#Rust Preventive Oils

Explore tagged Tumblr posts

Text

The Science Behind Rust Preventive Oils: Additives, Film Types, and Corrosion Inhibition Mechanisms

Introduction

Corrosion is a persistent enemy of metal across industries—from automotive and aerospace to manufacturing and construction. As metal surfaces are exposed to moisture, oxygen, and environmental contaminants, the risk of oxidation increases. To combat this, manufacturers rely heavily on Rust Preventive Oils, which serve as a barrier and chemical shield to protect metals during storage, transportation, and idle phases.

Understanding the science behind Rust Preventive Oils—from their chemical composition and additive packages to the way they form protective films and block corrosion—is essential for selecting the right solution for your specific application.

What Are Rust Preventive Oils?

Rust Preventive Oils are specially formulated protective lubricants applied to metal surfaces to prevent the onset of corrosion. They function by either forming a physical barrier or chemically neutralizing corrosion triggers, ensuring that air and moisture do not reach the metal substrate.

They are widely used in sectors such as:

Metalworking and machining

Automotive component manufacturing

Tool and die production

Military and aerospace storage

Industrial equipment preservation

Key Components and Additives

The performance of Rust Preventive Oils is largely determined by their base oil and the additives blended into them. Each ingredient plays a specific role in enhancing corrosion resistance, film adhesion, and longevity.

1. Base Oils

Base oils provide the medium in which active additives are dispersed. Depending on the application, manufacturers use mineral oils, synthetic oils, or water-based carriers. The base oil also affects viscosity, film thickness, and compatibility with other coatings or paints.

2. Corrosion Inhibitors

These are the most crucial additives in any rust preventive formula. They work by forming a monomolecular layer on the metal surface, displacing moisture and oxygen. Types of corrosion inhibitors include:

Polar inhibitors that adhere strongly to metal

Volatile corrosion inhibitors (VCIs) that release protective vapors

Passivating agents that neutralize acidic residues

3. Antioxidants

These slow down the oxidative degradation of the oil itself, ensuring the product remains stable over long periods.

4. Demulsifiers and Emulsifiers

In water-displacing or emulsifiable oils, these additives help either separate or stabilize water-oil mixtures for ease of removal or rinsing.

5. Wetting Agents

These improve the oil’s ability to spread and coat irregular metal surfaces, ensuring consistent film formation.

Types of Protective Films

The type of film left by a Rust Preventive Oil directly impacts its performance and usability in specific environments. There are several film types used depending on the desired duration and conditions of protection.

1. Dry-to-Touch Films

These leave a nearly invisible, non-oily film on the surface. They’re preferred for parts that will be handled frequently or assembled soon after storage.

2. Oily Films

These are more robust and designed for moderate to long-term protection. The oily residue provides lubrication and acts as a barrier against contaminants.

3. Waxy or Greasy Films

These thick, tacky coatings are ideal for extended outdoor storage or harsh environments. They can withstand heavy condensation, salt spray, and industrial pollutants.

4. Water-Displacing Films

These are specifically formulated to displace water from the surface before forming the protective layer, making them essential in high-humidity conditions.

Mechanisms of Corrosion Inhibition

Rust Preventive Oils work through a combination of physical protection and chemical inhibition, creating multiple layers of defense against corrosion.

1. Barrier Protection

The most straightforward mechanism is forming a physical film that seals off the metal from air and water. This film prevents the electrochemical reaction required for rust formation.

2. Adsorption on Metal Surfaces

Many additives, especially polar inhibitors, adsorb onto metal surfaces, creating a tightly bound molecular layer. This layer acts as a secondary defense if the primary oil film is breached.

3. Neutralization of Acids

Some additives are alkaline in nature and neutralize acidic contaminants that could accelerate corrosion.

4. Hydrophobic Action

The hydrophobic nature of oils inherently repels moisture, reducing the chance of water penetrating to the metal surface.

Application Methods

To be effective, Rust Preventive Oils must be applied correctly. Common application techniques include:

Dipping: Suitable for small or mass-produced parts

Brushing or Spraying: Best for large or irregular surfaces

Flooding or Draining: Ideal for internal cavities or precision equipment

Electrostatic Coating: In controlled environments for uniform film application

After application, it’s essential to allow sufficient time for the film to set or dry before moving or packaging the components.

Factors Affecting Performance

Several external factors can influence the effectiveness of Rust Preventive Oils:

Surface Preparation: Dirt, grease, or residual moisture can impair film formation

Environmental Conditions: Temperature, humidity, and air pollutants play a role in how long the oil remains effective

Oil Compatibility: Some Rust Preventive Oils must be removed before painting, welding, or coating

Storage Duration: Short-term vs. long-term storage calls for different oil types and film thicknesses

Sustainability and Safety Trends

Modern formulations of Rust Preventive Oils are increasingly focused on environmentally friendly and worker-safe alternatives. Many now contain:

Low-VOC solvents

Biodegradable base oils

Non-toxic additives

These innovations help companies align with safety regulations and sustainability goals without compromising corrosion protection.

Conclusion

The effectiveness of Rust Preventive Oils lies in their sophisticated chemistry and the synergy between their base oils, additives, and film-forming properties. By forming a comprehensive barrier and interacting chemically with the metal surface, these oils provide reliable, cost-effective protection against corrosion.

Understanding the science behind how they work empowers manufacturers, maintenance engineers, and procurement specialists to make informed decisions, extend equipment life, and prevent costly downtime.

0 notes

Text

Choosing the Right Rust Preventive Oil for Your Industry Needs

Rust and corrosion pose significant challenges across various industries, from automotive manufacturing to aerospace. The right rust preventive oil can protect metal surfaces, extending their lifespan and reducing maintenance costs. However, selecting the appropriate rust preventive oil requires understanding the specific needs of your industry and the characteristics of available products. This guide will help you choose the right rust preventive oil for your industry needs.

Understanding Rust Preventive Oils

Rust preventive oils are formulated to create a protective barrier on metal surfaces, preventing moisture, oxygen, and other corrosive elements from causing rust and corrosion. These oils not only protect against rust but also provide lubrication, which can reduce wear and friction on moving parts.

Types of Rust Preventive Oils

Solvent-Based Oils:

Characteristics: Thin and easy to apply, these oils evaporate quickly, leaving a protective film.

Applications: Ideal for temporary protection and for parts that need a quick drying time.

Oil-Based Oils:

Characteristics: Thicker with long-lasting protection, these oils provide robust barriers against moisture and corrosion.

Applications: Suitable for heavy-duty applications where prolonged protection is necessary.

Water-Based Oils:

Characteristics: Eco-friendly, these oils are easy to clean and often provide temporary protection.

Applications: Used in environments where environmental impact is a concern and for short-term protection.

Factors to Consider When Choosing Rust Preventive Oils

1. Type of Metal

Different metals react differently to rust preventive oils. It's crucial to select an oil compatible with the specific type of metal you are protecting. For example, aluminum may require a different formulation than steel.

2. Environmental Conditions

Consider the environmental conditions the metal will be exposed to:

Humidity: High humidity accelerates corrosion, requiring more robust protection.

Temperature: Extreme temperatures can affect the performance of the rust preventive oil.

Exposure to Salt: Coastal or marine environments need oils that can withstand salt corrosion.

3. Duration of Protection

Determine the length of time the metal needs protection:

Short-Term: For temporary storage or during transportation, a solvent-based oil might suffice.

Long-Term: For prolonged storage or in-service parts, an oil-based rust preventive oil is more suitable.

4. Application Method

Consider how the oil will be applied:

Spraying: Useful for large surfaces or hard-to-reach areas.

Brushing: Allows for precise application but can be labor-intensive.

Dipping/Immersion: Ideal for small parts or bulk items, ensuring complete coverage.

Wiping: Suitable for smaller areas or touch-up applications.

5. Industry-Specific Needs

Each industry has unique requirements:

Automotive: Requires oils that protect against road salts and chemicals.

Manufacturing: Needs oils that can protect machinery during both operation and storage.

Aerospace: Demands high-performance oils that can withstand extreme conditions.

Construction: Requires durable oils that can protect equipment exposed to the elements.

Selecting the Right Product

Research and Testing

Consult with Suppliers: Engage with suppliers to understand the best products for your needs. They can provide valuable insights and recommendations.

Test Products: Before making a final decision, test different oils under actual operating conditions. This will help you evaluate their effectiveness and suitability for your specific application.

Product Features to Look For

Film Thickness: Thicker films provide better protection but may be harder to remove.

Drying Time: Consider how quickly the oil needs to dry, especially if parts need to be handled or processed soon after application.

Removal Process: Some applications may require oils that are easy to remove before further processing or use.

Environmental Impact: Eco-friendly options are increasingly important, especially for industries with strict environmental regulations.

Conclusion

Choosing the right rust preventive oil is essential for protecting metal surfaces from corrosion and extending their lifespan. By considering factors such as the type of metal, environmental conditions, duration of protection, application method, and industry-specific needs, you can select the most suitable rust preventive oil for your requirements. Researching and testing products, consulting with suppliers, and focusing on key product features will ensure that you make an informed decision, safeguarding your metal assets and reducing maintenance costs. As industries continue to evolve, the importance of selecting high-quality rust preventive oils will only grow, making them a crucial component of effective maintenance and protection strategies.

0 notes

Text

rust preventive oil

Rust is a domestic word and is easily identified with its color and appearance.Its composition is iron oxide which is formed by the chemical reaction between iron, water / atmospheric moisture and oxygen. Iron surfaces need to be kept off contact with water and moisture by being covered with protective paint coating which is possible at a very basic level. There is a scenario change when it comes to an industrial environment, simple paint coatings may not be effective or even feasible. Its here that rust preventive oils come into play. Lets brush through the applications and features of rust preventive oils

0 notes

Text

"""Empowering effectiveness with Perennial Turbo Engine, Rust preventive manufacturer in Ahmedabad the special liquid used in thecooling systems of machinery,automobiles and industrial types of applications to control equipment temperature and control overheating Industrial Oil Industrial oil plays a pivotal role in the smooth and efficient operation of machinery and equipment across diverse industrial sectors. That’s why we carefully engineer a variety of top-tier engine oils specifically designed to surpass expectations and maintain your engine’s Effectiveness, and at peak performance.""Read More --https://https://perennialturbo.com/services/rust-preventive-manufacturer-in-ahmedabad// /"

#“”“”“”“Empowering effectiveness with Perennial Turbo Engine#Rust preventive manufacturer in Ahmedabad the special liquid used in theco#automobiles and industrial types of applications to control#equipment temperature and control overheating Industrial Oil Industrial oil plays a pivotal#role in the smooth and efficient operation of machinery and equipment across diverse industrial sectors.#That’s why we carefully engineer a variety of top-tier engine oils specifically designed to surpass#expectations and maintain your engine’s Effectiveness#and at peak performance.“”“”Read More --https://https://perennialturbo.com/services/rust-preventive-manufacturer-in-ahmedabad// /“” “#Rust preventive manufacturer in Ahmedabad

0 notes

Text

due to the moisture in the air just about everywhere in the world, even continuous oiling and waxing was not entirely sufficient to prevent the rusting of armour. because of this, sand and vinegar came in great handy for the removal of rust. even still, fabric that came into contact with the rust would be stained, and because armour was worn with specialised clothing, that clothing needed regular maintenance as well.

3K notes

·

View notes

Text

Poison🩸🌧️

got the feels and wanted to write about it

Ship: Old!Logan Howlett x Mutant!Fem!Reader 🩸

Rating: 13+

Wordcount: 786

Warnings: disease, injury, blood, aging, kind of age gap? (they're roughly the same age but reader doesn't show it), grief

Your nose scrunched as it was hit by the all-too familiar scent that followed Logan like a shadow. Acrid, sharp, deadly. Seeped into his blood from his metallic bones, poisoning him. Killing him. Leeching his life and healing mutation to where he was a husk of the X-Man he once was.

It was 29 years to the day since you’d met him. When he'd woken up, terrified, on that chrome stretcher and nearly choked you to death. The blood flowing through his thick arms pumping by your ears and only proving what you’d hypothesized: his blood wasn’t normal.

Logan’s blood ran thicker than every other person’s. Tasted more metallic, more iron in his blood than the rest of the mutants that filled Charles Xavier’s mansion. You had always found Logan’s blood to be tricky to manipulate. Whether it be to stimulate his healing or to form the thick ichor to your desire, it just didn’t want to cooperate.

That same difficulty faced you now as you kneeled in front of your and Logan’s shared bed. The room rattled as another freight train barreled by outside. Dusty picture frames swinging on rusted walls, bottles of medication bouncing on wire shelves, creaking bed groaning under Logan’s weight.

You held a clean rag to a shotgun blast in Logan’s gut. His blood had soaked through two others just like it, now lying in the dented bucket at your feet. A vein in your neck strained as you focused on healing the wound.

“It’s no use, doll. I’ll be fine,” Logan grunted. He tried to wave you off with a withered hand. You smacked it away from your face. A low hum rumbled his chest.

“Shut up, old man,” you said. That earned a rough chuckle from his chapped lips. You glanced up at him from where you knelt between his knees.

If pure reverence was an expression, what painted Logan’s face in broad strokes fit the bill. Crows feet bunched around his hazel eyes, smile lines deepend by his close-lipped smirk, graying eyebrows turned up at the edges. He ran a calloused hand along your unaged cheek.

“Beautiful as the day I met you,” he whispered softly. Grief struck you in the chest like a wooden stake.

It wasn’t fair. Logan’s adamantium skeleton sucked the life from him, making him age and decay, while you remained the same. Wrinkle-less, youthful, bright-eyed. You would pump your youth into him if you could.

But you couldn’t.

All you could do was prevent the inevitable. Prevent what once seemed impossible, yet hung over you like a thick fog.

Logan ran his thumb under your eye, collecting a tear that spilled from your clouded eyes. You blinked up at him as a thick lump formed in your throat. Words unspoken passed between the two of you. Adoration, understanding, sorrow. Leaking from the hot tears spilling from your eyes and into Logan’s leathery skin.

“I love you,” you breathed into his palm. You gave it one last attempt, healing the wound in his stomach. You could just barely feel the edges closing and the skin knitting together. The ligaments running through your neck and shoulder tensed under the effort.

“Love you too, doll,” he replied, using the hand not on your cheek to smooth down your strained muscles. Thinning fingers ran down your shoulder, passing over his borrowed flannel and your bare skin, then wrapped around the hand held to his gut. He laced the digits with yours, “Give it up. I’ll heal the old-fashioned way.”

A sigh rattled your lungs, anguish pooling in your chest like an oil spill. You let Logan drag your hand away from his stomach and to his face. Your crimson-stained fingers traced along the tough skin of his jaw.

“Always taking care of me,” he mumbled. Kind eyes ran across your pained expression.

He tucked his fingers under your chin and brought your mouth to his. Plump, full lips met chapped skin. You poured your devotion into the kiss, licking into Logan’s mouth and clutching at his white tank top. His fingers dug in your silken hair.

It wasn’t perfect. It never was, when it came to Logan. Nearly thirty years of being together had taught you that fact. He was messy, rude, rough around the edges. Not to mention metal-clawed and built like a fridge.

And yet, despite it all, he was yours. You woke up next to him every morning, went to bed with him every night, much like you’d done ever since you met. Your lives were so intertwined it was hard to tell where you stopped and he began.

You knew, decades after Logan was gone, you’d treasure your intimate connection like nothing else.

Want to be on the taglist? Fill out this form!

#wolverine#hugh jackman#logan howlett#wolverine fanfic#logan 2017#wolverine x reader#logan howlett fanfic#logan howlett x reader#f!reader#old!logan howlett x mutant!reader#i got the sadness brain worms and wanted to write this#have some ANGST because i'm sick and exhausted

316 notes

·

View notes

Text

Okay. OKAY. I need to talk about this.

So many people do NOT know how to take care of high maintenance kitchenware and I need to talk about it.

What do I mean by high maintenance kitchenware? I mean anything that needs to be one: hand washed and two: have some sort of maintenance done outside of washing for it to last and be useable.

Three items always fall into this category: cast iron, wooden utensils/cutting boards, and kitchen knives.

Cast Iron:

You will not believe the amount of times I’ve had a conversation like this:

Me: I love my cast iron skillet.

Someone: oh, I had one once but it rusted instantly.

Me: oh? Odd. How did you wash and store it?

Someone: oh, I put it in the dishwasher.

Do NOT, I repeat, DO NOT put cast iron in the dishwasher!!!!!!!!!!!!!!!

Why? Two HUGE reasons.

1.) It is non-coated iron that has been formed in a cast, as the name suggests. Because it is NON-COATED, any exposure to moisture can and WILL make it rust like crazy. And if rusts so bad and for so long it starts to PIT? Good luck. You have to take an angle grinder to get it smooth enough to cook on again. You need your surface to be mostly smooth so your food doesn’t stick while cooking AND to minimize the chance for bacteria to grow. This is the same reason why plastic cookware needs to be replaced OFTEN, especially after it is damaged.

2.) Dishwashers, especially modern day dishwasher, do a GREAT job at getting food residue and oil off of your dishes. Why is this a problem? Because to help prevent your cast iron from rusting from any residual moisture in the air and to season it to keep food from sticking you need to oil it. You also have to build up seasoning layer by layer every time you use it, and putting it in the dishwasher can CHIP OFF YOUR SEASONING.

So how do you take care of your cast iron anyways?

After you use your cast iron, yes, DIRECTLY after you use it, you need to clean it. For less messy meals, wiping it clean with a dry, LINT FREE paper towel is fine. For messier meals you need to bring it over to your sink and rinse it under HOT WATER, not cold, cold can cause your pan to crack, use HOT WATER until it cools down enough for you to handle it.

Once it is cool enough to handle, go ahead and use a washcloth to gently scrub any residue off. Some people say it’s fine to use dish soap but I don’t recommend it, it can damage the seasoning.

Okay, it’s clean now. So now you need to bring your skillet, pan, griddle, whatever back to the stove and put it on a burner and turn that up to high. You need ALL the water to dry up off of it and NOW. Why? Remember that thing about moisture? Yeah, letting cast iron sit for any length of time wet can make it rust. Let all the water dry up.

Next you need to turn off the stove and put a small amount of neutral oil into it, anything that it good for high heat. Do NOT put extra virgin olive oil, butter, or any oil that can burn easily into it to season, not only will it not be effective, the burn taste will linger. I recommend using a neutral seed oil like grape seed, but I’ve know people who like to use vegetable oil or even bacon grease to season theirs, but I always use grape seed. Things like tallow and lard have a tendency to go rancid, so if you chose to use that, make sure you check for rancidness before cooking with it again.

Once you have the oil in, use a LINT FREE (it is so important you use lint free because you do NOT want to be cooking your food on paper, I PROMISE) paper towel and spread it all around the inside of your pan. It needs to be a thin layer. Once it’s spread, take your pan off the burner and let it cool before putting it away somewhere dry.

But wait, you just bought a cast iron/ need to just completely reseason it because something happened to it? Do not worry, I know what to do.

Preheat your oven to 350 F (~175 C) with your top rack place in the middle and your other rack placed at the bottom.

Next thing you’re going to do is wash your pan. This is the only time I would recommend washing your cast iron with dish soap, and you need to SCRUB it. If you are reasoning, scrubbing with steel wool is the way to go but if it’s just new and needs to be seasoned, then a dish sponge will do fine.

If you have some light surface rust, I recommend pouring some course salt into pan and rubbing it with a paper towel. It actually does an INCREDIBLE job at getting rust up!

After that you need to dry it on the stove (bone dry once again) and let it cool.

Once it is cool, take a lint free paper towel and spread a SUPER THIN amount of oil ALL OVER it, cooking surface, handle, bottom, sides, ALL OVER. And I mean THIN. You need probably only about a teaspoon at MOST of oil total, and even sometimes THATS pushing it. Another thing you can use is vegetable shortening, I find that it’s personally very easy to achieve a thin, even coating of oil with it.

Then you’re going to put it in the oven, cooking side DOWN and a baking sheet under it to catch any oil that might drip off. You’re gonna let it sit in there for around three hours, really letting that oil bake. Once the time is up, turn off your oven and let it cool in there.

Once cool, I recommend using a super small amount of oil and just lightly oiling it again just for rust safety.

And there you have it! A seasoned, well maintained cast iron skillet/pan/pot/griddle/whatever.

Wooden Utensils/Cutting Boards:

Oh yes, these guys are high maintenance, too.

But WHY can’t you put them in the dishwasher???

Well, have you even keep a piece of wood under water? What happens to it?

That’s right, it expands and CRACKS.

That’s what happens when you put your wooden tools in the dishwasher OR let them soak. The cracking allows bacteria to THRIVE and can get food stuck in there and cause it to ROT. Always, ALWAYS hand wash your wooden tools and NEVER let them soak.

But what about that maintenance outside of washing?

Well, like cast iron, wood cutting board and utensils need to be seasoned with oil. Unlike cast iron though, you can use soap to wash your wooden tools.

So how to you season these guys? Well, it’s actually a lot simpler than cast iron, thank GOD, am I right?

First you need to wash your utensils well and then let them COMPLETELY dry, any moisture still left in the wood will seal into it if you do not let it dry and will cause the wood to expand and crack. A simple way of figuring out if it’s dry or not is by touching it. If it’s cool to the touch, it is not dry yet. If it’s room temp then perfect! It’s dry.

Now it’s time to oil them. I’ve seen people cooking oil to season it all the time, but I do not recommend it due to the fact seed oil can and WILL go rancid as well. I recommend using food grade mineral oil, as it neutral in flavor and doesn’t go rancid.

Oiling it is simple. You’re going to take a cloth and spread oil all over the utensil or cutting board and let it sit for 5 to 10 minutes. Then, you’re going to take another cloth and wipe away any excess oil. If it’s your first time oiling it, repeat this process three to five times.

Now you only need to oil it every month or two or when it’s starting to look like it might need some TLC! Hooray!!!

NOTE: if your wooden tools are looking worse for wear or have dents/cracks it them, it’s time to replace them. There is no saving them. Throw them out and get new ones.

Kitchen Knives:

Yeah, this one might be a shocker, but putting your knife in the dishwasher can absolutely damage it.

How does it damage it? The high heat and the movement can cause your blade to dull, dent, and even break in some cases. Not to mention, the heat can make a plastic handle crack and the water can make a wooden one do the same.

Washing your knife is so easy, just be CAREFUL to not cut yourself. Use a sponges and wipe your knife from the back to clean it, and then dry it on a cloth instantly. I like using a sleeve to keep it clean in the drawer but if you don’t have one/ Don’t keep it in a drawer, than don’t worry about it.

Of course the outside maintenance is sharpening your knife.

The best way to do it is with a wet stone, though those are often expensive and if you’re just a home cook, you don’t need to do it like that. If you want it really sharp but don’t want to spend the money on a wet stone, you can take it to get professionally sharpened, but I wouldn’t recommend doing that with a cheep, five dollar knife. If you want to, though, more power to you.

For the most part, all you’re going to need is a honing rod. You know, that weird metal rod you always see the tv chefs using to sharpen their knifes dramatically!

To sharpen your knife, place your blade starting at the point closest to the handle at the bottom of the honing knife, keeping it at a steep angle or the angle the edge of your knife (the actually sharp part of your knife). You’re going to apply even pressure, not too much or too little, and keeping you knife at that angle the entire time, drag your knife down the rod, slowly moving the entire blade across it, following the curve of your knife.

Next, bring the knife UNDER the honing rod and do the same to the other side. Go back and forth doing this multiple times until it has been sharpened, making sure to apply even pressure and keep your knife at a consistent angle. Once you get use to the action you can start to speed up and look really cool like the TV chefs.

NOTE: when sharpening or handling the knife, NEVER point or cut the blade towards you. If handing someone a knife, never offer it blade first, turn the knife with the blade faced down and handle out to the person you are passing it to.

Why is it important to keep a knife sharp? Easy, a sharp knife is a safe knife. What do I mean by that? With a dull knife, you don’t always know if it will cut through the thing you are trying to cut or it will randomly stop, a dull knife is predictable and can cause the item your cutting to be uneven or possibly cut YOU. And that’s not a clean cut, and those hurt the WORST. A sharp knife, on the other hand, it’s easy to figure out what direction it’s going to go while cutting, and that direction is through.

Anyways, I hope this is informative to everyone and if I made a mistake, feel free to go ahead and correct me, BE NICE ABOUT IT TOO. I’m only human, and just because I’m behind a screen doesn’t mean I don’t get hurt. But yes, please people, high maintenance cookware needs to be properly maintained for it to be used for as long as possible, and sometimes that means for generations. Happy cooking!

#Marcus barks#kitchen#kitchen utensil#kitchen utensil maintenance#can you tell I’m passionate about this

55 notes

·

View notes

Text

Love the idea of seekers wallowing in oil lakes like it’s a bird bath. They plunge themselves under the liquid, getting it into every nook and cranny before shaking themselves off.

I imagine it helps with the brightness of their paint and their hinges, prevents rust. It especially helps seekers like Sandstorm and Cloudcover who have lighter and less saturated colors show off.

It’s especially cute if you think about how they wallow. Some might flop onto their sides, others their backs to use their wings to help the oil cover them. Some might even just slip in and out, shaking themselves free.

I totally imagine that in the Skyseer AU one or two seekers may have accidentally mistaken a tar pit for an oil lake.

80 notes

·

View notes

Text

Why Electrostatic Oilers Are the Best Approved Solution for Rust Prevention

Rust and corrosion are major challenges in industries that rely on metal components, such as automotive manufacturing, aerospace, and industrial equipment production. Traditional rust prevention methods often result in uneven coatings, excessive oil use, and inconsistent protection. However, Electrostatic Oiler Approved Rust Preventing technology has emerged as the most effective and efficient solution for preventing rust while optimizing oil usage and reducing waste.

What Makes Electrostatic Oilers the Best Solution for Rust Prevention?

Electrostatic oilers use a revolutionary process in which oil droplets are electrically charged before being applied to metal surfaces. This process ensures that the oil is attracted to the metal, creating a uniform, precise, and efficient rust-preventing layer. Here’s why this method is superior to conventional oiling techniques:

1. Uniform and Complete Coverage

One of the biggest problems with traditional oiling methods is uneven application, which can lead to unprotected areas that are vulnerable to rust. With Electrostatic Oiler Approved Rust Preventing technology, the electrically charged oil droplets are naturally attracted to metal surfaces, ensuring a consistent and even coating on all areas—including hard-to-reach spots.

2. Significant Reduction in Oil Waste

Conventional oiling methods, such as spraying or dipping, often result in excess oil consumption and overspray. Electrostatic oilers minimize waste by ensuring that the oil adheres only to the intended surface, reducing the amount of oil needed while maintaining maximum protection. This leads to cost savings and a more environmentally friendly process.

3. Longer-Lasting Rust Protection

Because electrostatic oilers provide an even and controlled application, the protective layer they create is more effective at shielding metal surfaces from moisture, oxygen, and other rust-inducing factors. This results in superior and long-lasting rust prevention, which is crucial for industries where metal durability is a top priority.

4. Faster and More Efficient Process

Electrostatic oiling technology is designed for high-speed, automated production lines, making it ideal for large-scale industrial applications. The process eliminates the need for manual application, speeds up production, and ensures that every part receives the correct amount of oil for optimal rust prevention.

5. Approved and Industry-Recognized Solution

The Electrostatic Oiler Approved Rust Preventing method is widely accepted and used in industries that demand high-quality corrosion protection. Many manufacturing companies and regulatory bodies recognize electrostatic oiling as the best standard for rust prevention due to its efficiency, precision, and sustainability.

Key Industries Benefiting from Electrostatic Oilers

Electrostatic oilers are used across multiple industries where rust prevention is critical, including:

Automotive Manufacturing – Protecting car body panels, chassis, and undercarriage components from corrosion.

Steel and Metal Processing – Ensuring that steel sheets, coils, and fabricated metal parts remain rust-free during storage and transportation.

Aerospace Industry – Preventing oxidation and corrosion on aircraft components exposed to harsh environmental conditions.

Heavy Machinery and Equipment Production – Extending the lifespan of industrial machinery by preventing rust-related wear and tear.

Conclusion

The Electrostatic Oiler Approved Rust Preventing system is the best solution for rust protection due to its uniform application, reduced oil waste, enhanced efficiency, and long-lasting results. As industries continue to seek cost-effective and sustainable rust prevention methods, electrostatic oilers have proven to be the most reliable and approved choice.

By adopting this advanced technology, manufacturers can ensure superior rust protection, reduce operational costs, and enhance the durability of their metal products—making electrostatic oilers the gold standard in rust prevention.

#Electrostatic Oiler Approved Rust Preventing#rust preventive oil suppliers in india#rust preventive oil manufacturers in india#rust preventive oil

1 note

·

View note

Text

“You remember way back, when I told you about how our saliva neutralises the acid from our tails? Well, it’s also a really good rust repellent. Good for injuries that take longer to heal. Funnily enough, it was also useful back when we-” N stopped suddenly and Uzi felt him physically recoil. She shifted to throw a worried glance at him over her shoulder, and found him staring distantly at the small of her back, his mind far off.

---

So I know its not Wednesday, but over on Bluesky I really love posting a little wip from my fics I'm working on for WIP Wednesday, and I've been thinking about posting them over here now too! So have a little worldbuilding-y exploration snippet featuring our favourite little softies.

“It was… y-y’know,” he said his voice small and pained now. “Good for uh… for keeping…”

“…Your kills from going bad?” Uzi finished tentatively. N nodded silently, his face miserable and guilty. “That makes sense. I know you guys stashed a lot of dead bodies to eat later. Probably would have been bad for you if one went rusty and that found its way into your oil stream.”

N nodded with a quiet noise of affirmation, but it was only then that the realisation hit Uzi. Disassemblers were notoriously quick healers. Surely a little rust wouldn’t harm them – at least not in the same way it did for Workers. But if they had been programmed – or… mutated with such a specific feat…

“Can you…?”

“Rust? Yeah. It’s… it’s one of the few things our bodies really struggle to regenerate from. I heard stories of other Disassembly Drones on the planet picking through old corpses and succumbing to it. It’s scary stuff. Really nasty way to go.”

Uzi nodded slowly in understanding. The exposed metal of drones was galvanized; carefully coated to prevent rust, but wear and tear made them susceptible, and for reasons unknown, the oxidisation seemed to take a hold on drones faster than it did on dead metal. Much of their internals too were spared a safety coating, and so it spread like wildfire when it worked its way beneath the surface. She’d known Workers in the bunker who had gotten careless – not gotten deep wounds cleaned sooner. N was right. It was a horribly painful way to go, eating them away - sometimes from the inside out when it got into their metallic arteries and their oil carried it throughout their bodies. Caught quickly enough it was easy to treat. Caught too late and…

Uzi shuddered, and N pressed his forehead gently between her shoulder blades.

33 notes

·

View notes

Text

Rust is my most hated nemesis. I have stared more than once into the crumbling mess of red death that was, long ago, a pristine steel panel. Many evenings have been spent cutting out rust, only to find more rust, and cutting out that rust only to find yet more rust. Everything on my car is actively trying to return to the earth, but I won't let it.

Maybe you're lucky enough to only own new cars, or so absolutely fortunate that you live somewhere that cars don't rust even when they get scratched. If that's the case, you can pretend that the rest of this story is actually talking about croissants. Croissants are delicious, rich, and buttery, and I'd probably have learned how to make them myself if I didn't spend what my Daytimer® estimates is three-quarters of my waking life fixing body and structural rust on my harem of shitbox cars.

For years, car folks have been lured by a series of snake-oil paints, oils, dyes, dips, and other formulations that promise to help prevent rust. Virtually all of them are horseshit: elaborate scams produced by an industry that knows they have a desperate customer, just like parachute companies. The most effective rust prevention is to hose your car down with lanolin, which is a sort of wax you make by crushing up sheep. It works well, but the trick is doing it every year, forever, perfectly, until you miss a spot and your car disintegrates at highway speed, like a sand castle being hit by an errant volleyball.

If you talk to someone rich, they propose simply driving a bad car in the winter, and keeping your good cars cooped up. This is impossible for me: not only do I have exclusively what the rich would call "bad" cars, but I feel shrieking agony every time I am destroying any vehicle at all through my carelessness and malice. That is, of course, unless I am racing the car, in which case it is understood by all involved that dying in battle is the most noble way for the car to ascend to Valhalla. There is no honour in scrapping a car because the rear subframe prolapsed on your way to work, so I enter my most precarious vehicles in ice racing in order to give them a good end-of-life experience.

Unfortunately, it turns out that the gaping rust holes reducing the weight of the chassis, and my devil-may-care attitude bumping rivals off the lake in fact is the secret formula to produce winning race cars. Now, I'm not as rich as your Inoues or your Sennas, but the $50 gift certificates to the local tire place really add up. I hear they've got anti-rust underbody spray, which seems like a good thing to do to whatever chunks of cars I can frantically weld together this summer in the few weeks before the leaves turn again. The cycle of life.

278 notes

·

View notes

Note

What sort of treatment would you give a steel type pokemon at the shelter if one was brought in with chronic rusting issues? Purely out of curiosity, don't see too many discussions about steel type care on the blog and I think they're underrated.

great question! we don't see a ton of steel types at the shelter, but i'm currently working towards my steel type handling certification, so i've been reading a lot of recent literature on steel type care haha. the answer is that it really depends on the pokemon and what's causing the rusting issues.

in the vast majority of chronic rusting issues in pokemon with metallic components to their body, the cause lies with husbandry. poor diet is the most common culprit. steel types in the wild eat a much wider variety of metals than initially believed, and in fact- much like a gogoat- many obtain trace metal and mineral content by eating dirt/rocks outside of their main diet! fixing dietary imbalances results in the rusting clearing out over time in most cases.

sometimes chronic rusting can also be caused by failure to provide proper avenues for self-maintenance. for example, aggron are known to "polish" their metal by rolling in sand or coarse-grained dirt and rubbing up against oily plants. in these cases, providing opportunities for those natural maintenance behaviors will typically resolve the problem. some older steel types may need their trainer's assistance with polishing if they've developed mobility issues.

outside of those possibilities, it's a veterinary issue. those are tough to resolve in steel types. if it's because of a mechanical problem (such as a klinklang's gears not turning properly), it can sometimes be fixed, but otherwise the usual response is to treat the symptoms rather than cure the underlying cause. we just don't always have enough knowledge of care for some of the less organic steel types to know how to provide for their medical needs. treatment for chronic rust usually involves regular polishing with medical grade steel wool (which has been properly sanitized) and the application of some type of oil blend to help form a protective coat. custom-made raincoats to help prevent exposure to moisture as well as using a dehumidifier in spaces the pokemon frequents can also lower the risk of new rust forming.

70 notes

·

View notes

Text

YAAAY, my pawssss finally got around to finishing it~

i did it a long time ago, but i only finished it today^^

im sorry in advance for any mistakes, if any :')

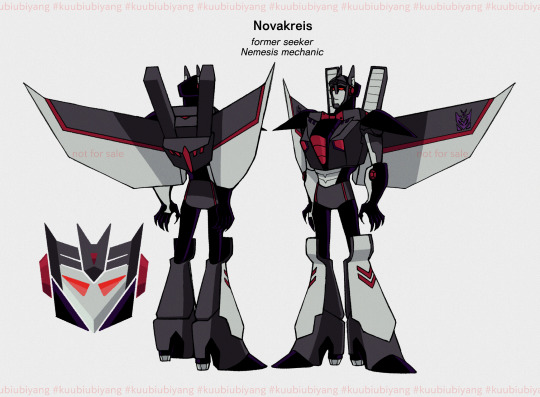

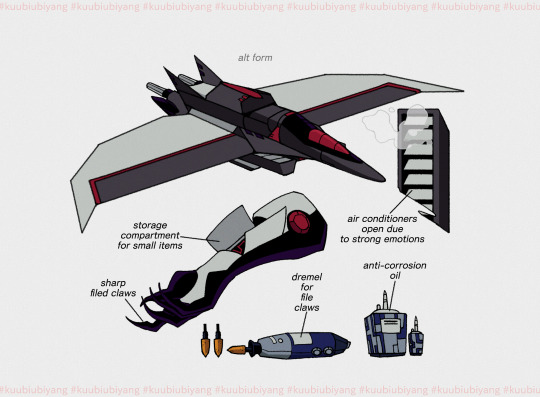

«____________•NOVAKREIS•____________»

Novakreis is Nemesis mechanic. Alt form: modified(?) fighter plane. Previously served as a seeker under Starscream's command, Novakreis was seriously wounded by shrapnel from a homing projectile in his first battle, rendering him unable to fight effectively.

«__________•appearance??•__________»

«______________•lmao•______________»

«______•a couple more things•______»

Thanks to his predisposition to engineering and good technical memory, he was able to remain on Nemesis as a mechanic of the ship’s internal systems. Novakreis himself outwardly takes his situation calmly, sometimes complaining about the unnecessarily slow and painful transformation. But in fact, the con regrets that at the time of the battle he did not react quickly enough and came under fire from his faction.

Novakreis has no built-in weapons - the original connectors for blasters were damaged and are now inactive, and he was denied a personal weapon due to the lack of need for them aboard the Nemesis (no, he just didn't learn how to use it properly, lol... he hurts himself more easily than anyone else).

Novakreis is capable of performing delicate repair work - for a better result, he files his claws, reducing the area of contact with the parts being repaired for the sake of jewelry work on them. Filing the claws is an unpleasant, slightly painful procedure, after which it is necessary to treat the claws with anti-corrosion oil to prevent rust.

By nature, Novakreis is choleric, purposeful and uncontrollable, expressive. He easily finds a common language with the colleagues, developing an individual approach to each cons. Sometimes he is too harsh with his superiors, causing problems for himself, but almost always gets away with it thanks to his positive reputation. The only Decepticon Novakreis avoids is Megatron.

Despite his talent for mechanics, he sometimes gets the job done wrong if something more interesting is on the horizon. Due to such conditions, Nemesis spare parts supplies are slightly lost.

While working in the repair bay, Novakreis had plenty of time to rethink his position in life. He is not a radical Decepticon, but still treats transformers of other factions with prejudice and suspicion. In an unfamiliar environment, Novakreis... is somewhat paranoid, so don't worry if you find a wiretapped bug on you - this is purely for self-defense ;>.

«________•INTERESTING FACTS•________»

•Novakreis is slightly taller than Starscream, but shorter than Megatron.

•Sometimes, while offline, Novakreis has nightmares about his execution on Cybertron.

•Novakreis hates being addressed as "Nova". "Novakreis" is better, or "Kreis" as a last resort. For the nicknames "Novi" or "Kri" or "Novakri" Novakreis is quite capable of hitting something heavy...

•Novakreis was never on Cybertron, his protoform was activated at the height of the last war between the Autobots and Decepticons - on Nemesis, in outer space. During the time when the Decepticons were expelled from Cybertron, several protoforms fell into their servos.

•Novakreis often neglects his health (and the integrity of his hull) if he gets too carried away with his work.

•Novakreis is not afraid to directly criticize the actions and decisions of superior Decepticons - but only in his thoughts and, preferably, not in their presence.

•Due to injury, some of Novakreis's mechanisms require constant calibration - in particular, his optics. Due to the small and painstaking work, the focusing of his vision quickly becomes upset, but, due to altruism (or stupidity), the con will not engage in calibration until it is absolutely necessary.

•The sound receivers, by the way, were not damaged; Novakreis hears better than many in his circle.

«______________•that's all•_______________»

if you've read this, then i give you all my gratitude and a kiss on the forehead, if you don't mind~~~

#art#oc#oc art#アート#絵画#original character#tfa#transformers animated#tfa oc#transformers#tf animated#desepcion#tfa ocs#tfa Novakreis#Novakreis

144 notes

·

View notes

Text

0 notes

Text

Custom Handmade Unique Set/Lot of 7 Different Knives with leather sheath - Best Gift For Him / Her

These can serve purpose as hunting knives, skinners and as chef knives set too. Different designs and materials made this set a unique gift for your loved ones.

Blade Material: All knives are made of D2 Steel

Handle Material: 5 knives have wooden handle and 2 knives have camle bone handle

Note:

Package contains 7 knives same as shown in pictures. These superb design knives are hand forged and comes in a pouch which is free of cost to avoid damages.

Features:

- Hand forged with a sharp blade.

- Hardness: 58-60 HRC.

- Supplied with a belt supportive protective pouch to prevent damage.

Shipping:

- Ships via DHL Express.

Care Tips:

- Avoid prolonged storage in the pouch to prevent rust.

- Apply oil to the blade after use.

- Clean the knife thoroughly after use.

Age Restriction:

- Buyers must be 18 years or older.

Visit our Etsy Store (Link in Bio)

https://www.etsy.com/shop/BlazingBladez

#swords#daggers#damascus#metalwork#knife knives edc knifeporn knifelife everydaycarry knifenut handmade blade knifemaker knifemaking knifecommunity edcknife#knifecollection#huntingknife#hunting season

25 notes

·

View notes

Note

sorry if it's a dumb question but i've wondered about the nations' skills or what suits their personalities, and who do u think would win in a swordfight between yao and kiku? japan does have such a kenjutsu culture but what about china, since china has a very old history too?

i have thought about this before, actually 🤔 when thinking about pre-modern sino-japanese power dynamics between yao and kiku. personally, i say it actually depends on which point in history. this is my headcanon:

before the kamakura period/shogunate (which overlaps with the sengoku/feudal era of japan) tbh I'd say yao wins. one reason is well, the symbolic power balance between china and japan. the first time china and japan properly met face-to-face in conflict was in the 7th century CE, during the baekje-tang war at the battle of baekgang in korea. long story short: it was a power struggle between korean kingdoms, and the korean kingdom of baekje (yong-soo's brother) was allied to japan, so japan came to help them. their enemy was the other korean kingdom of silla (aka: yong-soo long before he becomes south korea), who...was allied to china. despite being outnumbered 3 to 1, china pretty much crushed japan in that battle. then, kiku is very much an inexperienced upstart challenging the regional hegemon who has far far more notches on his sword. getting wrecked like that by yao is imo, quite a formative experience for kiku (to put it mildly).

but as the centuries go by, yeah no, kiku is the swordsman alright. because of samurai culture, and its elevation to power during the muromachi and edo period. further, there's of course the imjin war, where the samurai lord toyotomi hideyoshi invaded korea with the goal of overthrowing ming china too. even during the successive edo period/tokugawa shogunate, where japan was unified, far more peaceful under isolationism and many samurai became more like bureaucrats, i think kiku continued practising kenjutsu or at least in the form of kendo—swordsmanship and his swords became very much an extension of his personality and identity by then, as well as a way he'd blow off steam even during peacetime. his katana and wakizashi would always be properly maintained and you'd see him carefully oiling it with the mix of mineral and clove oil to prevent rusting, even during the most chill years of edo japan. they'd be nicely displayed like this somewhere in his quarters.

this is compared to how, for all that pre-modern china was an empire and all empires need military violence to expand themselves, warriors as a class in chinese culture never quite ascended to the same type of political prestige as the samurai. it was a very different cultural/political context. it's like, you can't underestimate yao still, as an experienced old empire (tm), but by the 1400s/ming dynasty, i think he might've shifted more to being that kind of general presiding over maps in his military tent, and directing strategy, compared to the younger warlord he was in his earlier years, who was down in the dirt all the time fighting in every single skirmish. so, while yao can and will get his hands dirty if need be with a blade, i think kiku edges him out by then in sheer focus, skill and devotion re: kenjutsu becoming a pretty core aspect of his personality/experiences. to me, it’s also an “old and experienced soldier surpassed by his younger, hungry protégé” dynamic too.

73 notes

·

View notes