#siemens controllers

Explore tagged Tumblr posts

Text

Why Siemens Industrial Automation is the Key to Your Success

These days, competing has become synonymous with the embracing of innovative technology. Siemens Industrial Automation is the solution for all businesses intending to increase productivity, streamline processes, and reduce operational costs. Siemens is deliberately focused on innovativeness; therefore, it features a variety of top-of-the-line automation products for diverse needs of the industry.

Why Choose Siemens Industrial Automation?

Siemens is the finest industrial automation provider. It has a complete range of products for industries of all sizes. Here is what makes Siemens special:

Advanced Technologies: Garden Industrial Solutions by Siemens construct with preventive innovations, that work flawlessly to automate daily tasks.

Applications: From manufacturing to energy grids, all kinds of applications and extreme efficiency are available from Siemens.

Reliability: Decades of accumulated experience make it last with the utmost reliability in products.

Explore Siemens Automation Products

Siemens has indeed a wide variety of products catering to industrial automation applications and among these popular Siemens Automation Products are:

Siemens Programmable Logic Controller (PLC): These sturdy controllers form the backbone of industrial automation, providing precise control over machinery and processes, whether small or large production lines or huge units, through their Siemens PLCs, which are reliable and scalable.

Siemens Controllers: Optimally designed Siemens controllers boost the efficiency of very large industrial systems. Everything from other Siemens solutions would seamlessly be integrated into a streamlined flexible workflow.

Benefits of Siemens Programmable Logic Controller

Siemens Programmable Logic Controllers are a fundamental part of automation today. They have the following functionalities:

Flexibility: Suitable for usage from small to large.

User-Friendly Programming: Simple programming that saves much time and resources.

Improving Efficiency: Less downtime and higher productivity.

Energy Saving: Help for the industries to achieve their sustainability goals.

Siemens PLCs are fitted according to every requirement be it automotive, food processing, or packaging industry.

Industries Benefiting from Siemens Industrial Automation

Siemens products are revolutionizing industries all around the world. Some examples are:

Manufacturing: Higher Efficacy Automation of Assembly Lines.

Energy: Optimize Grid Performance and Ensure Sustainable Energy Solutions.

Pharmaceuticals: Provide Precision in Production Processes.

Logistics: Optimize Warehouse Operations That Save Time in Deliveries.

Future-Proof Your Business with Siemens Controllers

Siemens Controllers play a major role in all industrial automation systems. They allow an industry to get real-time decision-making insights that can be trusted for quick decision making. Choosing Siemens controllers is investing in a future-proof investment and enables adaptation with evolving industrial demands.

Final Thoughts

Siemens Industrial Automation paves the way for businesses to excel in a competitive market. Unlock new avenues of efficiency and productivity with industry-leading Siemens Automation Products, including Siemens Programmable Logic Controllers and reliable Siemens Controllers.

Start your journey with Naksh Technology Solutions LLP towards smarter automation today. Check out the complete offerings of Siemens to see how you can transform your industrial operations.

#Siemens Industrial automation#Siemens Automation Products#Siemens Controllers#Programmable logic controllers

0 notes

Text

Siemens Controllers for Energy Management: Optimizing Efficiency and Reducing Costs

In an era where energy efficiency and cost management are paramount, Siemens controllers have emerged as a crucial tool for optimizing energy management systems. By integrating advanced Siemens controllers into energy management strategies, organizations can significantly enhance their efficiency, cut down operational costs, and contribute to sustainable energy practices. Here’s a comprehensive look at how Siemens controllers can revolutionize energy management and how they can be integrated with IoT technologies for even greater control and connectivity.

The Role of Siemens Controllers in Energy Management

Siemens controllers, including programmable logic controllers (PLCs) and motor controllers, are pivotal in managing and optimizing energy usage within industrial and commercial settings. These controllers provide precise control and monitoring capabilities that are essential for effective energy management.

1. Enhancing Efficiency with Siemens Controllers

Efficiency is at the core of effective energy management. Siemens controllers are designed to automate and optimize various processes, ensuring that energy use is as efficient as possible. For instance, Siemens’ SIMATIC PLCs are used to manage complex systems, from heating and cooling to lighting and machinery operations. By automating these systems, Siemens controllers reduce the need for manual intervention, which not only streamlines operations but also minimizes energy waste.

Siemens motor controllers play a crucial role in optimizing the performance of electric motors, which are significant consumers of energy. These controllers enable precise control over motor speed and operation, ensuring that motors run only as required and operate at peak efficiency. This optimization leads to reduced energy consumption and extended equipment lifespan, contributing to overall cost savings.

2. Reducing Costs through Advanced Automation

Cost reduction is a critical goal for any energy management strategy. Siemens controllers help achieve this by automating energy-intensive processes, which leads to more efficient energy use and lower utility bills. For example, by implementing Siemens’ automation technology, facilities can automate lighting, HVAC systems, and other energy-consuming equipment based on real-time data and operational needs.

The use of Siemens controllers in factory automation allows for the precise scheduling of machinery and equipment operations. This means that energy is used only when necessary, and equipment is operated under optimal conditions, leading to significant cost savings. Additionally, Siemens controllers provide real-time monitoring and data analysis, which helps identify inefficiencies and areas where further cost reductions can be achieved.

Integrating Siemens Controllers with IoT Technologies

The integration of Siemens controllers with Internet of Things (IoT) technologies offers enhanced connectivity and control, taking energy management to the next level. IoT integration allows Siemens controllers to collect and analyze data from various sensors and devices, providing a comprehensive view of energy usage and system performance.

1. Improved Connectivity and Control

By connecting Siemens controllers with IoT platforms, organizations can achieve improved connectivity across their energy management systems. This integration enables seamless communication between controllers, sensors, and other devices, facilitating real-time monitoring and control. For instance, energy consumption data from various sources can be aggregated and analyzed through IoT platforms, providing valuable insights into energy usage patterns and system performance.

This enhanced connectivity allows for more precise control over energy systems. For example, IoT-enabled Siemens controllers can adjust lighting levels, HVAC settings, and equipment operation based on real-time data, optimizing energy use and improving overall efficiency. The ability to remotely monitor and control energy systems also offers increased flexibility and responsiveness, enabling quick adjustments to address changing conditions and requirements.

2. Data-Driven Insights for Better Decision-Making

The integration of Siemens controllers with IoT technologies provides access to a wealth of data that can be used to drive better decision-making. Through advanced analytics and reporting tools, organizations can gain deep insights into their energy usage, identify trends and anomalies, and make informed decisions to further optimize their energy management strategies.

For example, IoT platforms can generate reports on energy consumption, equipment performance, and operational efficiency. These reports can be used to identify areas where energy is being wasted, track the performance of energy-saving initiatives, and set benchmarks for future improvements. By leveraging these data-driven insights, organizations can continuously refine their energy management practices and achieve long-term cost savings.

Implementing Siemens Controllers for Energy Management

To effectively implement Siemens controllers for energy management, organizations should follow several key steps:

Assess Current Systems: Evaluate existing energy management systems and identify areas where Siemens controllers can provide the most benefit. Consider factors such as equipment types, energy consumption patterns, and automation needs.

Select the Right Siemens Controllers: Choose Siemens controllers that best match your energy management requirements. Options include SIMATIC PLCs for complex automation tasks and motor controllers for precise motor control.

Integrate with IoT Technologies: Connect Siemens controllers with IoT platforms to enhance data collection, connectivity, and control. This integration will enable real-time monitoring and advanced analytics.

Configure and Deploy: Configure Siemens controllers and IoT integrations according to your specific energy management needs. Deploy the system and ensure that all components are properly calibrated and optimized.

Monitor and Optimize: Continuously monitor system performance and use data-driven insights to make ongoing improvements. Regularly review energy consumption data and adjust settings to maximize efficiency and cost savings.

Conclusion

Siemens controllers are revolutionizing energy management by providing advanced automation technology that enhances efficiency and reduces costs. Through precise control and real-time monitoring, Siemens controllers optimize energy usage, streamline operations, and contribute to significant cost savings. When integrated with IoT technologies, these controllers offer improved connectivity and data-driven insights, further enhancing their effectiveness in energy management. By adopting Siemens controllers, organizations can achieve a more efficient and cost-effective approach to energy management, driving both operational excellence and sustainability.

#siemens#siemens controller#siemens controllers#simatic#controllers#automation#controller#production#automated

0 notes

Text

Siemens Industrial Automation Suppliers and Dealers - Naksh Technology

When NAKSH TECHNOLOGY was established, its goal was to become an essential component of the worldwide supply chain for Siemens automation products. This is accomplished by combining the three factors of impeccable quality, cutting-edge technology, and timely delivery.

As a supplier, we work tirelessly to develop new ideas to meet the automation demands of our customers by providing products such as Siemens AC Drive, Siemens PLC, Siemens HMI, Siemens Servo System, SIMOTION Controller, and many more.

The demands on contemporary machines and plants are gradually increasing across all industries. Siemens automation products enable you to meet all criteria while maintaining optimum efficiency, flexibility, and cost effectiveness.

Every action we do is based on your long-term success. Our committed service professionals provide the best solutions for your specific needs today and in the future. This pledge is based on existing and upcoming trustworthy partnerships. Your trust is our pledge. We are there - Siemens Naksh Technology Services.

Why Choose Naksh Technology for Siemens Industrial Automation?

Precision, dependability, and efficiency are the most important features for Siemens industrial automation. It is important to choose the correct provider and ensure that your processes continue to function effectively and efficiently when you are incorporating Siemens automation products into your operations.

Smooth Integration to Maintain Operations

According to Naksh Technologies intelligent personnel, every second is precious in your place of work, and I hope that we have the most knowledgeable staff with us hence making sure that your system works properly as soon as you contact us for any inquiries related to Siemens Automation Products that we specialize in. Our r problem-solving specialists assure you that adoption procedure doesn't require too much effort whether one is setting up drives, sensors, HMIs or PLCs.

Experience

Naksh Technology has proven itself dependable and quality over time. We have several satisfied clients in different sectors. Choose Naksh Technology as your preferred distributor and partner on Siemens Automation Products to see how differently dependable, efficient and focused we are. And here is how you can get in touch with us to get more information about Siemens programmable logic controller and other associated services.

Visit Here fore More

0 notes

Text

what, and i CANNOT stress this enough, the FUCK is happening in america right now.

#anyways boycott hp and siemens and puma and sodastream and carrefour and#mcdonalds and papa johns and dominos and pizza hut and burger king and wix#like this mf country was founded on the basis of boycotting british tea#or at least that was a tipping point in its push for freedom from british control#they’re scared because they underestimated the power of boycotting and theyve seen how starbucks sales dropped#actually fucking insane though. to make boycotting illegal. how the hell are they going to enforce this#txt#soapbox#free palestine

29 notes

·

View notes

Text

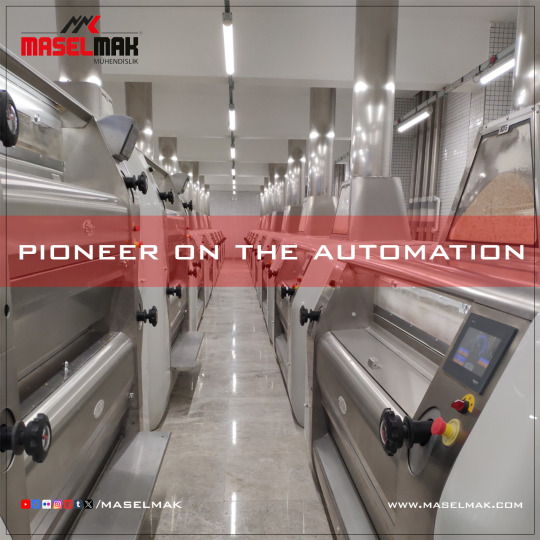

Maselmak Automation & Engineering - Maselmak Otomasyon ve Mühendislik

www.maselmak.com.tr

#turnkey#engineering#automation#company#business#machinery#controlling#remote#control#siemens#schenider#management#anahtar#teslim#otomasyon#sistemleri#değirmen#makineleri#süt#tesisi#kontrolü#işletme#maselmak#mühendislik#uygulamaları#turkiye#ankara#öncü#kuruluş

1 note

·

View note

Text

Why Reliserv Solution’s CRP Panels Are Setting Industry Standards in India.

We are supplier, trader, exporter, reseller and distributor of Arteche RPT Voltage presence indicators Arteche Supervision relays, buy now!

0 notes

Text

Night mode of industrial control LCD screen: making industrial display smarter and more comfortable

In the field of industrial automation, many devices need to run 24 hours a day, and night operation is the norm. However, ordinary LCD screens often have problems such as excessive brightness and glare when used at night, which affects the operator's visual experience and efficiency. The night mode of industrial control LCD screens came into being, providing a more comfortable display effect for night operation by intelligently adjusting brightness, color temperature and contrast.

Intelligent brightness adjustment, protect your eyes

The core of night mode is intelligent brightness adjustment. The industrial control LCD screen has a built-in ambient light sensor that can sense the intensity of surrounding light in real time and automatically reduce the screen brightness to avoid strong light stimulation. For example, outdoor high-brightness industrial displays will automatically lower the brightness at night to ensure that users are not glaring when operating, the brightness is soft, and the experience is better.

Color temperature optimization to reduce visual fatigue

In addition to brightness adjustment, night mode also optimizes the screen color temperature. By adjusting the backlight color temperature to warm tones (such as 6500K), blue light radiation is reduced and the operator's visual fatigue is reduced. Patent CN103617788B proposes a linear constant current drive circuit compensated by thermistors, which stabilizes the color temperature of LCD displays at around 6500K, meeting the strict color temperature requirements of aviation, aerospace and other fields.

Full lamination process to improve display effect

Night mode is usually combined with full lamination process to eliminate the air gap between the screen and the touch layer, reduce reflection and scattering, and further improve night visibility. This process can also prevent fogging inside the screen in low temperature environments, ensuring stable operation in cold areas.

Wide application scenarios

The night mode of industrial control LCD screens is widely used in outdoor charging piles, smart bus stops, port cranes and other scenarios. For example, when the port crane cab is operating at night, the high-brightness screen automatically switches to night mode, which not only ensures clear data visibility, but also avoids strong light interfering with the operator's vision, significantly improving the safety of the operation.

Energy saving and environmental protection, extended life

Night mode not only improves the user experience, but also has the advantages of energy saving and environmental protection. By reducing brightness and optimizing backlight control, energy consumption is reduced and the service life of the screen is extended. The power consumption of some industrial control LCD screens can be reduced by more than 30% in night mode, which is in line with the concept of green manufacturing.

At Shenzhen Zhiyan Optronics Co., Ltd., we’re here to help you source the right LCD screens for your business. From touch panels to LCD modules, we deliver quality products with fast service and factory pricing.

#touch switch crystal glass panel#23 inch touch panel#multi touch panel kit#32" touch screen panel kits#touch panel control#siemens touch panel tp177b#touch panel for siemens tp270#lighting control touch panel#20'' touch screen panel kit

0 notes

Text

The Siemens Simadyn D 6DD1683-0BC0 Control System Rack is a reliable and high-performance solution for industrial automation needs. Designed for use in complex control systems, this rack supports various Simadyn D modules and ensures smooth and efficient operation of automated processes. It offers robust connectivity, precise control, and easy integration with existing setups. Ideal for manufacturing, energy, and processing industries, the 6DD1683-0BC0 helps improve productivity and system reliability. Built by Siemens, a trusted name in industrial automation, this control rack delivers durability, flexibility, and long-term performance. Perfect for professionals seeking advanced automation support and seamless process control.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Siemens Simadyn#Control System#Power Supply

0 notes

Text

How Siemens Programmable Logic Controllers Improve Industrial Efficiency

In the current fast-paced industrial setting, automation is a necessity to increase productivity, efficiency, and precision. The Siemens Programmable Logic Controller (PLC) stands at the forefront of modern automation; it brought a paradigm shift in control systems in industries. Due to its reliability, flexibility, and performance, the Siemens PLC is the most preferred choice by manufacturers, engineers, and system integrators in the world.

What then is a Siemens Programmable Logic Controller?

A Siemens Programmable Logic Controller is a capable digital computer that is used to control machinery, processes, and equipment in industrial applications. It would receive inputs from sensors or user devices, consider those inputs under programmed logic, and create outputs that would appropriately control the processes or operations of machines and systems.

Siemens supplies a wide range of PLCs to suit the needs of various industries, ranging from compact ones for small applications to powerful modular systems for maximum control of automation. Considered to be popular are the SIMATIC S7-1200, S7-1500, and S7-300 series. Offered by these controllers is high-speed processing, built-in communication features, and compatibility of seamless scaling.

Also read, The Impact of Siemens PLC on Mining and Heavy Equipment

Reasons for Choosing a Siemens PLC

Siemens PLC is preferred in automation control owing to several factors:

Reliability: For 24-hour uptime in demanding industrial conditions.

Flexibility: It is configured and adapted with ease according to industries and processes.

Advanced Communication: Interface without any hindrance with the field devices, HMIs, SCADA systems, and cloud platforms.

Scalability: One can start small and grow as much as needed, without having to change the essence of the platform.

Integrated Safety: There are models that have been integrated with safety functions for the safe operation of the machinery.

Such features give Siemens PLC a future-ready status that also creates possibilities in manufacturing, water treatment, power generation, automotive, packaging, and related industries.

Siemens Controller vs. Siemens PLC

Many people tend to use Siemens controller and Siemens PLC interchangeably and, therefore, it is important to know the difference. Siemens controller is a broad term that includes PLCs, PC-based controllers, and distributed controllers, whereas Siemens PLC is a Programmable Logic Controller widely used in automation processes.

If you are setting up small-scale plants or running the setup of a big industrial plant, optimum performance and long-term success will ensue from the right choice of Siemens controller-especially Siemens PLC.

Learn more, Siemens PLC: Benefits of Using it in Industrial Automation

Application of Siemens PLC in Industries

The versatility of Siemens programmable logic controllers allows them to be applied to many applications:

Automated Assembly Lines

Process Control Systems

HVAC Control

Material Handling

Packaging Automation

Building Management Systems

By having a Siemens PLC, one can automate a series of repetitive tasks that can lead to errors, thereby enhancing productivity.

Conclusion: Partner with Naksh Technology Solutions LLP

If one looks forward to implementing a Siemens Programmable Logic Controller for their automation needs, it is crucial to associate with a trusted and experienced supplier. Naksh Technology Solutions LLP is a foremost supplier of Siemens automation products providing expert consultation, product support, and on-time delivery from an array of industries.

With vast knowledge of Siemens controllers and an exhaustive range of Siemens PLCs, Naksh Technology Solutions LLP is the best fit to attain industrial automation excellence.

0 notes

Text

#Active Harmonic Filter in UAE#Capacitor Bank in UAE#Voltage Optimizer in UAE#Power Quality Solutions in Dubai#Harmonic Studies in UAE#Sinexcel Distributor in UAE#Heat Pump System in Dubai#Energy Audit in Dubai#Power Quality Analyze in dubai#Smart Metering & Lighting in UAE#Static VAR Generator in UAE#Smell Removal in UAE#Air Purification System in Dubai#Uninterrupted Power Supply in UAE#Building Management System in UAE#Automation solution in UAE#Energy Management System In UAE#A-eberle Distributor in UAE#Siemens WinCC in UAE#Siemens System Integrator in Dubai#Siemens SCADA#Helmholz Distributor in Dubai#Sustainability solutions provider in Dubai#Demand Control Kitchen Ventilation System in UAE#EV Charger in Dubai

0 notes

Text

Optimize your manufacturing with Siemens Industrial Automation, provided by Naksh Technology Solutions LLP. From PLCs to HMIs and drive systems, Siemens offers advanced automation to boost productivity, precision, and scalability.

0 notes

Text

How Siemens Controllers Are Revolutionizing Music Production Studios

In the rapidly evolving world of music production, the quest for greater efficiency, precision, and creative control has led to significant advancements in technology. Among the innovations driving these changes are Siemens controllers, which are revolutionizing how music is produced, mixed, and mastered. By integrating Siemens' cutting-edge automation technology into music production studios, professionals are achieving new levels of productivity and sonic quality. Here's how Siemens controllers are making waves in the music industry.

Siemens Controllers: The Backbone of Modern Music Studios

Siemens controllers, including programmable logic controllers (PLCs) and motor controllers, are renowned for their reliability and precision in various industrial applications. However, their impact extends beyond traditional manufacturing environments. In modern music production studios, Siemens controllers are enhancing automation, improving control over studio equipment, and streamlining production processes.

One notable example is the use of Siemens’ SIMATIC PLCs in controlling and automating audio equipment. These advanced controllers manage everything from digital mixing consoles to automated fader adjustments, providing sound engineers and producers with a level of control that was previously unattainable.

Enhancing Efficiency with Siemens Automation Technology

Efficiency is paramount in a music production studio, where time is often as valuable as creativity. Siemens controllers play a crucial role in automating repetitive tasks and optimizing workflows. For instance, automated mixing and mastering processes are facilitated by Siemens controllers, which handle complex signal routing and processing tasks with precision.

By integrating Siemens’ automation technology, studios can reduce the time spent on manual adjustments and focus more on the creative aspects of music production. Automated systems controlled by Siemens controllers ensure that equipment settings are consistent and repeatable, which is essential for achieving high-quality results across multiple sessions and projects.

Precision Control with Siemens Motor and Motion Controllers

In a music studio, precise control over equipment is essential for achieving the desired sound quality. Siemens motor controllers and motion control systems provide unparalleled accuracy in adjusting audio equipment. Whether it’s controlling the movement of a motorized microphone stand or fine-tuning the position of speakers and monitors, Siemens controllers ensure that every adjustment is executed with pinpoint accuracy.

The ability to program and control these adjustments via Siemens’ programmable logic controllers allows sound engineers to create intricate setups and configurations that can be replicated with ease. This level of control enhances the overall quality of recordings and ensures that the production process is smooth and efficient.

Streamlining Production with Advanced Automation and Process Automation

Process automation is transforming music production studios by automating complex workflows and enhancing overall efficiency. Siemens controllers are at the heart of this transformation, offering solutions that streamline various aspects of the production process.

For example, Siemens controllers can automate the setup and calibration of audio equipment, reducing the time needed for manual adjustments. This automation extends to the management of recording sessions, where Siemens controllers handle tasks such as track switching, level adjustments, and signal routing with minimal human intervention.

Additionally, the integration of Siemens controllers into digital audio workstations (DAWs) allows for seamless control of software and hardware components. This integration ensures that all elements of the production process work in harmony, resulting in a more cohesive and efficient workflow.

The Impact of Siemens Controllers on Creative Processes

Beyond improving efficiency and precision, Siemens controllers also have a significant impact on the creative processes within music production studios. By automating routine tasks, these controllers free up time for producers and engineers to focus on creative experimentation and innovation.

The ability to program complex automation sequences and recall them with ease enables sound engineers to explore new creative possibilities. For instance, automated dynamic changes in a mix or the creation of intricate effects can be accomplished effortlessly using Siemens controllers, allowing for greater experimentation and artistic expression.

Implementing Siemens Controllers in Your Music Studio

Integrating Siemens controllers into a music production studio involves several key steps. First, assess your studio’s current setup and identify areas where automation and control improvements can be made. Siemens offers a range of controllers and automation solutions, including the SIMATIC PLCs and motor controllers, that can be customized to meet your specific needs.

Once the appropriate Siemens controllers are selected, the next step is to implement them into your studio’s infrastructure. This process may include configuring the controllers, integrating them with existing equipment, and training staff to utilize the new technology effectively.

Ongoing maintenance and support are essential to ensure that Siemens controllers continue to perform optimally. Siemens provides comprehensive support services, including technical assistance and software updates, to help you maximize the benefits of their controllers and maintain peak performance.

Conclusion

Siemens controllers are revolutionizing music production studios by enhancing efficiency, precision, and creativity. With their advanced automation technology, including programmable logic controllers (PLCs) and motor controllers, Siemens is setting new standards for control and automation in the music industry. By integrating Siemens controllers into your music production setup, you can streamline workflows, improve the quality of your productions, and unlock new creative possibilities. As the music industry continues to evolve, Siemens controllers will remain at the forefront of innovation, driving the future of music production.

#siemens#siemens controller#siemens controllers#industrial automation#programmable logic controllers#motor controllers#motion control#factory automation#automation technology#process automation#simatic#controllers#automation#controller#production#automated

0 notes

Text

0 notes

Text

SR Ranade: Your Trusted Partner for Siemens PLC Automation Solutions in Mumbai

We make sure that from the entire stock of Siemens S7 programmable logic controllers, a wide range of product lines is available, characterized by their reliability, flexibility, and productivity offering bespoke automated solutions that can be easily integrated into your current operational systems to boost efficiency and productivity. https://www.quora.com/profile/Drive-PLC/SR-Ranade-Your-Trusted-Partner-for-Siemens-PLC-Automation-Solutions-in-Mumbai

0 notes

Link

0 notes

Text

Factory Automation in pune | India

The total automation of the production process is what we mean when we talk about factory automation. Using technologies like robotic arms, hydraulic systems, and pneumatic systems to automate the construction of increasingly complicated systems is standard procedure in the manufacturing industry.

#Factory Automation Pune#Industrial Automation Control India#Process Automation Robotics India#Industrial Automation Siemens#Industrial Automation Industry Pune#Robotics Company India#Automotive for Assembly Lines Pune#Automation Solution India

0 notes