#Steel Structures

Explore tagged Tumblr posts

Text

#peb structures#peb manufacturers in maharashtra#peb manufacturers in india#pre engineered building manufacturers in india#peb building manufacturers in india#peb suppliers#prefab company in india#peb manufacturing companies#top peb manufacturers in india#top peb company in india#peb factory#pre building#pre engineered buildings#peb building#pre eng building#peb company#peb vendors#peb suppliers in india#prefab manufacturing#pre engineering building company in india#steel structures#peb engineering building#pre engineered building structures#peb engineering#peb steel structures#peb manufacturers near me#pre engineered structures#peb fabricators#peb steel buildings#peb manufacturers

1 note

·

View note

Text

Steel Structures & Metal Buildings (SSMB) Magazine - Advancing Steel Construction in India SSMB is India's premier magazine promoting steel in construction, offering insights, trends, and technical advancements. Reach 50,000+ professionals and boost your brand in the fast-growing steel construction sector.

#Steel Structures#Metal Buildings#SSMB Magazine#Indian construction#steel construction#Build with Steel#industry trends#construction magazine#steel industry India

0 notes

Text

Why Are Steel Structures the Future of Construction? Find Out Now!

Explore why steel structures are rapidly gaining popularity in modern construction. From durability and design flexibility to eco-friendliness and cost-effectiveness, discover how steel is transforming the future of building across industries in Saudi Arabia and beyond. Learn more about innovative trends, benefits, and expert insights driving the shift to steel today.

1 note

·

View note

Video

youtube

💪FIXDEX & GOODFIX steel structure connectors, high strength and rust-proof, a must-have for construction sites!

read more fastener product please visit our website :

Email: [email protected]

Web: www.fixdex.com

#youtube#Steel structure#steel buildings#steel buildings for sale#steel beam#general steel buildings#steel structures#steel structure buildings#steel building manufacturers#steel beam prices#steel construction#high quality steel structures#steel structures for sale#large steel building#solar bracket#solar panel brackets#solar panel mounting brackets#solar panel roof mounts#solar panel mounts#solar mounting brackets#solar panel fixing brackets#solar z brackets

0 notes

Text

Wire Binding: The Essential Guide to Strengthening Construction Projects

Wire Binding Fundamentals

Wire binding techniques have revolutionized modern construction, creating stronger, more reliable structures through precise reinforcement methods. When construction professionals understand how binding wire and construction rings work together, they can significantly enhance structural integrity while improving project efficiency.

Understanding Wire Binding Fundamentals

The relationship between binding wire and construction rings creates the foundation for reliable structural reinforcement. This connection system allows construction teams to secure reinforcement bars, mesh, and other critical components firmly in place during concrete pouring and throughout a structure's lifetime.

Types of Binding Wire

Several varieties of binding wire serve different construction needs:

Black Annealed Wire

Offers excellent malleability for easy tying

Provides strong rust resistance

Maintains consistent strength across temperature variations

Galvanized Wire

Features enhanced corrosion protection

Ideal for exposed structural elements

Ensures longer-lasting connections

Stainless Steel Wire

Delivers maximum durability in harsh environments

Resists chemical degradation

Perfect for specialized construction projects

Construction Rings: Key Components

Construction rings play a vital role in reinforcement systems by:

Creating secure attachment points

Maintaining proper spacing between components

Ensuring even distribution of structural loads

Facilitating faster installation processes

Integration of Components

The effectiveness of wire binding depends heavily on proper integration with construction rings. This combination creates a robust system that:

Prevents displacement during concrete pouring

Maintains structural integrity over time

Reduces installation time and labor costs

Ensures consistent spacing and alignment

Best Practices for Implementation

Successful wire binding requires attention to several key factors:

Proper Tensioning

Apply consistent pressure during installation

Avoid over-tightening that could stress materials

Ensure uniform tension across all connection points

Material Compatibility

When selecting binding wire and construction rings, consider:

Environmental exposure levels

Load-bearing requirements

Project-specific regulations

Long-term maintenance needs

Installation Techniques

Follow manufacturer specifications

Use appropriate tools and methods

Maintain consistent spacing

Verify secure connections

Quality Control Measures

Regular inspection of wire binding installations should check for:

Proper tension maintenance

Uniform spacing between construction rings

Signs of material stress or fatigue

Compliance with project specifications

Safety Considerations

Proper implementation of wire binding techniques ensures:

Structural stability during construction

Long-term durability of finished structures

Worker safety during installation

Compliance with building codes

Cost-Efficiency Factors

While quality materials may cost more initially, proper wire binding implementation offers long-term benefits:

Reduced maintenance requirements

Lower repair costs

Extended structure lifespan

Improved project reliability

Future Trends

The wire binding industry continues to evolve with:

Advanced material development

Improved installation techniques

Enhanced durability solutions

Innovative construction rings designs

Selection Criteria

When choosing materials for wire binding projects, consider:

Project requirements and specifications

Environmental conditions

Load-bearing needs

Budget constraints

Installation timeline

Making Informed Decisions

Successful construction projects rely on selecting the right combination of binding wire and construction rings. Consider these factors when making material choices:

Project scope and requirements

Environmental exposure levels

Budget limitations

Installation timeline

Maintenance expectations

The proper implementation of wire binding techniques, combined with quality construction rings, creates stronger, more reliable structures. By understanding these essential components and their interaction, construction professionals can ensure project success while maintaining efficiency and cost-effectiveness.

Industry Standards and Certification

Adherence to industry standards plays a vital role in wire binding applications. Professional construction projects require materials that meet specific certification requirements, ensuring safety and reliability. Leading manufacturers provide detailed specifications for both binding wire and construction rings, including tensile strength ratings, corrosion resistance levels, and load-bearing capacities. These standards not only guarantee quality but also provide construction teams with clear guidelines for material selection and installation procedures. Regular testing and certification updates help maintain high-quality standards across the construction industry, ensuring that wire binding solutions continue to meet evolving building requirements and safety regulations.

#wire binding#binding wire#construction rings#steel reinforcement#wire ties#rebar binding#structural support#concrete strength#building stability#construction tools#durable binding#secure fastening#wire loops#mesh reinforcement#steel structures#rebar ties#construction safety#industrial binding#load-bearing support#construction materials

0 notes

Text

Glenn Salamone and QSR Steel Corp: Redefining Steel Role in Modern Building

Glenn Salamone leadership at QSR Steel Corp is redefining how steel structures are integrated into modern construction projects for durability and flexibility.

0 notes

Text

Construction Company in Toronto- Crystal Constructions

Steel buildings in Canada are now viewed as a representation of resilience, creativity, and versatility. Crystal Concrete, a top construction company in Canada, focuses on building strong steel structures that adhere to the highest standards of quality and effectiveness. Steel buildings in Canada, whether they are tall skyscrapers or large warehouses, are well-known for their strength, versatility in design, and affordability.

Steel structures are built with structural steel elements, offering superior strength and durability. In contrast to conventional materials such as wood or brick, steel provides a superior strength-to-weight ratio, boosting structural integrity and decreasing required materials. This feature makes steel buildings in Canada perfect for regions susceptible to severe weather and seismic events, guaranteeing durability. The versatility in design is one of the most appealing aspects of steel buildings. The capability to design expansive, column-free interiors provides more flexibility in architectural design. Steel buildings in Canada can be customized to fulfill various functional needs, whether it is for a modern office building, retail space, or industrial facility. At Crystal Concrete, a reputable construction company in Toronto, we work closely with architects and engineers to turn creative designs into reality with accuracy.

The construction efficiency of steel buildings in Canada is unrivaled, along with their design flexibility. Pre-fabricated steel parts are made away from the construction site and transported to the site, leading to decreased on-site work and a significant reduction in construction time. This efficient method is a major benefit for developers looking to finish projects more quickly and see a faster return on investment. Crystal Concrete, a top construction company in Toronto, guarantees efficient erection of steel buildings with no compromise on quality.

Choosing steel is a responsible environmental decision as well. Much of the steel used in modern construction comes from recycled materials, making it completely recyclable. This sustainability, combined with the long-term durability of steel, makes it a smart choice for eco-conscious developers looking to minimize environmental impact. For a reliable construction company in Canada that specializes in innovative, sustainable steel buildings, Crystal Concrete is your go-to partner.

#Steel buildings in Canada#Crystal Concrete#construction company in Canada#steel buildings#Steel structures

0 notes

Text

6 Major Benefits Of Pre-Engineered Metal Buildings In 2024

Pre-engineered metal buildings (PEBs) are revolutionizing the construction industry, offering a dynamic solution that aligns with modern demands. These structures consist of solid, sustainable materials and are composed of steel beams, columns, roofs, and wall panels that are pre-designed and pre-engineered.

Let's dive into the major benefits of pre-engineered metal buildings.

1. Time-Saving

Traditional construction methods are often time-consuming, plagued by delays due to various factors like sourcing materials from different vendors, labor shortages, transportation issues, and adverse weather conditions. In contrast, pre-engineered metal buildings significantly reduce construction time. Once the requirements are gathered, all involved teams work in synchronization to ensure timely and quality deliverance. This efficiency can cut construction time by almost half compared to conventional methods.

2. Cost-Effective

PEB buildings are cost-effective due to their customizable nature and ease of transportation. Many parts can be recycled, which not only saves money but also reduces waste. The assembly process is straightforward, and once the structure is erected, it requires less maintenance than traditional buildings. This cost efficiency allows building owners to expand their market presence without incurring excessive expenses.

3. Fast Construction

For projects that demand quick and efficient completion, pre-engineered buildings are an ideal choice. Their simple implementation process makes them perfect for producing fast results. These structures are commonly used for warehouses, industrial sheds, factory buildings, cold storage, and industrial enclosures.

4. Easy to Adapt

PEB structures offer a high degree of adaptability and are multipurpose. Whether it's a small warehouse or a large manufacturing unit, there's a pre-engineered solution available. Their adaptability makes them a superior alternative to conventional buildings, capable of meeting diverse needs with ease.

5. Profitability

Pre-engineered building manufacturers use high-quality, recyclable materials. If you need to relocate, you can simply dismantle the structure, transport it, and reassemble it at the new site. This eliminates the need for demolition or selling the building based on land value, making PEBs a profitable investment with minimal extra costs compared to conventional structures.

6. Market Growth and Forecast

The demand for PEB structures is expected to grow due to their eco-friendly approach and various advantages. Pre-engineered metal building manufacturers provide comprehensive support, helping clients expand their operations efficiently. Investments in PEB structures offer mobility and flexibility, which can give businesses a competitive edge. The expansion of SEZs, new airports, and cold storage chains further boosts the popularity of PEB structures.

If you’re looking for high-quality pre-engineered metal buildings, EPACK Prefab is a reliable choice. As a leading manufacturer, EPACK Prefab combines precision and passion to deliver outstanding PEB construction. Choose EPACK Prefab for your next project and experience the unparalleled benefits of pre-engineered metal buildings.

Also Read: Pre Engineered Buildings: Components And Advantages

#Pre-Engineered Buildings#PEB#Metal Buildings#Construction Innovation#Sustainable Construction#Building Solutions#Steel Structures#Fast Construction#Cost-Effective Building#Building Adaptability#Eco-Friendly Buildings#Industrial Construction#Warehouse Design#Prefab Construction#EPACK Prefab#Building Efficiency#Modern Construction#Construction Trends#Building Benefits

2 notes

·

View notes

Text

In today's dynamic economic landscape, staying informed about the steel price per kg is essential for various stakeholders, including manufacturers, construction firms, and investors. Understanding the TMT steel price per kg today in India, in particular, holds significant relevance due to the nation's robust industrial and infrastructural activities. Let's delve into the intricacies of steel pricing, factors influencing fluctuations, and the current scenario in the Indian market.

Analyzing Steel Prices: A Comprehensive Overview

Steel, being a vital raw material across multiple industries, experiences fluctuations influenced by diverse factors. From global economic conditions to local market dynamics, various elements contribute to the price of steel per kg. Understanding these factors empowers businesses to make informed decisions and adapt to market changes efficiently.

Global Economic Trends Impacting Steel Prices: The global economy plays a pivotal role in determining steel prices. Economic indicators such as GDP growth rates, industrial output, and trade policies directly influence demand and supply dynamics, thereby affecting steel prices. Additionally, geopolitical tensions, currency fluctuations, and international trade agreements exert significant influence on global steel pricing trends.

Regional Market Dynamics in India: In the context of India, a burgeoning economy with a thriving manufacturing and construction sector, steel prices are subject to both domestic and international factors. Rapid urbanization, infrastructural development projects, and government initiatives such as "Make in India" drive steel demand, thus impacting prices. Moreover, regulatory policies, taxation, and raw material availability contribute to the TMT steel price per kg variation across different regions within India.

Factors Influencing Steel Price Fluctuations

Understanding the underlying factors driving fluctuations in steel prices provides valuable insights for businesses and investors. Several key determinants contribute to the volatility observed in steel pricing dynamics:

Read more

0 notes

Text

#apocalyptic#industrial ruins#dystopian#surreal#Asian children#futuristic decay#desolate landscape#tangled wires#steel structures#overcast sky#mountain backdrop#floral foreground#urban decay#mechanical wreckage#dramatic scenery#outdoor#detailed textures#ai#ai generated#ai generated images#ai image#rooftop#rooftop garden#slums#chamomile

1 note

·

View note

Text

SSMB is India's premier magazine promoting steel in construction, offering insights, trends, and technical advancements. Reach 50,000+ professionals and boost your brand in the fast-growing steel construction sector.

#Steel Structures#Metal Buildings#SSMB Magazine#Indian construction#steel construction#Build with Steel#industry trends#construction magazine#steel industry India

0 notes

Text

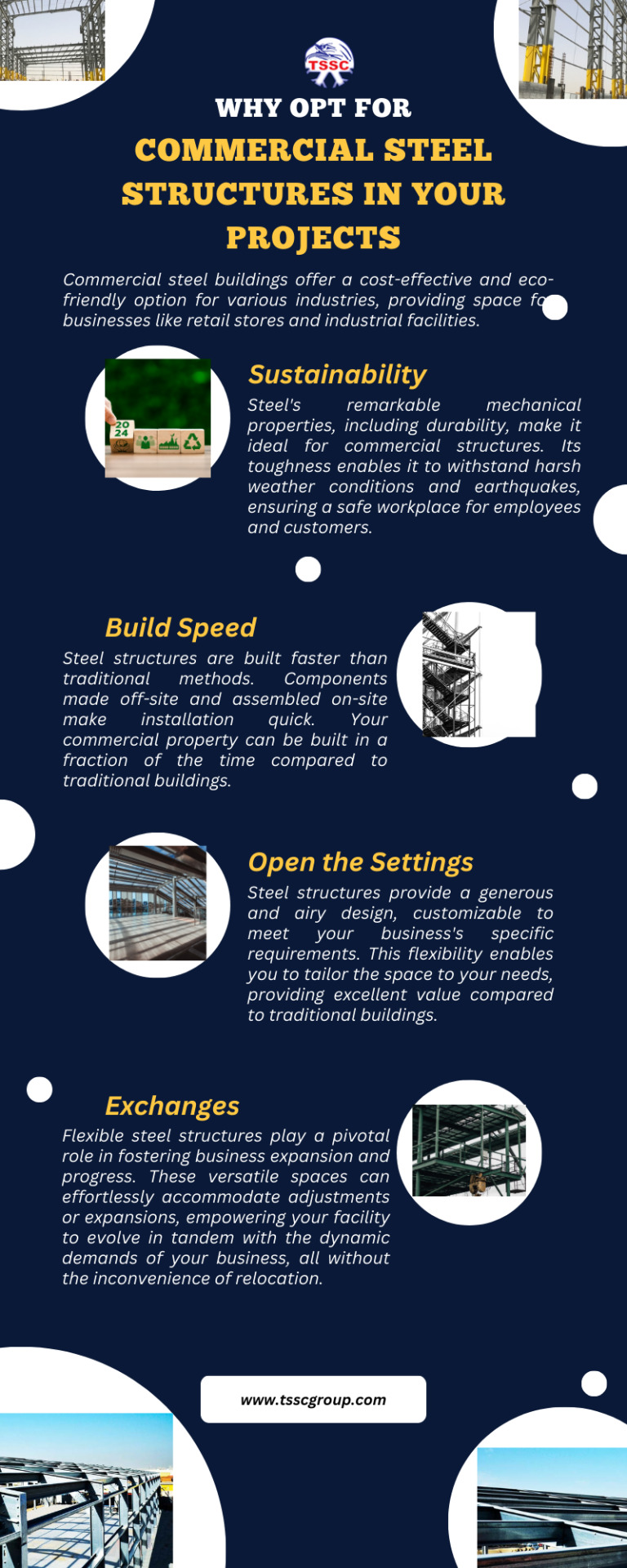

Why Opt for Commercial Steel Structures in Your Projects

Steel's remarkable mechanical properties, including durability, make it ideal for commercial steel structures. Its toughness enables it to withstand harsh weather conditions and earthquakes, ensuring a safe workplace for employees and customers.

0 notes

Text

Little P.Eng. Engineering: Pioneering Material Handling Facilities & Building Designs in Canada & US

The industries of today rely heavily on efficient material handling to maintain profitability, safety, and operational effectiveness. Little P.Eng. Engineering has carved a niche for itself in the design of material handling facilities and buildings across the vast terrains of Canada and the USA, addressing the unique challenges of each region and industry.

Material Handling – The Backbone of Modern Industries

Material handling facilities, be they storage, transport, or processing centers, form the linchpin around which modern industries revolve. From the unloading of raw materials to the shipping of finished goods, a streamlined material handling system significantly impacts a company's bottom line, safety record, and environmental footprint.

Little P.Eng. Engineering's Portfolio: A Deep Dive

Wagon / Truck Loading:

Role: Efficiently loading materials onto wagons or trucks for transport.

Little P.Eng. Approach: Designs that accommodate varied load sizes and types, ensuring quick loading while minimizing spillage and waste.

Wagon Unloading / Tripper:

Role: Unloading goods from wagons with precision and speed.

Little P.Eng. Insight: Systems that cater to different wagon designs and materials, using advanced mechanisms to prevent damage during unloading.

Rapid Train Load-Out Station:

Role: Fast-paced loading of trains, a crucial component in industries like mining.

Little P.Eng. Vision: Integration of automated systems to boost loading speeds, decrease wait times, and enhance safety.

Storage Pits:

Role: Holding areas for materials before processing or transport.

Little P.Eng.'s Precision: Designs that factor in material type, preventing contamination, and ensuring easy retrieval.

Tanks and Reservoirs:

Role: Storage for liquids or gases, be it water, oil, or chemicals.

Little P.Eng. Mastery: Focus on material compatibility, safety features, and maximizing storage space.

Pressure Vessels and Bullets:

Role: Storing gases or liquids at high pressures.

Little P.Eng.'s Craft: Adherence to stringent safety norms, designs that handle extreme conditions, and longevity.

Process Piping:

Role: Transport liquids or gases within facilities.

Little P.Eng.'s Expertise: Efficient layouts to minimize material travel, selection of durable materials, and designs that facilitate easy maintenance.

Pipe Racks:

Role: Hold multiple pipes, often seen in large industrial setups.

Little P.Eng. Specialty: Modular designs that can be expanded as needed, ensuring stability and safety.

Steel Structures:

Role: The skeleton for many industrial buildings, warehouses, and more.

Little P.Eng.'s Touch: Emphasis on durability, load-bearing capacities, and resistance to environmental factors.

Understanding the North American Challenge

Spanning two massive countries with diverse climates, terrains, and industrial needs, North America presents a unique set of challenges. Be it the cold of Canadian winters or the heat of American deserts, Little P.Eng. Engineering's designs consistently rise to the occasion. They prioritize sustainability, recognizing both countries' commitment to reducing industrial carbon footprints.

Conclusion

As industries across North America continue to grow and evolve, so does the demand for efficient, safe, and sustainable material handling facilities. Little P.Eng. Engineering, with its deep understanding of regional and industrial intricacies, positions itself as the go-to solution provider.

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Modular design

Material handling facilities

Wagon loading

Truck loading systems

Wagon unloading mechanisms

Rapid train load-out stations

Storage pits

Industrial tanks

Reservoirs design

Pressure vessels

Industrial bullets

Process piping systems

Pipe racks

Steel structures

Industrial solutions Canada

Material handling USA

Sustainable industrial design

Tripper systems

Automated loading systems

North American industry challenges

Industrial safety norms

Industrial storage solutions

Liquid storage engineering

Gas storage facilities

Material transport systems

Durable material handling facilities

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Modular design#Material handling facilities#Wagon loading#Truck loading systems#Wagon unloading mechanisms#Rapid train load-out stations#Storage pits#Industrial tanks#Reservoirs design#Pressure vessels#Industrial bullets#Process piping systems#Pipe racks#Steel structures#Industrial solutions Canada#Material handling USA#Sustainable industrial design#Tripper systems#Automated loading systems#North American industry challenges#Industrial safety norms#Industrial storage solutions#Liquid storage engineering#Gas storage facilities#Material transport systems#Durable material handling facilities

0 notes

Text

Why Binding Wire Is Essential for Reinforcing TMT Bar Manufacturers and Steel Structures

Strong structural integrity forms the backbone of modern construction, where every component plays a crucial role in ensuring building safety and longevity. A reliable steel pipe company understands that binding wire, often overlooked yet indispensable, serves as the critical connection point that holds reinforcement structures together, particularly in projects involving TMT bar manufacturers and steel fabrication.

Understanding Binding Wire's Role in Construction

Binding wire acts as the fundamental binding element in reinforced concrete structures, holding TMT bars and other reinforcement materials in place. This seemingly simple component prevents displacement during concrete pouring and ensures that steel reinforcements maintain their intended configuration throughout the construction process.

Quality steel pipe companies realize that proper reinforcement begins with selecting the right binding wire specifications. The wire must possess specific characteristics:

Maximum tensile strength for secure holding

Enough ductility for easy tying and handling

Resistant to corrosion and environmental conditions

Uniform diameter and surface quality

Important Construction Uses

TMT Bar companies state that binding wire is considerably used in the following applications:

Binding of Reinforcement Steel

Major Application

The main application is in concrete structures for reinforcing bar holding. Binding wire helps ensure that steel reinforcements are well arranged during the concreting process. It, therefore, complements the structure of buildings, bridges, and any infrastructure.

Mesh Fabrication

In mesh production, binding wire links crossing bars to form rebar grids. Those grids help reinforce concrete slabs, walls, and foundations by providing excellent support to loads placed in the structure.

Column and Beam Splicing

Steel pipe company professionals often highlight the importance of binding wire in vertical and horizontal reinforcements. Precise spacing between the bars and correct load distribution is ensured by it in structural elements.

Impact on Construction Quality

High-quality binding wire plays an important role in construction results:

Structural Integrity

Well-fastened reinforcements through quality binding wires ensure that all the steel pieces work in collaboration to strengthen and make the entire structure stronger and more durable.

Construction Efficiency

When TMT Bar Manufacturers give the construction team reliable binding wire, they will be able to work more effectively, thus decreasing the time needed for installation and still maintaining good quality.

Economy

Though binding wire takes up a relatively small percentage of construction costs, its quality impacts the long-term performance and maintenance requirements of the structure.

Choosing Appropriate Binding Wire

Construction workers should consider some factors when acquiring binding wire from a steel pipe company:

Quality of Material

Industry standards regarding strength, flexibility, and durability must be met by the wire. Quality material ensures effective bonding and long-term functionality.

Wire Gauge

Various applications require corresponding wire gauges. Size selection allows for maximized binding strength without affecting workability.

Surface Treatment

Galvanized and annealed provide different benefits for different construction environments and requirements.

Industry Standards and Compliance

Leading TMT Bar Manufacturers ensure their binding wire meets the set industry standards:

Tensile strength requirements

Dimensional tolerance specifications

Surface quality standards

Coating specifications for specialized applications

Future Considerations

As construction techniques evolve, binding wire continues to adapt to new requirements:

Enhanced coating technologies for better corrosion resistance

Improved manufacturing processes for consistent quality

Development of specialized varieties for specific applications

Integration with advanced construction methodologies

Making the Right Choice

Binding wire selection must be considered in accordance with project requirements as well as the quality standards of the construction process. Construction experts should find a reliable supplier of steel pipes who can understand the needs and accordingly produce the correct results.

For successful construction outcomes, professionals must recognize binding wire's essential role and make informed decisions about material selection and application. This attention to detail, combined with quality materials from trusted suppliers, creates the foundation for durable, safe, and reliable structures that stand the test of time.

#binding wire#TMT bars#steel ties#wire reinforcement#steel binding#wire for TMT#rebar ties#construction wire#steel structures#reinforcement wire#wire fastening#structural wire#concrete support#rebar binding#steel mesh wire#durable binding#secure construction#wire for steel#building reinforcement#binding material

0 notes