#Rack and Panel Connectors

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/interconnect--backplane-connectors--backpanel-connectors/188835-1-te-connectivity-3135983

Applications for Backpanel Connector, terminal block, barrier strip, strips

Z-PACK Series 154 Position 2 mm Pitch Press Fit Through Hole Backpanel Connector

#TE Connectivity#188835-1#Backplane Connectors#Rack and Panel Connectors#Applications#terminal block#barrier strip#strips#power connectors#what is a backpanel connector#edge connector#board mount receptacle#Header plug#card edge

1 note

·

View note

Text

https://www.futureelectronics.com/p/interconnect--backplane-connectors--backpanel-connectors/188835-1-te-connectivity-5170771

Backplane connector types, Wire connector Receptacles, Power Jacks

Z-PACK Series 154 Position 2 mm Pitch Press Fit Through Hole Backpanel Connector

#TE Connectivity#188835-1#Backplane Connectors#Rack and Panel Connector#Wire connector Receptacles#Power Jacks#card edge connector#high-speed#electronic connector#electric board edge connector#socket mount wire

1 note

·

View note

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the brand Zemic is dedicated to creating a better home life for every family. Brings you the easiest way to organizer your home, saving you space while decorating your home environment. We have a professional product development team and our products are affordable and Highly functional. At the same time we pay close attention to service, we will be standby for customers to solve product problems Transparent Door-Visible Style Frosted Door-Privacy Protect Narrow Tall Show Organizer How we get our start? The inception of Zemic stemmed from a passion for home living and a relentless pursuit of innovative shoe cabinet design,aiming to provide users with an unparalleled home living experience. What makes our products unique? 1.Unique design concepts and a modern minimalist style 2. Professional production line and R&D team What problem are we solving? Our factory enables comprehensive control over the entire production process, from material selection to craftsmanship, ensuring adherence to high-quality standards. After-Sales Service: over a year for after-sales service. 【𝟓 𝐒𝐡𝐞𝐥𝐟 𝐒𝐡𝐨𝐞 𝐑𝐚𝐜𝐤】Zemic 10 Pairs shoe rack provides a large space to store shoes, toys or handbags, etc.It can help you save more space. Dimension: 45cm(L) x 36cm(W) x 85cm(H). The Max. Load Capacity of Each Cube: 10kg. 【𝐒𝐭𝐨𝐫𝐞�� 𝐔𝐩 𝐭𝐨 𝟏𝟎 𝐏𝐚𝐢𝐫𝐬】Perfect for sneakers high-heeled shoes boots stilettos ballet shoes flats casual shoes children's shoes; Holds 10 pairs of shoes more than enough for you and your family's needs. 【𝐒𝐭𝐮𝐫𝐝𝐲 𝐒𝐡𝐨𝐞 𝐒𝐡𝐞𝐥𝐯𝐞𝐬】The cube storage organizer is made of PP plastic panels with metal frame and ABS connectors.Shoe organizer for closet, living room, entry, bedroom, office to make your home tidy. 【𝐄𝐚𝐬𝐲 𝐀𝐬𝐬𝐞𝐦𝐛𝐥𝐲】Shoe storage rack with corresponding installation tools, enough connectors,hammer and installation instructions to help you install it quickly and easily.It is worth noting that each plastic diaphragm and connector need to be tightly connected together, which is inseparable from the help of the hammer. 【𝐄𝐚𝐬𝐲 𝐭𝐨 𝐂𝐚𝐫𝐞】The shoe organizer is made of plastic materials, offering excellent waterproof properties that make it easy to clean with water. Door holes feature is designed for air circulation to prevent buildup odor.

0 notes

Text

Why the E-PRO BRLSSFN-1 Brushless Fan is the Ideal Choice for Advanced Cooling

Introduction to E-PRO BRLSSFN-1 Brushless Fan

In the evolving world of electronics and thermal control, the demand for efficient and reliable cooling solutions is critical. The E-PRO BRLSSFN-1 Brushless Fan is a high-performance solution engineered to manage heat in systems packed with sensitive electronic components. It ensures thermal stability in applications involving microprocessors, controllers, LEDs, capacitors, and sensors. Designed for reliability and durability, this fan is suitable for both industrial and consumer-grade systems where effective airflow is a priority.

What Makes Brushless Fans Stand Out?

Brushless fans have become increasingly popular due to their mechanical efficiency and electronic advantages. They operate without brushes, which significantly reduces friction and wear. This leads to longer operational life and quieter performance compared to traditional brushed fans.

Advantages of the E-PRO BRLSSFN-1

Delivers powerful airflow while maintaining low noise levels

Reduces energy consumption in long-term applications

Offers a long service life due to minimal mechanical wear

Compatible with various enclosures, including compact electronics and laptops

Prevents overheating in sensitive parts like thermal pads, switches, and fuses

Application Versatility of the BRLSSFN-1 Fan

The E-PRO BRLSSFN-1 Brushless Fan is widely adaptable, making it useful in many types of systems and electronic assemblies. Its compact structure and powerful performance enable it to be used in devices requiring consistent cooling.

Where It Can Be Used

Laptops, PCs, and embedded computers

Electrical control panels and PLC enclosures

Industrial machines housing contactors, relays, and microcontrollers

LED lighting units and smart lighting drivers

Communication and networking hardware including routers and switches

Server racks and IT equipment that rely on regulated thermal environments

Test benches using microprocessors, connectors, cables, and sensors

Enhanced Thermal Management Capabilities

Maintaining optimal operating temperatures is essential for electronic longevity and performance. The E-PRO BRLSSFN-1 excels in rapid heat dissipation and airflow consistency, keeping internal electronics cool and efficient.

Key Thermal Features

Effective cooling of capacitors, microchips, and power supplies

Maintains ideal temperatures for tools, controllers, and power modules

Supports systems with dense cabling and thermal-sensitive layouts

Protects delicate components from heat-related degradation

Ideal for systems that use oils, thermal pads, and insulators

Benefits in Industrial and Commercial Electronics

From small desktop devices to heavy-duty industrial controllers, the BRLSSFN-1 supports broad integration. Its performance stability and low power draw make it suitable for multiple industries.

Reasons to Consider This Fan

Reduces risk of thermal failure in mission-critical equipment

Easy installation in enclosures with cables, grips, and sensor arrays

Designed for environments where safety and thermal reliability are key

Contributes to energy-efficient operation over prolonged periods

Built with strong materials for use in harsh environments

Integration with Modern Electronic Components

The E-PRO BRLSSFN-1 Brushless Fan is designed to work seamlessly with modern components, from basic circuit designs to advanced electronic systems. It ensures that components like LEDs, fuses, switches, and microcontrollers operate within safe thermal limits.

Perfect Match for Compact and High-Tech Systems

Compact enough for use in laptops and tablets

Supports active cooling for embedded boards and IoT systems

Assists in thermal regulation for high-speed processing units

Works alongside capacitors, connectors, and digital sensors

Ensures longevity in battery-powered devices and portable equipment

Why You Should Choose E-PRO BRLSSFN-1

Choosing a high-quality cooling fan impacts the overall performance and lifespan of your electronic equipment. The E-PRO BRLSSFN-1 provides an edge by balancing performance, energy savings, and versatility.

Top Reasons to Buy

Trusted by electronics professionals for thermal reliability

Suitable for integration into complex systems with minimal modifications

Helps extend service life of devices by preventing overheating

Reduces maintenance needs and replacement frequency

Compatible with modern components like microprocessors, contactors, and tools

Conclusion

As electronics continue to evolve, so must the cooling systems that support them. The E-PRO BRLSSFN-1 Brushless Fan is a dependable choice for maintaining thermal balance across a wide range of systems—from industrial controllers and thermal pads to laptops and LED circuits. Whether you're upgrading your thermal management system or designing a new one from scratch, this fan provides long-term value, performance, and peace of mind.

0 notes

Text

5 Critical Mistakes That Cause Network Downtime in Data Centers

Network downtime in data centers isn't just an inconvenience—it's a business catastrophe that can cost companies millions of dollars per hour. According to recent industry studies, the average cost of data center downtime has reached $9,000 per minute, making prevention not just a technical priority but a critical business imperative.

After analyzing hundreds of data center failures over the past decade, we've identified five recurring mistakes that consistently lead to network outages. Understanding these common pitfalls can help your organization implement better system downtime prevention strategies and maintain the reliability your business depends on.

Mistake #1: Inadequate Cable Management and Infrastructure Planning

The foundation of any reliable data center network lies in its physical infrastructure, yet cable management remains one of the most overlooked aspects of data center design. Poor cable organization doesn't just look unprofessional—it creates a cascade of problems that inevitably lead to network failures.

When fiber optic patch cords are haphazardly routed through racks without proper planning, technicians face several challenges. First, identifying specific connections becomes nearly impossible during emergency situations when every second counts. Second, the risk of accidental disconnection increases dramatically when cables are tangled or improperly secured.

More critically, inadequate cable management creates airflow restrictions that can lead to overheating. When network infrastructure components operate outside their optimal temperature ranges, failure rates increase exponentially. We've seen cases where simple cable reorganization reduced equipment failure rates by over 40%.

The solution involves implementing structured cabling systems with proper patch panel solutions that provide clear labeling, organized routing, and easy access for maintenance. Professional-grade patch panels not only improve organization but also provide better signal integrity and easier troubleshooting capabilities.

Mistake #2: Using Substandard Network Components

In an effort to reduce initial costs, many organizations make the critical error of choosing cheap, low-quality network components. This penny-wise, pound-foolish approach almost always results in higher long-term costs due to increased failure rates and more frequent replacements.

Substandard fiber optic cables and connectors are particularly problematic because they're often the last components suspected when network issues arise. Poor-quality cables may work initially but degrade over time due to inferior materials, inadequate shielding, or manufacturing defects. When these components fail, they rarely fail completely—instead, they create intermittent issues that are difficult to diagnose and can plague networks for months.

Quality fiber optic patch cords and adapters use premium materials and undergo rigorous testing to ensure consistent performance over their entire lifespan. While the initial investment may be higher, the reduced maintenance costs, lower failure rates, and improved reliability more than justify the expense.

Consider this real-world example: A financial services company saved $50,000 on network components during their initial build-out by choosing cheaper alternatives. Within eighteen months, they had spent over $200,000 on emergency repairs, replacement components, and lost productivity due to network instability. They eventually replaced their entire infrastructure with enterprise-grade components.

Mistake #3: Insufficient Redundancy and Single Points of Failure

One of the most dangerous assumptions in data center design is that individual components will always function as expected. Networks without proper redundancy are essentially gambling with business continuity, and the house always wins eventually.

Single points of failure can exist at multiple levels of network infrastructure. At the physical layer, having only one path for critical data flows means any component failure results in complete service disruption. At the equipment level, relying on single switches, routers, or even power sources creates unnecessary vulnerability.

Effective redundancy planning requires identifying every potential failure point and implementing backup systems. This includes redundant fiber optic cable paths, backup power systems, and duplicate network equipment. However, redundancy isn't just about having backup components—it's about ensuring those backups can seamlessly take over when needed.

Many organizations make the mistake of implementing redundancy systems but never properly testing them. Regular failover testing is essential to ensure backup systems work correctly when they're actually needed. We recommend monthly testing of all redundancy systems and immediate investigation of any failover delays or issues.

Mistake #4: Inadequate Environmental Monitoring and Control

Data center environments are more fragile than many realize. Temperature fluctuations, humidity changes, and power anomalies can all contribute to network equipment failures. Yet many organizations implement insufficient environmental monitoring, leaving their networks vulnerable to preventable outages.

Temperature control is particularly critical for fiber optic infrastructure. Extreme heat can cause cable jackets to degrade, while rapid temperature changes can create expansion and contraction that stresses connections. Humidity problems can lead to corrosion in metal components and affect the performance of sensitive electronic equipment.

Comprehensive environmental monitoring should include temperature sensors throughout the facility, humidity monitoring, power quality assessment, and air quality measurements. Modern monitoring systems can predict potential problems before they cause failures, allowing for proactive maintenance rather than reactive repairs.

Additionally, proper ventilation design ensures that heat generated by network infrastructure components is effectively removed. Strategic placement of equipment and careful attention to airflow patterns can prevent hot spots that accelerate component degradation.

Mistake #5: Poor Change Management and Documentation

Perhaps the most insidious cause of data center network downtime is poor change management. Well-intentioned modifications, updates, and expansions can have unintended consequences when proper procedures aren't followed.

Undocumented changes are particularly problematic because they create confusion during troubleshooting. When network issues arise, technicians need accurate information about current configurations, recent changes, and equipment specifications. Without proper documentation, diagnosis time increases dramatically, extending outage duration.

Effective change management requires formal procedures for any network modifications, comprehensive documentation of all changes, and thorough testing before implementation. Every change should be traceable, reversible, and fully documented before it's approved.

Furthermore, regular audits of network documentation help ensure accuracy and identify discrepancies before they cause problems. We recommend quarterly reviews of network diagrams, equipment inventories, and configuration documentation.

Building a More Reliable Future

Preventing data center network downtime requires a comprehensive approach that addresses physical infrastructure, component quality, redundancy planning, environmental controls, and operational procedures. While implementing these improvements requires initial investment, the cost of prevention is always lower than the cost of recovery.

Organizations that prioritize network reliability through proper planning, quality components, and rigorous procedures consistently experience fewer outages and lower total cost of ownership. In today's digital economy, network reliability isn't just a technical requirement—it's a competitive advantage that directly impacts business success.

By avoiding these five critical mistakes and implementing robust network reliability best practices, your organization can significantly reduce the risk of costly network downtime and maintain the reliable connectivity that modern business demands.

0 notes

Text

Ozone Aging Test Chamber Manufacturer by Effective Lab India

Nothing compares to the effectiveness of ozone aging in evaluating the durability of rubber and polymer materials. The best way to simulate ozone exposure and examine how materials behave under prolonged stress is to use a laboratory ozone aging test chamber. This blog examines the factors that set Effective Lab India apart as the leading producer of ozone aging test chambers in India.

An Ozone Aging Test Chamber: What Is It?

A laboratory tool called an ozone aging testing chamber replicates how ozone affects rubber, plastics, and other elastomers. It aids in forecasting the aging and degradation of materials in ozone-rich environments, which is a typical situation for industrial, construction, and automotive applications.

Why Ozone Testing is Crucial

Ever noticed cracks in tires or seals after just a few years? That’s ozone damage. Testing helps manufacturers identify weaknesses early on. It saves time, money, and ensures safety in real-world applications.

About Effective Lab India

Who Are They?

One of the top producers of superior laboratory testing apparatus is Effective Lab India. They have established themselves as a reputable brand in the ozone resistance test chamber sector thanks to years of experience and an emphasis on innovation.

Their Objective

To supply accurate, dependable, and reasonably priced testing equipment that satisfies Indian and global quality requirements.

Why Opt for an Indian-Made Solution?

Selecting an Indian manufacturer offers you value for money, quicker delivery, and localised assistance without sacrificing performance.

Features of Effective Lab India’s Ozone Aging Test Chamber

1. Accurate Ozone Management

Throughout your testing cycle, obtain precise and reliable ozone concentrations. It contributes to reliable and repeatable outcomes.

2. Construction That Is Resistant to Corrosion

The chamber is made to survive constant exposure to ozone and is constructed with rust-proof components and stainless steel interiors.

3. Digital Interface with Touchscreen

A user-friendly interface makes it simple to control test parameters. Setting, monitoring, and modifying test conditions is made simple by the touchscreen.

4. Cycles that can be programmed

Ideal for automatic and customised tests, you may program the temperature, humidity, ozone concentration, and testing length.

How It Operates

Ozone Generator: Generates a regulated amount of ozone.

The air circulation system makes sure that the ozone is distributed evenly throughout the chamber.

Mounting Samples: Attach rubber or polymer samples to either stationary or revolving racks.

Control System: Use the digital panel to adjust the temperature, time, and ozone levels.

Monitoring: Keeping tabs on the test's surroundings in real time.

Advantages of Effective Lab The Chamber of India

High Accuracy: Reliable measurements with exact control.

Sturdy Construction: Sturdy stainless steel framework.

Low Maintenance: Minimal downtime and an easy-to-clean design.

Energy-efficient: Power usage for daily testing was optimised.

Where Is It Used?

Automobile Industry: For testing tires, seals, and belts.

Electrical Industry: To assess cable insulations and connectors.

Rubber Products: Testing hoses, gaskets, and O-rings.

Footwear Manufacturing: To check the aging of soles and straps.

Why Choose Effective Lab India?

Tailored Solutions

Get chambers customised to your size, control features, and testing needs.

Fast Delivery

Quick manufacturing and shipping throughout India with installation support.

After-Sales Service

From troubleshooting training, Effective Lab India provides comprehensive support after purchase.

What Customers Have to Say

"Effective Lab India has tested hundreds of rubber samples in the ozone chamber. Every time, the outcomes are perfect! — Automobile Original Equipment Manufacturer

"The equipment has been operating faultlessly since a seamless installation. Excellent value and service. — Polymer Testing Laboratory

What about the cost?

The good news for those who are concerned about the cost of an ozone test chamber is that Effective Lab India provides excellent quality at a very competitive price. Whether you are an established company or a startup lab, you will discover a model that meets your budget.

How to Place an Order with Effective Lab India

Placing an order is simple:

Check out www.effectivelabindia.com.

Please contact [email protected] or call +91-9555515525.

They provide technician installation, doorstep delivery, and comprehensive post-purchase training.

Conclusion

When it comes to testing rubber and polymers, Effective Lab India's ozone aging test chamber is your trustworthy partner. It's a long-term investment with state-of-the-art features, excellent precision, reasonable prices, and trustworthy after-sales assistance. It is no longer optional to test for ozone resistance, regardless of your industry—automotive, cable production, or footwear. It is essential!

FAQs

1. For what purpose is an ozone aging test chamber used?

It helps forecast the life and performance of products by testing rubber and polymer's resistance to ozone exposure.

2. How should the ozone chamber be maintained?

For best results, frequently clean the inside, look for gas leaks, and calibrate sensors.

4. Is training provided with the machine?

Absolutely! Training and installation support are part of the package.

5. How long does it take to deliver the machine?

Usually between 2–4 weeks, depending on customisation and location.

#ozone chamber guide#ozone test machine#ozone chamber manufacturer#ozone aging test chamber#ozone test chamber

0 notes

Text

High-Performance PLC Splitters by Nextik: Optimizing Fiber Optic Networks

PLC Splitters | PLC Splitters Suppliers| PLC Splitters Manufacturer

In today's data-driven world, a strong and reliable fiber optic infrastructure is critical for efficient communication. At the center of this infrastructure is the PLC Splitter, a passive optical device that splits optical signals without impacting signal integrity. Nextik, an established name in fiber optic systems, offers a wide selection of PLC splitters to satisfy the changing demands of modern networks, from urban FTTH deployments to large-scale telecom applications.

What is a PLC Splitter?

A PLC (Planar Lightwave Circuit) Splitter is a critical component of fiber optic networks. It equally distributes or divides a single optical signal into many outputs. PLC splitters are designed using modern silicon glass wavelength technology to provide limited insertion loss and great reliability, making them suitable for both central and distributed optical networks.

Compared to typical FBT (Fused Biconical Taper) splitters, PLC splitters have more constant splitting ratios and function better across a broader variety of wavelengths, making them ideal for high-speed, high-capacity systems.

Why Choose Nextik for Your PLC Splitter Needs?

Nextik is a leading PLC splitter manufacturer and supplier in India, providing high-performance solutions designed to customer-specific applications. Nextik's manufacturing experience, tight quality control, and customer-first attitude ensure that you obtain long-lasting, high-precision PLC splitters for any deployment.

Key Benefits of Nextik PLC Splitters:

High Network Capacity: Engineered for demanding network environments, ensuring high bandwidth support.

Low Failure Rate: Built with top-grade materials and tested under extreme conditions.

Excellent Environmental Stability: Consistent performance in diverse weather and temperature variations.

Compact Design: Easy installation in tight or complex network environments.

Low Insertion Loss and Uniform Splitting: Ensures optimal performance across all outputs.

Types of PLC Splitters Offered by Nextik

To meet the wide range of fiber optic applications, Nextik offers various configurations and packaging types. These include:

1. Bare Fiber PLC Splitter

Bare fiber splitters are basic, unprotected versions of PLC splitters that are ideal for integration into larger assemblies. They are lightweight and compact, suitable for use inside fiber distribution units or customized enclosures.

2. ABS Box Type PLC Splitter

Encased in an ABS plastic box, this type of splitter offers enhanced protection against physical and environmental impacts. It is perfect for both indoor and outdoor installations and can be easily mounted in optical distribution boxes or cabinets.

3. Fan-Out Fiber PLC Splitter

Fan-out splitters include connectors on the output fibers, allowing easy connection to other components. This configuration is widely used in FTTH and PON systems due to its convenience and quick deployment.

4. 1U 19-Inch Rack-Mount PLC Splitter

This rack-mounted splitter is designed for standard 19-inch racks and offers a neat and professional appearance. Ideal for central offices or network operation centers, it supports easy management and high-density installations.

5. Cassette or Card Type PLC Splitter

Cassette splitters are compact and modular, designed for integration into fiber patch panels or optical distribution frames (ODFs). They offer high performance and ease of handling in structured cabling environments.

Applications of PLC Splitters

Nextik’s PLC Splitters serve multiple industries and network architectures. They play a vital role in:

FTTH (Fiber to the Home): Distributes optical signals from a central office to multiple homes with high reliability and minimal loss.

Passive Optical Networks (PON): Widely used in GPON and EPON systems to connect Optical Line Terminals (OLT) to multiple Optical Network Units (ONU).

CATV (Cable Television): Ensures the even distribution of optical signals to multiple TV subscribers.

Data Centers and Enterprise Networks: Supports high-capacity, low-latency data transmission across large networks.

Security and Surveillance Systems: Maintains consistent video signal quality across multiple cameras and monitoring points.

Quality Assurance and Testing

Every PLC Splitter from Nextik undergoes rigorous testing procedures to ensure compliance with international standards. Quality assurance processes include:

Optical performance testing for insertion loss, return loss, and uniformity.

Environmental testing to simulate harsh conditions including humidity, temperature fluctuation, and vibration.

Mechanical testing to assess durability during handling and installation.

These strict protocols guarantee that Nextik PLC splitters perform reliably in real-world environments.

Customization and Flexibility

Nextik offers custom splitter configurations to meet specific network requirements. Whether you need different fiber lengths, connector types (SC, LC, FC, etc.), or customized packaging, Nextik can deliver solutions tailored to your infrastructure needs.

Available splitter ratios include standard options such as 1x2, 1x4, 1x8, 1x16, 1x32, and 1x64, as well as 2xN configurations for advanced applications.

Why Network Professionals Trust Nextik

Expert Engineering: Experienced professionals with in-depth knowledge of fiber optics.

Reliable Supply Chain: Quick turnaround times and dependable delivery.

Affordable Pricing: Competitive rates without compromising quality.

Post-Sales Support: Comprehensive customer assistance to ensure satisfaction and product performance.

Serving India and Beyond

Based in Noida, India, Nextik supplies PLC splitters across the country and to global markets. As a preferred choice for telecom companies, system integrators, and government projects, Nextik’s commitment to innovation and quality ensures its continued leadership in fiber optic technology.

Conclusion

As fiber optic networks expand, the value of high-quality components such as the PLC Splitter cannot be overstated. Nextik provides the performance, stamina, and flexibility required for a city-wide FTTH network or an upgrade to a corporate data infrastructure. Nextik is your one-stop shop for PLC splitters, offering a wide selection of options, affordable prices, and dependable customer service. Experience the difference of working with a reliable fiber optic partner who is dedicated to excellence. Book now

0 notes

Text

Must-Have Cable Tray Accessories for Secure & Efficient Installations

Introduction

A well-designed cable tray system is crucial for organized and safe electrical wiring in industrial, commercial, and data center applications. However, the real strength of a cable tray system lies in its accessories—components that ensure stability, safety, and ease of maintenance.

In this guide, we’ll explore the essential cable tray accessories that every installer, contractor, and project manager should consider for secure, efficient, and long-lasting installations.

Cable Tray Accessories

Why Are Cable Tray Accessories Important?

Cable tray accessories enhance: ✔ Safety – Prevent cable slippage, short circuits, and fire hazards. ✔ Durability – Reinforce joints and protect against corrosion. ✔ Flexibility – Allow bends, expansions, and directional changes. ✔ Ease of Maintenance – Simplify inspections and future upgrades.

Without the right accessories, cable trays may fail under stress, leading to costly downtime and safety risks.

Cable Tray Manufacturer

Top 10 Must-Have Cable Tray Accessories

1. Cable Tray Brackets & Supports

Purpose: Securely mount trays to walls, ceilings, or structures.

Types: Cantilever brackets, trapeze hangers, and wall-mounted supports.

Best for: Overhead installations in factories and data centers.

2. Cable Tray Clamps (Straps & Fasteners)

Purpose: Hold cables firmly in place to prevent movement.

Types: Stainless steel clamps, nylon straps, and snap-in clips.

Best for: High-vibration environments like power plants.

3. Splice Plates (Connectors)

Purpose: Join two cable tray sections seamlessly.

Types: Straight, adjustable, and hinge-type splice plates.

Best for: Extending tray runs without weak points.

4. Reducers & Transition Pieces

Purpose: Connect trays of different widths or depths.

Types: Tapered reducers, offset transitions.

Best for: Adapting tray sizes in complex layouts.

5. Elbows & Bends

Purpose: Change direction (90°, 45°, or custom angles).

Types: Horizontal, vertical, and adjustable elbows.

Best for: Routing cables around obstacles.

6. Cable Tray Covers (Lids)

Purpose: Protect cables from dust, moisture, and physical damage.

Types: Solid, ventilated, and lockable covers.

Best for: Outdoor or hazardous locations.

7. Dropout Plates & Cable Entry Plates

Purpose: Allow cables to exit/enter trays neatly.

Types: Knockout plates, gland plates.

Best for: Linking trays to control panels or junction boxes.

8. Grounding Kits & Bonding Jumpers

Purpose: Ensure electrical safety by grounding metal trays.

Types: Copper braids, grounding clamps.

Best for: Compliance with NEC/IEC standards.

9. Cable Tie Mounts & Cleats

Purpose: Organize and bundle cables within trays.

Types: Adhesive mounts, screw-fixed cleats.

Best for: Preventing tangled wires in IT racks.

10. End Caps & Splash Guards

Purpose: Seal tray ends to prevent debris/rodent entry.

Types: Rubber grommets, metal caps.

Best for: Food processing plants and outdoor setups.

Wire Mesh Cable Tray Accessories

How to Choose the Right Accessories?

Consider these factors: 🔹 Material (Stainless steel for corrosive areas, galvanized for general use). 🔹 Load Rating (Match accessories to tray weight capacity). 🔹 Fire Resistance (Critical for tunnels and high-risk zones). 🔹 Ease of Installation (Quick-fit vs. bolt-on designs).

Common Mistakes to Avoid

❌ Ignoring corrosion protection (Use zinc-plated or powder-coated accessories in humid areas). ❌ Overlooking expansion joints (Prevent warping in long runs). ❌ Skipping grounding (Avoid electrical hazards).

Conclusion

The right cable tray accessories make the difference between a safe, efficient installation and a hazard-prone mess. Whether you’re working on a data center, factory, or commercial building, investing in high-quality accessories ensures long-term reliability and compliance.

🚀 Pro Tip: Partner with a trusted manufacturer who provides certified, custom-ready accessories for your project needs!

Call to Action

📞 Need expert advice on cable tray accessories? Contact Less Wire Forms today! 📧 Email: [email protected] | 🌐 Website: www.madewithless.in

#Wire mesh cable tray manufacturer#Industrial cable trays#Cable tray manufacturer#Wire mesh cable tray

0 notes

Text

Solar Panel Racking Systems & Rail Connectors | Corigy

Explore Corigy’s solar panel racking systems and rail connectors designed for durability, safety, and high performance in all solar installations. Feel free to contact us; we are here for you 24/7. Call us at +61 412649818.

0 notes

Text

FIBER PATCH PANELS

Understanding Fiber Patch Panels: The Key to Efficient Fiber Optic Network Management

In today’s high-speed, data-driven world, the demand for faster and more reliable internet connections continues to grow. Central to ensuring this demand is met is fiber optic technology, which has revolutionized the way data is transmitted. As organizations, data centers, and homes rely increasingly on fiber optic networks, the need for efficient management and organization of these networks has led to the widespread use of fiber patch panels.

In this blog, we’ll dive into what fiber patch panels are, their role in fiber optic networks, the benefits they offer, and how they’re used to streamline the connectivity and maintenance of fiber optic systems.

What is a Fiber Patch Panel?

A fiber patch panel is a crucial component in a fiber optic network used to connect, manage, and organize fiber optic cables. It’s essentially a hardware unit that acts as a central hub where fiber optic cables come together, allowing for easy patching, routing, and testing of fiber connections.

Fiber patch panels are typically installed in data centers, telecommunications rooms, or server rooms, where large volumes of network cables need to be organized and managed efficiently. They provide a structured system for distributing fiber optic connections to various devices or endpoints across the network, all while maintaining high performance, reducing clutter, and ensuring a clean and organized setup.

How Do Fiber Patch Panels Work?

Fiber patch panels serve as a central point where all incoming and outgoing fiber optic cables are terminated and connected. Here’s how they generally work:

Fiber Termination: The fiber optic cables are terminated and connected to adapters or ports on the patch panel. This allows for a connection to be made between the fiber optic cable and the network equipment (like routers, switches, or servers).

Patching: Fiber patch cables (shorter fiber optic cables with connectors) are used to establish temporary or permanent connections between ports on the patch panel and other networking equipment. This step is called "patching" because the fiber patch cables are used to make these connections.

Testing & Maintenance: Patch panels make it easy to test and maintain fiber optic connections. Network technicians can simply plug test equipment into the panel’s ports without needing to deal with the messy, complicated task of accessing individual fiber cables within a network.

Cross-Connection: The patch panel allows for easy cross-connections. This is helpful for rerouting or modifying connections without physically changing the fiber optic infrastructure, which is time-consuming and potentially disruptive.

Types of Fiber Patch Panels

There are a few different types of fiber patch panels, each designed to suit specific needs depending on the application and the type of fiber optic cables in use. These include:

1. Rack-Mount Patch Panels

Rack-mount patch panels are designed to be installed in standard 19-inch equipment racks, which are commonly used in data centers and server rooms. These panels can be used to manage large quantities of fiber connections, with different configurations of ports available (e.g., 12, 24, or 48 ports).

Advantages:

Ideal for high-density fiber optic networks.

Space-efficient when mounted in racks.

Can house multiple fiber optic connections in a single unit.

2. Wall-Mount Patch Panels

As the name suggests, wall-mount patch panels are mounted directly to a wall. These are typically used in smaller installations or spaces where a traditional rack setup isn’t practical.

Advantages:

Great for smaller spaces or environments where rack space is limited.

Easier to install and maintain for smaller network setups.

3. Modular Patch Panels

Modular patch panels allow for flexibility in the number of ports and configurations. They typically have removable and replaceable modules that can be swapped out depending on the needs of the network. This makes them ideal for networks that need to scale or change over time.

Advantages:

Highly customizable.

Easily scalable to accommodate growing fiber optic networks.

4. Enclosed Patch Panels

Enclosed fiber patch panels offer additional protection for the fiber optic cables, making them suitable for environments that need to protect equipment from dust, moisture, or physical damage. These panels often come with a hinged cover that can be opened for easy access to the ports.

Advantages:

Added protection for the fiber optic infrastructure.

Ideal for environments where fiber cables need to be protected.

Benefits of Using Fiber Patch Panels

The use of fiber patch panels in fiber optic networks offers several advantages that help ensure the efficiency and organization of these networks:

1. Improved Cable Management

One of the most important benefits of fiber patch panels is their ability to organize and manage fiber optic cables. Fiber optic cables can be tricky to handle, and without proper management, they can become tangled, damaged, or difficult to troubleshoot. Patch panels provide a clean and orderly system for managing cables, helping to reduce clutter and ensuring that cables are easy to trace and identify.

2. Easy Access and Maintenance

Fiber patch panels allow for easy access to fiber optic connections. When network changes or maintenance needs to be performed, technicians can quickly make adjustments without having to disturb the physical fiber cables. Patching, rerouting, and testing fiber connections become more efficient and less disruptive.

3. Scalability

As network demands grow, fiber optic networks need to be scaled up. Patch panels allow for easy expansion, as new ports can be added, and additional fiber connections can be terminated on the patch panel. This scalability ensures that a network can evolve to meet increasing capacity requirements.

4. Flexibility

Fiber patch panels provide the flexibility to modify connections easily. Instead of re-running cables or making permanent changes to the network’s infrastructure, patch panels allow technicians to quickly adjust configurations, reroute signals, or replace faulty connections. This is particularly useful in environments that require frequent changes, such as data centers or telecommunication hubs.

5. Reduced Downtime

Having a central point for managing fiber optic connections helps reduce downtime during maintenance or troubleshooting. Technicians can quickly identify where a fault lies and either repair the issue or reroute connections to maintain network uptime. This is crucial for keeping businesses and services running without significant disruptions.

6. Improved Performance

By maintaining organized, high-quality connections, fiber patch panels help improve the overall performance of a fiber optic network. Properly managed cables reduce the chances of signal degradation, interference, or network errors, ensuring a fast and reliable connection across the network.

Applications of Fiber Patch Panels

Fiber patch panels are used in a wide range of environments and industries, including:

Data Centers: Fiber patch panels are crucial for organizing and managing the vast number of fiber optic connections in data centers, where high-speed data transmission is required across numerous servers and networking equipment.

Telecommunications: Telecom companies use fiber patch panels to manage the fiber optic cables that carry data, voice, and video signals across networks.

Enterprises and Offices: Businesses use fiber patch panels to organize and distribute fiber connections across multiple floors or departments, ensuring reliable connectivity and ease of maintenance.

Home Networking: For large homes or small businesses that use fiber optic broadband, patch panels can help organize and manage the fiber connections in a centralized location, providing easy access for maintenance or upgrades.

Conclusion

Fiber patch panels are a critical component in ensuring the organization, efficiency, and scalability of modern fiber optic networks. By providing a central location for managing and connecting fiber optic cables, patch panels simplify maintenance, increase performance, and allow for easy scalability. Whether you’re building a data center, setting up a small office network, or upgrading your telecommunications infrastructure, investing in a fiber patch panel system will help keep your network clean, organized, and running smoothly.

With the ever-increasing demand for bandwidth and faster data transmission speeds, fiber patch panels are more important than ever. They ensure that fiber optic networks can support the growing needs of businesses, institutions, and consumers alike, all while maintaining the reliability and performance essential for today's connected world.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the brand Choose AYSIS Choose the perfect Storage Organizer AYSIS have many years of experience in shoe racks, and are committed to providing our customers with high-quality and cost-effective home products.AYSIS focuses on the research and development of household products, providing humanized design, fashionable appearance and high-quality products.Providing the best products and the most sincere service to every family has always been AYSIS constant goal. Plastic Shoe Rack Transparent Door-Visible Style 12 Shelf Shoerack 6 Shelf Shoerack 【𝟔 𝐒𝐡𝐞𝐥𝐟 𝐒𝐡𝐨𝐞 𝐑𝐚𝐜𝐤】AYSIS 12 Pairs shoe rack provides a large space to store shoes, toys or handbags, etc.It can help you save more space. Dimension: 44cm(L) x 32cm(W) x 96cm(H). The Max. Load Capacity of Each Cube: 10kg. 【𝐒𝐭𝐨𝐫𝐞𝐬 𝐔𝐩 𝐭𝐨 𝟏𝟐 𝐏𝐚𝐢𝐫𝐬】Perfect for sneakers high-heeled shoes boots stilettos ballet shoes flats casual shoes children's shoes; Holds 12 pairs of shoes more than enough for you and your family's needs. 【𝐒𝐭𝐮𝐫𝐝𝐲 𝐒𝐡𝐨𝐞 𝐒𝐡𝐞𝐥𝐯𝐞𝐬】The cube storage organizer is made of PP plastic panels with metal frame and ABS connectors.Shoe organizer for closet, living room, entry, bedroom, office to make your home tidy. 【𝐄𝐚𝐬𝐲 𝐀𝐬𝐬𝐞𝐦𝐛𝐥𝐲】Shoe storage rack with corresponding installation tools, enough connectors,hammer and installation instructions to help you install it quickly and easily.It is worth noting that each plastic diaphragm and connector need to be tightly connected together, which is inseparable from the help of the hammer. 【𝐄𝐚𝐬𝐲 𝐭𝐨 𝐂𝐚𝐫𝐞】The shoe organizer is made of plastic materials, offering excellent waterproof properties that make it easy to clean with water. Door holes feature is designed for air circulation to prevent buildup odor. 【𝐀𝐝𝐚𝐩𝐭𝐚𝐛𝐥𝐞 𝐚𝐧𝐝 𝐕𝐞𝐫𝐬𝐚𝐭𝐢𝐥𝐞】This cube storage rack is portable and can be personalized according to your needs. It can also be split into 2 or 3 separate rows, or separate small shelf units to organize shoes, or belongings in your wardrobe, bathroom, or any other desired space. [ad_2]

0 notes

Text

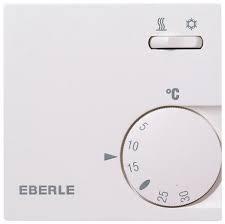

Why Are Changeover Thermostats Essential for Precision Temperature Control?

Introduction to Changeover Thermostats

Changeover thermostats are innovative temperature control devices designed to switch between heating and cooling systems automatically. They play a significant role in maintaining consistent thermal conditions in both commercial and industrial environments. Integrated with various components like sensors, contactors, controllers, and thermal pads, these thermostats are becoming increasingly vital for optimizing energy use and safeguarding sensitive electronics.

How Do Changeover Thermostats Work?

Changeover thermostats operate by detecting the surrounding temperature and toggling between heating or cooling outputs to maintain a desired setpoint. This dual-mode functionality ensures energy-efficient temperature control without requiring manual intervention. They are widely used alongside cables, connectors, capacitors, and switches to automate HVAC systems, server racks, control panels, and more.

Key Features of Changeover Thermostats

Dual Operation

These thermostats automatically alternate between heating and cooling, making them ideal for dynamic environments.

Broad Temperature Range

They offer flexibility with a wide operational range, making them suitable for various industrial and electronics-based setups.

Easy Integration

Compatible with multiple system components such as fuses, microcontrollers, and sensors, changeover thermostats are easy to install into existing infrastructure.

Compact and Durable Design

Built for tough conditions, many models feature robust grips, weather-resistant casing, and compact form factors suitable for enclosures or panels.

Benefits of Using Changeover Thermostats

Enhanced Energy Efficiency

By automatically adjusting heating or cooling, these devices minimize unnecessary power usage. This not only reduces energy bills but also aligns with green building standards.

Equipment Protection

In environments involving electronics like laptops, microprocessors, and controllers, excessive heat can lead to failure. Changeover thermostats help prevent such incidents by ensuring thermal safety.

Reduced Maintenance

Automated thermal regulation reduces the load on HVAC systems and related hardware, extending the lifespan of components like contactors, cables, and tools.

Versatility Across Industries

These thermostats are used in industries ranging from manufacturing to agriculture and IT, thanks to their ability to control temperature across a variety of machinery and setups.

Typical Applications of Changeover Thermostats

HVAC Systems

Perfect for climate control in commercial buildings, these thermostats ensure efficient heating and cooling cycles.

Industrial Control Panels

With components like thermal pads, fuses, and capacitors housed inside, temperature stability becomes crucial, and changeover thermostats handle that seamlessly.

Server Rooms and Data Centers

To protect microcontrollers and microprocessors from heat damage, maintaining a stable thermal environment is essential.

Greenhouses and Agricultural Environments

Temperature control is key to crop health, and these thermostats enable precise environmental regulation.

Laboratory Equipment and Testing Environments

Ensuring consistent thermal conditions is necessary for accurate results, and changeover thermostats support this need effectively.

Types of Changeover Thermostats

Manual Changeover Thermostats

These require user input to toggle between modes. They are cost-effective and suited for simpler systems.

Automatic Changeover Thermostats

Fully autonomous, these units detect and switch modes based on environmental changes. They're ideal for sophisticated systems involving sensors, controllers, and electronics.

Factors to Consider When Choosing a Changeover Thermostat

Temperature Range and Accuracy

Ensure that the thermostat supports the temperature thresholds your system requires, particularly when managing electronics like switches or capacitors.

Electrical Compatibility

Check if the unit can handle your setup’s voltage and current ratings, especially when integrating it with contactors, cables, or power distribution tools.

Installation Environment

Choose a model with appropriate ingress protection (IP rating) if it will be exposed to oils, moisture, or dust.

Integration Support

Make sure the thermostat can connect with other system elements like connectors, sensors, and safety modules for seamless operation.

Why Are Changeover Thermostats Important for Electronic Systems?

Electronics such as microcontrollers, capacitors, and switches generate heat during operation. Without a reliable way to manage this thermal load, performance can degrade, and safety hazards may emerge. Changeover thermostats serve as a control center, automatically regulating heating or cooling to protect sensitive equipment and optimize performance.

Additionally, industries working with tools, LEDs, cables, and thermal interfaces benefit from the precise control these thermostats offer, helping prevent downtime and extending component lifespan.

Conclusion

Changeover thermostats are essential tools for smart temperature control in today's complex environments. Their ability to switch between heating and cooling ensures efficient energy usage, system protection, and ease of automation. Whether installed in HVAC systems, control panels, or electronics enclosures, these thermostats are integral to maintaining safe and stable operational conditions.

As technology evolves, integrating components such as fuses, sensors, connectors, thermal pads, and microprocessors requires robust and reliable thermal management solutions. Changeover thermostats offer exactly that, helping industries stay ahead in terms of safety, sustainability, and performance.

0 notes

Text

Step-by-Step Guide to Installing Solar Panels in Lucknow

India’s energy landscape is shifting towards sustainable solutions, and solar panels in Lucknow are leading the way. With abundant sunshine, Lucknow is an ideal location for harnessing solar energy. Whether for your home or business, installing rooftop solar panels can reduce electricity bills and promote green energy. Here’s a step-by-step guide to help you through the process.

Steps to Install Solar Panels in Lucknow

1. Site Assessment

Begin by evaluating your rooftop or installation area. Check the structural integrity of the roof to ensure it can support the weight of the solar panels. A proper assessment ensures a seamless installation process.

2. Calculate Energy Needs

Determine your energy requirements. For homes, a 400-watt solar panel may suffice, while businesses may need higher capacity systems. Consulting a trusted solar panel installer in Lucknow can help you design a system tailored to your needs.

3. Design the System

Create a layout for your rooftop solar panels, considering factors like sunlight exposure and roof space. Choose the right inverter, wiring, and mounting system to ensure optimal performance.

Permission to Install Solar Panels

4. Obtain Required Permits

Contact local authorities to secure necessary permits for solar panel installation. Submit your system design and documentation for approval.

5. Interconnection Agreement

Apply for an interconnection agreement with your utility company. This allows you to connect your solar system to the grid and earn credits for excess energy produced.

Final Installation Process

6. Install Mounting System and Solar Panels

Secure mounting racks to your roof and align them properly. Attach the solar panels to the racks and connect them using appropriate connectors.

7. Wire the System

Run wiring from the solar panels to the inverter. Ensure all connections are secure and protected from weather conditions.

8. Install the Inverter and Connect to Grid

Mount the inverter near your electrical panel and connect it to the solar panels. Link the inverter to the grid using a dedicated circuit breaker.

Connections and Activation

9. Turn on the Inverter and Test

Switch on the inverter and test the system using a multimeter. Ensure the system is generating power efficiently.

10. Monitor the System

Install a monitoring system to track energy production and consumption. Schedule regular maintenance to keep your solar panels performing optimally.

Conclusion

Installing solar panels in Lucknow is a smart investment for reducing energy costs and promoting sustainability. By following these steps, you can seamlessly transition to solar energy. For expert assistance, connect with trusted solar panel installers in Lucknow and enjoy the benefits of clean, renewable energy.

0 notes

Text

The Ultimate Checklist for Network Cable Organization

Network administrators and IT professionals know the frustration of dealing with tangled cables, unlabeled connections, and chaotic server rooms. Poor cable organization checklist implementation can lead to downtime, maintenance headaches, and reduced network performance. Whether you're setting up a new data center or reorganizing an existing infrastructure, proper network cable management is essential for maintaining a professional, efficient, and scalable network environment.

A well-organized cabling system isn't just about aesthetics—it directly impacts your network's reliability, troubleshooting efficiency, and future expansion capabilities. This comprehensive structured cabling guide will walk you through the essential steps to transform your cable chaos into a well-organized, professional network infrastructure.

Planning Your Cable Organization Strategy

Before diving into physical organization, successful network cable management begins with careful planning. Start by documenting your current network topology and identifying all connection points. This initial assessment helps you understand the scope of work and prevents costly mistakes during implementation.

Create a detailed floor plan that includes rack locations, cable pathways, and connection requirements. Consider both current needs and future expansion when designing your layout. A good rule of thumb is to plan for 30% additional capacity to accommodate growth without major reorganization.

When planning cable routes, prioritize the shortest paths while maintaining proper separation between power and data cables. This approach minimizes signal interference and reduces cable costs. Remember that well-planned cable arrangement tips can save hours of troubleshooting later.

Essential Tools and Materials for Cable Organization

Professional cable organization requires the right tools and materials. Your toolkit should include cable ties, velcro straps, cable labels, cable management arms, and a quality label printer. Invest in proper cable management hardware—it's worth the upfront cost for long-term maintenance benefits.

For fiber optic installations, specialized tools become crucial. Fiber optic patch cords require careful handling and specific organizational methods to prevent damage. Unlike copper cables, fiber connections are more sensitive to bending and stress, making proper support systems essential.

Cable management panels and horizontal cable managers help maintain organized pathways in rack environments. These components work together with your fiber optic patch panel to create clean, professional installations that are easy to maintain and modify.

Color Coding and Labeling System

Implementing a consistent color coding system is one of the most effective cable arrangement tips for maintaining organization. Establish color standards for different cable types, network segments, or departments. For example, use blue for data connections, yellow for voice, and red for critical systems.

Your labeling system should be comprehensive and standardized across the entire organization. Each cable should have labels at both ends, clearly identifying source and destination points. Use a consistent naming convention that includes rack numbers, port numbers, and connection purposes.

When working with fiber optic cables, pay special attention to connector types and specifications. An MPO/MTP cassette system may require different labeling strategies compared to standard SC or LC connections. Document these differences in your organization standards to ensure consistency across teams.

Rack Organization Best Practices

Server rack organization forms the backbone of effective network cable management. Start by installing proper cable management infrastructure, including vertical and horizontal cable management systems. These components provide organized pathways for cables and prevent the spaghetti-like tangles that plague poorly managed installations.

Position your fiber optic patch panel at an appropriate height for easy access while maintaining proper cable bend radius requirements. The patch panel should be easily accessible for maintenance while keeping cables organized and protected.

Implement the "service loop" concept by creating small, organized loops of extra cable length near connection points. This practice allows for future equipment moves without requiring complete cable replacement. However, avoid excessive cable length that creates unnecessary clutter.

Power and Data Separation

One critical aspect of structured cabling guide implementation is maintaining proper separation between power and data cables. Electrical interference from power cables can significantly impact network performance, especially for copper-based connections.

Maintain at least 12 inches of separation between power and data cables when running parallel routes. When cables must cross, do so at 90-degree angles to minimize interference. This separation is particularly important when installing sensitive equipment like fiber optic cables alongside power feeds.

Use separate cable management systems for power and data whenever possible. This separation not only reduces interference but also simplifies troubleshooting and maintenance procedures.

Documentation and Maintenance

No cable organization checklist is complete without proper documentation procedures. Create and maintain accurate cable documentation that includes cable schedules, connection diagrams, and testing records. This documentation becomes invaluable during troubleshooting and future modifications.

Establish regular maintenance schedules to inspect cable organization and update documentation. Cable management isn't a one-time activity—it requires ongoing attention to maintain effectiveness. Regular audits help identify issues before they become major problems.

When working with specialized components like MPO/MTP cassette systems, maintain detailed records of connector types, fiber counts, and polarity configurations. This information is crucial for future expansions or modifications.

Advanced Organization Techniques

For complex installations, consider implementing zone-based cable management strategies. This approach groups cables by function, destination, or service level, making troubleshooting and maintenance more efficient. Zone-based organization works particularly well in large data centers with diverse equipment types.

Implement proper cable support systems throughout the installation. Cables should be supported every 4-6 feet to prevent sagging and stress on connections. Pay particular attention to fiber optic patch cord installations, as these cables are more susceptible to damage from improper support.

Consider implementing intelligent cable management systems that provide automated documentation and monitoring capabilities. These advanced systems can track cable connections, monitor performance, and alert administrators to potential issues.

Troubleshooting and Problem Prevention

Well-organized cables significantly reduce troubleshooting time and improve problem resolution. When cables are properly labeled and organized, technicians can quickly identify and isolate issues without disrupting unrelated systems.

Create troubleshooting procedures that take advantage of your organized cable infrastructure. Include cable tracing procedures, connection verification steps, and escalation protocols in your documentation. This preparation pays dividends during critical outages.

Regular testing and inspection of cable connections helps prevent problems before they impact operations. Establish testing schedules that align with your organization's change management and maintenance windows.

Future-Proofing Your Cable Organization

Design your cable organization system with future growth in mind. Leave space for additional cables, plan for new equipment installations, and consider emerging technologies that might require different cable types or organization strategies.

Stay informed about industry trends and new cable management products. Technologies like high-density fiber optic cable solutions continue to evolve, offering new opportunities for improved organization and performance.

Conclusion

Effective network cable management requires careful planning, proper tools, and ongoing maintenance. By following this comprehensive cable organization checklist, you'll create a professional, efficient, and scalable network infrastructure that supports your organization's current needs while preparing for future growth.

Remember that good cable organization is an investment in your network's long-term reliability and maintainability. The time spent implementing proper cable arrangement tips and structured cabling practices will pay significant dividends in reduced troubleshooting time, improved network performance, and easier future modifications.

Whether you're working with traditional copper connections or advanced fiber optic systems, the principles of good cable organization remain consistent. Plan carefully, implement systematically, and maintain diligently for the best results.

0 notes