#SmartMaintenance

Explore tagged Tumblr posts

Text

#cmms software#innomaint#maintenance management software#maintenancemanagement#digitaltransformation#smartfactory#smartmaintenance#industrialautomation#iiot#iotformanufacturing#predictivemaintenance#digitaltwin

0 notes

Text

#GreaseSelection#EquipmentCare#LubricationTips#IndustrialMaintenance#ClimaxGrease#MachineHealth#HeavyDutyGrease#LubricantGuide#MachineryCare#GreaseCompatibility#NextOilSolutions#GreaseMatters#EquipmentLife#MaintenanceTips#IndustrialGrease#LubricationMatters#SmartMaintenance#GreaseGuide#OilAndGrease#RightGreaseChoice#oilfieldequipment

0 notes

Text

Beyond Algorithms: Building Smarter Industrial AI with Engineering Insight

In the race to adopt Artificial Intelligence, industries often fall into the trap of thinking that AI equals algorithms. But as Professor Jay Lee reminds us, in his book Industrial AI, AI is fundamentally a cognitive science—one that must involve reasoning, learning, perception, and problem-solving. This distinction matters deeply in industrial settings, where false alarms, misdiagnoses, and…

0 notes

Text

Eyes in the Sky, Power from the River

Where technology meets nature for a cleaner tomorrow.

The river had long since changed its course, leaving behind a wide, cracked bed where nothing grew—until the panels came. Now, that forgotten riverbed pulses with power, lined with solar arrays soaking up the sun.

Ava stood at the edge of the site, tablet in hand, as her drone rose smoothly into the sky. She wasn’t just launching a machine—she was launching a mission. Every flight was part of a smarter way forward: Solar Drone Inspection.

Once upon a time, people walked these rows, searching for damaged cells and faulty connections under a scorching sun. But the drone? It flew over in minutes, capturing heat signatures, spotting inefficiencies, and reporting back with perfect precision.

Today, it flagged a panel running hot—something invisible to the naked eye. Ava logged it with a tap, already planning the fix. No ladders, no downtime, no guesswork. Just clean, intelligent action.

As the drone circled back and the riverbed shimmered beneath her, Ava smiled. This wasn’t just technology—it was stewardship. And the river, though quiet now, had found a new way to flow—into the grid, into the future.

#dronetech#droneinspection#solardroneinspection#solarrevolution#SmartMaintenance#SustainableFuture#RiverbedRenewables

0 notes

Text

Say goodbye to unexpected breakdowns! Infrared and AI-powered predictive maintenance is changing how industries stay ahead. Smarter insights, faster action, and reliable performance—this is the future of maintenance.

0 notes

Text

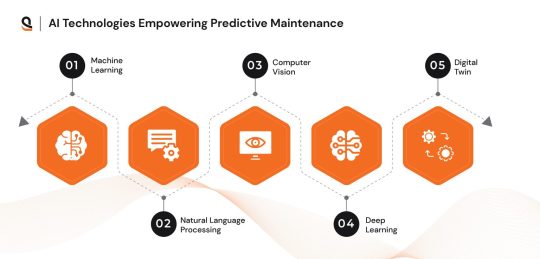

AI is making predictive maintenance smarter and more efficient than ever! Technologies like Machine Learning, NLP, Computer Vision, Deep Learning, and Digital Twin work together to analyze data, spot potential issues early, and prevent costly breakdowns. This means businesses can reduce downtime, cut maintenance costs, and keep operations running smoothly.

At AQe Digital, we help companies embrace AI and cloud solutions to drive innovation and long-term growth. By leveraging advanced tech, we empower businesses to stay ahead in a fast-evolving world. 🌍⚙️

Let me know if you want any tweaks! 🚀👉 www.aqedigital.com

#AI#PredictiveMaintenance#AIPowered#MachineLearning#DeepLearning#DigitalTwin#SmartMaintenance#Innovation#CloudSolutions#BusinessGrowth#TechForGood#Efficiency#Automation#Industry40#FutureOfWork#AIDriven#TechInnovation#ManufacturingTech#SmartBusiness

0 notes

Text

Condition-Based Maintenance: How It Works & Why It Matters

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

0 notes

Text

Effective maintenance key performance indicators tracking and analysis are fundamental for long-term success in maintenance management. These maintenance KPIs yield important insights about your maintenance operations, thereby showing you areas of inefficiency, unplanned downtime, and reduced equipment reliability. With contemporary tools such as a computerized maintenance management system or preventive maintenance software, facility managers can track the maintenance KPIs in real time, thus ensuring optimal allocation of resources and measurable progress.

Innomaint - Pinnacle Infotech Product Elcot IT Park, Plot No 5,6,7 & 8 Near Madurai Kamaraj University Vadapalanji, Madurai, Tamil Nadu – 625021 innomaint.com +917539978399

#MaintenanceKPI#FacilityManagement#CMMS#AssetManagement#MaintenanceStrategy#PlannedMaintenance#PreventiveMaintenance#PredictiveMaintenance#MaintenanceMatters#SmartMaintenance#DataDrivenMaintenance#OperationalExcellence#MaintenanceMetrics#MaintenancePerformance#MaintenanceAnalytics#AssetPerformance#EquipmentEfficiency#OEE#DowntimeReduction#EfficiencyMetrics#FacilitiesManagement#MaintenanceManagers#FacilityOps#BusinessContinuity#MaintenanceROI#CostEfficiency#FacilityProductivity#MaintenanceInnovation#MaintenanceGoals#WorkOrderTracking

0 notes

Text

CMMS enhances safety and risk management with preventive maintenance, real-time monitoring, and compliance tracking for a secure and efficient workplace.

For more details read our blog:

#safetysoftware#riskmanagementtools#riskmanagementsolutions#riskmanagementstrategies#smartmaintenance#cmms#cmmssoftware#cmmsmaintenance#safetyatworkplace#safetyinformation#riskanalysissoftware#industrialsafety#machinesafety#cmmsfeatures

0 notes

Text

Predictive maintenance powered by AI is revolutionizing how businesses approach equipment upkeep. By analyzing data in real-time, AI can predict potential failures before they happen, saving companies both time and money. Instead of relying on scheduled maintenance or waiting for a breakdown, AI-driven insights ensure that machinery is serviced exactly when needed. This not only reduces downtime but also extends the lifespan of critical assets. Embrace AI in predictive maintenance to maximize efficiency and maintain a competitive edge in today's fast-paced world.

Read more:

#AIPredictiveMaintenance#SmartMaintenance#Industry4#Innovation#TechSolutions#FutureOfWork#BusinessEfficiency

0 notes

Text

Drones for Solar Panel Inspection: The Game-Changer in Solar Farm Maintenance

Manual inspections and SCADA systems are no longer enough for maintaining modern solar farms. Enter drones for solar panel inspection—an innovative solution that’s speeding up inspections, reducing costs, and improving accuracy across the U.S.

Traditional systems might detect performance drops, but they fail to pinpoint the exact problem. Drones equipped with thermal cameras and AI analytics can scan thousands of panels in just hours, identifying micro-cracks, hotspots, and underperforming panels that would otherwise go unnoticed.

In extreme environments like the Mojave Desert, drone technology has proven invaluable. Clearspot.ai, for instance, helped a Nevada solar farm cut inspection time by 80% while reducing energy loss—thanks to fast, real-time fault detection.

More than just aerial imaging, Clearspot.ai’s platform transforms drone footage into actionable insights. This means faster maintenance, smarter servicing, and improved ROI. As the solar industry scales, drone inspections are not just a trend—they’re the new standard.

🚀 Let your solar maintenance take flight. Schedule an inspection with Clearspot.ai and unlock the full potential of your solar investment.

0 notes

Text

Wind Turbine Engine Failure Prediction - Innodatatics

By using cutting-edge machine learning algorithms and real-time data analytics, a wind turbine engine failure prediction model can predict potential engine problems, improving maintenance effectiveness and decreasing downtime. The model identifies wear and anomalies that precede mechanical issues by combining sensor data—such as vibration, temperature, and rotational speed—with historical maintenance records and environmental variables.

#WindEnergy#PredictiveMaintenance#RenewableTech#DataAnalytics#GreenTech#WindPower#Sustainability#AIinEnergy#EngineFailurePrediction#SmartMaintenance#Wind Turbine Failure Prediction#Wind Turbine Breakdown Prediction Model#Wind Turbine Failure Prediction Model Innodatatics#Innodatatics

0 notes

Text

Cathodic Protection Market Growth to $13.81B by 2034

Cathodic Protection Market is on a growth trajectory, projected to expand from $9.8 billion in 2024 to $13.81 billion by 2034, growing at a CAGR of 3.5%. As industries strive to protect critical infrastructure and extend asset lifespans, cathodic protection has become more essential than ever.This market revolves around electrochemical methods used to prevent corrosion in pipelines, marine structures, storage tanks, and more. Key technologies include sacrificial anodes, impressed current systems, and hybrid systems, supported by advanced monitoring and maintenance services.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS22552 &utm_source=SnehaPatil&utm_medium=Article

🔧 The oil & gas sector dominates the market, using cathodic protection to secure vast pipeline networks and offshore platforms. 🌊 The water and wastewater industry follows, driven by infrastructure upgrades and water quality mandates. 🌎 Regionally, North America leads with aging infrastructure demanding protection, while Asia-Pacific surges ahead due to rapid industrialization — particularly in China and India.

In 2024, the market volume hit 320 million units, with sacrificial anode systems claiming the largest share (45%), followed by impressed current systems at 35%. Hybrid systems are gaining popularity for their flexibility and cost efficiency.

Top players in the market are focusing on smart monitoring, energy-efficient rectifiers, and remote diagnostics, making corrosion prevention smarter and more sustainable.

💡 As infrastructure ages and environmental regulations tighten, cathodic protection is more than a necessity — it’s a strategic investment in resilience and safety.

#cathodicprotection #corrosioncontrol #pipelineintegrity #marineengineering #oilandgasindustry #infrastructureprotection #assetmanagement #waterinfrastructure #smartmonitoring #industrialsolutions #corrosionengineering #sacrificialanode #impressedcurrent #hybridsystems #energyinfrastructure #subseatechnology #steelprotection #offshoremaintenance #urbaninfrastructure #industrialcoatings #structuralresilience #infrastructuremaintenance #remoteinspections #watertreatmenttech #metalinfrastructure #smartmaintenance #powertransmission #corrosionresistance #technologicalinnovation #smartinfrastructure #anodetechnology #oilfieldservices #sustainablesolutions #industrialresilience #publicsafetytech #aginginfrastructure #constructiontech #environmentalsolutions #coatingsindustry #digitalinspection

Research Scope:

· Estimates and forecast the overall market size for the total market, across type, application, and region

· Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

· Identify factors influencing market growth and challenges, opportunities, drivers, and restraints

· Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

· Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Losses Aren’t Just Numbers.

They’re the Hidden Language of Pumping Systems.

Most engineers classify head losses—whether static, friction, or velocity—as simple design constants. But in critical water systems, losses are more than numbers; they’re real-time indicators of system performance, efficiency shifts, and potential operational risks.

Let’s redefine how we interpret losses.

◾ Static Head: Often viewed as stable, yet in systems with variable tank levels or tidal influence, this "stability" can mask dynamic shifts—altering pressure distribution over time.

◾ Friction Losses: They rarely stay constant. Internal scaling, sediment buildup, or even biofilm accumulation can lead to creeping inefficiencies that go unnoticed.

◾ Velocity Head: Commonly neglected. In undersized systems or poorly balanced loops, even modest velocity surges can drastically elevate energy costs.

Here’s the deeper insight:

When the differential pressure (ΔP) across a pump increases without an increase in flow, that’s not coincidence—it’s a message.

◾ Early-stage internal fouling?

◾ Progressive valve degradation?

◾ Partial blockages?

All of these create hidden head losses that slowly erode efficiency and reliability—unless they’re actively monitored.

Field example:

In a coastal supply network, engineers observed a gradual 12% rise in differential pressure over several months—with stable flow conditions.

There was no direct alert, but historical trend data indicated a growing anomaly.

Upon inspection, biofilm buildup in an upstream pipeline segment was discovered—still in its early stage.

Timely intervention prevented further escalation and avoided service interruptions.

🔷️Recommended practice for professionals:

🔹️Log baseline ΔP readings during commissioning

🔹️Analyze long-term pressure trends, not just real-time values

🔹️ Utilize differential pressure sensors across key segments

🔹️ Integrate with system-level monitoring (e.g., SCADA or data acquisition platforms) to catch early drifts

🔹️View every head loss as a signal—not just a design number

✅ In advanced systems, head losses are not margins to tolerate.

They are silent indicators that, when understood, become powerful tools for decision-making.

#AdvancedPumps #HydraulicLosses #Sustainability #PressureMonitoring #SmartWaterSystems #EnergyEfficiency #DigitalTwin #MechanicalEngineering #PumpingSolutions #SmartMaintenance #WaterIndustry #WaterTechnology #PumpDiagnostics #Engineering #EngineeringLeadership #ProcessOptimization

0 notes

Text

AI is Taking Off! Aviation Market to Soar to $22.1B by 2034 ✈️

AI in Aviation Market is revolutionizing the industry by integrating machine learning, predictive analytics, and automation to enhance operational efficiency, safety, and passenger experience. AI-driven solutions optimize predictive maintenance, air traffic management, and autonomous aircraft systems, reducing costs and improving decision-making.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS33001 &utm_source=SnehaPatil&utm_medium=Article

The market is experiencing strong growth, with the autonomous aircraft segment leading at 45% market share, fueled by advancements in drone technology and pilotless aircraft systems. Predictive maintenance holds 30%, ensuring reduced downtime and cost-efficient operations. Flight operations optimization, at 25%, enhances fuel efficiency and environmental sustainability.

North America dominates AI adoption in aviation, supported by aerospace innovation and regulatory advancements. Europe follows, focusing on sustainability and compliance, while Asia-Pacific emerges as a fast-growing region, driven by expanding commercial aviation markets and AI-supportive government initiatives.

By 2028, the market is projected to expand beyond $10 billion, with major players like Boeing, Airbus, and Lockheed Martin investing heavily in AI-driven innovations. Regulatory bodies like the FAA and EASA shape the landscape, ensuring safe AI adoption while addressing cybersecurity challenges.

#ai #aviation #machinelearning #predictivemaintenance #autonomousaircraft #airtrafficmanagement #computervision #deeplearning #unsupervisedlearning #reinforcementlearning #neuralnetworks #airlines #drones #smartaviation #flightoptimization #cybersecurity #cloudcomputing #airports #automation #aircraftmaintenance #digitalaviation #pilotlessaircraft #airlinesafety #dataanalytics #aviationtechnology #airtransport #bigdata #avionics #intelligentautomation #iot #smartmaintenance #cloudai #aircraftsystems #passengerexperience #aviationregulations #smartairports #aviationsecurity #aircraftrouting #fueloptimization #industry40 #aviationinnovation

Would you like any refinements or additional insights?

0 notes

Text

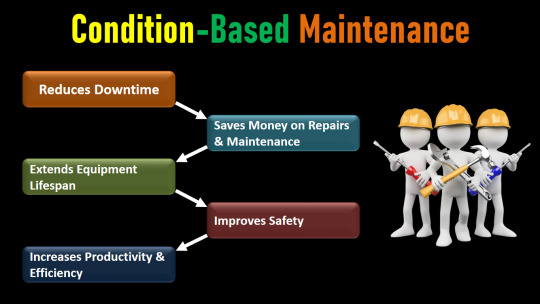

Condition-Based Maintenance: How It Works & Why It Matters

Imagine if your car could tell you exactly when it needs an oil change rather than following a fixed schedule. Instead of guessing or changing the oil too early, you’d only do it when it’s actually necessary, saving time and money while keeping your engine in top shape. That’s the core idea behind Condition-Based Maintenance (CBM) in industries.

CBM is a smart maintenance strategy that monitors the real-time condition of machines and equipment. Instead of performing maintenance on a fixed schedule (like every three months), CBM uses sensors and data analysis to determine when maintenance is truly needed. This approach helps prevent unnecessary servicing while avoiding unexpected breakdowns.

➥ How Does Condition-Based Maintenance Work?

CBM relies on real-time monitoring and data-driven decision-making. Here’s a simple breakdown of how it works:

✅ 1. Sensors Collect Real-Time Data

Machines are equipped with sensors that track critical performance indicators such as:

Temperature – Helps detect overheating issues.

Vibration – Identifies misalignments or wear in rotating equipment.

Pressure Levels – Ensures pumps, compressors, and hydraulic systems are working properly.

Oil Quality – Measures contamination or degradation in lubricants.

✅ 2. Data Is Analyzed to Detect Problems

The collected sensor data is continuously monitored and compared to normal operating conditions. If the system detects unusual behavior, like excessive vibration or rising temperature, it signals a potential issue.

For example, if a motor starts vibrating abnormally, it could indicate a misalignment, loose parts, or an upcoming failure. Maintenance teams receive an alert, allowing them to inspect and fix the issue before the motor breaks down.

✅ 3. Maintenance Is Performed When Needed

Instead of following a fixed maintenance schedule (which can either be too frequent or too late), CBM ensures maintenance is done only when the data suggests it's necessary. This reduces unnecessary downtime and repair costs while keeping machines running efficiently.

Read in detail: https://www.knowledgewale.com/2025/03/condition-based-maintenance.html

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

1 note

·

View note