#Robotic Palletizing

Explore tagged Tumblr posts

Text

Revolutionizing Manufacturing: Robotic Palletizing in the Production Line

The landscape of manufacturing is undergoing a significant transformation, with advanced technologies reshaping traditional processes. Among these innovations, robotic palletizing systems have emerged as key players in revolutionizing the efficiency, accuracy, and overall productivity of production lines. This article explores the impact of robotic palletizing in manufacturing, shedding light on its benefits, applications, and the future of this transformative technology.

0 notes

Text

https://www.twspl.com/robotic-palletizer.php

TWSPL offers Robotic Palletizer for loading and unloading boxes, bags & containers to and from pallets in an industrial setup. This type of palletizer is transferable and can handle different pallet patterns

#Robotic Palletizer#Robotic Palletizers#Robotic Palletizing#Robotic Palletizing System#Robotic Bag Palletizer#Robotic Case Palletizer

0 notes

Note

Omega with Expression H8 in the Arson color palette

I like how you ask for the OC with literally no facial skin for the expressions challenge. Anyways his boss is going awol and he's so jover it 😔

#ruckis vandalizes#art#artists on tumblr#non fandom#order of the stars#original character#oc#anthro#furry#cyborg#Robot#jackalope#lich#undead#skeleton#zombie#ask challenge#expression challenge#digital art#color pallete challenge#abisalli emotion challenge#abisalli color palette challenge#omega (clover)#rabbit#lagomorph#furry art#fantasy art#cartoon art#scifi#mechanoid

26 notes

·

View notes

Text

Trying something a lil subtler w this guys pallet✨✨

#makes my bad guy a walking robot boil#villain#oc art#character design#ambsguys#integrator#robophilia#robot oC#cyborg#villain core#color pallet

9 notes

·

View notes

Text

Send me random color pallets and characters/ocs!! I might only do a few so don't be upset if I don't get to you!!

I'm bored and I wana step out of my comfort zone and do a color pallet challenge..

#transformers#maccadam#fursona#furry#fursona art#oc#oc art#color pallet challenge#color pallet#drawing your ocs#drawing challenge#taking drawing requests#tmnt#pacman and the ghostly adventures#robots#bugs#sona art#sona#persona#batim#fnaf#batdr#sgrb#super giant robot brothers#character suggestions#original characters#original species#original character

8 notes

·

View notes

Text

idk really what to make when creators from the western half of the tf Franchise Conglomerate are like. were doing something japanese inspired as homage to tfs being japanese. well one cause its results is a lot samurais, ninjas and kabuki makeup. and two. cause its like. man. those things are just over there. about like half of all tf shows are animes and yeah. they will make a ronin or ninja from time to time! also a tanuki 10/10 no notes this is a heinrich stan account.

but also third. how are you forgetting about the TRAINS??? go make some fucking bullet train bots again. u dweebs. indulge for a second in the idea of high speedrail.

#some shit#its not called cisformers#if i were to try and best and articulate obv im notsaying. noooo never reference jpn culture in ur alien robot ficiton#just more like. the obvious limited pallet of jpn culture they DO think to reference? u understand.#its never like. this tf practices kendo the same like. tfs might do american sports#and also. limited references to like. jpn vehicle culture? which? seems like the obvious gimmie?#i mean one of those homage characters if a samurai AND a reference to car drifting. which. is smth i guess.#been thinking about this cause the last show but really inspired by tf GO which has an oppie that is both a bullet train and a DRAGON#u fucking wish. u fucking wish u had that swag hasbro.

2 notes

·

View notes

Text

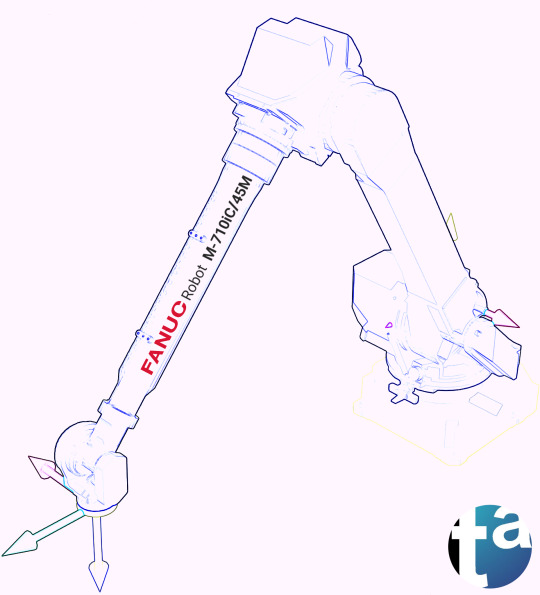

🦾 A007 - Palletizing Robot FANUC M-710iC/45M FanucAmerica Vision Reading QRCodes Automation Manipulator MaterialHandling Robotics ▸ TAEVision Engineering on Pinterest

Data A007 - Jul 17, 2023

#automation#robot#robotics#palletizing#FANUC#FanucAmerica#M-710iC/45M#FANUC M-710iC/45M#Vision Reading QRCodes#manipulator#MaterialHandling

5 notes

·

View notes

Text

#Robotic Case Packing Machine#Packaging Robots#Robotic Packaging Automation#Robotic Case Packers#Robotic Palletizers#packaging machine#packaging automation#lube oil blending plant#lube oil blending machinery

0 notes

Text

Industrial Robotics Market to be Worth $37.1 Billion by 2031

Meticulous Research®—a leading global market research company, published a research report titled ‘Industrial Robotics Market—Global Opportunity Analysis and Industry Forecast (2024-2031)’. According to this latest publication, the industrial robotics market is projected to reach $37.1 billion by 2031, at a CAGR of 6.8% from 2024–2031.

The industrial robotics market is experiencing growth due to government support encouraging the adoption of industrial robots and the increasing use of robots in the manufacturing sector. However, market growth is hindered by high initial investment requirements and performance issues with robots.

In addition, the increasing automation across the automotive and electronics sectors and the rising focus on reducing human labor across industries are potential growth opportunities for market players. The market faces substantial challenges, including a lack of skilled professionals and safety issues with robots while working with other industrial systems.

Furthermore, the surging adoption of IoT technology for remote monitoring and control of robotic systems and the growing use of human-robot collaboration to automate tasks are prominent trends in the industrial robotics market.

Key Players:

The industrial robotics market is characterized by a moderately competitive scenario due to the presence of many large- and small-sized global, regional, and local players. The key players operating in the industrial robotics market are ABB Ltd (Switzerland), Fanuc Corporation (Japan), YASKAWA Electric Corporation (Japan), KUKA AG (Germany), Mitsubishi Electric Corporation (Japan), Kawasaki Heavy Industries, Ltd. (Japan), Universal Robots A/S (A Part of Teradyne Inc,) (Denmark), Stäubli International AG (Switzerland), Techman Robot Inc (Taiwan), Denso Corporation (Japan), OMRON Corporation (Japan), HD Hyundai Co Ltd (South Korea), Bosch Rexroth AG (A Part of Robert Bosch GmbH) (Germany), Seiko Epson Corporation (Japan), Dürr Aktiengesellschaft (Germany), Comau S.p.A. (Italy), F&P Robotics AG (Switzerland), and Franka Robotics GmbH (Germany).

The industrial robotics market is segmented based on component, payload, application, and end-use industry. The report also evaluates industry competitors and analyzes the industrial robotics market at the regional and country levels.

Among the components studied in this report, the robots segment is anticipated to dominate the industrial robotics market in 2024. The widespread adoption of robots by consumers is driving the expansion of their application across various industries. Robots are increasingly utilized to perform repetitive and hazardous tasks with consistent precision, accuracy, and quality. Key factors contributing to the segment's dominant position in the industrial robotics market include the growing demand for robots to enhance workplace safety, reduce labor costs, improve productivity and profitability, and minimize the risk of physical injury by reducing reliance on human labor for potentially dangerous activities.

Among the payload studied in this report, the up to 60 kg segment is anticipated to dominate the industrial robotics market in 2024. The rising demand for robots with payload capacities of up to 60 kg, driven by increased automation in the electrical and electronics industries for assembly and handling applications, is a key factor in the growth of this segment. Additionally, the widespread adoption of these robots across diverse sectors, including automotive, electronics, logistics, food, pharmaceuticals, and cosmetics, further strengthens their dominant position in the industrial robotics market.

Among the applications studied in this report, the material handling segment is anticipated to dominate the industrial robotics market in 2024. The growing adoption of material handling robots to automate repetitive, labor-intensive, and hazardous tasks on production lines is a key factor driving the growth of this segment. Additionally, the rising demand for material handling robots to enhance production line efficiency and improve customer satisfaction by ensuring timely delivery of high-quality products further contributes to the segment's dominant position in the industrial robotics market.

Among the end-use industries studied in this report, the automotive segment is anticipated to dominate the industrial robotics market in 2024. The growing adoption of robotics in the automotive industry is driven by manufacturers' need to accelerate production, reduce costs, enhance quality, and ensure worker safety. Key benefits offered by industrial robots in this sector���including cost-effectiveness, improved efficiency, enhanced safety, and increased speed and precision—are significant factors contributing to the segment’s dominant position in the industrial robotics market.

Geographic Review

This research report analyzes major geographies and provides a comprehensive analysis of Asia-Pacific (China, Japan, South Korea, Taiwan, Singapore, India, Thailand, Australia & New Zealand, Indonesia, and Rest of Asia-Pacific), Europe (Germany, Italy, Sweden, France, Austria, Denmark, Spain, Netherlands, Norway, U.K., and Rest of Europe), North America (U.S. and Canada), Latin America (Mexico, Brazil, and Rest of Latin America), and Middle East & Africa (UAE, Israel, Saudi Arabia, and Rest of Middle East & Africa).

Asia-Pacific is anticipated to dominate the industrial robotics market in 2024. The widespread adoption of robotics in the region is driven by rising labor costs and the increasing need for manufacturers to automate production processes to manage cost expenses effectively. Additionally, the growing demand for robotics, fueled by the rapid development of industries such as automotive, electronics, consumer goods, and pharmaceuticals, is a key factor contributing to the region's dominant position in the industrial robotics market.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5278

Key Questions Answered in the Report-

What is the value of revenue generated by the sale component, payload, application, and end-use industry?

At what rate is the global demand for industrial robotics projected to grow for the next five to seven years?

What is the historical market size and growth rate for the industrial robotics market?

What are the major factors impacting the growth of this market at global and regional levels?

What are the major opportunities for existing players and new entrants in the market?

Which offering segments create major traction in this market?

What are the key geographical trends in this market? Which regions/countries are expected to offer significant growth opportunities for the manufacturers operating in the h industrial robotics market?

Who are the major players in the industrial robotics market? What are their specific product offerings in this market?

What recent developments have taken place in the industrial robotics market? What impact have these strategic developments created on the market?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Industrial Robots Market#SCARA Robot#Robotics Technology#Robotics and Automation Engineering#Palletizing Robot#Manufacturing Robots#Automation Robotics

0 notes

Text

Palletizing robots work by combining precise motion control with advanced sensors. They’re programmed to stack various product types quickly and safely. Learn how they streamline repetitive tasks and reduce labor costs.

0 notes

Video

Palletizing & Machine Tending: The Future of Robotic Automation in Manufacturing

0 notes

Text

Autonomous Forklifts: A Smarter and Safer Solution

The self-governing forklift is actually perhaps one of the very most functional and essential devices in modern storehouse functions. These driverless equipments are developed to relocate sizable and massive bunches effectively and properly, without the necessity for human drivers. They are actually geared up along with enhanced navigation systems that enable all of them to run in a range of atmospheres, from slender alleys to busy loading docks. For providers searching to acquire driverless forklifts in the USA, NJ, Atlanta, and California, the benefits are actually very clear.

For more information: https://araplraas.com/

0 notes

Text

Palletizing systems automate stacking items – like boxes, bags, or drums – onto pallets for secure shipping and storage. Once a manual, labour-heavy task, modern pallet handling systems are fully automated systems that increase safety and precision, reducing the risk of injury and ensuring a smoother workflow.

0 notes

Text

Yeah okay I think I can confirm that exercising the stuck dead shoulder still makes it worse, thanks for not taking my word for it again

#Holy shit dude#unless i invent some way to pull some solution out of my ass I'm just going to be bent sideways the rest of my life#if i could fucking reach it I'd just do it myself holy fuck#do i have to build a telemetry robot out of garbage#because i am pretty sure i could build some kind of giant pantograph out of salvaged shipping pallet wood#i will goddamn da vinci my shit out of this if i have to and im going to probably stay reasonably pissed about it for a while#holy fuck dude

1 note

·

View note

Text

Global Palletizing Robot Market is expected to surge a value of USD 2,834.6 million by 2033 at a CAGR of 6.1%.

Global Palletizing Robot Market: An In-Depth Analysis

The Global Palletizing Robot Market is on a trajectory of substantial growth, fueled by advancements in automation technology and increasing demand across various industries. As businesses aim to enhance operational efficiency and reduce labor costs, the integration of robotic solutions in palletizing processes has become more prominent. This article explores the market dynamics, key trends, growth drivers, and regional insights surrounding the Global Palletizing Robot Market.

Market Overview

The Global Palletizing Robot Market is expected to reach a valuation of USD 1,659.6 million in 2024, with projections indicating further growth to USD 2,834.6 million by 2033, reflecting a compound annual growth rate (CAGR) of 6.1%. This remarkable growth underscores the increasing reliance on automation in sectors such as e-commerce, food and beverages, and pharmaceuticals.

Growth Analysis

In recent years, the palletizing robot market has experienced notable expansion, primarily driven by the surge in demand for automation. Palletizing robots streamline the process of stacking products such as boxes, cases, and bags onto pallets, thereby significantly enhancing productivity and operational efficiency. The rising demand for automation is particularly pronounced in key sectors like e-commerce and manufacturing, where repetitive tasks can benefit immensely from robotic solutions.

Moreover, advancements in articulated, gantry, and collaborative robotic technologies have made it possible for these robots to adapt to a variety of palletizing tasks. Continuous innovation in this space is crucial as manufacturers strive to develop intelligent robotic solutions that cater to diverse packaging needs.

Request Your Complimentary PDF Sample Today!@ https://dimensionmarketresearch.com/report/palletizing-robot-market/request-sample

Technological Advancements

The growth of the Global Palletizing Robot Market is closely linked to advancements in robotics technology. The integration of artificial intelligence (AI) and machine learning has revolutionized the functionality of palletizing robots, enabling them to handle complex tasks such as mixed-product palletizing. AI enhances operational efficiency by optimizing spacing and reducing costs associated with manual errors. Collaborative robots (cobots) have also gained traction, especially among small and medium-sized enterprises (SMEs), due to their cost-effectiveness and ability to work alongside human operators safely.

Regional Insights

North America

North America holds a dominant position in the Global Palletizing Robot Market, anticipated to capture approximately 39.2% of the market share by the end of 2024. The region's advanced industrial landscape and high adoption rates of automation technologies are pivotal factors driving this growth. Key sectors like food and beverages, e-commerce, and pharmaceuticals are increasingly leveraging palletizing robots to improve efficiency and reduce operational costs.

Asia-Pacific

The Asia-Pacific region is poised for rapid growth, with emerging economies such as China and India spearheading demand for automation solutions. The surge in industrialization and modernization efforts in these countries is expected to propel the market further.

The U.S. Market

The U.S. Palletizing Robot Market is projected to reach USD 547.1 million in 2024, eventually growing to USD 903.5 million by 2033, at a CAGR of 5.7%. The market's growth is primarily driven by the increasing demand for automated palletizing systems across various industries, particularly in food and beverages, e-commerce, and pharmaceuticals.

Key Market Drivers

Increasing Demand for Automation

The accelerated growth of e-commerce, particularly post-pandemic, has amplified the demand for automated warehousing and logistics solutions. Palletizing robots play a crucial role in efficiently sorting, stacking, and packaging products for shipment, thereby reducing human labor and speeding up order fulfillment.

Labor Shortages and Rising Costs

Labor shortages, especially in developed economies, are prompting businesses to seek automation solutions. The high costs associated with manual labor, coupled with the challenges posed by the pandemic, have led to increased reliance on palletizing robots, which provide a cost-effective alternative.

Buy this Exclusive Report Here Only@ https://dimensionmarketresearch.com/checkout/palletizing-robot-market/

Market Challenges

High Initial Investment Costs

One of the significant barriers to entry for many businesses, particularly SMEs, is the high initial investment required for robotic systems. The cost of hardware, software, and necessary infrastructure modifications can be prohibitive, limiting widespread adoption.

Technical Challenges and Maintenance

The integration of robotic palletizing systems into existing production lines can pose challenges, especially in facilities with outdated machinery. The need for skilled technicians for setup and maintenance further complicates the implementation process.

Key Players

The Global Palletizing Robot Market features several key players, including:

These companies are committed to innovation, focusing on developing efficient and intelligent robotic solutions that cater to the evolving needs of various industries.

Use Cases of Palletizing Robots

Food and Beverage Industry

Palletizing robots are invaluable in the food and beverage sector, where they handle products like cans, bottles, and packaged goods. Their precision in stacking optimizes space on pallets and enhances overall operational efficiency.

E-commerce and Retail

The booming e-commerce sector has increased the demand for effective warehousing solutions. Palletizing robots are utilized to manage the ever-growing volume of parcels, ensuring efficient stacking and shipping.

Pharmaceutical Industry

Given the sensitivity of pharmaceutical products, including medicines and vaccines, palletizing robots are essential in this industry. They ensure high precision in stacking and minimize contamination risks during packaging.

Manufacturing and Automotive

In manufacturing and automotive sectors, palletizing robots automate the stacking of heavy components, significantly speeding up production lines while ensuring safety in handling bulk and irregularly shaped items.

Market Dynamics

Trends

Integration of AI and Machine Learning

The adoption of AI and machine learning in palletizing robots represents a significant trend in the market. AI enables robots to learn from operational data and make dynamic adjustments, enhancing flexibility and efficiency.

Rise of Collaborative Robots (Cobots)

Cobots are increasingly being used alongside human operators in palletizing tasks, enhancing productivity while ensuring safety. Their adaptability to existing systems without major infrastructural changes makes them attractive for SMEs.

Growth Opportunities

Expansion into Emerging Markets

Emerging markets in Asia-Pacific and Latin America are viewed as prime opportunities for growth. Investment in automation technologies is rising as industries modernize their operations.

Development of Customizable Solutions

The demand for customizable and modular palletizing systems is growing, enabling businesses to scale operations without extensive reconfigurations. This adaptability is crucial in industries with fluctuating demand.

Restraints

High Initial Investment Costs

The upfront costs associated with robotic systems can deter many businesses from adoption, particularly in sectors sensitive to price fluctuations.

Technical Challenges

Integrating robotic systems into existing workflows requires technical expertise that may not be readily available in all regions, particularly in emerging markets.

Research Scope and Analysis

By Component

Robotic arms dominate the component segment of the palletizing robot market, holding 37.1% of the market share in 2024. Their versatility and precision make them ideal for handling a variety of products across different industries.

By Technology

Articulated robots are expected to lead the robotic palletizers' technology segment with a market share of 35.0% in 2024. Their flexibility and ability to perform complex palletizing tasks contribute to their popularity.

By Payload Capacity

Medium payload robots (101–500 kg) are gaining traction due to their versatility, making them suitable for a wide range of applications across industries.

By Application

The case palletizing segment is expected to dominate the application area, driven by high demand in food and beverages, pharmaceuticals, and consumer goods.

By End User

The pharmaceutical industry is the leading end-user segment, driven by stringent requirements for precision, hygiene, and operational efficiency.

FAQs

1. What is the expected growth rate of the Global Palletizing Robot Market?

The Global Palletizing Robot Market is expected to grow at a CAGR of 6.1% from USD 1,659.6 million in 2024 to USD 2,834.6 million by 2033.

2. What industries are driving the demand for palletizing robots?

Key industries driving demand include food and beverages, e-commerce, pharmaceuticals, and manufacturing.

3. What are the key technological trends in the palletizing robot market?

The integration of AI and machine learning, along with the rise of collaborative robots (cobots), are significant technological trends in the market.

4. What challenges does the palletizing robot market face?

Challenges include high initial investment costs and technical difficulties in integrating robotic systems into existing production lines.

5. Which region is expected to dominate the Global Palletizing Robot Market?

North America is projected to dominate the market, expected to hold about 39.2% of the share by the end of 2024, due to advanced industrial sectors and high adoption of automation technologies.

Conclusion

The Global Palletizing Robot Market is on a robust growth trajectory, driven by technological advancements and an increasing demand for automation across various sectors. While challenges such as high initial investment costs and technical integration remain, the opportunities for growth, especially in emerging markets and through innovative solutions, are significant. As businesses continue to prioritize efficiency and cost-effectiveness, the adoption of palletizing robots will likely accelerate, shaping the future of automated manufacturing and logistics.

0 notes