#durable structures

Explore tagged Tumblr posts

Text

Why You Should Invest in High-Quality TMT Bars and Super Rings

TMT bars shape the spine of modern creation initiatives, yet their significance in structural integrity is often underestimated. These thermo-robotically dealt with metallic reinforcements that determine the protection, durability, and durability of homes. Choosing the right construction substances is going beyond assembly's fundamental requirements—it's approximately developing structures that withstand a long time of environmental strain.

The Hidden Risks of Substandard Reinforcement Materials

Experienced engineers investigating structural failures regularly discover the same perpetrator: insufficient reinforcement. Low-quality TMT bars compromise buildings in crucial methods:

Premature Corrosion

Substandard TMT bars lack proper anti-corrosion properties, leading to internal rusting that expands and cracks concrete over time.

Inconsistent Load Bearing

Economy TMT bars are regularly afflicted by irregular inner structures, growing unpredictable vulnerable points at some point in the reinforcement community.

Reduced Earthquake Resistance

During seismic events, notable TMT bars flex without breaking. Lower-grade alternatives lack this vital ductility, making buildings extensively more prone.

Connection Failures

When binding wires and splendid earrings don't keep proper tension, the reinforcement grid loses cohesion, compromising structural integrity at some stage in pressure events.

Engineering Excellence Through Quality Components

The difference between trendy assembly and first-rate creation starts with material choice. High-first-rate TMT bars dramatically improve structural performance:

Superior Metallurgical Composition

Premium TMT bars go through rigorous management, making sure of perfect carbon distribution and removing microscopic flaws.

Enhanced Yield Strength

Top-tier TMT bars provide yield strength values exceeding 500 MPa compared to financial system alternatives at 415 MPa, offering a crucial protection margin.

Improved Bend Performance

Quality TMT bars preserve structural integrity even if bent to shape complex reinforcement shapes for columns and beams.

Systematic Integration

Professional-grade wonderful rings preserve the best spacing among reinforcements, while high-tensile binding wires steady complicated grids without slippage beneath load.

Optimizing the Reinforcement System

Creating resilient structures calls for viewing TMT bars, super earrings, and binding wires as included devices:

Precision Grid Formation

High-grade great earrings hold precise spacing between primary and secondary TMT bars, making sure proper concrete goes with the flow at the same time as keeping structural geometry.

Tension Maintenance

Quality binding wires face up to stretching over the years, retaining the reinforcement grid's integrity in the course of the concrete's lifespan.

Seismic Performance

Properly hooked up, tremendous rings prevent TMT bars from buckling during earthquakes, retaining structural integrity for the duration of the lateral loading cycles.

The Investment Perspective

Analyzing creation materials through a long-term funding lens well-known shows the true economics of quality:

Extended Service Life

Buildings with top-rate TMT bars mechanically exceed their layout lifespan by a long time, creating a sizable extra fee.

Reduced Maintenance

High-nice reinforcement structures limit concrete cracking, dramatically lowering ongoing protection charges.

Enhanced Market Value

Properties constructed with documented top-class materials command better resale expenses as consumers increasingly demand the creation of first-class.

Regulatory Compliance

As building codes become increasingly stringent, top-class TMT bars provide a margin of safety that helps future-proof structures towards evolving necessities. This proactive technique prevents expensive retrofitting that often turns into important when the use of minimally well-known materials.

Testing Certification

Quality producers provide comprehensive testing documentation for his or her TMT bars and notable earrings, imparting proof of performance abilities that exceed project specifications. This documentation serves as a treasured first-class guarantee for inspectors, engineers, and destiny property assessments.

Investing in advanced TMT bars, expert-grade excellent earrings, and excessive-tensile binding wires usually adds the best 1-3% to preliminary construction costs whilst probably extending structure lifespan with the aid of 30-50%—an splendid go back on investment.

Buildings represent multi-decade commitments. The TMT bars, notable rings, and binding wires selected today will decide structural overall performance for generations. Choosing top-class reinforcement materials isn't merely a production selection—it is a legacy choice in order to impact limitless lives for many years to come.

#TMT bars#super rings#construction#steel bars#building safety#reinforcement#earthquake resistance#durable structures#high-strength steel#anti-corrosion#load-bearing#premium TMT#concrete support#seismic safety#strong foundation#quality materials#binding wires#steel reinforcement#civil engineering#structural integrity

0 notes

Text

How to Effectively Use Construction Rings in Your Concrete Reinforcement

Construction rings shape the backbone of reliable concrete reinforcement systems, but their proper implementation remains a misunderstood thing of structural engineering. While experienced contractors understand their crucial importance, many production tasks suffer from flawed ring placement, inadequate security techniques, or terrible-quality materials. These oversights can result in devastating structural failures that compromise safety and generate massive repair prices.

The Critical Role of Construction Rings in Structural Integrity

Concrete, regardless of its extraordinary compressive power, performs poorly beneath anxiety. Construction earrings cope with this essential weak spot by means of creating a framework that distributes tensile forces during the structure. When properly installed, these rings prevent catastrophic failures during:

Seismic events that create lateral loading

Temperature fluctuations causing expansion and contraction

Settlement shifts that occur as foundations stabilize

Load-bearing stress that exceeds concrete's natural capacity

The placement pattern of construction rings significantly influences structural performance. In columns, closely spaced rings near the top and bottom prevent buckling and shear failure. For beams, concentrated rings at the supports and at calculated intervals throughout the span ensure both flexibility and sheer capacity.

Understanding Binding Wire: The Unsung Hero

The effectiveness of construction rings depends heavily on the quality and application of binding wire. This reputedly minor factor serves the vital function of preserving ring positioning at some point of concrete pouring and curing.

Professional contractors select binding wire based on several critical factors:

Tensile strength: Must withstand the forces exerted during pouring and vibration

Corrosion resistance: Particularly important in exposed or high-humidity environments

Ductility: Allows for tight securing without breaking during manipulation

Compatibility: Must not react adversely with the concrete chemistry

Standard binding wire comes in numerous gauges, with 16-gauge and 18-gauge being normally used for fashionable production. However, specialized applications can also require exclusive specs. Bridge creation and marine systems commonly call for stainless steel binding cord because of its superior corrosion resistance, even as high-upward thrust homes may require higher-gauge cord to aid heavier reinforcement configurations.

Mastering Wire Binding Techniques for Optimal Results

Wire binding connects the theoretical engineering design to real-world structural performance. Even perfectly designed construction rings will fail to perform if improper binding techniques are employed. The most effective wire binding approaches include:

The Figure-Eight Method

This technique creates an exceptionally secure connection by forming a figure-eight pattern around intersecting rebar and construction rings. The binding wire wraps around both components twice before being twisted tight, creating redundancy that prevents failure even if one loop loosens.

The Saddle Tie

Ideal for connecting parallel bars to construction rings, the saddle tie wraps binding wire around both components in a U-shape before twisting the ends together. This method provides excellent lateral stability while maintaining the precise spacing required by engineering specifications.

The Continuous Spiral

For extensive column reinforcement, the continuous spiral technique enables efficient wire binding along the entire length. This approach maintains consistent tension on the binding wire, preventing the loosening that often occurs with individual ties.

Common Wire Binding Mistakes to Avoid

Construction projects frequently suffer from these avoidable binding errors:

Insufficient twisting: Binding wire must be twisted at least 3-4 full rotations to achieve proper tension.

Improper cutting: Sharp wire ends create safety hazards and can damage waterproofing membranes. Always bend cut ends back toward the main structure.

Inconsistent spacing: Haphazard wire binding leads to irregular construction ring positioning, compromising structural integrity.

Mixing incompatible materials: Using galvanized binding wire with non-galvanized construction rings accelerates corrosion through galvanic reaction.

Field-Tested Best Practices for Wire Binding

Experienced structural engineers recommend these practical approaches:

Pre-cut binding wire into appropriate lengths before beginning work to improve efficiency

Employ dedicated wire binding tools rather than improvised alternatives

Verify tie security by applying moderate pressure after completion

Implement systematic quality control inspections before concrete placement

Document binding wire specifications and batch information for quality assurance

Integration with Modern Construction Technology

Advanced construction techniques now incorporate specialized binding wire systems designed specifically for construction rings. These innovations include:

Self-locking binding mechanisms that maintain tension without twisting

Color-coded wire for different structural elements to prevent confusion

Pre-measured wire lengths optimized for specific connection types

Corrosion-inhibiting coatings that extend service life

Ensuring Long-Term Structural Performance

The longevity of concrete structures depends significantly on proper construction ring installation and secure wire binding. Structures built with attention to these details consistently outperform those with corners cut during the reinforcement phase.

For critical infrastructure projects, implementing third-party inspection of construction ring placement and binding wire application provides valuable quality assurance. This additional oversight often identifies potential issues before concrete placement makes corrections impossible.

By investing in quality construction rings, appropriate binding wire, and proven wire binding techniques, construction professionals ensure the structural integrity that underpins safe, long-lasting concrete structures. These foundational elements may remain hidden within the finished structure, but their performance determines whether that structure stands the test of time.

#construction rings#concrete rings#reinforcement#binding wire#wire binding#steel rings#structural support#TMT rings#rebar rings#concrete strength#foundation rings#strong buildings#steel reinforcement#building safety#column rings#slab rings#durable structures#cement support#RCC rings#rebar binding

0 notes

Text

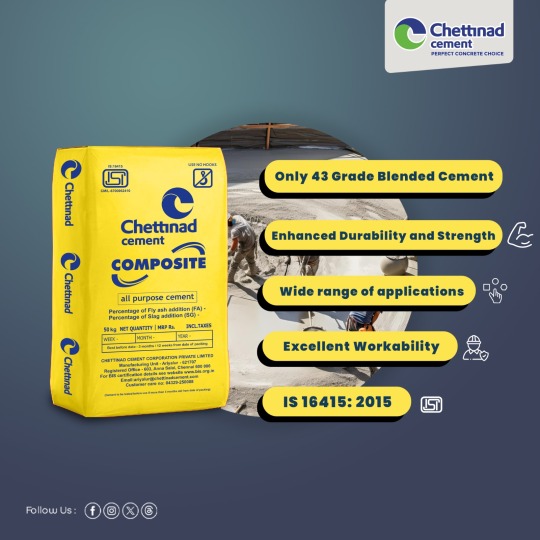

Why OPC 43 Grade Cement is the Ultimate Choice for Your Construction Projects

OPC 43 Grade Cement is widely regarded as the ultimate choice for construction projects due to its numerous advantages, ensuring high-quality results and durability.

Here are five key reasons why it is the preferred option:

Superior Strength: OPC 43 Grade Cement offers exceptional compressive strength, making it ideal for medium-strength applications, ensuring stability and long-term durability in structures.

Faster Setting Time: With quick setting time, allows for faster construction and early strength development, reducing project timelines without compromising on quality.

Versatility: Suitable for a wide range of applications, from residential buildings to large infrastructure projects, OPC 43 Grade Cement ensures versatility in construction.

Cost-Effective: Known for being economically efficient, OPC 43 Grade Cement provides an optimal balance between price and performance, making it a cost-effective solution for large-scale projects.

Reliable Quality: Manufactured to meet stringent quality standards, OPC 43 Grade Cement ensures consistency and uniformity in every batch, making it a dependable choice for construction.

Contact Us:

For more information on our products and services, contact us at [email protected]. We’re here to help you make your dream home a reality.

If you want more information visit this website Chettinad Cement

Contact us: 6385 194 588

Facebook: Chettinad Cement

Twitter: Chettinad Cement

Instagram: Chettinad Cement

#OPC43 Grade Cement#Construction Excellence#Durable Structures#Quality Cement#Cost Effective Building

0 notes

Text

tangle is so fun because she is a juxtaposition of something collected and contained with something loose and free and in motion

she’s a rough brawler but she has a stance and a style. she’s impulsive and thrillseeking, but she wraps her arms in sports tape to protect them, a precaution. she longs for adventure and action but she will always need to come to rest at home with friends. she’s bouncy and restless, but she’s an intent listener and considerate. she’s got months of off-and-on experience fighting badniks, but is still so new to real Adventure.

and while there’s plenty of traits sonic and tangle share, you can’t reduce her to ‘girl sonic’ without neglecting something of her own characterization. she fundamentally wants something different out of life than sonic does, because she doesn’t need to be anchorless; she isn’t a backpacker, sleeping somewhere new every night. she’s more like a goose, or a frigate bird; flying free for ages and ages, knowing she wants to go somewhere, until time comes to call her back to her origin.

#random rambling at midnight oclock#i love love love contrasting characters who are very similar but have important subtle distinctions#like sonic is very self-determined. he knows what he wants#tangle is not yet. shes chasing adventure because she knows thats how she’ll *find* what she wants#she chases whisper because she knows whisper is better with a friend around. but also because whisper is a gateway to adventure#she’ll even bind herself with structure and expectations if it means coming back to whisper#^ sonic didnt want to join the restoration even for amy. tangle stayed because jewel needed her even if she hated it#or even just because itd help jewel. jewel didnt necessarily need tangle - especially if tangle had the free time to cause Incidents#shes like. selfless for partially selfish reasons. she wants adventure so bad & helping ppl is an adventure#she obviously still cares about people and wants to help too. but still#shes also this mix of. very competent and frightening in ability & strength. but also never really put on a level with most of the main cas#extremely durable tail that can punch metal out + lengthen to any size or reach (at high speed too!!) + hulk loki toss people#plus above average ability/acrobatics + some durability cause she fell a ways in the portal tower arc finding sonic/amy/tails#but also. still not applied as much as she could be + often disadvantaged against characters like surge/mimic/guns#but like. she also was fighting off zombots for some period of time while getting 0% more infected; creatively using chairs & stools#i feel like being true to *that* tangle necessitates her having some sort of plan against surge if/when they clash again.#she DOES strategize even if it’s on the fly. and she does have a pretty good sense of where her own body is/isn’t Marinette clumsy#anyways. au where i rewrite tangle’s recent appearances in line with her characterization for the first ~30 issues#forever anytime i see tangle being characterized as a sonic fangirl im like ‘she wouldnt do that.’#she would ADMIRE sonic absolutely!! she would not Fangirl. they are different. issue 4 she was so chill abt meeting sonic#ive been awake too long….. goodnight

8 notes

·

View notes

Text

ngl i'm a little scared rn bc i can't stop almost fainting again and my anxiety is making me lie here doing differential diagnoses on myself bc this time i do have enough nutrients in my body so it's like oh okay so i'm at death's door 👍🏻 and also why tf is it happening now that i have an exam to study for and i'm already way behind schedule :(

#i've been laying here for the past 40 minutes when i could've read a whole pdf on seismic actions according to the eurocode in that time 😭#can't i have a health crisis next week i need to learn about structural durability rn!!#(...)

2 notes

·

View notes

Text

i need work pants

#ive had this problem i hate all pants and have noooo money#i need black pants that are durable for moving things#but im alllll legs#txt#like i need tall comfortable but practical structured black pants

3 notes

·

View notes

Text

and the ita bag ita'd today 😼

#its good and durable But it kinda lacks some structure so its a little filmsy at the top which is a bit annoying#maybe ill try to find something to sew onto it.. 💭

6 notes

·

View notes

Text

Ellora : Le Plus Grand Temple Monolithique du Monde et Ses Secrets

Les grottes d'Ellora et Ajanta vous transportent à travers le temps, dévoilant les trésors artistiques et spirituels de l'Inde ancienne. Découvrez ces merveilles lors de votre prochain voyage solo ! ✨🌏 #GrottesEllora #VoyageEnInde #PatrimoineUNESCO

À la Découverte des grottes d’Ellora : Un Trésor Spirituel et Architectural Aujoud´hui nous largons les amares et commençons un tour du monde anciens et le mystère de ses mégastructures. comme celles qu’on peut trouver dans les grottes de Ellora y Ajanta de le Maharashtra. Maharashtra : Sur les Traces du Monde Ancien avec les Grottes d’Ellora Voyager en solo en Inde est une aventure en soi,…

#365JoursDeVoyage#Architecture monolithique#Art indien ancien#Aventure en Inde#Découverte#Découverte spirituelle#Exploration Inde#Grottes Ellora#Histoire ancienne Inde#Inde#Inspiration de Voyage#Méga structures#Monuments anciens#Noirenvoyage#Patrimoine mondial#Patrimoine UNESCO#Sites historiques Inde#Spiritualité indienne#Tourisme culturel Inde#Tourisme durable#Trésors cachés Inde#Unesco#Voyage culturel#Voyage hors des sentiers battus#Voyage solo

1 note

·

View note

Text

Basalt Fiber Reinforcement in Construction: A Sustainable Paradigm Shift

Introduction In the contemporary construction landscape, a notable shift towards sustainable and eco-friendly building materials is underway. Among the alternatives gaining prominence is basalt fiber reinforcement, positioning itself as a compelling substitute for traditional steel reinforcement. This transition is fueled by a collective desire to reduce environmental impact and elevate the…

View On WordPress

#alternative to steel reinforcement#basalt fiber applications#basalt fiber properties#Basalt fiber reinforcement#basalt mesh in concrete#BFRP composites#construction industry sustainability#corrosion-resistant materials#durability in construction#eco-friendly building#environmental impact of construction#future of construction materials.#green building practices#lightweight construction materials#seismic resilience in buildings#steel replacement in construction#strength-to-weight ratio#Sustainable Construction Materials#sustainable structural design#thermal insulation in construction

2 notes

·

View notes

Text

How a Reliable TMT Saria Manufacturer Contributes to Stronger Concrete Structures

Every remarkable structure begins with exceptional materials. The strength and longevity of concrete construction greatly depend on the quality of its reinforcement parts—particularly TMT Saria, binding wires, and dowel bars. When these essentials align under flawless manufacturing standards, they form the core of robust infrastructure.

Understanding TMT Saria: The Foundation of Structural Integrity

TMT Saria is more than just steel reinforcement; it is the structural strength that ensures a building stands tall against decades of stress and environmental challenges. A good TMT Saria manufacturer utilizes advanced metallurgical processes to ensure that each bar is consistent in its tensile strength, ductility, and durability.

The manufacturing process requires precise temperature control and quenching techniques that create a tough outer layer while maintaining a ductile core. This dual-nature characteristic proves crucial when structures face seismic activities or unexpected loads, allowing the reinforcement to flex without failing.

The Synergy of Components

While TMT Saria forms the major reinforcement, equally important binding wires hold reinforcement grids in place. Quality binding wires ensure proper positioning of steel during concrete pouring, avoiding displacement that could compromise structural integrity.

Dowel bars are another vital component, transferring loads efficiently across concrete joints. When procured from reputable manufacturers, dowel bars work in perfect harmony with TMT Saria to form a cohesive structural system. The accuracy in the production of these parts directly impacts their load-carrying capacity and durability.

Manufacturing Excellence: More Than Just Standard Requirements

The best TMT Saria manufacturers go beyond industry-standard requirements through rigorous quality control processes, reflected in several ways:

1. Metallurgical Precision

Advanced testing facilities ensure consistent chemical composition across batches, guaranteeing uniform strength properties throughout the reinforcement network.

2. Surface Engineering

Unique ribbing patterns enhance the bond between concrete and rebar. Precise dimensional control optimizes interaction with binding wires and dowel bars, ensuring a robust mechanical interlock.

3. Quality Assurance Systems

Comprehensive testing protocols verify crucial mechanical properties like yield strength, ultimate tensile strength, and elongation. These characteristics are essential for structures to withstand static and dynamic loads.

Impact on Construction Quality

The choice of a TMT Saria manufacturer significantly affects construction outcomes. High-quality reinforcement makes installation easier and reduces the chances of errors in binding wires. Coupled with properly manufactured dowel bars, these components create strong structural systems capable of enduring intense environmental stresses.

Superior TMT Saria also minimizes material wastage during construction. With tight manufacturing tolerances, fewer pieces are rejected, ensuring a smoother construction process and greater efficiency.

Economic Effects of Quality Production

Although premium TMT Saria may come at a higher cost, its long-term benefits outweigh the initial investment. Structures built with high-quality reinforcement require less maintenance and offer excellent resistance to deterioration, saving significant costs over their lifespan.

Reliable binding wires and dowel bars from established manufacturers also accelerate construction timelines. Their consistency reduces rework requirements, helping projects stay on schedule and within budget.

Future-Proofing Construction Projects

As construction technologies evolve, leading TMT Saria manufacturers continue to innovate. Their research and development efforts focus on addressing emerging challenges in construction, including environmental concerns and enhanced seismic resistance.

This forward-thinking approach ensures that TMT Saria, along with complementary materials like binding wires and dowel bars, meets the rigorous demands of modern construction projects. By investing in innovation, manufacturers enable the creation of durable and safe structures.

Conclusion

For construction professionals aiming for excellence, partnering with a reliable TMT Saria manufacturer is a crucial decision. The quality of reinforcement materials directly impacts structural integrity, construction efficiency, and long-term success.

By choosing manufacturers committed to quality and innovation, builders invest in the future of construction itself, ensuring safety, durability, and economic efficiency for generations to come.

#TMT Saria#concrete strength#durable structures#TMT bars#construction steel#TMT manufacturer#rebar quality#tensile steel#strong concrete#seismic resistant#building materials#steel reinforcement#structural durability#TMT steel rods#concrete bars#quality TMT#steel strength#rebar supplier#TMT production#durable rebar

0 notes

Text

Why the Best TMT Bar is Essential for Long-lasting Structures

Modern construction demands substances that can face up to a long time of stress, demanding environmental situations, and seismic activities. At the coronary heart of those necessities lies a critical element regularly omitted during planning stages: reinforcement steel. Specifically, the Best TMT Bar turns into the invisible spine determining whether or not a structure will stand sturdy for generations or require untimely maintenance.

Understanding TMT Technology: Beyond Basic Steel

Thermo-Mechanically Treated (TMT) Bars represent an innovative advancement in creation materials. Unlike conventional metal reinforcement, those specialized bars go through a complicated three-level technique:

Quenching: Hot-rolled metal passes via water jets, rapidly cooling the outer surface at the same time as retaining a hot center.

Self-tempering: Heat from the bar's core flows outward, growing a tempered center layer.

Atmospheric cooling: The final step completes the metallurgical transformation.

This technique creates a unique microstructure presenting a tough martensitic surface with a ductile ferrite-pearlite core—the suitable aggregate of strength and flexibility. However, now not all TMT Bars deliver identical performance, and choosing the Best TMT bar is critical for structural integrity.

Critical Factors Separating the Best TMT Bar from Standard Options

The construction panorama offers countless TMT Bars from several TMT Bar Manufacturers, creating confusion for engineers and contractors. These key differences separate premium options from widespread products:

1. Tensile Strength and Yield Point

The Best TMT Bar provides higher tensile power with yield factors exceeding 500 MPa (Fe 500 grade and above). This interprets immediately into superior load-bearing potential and resistance to deformation under strain. Lesser-grade TMT Bars would possibly keep preliminary charges but compromise structural capability, particularly at some point of seismic events.

2. Ductility and Bendability

Premium TMT Bars show super elongation percentages, allowing them to bend without breaking. These assets prove important during earthquakes while structures have to flex instead of fail catastrophically. Tests show top-tier options hold integrity even at one hundred eighty-degree bends, whilst inferior products expand microscopic fractures for the duration of set up.

3. Ribs and Bond Strength

The one-of-a-kind rib sample on great TMT Bars creates mechanical interlocking with the surrounding concrete. The Best TMT Bar capabilities optimized rib designs that boom bond electricity by using up to 40% as compared to standard alternatives. This prevents slippage below load—a common failure point in systems that use inferior reinforcement.

4. Corrosion Resistance

Concrete's alkaline environment normally protects embedded metals; however, as soon as carbonation or chloride ingress happens, corrosion begins. Leading TMT Bar Manufacturers contain particular copper percentages and specialised coatings that dramatically decorate corrosion resistance, extending shape lifespan with the aid of a long time compared to standard options.

Evaluating TMT Bar Manufacturers: Beyond Marketing Claims

With several TMT Bar Manufacturers making comparable claims, objective evaluation turns essential:

Manufacturing Process Authentication

The Best TMT Bar outcomes from tightly managed quenching parameters. Reputable producers welcome third-party facility inspections and offer transparency concerning their precise processes. This openness indicates confidence in the satisfactory manipulation of systems.

Certifications and Testing

Premium TMT Bar Manufacturers maintain comprehensive certification portfolios, along with ISO 9001 and product-precise validations. They carry out batch-by-using-batch checking out as opposed to statistical sampling, ensuring each ton of metal meets exact specifications.

Consistency Across Production Runs

Lesser manufacturers frequently show fine variations among manufacturing batches. The Best TMT Bar comes from facilities demonstrating steady metallurgical properties across all manufacturing runs, confirmed through statistical evaluation of take a look at consequences.

Making the Right Selection for Your Project

When comparing TMT Bars for production initiatives, recall these important factors:

Grade appropriateness: Match TMT Bar specs to structural requirements rather than defaulting to minimal standards.

Manufacturer popularity: Research TMT Bar Manufacturers' music data and high-quality control tactics.

Independent testing: Verify claimed properties through impartial laboratory analysis.

Cost as opposed to fee: Calculate lifecycle costs in place of focusing solely on preliminary expense.

The Long-Term Perspective

Structures built these days will face a long time of demanding situations—from increasing weather extremes to evolving utilization styles. The Best TMT Bar offers the essential electricity and sturdiness important to satisfy those demanding situations, making the cautious selection of reinforcement substances one of the maximum consequential choices in the construction process.

The distinction between preferred TMT Bars and the Best TMT Bar may additionally seem subtle on paper, however, this difference in the long run determines whether or not a shape will stand strong for generations or require premature intervention. For tasks designed to create lasting fee, the choice will become clear.

#TMT bar#best TMT bar#durable structures#strong TMT bars#high-quality TMT#construction steel#reinforced bars#building strength#steel rods#TMT steel#long-lasting TMT#structural steel#top TMT brands#best steel bars#construction material#reinforced steel#TMT bar quality#superior TMT bars#TMT bar benefits#steel reinforcement

0 notes

Text

The above article is fascinating. If you can't click into it right now, it talks about actual testing done to determine whats in all these "plant-based" leather substitutes and surprise surprise, ALL OF THEM are still petroleum based. And many MANY of them also contain toxic and banned chemicals!

Like DMF (dimethylformamide) which is known to cause very bad skin irritation, breathing issues, and BIRTH DEFECTS.

"Vegan Leather"

Plastic. just say plastic.

#plant-based leather is a LIE#it is going to REMAIN a lie!#the complex structure of leather and the durability just isn't a thing that we can reproduce artificially#sustainable vegetable tanned leather will last for DECADES if it's taken care of#whereas these plastic based crap options degrade to unusable trash within 1 or 2 years#current events 2023

113K notes

·

View notes

Text

The Ultimate Guide to the Best Cat Tree with Litter Box: A Detailed Review of the Heybly Cat Tree with Litter Box Enclosure

As a cat owner, finding furniture that balances functionality, aesthetics, and your pet’s comfort can feel like a daunting task. A cat tree with litter box is a game-changer, combining a cozy hideaway for your cat’s bathroom needs with a fun, engaging play structure. After scouring Amazon for top-rated options, I’ve chosen the Heybly Cat Tree with Litter Box Enclosure, 60-inch as the star of this…

#cat condo#cat furniture#cat hideaway#cat litter cabinet#cat perch#cat play structure#cat scratching post#cat tower#cat tree for small spaces#cat tree with litter box#durable cat tree#feline furniture#hidden litter box#litter box enclosure#modern cat furniture#multi-level cat tree#odor control cat tree#pet furniture#space-saving cat tree#stylish cat tree

0 notes

Text

Duraneo GFRP Bent Rebars – Durable, Flexible Reinforcement for Complex Concrete Structures

Duraneo’s GFRP bent rebars are engineered to provide reliable reinforcement in intricate concrete shapes such as corners, hooks, and stirrups. Made from corrosion-resistant glass fiber reinforced polymer, these bars ensure long-lasting performance in harsh environments while being lightweight and easy to handle. Perfect for infrastructure projects demanding strength, flexibility, and durability without the drawbacks of traditional steel.

#GFRP bent rebar#composite reinforcement#corrosion-resistant rebar#glass fiber reinforced polymer#bent rebars#lightweight reinforcement#durable rebar#structural reinforcement#concrete reinforcement#non-metallic rebar#corrosion-free rebars#reinforced concrete solutions#precision-formed rebar#infrastructure reinforcement#marine-grade rebar

0 notes

Text

Exploring the Benefits of Checker Plate Aluminium in the Construction Industry

Checker plate aluminium is becoming increasingly popular in the construction and industrial materials sectors, particularly for its durability and aesthetic appeal. Minmetals East is at the forefront of offering high-quality checker plate aluminium that meets the diverse needs of various industries.

The unique design of checker plate aluminium provides excellent slip resistance, making it an ideal choice for flooring, walkways, and ramps. This safety feature enhances workplace environments, reducing the risk of accidents and ensuring a secure footing for workers.

In addition to safety, checker plate aluminium is lightweight yet strong, making it easy to handle and install while maintaining structural integrity. Minmetals East's commitment to quality ensures that customers receive products that are not only functional but also sustainable, contributing to environmentally friendly construction practices.

Moreover, the versatility of checker plate aluminium allows it to be used in a variety of applications, including in the manufacturing of industrial materials and water treatment facilities. As industries continue to innovate, Minmetals East remains dedicated to providing solutions that meet the evolving demands of the market.

Embrace the advantages of checker plate aluminium and elevate your projects with the superior products from Minmetals East!

#structural integrity#Minmetals East#lightweight#water treatment facilities#durability#safety#versatility#construction industry

0 notes

Text

The Value of a Residential Estimating Service in 3D Printed Home Construction

The rise of 3D printed homes is revolutionizing the construction industry. By using additive manufacturing technology, builders can create homes with greater precision, less waste, and reduced labor costs. However, while the technology promises cost savings, the unique nature of 3D printed homes requires specialized budgeting and planning to ensure projects are financially viable. A residential estimating service plays a crucial role in this process by helping to forecast accurate costs, accounting for the intricacies and potential challenges that arise in 3D printed home construction.

As 3D printing technology continues to evolve, homeowners and developers need reliable estimating services to navigate the complexities of this innovative construction method. These services help ensure that projects stay within budget while meeting quality standards and project timelines.

Understanding 3D Printed Home Construction

3D printing in home construction involves the use of a printer to create walls, floors, and other structural components layer by layer. The primary materials used in 3D printing for homes include concrete, clay, or composites, with printers capable of creating intricate designs that traditional methods cannot easily replicate.

While 3D printing offers numerous advantages—such as rapid construction, reduced labor, and customization options—its costs can vary significantly. Factors such as material choice, print size, project complexity, and technology specifications all impact the overall cost of a 3D printed home.

Budgeting for 3D Printing Materials

One of the primary considerations in estimating the cost of 3D printed homes is the material used. The quality, type, and quantity of the material play a major role in determining the total cost of the build. Concrete, often used in 3D printing due to its strength and durability, is typically more affordable than other materials, but the cost can still fluctuate depending on the supplier and local availability.

A residential estimating service helps clients understand the cost implications of using various 3D printing materials. The estimator will provide a detailed breakdown of material costs, considering factors such as material waste, transportation, and handling fees. Since the technology is still relatively new, these costs may not always be predictable, making an expert estimator’s role all the more vital in forecasting potential variances.

Labor and Printing Time Considerations

While 3D printing eliminates many manual construction tasks, such as bricklaying and framing, there are still labor costs associated with setup, monitoring the printing process, and post-printing tasks. The process of setting up the printer, maintaining equipment, and overseeing quality control requires skilled labor. The printing itself, although automated, is not instantaneous and can take days or even weeks depending on the complexity of the design.

A residential estimating service accounts for these labor costs and the printing time, which can be significantly different from traditional construction projects. The estimator can calculate labor costs for monitoring, troubleshooting, and finishing tasks, ensuring that these costs are incorporated into the budget. They also take into account any additional time required for material delivery, setup, and calibration.

Design Flexibility and Customization

One of the most attractive aspects of 3D printed homes is their design flexibility. With the ability to create complex, customized shapes and structures, 3D printing allows for architectural freedom that traditional construction methods often cannot achieve.

However, this flexibility can impact the budget. More intricate designs may require more material or longer printing times, leading to higher costs. A residential estimating service evaluates the design’s complexity and integrates these factors into the overall estimate. By balancing custom features with cost constraints, the estimator ensures that the project’s design vision aligns with the budget.

Site Preparation and Foundation Costs

Although 3D printing reduces the amount of manual labor required during construction, site preparation remains a crucial part of the process. Depending on the location, this could involve clearing the land, leveling the site, and ensuring the foundation is properly prepared to support the printed structure.

For a 3D printed home, the foundation typically consists of a reinforced concrete slab, which must be poured and cured before printing can begin. The residential estimating service accounts for these additional costs and provides a clear picture of what needs to be done to prepare the site. This includes evaluating soil conditions, assessing the need for grading, and determining the cost of the foundation installation.

Regulatory and Permit Costs

Like traditional construction, 3D printed homes must comply with local building codes and regulations. In some areas, building codes may not yet address 3D printed structures, making it necessary to consult with local authorities and engineers to ensure that the construction meets safety and code standards.

The residential estimating service plays a key role in navigating these regulatory challenges. The estimator helps identify the necessary permits, certifications, and inspections required for a 3D printed home, and factors these into the overall project budget. This helps avoid costly delays caused by missing permits or non-compliance with regulations.

Maintenance and Long-Term Durability

While 3D printed homes offer a unique and innovative building solution, homeowners and builders must also consider the long-term durability and maintenance of the materials used. 3D printed homes are generally built to last, but depending on the material used, they may require specific maintenance or repairs over time.

A residential estimating service can factor in the cost of maintaining the home in the future. For example, if the home is constructed with concrete or composite materials, the estimator will consider the potential for cracking, erosion, or other wear-and-tear issues. This long-term perspective helps homeowners budget for future repairs or upgrades that may be needed after construction.

Conclusion

The rise of 3D printed homes presents both exciting opportunities and unique challenges. While the technology promises cost savings and design freedom, accurately budgeting for a 3D printed home requires a detailed understanding of the materials, labor, site preparation, and regulatory considerations involved. A residential estimating service offers valuable expertise in these areas, helping homeowners and developers navigate the complexities of 3D printed home construction while staying on budget.

By providing a clear, comprehensive estimate, residential estimators ensure that all aspects of the project—from the initial design to the final finishing touches—are accounted for. With their help, homeowners can confidently embrace this innovative construction method while avoiding unexpected costs or delays.

#residential estimating service#3D printed homes#additive manufacturing#3D printing materials#construction budgeting#customized home design#concrete printing costs#labor for 3D printing#site preparation for 3D homes#3D printing labor#home foundation costs#regulatory compliance#building code for 3D printed homes#printing time budgeting#home design flexibility#customized home construction#printing equipment setup#3D printed structure#material waste costs#home permit fees#architectural freedom#future home maintenance#3D home durability#building with composites#3D printing in construction#site grading costs#local construction regulations#3D printed home foundation#labor for finishing#project timeline costs

0 notes