#Slab Formwork System

Explore tagged Tumblr posts

Text

High-Performance Slab Formwork System for Efficient Concrete Construction

Discover Biiformtek's advanced Slab Formwork System, engineered for speed, safety, and precision in concrete construction. Manufactured through a robust Sheet Metal Fabrication Process and compatible with the Slab Tableform system, our solutions ensure fast assembly, superior durability, and consistent results for residential, commercial, and industrial projects.

Link:- https://www.prbusinesswires.com/Slab-Formwork-System:-The-Backbone-of-Efficient-Concrete-Construction

Link:- https://www.bipsanfrancisco.com/Slab-Formwork-System:-Precision,-Efficiency-&-Modern-Construction-Excellence

0 notes

Text

High-Quality Slab Formwork System | Slab Edge Protection & Tableform Solutions

Discover advanced Slab Formwork System for efficient concrete construction. Ensure safety with Slab Edge Protection System and enhance productivity with Slab Tableform System. Contact us today!

0 notes

Video

youtube

Scaffold U Head Manufacturing (Robot) - Wellmade China - Crab 60 Shoring...

#youtube#u head jacks#scaffold u head#u head#scaffolding u head#crab 60 shoring system#crab 60 shoring scaffold#shoring scaffold#c60 scaffolding#crab 60 scaffolding#slab formwork#slab shoring#wellmade scaffold#china scaffolding#china factory

0 notes

Text

The Backbone of Infrastructure: Advanced Formwork for Bridges and Tunnels

In today’s fast-paced world, elevating roads into bridges and merging them underground as tunnels has become a cornerstone of modern infrastructure. These engineering marvels not only ease traffic congestion and reduce travel time but also connect communities, enhance urban landscapes, and protect natural environments. However, constructing such complex infrastructure is no small feat. It involves overcoming geological challenges, ensuring structural integrity, and adhering to strict safety and environmental standards. At the heart of these projects lies formwork. In this blog, we explore the challenges of formwork for tunnels and bridges and how innovative solutions are transforming the way we build.

The Role of Formwork in Bridge and Tunnel Construction

Formwork is the backbone of any concrete construction project. For bridges and tunnels, it plays a critical role in ensuring structural integrity, precision, and efficiency. The formwork must withstand immense loads, adapt to complex geometries, and meet strict safety standards. It also directly impacts project timelines and costs, making it essential to choose the right systems and techniques.

At Allmarc Industries, we offer a wide range of formwork solutions designed to meet the diverse needs of infrastructure projects. Our Infrastructure and Building Formwork System is engineered to drive construction excellence, laying the foundation for sturdy and sustainable structures.

Challenges in Formwork for Bridges and Tunnels

Constructing bridges and tunnels presents unique challenges that demand specialised formwork solutions:

Complex Geometries and Load-Bearing Requirements Bridges and tunnels are built to support heavy loads and often feature intricate designs. Formwork systems must be adaptable and robust to meet these challenging demands of modern infrastructure.

Environmental and Site-Specific Challenges Construction sites for bridges and tunnels can be in remote or challenging locations, such as over water, in mountainous regions, or underground. Such locations contribute to the heavy loads and require strategic designs to construct infrastructure that can withstand the conditions. Formwork must be designed to handle these conditions.

Safety Concerns and Regulatory Compliance Bridge and tunnel construction involves significant risks if safety measures are compromised. Formwork systems must comply with strict regulations to protect workers and ensure the longevity of the structure.

Time Constraints and Efficiency Delays in construction can lead to additional costs and client dissatisfaction. Efficient formwork systems are essential to keep projects on schedule without compromising quality.

Modern construction techniques and innovative formwork solutions are efficiently overcoming these challenges.

Modern Bridge Construction Techniques and Formwork Solutions

Innovative formwork solutions are revolutionising bridge construction. Here are some of the most impactful techniques:

Prefabricated Formwork for Bridges Prefabricated formwork systems are pre-assembled off-site, allowing for faster installation and reduced on-site labour. These modular systems are ideal for repetitive structures like bridge piers and girders.

Self-Climbing Formwork Systems For high-rise bridge components, self-climbing formwork systems are a game-changer. These systems use hydraulic mechanisms to move upward as construction progresses, eliminating the need for cranes and reducing downtime.

Sustainable Formwork Solutions Eco-friendly formwork systems made from reusable or recyclable materials are gaining popularity in the bridge construction formwork sector. These solutions not only reduce environmental impact but also lower long-term costs.

At Allmarc, we deliver high-precision prefabricated formwork for bridges, optimising speed and efficiency in construction. Our Precast Infra Formwork Moulds include:

Noise Barrier Moulds – For high-speed rail, highways, and urban noise reduction.

U Cable Duct Moulds – Protect underground cables with durable U-shaped ducts.

Track Slab Moulds – Ensure stable, long-lasting railway track slabs.

FSLM Moulds – Enable rapid full-span girder installations.

U & I Girder Moulds – High-strength girders for bridges and flyovers.

Long & Short Line Segment Moulds – Versatile solutions for tunnels and bridges.

Drainage & Box Culvert Moulds – Essential for efficient water management and road infrastructure.

Retaining Wall Moulds – Precast panels for robust soil retention.

Built for speed, strength, and precision, our moulds redefine infrastructure efficiency.

Innovative Tunnel Formwork Design

Tunnel construction demands versatile and robust formwork that can accommodate varying shapes and sizes while maintaining structural integrity, safety, and efficiency. Modern tunnel formwork solutions include:

Adaptable Formwork Systems – Engineered to handle the complex curved and irregular geometries of tunnels, these systems ensure precise concrete placement, reducing material wastage and construction time.

Advanced Materials – Utilising high-strength, lightweight materials, such as aluminium alloys and composite panels, enhances durability, ease of handling, and faster assembly, making tunnel construction more efficient and cost-effective.

These innovations contribute to safer, faster, and more resilient tunnel infrastructure. At Allmarc, we offer speciality formwork solutions for tunnel construction. Our Allwell Deep Foundations excel in large-diameter excavations. This system uses corrugated steel liner plates and meticulous grouting for enhanced soil stabilisation. Ideal for urban and railway-adjacent projects, it ensures robust support and minimal disruption.

High-Rise Formwork Systems for Complex Structures

High-rise formwork systems are not limited to skyscrapers—they are also essential for tall bridge piers and other vertical structures. At Allmarc, we address all the elevated construction demands with our advanced construction formwork systems. Our Cast-In Situ Moulds offer adaptability and precision for complex structures.

Pier Moulds: Expertly designed to create sturdy and dependable pier structures, ensuring durability for demanding infrastructure projects.

Pier Cap Moulds: Crafted to produce high-quality pier caps, providing essential support for superstructures.

Track Bed Moulds: Designed with precision to create perfectly aligned and stable track beds, vital for rail and transportation infrastructure.

With our advanced formwork solutions, we offer enhanced efficiency with faster construction timelines through modular and reusable components, as well as improved safety with integrated features to reduce the risk of accidents.

Slab Formwork: A Critical Component

Slab formwork is a key element in bridge and tunnel construction, particularly for decks and platforms. Allmarc’s Slab Formwork is engineered for durability, featuring strong props, versatile steel timber beams, and resilient birch plywood. These systems ensure durable and efficient concrete construction, making them ideal for large-scale infrastructure projects.

Conclusion

Formwork is a critical component of bridge and tunnel construction, and overcoming its challenges requires innovative solutions. From prefabricated and self-climbing formwork systems to sustainable and adaptable designs, modern formwork technology is transforming the way we build.

At Allmarc Industries, we are committed to providing state-of-the-art formwork solutions that meet the demands of today’s construction projects. Whether you’re building a bridge, tunnel, or any other complex structure, we have the expertise and technology to ensure your project’s success.

Partner with Allmarc Industries for your next project and discover cutting-edge formwork solutions for modern infrastructure.

#U Cable Duct Moulds#Track Slab Moulds#SLM Moulds#U & I Girder Moulds#Long & Short Line Segment Moulds#Drainage & Box Culvert Moulds#Retaining Wall Moulds#construction formwork systems#advanced formwork solutions#Slab Formwork

0 notes

Text

NOVA Beam Formwork - Robust and Multifunctional

Beam formworks are lightweight and extremely resilient, making them ideal for horizontal applications

#formwork construction#plastic formwork#nova plastic formwork#beam formwork system#beam formwork#beam construction#slab and beam#concrete beam formwork

0 notes

Text

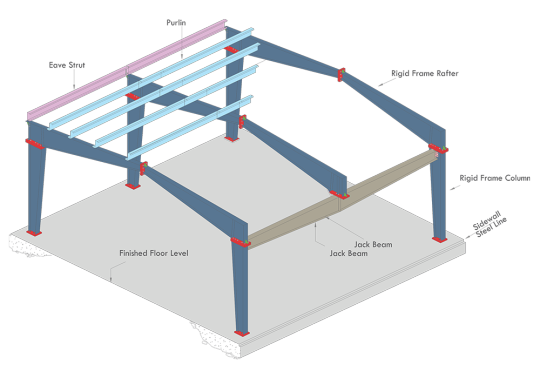

Smith Structure| Jack Beam Elevating Structural Support

Smith Structure introduces jack beams structural component used in construction for temporary or permanent support of floors, roofs, or load-bearing elements

#Jack Beam#Isometric Jack Beam at Sidewall#Isometric Jack Beam at Interior Column Location#Mezzanine System#mezzanine framing system#steel deck support#mezzanine beams#Mezzanine Plan#steel formwork#oncrete slab construction#Mezzanine Cross Section#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

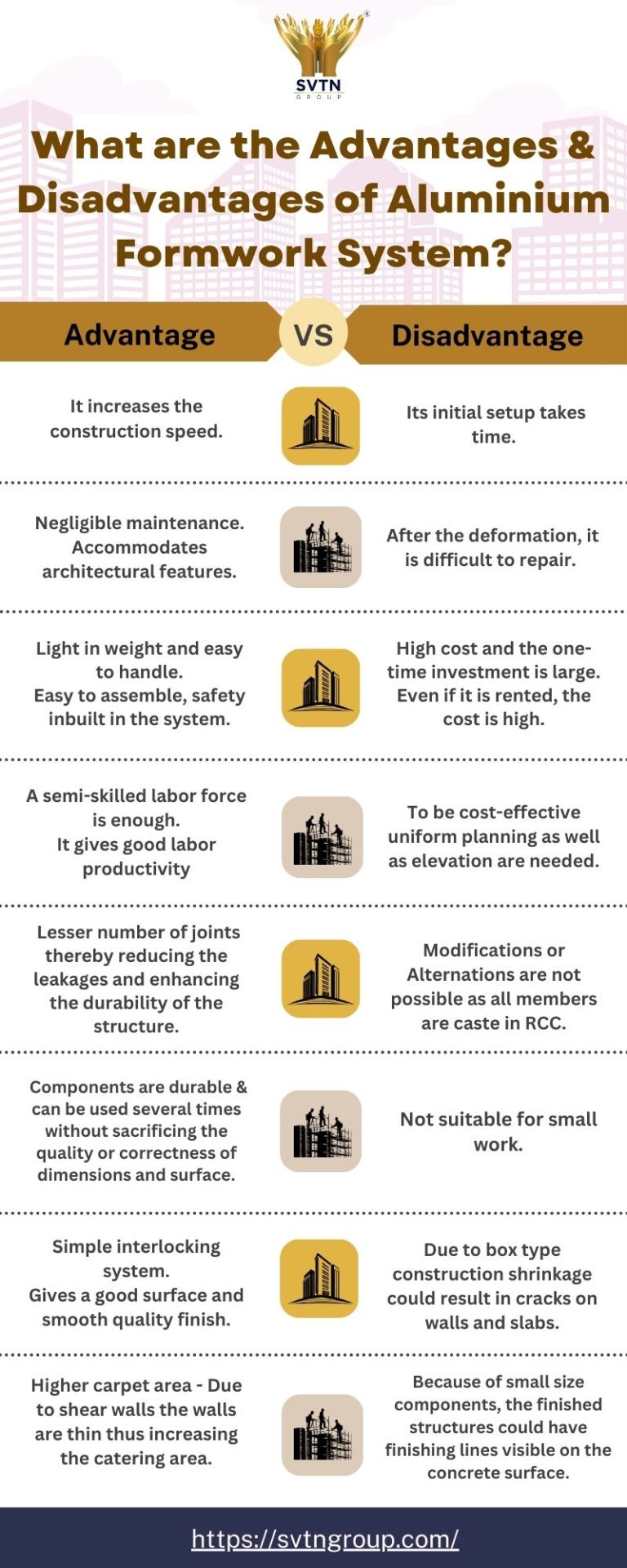

One of the most adaptable modern construction technologies is the Aluminum Formwork System, often known as Alu-Form Technology. It provides additional benefits and may be used for both high-rise and low-rise construction, unlike other methods. The speed factor of the Alu-Form system is its primary feature. All interior and external walls, beams, floor slabs, staircases, and other concrete building components can be cast quickly, precisely, and consistently with its help. This technique integrates plumbing and electrical fixtures more effectively into the overall building design.

#SVTN#aluform construction technology#alu form construction#aluform formwork#top contractors in pune#pune best construction company#best construction work company in pune#best construction company in pune#aluform construction#quality construction work#quality construction works#quality construction works llc#Affordable and Quality Construction Works#building contractors in pune#contractors in pune#civil contractors in pune#SVTN Group

3 notes

·

View notes

Text

A Complete Guide to Mivan Shuttering Components

In today’s fast-paced construction industry, time, efficiency, and structural precision are everything. Among the many technologies revolutionising building methods, Mivan shuttering stands out as a game changer. Known for its speed, strength, and superior finish, Mivan technology uses a monolithic concrete pouring system with reusable aluminium formwork components—making it ideal for mass housing and high-rise structures.

At BSL Scaffolding, we’ve helped hundreds of developers and contractors improve project timelines and quality through premium-grade aluminium formwork systems. One of the most common questions we’re asked is: What are the components of Mivan shuttering?

This blog provides a detailed explanation of all the key Mivan shuttering components, their functions, and how they come together to create fast, cost-effective, and structurally sound buildings.

What Is Mivan Shuttering?

Mivan shuttering is a construction system developed by a European company called Mivan Company Ltd, designed for rapid cast-in-place construction using aluminium formwork. It uses a modular aluminium framework to form the structural elements of a building—such as walls, slabs, beams, staircases, and columns—all poured in a single cycle.

This technique eliminates the need for traditional brickwork or blockwork, ensuring uniformity, speed, and strength across the project.

The success of this system heavily depends on the precision and quality of its components.

Core Mivan Shuttering Components

Let’s break down the major components of a Mivan shuttering system. Each part is manufactured from lightweight yet durable aluminium, making it reusable, easy to handle, and capable of withstanding multiple construction cycles.

1. Wall Panels Wall panels are vertical aluminium plates used to form the external and internal walls of the building. They are precisely engineered to match the wall dimensions of the floor plan.

Function: To form the vertical concrete surfaces (walls), ensuring straightness and alignment.

BSL Advantage: At BSL Scaffolding, our aluminium wall panels are manufactured with tight tolerances and reinforced edges to ensure dimensional stability and long-term reusability.

2. Beam Side and Soffit Panels These are horizontal shuttering components that form the sides (beam side panels) and underside (soffit panels) of the structural beams.

Function: They help in shaping the beams precisely, ensuring uniform dimensions and clean finish for structural integrity.

Secondary Keyword Target: beam shuttering with aluminium formwork

3. Deck Panels Deck panels are flat plates that form the horizontal surface of the floor slab. They are supported by props and deck beams to maintain correct elevation.

Function: To support the weight of wet concrete for slabs until it sets completely.

Why It Matters: Uniform deck panels from BSL ensure no slab leakage or undulations—critical for residential and commercial projects.

4. Deck Beams These are horizontal members that support the deck panels and transfer their load to the vertical supports (props).

Function: They provide intermediate support to deck panels, enhancing formwork stability during pouring.

Pro Tip: Proper alignment of deck beams ensures flat slab finishes and avoids deviations during multiple floor constructions.

5. Soffit Length and Prop Head Soffit Length: Connects the wall panel to the deck panel horizontally and provides form for the slab's edge.

Prop Head: Holds the beam and deck system in place from below with vertical support props.

Function: To balance and lock the framework from below, supporting the system during concrete curing.

BSL's Offering: Our prop systems are high-strength yet easy to adjust on site, reducing labour and setup time.

6. Pins and Wedges These are mechanical fasteners used to lock different formwork panels together. Their design allows easy assembly and disassembly.

Function: To hold panels rigidly in position, ensuring leak-proof concrete casting and exact alignment.

Relevance: Reliable locking is essential for a monolithic structure; BSL’s pins and wedges are precision-engineered for seamless operations.

7. External Corners and Internal Corners These components help in joining panels at the junctions—where walls meet at 90° angles or where slabs meet walls.

Function: To complete corners and edges with proper geometry, reducing joint lines and plastering needs.

Construction Tip:

Tight-fitting corners lead to better waterproofing and finish, reducing maintenance in the long term.

Why Are These Components Critical?

Each of the Mivan shuttering components plays a specific role. The performance of the entire aluminium formwork system depends on the precision, durability, and alignment of every part. Using poor-quality components can result in:

Concrete leakage

Misaligned structures

Poor finishes

Delays in reuse and dismantling

At BSL Scaffolding, we focus on delivering formwork systems built to last. Every component is tested for load capacity, corrosion resistance, and alignment to ensure top-notch construction performance.

Benefits of Using BSL Aluminium Formwork Systems

Faster Construction: Our systems cut down cycle time per floor dramatically

Superior Finish: Clean, straight walls and slabs mean less plastering or rework

Durability: Up to 200+ reuses without compromising performance

Lightweight & Labour-Friendly: Easy handling with less skilled labour

Custom Design Support: Tailored formwork plans for your exact project specs

Whether you are building mass housing, townships, or luxury high-rises, our Mivan formwork solutions scale with your needs.

Build Smarter with the Right Mivan Shuttering Components

Understanding the components of Mivan shuttering is essential for any builder or developer aiming for efficiency, strength, and long-term cost savings. As India pushes towards rapid urban housing and vertical growth, choosing the right formwork partner becomes even more crucial.

At BSL Scaffolding, we don’t just supply aluminium formwork—we deliver complete construction solutions that support your vision from foundation to finish.

Whether you’re switching from traditional methods or scaling up Mivan-based projects, we’re here to help you build faster, smarter, and stronger.

#mivan shuttering system#mivan technology#modern construction technique#aluminium formwork system#Components of Mivan Shuttering

0 notes

Text

Formwork Panels: Revolutionizing Concrete Construction with Nova Formworksblr

In the world of modern construction, the efficiency and quality of a project depend heavily on the tools and systems used. Among these, formwork panels play a crucial role in shaping concrete structures and influencing construction timelines. For developers and contractors seeking high-performance and durable formwork solutions, Nova Formworksblr stands out as a trusted name offering innovation, reliability, and eco-friendly alternatives.

What Are Formwork Panels?

Formwork panels are temporary or permanent molds into which concrete is poured to form structural components such as walls, columns, beams, and slabs. These panels support the wet concrete until it sets and gains sufficient strength to support its weight. Traditionally, materials like timber and plywood were used, but the construction industry is now rapidly shifting toward plastic and modular panel systems for enhanced efficiency and durability.

At Nova Formworksblr, formwork panels are designed with cutting-edge technology using high-strength plastic polymers that are lightweight, reusable, and weather-resistant—making them ideal for today’s fast-paced construction environments.

Key Features of Nova Formworksblr Formwork Panels

Nova Formworksblr specializes in plastic modular formwork systems that redefine the concept of reusable shuttering. Here’s what sets their formwork panels apart:

Durability and Reusability

Unlike conventional plywood formwork that degrades over repeated usage, Nova’s plastic formwork panels can be reused more than 100 times with proper care. Their panels do not absorb water, resist corrosion, and are unaffected by extreme weather, making them long-lasting and cost-effective.

Easy Handling and Installation

The modular design of Nova’s panels makes them incredibly user-friendly. They are light enough to be moved manually without the need for cranes or other heavy equipment. Their easy-locking mechanisms allow for quick assembly and dismantling, reducing labor costs and saving time on site.

Superior Surface Finish

Nova Formworksblr ensures that the final concrete surface is smooth and uniform. The high-quality plastic used in the panels provides a sleek finish without requiring additional plastering, thus saving time and material costs in the finishing stage.

Eco-Friendly Construction

By reducing the dependence on timber and offering reusable panels, Nova Formworksblr contributes to sustainable construction practices. The plastic used is recyclable, which helps reduce the carbon footprint of construction activities.

Types of Formwork Panels Offered by Nova Formworksblr

Nova Formworksblr offers a variety of formwork panels suited for different construction needs:

Wall Formwork Panels: Designed to handle vertical concrete pressure, ideal for constructing high-rise walls and retaining structures.

Column Formwork Panels: Adjustable systems to accommodate various column sizes and shapes with excellent stability.

Slab Formwork Panels: Modular panel systems supported with props, designed to simplify slab casting while maintaining strength and alignment.

Custom Panels: Tailored for specific project requirements, including curved or irregular designs, enabling architectural flexibility.

Advantages of Using Nova Formworksblr Panels in Your Project

Builders, contractors, and architects benefit immensely from choosing Nova’s advanced formwork panels. Some notable advantages include:

Cost Savings: Although the initial investment might be higher than timber, the reuse potential and reduced labor make these panels more economical over multiple projects.

Time Efficiency: Faster assembly and dismantling speed up the construction cycle.

Safety: Lightweight panels reduce the risk of on-site accidents and injuries.

Low Maintenance: Easy to clean and store, these panels require minimal upkeep between uses.

Applications of Formwork Panels in Construction

Formwork panels from Nova Formworksblr are used across a wide range of construction projects, such as:

Residential buildings

Commercial complexes

Infrastructure projects like bridges and tunnels

Educational and institutional buildings

Industrial and warehouse structures

Whether it’s a high-rise apartment or a government-funded public utility project, Nova Formworksblr’s systems ensure that the formwork process is streamlined, sustainable, and safe.

Why Choose Nova Formworksblr?

With years of expertise in the field and a commitment to quality and innovation, Nova Formworksblr has become a go-to solution provider for builders across India. The company not only delivers cutting-edge formwork panels but also offers end-to-end technical support and guidance to ensure successful project execution.

Their team works closely with clients to understand project-specific challenges and provides tailored solutions that enhance performance, reduce construction time, and ensure long-term value. From on-site training to after-sales support, Nova’s customer-centric approach has earned them a strong reputation in the industry.

Final Thoughts

As the construction industry evolves, the need for smarter, faster, and more sustainable solutions becomes increasingly important. Formwork panels have a direct impact on construction speed, structural integrity, and project costs. Companies like Nova Formworksblr are at the forefront of this transformation, offering next-generation plastic modular formwork systems that meet the demands of modern construction.

If you're planning your next construction project and want to adopt cost-effective and high-performance shuttering solutions, look no further than Nova Formworksblr. Their formwork panels are designed to deliver consistent results, project after project.

0 notes

Text

Adjustable Props and Span in Greater Noida At Best Price | JK Timber Mart

A dynamic and ever-growing construction sector, Props and Span play a pivotal role in ensuring structural safety, efficiency, and flexibility on building sites. Whether for residential, commercial, or infrastructure projects, these essential components offer reliable support during various construction phases. If you are looking for high-quality Props and Span in Greater Noida, Adjustable Props, or Adjustable Span at the best price, JK Timber Mart is your trusted partner.

We specialize in providing a wide range of Construction Materials in Greater Noida, ensuring builders, contractors, and developers have access to superior products that meet all structural and project needs.

What Are Props and Span?

Props and Span are temporary yet vital construction elements used to support formwork, beams, floors, and ceilings during the construction or renovation process. They ensure stability while concrete cures and strengthens or when new structural changes are being made.

Adjustable Props

Adjustable Props (commonly known as telescopic props or scaffolding props) are vertical supports used to hold up temporary or permanent structures. The key feature is their adjustability in height, allowing for precise leveling and load distribution across various site conditions.

Adjustable Span

Adjustable Span refers to extendable beams used to support shuttering plates, slabs, or walls during construction. The span length can be modified based on project requirements, making it a flexible and reusable solution for supporting horizontal formwork.

Whether you need Props in Greater Noida for high-rise developments or Span in Greater Noida for commercial slabs, JK Timber Mart offers reliable and durable products for all construction needs.

Key Features of Adjustable Props and Span

Strength and Load Capacity: Our Adjustable Props and Adjustable Span systems are manufactured using high-quality steel, ensuring superior strength and the ability to bear substantial loads without deformation.

Height and Length Adjustability: With easy-to-operate mechanisms, the adjustable props allow for fine-tuning of height, while adjustable spans can extend to accommodate varying widths, offering unmatched versatility on site.

Reusability: These components are designed for multiple uses across different projects, offering excellent value and reducing the need for one-time materials.

Easy Handling and Installation: Lightweight yet robust, our Props and Span in Greater Noida are easy to transport, position, and install, saving valuable time during construction.

Safety and Compliance: Our products comply with industry standards and safety requirements, ensuring reliable performance under demanding site conditions.

Applications of Adjustable Props and Span

Whether you’re building a residential complex, commercial tower, or industrial facility, Props and Span find widespread application:

Supporting formwork for slabs and beams

Holding up temporary ceilings and platforms

Creating safe working platforms

Reinforcing vertical structures during renovation

Used in scaffolding systems

No matter the size or complexity of your project, JK Timber Mart supplies the most dependable Construction Materials in Greater Noida for your structural needs.

Advantages of Using Adjustable Props and Span

Enhanced Flexibility: Adjustable Props and Adjustable Span can easily adapt to varying project demands. Whether you’re working on a small room or a large industrial site, the adjustability allows for efficient and accurate placement.

Cost Efficiency: Because our props and spans are reusable across many construction cycles, they offer long-term savings. Their durability reduces the need for constant replacements, helping contractors manage project costs effectively.

Improved Site Safety: When it comes to safety on construction sites, reliable support systems are non-negotiable. Our Props and Span in Greater Noida provide sturdy, stable backing for critical structural elements, ensuring that workers can operate in a safe environment.

Time-Saving Installation: Engineered for simplicity, our adjustable props and spans require minimal time for setup and dismantling, keeping projects on track and increasing overall productivity.

Why Choose JK Timber Mart for Props and Span in Greater Noida?

When it comes to sourcing Adjustable Props, Adjustable Span, and other Construction Materials in Greater Noida, JK Timber Mart is the name you can trust. Here’s why:

Comprehensive Product Range: We stock an extensive inventory of Props in Greater Noida and Span in Greater Noida, catering to various project scales and construction types.

Superior Quality: All our Adjustable Props and Adjustable Span products are manufactured to meet stringent quality standards. From materials to design, we ensure every product delivers lasting performance.

Competitive Pricing: At JK Timber Mart, we understand the importance of cost management in the construction business. That’s why we offer Props and Span in Greater Noida at Best Price — providing unbeatable value without compromising on quality.

Trusted Supplier: With years of experience and a strong reputation in the industry, we are known for reliability, timely delivery, and exceptional customer service.

Expert Guidance: Our knowledgeable team is always ready to assist you in selecting the right Adjustable Props and Adjustable Span for your specific project requirements.

Growing Demand for Props and Span in Greater Noida

Greater Noida is one of India’s fastest-growing construction hubs. With numerous residential, commercial, and industrial developments underway, the demand for high-quality Construction Materials in Greater Noida — including Props and Span — is rising steadily.

Builders and contractors understand that investing in superior props and spans from trusted suppliers like JK Timber Mart contributes directly to structural integrity, safety, and project success.

Export Opportunities

In addition to serving the domestic market, JK Timber Mart also supplies Adjustable Props and Adjustable Span to clients across India and international markets. Our commitment to quality, value, and service has made us a preferred choice for construction professionals beyond Greater Noida.

Whether you’re working on a residential complex, commercial building, or infrastructure project, having access to premium Props and Span is crucial. These adjustable components provide the essential support needed to complete formwork and structural processes safely and efficiently.

At JK Timber Mart, we take pride in offering the best Adjustable Props and Adjustable Span in Greater Noida at competitive prices. Our goal is to support your construction success by providing products that deliver on quality, strength, and performance — every time.

Ready to equip your site with top-quality Props and Span?

Contact JK Timber Mart today to explore our full range of Adjustable Props, Adjustable Span, and Construction Materials in Greater Noida — and get the best price for your project. Let us help you build with confidence! For more info:https://www.scaffoldingrental.co.in/Email ID:[email protected]:+91 9810790456Location: 143, Ecotech III, Greater Noida, 201306 Noida, Uttar Pradesh, (India)

#Props and Span#Props and Span in Greater Noida#Props in Greater Noida#Span in Greater Noida#Adjustable Props#Adjustable Span#Construction Materials Greater Noida

0 notes

Text

High-Precision Raft Formwork by TeamTech Formwork Solutions

TeamTech Formwork Solutions, Hyderabad, offers durable and adaptable raft formwork systems ideal for heavy foundation works in commercial & industrial projects. Designed to handle large concrete pours with precision, their formwork ensures uniform slab thickness, stability, and excellent surface finish.

TeamTech’s modular design simplifies installation, enhances safety, and minimizes labor costs — making it a smart choice for time-bound projects. Their high-quality materials ensure reusability and long-term performance on-site.

For efficient and reliable raft formwork systems, visit https://teamtechengg.com/.

0 notes

Text

Robust Slab Formwork System for Fast & Reliable Construction – Bii Formtek

Bii Formtek offers advanced slab formwork systems designed for strength, reusability, and quick installation. Ideal for residential, commercial, and infrastructure projects, our systems ensure smooth concrete finishes, high load-bearing capacity, and reduced labor time. Made from durable, corrosion-resistant materials, our modular slab formwork enhances efficiency and safety on every construction site.

Explore more: https://biiformtek.in/products/slab-formwork-system/

0 notes

Text

The Future of Construction: Slab Formwork Systems for Safer, Faster, and More Efficient Projects

In today’s fast-paced construction industry, achieving precision, safety, and cost-efficiency is paramount. This is where modern Slab Formwork Systems come into play. Whether you are building a high-rise skyscraper, a residential complex, or any other concrete structure, having the right formwork system can significantly impact the quality of the project and the safety of the workers involved.

At Bii Formtek, we specialize in advanced Slab Formwork Systems that are designed to make your construction processes smoother, faster, and more efficient. Our products, including the Slab Tableform System and Slab Edge Protection System, are engineered to meet the demands of modern construction while prioritizing worker safety and structural integrity.

What is a Slab Formwork System?

A Slab Formwork System is a temporary structure used to support wet concrete while it sets and hardens. It’s essential for forming the shape and strength of concrete slabs, which are a crucial component of any building’s structure. The formwork ensures the concrete is poured into the desired shape and gives it the strength needed to carry heavy loads once it hardens.

Our Slab Formwork Systems are designed to be sturdy, efficient, and easy to set up, minimizing downtime and reducing labor costs. The modular design allows for flexibility, making it suitable for a variety of projects, including large-scale construction.

The Benefits of the Slab Tableform System

The Slab Tableform System is an innovative solution that speeds up the process of slab construction. Traditional formwork systems can be cumbersome and time-consuming, requiring significant labor and material costs. The Slab Tableform System offers a game-changing approach to formwork by incorporating large, pre-assembled tables that can be easily moved into position for slab construction.

Key Advantages:

Faster Setup: The tableform system can be quickly assembled and moved, significantly reducing the time required for formwork setup.

Cost-Effective: By reducing labor costs and minimizing material waste, the Slab Tableform System helps lower the overall cost of the project.

Reusability: The system is designed for repeated use across multiple projects, offering excellent long-term value.

High Precision: With its modular design, the Slab Tableform System ensures high accuracy in the shape and dimension of the slab.

Why Choose a Slab Edge Protection System?

Safety is a critical concern on any construction site, especially when working with large-scale formwork. The Slab Edge Protection System is designed to ensure that workers remain safe from the dangers posed by unprotected slab edges. This system is a vital addition to any construction site, particularly for multi-story buildings where the risk of falls and accidents is elevated.

Key Benefits:

Worker Safety: The edge protection system acts as a barrier, reducing the risk of workers falling off the edge of slabs during construction.

Durability: Designed to withstand the harsh conditions of construction sites, the Slab Edge Protection System is made of high-quality materials that offer long-lasting performance.

Easy Installation: The system is easy to install and can be quickly adjusted to accommodate different slab dimensions.

Compliance with Safety Regulations: Our Slab Edge Protection System helps ensure your project complies with safety standards and regulations, protecting both workers and the overall site.

Why Choose Bii Formtek’s Slab Formwork Systems?

At Bii Formtek, we understand the challenges faced by construction professionals in the fast-paced world of modern construction. Our Slab Formwork Systems are engineered to meet the highest standards of safety, efficiency, and quality. We offer innovative solutions that help you reduce construction time, enhance worker safety, and improve the overall quality of your concrete structures.

With our comprehensive range of products, including the Slab Tableform System and the Slab Edge Protection System, we ensure that your projects are completed on time, within budget, and to the highest standards of safety and quality.

Conclusion

Investing in a high-quality Slab Formwork System is crucial for any construction project, large or small. The right system ensures faster construction, reduces costs, and, most importantly, keeps workers safe. At Bii Formtek, we provide state-of-the-art solutions like the Slab Tableform System and Slab Edge Protection System to help you achieve success in your construction endeavors. Explore our products today and take your construction projects to the next level!

0 notes

Video

youtube

Fixed Fork Head - Wellmade Scaffold, China - Slab and Beam Formwork Top ...

#youtube#fork head#fixed fork head#forkhead#slab shoring scaffold#shoring scaffold#shoring system#slabs#slab scaffolding#slab formwork#slab shuttering#beam formwork#formwork scaffolding#construction scaffolding#building scaffolding#formwork#wellmade scaffold

0 notes

Text

Top Shuttering Ply Manufacturer in Bihar – Quality You Can Trust by VeneerGanesh

When it comes to construction, the strength and reliability of your materials can make or break the project. One of the most critical components in any concrete formwork system is shuttering plywood. If you're looking for a trusted shuttering ply manufacturer in Bihar, look no further than VeneerGanesh – a name synonymous with quality and durability.

Why Shuttering Ply Matters in Construction

Shuttering plywood, also known as formwork ply, is used to mold concrete into desired shapes and hold it in place while it sets. This means it needs to be:

Strong enough to withstand the pressure of wet concrete

Water-resistant to handle high-moisture environments

Reusable, offering cost-efficiency over multiple cycles

Choosing the right shuttering ply ensures the safety, finish, and structural integrity of your building.

VeneerGanesh – Leaders in Shuttering Plywood in Bihar

VeneerGanesh has earned a reputation in Bihar and beyond for manufacturing high-grade shuttering ply manufacturers in bihar that meets the highest industry standards. Here’s what sets them apart:

✅ IS Standard Quality: Manufactured using premium hardwood and bonded with waterproof adhesives, ensuring high load-bearing capacity.

✅ Durability: Resistant to warping, swelling, and delamination – ideal for harsh construction conditions.

✅ Eco-Friendly Manufacturing: Committed to sustainable practices without compromising product strength.

✅ Customization: Available in different sizes and thicknesses to suit varied construction needs.

Applications of VeneerGanesh Shuttering Ply

Residential and commercial building construction

Infrastructure projects like bridges and highways

Columns, beams, and slab casting

Temporary structures and frameworks

Why Choose a Local Manufacturer?

Working with a local manufacturer like VeneerGanesh in Bihar offers multiple advantages:

Faster delivery and reduced logistics costs

Local customer service and technical support

Better understanding of regional construction challenges

Final Thoughts

Whether you're a builder, contractor, or supplier, VeneerGanesh is your go-to source for reliable shuttering ply in Bihar. With an unmatched combination of strength, durability, and affordability, they’re helping shape the infrastructure of tomorrow—one sheet at a time.

Visit:- https://www.ganeshveneer.com/shuttering-ply-bihar.php

0 notes

Text

Beat the Heat: How Plastic Formwork Speeds Up Summer Construction Projects

Summary

When heat from summer begins to slow down construction operations, plastic formwork comes as the ideal solution for speeding up, securing, and making concrete work more efficient. Unlike conventional materials, plastic formwork doesn’t succumb to high temperature, has stable curing conditions, and accelerates setup and stripping — which is perfect for slab construction and beam slab formwork in Hyderabad’s scorching heat. It’s reusable, economical, and minimizes curing delays, making it an intelligent option for time-critical jobs in June. Reliable manufacturers such as Navnirman are at the forefront with formwork systems that are built to meet summer’s greatest challenges, keeping workers cool and projects on schedule.

When the Sun is Blazing Hot

When the sun is blazing hot and the temperatures are over 40°C, Indian building sites—particularly in the city of Hyderabad—are akin to working in a huge oven. Concrete operations become sluggish, materials dry out way too quickly, and the workers tire out much sooner. But suppose there was a cleverer, cooler method of carrying out slab operations, beam slab formwork in Hyderabad, and other concrete operations without buckets of perspiration dripping off. There is — and it’s plastic formwork.

Let’s dive into how this new construction superhero is gaining traction (or should I state, cooling down) in the world of construction and why it’s perfect for quick turnaround construction on those scorching June afternoons.

Why Plastic Formwork is a Summer Game-Changer

So why is plastic formwork so important? For starters, it’s light, reusable, and heat-resistant — a trifecta of advantages that make it perfect for summer building. Old-school construction formwork, like metal or wood, soaks up heat and transfers it to the concrete, speeding up evaporation and interfering with curing cycles. Not a good thing for any project that demands crack-resistant, durable concrete.

Plastic formwork, on the other hand, is heat-resistant by nature. It won’t absorb the heat, as metal does, or warp and splinter, as wood does. Instead, it offers a smooth, cool climate for the concrete to cure at the ideal rate. The benefit? Less downtime, less rework, and concrete work that is still gorgeous even when the weather isn’t.

Quicker Installation, Smaller Crews

But yet another reason why contractors are going head over heels about plastic formwork is its speed of installation and deinstallation. Anybody who has ever worked with beam slab formwork will tell you that in Hyderabad’s hot summers, for every minute you save, you’re grateful. The longer you stand under the sun, the tougher it becomes — not so much on your deadline, but on your workers’ health.

With plastic formwork, you can quickly assemble it. The panels are lightweight and designed for fast-lock systems, so you can install and take them down without heavy machinery or specialty tools. It’s a huge time-saver, and when you’ve got a clock to beat (and a temperature gauge, too), that’s time worth its weight in gold.

Even better, the panels can be used dozens of times without ever losing shape or effectiveness. No warping, no cracking, no annoying maintenance. Just clean them off and get them ready for the next pour. For concrete work jobs with tight schedules, this means less downtime and more production — exactly what you need in mid-June.

Ideal for Slab and Beam Construction in the Hottest Cities

Summer headaches are accompanied by slab construction and beam slab formwork in Hyderabad too. Premature drying of the top surface of the concrete because of high temperatures causes cracking and reduced durability. Not exactly what you would like in a building that’s supposed to stand the test of time for decades.

This is where plastic formwork construction really shines. Its heat resistance provides an even curing environment, which prevents those unsightly surface cracks and keeps your slab construction on schedule. And since plastic won’t absorb water, there’s less chance of evaporation of moisture from the concrete, which will set evenly across the board.

If you’ve ever had to delay a project because the concrete hardened too fast in the sunlight of noon, you’ll love how much plastic formwork eases your life. It’s literally a sunshade for your concrete work — a minor tweak that makes a gigantic difference.

Not Only Heat-Resistant — It’s Cost-Effective Too

Face it: summer construction usually equals added expense. From curing water to added labor and protective equipment, expenses add up quickly. But with plastic formwork, you can cut a lot of those extras.

Since plastic formwork panels can be used repeatedly without weakening, your initial investment will pay for itself in no time. Less repair, less replacement, and faster cycles mean more on-schedule projects, even in the hot month of June. It’s a cost-effective solution for small builders and large developers.

And when you’re building public structures or residential complexes in a city like Hyderabad, being able to stick to your budget without any cuts on safety or quality is a huge win.

Where to Find the Best Plastic Formwork for Summer Projects

If you’re considering using plastic formwork for your summer construction project next summer, you’re certainly not alone. More and more builders are switching to plastic formwork, and one of the producers you can rely on is Navnirman. Renowned for robust, easy-to-use, and thermally efficient formwork for construction, Navnirman systems are built to withstand India’s sweltering summers.

Whether it’s a residential building, commercial complex, or large public work project, their concrete formwork solutions help construction crews outsmart the heat while improving safety, speed, and end-concrete quality.

Conclusion: Stay Cool, Build Smart

Summer construction doesn’t have to mean a sweltering, stressful fight against the clock. With intelligent decisions such as plastic formwork, you can work quicker, safer, and more economically — even when the mercury rises. It’s all about keeping your workers cool, your concrete content, and your jobs rolling. If you’re having a beam slab formwork coming to Hyderabad or a hard slab pour in June, you should probably opt for plastic formwork. You’ll wonder how you ever built it without it.

0 notes