#Silicone Anode Material

Explore tagged Tumblr posts

Text

Global Top 7 Companies Accounted for 25% of total Silicone Anode Material market (QYResearch, 2021)

According to the new market research report “Global Silicone Anode Material Market Report 2023-2029”, published by QYResearch, the global Silicone Anode Material market size is projected to reach USD 4.99 billion by 2029, at a CAGR of 45.7% during the forecast period.

Figure. Global Silicone Anode Material Market Size (US$ Million), 2018-2029

Figure. Global Silicone Anode Material Top 7 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Silicone Anode Material include Beiruite, Tianmuxiandao, etc. In 2022, the global top three players had a share approximately 25.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Global Silicon Anode Battery Market Is Estimated To Witness High Growth Owing To Increasing Demand for High-performance Batteries and Technological Advancements

The global Silicon Anode Battery Market is estimated to be valued at US$ 170.0 Mn in 2019 and is expected to exhibit a CAGR of 21.5% over the forecast period, as highlighted in a new report published by Coherent Market Insights. A) Market Overview: Silicon anode batteries are a type of lithium-ion batteries that utilize silicon as the anode material. These batteries offer higher energy density and longer lifespan compared to traditional lithium-ion batteries, making them suitable for a wide range of applications including electric vehicles, portable electronics, and renewable energy storage. Silicon anode batteries have the potential to revolutionize the energy storage industry by providing higher energy capacity and faster charging capabilities. These batteries offer up to 10 times higher energy density compared to conventional graphite anode batteries, resulting in longer battery life and increased performance. B) Market Dynamics: 1. Driver: Increasing demand for high-performance batteries The growing need for high-performance batteries in various sectors such as automotive, electronics, and renewable energy is driving the demand for silicon anode batteries. These batteries offer improved energy storage capabilities, faster charging times, and longer lifespan, making them an ideal choice for electric vehicles, smartphones, and grid energy storage systems. For example, electric vehicles require high-performance batteries to offer longer driving range and faster charging times. Silicon anode batteries can provide higher energy density, enabling electric vehicles to travel longer distances on a single charge. 2. Driver: Technological advancements Advancements in Silicon Anode Battery Market, such as the development of nanostructured silicon anodes and silicon-graphene composite anodes, are driving the market growth. These advancements address the limitations of silicon anodes, such as large volume expansion during charging and discharging cycles, leading to battery degradation. For instance, companies like Nexeon Limited and Enevate Corporation are developing silicon anode batteries with advanced materials and manufacturing techniques to overcome the challenges associated with silicon anodes. These advancements are expected to boost the adoption of silicon anode batteries in various applications. C) SWOT Analysis: Strengths: 1. Higher energy density 2. Longer lifespan Weaknesses: 1. Large volume expansion during charging and discharging cycles 2. Higher manufacturing costs compared to conventional lithium-ion batteries Opportunities: 1. Growing demand for electric vehicles 2. Increasing investments in renewable energy storage systems Threats: 1. Intense competition from other battery technologies 2. Environmental concerns related to the extraction and disposal of silicon D) Key Takeaways: 1. The global silicon anode battery market is expected to witness high growth, exhibiting a CAGR of 21.5% over the forecast period, due to the increasing demand for high-performance batteries and technological advancements. 2. Asia Pacific is expected to be the fastest growing and dominating region in the silicon anode battery market, driven by the growing adoption of electric vehicles and government initiatives promoting renewable energy. 3. Key players operating in the global silicon anode battery market include Nexeon Limited, Enevate Corporation, OneD Material, XG Sciences Inc., Nanotek Instruments, Inc.,

0 notes

Text

Mesoporous silicon: Etching technique reveals unique electronic transport properties

Silicon is the best-known semiconductor material. However, controlled nanostructuring drastically alters the material's properties. Using a specially developed etching apparatus, a team at HZB has now produced mesoporous silicon layers with countless tiny pores and investigated their electrical and thermal conductivity. For the first time, the researchers elucidated the electronic transport mechanism in this mesoporous silicon. The material has great potential for applications and could also be used to thermally insulate qubits for quantum computers. The work is published in Small Structures. Mesoporous silicon is crystalline silicon with disordered nanometer-sized pores. The material has a huge internal surface area and is also biocompatible. This opens up a wide range of potential applications, from biosensors to battery anodes and capacitors. In addition, the material's exceptionally low thermal conductivity suggests applications as thermal insulator.

Read more.

15 notes

·

View notes

Text

Aluminium 6061 T6 Plates Stockists in India – Meta Aerospace

When your projects require strong, lightweight, and corrosion-resistant materials, Aluminium 6061 T6 Plates are one of the best choices. Known for their high performance and reliability, these plates are used in many industries across the world. As a trusted name in the metal industry, Meta Aerospace proudly stands among the top Aluminium 6061 T6 Plates Stockists in India, offering high-quality products with excellent service.

About Aluminium 6061 T6 Plates

Aluminium 6061 T6 is a heat-treated aluminum alloy that contains magnesium and silicon. The “T6” temper means the metal has been solution heat-treated and artificially aged to achieve increased strength and toughness. This process makes the alloy perfect for heavy-load applications while still being lightweight.

It offers great machinability, weldability, and corrosion resistance, making it one of the most popular aluminum grades for structural and mechanical use.

Why Choose Meta Aerospace?

At Meta Aerospace, we believe in delivering more than just materials — we deliver trust, quality, and value. As a leading stockist of Aluminium 6061 T6 Plates in India, we maintain a large and ready-to-dispatch inventory that serves clients across a wide range of industries.

Our plates are available in multiple sizes, finishes, and thicknesses, ready to meet your urgent or customized project needs. Whether you require small quantities or bulk orders, we are fully equipped to supply high-grade materials on time and with full documentation.

Ready Stock, Quick Delivery

One of the biggest advantages of choosing Meta Aerospace is our well-managed stock system. We ensure that our warehouse is always equipped with a wide range of Aluminium 6061 T6 Plates so you don’t have to wait. Our team understands the importance of deadlines and ensures that every order is processed and dispatched quickly and safely.

We offer cut-to-size services and custom packaging so your plates are ready to use as soon as they arrive at your site.

Product Specifications

We stock Aluminium 6061 T6 Plates in various sizes and dimensions. Below are some standard specifications:

Thickness: 0.5 mm to 150 mm

Width: Up to 2000 mm

Length: As per customer requirement

Temper: T6

Finish: Mill finish, brushed, anodized

Standards: ASTM B209, EN 485, AMS 4027

Applications Across Industries

Thanks to its strength and versatility, Aluminium 6061 T6 Plates are used in a variety of industries, such as:

Aerospace: Aircraft frames, wings, and structural components

Automotive: Chassis, panels, and suspension parts

Marine: Boat hulls, decks, and underwater structures

Defense: Armored vehicles, military gear, and protective covers

Construction: Beams, columns, and structural assemblies

Engineering: Molds, machine parts, and tools

No matter the industry, our aluminium plates are trusted for their quality and durability.

Nationwide and Global Reach

As one of the reliable Aluminium 6061 T6 Plate stockists in India, Meta Aerospace not only caters to domestic clients but also serves customers worldwide. Our strong logistics and delivery network allow us to export to regions such as the Middle East, Europe, North America, and Southeast Asia.

We ensure safe packaging, timely shipping, and full support for export documentation and customs clearance.

Commitment to Quality

Every plate that we stock undergoes a strict quality check before dispatch. We believe in offering materials that are consistent, strong, and ready for high-performance use. Our expert team follows international quality standards and ensures that each product meets the required specifications.

We also provide technical support to help customers choose the right product for their applications.

Contact Meta Aerospace

If you’re looking for high-quality Aluminium 6061 T6 Plates from reliable stockists in India, look no further than Meta Aerospace. We are here to support your projects with the right materials, at the right time, and at the right price.

📍 Website: https://www.metaaerospaces.com/aluminium-6061-t6-plates-manufacturer-exporter-supplier-stockist.html 📧 Email: [email protected] 📞 Phone: +91-9930066862

Conclusion

Aluminium 6061 T6 Plates are known for their strength, light weight, and excellent performance in demanding environments. At Meta Aerospace, we are proud to be one of the most trusted stockists in India, providing ready-to-ship materials that meet both local and international standards.

Choose Meta Aerospace — where quality, service, and reliability come together to support your success.

#Aluminium 6061 T6 Plates#Aluminium 6061 T6 Plates Manufacturers#Aluminium 6061 T6 Plates Suppliers#Aluminium 6061 T6 Plates Stockists

0 notes

Text

Sheet Metal Fabrication in Bangalore: The Hub of Precision Engineering

Summary

Explore the growing demand for sheet metal works in Bangalore and discover how top fabrication companies in Bangalore deliver precision, quality, and reliability across industries with advanced manufacturing solutions.

Introduction

Bangalore, often celebrated as the Silicon Valley of India, is rapidly emerging as a powerhouse in industrial and manufacturing sectors. Among the many services that support the city's booming industries, sheet metal fabrication stands out as a core component of product development and engineering. From intricate enclosures to heavy-duty industrial parts, the demand for sheet metal works in Bangalore has grown significantly in recent years.

In this article, we explore the scope, strengths, and advantages of working with sheet metal fabrication companies in bangalore, and why this city is now one of India’s most reliable manufacturing destinations.

What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of transforming flat metal sheets into desired shapes and structures through techniques such as cutting, bending, welding, and assembling. It is a critical process in numerous industries, including:

Automotive and Aerospace

Electrical and Electronics

Construction and Infrastructure

Medical Devices

Consumer Appliances

Telecom and Energy Equipment

Precision and consistency are vital in sheet metal works, especially when dealing with mass production or custom prototyping.

Why Bangalore?

1. Industrial Infrastructure

Bangalore boasts advanced industrial zones such as Peenya Industrial Area, Bommasandra, and Electronic City that are home to a dense concentration of engineering and fabrication units. These hubs are equipped with the latest machinery and logistics systems, making Bangalore a manufacturing-ready city.

2. Skilled Workforce

The city benefits from a large pool of engineers, machine operators, and designers who specialize in CNC operations, CAD software, laser cutting, and mechanical fabrication. This ensures high accuracy in output and reduced turnaround times.

3. Tech Integration

Bangalore’s fabrication industry is quick to adopt emerging technologies such as automation, CNC machining, and laser-based systems. These innovations improve efficiency, reduce human error, and support high-volume production.

Services Offered by Fabrication Companies in Bangalore

Fabrication companies in Bangalore typically offer a wide range of services to meet the diverse needs of various sectors. Some of the key services include:

● CNC Laser Cutting

Using high-powered lasers, materials such as stainless steel, aluminum, and copper are cut with pinpoint accuracy. This allows for the creation of complex and clean-edged parts.

● CNC Bending & Forming

Precision press brake machines are used to bend and form sheets into desired shapes. This is essential for creating brackets, enclosures, chassis, and cabinets.

● MIG/TIG/Spot Welding

Welding is crucial in combining different components. Fabrication shops in Bangalore offer MIG, TIG, and spot welding for both heavy and thin-gauge metals.

● Punching & Stamping

CNC turret punching machines help in making holes, cutouts, and complex designs efficiently and accurately.

● Surface Finishing

To protect against corrosion and improve aesthetics, services like powder coating, anodizing, and galvanizing are offered.

● Prototyping & Assembly

Many sheet metal works in Bangalore also include prototyping services for startups and R&D teams. Full or partial assembly services are also available for ready-to-install products.

Industries Served

The versatility and precision of fabrication companies in Bangalore make them well-suited to serve a wide range of industries, such as:

Aerospace: Lightweight yet strong components with tight tolerances

Medical Devices: Sterile, corrosion-resistant equipment housings

Automotive: Customized body panels, brackets, and engine parts

Telecom: Enclosures, racks, and panels for networking equipment

Green Energy: Structures for solar panels, battery cabinets, and more

These companies often follow international quality standards such as ISO 9001, ISO 14001, and AS9100, depending on the industry.

Advantages of Choosing Fabrication Companies in Bangalore

Cost-Effective Production

Thanks to the competitive manufacturing ecosystem, fabrication services in Bangalore often come at a lower cost compared to other major cities without compromising on quality.

Fast Turnaround

Whether it's a prototype or a large batch order, turnaround times are kept short due to advanced scheduling systems, CNC automation, and a dedicated workforce.

Customization & Flexibility

Most sheet metal fabricators offer complete design-to-delivery solutions. Whether it’s a one-off design or a recurring production order, clients benefit from flexibility and tailored service.

Scalability

With a wide network of suppliers and sub-contractors, sheet metal works in Bangalore can scale production rapidly to meet growing business needs.

What to Look for in a Fabrication Partner?

When selecting a fabrication company, it’s important to consider:

Technical Capabilities: Does the shop have modern CNC and laser cutting equipment?

Quality Standards: Are they ISO-certified? Do they follow lean manufacturing practices?

Material Expertise: Can they work with multiple metals like SS, MS, GI, and aluminum?

Communication & Transparency: How well do they share project timelines, reports, and updates?

Delivery & Packaging: Can they ensure secure, on-time delivery with proper documentation?

Many companies also offer online quote portals where customers can upload CAD files and get instant estimates.

Future of Sheet Metal Works in Bangalore

With the rise of Industry 4.0, IoT integration, and smart manufacturing, Bangalore’s fabrication sector is set to become more digital and data-driven. Technologies like 3D printing, robotic welding, and AI-powered inspection systems are already being tested in forward-thinking fabrication workshops.

The increasing focus on electric vehicles, renewable energy, and medical technology is also expected to drive demand for precision sheet metal fabrication in the city.

Conclusion

Whether you're a startup needing a prototype or an OEM looking for a high-volume production partner, fabrication companies in Bangalore offer the technical know-how, flexibility, and reliability required to meet your goals. With a strong industrial foundation, skilled professionals, and cutting-edge technology, sheet metal works in Bangalore are setting benchmarks in quality and innovation.

So, if you’re looking for dependable and cost-effective sheet metal solutions, Bangalore might just be the perfect place to start.

FAQ

Q1. What services are commonly offered by sheet metal fabrication companies in Bangalore? Most fabrication companies in Bangalore offer CNC laser cutting, punching, bending, welding, powder coating, and custom prototyping for a variety of industries.

Q2.Why is Bangalore considered a hub for sheet metal works? Bangalore has advanced industrial zones, a highly skilled workforce, and access to the latest fabrication technologies, making it a prime location for precision sheet metal works.

Q3.Do fabrication companies in Bangalore handle custom or small-batch projects? Yes, many sheet metal fabricators in Bangalore specialize in both mass production and small-batch/custom fabrication for startups, R&D teams, and niche applications.

Q5.What industries rely on sheet metal works in Bangalore? Industries like aerospace, automotive, electronics, telecom, renewable energy, and medical devices frequently depend on Bangalore-based fabrication services.

Q6. Are Bangalore fabrication companies equipped with advanced technologies like CNC and laser cutting? Absolutely. Many fabrication companies in Bangalore use modern CNC machines, laser cutters, and automated welding systems to ensure precision and quality.

Q7. How do I get a quote from a fabrication company in Bangalore? Most companies offer online quote systems where you can upload CAD files and get pricing based on material, quantity, and specifications. Q8. What materials are typically used in sheet metal fabrication in Bangalore? Common materials include stainless steel (SS), mild steel (MS), aluminum, galvanized iron (GI), and sometimes copper or brass depending on the project.

#sheet metal fabricators in bangalore#heavy fabrication companies in bangalore#fabrication companies in bangalore#sheet metal works in bangalore

0 notes

Video

youtube

Mercedes AMG GT XX Concept - Full Tech Specs and Performance

Mercedes-AMG presents the GT XX Concept, a four-door performance sedan previewing its first dedicated electric model on the AMG.EA platform.

At the heart of the GT XX is a tri-motor setup featuring advanced axial-flux technology. Two motors are mounted on the rear axle, and a third drives the front. This configuration enables fully variable AMG Performance 4MATIC+ all-wheel drive, with the front motor decoupling when not needed for optimal efficiency.

Combined output exceeds 1,341 horsepower, with the car capable of accelerating beyond 223 mph. The rear motors each include a planetary gearset, water-cooled inverter, and oil cooling to ensure durability under sustained high-performance use.

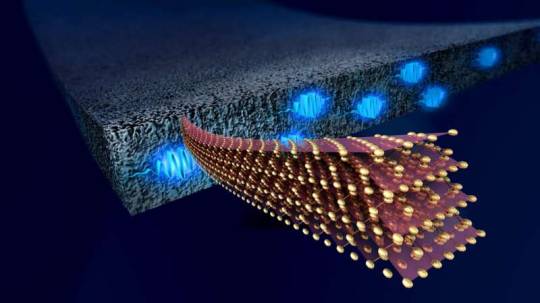

Power is supplied by a newly engineered high-performance battery. It features cylindrical NCMA cells with silicon-enhanced anodes and a laser-welded aluminum housing. Direct cell cooling via non-conductive oil ensures thermal stability and repeatable peak output.

The 800-volt system supports ultra-fast charging at over 850 kW, enabling up to 400 kilometers of range to be recharged in approximately five minutes.

The GT XX’s chassis is built on a lightweight aluminum-steel composite matrix, with the battery centrally integrated for added stiffness and crash safety.

Aerodynamically, the concept achieves a drag coefficient of just 0.198. Active aerodynamic elements include a movable front splitter, side air curtains, and 21-inch forged wheels with carbon-fiber aero panels. These panels adjust based on cooling needs and are powered by energy recovered from wheel motion.

The exterior design features a low, coupe-like silhouette with a sharply raked windscreen, no rear window, flush door handles, and bold side skirts. At the front, an illuminated AMG grille is paired with stacked LED headlights and integrated auxiliary lighting. The rear includes pronounced haunches, an active airbrake, a carbon-fiber diffuser, and triple circular LED tail lights.

Lighting technology plays a key role, with over 700 RGB LEDs in the MBUX Fluid Light Panel capable of displaying data and effects. Exterior speakers embedded in the headlights can project a simulated AMG V8 sound profile.

Inside, the GT XX Concept features a minimalist, performance-focused cockpit. A 10.25-inch digital instrument display and a 14-inch MBUX touchscreen dominate the center console. The flat-top AMG One-style yoke includes paddles to control regenerative braking modes.

Lightweight carbon-fiber bucket seats include 3D-printed padding and are upholstered in LABFIBER—a sustainable material derived from recycled GT3 tires and biopolymer textiles. Orange-accented structural elements and exposed tubing contribute to the high-tech, motorsport-inspired interior design.

The AMG GT XX Concept represents Mercedes-AMG’s next step toward electrified performance. With cutting-edge propulsion, battery, and aerodynamics, it sets the tone for AMG’s future in the era of high-performance electric mobility.

0 notes

Text

0 notes

Text

Silicon Anode Battery Market Projected to Surge with Technological Advancements in Energy Storage Systems

The silicon anode battery market is gaining significant momentum as industries seek advanced energy storage solutions to power the next generation of electronics, electric vehicles (EVs), and renewable energy systems. Silicon, with its high theoretical capacity—nearly ten times more than graphite—has emerged as a revolutionary material for battery anodes. As global energy demands increase and lithium-ion battery technologies approach their performance limits, silicon anodes offer a pathway to higher efficiency, faster charging, and longer battery lifespans.

Market Drivers

A key driver for the growth of the silicon anode battery market is the rapid expansion of the electric vehicle industry. EV manufacturers are under constant pressure to improve driving range, charging speed, and battery longevity. Silicon anodes offer a promising solution by increasing energy density significantly, which directly translates into longer driving ranges per charge. Leading EV companies like Tesla, BMW, and General Motors have invested heavily in silicon battery research and are working with battery technology firms to accelerate commercial deployment.

Another driver is the growing need for efficient energy storage systems to support renewable energy generation. Solar and wind energy are intermittent by nature and require robust energy storage to balance supply and demand. High-capacity silicon anode batteries can enhance grid-level energy storage, enabling more stable and reliable renewable integration.

Additionally, the increasing use of consumer electronics such as smartphones, laptops, and wearables has heightened the need for batteries that are not only compact and lightweight but also long-lasting and fast-charging. Silicon anodes can fulfill these expectations, making them increasingly attractive to electronics manufacturers.

Challenges in the Market

Despite the compelling advantages, silicon anodes face critical challenges that must be addressed to enable large-scale commercialization. One of the primary issues is the significant volume expansion of silicon during charge-discharge cycles—up to 300%—which can lead to electrode degradation, reduced battery life, and safety concerns. This expansion causes mechanical stress, cracking, and unstable solid-electrolyte interphase (SEI) formation.

To mitigate these issues, companies and research institutions are investing in nano-engineering solutions, such as using silicon nanoparticles, nanowires, or developing composite anodes by blending silicon with graphite or other materials. These innovations aim to maintain structural integrity while maximizing silicon’s capacity benefits.

Market Segmentation and Regional Insights

The silicon anode battery market can be segmented by material type, application, and region. By material type, the market includes pure silicon, silicon oxide, silicon-carbon composites, and others. Silicon-carbon composites currently dominate the segment due to their balance of performance and durability.

In terms of applications, the market is divided into automotive, consumer electronics, medical devices, aerospace, and energy storage systems. Automotive remains the leading segment, driven by electrification and sustainability goals, while consumer electronics is a close second due to the constant demand for more powerful devices.

Regionally, North America and Asia-Pacific are the leading markets. The United States is a major player due to its advanced R&D infrastructure and presence of EV and battery tech giants. China, on the other hand, dominates the manufacturing side and is rapidly scaling up production with significant investments in battery startups and research. Europe is also catching up, especially with its ambitious climate goals and initiatives to reduce dependence on fossil fuels.

Key Players and Industry Developments

Prominent players in the silicon anode battery market include Amprius Technologies, Enevate Corporation, Sila Nanotechnologies, Nexeon, XG Sciences, and OneD Material. These companies are pioneering innovations in silicon anode design, aiming for cost-effective, scalable, and commercially viable solutions.

Many of these firms have secured substantial funding rounds and are partnering with automakers and battery manufacturers to accelerate product launches. For instance, Amprius has developed ultra-high energy density batteries used in aerospace applications, while Enevate’s fast-charging silicon anode batteries are targeting the EV market.

Future Outlook

The future of the silicon anode battery market looks promising, with analysts projecting robust growth over the next decade. According to industry forecasts, the market is expected to grow at a compound annual growth rate (CAGR) exceeding 30% during 2024–2030, driven by continuous innovation, scaling of production technologies, and increasing commercial adoption.

While technical hurdles remain, sustained R&D and strategic partnerships between battery developers and OEMs will likely unlock silicon’s full potential. As the world transitions toward electrification and sustainable energy, silicon anode batteries are poised to become a cornerstone technology in powering that future.

0 notes

Text

High-Power Rectifiers Market Emerging Trends Transforming Industrial Power Systems

The high-power rectifiers market is witnessing significant transformation driven by technological advancements, rising energy demands, and the need for improved efficiency in industrial operations. High-power rectifiers are essential for converting alternating current (AC) to direct current (DC) in applications requiring high-voltage and high-current supply. These devices are critical across a range of sectors including power utilities, electrochemical processing, electric arc furnaces, railway traction systems, and renewable energy integration. As industrial infrastructure modernizes and the shift towards electrification accelerates, several emerging trends are shaping the future trajectory of this market.

Integration with Smart Grid Systems

One of the most prominent trends in the high-power rectifiers market is their growing integration with smart grid technologies. As utilities upgrade legacy grids to improve load balancing, efficiency, and fault detection, high-power rectifiers are being adapted to work in tandem with intelligent monitoring and control systems. These rectifiers are increasingly being embedded with digital interfaces and sensors that enable real-time diagnostics, remote monitoring, and predictive maintenance, thereby enhancing operational reliability and lifespan.

Surge in Demand from Green Energy Applications

The transition to renewable energy sources is another key driver influencing the high-power rectifiers market. With increased investment in solar photovoltaic plants, wind farms, and hydroelectric facilities, there is a corresponding demand for high-capacity rectifiers to ensure consistent and efficient power conversion. These systems are particularly crucial in storing renewable energy in battery systems or integrating it into high-voltage DC (HVDC) transmission lines, which require stable rectification systems to handle variable input loads.

Advancements in Semiconductor Materials

Recent innovations in semiconductor technologies, particularly the adoption of silicon carbide (SiC) and gallium nitride (GaN), are enabling the development of high-power rectifiers with superior performance characteristics. These wide-bandgap materials offer higher thermal conductivity, voltage tolerance, and switching speeds compared to traditional silicon-based rectifiers. This allows rectifiers to operate at higher frequencies with greater efficiency, making them ideal for compact, high-performance industrial systems. As manufacturing costs for SiC and GaN devices decrease, their adoption in high-power rectifiers is expected to rise significantly.

Growing Adoption in Electrochemical and Metallurgical Processes

High-power rectifiers are indispensable in electrochemical industries, especially in applications such as metal electrolysis, electroplating, and anodizing. With the revival of infrastructure projects and increasing demand for metals like copper, aluminum, and zinc, industries are scaling up their production facilities. Modern rectifiers now offer precise control over voltage and current, which is crucial for maintaining product quality in such processes. Additionally, there is a rising trend towards using energy-efficient rectifiers that reduce electricity consumption and lower carbon emissions in metallurgical operations.

Customization and Modular Design

Industrial end-users are increasingly seeking customized high-power rectifier solutions tailored to specific application needs. This has led manufacturers to develop modular rectifier systems that offer scalability and flexibility. Modular designs not only facilitate easier maintenance and upgrades but also enable rapid deployment in remote or space-constrained environments. This trend is particularly relevant in mining operations, offshore platforms, and mobile power stations where adaptability and resilience are key requirements.

Expansion in Railway Electrification Projects

As countries invest in railway electrification to reduce dependence on fossil fuels, high-power rectifiers are becoming a vital component of traction substations. These systems are required to supply reliable DC power for electric locomotives and auxiliary systems. The ongoing electrification of rail networks in regions such as Asia-Pacific, Latin America, and parts of Africa is driving demand for rugged, high-efficiency rectifier units that can withstand harsh operating conditions while maintaining high performance.

Emphasis on Energy Efficiency and Sustainability

Environmental concerns and regulatory pressures are compelling industries to adopt energy-efficient rectification technologies. Modern high-power rectifiers now come with features like low harmonic distortion, soft-start capabilities, and regenerative energy systems that contribute to overall energy savings. Manufacturers are focusing on creating eco-friendly designs that minimize energy waste and contribute to sustainability goals, a trend that is increasingly resonating with environmentally conscious stakeholders.

Digital Twin and Predictive Maintenance

The implementation of digital twin technology is another cutting-edge trend impacting the high-power rectifiers market. By creating a virtual replica of the physical rectifier system, operators can simulate various operational scenarios, optimize performance, and predict maintenance needs. This approach helps in reducing unplanned downtime and extending the service life of the equipment. Predictive maintenance powered by AI and IoT is gaining traction among large-scale industrial users for its cost-efficiency and effectiveness.

Conclusion

The high-power rectifiers market is undergoing a dynamic evolution, influenced by innovations in materials, automation, energy integration, and sustainability. As industries continue to digitize and decarbonize, the demand for smarter, more efficient rectification systems will only intensify. Manufacturers that embrace these emerging trends and invest in R&D for next-generation technologies will be best positioned to capture the expanding opportunities in this essential industrial sector.

0 notes

Text

0 notes

Text

Material Trends and Opportunities in the Satellite Lithium-Ion Battery Market

The global lithium-ion satellite battery materials is specialized components designed to power spacecraft and satellites. These materials include cathodes (e.g., lithium cobalt oxide, nickel manganese cobalt oxide), anodes (typically graphite or silicon-based), and electrolytes (liquid or solid-state). They are engineered to deliver high energy density, long cycle life, and reliability under extreme space conditions such as vacuum, radiation, and temperature fluctuations. These batteries are essential for maintaining satellite operations during eclipse periods and ensuring mission success over extended durations.

The Lithium-Ion Satellite Battery Materials Market, valued at $1.62 billion in 2024, is projected to reach $2.57 billion by 2034. It is expected to grow at a CAGR of 4.72% during the forecast period from 2025 to 2034.

Market Segmentation

By Application:

GEO Satellites Lithium-Ion Battery

LEO Satellites Lithium-Ion Battery

MEO Satellites Lithium-Ion Battery

By Product Type:

Cathodes Material

Anodes Material

Others

By Region:

North America (U.S., Canada, Mexico)

Europe (Germany, France, Italy, Spain, U.K., Rest-of-Europe)

Asia-Pacific (China, Japan, South Korea, India, Rest-of-Asia-Pacific)

Demand Drivers

Growing Requirements for Connectivity: Satellite deployments, particularly in low-Earth orbit (LEO), are being driven by the growing demand for satellite-based communication and high-speed internet worldwide. This is creating a need for better lithium-ion battery materials that guarantee continuous, long-term operations.

Satellite Constellation Expansion: Lithium-ion batteries are a perfect option for projects requiring compact, lightweight, and long-lasting power sources, such as those supporting IoT networks, climate monitoring, and broadband services, which include vast fleets of tiny satellites.

Market Challenges

Technical Difficulties in Space Settings: Extreme radiation, temperature swings, and vacuum are all challenges for batteries in space. It is still very difficult to guarantee that materials will continue to function well under such circumstances for thousands of charge cycles.

High Costs of Production and Testing: High-purity materials, precise engineering, and stringent quality controls are required to manufacture space-grade lithium-ion batteries, which raises costs and delays mass-scale affordability and deployment.

Competition Synopsis

Established and up-and-coming companies are vying for market share in this fiercely competitive industry. Prominent businesses include of:

Umicore

Sumitomo Metal Mining

BASF

LG Chem

EcoPro BM

Toda Kogyo

Nichia Corporation

To stay competitive, major players are making R&D investments and partnering with aerospace companies. In the meantime, newcomers are concentrating on creating affordable and ecologically friendly substitutes to satisfy changing market demands.

Regional Insights

Due to its strong manufacturing capabilities, growing investments in the space sector, and the presence of material technology leaders, Asia-Pacific is predicted to dominate production. Because of their well-established space programs and robust aerospace R&D, North America and Europe will continue to be important consumers.

Download Our Sample Report Now!

Learn more about Aerospace Vertical. Click Here!

Future Outlook

Through 2034, the market for lithium-ion satellite battery materials is expected to continue to grow. Sustained growth will be fueled by the growing number of satellite launches, the need for extended mission durations, and ongoing advancements in battery chemistry, especially in cathode and anode innovation.

Future market dynamics will be shaped by Asia-Pacific's dominance in material manufacturing as well as worldwide trends in the development of battery components that are lighter, more effective, and more ecologically friendly. To overcome current obstacles, especially those related to cost and durability, strategic alliances and technological innovation will be essential.

Conclusion

Thanks to developments in satellite design, increased emphasis on energy efficiency, and an increase in the frequency of launches, the global market for lithium-ion satellite battery materials is steadily developing. Even though there are still financial and technological barriers, the impetus created by telecom, space exploration, and Earth observation initiatives will encourage further investment in high-performance battery materials. Unlocking the next generation of dependable and sustainable satellite power systems will require cooperation between the materials science and aerospace industries.

#lithium-ion satellite battery materials#lithium-ion satellite battery materials market#lithium-ion satellite battery materialsindustry#lithium-ion satellite battery materials report#aerospace

0 notes

Text

0 notes

Text

Battery Silicon Anode Material Market 2025

Battery Silicon Anode Material refers to advanced anode materials used in lithium-ion batteries to enhance energy storage capacity. Silicon anodes offer significantly higher charge capacity compared to traditional graphite anodes, making them a crucial innovation for high-performance batteries. Despite their advantages, challenges such as volume expansion and degradation during charge cycles have led to the development of nanostructured silicon, including silicon nanowires and nanoparticles, to improve cycle stability and overall battery performance.

Get more reports of this sample : https://www.intelmarketresearch.com/download-free-sample/638/global-battery-silicon-anode-material

Market Size

The global Battery Silicon Anode Material market was valued at USD 401 million in 2023 and is projected to reach USD 4645.38 million by 2030, reflecting a robust CAGR of 41.90% during the forecast period. This significant growth is driven by the rising demand for energy-dense batteries, particularly in electric vehicles (EVs), renewable energy storage systems, and consumer electronics.

Key Statistics:

The North American market was valued at USD 104.49 million in 2023, expected to grow at a CAGR of 35.91% from 2025 to 2030.

Silicon anodes are highly sought after in the EV industry due to their higher energy density.

Advances in nanostructured silicon materials are boosting market expansion.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers:

High Energy Density: Silicon anodes provide much greater charge storage than graphite, making them ideal for high-performance batteries.

Electric Vehicle (EV) Growth: Increasing global EV adoption necessitates advanced battery technologies with longer-lasting, high-capacity solutions.

Technological Innovations: Advancements in silicon nanostructures, such as silicon-carbon composites, address expansion issues and improve battery cycle life.

Renewable Energy Storage: High-performance silicon anodes support large-scale energy storage systems, crucial for solar and wind energy applications.

Restraints:

Volume Expansion Issues: Silicon's tendency to expand and contract during charge cycles leads to capacity degradation and mechanical stress.

High Production Costs: Manufacturing silicon-based anodes remains expensive compared to graphite alternatives, limiting widespread adoption.

Material Stability Concerns: Achieving long-term stability while preventing performance degradation is an ongoing challenge.

Opportunities:

Hybrid Anode Solutions: Silicon-graphite composites are being developed to combine high energy density with improved stability.

Growing Consumer Electronics Market: Increased demand for extended battery life in portable devices presents a lucrative opportunity.

Government Policies & Incentives: Support for EVs and renewable energy initiatives accelerates the adoption of silicon anode materials.

Challenges:

Scaling Up Production: Large-scale manufacturing of high-quality silicon anodes while keeping costs down remains a significant hurdle.

Alternative Battery Technologies: Emerging technologies, such as solid-state batteries and lithium-sulfur batteries, pose potential competition.

Long-Term Performance Issues: The degradation of silicon anodes over extended use cycles limits their commercial viability unless addressed.

Regional Analysis

North America:

Led by the U.S., with strong demand from EV manufacturers such as Tesla and General Motors.

Investments in battery production and renewable energy storage drive market expansion.

Europe:

Countries like Germany, France, and the U.K. are heavily investing in EV adoption and renewable energy integration.

Favorable government policies and initiatives support silicon anode market growth.

Asia-Pacific:

China dominates the region due to its aggressive push for electric vehicles and battery manufacturing.

Japan and South Korea are key players in lithium-ion battery innovation.

Middle East & Africa:

Increasing investments in EVs and renewable energy contribute to the growing demand for advanced battery materials.

Get more reports of this sample : https://www.intelmarketresearch.com/download-free-sample/638/global-battery-silicon-anode-material

Competitor Analysis

Key companies in the Battery Silicon Anode Material market include:

Sila Nanotechnologies

Enovix Corporation

XG Sciences

IMEC

These companies focus on innovative material solutions, strategic partnerships, and scaling production to meet rising market demands.

Global Battery Silicon Anode Material: Market Segmentation Analysis

This report provides a deep insight into the global Battery Silicon Anode Material market, covering essential aspects such as market size, competitive landscape, development trends, key drivers, and challenges. The analysis helps stakeholders understand competitive dynamics and formulate strategic business decisions.

Market Segmentation (by Application)

Consumer Electronics: Smartphones, laptops, and wearables.

Electric Vehicles (EVs)

Energy Storage Systems (ESS)

Aerospace & Defense

Industrial Applications

Market Segmentation (by Type)

Silicon Nanowires

Silicon Nanoparticles

Silicon-Graphite Composites

By Material Type

Pure Silicon Anode

Silicon-Carbon (Si-C) Composite Anode

Silicon-Oxide (SiO) Anode

Silicon-Graphene Composite Anode

Other Silicon-Based Anode Materials

By Battery Type

Lithium-Ion Batteries (Li-ion)

Next-Generation Batteries (Solid-State, Li-S, etc.)

By End-Use Industry

Automotive

Consumer Electronics

Renewable Energy & Grid Storage

Aerospace & Defense

Industrial Manufacturing

Geographic Segmentation

North America

Europe

Asia-Pacific

Middle East & Africa

FAQ Section :

▶ What is the current market size of the Battery Silicon Anode Material market?

The market was valued at USD 401 million in 2023 and is expected to reach USD 4645.38 million by 2030.

▶ Which are the key companies operating in the Battery Silicon Anode Material market?

Leading companies include Sila Nanotechnologies, Enovix Corporation, XG Sciences, and IMEC.

▶ What are the key growth drivers in the Battery Silicon Anode Material market?

Growth drivers include increasing EV adoption, advancements in nanostructured silicon, and rising demand for high-capacity batteries.

▶ Which regions dominate the Battery Silicon Anode Material market?

North America, Asia-Pacific, and Europe lead the market due to strong EV demand and technological advancements.

▶ What are the emerging trends in the Battery Silicon Anode Material market?

Trends include hybrid silicon-graphite anodes, advancements in nanostructured silicon, and expanding energy storage applications.

Get more reports of this sample : https://www.intelmarketresearch.com/download-free-sample/638/global-battery-silicon-anode-material

0 notes

Text

0 notes

Text

Exploring the Best Sheet Metal Fabrication Companies in Bangalore

Summary

Explore top sheet metal fabrication companies in Bangalore offering precision cutting, bending, and assembly services for diverse industries. Learn how to choose the best fabrication partner for quality and reliability.

Introduction

Bangalore, often hailed as the Silicon Valley of India, is not just a tech hub but also a thriving center for manufacturing and fabrication industries. Among its many industrial strengths, sheet metal fabrication stands out as a critical sector supporting various fields such as construction, automotive, electronics, aerospace, and more. If you are searching for top-notch sheet metal fabrication companies in Bangalore, this blog will guide you through everything you need to know — from industry insights and services offered to how to select the best partner for your needs.

Understanding Sheet Metal Fabrication

Sheet metal fabrication involves cutting, bending, and assembling thin metal sheets into desired shapes and structures. These metal sheets can be made from steel, aluminum, copper, brass, or other alloys. Fabricators use a combination of manual labor and advanced machinery such as CNC machines, laser cutters, and press brakes to create components that are vital in manufacturing everything from industrial machinery parts to architectural elements.

The process typically includes:

Cutting: Laser cutting, plasma cutting, or shearing to shape metal sheets.

Bending: Using press brakes or rollers to bend sheets into forms.

Welding and Assembly: Joining metal pieces to create the final product.

Finishing: Surface treatments like painting, powder coating, or galvanizing to enhance durability and appearance.

Given the precision and expertise required, choosing the right sheet metal fabrication companies in Bangalore is crucial for high-quality results.

Why Bangalore is a Hub for Sheet Metal Works

Bangalore's industrial ecosystem is a blend of innovation and traditional manufacturing expertise. Its strategic location, skilled workforce, and access to raw materials make it an ideal place for sheet metal works in Bangalore.

Key reasons Bangalore shines in this sector include:

Skilled Labor: The city attracts engineers, designers, and skilled fabricators well-versed in modern fabrication technologies.

Advanced Machinery: Many fabrication companies in Bangalore invest in state-of-the-art equipment, ensuring precision and faster turnaround times.

Diverse Industry Demand: From IT hardware to aerospace and automotive components, the city’s diverse industrial base creates sustained demand for sheet metal products.

Proximity to Suppliers: Easy access to raw materials and logistics networks helps keep costs competitive.

Because of these factors, Bangalore hosts many renowned fabrication companies in Bangalore offering custom sheet metal fabrication services.

Services Offered by Sheet Metal Fabrication Companies in Bangalore

If you are evaluating fabrication companies in Bangalore, it’s important to understand the range of services they typically offer:

1. Custom Sheet Metal Fabrication

Tailored solutions to meet unique design specifications. Whether it’s prototype development or mass production, companies offer customized cutting, bending, and assembly services.

2. CNC Sheet Metal Machining

Computer Numerical Control (CNC) machining ensures high precision and consistency, particularly for complex shapes and tight tolerances. CNC technology allows for intricate cuts and bends that manual methods can’t easily replicate.

3. Welding and Joining

Fabricators provide expert welding techniques such as MIG, TIG, and spot welding to ensure strong, durable joints in metal assemblies.

4. Surface Finishing

Finishing services like powder coating, painting, anodizing, and galvanizing improve the corrosion resistance and aesthetics of metal parts.

5. Sheet Metal Prototyping

For industries requiring design validation and testing, many fabrication companies in Bangalore offer prototyping services to create functional samples before full-scale production.

6. Assembly and Packaging

Some companies provide end-to-end solutions, including assembly of fabricated parts into sub-assemblies or finished products, along with packaging and delivery.

Industries Served by Sheet Metal Fabrication Companies in Bangalore

The applications of sheet metal fabrication are extensive, and Bangalore’s fabricators cater to a variety of sectors:

Automotive: Manufacturing chassis components, brackets, exhaust parts, and custom panels.

Aerospace: Precision parts requiring high-strength, lightweight materials.

Construction and Architecture: Decorative panels, roofing sheets, ducts, and structural elements.

Electronics: Enclosures, heat sinks, and mounting hardware.

Healthcare: Surgical instruments and equipment casings.

Industrial Machinery: Machine guards, control panels, and frames.

Choosing the right sheet metal fabrication companies in Bangalore that specialize in your industry can significantly enhance product quality and compliance.

How to Choose the Right Sheet Metal Fabrication Company in Bangalore

When selecting a fabrication partner, consider these key factors:

1. Experience and Expertise

Look for companies with a proven track record in sheet metal works in Bangalore. Industry-specific experience is a big plus.

2. Technology and Equipment

Modern CNC machines, laser cutters, and automated welding systems indicate a company’s ability to handle complex jobs with precision.

3. Quality Certifications

ISO certifications and compliance with industry standards ensure quality and reliability.

4. Customization Capability

The ability to handle custom designs and rapid prototyping is essential for businesses needing unique solutions.

5. Turnaround Time and Scalability

Evaluate their capacity to meet deadlines and scale production according to your needs.

6. Customer Support and Service

Good communication, transparency in pricing, and after-sales support make collaboration smoother.

7. Client Testimonials and Portfolio

Review past projects and client feedback to gauge reliability and craftsmanship.

Leading Fabrication Companies in Bangalore

While there are many players in the market, some stand out for their quality and service excellence. It’s advisable to request quotes and sample works from multiple fabrication companies in Bangalore before making a decision.

Many companies also offer integrated services, covering everything from design assistance to final assembly, providing end-to-end convenience.

Future Trends in Sheet Metal Fabrication

The industry is rapidly evolving with new technologies:

Automation and Robotics: Increasing adoption of robotic welding and bending to improve precision and reduce costs.

Additive Manufacturing Integration: Combining 3D printing with traditional sheet metal fabrication for hybrid parts.

Sustainability: Use of eco-friendly materials and processes to reduce environmental impact.

IoT and Smart Manufacturing: Real-time monitoring and quality control through connected devices.

Leading sheet metal fabrication companies in Bangalore are investing in these technologies to stay competitive and deliver cutting-edge solutions.

Conclusion

Whether you’re in construction, automotive, electronics, or any sector requiring durable, precisely fabricated metal components, Bangalore offers some of the best sheet metal fabrication companies in Bangalore. The city’s skilled workforce, advanced technology, and diverse industry base make it an ideal choice for all your sheet metal works in Bangalore.

By carefully choosing your fabrication partner — focusing on experience, technology, quality, and service — you can ensure your projects are completed efficiently, on time, and to the highest standards.

If you’re ready to explore or upgrade your fabrication requirements, start by connecting with trusted fabrication companies in Bangalore today and take advantage of the city’s manufacturing expertise to drive your business forward.

1. What services do sheet metal fabrication companies in Bangalore typically offer?

Sheet metal fabrication companies in Bangalore provide a wide range of services including cutting, bending, welding, CNC machining, surface finishing, prototyping, and assembly. These services cater to various industries like automotive, aerospace, electronics, and construction.

2. How do I choose the right sheet metal fabrication company in Bangalore?

Consider factors such as industry experience, technology and machinery used, quality certifications, customization capabilities, turnaround time, and client testimonials. Requesting quotes and samples can also help in making an informed decision.

3. What materials are commonly used in sheet metal works in Bangalore?

Common materials include mild steel, stainless steel, aluminum, copper, and brass. The choice depends on the application’s strength, corrosion resistance, and budget requirements.

4. Are there any quality certifications to look for in fabrication companies in Bangalore?

Yes, ISO 9001 certification is commonly sought after as it ensures adherence to quality management standards. Some companies may also comply with industry-specific certifications depending on the sector they serve.

5. Can sheet metal fabrication companies in Bangalore handle custom and prototype orders?

Absolutely. Many companies specialize in custom sheet metal fabrication and offer prototyping services to help clients test and refine designs before mass production.

6. How advanced is the technology used by sheet metal fabrication companies in Bangalore?

Many fabrication companies in Bangalore use advanced machinery such as CNC laser cutters, press brakes, robotic welders, and automated finishing lines, enabling high precision and efficiency.

7. What industries in Bangalore rely heavily on sheet metal fabrication?

Key industries include automotive manufacturing, aerospace, electronics, healthcare equipment, construction, and industrial machinery.

8. How long does a typical sheet metal fabrication project take?

Project timelines vary based on complexity and scale. Simple parts may take a few days, while larger or more complex assemblies could take several weeks. Reliable companies provide clear project timelines upfront.

#sheet metal works in bangalore#fabrication companies in bangalore#heavy fabrication companies in bangalore#sheet metal fabricators in bangalore

0 notes

Text

Aluminum Alloy Profiles: The Material Behind Smart, Sustainable Structures

In today’s fast-paced construction industry, aluminum alloy profiles are a key material transforming how buildings and products are designed. With a blend of lightweight structure and superior strength, they offer a practical solution for a wide range of applications—from exterior facades to indoor partitions and industrial equipment.

Engineered for Performance

Aluminum alloy profiles are created by mixing aluminum with elements like silicon and magnesium, enhancing mechanical properties like strength, flexibility, and corrosion resistance. This makes them perfect for structural frameworks, load-bearing supports, and even lightweight movable systems.

Ideal for Harsh Climates

Especially in hot and humid environments like the UAE, aluminum alloy profiles provide long-term performance. They don’t rust, crack, or deform, even when exposed to sunlight and moisture. Their low maintenance requirement makes them a smart choice for both builders and property owners.

Style Meets Function

Whether it's for minimalistic interiors or high-tech commercial spaces, aluminum alloy profiles offer clean lines and sleek finishes. With options like anodizing and powder coating, these profiles can be finished in a range of colors and textures to match any architectural theme.

A Greener Alternative

Aluminum is one of the most recyclable materials on the planet. Using aluminum alloy profiles in construction helps reduce environmental impact while also lowering energy use and long-term costs.

Final Words: If you're looking for a reliable, stylish, and eco-friendly material for your next project, aluminum alloy profiles check every box. Their ability to balance aesthetics with high performance makes them a go-to solution for modern design and construction needs.

0 notes