring comes in—a game-changing feature that turns your PLC Panel into a smart control center for your entire plant.

What is Remote Monitoring in PLC Panels?

Remote monitoring allows real-time access to your PLC Panel’s data through cloud-based platforms or networked software systems. It enables you to:

View machine status live

Monitor performance metrics

Receive alerts and diagnostics

Control start/stop operations remotely

Whether you’re at another site, at home, or travelling, you can manage your plant operations with just a laptop or smartphone.

Benefits of Remote Monitoring with PLC Panels

Real-Time Oversight Instantly check the status of equipment and production without being on-site.

Faster Problem Resolution Receive immediate alerts for faults, so downtime can be minimized.

Cost Savings Reduce the need for constant physical supervision and travel between sites.

Improved Decision-Making Access to live data helps you make informed decisions quickly.

Enhanced Safety Monitor high-risk processes remotely, minimizing exposure for workers.

Ready to take control from anywhere? Partner with a reliable PLC Panel Manufacturer to implement secure, remote-ready automation systems.

Key Features to Look For in Remote-Ready PLC Panels

Ethernet and Wi-Fi Connectivity Enables seamless data transfer between your PLC and remote devices.

Cloud Integration Support Compatible with platforms like MQTT, OPC UA, or custom dashboards.

Secure Access Protocols SSL encryption, VPN access, and password protection keep your system safe.

User-Friendly Interfaces Easy-to-use mobile or web apps that show real-time visualizations.

SCADA or HMI Compatibility Gives a centralized view with alarms, trends, and historical data logs.

Industries That Benefit the Most

Water Treatment Plants – Monitor pumps, levels, and chemical dosing remotely

Renewable Energy Farms – Supervise solar or wind operations from central control

Cold Storage Units – Keep track of temperature and humidity offsite

Manufacturing Units – Detect faults or delays without halting production

Agricultural Automation – Manage irrigation or feeding schedules remotely

How to Get Started

Collaborate with an experienced Programmable Logic Controller Panel Manufacturer who can:

Customize the panel with remote access modules

Integrate your system with cloud services

Train your team to monitor and control remotely

Ensure top-level cybersecurity protocols are in place

Conclusion

Remote monitoring with PLC Panels is no longer a luxury—it’s a necessity in a digital-first industrial world. It saves time, boosts productivity, and enhances control like never before. To enable this, choose a PLC Panel Manufacturer that delivers smart, secure, and remote-ready solutions tailored to your industry.

Control your plant from anywhere—talk to a trusted PLC Panel Manufacturer and upgrade your operations today.

Also read:

PLC Panels vs. SCADA Systems: Understanding Their Roles and Differences

Why PLC Panels Are a Must-Have for Small and Medium Enterprises (SMEs)

Retrofitting Old Machinery with Modern PLC Panels

Using PLC Panels in HVAC Automation for Commercial Buildings

#plc electrical panel#plc#electrical panel#plc panel#Programmable Logic Controller Panel Manufacturer#PLC Panel Manufacturer

0 notes