#Silicon Controlled Rectifiers

Explore tagged Tumblr posts

Text

Powerex KSB13060: The Powerhouse of Silicon-Controlled Rectifiers (SCRs)

Buy KSB13060 and other power semiconductors for as low as $1 at https://www.uscomponent.com/buy/Powerex/KSB13060.

In the dynamic field of power electronics, ensuring robust and efficient control of high-power applications is critical. Powerex introduces the KSB13060, a high-performance Silicon Controlled Rectifier (SCR) designed to meet the rigorous demands of industrial and commercial power control systems. Whether you are managing motor drives, power supplies, or industrial heaters, the KSB13060 delivers unmatched performance, reliability, and efficiency.

Exceptional Performance

The Powerex KSB13060 is engineered to deliver outstanding performance across a broad range of applications. With a voltage rating of 600V and a current rating of 130A, this SCR is capable of handling significant power loads with ease. Its high surge current capability ensures reliable operation even under extreme conditions, making it an ideal choice for applications requiring high power and durability.

Robust Construction

Reliability and durability are at the core of the Powerex KSB13060. Constructed with high-quality materials and advanced manufacturing processes, this SCR is designed to withstand harsh environments and demanding operating conditions. Its rugged design ensures long-term stability and performance, reducing maintenance costs and downtime.

Versatile Applications

The versatility of the KSB13060 makes it suitable for a wide range of applications. In motor control systems, it provides precise and reliable power control, ensuring smooth operation and extended motor life. For power supplies and rectifiers, the KSB13060 ensures efficient and stable power conversion. It is also an excellent choice for industrial heating applications, where precise temperature control is essential for optimal performance.

Easy Integration

Powerex understands the importance of seamless integration in your power control systems. The KSB13060 is designed for easy installation and compatibility with a variety of control circuits. Its standard package size and configuration simplify the upgrade process, allowing for quick and hassle-free implementation in existing systems. This ease of integration helps minimize downtime and ensures a swift return on investment.

Superior Control

The KSB13060 offers superior control capabilities, with fast switching speeds and low switching losses. Its excellent thermal management ensures consistent performance, even under heavy load conditions. This high level of control enhances the efficiency and reliability of your power systems, contributing to improved overall performance and reduced energy consumption.

Environmentally Conscious

In an era where energy efficiency and environmental responsibility are paramount, the KSB13060 stands out as an eco-friendly solution. By enhancing the efficiency of power control systems and reducing energy losses, it helps lower your carbon footprint and supports sustainable operations. Integrating the KSB13060 into your systems is a step towards greener and more responsible technology solutions.

Conclusion

The Powerex KSB13060 SCR is more than just a semiconductor device; it's a cornerstone of advanced power control systems. With its exceptional performance, robust construction, versatile applications, easy integration, superior control, and environmental benefits, the KSB13060 sets a new benchmark in the industry.

Upgrade your power control solutions with the Powerex KSB13060 and experience the future of high-power applications. For more information and to see how this powerful SCR can enhance your operations, visit our website or contact our sales team. Embrace the power of innovation with Powerex.

#SCR#Semiconductor#Transistor#Silicon Controlled Rectifiers#Powerex#Electronic Components Distributor#SCR Electronics#SCR Silicon Controlled Rectifier#Power SCR#Powerex SCR#SCR Transistor#High Voltage SCR#Powerex Distributor

0 notes

Text

Silicon controlled rectifier, Triac thyristor circuits, triacs, alternating current

Q6040K7 Series 40 A 600 V Bidirectional Alternistor TRIAC - TO-218AC

0 notes

Text

Silicon Controlled Rectifier Module Market

0 notes

Text

Infineon TT162N16KOF Thyristor (SCR) – High-Voltage Power Module for Motor Control and Power Electronics

For purchasing or more information, https://uscomponent.com/buy/INFINEON/TT162N16KOF is the official distributor of the Infineon TT162N16KOF and other power electronics components.

The Infineon TT162N16KOF is a silicon controlled rectifier (SCR), also known as a thyristor, specifically designed for high-voltage and high-current applications. It is a key component in power electronics, motor control systems, and other high-power applications where reliable performance and efficiency are essential.

Key Features and Specifications:

Maximum Voltage Rating: 1600V

Maximum Current Rating: 160A

Package Type: KOF (indicates pin configuration and package style)

Type: Normal Thyristor (not designed for fast switching)

Applications: Ideal for systems requiring surge current protection, voltage control, and high transient tolerance

The TT162N16KOF part number provides valuable insight into its design. "TT" identifies it as a thyristor, while "162" signifies the voltage rating of 1600V, making it suitable for high-voltage applications. The "N" indicates that it is a normal thyristor, optimized for standard switching operations rather than fast switching. The "16" refers to its current rating of 160 amps, which allows it to handle high-current circuits. The KOF suffix indicates the package type and pin configuration, ensuring it meets industrial requirements for optimal heat dissipation and mounting.

Thyristors, such as the TT162N16KOF, are semiconductor devices used to regulate the flow of current in a circuit, acting as a high-power switch. These devices consist of four alternating layers of P-type and N-type semiconductor material, with a gate electrode connected to the P-type material. They are designed to handle high voltage and high current loads, making them ideal for use in demanding power electronics and motor control systems.

Applications:

Power electronics

Motor control systems

Industrial power modules

High-voltage power switching

Surge current and transient protection in electrical circuits

The Infineon TT162N16KOF SCR is engineered to provide reliable performance in high-voltage and high-current environments. Its impressive voltage and current ratings make it perfect for applications requiring voltage control and current handling capabilities. This thyristor also offers superior surge protection, making it ideal for transient protection in industrial automation and power electronics systems.

#Silicon Controlled Rectifier#SCR Silicon Controlled Rectifier#SCR Controlled Rectifier#SCR Rectifier#SCR Silicon#IGBT Module#IGBT Transistor Modules#Infineon IGBT Module#Infineon IGBT Modules#IGBT Power Module#Infineon IGBTs#Infineon IGBT#Silicon Diode Rectifier#TT162N16KOF#Infineon TT162N16KOF

0 notes

Text

triac thyristor, Silicon controlled rectifier, Triac thyristor circuits

BTA12 Series 600 Vdrm 12 A Flange Mount Snubberless Triac - TO-220AB

0 notes

Text

Triac thyristor circuits, what is a power thyristor, Types of Power Thyristors

Snubberless Triac AC Switch Surface Mount - TO-252

#STMicroelectronics#T435-600B-TR#Circuit Protection#Protection Thyristors#triac thyristor#Power thyristors#What is a power thyristor#Types of Power Thyristors#Alternating current#Silicon controlled rectifier#Triac thyristor circuit

1 note

·

View note

Text

What is thyristor, on-off switches, Power Control, Switching Device

T435 Series 600 Vdrm 4 A Snubberless Triac AC Switch Surface Mount - TO-252

#Circuit Protection#Protection Thyristors#T435-600B-TR#STMicroelectronics#Types of Power Thyristors#Silicon controlled rectifier#Applications for thyristors & triacs#SCR#triac circuit#alternating current#Power thyristor applications#triac thyristor

1 note

·

View note

Text

#Global Silicon Controlled Rectifier Module Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast

0 notes

Text

Silicon is the king of electronics, but it wasn’t always that way. In the early days, materials like germanium and selenium were used in making transistors and diodes. Germanium was great because it had high conductivity and worked well in early circuits, but it had one big problem—it couldn’t handle high temperatures. Selenium was used in rectifiers, but it wasn’t as efficient as today’s semiconductors. Then came silicon, and it changed everything.

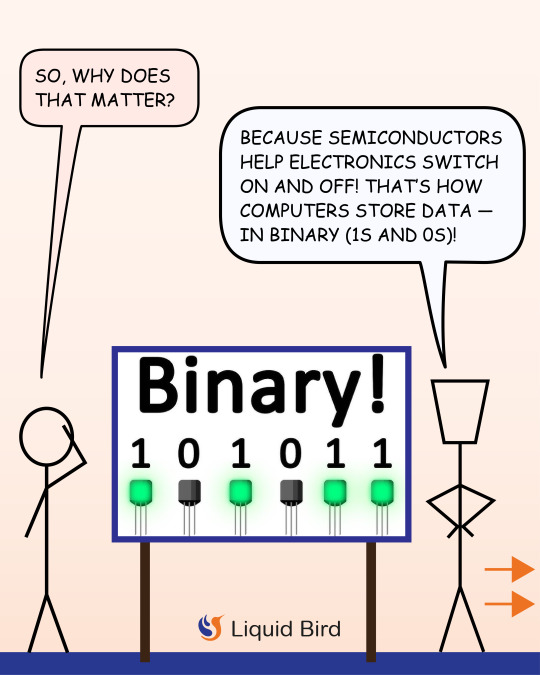

Silicon became the top choice because it has the perfect balance of electrical properties and stability. It’s a semiconductor, meaning it can act as both a conductor and an insulator, depending on how it’s treated. This makes it ideal for transistors, microchips, and other electronic components. One major advantage is its ability to withstand high temperatures, unlike germanium, which breaks down easily when things heat up. Silicon also has a stable crystalline structure, which makes it reliable for long-term use in circuits.

Another big reason for silicon’s dominance is how easy it is to “dope.” Doping is the process of adding tiny amounts of other elements to change how silicon conducts electricity. By adding phosphorus or boron, engineers can create either n-type or p-type silicon, which are essential for making diodes, transistors, and integrated circuits. This precise control over its conductivity is what makes modern electronics possible.

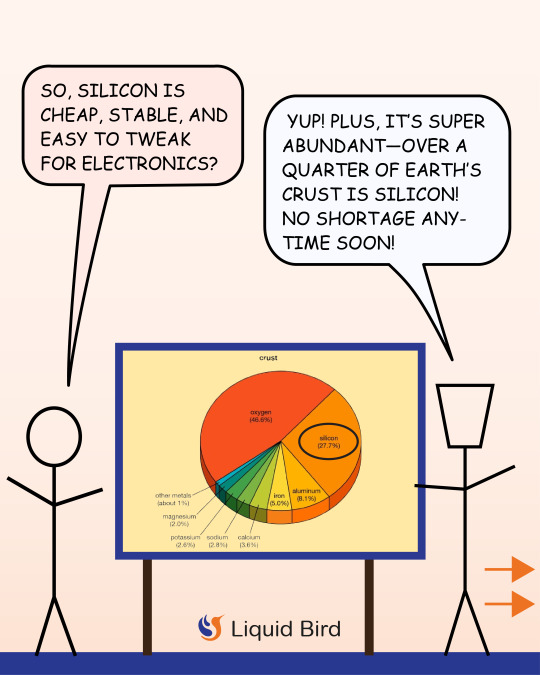

On top of all that, silicon is incredibly abundant. It’s the second most common element in Earth’s crust, found in sand and quartz. This makes it cheap and easy to source compared to rarer materials. Because of this, silicon-based chips are affordable and mass-producible, making electronics available to everyone.

From the first germanium transistors to today’s advanced silicon microprocessors, technology has come a long way. And thanks to silicon, we have everything from smartphones to supercomputers.

Follow for more such educational content daily!

Check, our substack for more in-depth articles on such topics.

#comics#sciencecomics#webcomics#science#stem#educationalcomics#liquidbird#becurious#comicstrips#rockets#space#electronics#aircraft

5 notes

·

View notes

Text

Boost System Performance with Intelligent Managed IT support services & Remote IT support

What Are Managed IT Support Services, and Why Do You Need Them?

Outsourced IT services means that one contracts the management of his or her IT functions to a third party IT provider. These experts are responsible for making all your IT systems run smoothly by diagnosing problems, solving them before they occur. For businesses, the benefits are manifold:

Cost Efficiency: Rather than employing costly internal IT department, the businesses can gain the services of IT outsourcing at relatively cheaper cost.

Expertise at Your Fingertips: Managed service providers always employ people with experience to deal with IT changes and trends.

Proactive Solutions: Prevent havoc with constant computer checks and updates anytime of the day.

Outsourcing with a managed IT support services provider means great sigh of relief as the IT infrastructure of the company is under trustworthy management and control.

The Growing Importance of Remote IT Support

With the changing trend of having employees work from home and using a mix of online and offline working, outsourcing IT support services is a must. Having employees work remotely means that having a stable information technology solution is crucial to continuing business.

How Does Remote IT Support Work?

IT assistance for distant access employs sophisticated instruments and applications to identify and solve problems without the use of personal computers. Key features include:

Real-Time Assistance: To avail on the spot support for rectifying different issues.

Cost Savings: Reduces travelling expenses and enhances response times.

Scalability: Is deployable for growing teams and increasing proportions of IT requirements easily.

Why Businesses in Bangalore Are Turning to Remote IT Support

Bangalore, India is renowned as the silicon valley of India is an important technology hub at the moment. This has been made possible by the giants in information technology as well as other SMEs and startups taking place here making the demand for remote IT support in Bangalore to rise. There is a focus on defense mechanisms in order to reduce adverse effects to flexibility and reliability for the companies in the city.

Benefits of Remote IT Support in Bangalore

Round-the-Clock Assistance: Due to Bangalore being an avid hub in the technological world the businesses they have demanded round the clock support for the various clients they have all over the world.

Access to Expertise: Outsourced IT solutions giving providers in Bangalore have better mastery of the domain, which helps in quick problem escalation.

Cost-Effective Solutions: By charging fairly, the business small and large can receive quality assistance while not breaking the bank.

Choosing the Right Provider for Managed IT Support Services and Remote IT Support

When selecting a provider for managed IT support services or remote IT support, consider the following:

Experience and Expertise: First and foremost, make sure the provider has experience an unblemished record with delivering similar projects in the past.

Range of Services: Choose services that come with a package including monitoring, maintenance, and any issues troubleshooting.

Customer Support: A quick and efficient customer support is one of the most important aspects in any business that wished to solve problems promptly.

Conclusion

Thus, managed IT support services and remote IT support help to become critical in providing a competitive advantage for modern businesses with high efficiency. These services are not luxuries that organizations can now afford to lack as they adopt new ways of working due to digitalization. Thus, the access to the remote IT support in Bangalore can become the effective way for the business in this city to open new Heights.

Are you willing to have one of the most powerful structures for your IT business?

1 note

·

View note

Text

Silent Powerhouses: How igbt rectifiers Are Redefining Industrial Energy Conversion

Picture a bustling manufacturing floor at dawn. Conveyor belts glide, robotic arms pivot with precision, and high-power motors hum in perfect synchrony. All of this choreographed action relies on stable direct current—even though the utility grid delivers alternating current. Converting AC to DC might sound mundane, yet it’s the unglamorous heartbeat of virtually every modern factory, data center, and electric-rail system. Tucked inside control cabinets and power bays, igbt rectifiers are the silent powerhouses making this conversion cleaner, smarter, and dramatically more efficient.

From Diodes to Digital Brains

For decades, silicon diodes and thyristors dominated rectification. They were sturdy, inexpensive, and—let’s be honest—fairly dumb. They could only switch on and off in crude, bulk fashion, producing DC that was rife with voltage ripple and harmonic distortion. That was acceptable in an analog world, but today’s precision-driven operations need better. Enter the Insulated Gate Bipolar Transistor (IGBT): a semiconductor that marries the high-current capability of a bipolar transistor with the fast switching of a MOSFET.

When engineers embed IGBTs in rectifier topologies, the result is a new class of high-frequency converters capable of pulse-width modulation (PWM), soft-start functions, and active power-factor correction. Suddenly, rectification isn’t just about flipping waveform polarity—it’s about sculpting perfect current for sensitive loads, saving megawatts in the process.

A Day in the Life: Humanizing High Tech

Let’s walk in the shoes of Ananya, maintenance lead at a sprawling metro-rail depot in Bengaluru. She remembers the era when traction substations ran on mercury-arc or SCR rectifiers. “It was like taming a dragon,” she jokes. Voltage spikes chewed through bearings, transformers overheated, and harmonics crept back onto the grid. Then came the retrofit: a modular cabinet stuffed with igbt rectifiers. Overnight, the depot saw a 6 % drop in energy losses and, more surprisingly, quieter lines. “Passengers didn’t notice the upgrade,” Ananya says, “but my team sleeps better knowing the system’s self-diagnostics flag issues before they escalate.”

That’s the hidden human upside—less emergency call-outs, more predictive maintenance, and a work culture that shifts from crisis mode to optimization mode.

Under the Hood: Why IGBT Architecture Shines

High-Frequency Switching IGBTs can switch tens of kilohertz, shrinking bulky transformers and filters. Smaller magnetics mean lighter enclosures and better thermal management.

Low Conduction Losses Compared to MOSFETs at high voltage, IGBTs maintain lower on-state resistance, translating into cooler operation and longer component life.

Built-In Protection Advanced gate-driver ICs monitor temperature, current, and voltage in real time, shutting down the device within microseconds if thresholds are breached.

Bidirectional Capability Paired with appropriate circuitry, they enable regenerative braking in electric locomotives, feeding energy back to the grid instead of dumping it as heat.

Sustainability by Design

Energy efficiency isn’t just a line on a spec sheet—it’s a planetary necessity. Traditional 12-pulse SCR rectifiers often hover near 90 % efficiency under ideal loads. Modern PWM-controlled igbt rectifiers push beyond 97 %, slicing gigawatt-hours off cumulative utility bills over their service life. Multiply that by thousands of installations and you have a tangible dent in global CO₂ emissions.

Moreover, precise DC output means motors run cooler, electrolytic capacitors last longer, and upstream generators experience smoother load profiles. Less wear equals fewer raw materials mined, shipped, and processed for replacements—a virtuous cycle of resource conservation.

Beyond the Factory: Emerging Frontiers

Data Centers – Hyperscale operators love IGBT rectifiers for redundant, hot-swappable power shelves that squeeze more watts per rack while meeting stringent harmonic limits (IEEE 519).

Electrolysis for Green Hydrogen – Stable, low-ripple DC is crucial for membrane longevity. As electrolyzer farms scale into the gigawatt realm, PWM rectifiers slash idle losses and enable dynamic ramp-up tied to renewable generation.

EV Hyper-Chargers – Ultra-fast DC stations (350 kW and higher) rely on modular IGBT blocks to convert grid AC into tightly regulated DC that won’t fry delicate vehicle battery chemistries.

Challenges on the Road Ahead

No technology is perfect. IGBT modules are sensitive to over-voltage transients and require sophisticated snubber networks. Their thermal cycling limits call for meticulous heatsink design and, in harsh climates, liquid cooling. Meanwhile, wide-bandgap semiconductors—silicon carbide (SiC) and gallium nitride (GaN)—are nipping at IGBT heels, promising even faster switching and lower losses.

Yet cost remains king. For high-power (≥ 1 MW) applications, mature supply chains and proven robustness keep igbt rectifiers solidly in the lead. Hybrid topologies that mix SiC diodes with IGBT switches already deliver incremental gains without breaking budgets.

Skills and Workforce Implications

Technicians who once wielded soldering irons on analog boards now brandish oscilloscopes with gigahertz bandwidth to capture nanosecond edge transitions. Training programs are evolving: power-electronics courses in Indian ITIs and polytechnics now include gate-drive design, thermal simulation, and module-level repair practices.

For young engineers, this field offers a blend of hands-on tinkering and digital analytics. Predictive-maintenance dashboards stream real-time data—junction temperatures, switching losses, harmonic spectra—turning power rooms into high-tech command centers.

Final Reflections: Small Silicon, Massive Impact

It’s easy to overlook the humble converter tucked behind a metal door. But in the grand choreography of electrification, igbt rectifiers are the quiet conductors, synchronizing renewable surges, feeding smart grids, and keeping industry humming. They exemplify how incremental innovations—faster switches, smarter firmware, better cooling—compound into game-changing efficiency.

Next time you glide on an electric train, boot up a cloud server, or see a wind farm blinking on the horizon, remember: somewhere underneath, tiny gates are opening and closing thousands of times a second, silently shaping the clean-energy era. And that is technology worth celebrating, even if it never seeks the spotlight.

0 notes

Text

T571N65TOF: High Voltage, High Current Silicon-Controlled Rectifier (SCR) for Reliable Power Control in Demanding Applications

As an authorized distributor of Eupec Infineon products, USComponent offers the T571N65TOF SCR to meet the needs of industries requiring high surge current tolerance and robust thermal stability. Its high voltage and current capabilities ensure it can handle the most demanding power switching requirements efficiently. Whether for industrial power systems, motor control, or high-voltage power supplies, the T571N65TOF, available through https://www.uscomponent.com/buy/INFINEON/T571N65TOF, provides a reliable solution for reliable performance in harsh operating conditions.

T571N65TOF is a high voltage, high current silicon-controlled rectifier (SCR), also known as a thyristor. It is manufactured by STMicroelectronics and is designed for use in high power applications.

The "T" in the part number indicates that it is a thyristor. The "571" indicates the voltage rating of the device, which is 6500 volts. The "N" indicates a standard (non-fast) thyristor. The "65" indicates the maximum current rating of the device, which is 65 amps. The "TOF" indicates the package type.

SCRs are semiconductor devices that are used to control the flow of current in a circuit. They are commonly used in applications that require high-voltage and high-current switching capabilities. The T571N65TOF is designed for use in power electronics applications, such as motor control systems, power supplies, and industrial controls.

The T571N65TOF is capable of handling high surge currents and has a high-temperature capability, making it suitable for use in harsh environments. Its high voltage and current ratings make it ideal for high power applications where reliable and efficient switching is required.

Overall, the T571N65TOF SCR is a reliable and efficient component for high voltage, high current switching applications in power electronics and motor control systems.

#Silicon Controlled Rectifier#SCR Silicon Controlled Rectifier#SCR Controlled Rectifier#Controlled Rectifier#Rectifier Silicon#SCR Rectifier#SCR Silicon#IGBT Module#IGBT Transistor Modules#Infineon IGBT Module#Infineon IGBT Modules#IGBT Power Module#Infineon IGBTs#Infineon IGBT#Eupec IGBT

0 notes

Text

Renewable Energy Surge Elevates Demand for Power Modules

The global power semiconductor market reached US$ 56,155 million in 2022 and is projected to grow to US$ 171,709 million by 2031, at a CAGR of 15.0% during 2024–2031, fueled by rising demand across automotive, industrial, consumer electronics, and defense sectors. Asia Pacific leads the surge, driven by booming EV adoption and industrial automation. Power semiconductors like MOSFETs, IGBTs, and diodes are critical for efficient energy conversion, while key players such as STMicroelectronics, Toshiba, and Texas Instruments drive innovation in the competitive landscape.

Unlock exclusive insights with our detailed sample report :

Key Market Drivers

1. Electrification of Transportation

With EVs gaining global momentum, power semiconductors are essential in managing electric drive systems, inverters, DC/DC converters, and battery management systems. Their role in achieving efficiency and thermal control is critical in both vehicles and EV charging stations.

2. Renewable Energy Integration

Power semiconductors are pivotal in solar inverters, wind power systems, and energy storage solutions. These devices ensure efficient energy conversion, grid synchronization, and load balancing, essential for stable and sustainable energy infrastructure.

3. Wide Bandgap Material Adoption

The shift from silicon to SiC (Silicon Carbide) and GaN (Gallium Nitride) semiconductors is transforming power electronics. These materials offer superior switching speeds, thermal resistance, and power density, critical for next-gen EVs, 5G, and aerospace.

4. Smart Grids and Industrial Automation

As smart cities and Industry 4.0 evolve, power semiconductors underpin intelligent energy management, motor control, and automation systems, allowing real-time efficiency in manufacturing and smart infrastructure.

5. 5G Network Expansion

The rapid deployment of 5G networks requires high-performance RF components, power amplifiers, and energy-efficient base stations, creating robust demand for advanced power semiconductor devices.

Regional Insights

United States

The U.S. remains a major consumer and innovator in power semiconductors due to:

Massive investment in semiconductor manufacturing (CHIPS and Science Act).

Booming EV market led by Tesla, GM, and Ford, all reliant on SiC and GaN power components.

High demand for data center power solutions to support AI, cloud computing, and 5G networks.

U.S. companies such as Texas Instruments, ON Semiconductor, and Wolfspeed are leading domestic innovation in wide bandgap technologies.

Japan

Japan is renowned for its expertise in high-efficiency, compact power electronics. Key developments include:

Leadership in SiC development with companies like ROHM, Mitsubishi Electric, and Fuji Electric.

Advanced integration of power semiconductors in robotics, railway systems, and renewables.

Government-backed efforts to secure local chip production and reduce import dependency.

Japanese innovation focuses on packaging technology, ultra-low-loss switching, and EV-grade reliability.

Speak to Our Senior Analyst and Get Customization in the report as per your requirements:

Market Segmentation

By Device Type:

Power MOSFET

IGBT

Diode & Rectifier

Thyristor

Bipolar Junction Transistor (BJT)

By Material:

Silicon

Silicon Carbide (SiC)

Gallium Nitride (GaN)

Others

By Application:

Automotive & Transportation

Consumer Electronics

Industrial

ICT (5G, IoT, Cloud)

Energy & Utilities (Solar, Wind, Smart Grid)

By Packaging Type:

Surface Mount Devices (SMD)

Through-Hole Devices

Chip-scale Packages

Wafer-Level Packages

Latest Industry Trends

Shift Toward Wide Bandgap (WBG) Devices Automakers and energy firms increasingly shift to SiC and GaN to reduce energy losses and improve high-voltage application efficiency.

Integration of AI in Power Management Systems AI-enabled power modules allow predictive control in electric grids, optimizing load sharing, energy storage, and consumption.

Advancements in Thermal Management and Packaging New materials like copper sintering, ceramic substrates, and 3D packaging enhance heat dissipation and longevity.

Collaborative R&D Projects Between U.S. and Japan Research alliances focus on compound semiconductor scalability, reliability testing, and supply chain development.

Miniaturization and Integration for Consumer Devices Compact, high-efficiency power semiconductors are being integrated into smartphones, wearables, and VR systems to manage battery and power usage.

Buy the exclusive full report here:

Growth Opportunities

Fast-Growing EV Ecosystem: Demand for SiC-based inverters and DC/DC converters in EVs and charging stations.

Offshore Wind and Solar Energy: New power conversion architectures using WBG devices to improve offshore energy output efficiency.

Asia-Pacific Smart Grid Projects: Growth in APAC utilities deploying next-gen power modules for smart metering and substation automation.

Defense and Aerospace Applications: Lightweight, ruggedized power semiconductors essential for drones, satellites, and avionics.

Data Center Electrification: Rising need for high-efficiency power supplies to handle AI and cloud computing workloads.

Competitive Landscape

Major players include:

Infineon Technologies AG

Texas Instruments Inc.

ON Semiconductor

STMicroelectronics

Mitsubishi Electric Corporation

Toshiba Corporation

Wolfspeed, Inc.

ROHM Semiconductor

Vishay Intertechnology

Renesas Electronics Corporation

These companies are:

Expanding SiC and GaN production lines.

Collaborating with automotive OEMs for integrated solutions.

Investing in next-gen fabrication plants and foundries across the U.S. and Japan.

Stay informed with the latest industry insights-start your subscription now:

Conclusion

The power semiconductor market is experiencing a major growth phase as global industries shift toward electrification, renewable energy, and smart technologies. Driven by advances in wide bandgap materials, packaging, and AI integration, power semiconductors are becoming essential to energy-efficient design across sectors.

With ongoing support from governments, rising sustainability mandates, and transformative innovations in the U.S. and Japan, the market is set to play a central role in the next wave of global industrial and technological progress.

About us:

DataM Intelligence is a premier provider of market research and consulting services, offering a full spectrum of business intelligence solutions—from foundational research to strategic consulting. We utilize proprietary trends, insights, and developments to equip our clients with fast, informed, and effective decision-making tools.

Our research repository comprises more than 6,300 detailed reports covering over 40 industries, serving the evolving research demands of 200+ companies in 50+ countries. Whether through syndicated studies or customized research, our robust methodologies ensure precise, actionable intelligence tailored to your business landscape.

Contact US:

Company Name: DataM Intelligence

Contact Person: Sai Kiran

Email: [email protected]

Phone: +1 877 441 4866

Website: https://www.datamintelligence.com

#Power semiconductor market#Power semiconductor market size#Power semiconductor market growth#Power semiconductor market share#Power semiconductor market analysis

0 notes

Text

High-Power Rectifiers Market Emerging Trends Transforming Industrial Power Systems

The high-power rectifiers market is witnessing significant transformation driven by technological advancements, rising energy demands, and the need for improved efficiency in industrial operations. High-power rectifiers are essential for converting alternating current (AC) to direct current (DC) in applications requiring high-voltage and high-current supply. These devices are critical across a range of sectors including power utilities, electrochemical processing, electric arc furnaces, railway traction systems, and renewable energy integration. As industrial infrastructure modernizes and the shift towards electrification accelerates, several emerging trends are shaping the future trajectory of this market.

Integration with Smart Grid Systems

One of the most prominent trends in the high-power rectifiers market is their growing integration with smart grid technologies. As utilities upgrade legacy grids to improve load balancing, efficiency, and fault detection, high-power rectifiers are being adapted to work in tandem with intelligent monitoring and control systems. These rectifiers are increasingly being embedded with digital interfaces and sensors that enable real-time diagnostics, remote monitoring, and predictive maintenance, thereby enhancing operational reliability and lifespan.

Surge in Demand from Green Energy Applications

The transition to renewable energy sources is another key driver influencing the high-power rectifiers market. With increased investment in solar photovoltaic plants, wind farms, and hydroelectric facilities, there is a corresponding demand for high-capacity rectifiers to ensure consistent and efficient power conversion. These systems are particularly crucial in storing renewable energy in battery systems or integrating it into high-voltage DC (HVDC) transmission lines, which require stable rectification systems to handle variable input loads.

Advancements in Semiconductor Materials

Recent innovations in semiconductor technologies, particularly the adoption of silicon carbide (SiC) and gallium nitride (GaN), are enabling the development of high-power rectifiers with superior performance characteristics. These wide-bandgap materials offer higher thermal conductivity, voltage tolerance, and switching speeds compared to traditional silicon-based rectifiers. This allows rectifiers to operate at higher frequencies with greater efficiency, making them ideal for compact, high-performance industrial systems. As manufacturing costs for SiC and GaN devices decrease, their adoption in high-power rectifiers is expected to rise significantly.

Growing Adoption in Electrochemical and Metallurgical Processes

High-power rectifiers are indispensable in electrochemical industries, especially in applications such as metal electrolysis, electroplating, and anodizing. With the revival of infrastructure projects and increasing demand for metals like copper, aluminum, and zinc, industries are scaling up their production facilities. Modern rectifiers now offer precise control over voltage and current, which is crucial for maintaining product quality in such processes. Additionally, there is a rising trend towards using energy-efficient rectifiers that reduce electricity consumption and lower carbon emissions in metallurgical operations.

Customization and Modular Design

Industrial end-users are increasingly seeking customized high-power rectifier solutions tailored to specific application needs. This has led manufacturers to develop modular rectifier systems that offer scalability and flexibility. Modular designs not only facilitate easier maintenance and upgrades but also enable rapid deployment in remote or space-constrained environments. This trend is particularly relevant in mining operations, offshore platforms, and mobile power stations where adaptability and resilience are key requirements.

Expansion in Railway Electrification Projects

As countries invest in railway electrification to reduce dependence on fossil fuels, high-power rectifiers are becoming a vital component of traction substations. These systems are required to supply reliable DC power for electric locomotives and auxiliary systems. The ongoing electrification of rail networks in regions such as Asia-Pacific, Latin America, and parts of Africa is driving demand for rugged, high-efficiency rectifier units that can withstand harsh operating conditions while maintaining high performance.

Emphasis on Energy Efficiency and Sustainability

Environmental concerns and regulatory pressures are compelling industries to adopt energy-efficient rectification technologies. Modern high-power rectifiers now come with features like low harmonic distortion, soft-start capabilities, and regenerative energy systems that contribute to overall energy savings. Manufacturers are focusing on creating eco-friendly designs that minimize energy waste and contribute to sustainability goals, a trend that is increasingly resonating with environmentally conscious stakeholders.

Digital Twin and Predictive Maintenance

The implementation of digital twin technology is another cutting-edge trend impacting the high-power rectifiers market. By creating a virtual replica of the physical rectifier system, operators can simulate various operational scenarios, optimize performance, and predict maintenance needs. This approach helps in reducing unplanned downtime and extending the service life of the equipment. Predictive maintenance powered by AI and IoT is gaining traction among large-scale industrial users for its cost-efficiency and effectiveness.

Conclusion

The high-power rectifiers market is undergoing a dynamic evolution, influenced by innovations in materials, automation, energy integration, and sustainability. As industries continue to digitize and decarbonize, the demand for smarter, more efficient rectification systems will only intensify. Manufacturers that embrace these emerging trends and invest in R&D for next-generation technologies will be best positioned to capture the expanding opportunities in this essential industrial sector.

0 notes

Text

0 notes

Text

0 notes