#Seismic Engineering

Explore tagged Tumblr posts

Photo

External seismic bracing ~ Tokyo, Hongo (2015) by Jan Vranovský ⌘ When survival becomes sculpture ◆

#modern#2015#seismic engineering#black#jan vranovský#tokyo#hongo#tokyo architecture#gray#2010s#photography#architecture

95 notes

·

View notes

Text

Steady, secure, and built to last! 🏗️⚙️ Tecoustics delivers cutting-edge vibration and seismic solutions to protect structures, equipment, and people. Because stability matters! 🌍🔩

#vibration and seismic control#vibration control ottawa#vibration control Ontario#seismic engineering#mason industries ontario#acoustical consultant ontario

0 notes

Text

Starken Philippines Shakes Up Earthquake Preparedness with Groundbreaking Seismic Test

Starken Philippines, a frontrunner in construction innovation, unveiled a game-changing breakthrough in earthquake preparedness at the recent CoNNEX 2024 event. This innovation has the potential to revolutionize earthquake safety in the Philippines. The company showcased the results of a pioneering earthquake test, marking a significant milestone in seismic engineering. Led by Engr. Rolando B…

View On WordPress

#autoclaved aerated concrete#CoNNEX 2024#Construction safety#earthquake#Earthquake Disaster Preparedness#Earthquake Mitigation#earthquake preparedness#Earthquake-resistant building materials#Seismic engineering#Starken Philippines

0 notes

Text

Little P.Eng. for Blue Hydrogen and Ammonia Engineering Services: A Comprehensive Engineering Aspect

Table of Contents

Introduction

Blue Hydrogen: An Overview

Importance of Engineering Services in Blue Hydrogen Production

Piping Stress Analysis

Structural Engineering

Seismic Engineering

Tank Design

Pressure Vessel Design

Ammonia Engineering Services: The Connection

Conclusion

1. Introduction

As the world accelerates its efforts to combat climate change, the focus on cleaner energy sources has never been sharper. Blue hydrogen, derived primarily from natural gas with the carbon emissions being captured and stored, presents a viable option in the pursuit of decarbonization. Its potential integration with ammonia production further highlights its significance. At the heart of this transformative energy landscape lies the vital role of engineering services. 'Little P.Eng.', a forerunner in this niche, offers specialized services such as piping stress analysis, structural and seismic engineering, and the design of tanks and pressure vessels. This article delves deep into these pivotal engineering domains and the implications for blue hydrogen and ammonia production.

2. Blue Hydrogen: An Overview

Blue hydrogen is produced when natural gas (primarily methane) undergoes steam methane reforming (SMR) to produce hydrogen and carbon dioxide. Unlike gray hydrogen, where CO2 is released into the atmosphere, blue hydrogen incorporates carbon capture and storage (CCS) technology. This ensures that a significant portion of the carbon emissions are captured and sequestered, making blue hydrogen a cleaner option.

3. Importance of Engineering Services in Blue Hydrogen Production

Engineering services ensure the efficiency, safety, and reliability of blue hydrogen production plants. Key considerations range from handling high pressures and temperatures to mitigating the effects of seismic events. Herein, Little P.Eng.'s expertise comes to the fore.

4. Piping Stress Analysis

Piping systems in hydrogen production facilities face stresses from internal pressures, thermal loads, and dynamic forces. Piping stress analysis ensures that pipes, flanges, and fittings can withstand these stresses without failure.

Objectives:

Safety of the piping system and its associated components.

Compliance with international standards, codes, and best practices.

Reduction of operational disruptions due to piping failures.

Little P.Eng. employs advanced computational tools and methodologies to evaluate the behavior of piping systems under various loading conditions, optimizing design and ensuring longevity.

5. Structural Engineering

Facilities producing blue hydrogen demand robust structures capable of supporting equipment, piping, and personnel.

Key Challenges:

Dynamic loads from equipment and flow-induced vibrations.

Corrosive environments due to the presence of hydrogen, steam, and other chemicals.

Little P.Eng.'s structural engineering services provide innovative solutions, ensuring that structures remain integral and safe throughout their operational life.

6. Seismic Engineering

Many industrial facilities are located in seismic zones. Earthquakes can be catastrophic for hydrogen production facilities, leading to leaks, explosions, and fires.

Seismic Analysis: Little P.Eng. evaluates potential seismic risks and designs structures and systems that can withstand seismic events. This encompasses:

Site-specific seismic hazard assessments.

Design of foundations and structural elements with sufficient ductility and resilience.

7. Tank Design

Storage tanks play a pivotal role in hydrogen and ammonia plants. They store feedstock, intermediate products, and final products.

Design Principles:

Safety: Ensuring that tanks do not leak or rupture.

Efficiency: Maximizing storage capacity while minimizing footprint.

Longevity: Ensuring resistance to corrosion, wear, and tear.

With advanced modeling and simulation, Little P.Eng. optimizes tank designs to meet these principles, while also adhering to strict regulatory standards.

8. Pressure Vessel Design

Pressure vessels in hydrogen production plants hold gases at high pressures. Their design is crucial for safety and efficiency.

Design Aspects:

Material selection to resist hydrogen embrittlement.

Wall thickness determination to withstand internal pressures.

Compliance with international standards, such as ASME codes.

Little P.Eng. employs a rigorous approach to pressure vessel design, ensuring optimal performance and safety.

9. Ammonia Engineering Services: The Connection

Ammonia, NH3, is produced by combining nitrogen from the air with hydrogen. As such, blue hydrogen can provide a clean hydrogen source for ammonia production. The engineering challenges in ammonia production mirror those of blue hydrogen: high pressures, corrosive environments, and the need for robust structures and equipment. Little P.Eng.'s suite of services naturally extends to this domain, further enhancing the synergies between blue hydrogen and ammonia production.

10. Conclusion

The transformation of the energy landscape hinges on the adoption of cleaner technologies, and blue hydrogen stands out in this endeavor. The role of engineering services, as championed by Little P.Eng., is paramount, ensuring that the transition is not just sustainable but also safe and efficient. From intricate piping designs to robust structural solutions, the contributions of engineering cannot be overstated. As we gaze into the future of energy, it's clear that the expertise of firms like Little P.Eng. will be at the very heart of this revolution.

Tags:

Engineering Services

Seismic Engineering

Little P.Eng.

Piping Stress Analysis

Structural Engineering

Material Selection

Tank Design

Pressure Vessels

ASME Codes

Clean Energy

Ammonia Production

Steam Methane Reforming

Computational Analysis

Infrastructure Safety

Blue Hydrogen

Carbon Capture

Simulation and Modeling

Ammonia Synthesis

Fluid Dynamics

Industrial Standards

Decarbonization

Load-bearing Structures

Industrial Integrity

Earthquake-Resilient Designs

Energy Transition

Environmental Factors

Hydrogen Storage

Seismic Zones

Foundation Designs

Hydrogen Embrittlement

Hydrogen Production Plant Design

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Engineering Services#Seismic Engineering#Little P.Eng.#Piping Stress Analysis#Structural Engineering#Material Selection#Tank Design#Pressure Vessels#ASME Codes#Clean Energy#Ammonia Production#Steam Methane Reforming#Computational Analysis#Infrastructure Safety#Blue Hydrogen#Carbon Capture#Simulation and Modeling#Ammonia Synthesis#Fluid Dynamics#Industrial Standards#Decarbonization#Load-bearing Structures#Industrial Integrity#Earthquake-Resilient Designs#Energy Transition#Environmental Factors#Hydrogen Storage#Seismic Zones#Foundation Designs#Hydrogen Embrittlement

0 notes

Text

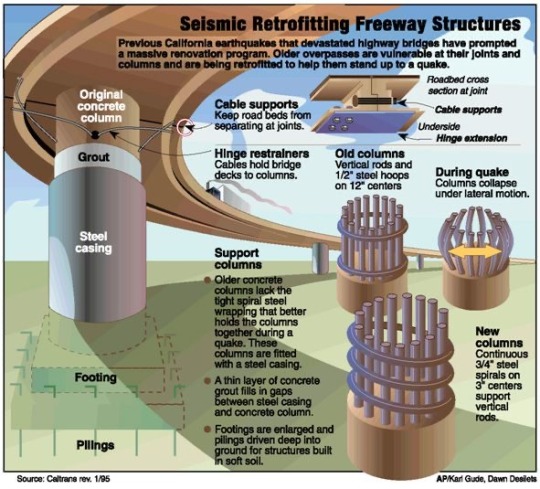

Seismic Retrofitting

35 notes

·

View notes

Text

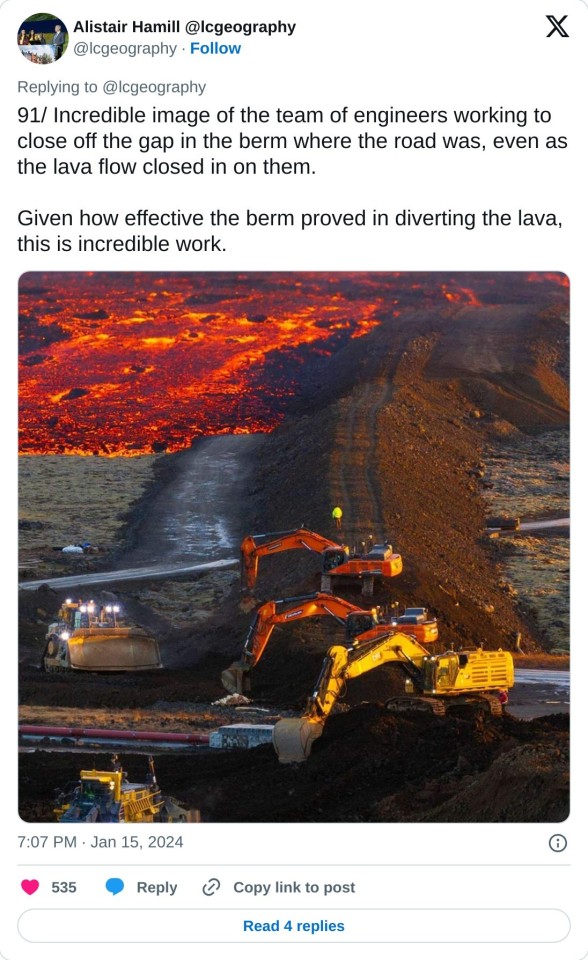

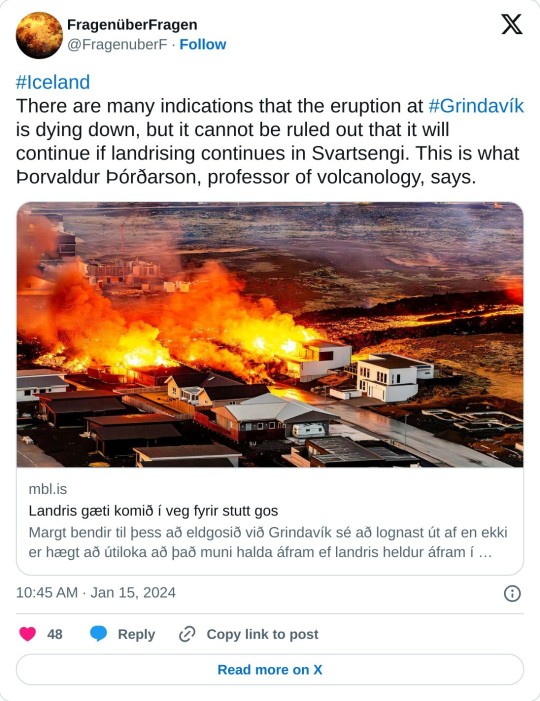

#iceland#bravo nicely done! Phew.....#news#engineer#engineering#lava#Grindavik#volcanic eruption#good people#Seismic

4 notes

·

View notes

Text

Little P.Eng. for Engineering Services

BUSINESS ADDRESS:

330 St Mary Ave

Winnipeg, MB

R3C 3Z5

BUSINESS PHONE NO:

(587) 802-4050

BUSINESS EMAIL ADDRESS:

WEBSITE:

ABOUT US:

Little P.Eng. Engineering delivers expert engineering services across North America. We specialize in Bulk Material Handling Engineering, Seismic Hazards Analysis & Bracing Design, and Structural Engineering, ensuring safe and efficient industrial systems. Our team excels in Piping Stress Analysis, Above-Ground Tank Design, and Pressure Vessel Design, adhering to leading industry codes. We also offer CRN Registration support for Canadian compliance. With advanced Discrete Element Modeling (DEM), we optimize bulk flow systems, and our CIPP Liner solutions provide reliable Pipeline Rehabilitation. Trust Little P.Eng. for innovative, code-compliant, and cost-effective engineering services.

WORKING HOURS:

Mon - Fri: 6:00 am - 6:00 pm

PAYMENT METHODS:

All Methods

SOCIAL LINKS:

https://x.com/Little_P_Eng

https://www.linkedin.com/company/little-p-eng-for-engineering-services

#Piping Stress Engineer#Seismic Bracing Engineer#Silo Design#Tank Design#Belt Conveyor Design#Pressure Vessel Design#CRN registration

1 note

·

View note

Text

Column Jacketing: Types and Benefits Explained

Column jacketing strengthens columns and improves their load-carrying capacity. Engineers add materials around existing columns to boost their strength, stiffness, and durability. This method helps repair and upgrade structures to meet modern safety standards. Jacketing of columns increases their resistance to seismic forces, making buildings safer during earthquakes. It also improves the…

#building rehabilitation#building renovation#civil engineering#column jacketing#column strengthening#composite jacketing#concrete jacketing#construction repair#FRP jacketing#infrastructure upgrade#load-bearing capacity#reinforced concrete#retrofitting columns#seismic retrofitting#steel jacketing#Structural Engineering#Structural Integrity#structural reinforcement#structural stability#structural strengthening

0 notes

Text

Why You Should Invest in High-Quality TMT Bars and Super Rings

TMT bars shape the spine of modern creation initiatives, yet their significance in structural integrity is often underestimated. These thermo-robotically dealt with metallic reinforcements that determine the protection, durability, and durability of homes. Choosing the right construction substances is going beyond assembly's fundamental requirements—it's approximately developing structures that withstand a long time of environmental strain.

The Hidden Risks of Substandard Reinforcement Materials

Experienced engineers investigating structural failures regularly discover the same perpetrator: insufficient reinforcement. Low-quality TMT bars compromise buildings in crucial methods:

Premature Corrosion

Substandard TMT bars lack proper anti-corrosion properties, leading to internal rusting that expands and cracks concrete over time.

Inconsistent Load Bearing

Economy TMT bars are regularly afflicted by irregular inner structures, growing unpredictable vulnerable points at some point in the reinforcement community.

Reduced Earthquake Resistance

During seismic events, notable TMT bars flex without breaking. Lower-grade alternatives lack this vital ductility, making buildings extensively more prone.

Connection Failures

When binding wires and splendid earrings don't keep proper tension, the reinforcement grid loses cohesion, compromising structural integrity at some stage in pressure events.

Engineering Excellence Through Quality Components

The difference between trendy assembly and first-rate creation starts with material choice. High-first-rate TMT bars dramatically improve structural performance:

Superior Metallurgical Composition

Premium TMT bars go through rigorous management, making sure of perfect carbon distribution and removing microscopic flaws.

Enhanced Yield Strength

Top-tier TMT bars provide yield strength values exceeding 500 MPa compared to financial system alternatives at 415 MPa, offering a crucial protection margin.

Improved Bend Performance

Quality TMT bars preserve structural integrity even if bent to shape complex reinforcement shapes for columns and beams.

Systematic Integration

Professional-grade wonderful rings preserve the best spacing among reinforcements, while high-tensile binding wires steady complicated grids without slippage beneath load.

Optimizing the Reinforcement System

Creating resilient structures calls for viewing TMT bars, super earrings, and binding wires as included devices:

Precision Grid Formation

High-grade great earrings hold precise spacing between primary and secondary TMT bars, making sure proper concrete goes with the flow at the same time as keeping structural geometry.

Tension Maintenance

Quality binding wires face up to stretching over the years, retaining the reinforcement grid's integrity in the course of the concrete's lifespan.

Seismic Performance

Properly hooked up, tremendous rings prevent TMT bars from buckling during earthquakes, retaining structural integrity for the duration of the lateral loading cycles.

The Investment Perspective

Analyzing creation materials through a long-term funding lens well-known shows the true economics of quality:

Extended Service Life

Buildings with top-rate TMT bars mechanically exceed their layout lifespan by a long time, creating a sizable extra fee.

Reduced Maintenance

High-nice reinforcement structures limit concrete cracking, dramatically lowering ongoing protection charges.

Enhanced Market Value

Properties constructed with documented top-class materials command better resale expenses as consumers increasingly demand the creation of first-class.

Regulatory Compliance

As building codes become increasingly stringent, top-class TMT bars provide a margin of safety that helps future-proof structures towards evolving necessities. This proactive technique prevents expensive retrofitting that often turns into important when the use of minimally well-known materials.

Testing Certification

Quality producers provide comprehensive testing documentation for his or her TMT bars and notable earrings, imparting proof of performance abilities that exceed project specifications. This documentation serves as a treasured first-class guarantee for inspectors, engineers, and destiny property assessments.

Investing in advanced TMT bars, expert-grade excellent earrings, and excessive-tensile binding wires usually adds the best 1-3% to preliminary construction costs whilst probably extending structure lifespan with the aid of 30-50%—an splendid go back on investment.

Buildings represent multi-decade commitments. The TMT bars, notable rings, and binding wires selected today will decide structural overall performance for generations. Choosing top-class reinforcement materials isn't merely a production selection—it is a legacy choice in order to impact limitless lives for many years to come.

#TMT bars#super rings#construction#steel bars#building safety#reinforcement#earthquake resistance#durable structures#high-strength steel#anti-corrosion#load-bearing#premium TMT#concrete support#seismic safety#strong foundation#quality materials#binding wires#steel reinforcement#civil engineering#structural integrity

0 notes

Text

Why Super Rings Are Essential for Concrete Reinforcement

Super rings play an essential but regularly not noted function in modern creation, functioning as the unsung heroes that make certain concrete structures maintain their integrity over many years of use. These specialized additives work along with TMT bars to create a reinforcement device that withstands top-notch stress and environmentally demanding situations. Understanding their significance requires looking at how they complement other reinforcement factors and why construction specialists should not compromise on their pleasant.

The Critical Function of Super Rings in Structural Integrity

When concrete pillars and columns undergo large loads, they face both vertical compression and lateral enlargement forces. Super Rings save you this lateral expansion with the aid of creating a containment system across the primary reinforcement. Unlike a simple binding cord, those engineered components distribute stress flippantly at some point in the structure.

The dating among Super Rings and TMT bars creates a synergistic impact that dramatically increases load-bearing ability. While TMT steel bars offer tensile electricity alongside their duration, they want lateral assist to prevent buckling beneath compression. This partnership forms the backbone of the modern-day bolstered concrete era.

Material Composition and Manufacturing Standards

High-pleasant Super Rings derive from the same manufacturing tactics that produce top-class TMT bars. The thermo-mechanical treatment offers those components their one-of-a-kind blend of pliability and electricity—homes essential for withstanding seismic hobby and stopping catastrophic failure.

TMT metal bars undergo an advanced quenching and self-tempering procedure that creates a tough outer layer while maintaining a ductile center. This same technology applies to manufacturing Super Rings, resulting in additives that flex without breaking for the duration of ground movement or settlement.

Modern creation codes specify minimum requirements for spacing and diameter of Super Rings based on:

Column dimensions and height

Expected load calculations

Seismic sector classifications

Environmental publicity situations

Professional developers recognize that meeting these minimum requirements represents simply the place to begin for first-rate production.

Impact on Long-Term Structural Performance

Properly mounted Super Rings working alongside fine TMT bars appreciably expand building lifespans. The proof appears in systems built many years in the past that preserve to perform admirably regardless of publicity to harsh conditions.

The reinforcement gadget created by means of combining Super Rings with TMT metallic bars offers essential safety in opposition to:

Concrete cracking from thermal enlargement

Corrosion progression in marine environments

Structural degradation all through seismic occasions

Load redistribution as homes settle

These blessings translate immediately to reduced preservation costs and higher asset values over time—considerations that forward-thinking builders and homeowners increasingly prioritize.

Selecting Quality Components for Superior Results

Not all TMT metal bars meet the identical standards, and further, Super Rings require cautious sourcing. Construction professionals should confirm:

Proper certification from recognized government

Consistent diameter and spacing specifications

Appropriate binding mechanisms and overlaps

Compatibility with the challenge's grade of TMT bars

"The difference between economic system-grade and top-class reinforcement substances becomes apparent years later," notes structural consultant Rahul Sharma. "Unfortunately, with the aid of then, remediation charges far exceed what might have been spent on exceptional substances to begin with."

Conclusion

Super Rings constitute a vital thing in concrete reinforcement structures, working in concord with TMT bars to create structures designed to withstand decades of use. Their role in preventing lateral growth, distributing masses, and preserving structural integrity cannot be overstated.

Construction specialists who prioritize high quality in both TMT metal bars and their complementary components ultimately supply superior fees to their customers. As homes face an increasing number of traumatic overall performance necessities, those essential reinforcement factors emerge as even more crucial to long-term achievement.

The modest additional funding in top-class reinforcement materials yields great returns via prolonged service lifestyles, decreased upkeep, and stronger structural performance—making the selection to prioritize excellence a clean one for knowledgeable developers and asset owners.

#Super Rings#Concrete#Reinforcement#TMT Bars#Steel Bars#Strength#Durability#Structural#Construction#Support#Stability#Load-bearing#Building#Engineering#Seismic Safety#Quality#Longevity#Infrastructure#Strong Base#Foundation

0 notes

Text

Small Construction Projects for School

Small Construction Projects for Schools focus on enhancing learning environments through efficient design and execution. TB Engineering Inc. specializes in renovations, classroom expansions, accessibility improvements, and infrastructure upgrades, ensuring safe, functional, and modern educational spaces.

0 notes

Text

Innovative Designs for Infrastructure Excellence

Our general engineering contractors are dedicated to creating innovative solutions for complex engineering challenges, combining advanced technology with unparalleled craftsmanship. Contact us now!

#Engineering Contractor#Seismic#Construction#Structural#Soft-Story#Retrofit#Earthquake#Non-Ductile#Ordinance#Multifamily Construction

0 notes

Text

Leverage on Tecoustics’ Mason Industries’ products like Expansion Compensators, Flex Connectors, Floating Floors, Neoprene Mounts and Pads to ensure your project's success in noise and vibration control in Ontario.

0 notes

Text

Seismic Restraint Australian Standards

Archi ENG is a seismically specific company focusing on top-notch seismic design Australia & seismic restraint Australian standards. We understand the imperative importance of seismic restraint, strictly adhering to regulations and rules in accordance with Australian standards. This compliance ensures that structures can resist earthquake hazards, enhancing their durability over time. Our team of expert architectural engineers employs innovative design techniques and rigorous analysis to create solutions that meet aesthetic requirements while satisfying safety criteria. We are committed to sustainability and efficiency, ensuring that each project aligns with regulatory requirements and is environmentally friendly. Whether you’re embarking on a new build or retrofitting an existing structure, Archi ENG guides you through the complexities of construction engineering. Trust us to bring your vision to life with precision and care, making your structures more resilient and beautifully designed. Choose Archi ENG for expert seismic design and structural engineering services tailored to Australian needs.

0 notes

Text

Comprehensive Seismic Engineering Design Services Offered by Little P.Eng. and its Importance in Piping Stress Analysis

In the world of engineering and construction, seismic engineering is a specialized field crucial for ensuring the safety and resilience of structures in earthquake-prone regions. Little P.Eng. is a renowned seismic engineering firm that provides a wide range of services to address the unique challenges posed by seismic activity. In this comprehensive article, we will explore the multitude of services offered by Little P.Eng., highlighting their expertise, innovation, and dedication to creating structures that can withstand the forces of nature.

Seismic Risk Assessment

One of the foundational services offered by Little P.Eng. is seismic risk assessment. Before embarking on any seismic engineering project, it's essential to understand the level of risk posed by potential earthquakes in a specific area. Little P.Eng. utilizes advanced methodologies and data analysis to assess seismic hazards accurately. This assessment helps clients make informed decisions about construction and retrofitting, ensuring the safety of occupants and the protection of valuable assets.

Structural Analysis and Design

Seismic engineering begins with the structural analysis and design of buildings and infrastructure. Little P.Eng.'s team of experienced engineers specializes in developing seismic-resistant structural systems. They work closely with architects, builders, and developers to create designs that can withstand seismic forces, ensuring structural integrity and occupant safety during earthquakes.

Retrofitting Existing Structures

In regions with older buildings, retrofitting is often necessary to bring them up to current seismic safety standards. Little P.Eng. offers retrofitting services that involve the modification and strengthening of existing structures. Their engineers assess the specific needs of each building, considering factors such as its age, construction materials, and seismic vulnerabilities. They then implement retrofitting strategies that enhance the building's earthquake resistance, preserving its historical value while ensuring safety.

Foundation Design and Soil Analysis

The foundation is the bedrock of any structure's stability during an earthquake. Little P.Eng. conducts in-depth soil analysis to understand the geotechnical characteristics of the site. Based on this analysis, they design and recommend appropriate foundation systems tailored to the specific needs of the project. Their expertise in foundation design ensures that structures can effectively dissipate seismic forces into the ground, preventing catastrophic failure.

Compliance with Seismic Codes

Adherence to seismic codes and standards is paramount in seismic engineering. Little P.Eng. has an in-depth understanding of local, national, and international building codes related to earthquake-resistant construction. They ensure that all their designs and retrofitting projects comply with these regulations, providing clients with peace of mind that their structures meet the highest safety standards.

Advanced Computer Modeling and Simulation

Little P.Eng. leverages cutting-edge computer modeling and simulation tools to analyze and predict how structures will respond to seismic forces. These simulations allow for precise refinement of designs and provide valuable insights into structural performance during earthquakes. By simulating a wide range of seismic scenarios, engineers can optimize designs for maximum safety and efficiency.

Continuous Monitoring and Evaluation

The commitment of Little P.Eng. extends beyond the design and construction phase. They recommend and implement structural health monitoring systems that allow for real-time assessment of a building's integrity. Continuous monitoring enables early detection of potential issues, ensuring prompt maintenance or repairs to preserve structural stability.

Research and Innovation

Innovation is at the heart of Little P.Eng.'s approach to seismic engineering. Their team actively engages in research and development to push the boundaries of seismic-resistant technologies and construction practices. They explore innovative materials, construction techniques, and design methodologies to advance the field and provide clients with the latest and most effective solutions.

Emergency Response Planning

In addition to structural engineering services, Little P.Eng. assists communities, businesses, and organizations in developing emergency response plans for seismic events. They collaborate with stakeholders to create comprehensive strategies for minimizing risks, protecting lives, and reducing damage during earthquakes.

Public Education and Outreach

Little P.Eng. recognizes the importance of public awareness and education regarding seismic risks and safety. They engage in outreach programs to educate communities on earthquake preparedness, emergency response, and the importance of seismic-resistant construction.

Conclusion

Seismic engineering design plays a crucial role in piping stress analysis within industrial facilities, especially in regions prone to earthquakes. Piping stress analysis involves evaluating the forces and stresses that piping systems experience during various operational conditions, including seismic events.

Here's how seismic engineering design is important for piping stress analysis:

Safety and Structural Integrity: Seismic engineering design ensures that the entire facility, including piping systems, is built to withstand the forces generated by earthquakes. The structural integrity of piping systems is paramount for preventing leaks, ruptures, or catastrophic failures during seismic events. Piping stress analysis assesses the impact of seismic forces on the pipes, supports, and attachments to verify that they can withstand the dynamic loads and deformations caused by earthquakes.

Compliance with Building Codes: Piping systems within industrial facilities must adhere to building codes and standards related to earthquake-resistant design. Seismic engineering design ensures that piping systems are compliant with these codes. Non-compliance can lead to costly retrofitting efforts or, in the worst-case scenario, dangerous failures during an earthquake.

Identifying Vulnerabilities: Seismic engineering design involves conducting a seismic risk assessment for the facility. This assessment helps identify vulnerabilities in the piping systems, such as weak points in support structures or connections that may be prone to failure during seismic events. Piping stress analysis considers these vulnerabilities and recommends improvements to enhance seismic resilience.

Optimal Pipe Routing and Support: Piping stress analysis incorporates considerations for seismic forces when determining the routing of pipes and the design of pipe supports. Proper pipe routing and support are essential to prevent excessive stresses, vibrations, and displacements during an earthquake. Seismic engineering design helps optimize these factors to minimize potential damage to the piping systems.

Dynamic Load Analysis: Seismic events introduce dynamic loads on piping systems, which are significantly different from static loads. Piping stress analysis uses dynamic load analysis techniques to simulate the effects of seismic forces on pipes, fittings, and supports. This analysis ensures that the piping systems can handle the dynamic loads without exceeding their stress limits.

Retrofitting and Modifications: In existing facilities, seismic engineering design may involve retrofitting or modifying piping systems to meet current seismic standards. Piping stress analysis helps identify areas that require reinforcement, redesign, or additional support. Retrofitting ensures that older facilities can withstand seismic events and meet modern safety requirements.

Mitigation Strategies: Seismic engineering design doesn't only focus on evaluating existing conditions but also includes the development of mitigation strategies. These strategies may involve the use of seismic expansion joints, dampers, or flexible connectors to absorb seismic energy and reduce stress on the piping systems.

Emergency Response Planning: In the event of a seismic event, having a well-designed piping system is crucial for quick recovery and minimizing damage. Seismic engineering design contributes to emergency response planning by ensuring that piping systems are less likely to rupture or leak during an earthquake, reducing potential hazards and environmental damage.

In summary, seismic engineering design is vital for piping stress analysis because it ensures the safety, compliance, and resilience of piping systems in the face of seismic events. It helps identify vulnerabilities, optimize designs, and implement mitigation measures, ultimately safeguarding industrial facilities and the surrounding environment during earthquakes.

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Meena Rezkallah

Little P.Eng.

piping stress analysis

Piping stress analysis

Structural analysis

Seismic engineering

Seismic risk assessment

Retrofitting

Foundation design

Compliance with seismic codes

Computer modeling

Advanced simulation

Optimal pipe routing

Support systems

Pipe design

Seismic forces

Seismic expansion joints

Flexible connectors

Engineering Services

Pipe Stress Analysis Services

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Meena Rezkallah#Little P.Eng.#piping stress analysis#Piping stress analysis#Structural analysis#Seismic engineering#Seismic risk assessment#Retrofitting#Foundation design#Compliance with seismic codes#Computer modeling#Advanced simulation#Optimal pipe routing#Support systems#Pipe design#Seismic forces#Seismic expansion joints#Flexible connectors

0 notes

Text

seismic retrofitting

15 notes

·

View notes