#System on Module (SOM) industry

Explore tagged Tumblr posts

Text

Application Solution of Forklift Driver Face Recognition and Permission Collector Based on FET3568J-C SoM

Forklift is an indispensable equipment in modern industrial production and logistics transportation, but at the same time, it is also a mechanical equipment with certain risks. If operated improperly or managed poorly, it can easily lead to safety accidents, causing injuries and property losses. Therefore, improving the safety awareness and management level of forklift drivers is of great significance in ensuring the safety and smooth operation of enterprise production and logistics transportation.

In the safety protection and protective devices, it is stated that forklifts must be equipped with a driver authorization information collector. This collector is used to bind the driver's personal identity information with biometric information such as fingerprints, iris, facial features, or magnetic cards. The forklift can only be started after the driver's permission is verified.

The forklift facial recognition driver authorization collector is primarily used for driver permission management. With high-precision cameras and facial recognition algorithms, this system can accurately identify and determine the driver’s identity information. It helps ensure that only authorized individuals can operate the forklift, improving safety and security in the workplace.

Only drivers who have undergone professional training and obtained authorization will have their information entered into the system and be granted permission to operate the forklift. Once the system detects an unauthorized person attempting to operate the forklift, it immediately triggers an alarm and takes measures to prevent the forklift from starting, ensuring the safety of operations.

The forklift facial recognition driver authorization collector has the following notable features:

Facial recognition: By using cameras to capture facial information, it can accurately identify the facial features of drivers in a short period of time with high precision, without the need for manual intervention, greatly improving management efficiency.

Security: The system is designed with high security in mind. It effectively prevents others from impersonating drivers and provides dual protection for forklift operations.

Integration: The system can not only operate independently but also seamlessly integrate with other security devices, access control systems, etc., forming a comprehensive security management system to further enhance safety.

Scalability: The system supports the integration of finger print recognition and card recognition systems, allowing for the expansion of corresponding functions based on specific needs.

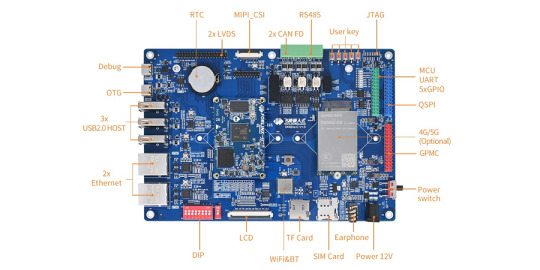

The overall solution for the forklift driver authorization collector based on FET3568J-C system on module is as follows:

FET3568J-C industrial-grade SoM is provided by Forlinx Embedded, which serves as the core of the forklift driver authorization collector. It features a four-core 64-bit Cortex-A55 architecture with a high frequency of up to 1.8GHz, providing powerful performance support. Additionally, it is equipped with a built-in NPU with 1TOPS computational power, meeting the requirements for lightweight edge AI computing.

The SoM has advantages such as high performance, low power consumption, and low cost.

Forlinx RK3568J industrial-grade SoM provides abundant interface resources, making it easy to connect with external modules.

Supports DVP, MIPI-CSI, USB, and network camera interfaces.

Supports RGB, LVDS, HDMI4, MIPI, and eDP display interfaces, making it convenient to connect external displays for facial recognition and comparison display.

Supports 2*1000M Ethernet ports, WiFi, 4G, and 5G interfaces, enabling remote monitoring, control, and data transmission functionalities.

Supports 3*CAN bus interfaces, allowing the collector to communicate with the forklift system through CAN bus interfaces to obtain vehicle status and driver information.

Supports GPIO interfaces, allowing connection and control of other devices on the forklift through GPIO interfaces, such as controlling the start and stop functions of the forklift.

Supports 10 UART interfaces, which can be used for connecting and communicating with RS232/RS485 external sensors through level conversion. The rich high-speed interfaces make function expansion and connection more efficient and simple.

Originally published at www.forlinx.net.

#Forklift safety#Driver authorization collector#Facial recognition system#rk3568j system on module#Industrial grade SoM

0 notes

Text

Intelligent Pigging Service Market to Reach US$ 1.8 Bn by 2034: Key Drivers & Trends

The global intelligent pigging service market was valued at US$ 907.2 million in 2023, and it is expected to reach US$ 1.8 billion by the end of 2034, expanding at a compound annual growth rate (CAGR) of 6.7% during the forecast period from 2024 to 2034.

Introduction: Smart Pipeline Monitoring on the Rise

Intelligent pigging, also known as smart pigging, is a technique used primarily in the oil & gas sector to inspect pipelines internally without disrupting the flow of product. These tools—commonly referred to as “pigs”—leverage advanced sensor technologies to detect issues such as metal loss, corrosion, cracks, leaks, and geometry changes. Among the most used techniques are Magnetic Flux Leakage (MFL), Ultrasonic Testing (UT), and Caliper Pigging.

As the world grapples with increasing energy demands and the aging of oil & gas infrastructure, the adoption of intelligent pigging services is accelerating across key markets.

Rise in Focus on Pipeline Corrosion Control

Corrosion remains one of the biggest threats to pipeline systems. Factors such as water, oxygen, carbon dioxide (CO₂), hydrogen sulfide (H₂S), and microbial activity can significantly degrade pipeline integrity. If left undetected, corrosion can lead to metal loss, system failures, environmental hazards, and loss of life.

To address this, intelligent pigging tools are being widely employed to monitor internal pipeline conditions in real-time. These tools are capable of detecting early-stage corrosion, allowing pipeline operators to take corrective action before more serious damage occurs.

The industry’s focus on pipeline safety and reliability is driving the demand for these services. Intelligent pigs are equipped with sensors that quantify metal loss, assess wall thickness, and detect anomalies, thereby reducing the risk of unplanned downtime and catastrophic failure.

Investment in Oil & Gas Infrastructure

With the global energy demand on the rise, countries are stepping up investments in oil & gas infrastructure to ensure energy security. For instance, Vedanta, an India-based energy conglomerate, announced a US$ 4 billion investment to double its oil & gas output by 2027. Similarly, state-run Indian companies such as ONGC and Indian Oil Corporation plan to invest over US$ 143.6 billion in 2024–2025 across exploration, refining, petrochemicals, and pipeline infrastructure.

These investments naturally lead to increased demand for intelligent pigging services, as newly commissioned pipelines must undergo routine non-destructive inspection (NDI) to comply with safety and operational standards.

Technological Advancements Driving Market Dynamics

Modern intelligent pigging tools are evolving rapidly. Manufacturers are combining cleaning pig design with advanced sensor arrays, enabling multifunctional pigs that are easier to operate and more efficient.

Key innovations include:

System-on-Module (SoM) architectures for autonomous and remote inspections

High-resolution cameras and vision systems for visual validation

AI-powered data analytics for real-time pipeline health reports

Such innovations allow for predictive maintenance and significantly reduce manual inspections. These advancements are reshaping pipeline monitoring practices and transforming the industry into a more digitally connected and proactive ecosystem.

Regional Insights: Asia Pacific Leads the Way

Asia Pacific emerged as the dominant regional market in 2023 and is expected to retain this position through 2034. The rapid industrialization, strong investment in energy infrastructure, and initiatives by public sector undertakings in countries such as India, China, and Japan are fueling the demand.

In India, the government’s push for energy self-sufficiency has led to large-scale pipeline construction projects, especially in underserved and remote regions. This directly contributes to the expansion of the intelligent pigging services sector.

Competitive Landscape: Strategic Moves and Innovation

Key players such as LIN SCAN, T.D. Williamson, Inc., Baker Hughes, GE Vernova, NDT Global, and Shell Plc are focusing on expanding their product lines with multi-sensor pigs, enhanced digital data reporting, and partnership-based service delivery models.

For instance, in May 2024, ConocoPhillips entered a strategic agreement to acquire Marathon Oil, strengthening its position in upstream production and indirectly influencing downstream pipeline inspection needs. Likewise, partnerships such as the one between Artera Services and T.D. Williamson in 2022 demonstrate a shift toward integrated solutions.

Conclusion: A Market Poised for Predictive Integrity Management

The intelligent pigging service market is entering a new phase—driven not only by regulatory compliance but also by technological innovation and a heightened focus on predictive pipeline integrity. As energy infrastructure expands, especially in high-growth regions like Asia Pacific, the demand for intelligent pigging solutions will rise steadily.

With the fusion of AI, IoT, and real-time diagnostics, intelligent pigging is becoming an essential tool in ensuring the safe, sustainable, and efficient delivery of energy across the globe.

0 notes

Text

Wireless SOM Reference Design

Tailored for industrial and consumer use,wireless SOM Reference Design offers a compact, pre-certified module for adding Wi-Fi, Bluetooth, secure connectivity, and efficient power management to embedded applications. The SAMA5D27 Wireless System-on-Module (WLSOM1) is a highly integrated reference design by Microchip Technology tailored for consumer and industrial applications, particularly within…

0 notes

Text

Low-Power Design Strategies with Renesas SOM and AMD Ryzen Embedded 8000

In the evolving landscape of embedded systems, low-power design has become a pivotal element, especially in sectors where energy efficiency is crucial. Devices operating in remote locations, battery-operated modules, or environments with strict thermal limitations benefit greatly from components that prioritize low energy consumption without sacrificing performance. The challenge is to maintain computational integrity and feature-richness while adhering to power budgets. With the increasing demand for edge computing and real-time data processing, the importance of efficient power management strategies has grown.

Modern embedded platforms are rising to meet these demands. Companies now offer sophisticated System-on-Modules (SOMs) that are tailored to deliver high performance in compact, energy-efficient packages. Among the industry leaders, Renesas and AMD have produced highly capable platforms that balance performance and power efficiency. Specifically, the Renesas SOM and AMD Ryzen Embedded 8000 family present compelling options for developers who need to address the growing constraints of power, space, and thermal design.

This article explores comprehensive strategies for low-power design using these two platforms. It will delve into hardware-level tactics, software optimizations, and application-level considerations, offering a roadmap for engineers seeking to create efficient and resilient embedded solutions.

The Fundamentals of Low-Power Design

Understanding Power Consumption in Embedded Systems

Power consumption in embedded systems is influenced by a variety of factors, ranging from the silicon architecture and process technology to system software and workload management. In general, total power usage can be broken down into dynamic and static power components. Dynamic power relates to the active switching of transistors, which occurs during computational tasks, while static power is associated with leakage currents when the system is idle.

Key contributors to power consumption include CPU usage, memory access, peripheral activity, and I/O operations. Managing these factors requires a holistic approach, incorporating both hardware selection and software design. Techniques like clock gating, voltage scaling, and power domain management are crucial at the hardware level. Meanwhile, efficient coding practices, power-aware scheduling, and judicious use of peripherals can significantly reduce software-induced power drain.

Designing for low power is not a one-size-fits-all approach. It demands a thorough understanding of the system's operational context. What kind of tasks will the system perform? How frequently will it be active? What are the thermal and energy constraints? Only by answering these questions can designers effectively implement strategies that deliver optimal energy efficiency.

The Role of SOMs in Power Efficiency

System-on-Modules (SOMs) simplify the design of complex embedded systems by integrating processors, memory, and essential interfaces into a single module. This modularity accelerates development and reduces risk, but it also opens opportunities for enhanced power efficiency. SOMs can be engineered with features like dynamic voltage scaling, sleep modes, and modular power domains, all of which contribute to lower energy consumption.

The advantage of using SOMs in low-power applications lies in their configurability. Developers can tailor system performance to match the needs of the application, reducing unnecessary power draw. For instance, a device that performs periodic sensor readings can be designed to spend most of its time in low-power standby mode, waking only when necessary.

Moreover, leading SOM platforms incorporate advanced power management ICs (PMICs) and firmware-level support for power-saving features. These systems are often pre-validated for compliance with low-power standards, enabling developers to focus more on application-specific challenges rather than the intricacies of power management.

Hardware-Level Power Optimization

Efficient Component Selection

Choosing components with inherent power-saving features is a foundational step in low-power design. Processors, memory modules, and peripherals should be evaluated not just on performance but also on their power profiles. Multi-core CPUs with independent power domains, LPDDR memory, and low-leakage I/O controllers can contribute significantly to reducing system power consumption.

Beyond the core components, developers should consider the power characteristics of secondary elements like voltage regulators, clock sources, and sensors. Devices that support dynamic power scaling and offer idle or sleep modes are preferable. It's also important to use components from the same vendor family or ecosystem, as these are more likely to have coordinated power management features.

For embedded systems expected to operate under variable loads, components with wide dynamic performance ranges are especially valuable. These allow the system to scale its power consumption in real-time based on the workload, avoiding the inefficiencies of static, high-power configurations.

Power Domains and Isolation

Power domains refer to independently controlled sections of an integrated circuit or system that can be powered on or off depending on system requirements. Utilizing power domains allows certain parts of the system to be shut down when not in use, thereby conserving energy.

For example, in a multimedia processing unit, the video encoder might only be powered during active video capture, while remaining dormant the rest of the time. Isolating these functions into distinct power domains ensures that energy isn't wasted on unused circuitry. Modern processors, including those used in the Renesas SOM and AMD Ryzen Embedded 8000, support sophisticated power domain architectures.

Effective use of power domains requires coordination between hardware and firmware. Developers must design software routines that can trigger domain transitions without disrupting system stability. Careful planning is required to handle wake-up events, ensure data integrity, and manage timing delays associated with power cycling.

Software Strategies for Power Management

Dynamic Voltage and Frequency Scaling (DVFS)

DVFS is a powerful software-controlled mechanism that adjusts the voltage and frequency of a processor based on workload demands. When high performance is needed, the processor runs at higher frequencies and voltages. During idle or low-load periods, the system scales down to conserve energy.

This technique is widely supported in modern embedded platforms and often integrated into the operating system’s power management framework. Linux, for example, includes governors like "ondemand" and "conservative" that manage DVFS in real time. Custom policies can also be implemented to match specific application profiles.

However, DVFS must be applied judiciously. Frequent transitions between power states can introduce latency and increase wear on components. The key is to balance responsiveness with efficiency, ensuring that the system remains agile without excessive energy costs. Profiling tools and telemetry data can aid developers in fine-tuning DVFS parameters for optimal results.

Efficient Task Scheduling

Task scheduling plays a significant role in power consumption. By organizing computational tasks efficiently, systems can spend more time in low-power states. Techniques such as batching similar operations, aligning wake-up intervals, and prioritizing critical tasks help reduce CPU wake cycles and context switching overhead.

Real-time operating systems (RTOS) and middleware frameworks often provide hooks for power-aware scheduling. These include APIs to manage sleep modes, delay operations, and synchronize peripheral activity. Developers should leverage these capabilities to ensure that tasks are executed only when necessary.

Power-aware task scheduling becomes particularly important in systems with multiple execution contexts or peripherals. For instance, sensor data collection, communication, and UI updates can be coordinated to occur in clusters, allowing the processor to return to sleep mode between activity bursts. This coordinated scheduling is crucial for extending battery life in portable and remote devices.

Peripheral and System-Level Considerations

Smart Peripheral Management

Peripherals can be significant sources of power consumption, especially when left in active states unnecessarily. Smart peripheral management involves configuring devices to enter low-power or idle modes when not in use and waking them only as needed.

This approach often requires a combination of hardware support and software control. Many modern peripherals include built-in support for sleep states, wake-on-interrupt features, and programmable thresholds. Developers must ensure that system firmware is capable of managing these modes without introducing latency or instability.

Moreover, communication interfaces like I2C, SPI, and UART can be optimized for power by adjusting clock rates, using DMA transfers, and disabling unused channels. For systems with wireless connectivity, aggressive management of radio transceivers is essential, as these can rapidly deplete energy reserves.

Thermal and Mechanical Design

Thermal management is closely linked to power efficiency. Excessive heat can not only degrade performance but also lead to higher leakage currents and premature component failure. Designing systems with efficient thermal paths—such as heat sinks, spreaders, and airflow considerations—can reduce the need for active cooling, which consumes additional power.

Mechanical design also plays a role in optimizing power use. Enclosures should be engineered to support passive cooling, minimize dust ingress, and facilitate modular expansion without excessive overhead. Compact designs with integrated shielding can also reduce EMI, improving system stability and reducing the need for error correction processing that adds to the power burden.

Battery and Power Supply Design

For battery-operated systems, choosing the right battery technology and capacity is essential. Lithium-ion, LiFePO4, and other advanced chemistries offer different trade-offs in terms of energy density, discharge rates, and lifespan. The power supply circuitry should be optimized for efficiency, using synchronous regulators, low-dropout converters, and energy-harvesting technologies where applicable.

Accurate battery monitoring, including state-of-charge and health estimation, enables better power budgeting and prevents unexpected shutdowns. These metrics can also feed into the software power management algorithms, allowing dynamic adjustments based on available energy reserves.

Practical Applications and Case Studies

Industrial Automation

In industrial environments, embedded systems often operate in harsh conditions where reliability and power efficiency are critical. Systems may be deployed in locations with limited access to power or require uninterrupted operation during outages. Using platforms like the Renesas SOM allows engineers to design solutions that are both robust and energy-efficient.

For example, programmable logic controllers (PLCs) and remote sensor hubs can benefit from the SOM's low-power sleep modes and fast wake-up capabilities. These features enable real-time data acquisition and processing without maintaining full system activity. Energy savings compound over time, resulting in lower operational costs and improved system longevity.

Smart Surveillance Systems

Modern surveillance systems require high-performance processing for video analytics, yet must operate reliably in various environmental conditions. Here, the AMD Ryzen Embedded 8000 excels by offering a combination of CPU and GPU performance within a manageable power envelope.

These systems can dynamically adjust processing workloads based on motion detection or event triggers. When no motion is detected, the system scales down or enters a low-power state. When activity resumes, the full processing power becomes available to analyze footage and perform recognition tasks. This approach significantly reduces the energy footprint without compromising surveillance capabilities.

Portable Medical Devices

Portable medical devices present stringent requirements for power efficiency, accuracy, and reliability. Whether it's patient monitoring equipment or diagnostic tools, these devices must function for extended periods on battery power. The Renesas SOM offers a practical foundation for such applications.

Its support for advanced power management features, along with its compact form factor, enables the creation of lightweight, energy-efficient devices. Developers can implement task-based scheduling to manage sensors, displays, and communications in a way that prioritizes critical functionality while preserving battery life. In regulated markets, the added reliability of a tested SOM platform also simplifies certification and compliance efforts.

Conclusion

Low-power design is no longer a niche requirement—it is an essential discipline in embedded systems engineering. As devices become more autonomous, connected, and pervasive, the need to manage power consumption grows in tandem. System-on-Modules like the Renesas SOM and AMD Ryzen Embedded 8000 represent the forefront of this evolution, offering the performance developers need alongside the efficiency that modern applications demand.

By combining hardware capabilities with intelligent software design and system-level planning, engineers can create embedded solutions that are both powerful and sustainable. The strategies discussed in this article provide a blueprint for approaching low-power design holistically, ensuring that every component and line of code contributes to energy-conscious innovation.

0 notes

Text

Common Interface Problems and Troubleshooting Ideas of Forlinx Embedded AM62x Development Board (Phase 1)

AM62x processor, as a new generation of high-performance and low-power processor, has been widely used in industrial control, human-computer interaction, edge computation and other fields. OK62xx-C development board based on AM62x processor provides abundant hardware interface resources for developers. This article will provide systematic troubleshooting ideas and solutions for various interface problems that may be encountered in the development process to help developers quickly locate and solve problems.

General Troubleshooting

In the process of hardware debugging, the systematic troubleshooting method can significantly improve the efficiency. The following is the general troubleshooting process:

Chip consistency verification:

First, make sure that the functional chip used is exactly the same as the reference design schematic. If the chip model is different, driver migration may be required, including modifying the device tree configuration and driver.

1. Basic signal checking:

For modules that fail feature verification, check in order:

Whether the power supply voltage is within the allowable range;

Check whether the reset signal timing meets the requirements;

Check whether the frequency and amplitude of the clock signal are normal.

2. Cross Test:

By replacing either the System on Module (SoM) or the carrier board, quickly identify the source of the problem.

3. Signal integrity check:

Measure whether the pin level is as expected;

Check whether the data signal is output normally;

Confirm whether the signal idle state is normal

4. Welding quality inspection:

Check the welding problems, whether the resistance and capacitance devices have problems such as cold welding, continuous welding, missing welding, wrong welding, etc;

Check the welding direction of the device to see if there is a problem that the pin 1 of the welded device does not correspond to the pin 1 of the carrier board.

5. Pin Multiplexing Checking:

Refer to the AM62x Technical Reference Manual to confirm whether the function multiplexing configuration of the used pins is correct. Pay special attention to the default functions of the pins related to startup.

Troubleshooting of System Failure to Start

Follow the steps below to troubleshoot the issue of system failure to start:

1. Key signal inspection:

Measure the VCC3V3_SYS-PG (RD60) signal to ensure that the power supply is functioning properly;

Check if all power rail voltages are within the allowable range;

Verify whether the timing of the reset signal meets the requirements of the processor.

2. Start Configuration Check:

Confirm that the GPMC bus related startup pins have been correctly pulled up and down in the carrier board design;

Pay special attention to not affecting the startup configuration level when connecting external devices such as FPGA;

Check the level status of the boot mode selection pin.

3. I2C bus conflict troubleshooting:

RU50 and RU52 are I2C0 buses, and the SoM may have multiple devices mounted;

Ensure that the bottom board does not float these pins, and other functions do not reuse I2C0;

Check if the pull-up resistor on the I2C bus is normal.

4. Cross Test:

Replace the SoM or carrier board and confirm if it is an isolated issue.

Troubleshooting of I2C Interface Issues

Common problems and solutions of I2C bus:

1. Basic configuration check:

Confirm that both SCL and SDA lines have pull-up resistors;

Check if there are any conflicts in the addresses of devices mounted on the I2C bus within the same group.

2. Signal quality analysis:

Measure whether the idle state is at a high level;

Observe whether the waveform is complete and whether there is overshoot or ringing during data transmission;

Use a logic analyzer to capture the complete communication process.

3. Impedance matching adjustment:

If the rising edge of the waveform is slow, the pull-up resistance value can be reduced;

If the low level is too high, the pull-up resistor value can be increased.

4. Diagnostic tool usage:

Use the I2Ctool tool to check if any devices are mounted on the bus:i2cdetect-l//Check how many groups of I2C are on the system i2cdetect-r-y2//Detect mounted devices on the I2C second set of buses

Troubleshooting of SPI Interface Issues

Key points for troubleshooting SPI communication faults:

1. Confirmation of hardware connections:

MOSI and MISO must be cross-connected;

Confirm that the chip select signal is correctly connected and not multiplexed by other functions;

Check if the SPI clock line is connected.

2. Verification of mode configuration:

Confirm that the CPOL and CPHA settings of the master and slave devices are consistent;

Check if the clock frequency is within the range supported by the device;

Verify if the data bit width setting is correct.

3. Signal measurement:

Use an oscilloscope to measure the quality of the clock signal;

Observe the signal changes on the data line during the active period of the chip select signal;

Check the level states of each signal line in the idle state.

Troubleshooting of USB Interface Issues

Common problems with USB interfaces (2.0/4G/5G):

1. Power supply check:

Measure whether the USB_VBUS_3V3 signal is a stable 1.8V;

Confirm that the VBUS current supply capacity meets the device requirements.

2. Confirmation of signal connections:

Confirm that an AC coupling capacitor is connected in series with the USB transmission signal.

3. Special notes for USB:

Generally, an AC coupling capacitor has already been added to the transmission signal of the USB device end, so the receiving end does not need to add another coupling capacitor;

Check of level configuration:

Troubleshooting of SDIO Issues

1. Optimization of signal integrity:

The pin levels of the SDIO interface are related to the transmission speed. The default operating voltage is 3.3V, and it needs to be switched to 1.8V in high-speed mode;

The SDIO signal cannot pass through a level conversion chip and must be directly connected.

2. Optimization of signal integrity:

Confirm that the SDIO bus has been subjected to equal-length processing.

3. Pull-up resistor configuration:

Configure appropriate pull-up resistors according to the specifications;

Check the level state of the card detection pin.

The above are the common problem types and troubleshooting ideas during the development process of the OK62xx-C development board. This article first introduces six major types of problems, including general ideas, non-startup problems, I2C interface problems, SPI interface problems, USB problems, and SDIO problems. Subsequently, problems with interfaces such as LVDS, PCIe, UART, and CAN and their solution ideas will also be introduced. We hope that you will continue to pay attention.

0 notes

Text

ARMxy Cortex-A53 based Computers BL340 for Wind Farm Monitoring

Hardware Support for Wind Farm Monitoring Needs

High-Performance Processor: The BL340 is equipped with the Allwinner T507-H quad-core ARM Cortex-A53 processor (up to 1.4GHz), supporting real-time data processing for monitoring wind turbine operational status and data analysis.

Flexible I/O Configuration:

(1)X and Y Series IO Boards support interfaces such as RS485, RS232, DI/DO, AI/AO, enabling connections to wind turbine sensors (e.g., vibration, temperature, rotational speed) and actuators (e.g., braking systems).

(2)For example, Y51/Y53 (PT100/PT1000) can be used for precise temperature monitoring, while Y95/Y96 (PWM output and pulse counting) are suitable for wind speed and rotor speed measurement.

Communication Interfaces:

(1)Provides 1-3 10/100M Ethernet ports, supporting networked device communication within the wind farm for centralized data management.

(2)The Mini PCIe interface supports 4G/WiFi modules, ensuring remote data transmission to cloud platforms, ideal for remote wind farms.

Environmental Durability: Certified for operation from -40°C to 85°C and with IP30 protection, it is well-suited for the harsh environments of wind farms.

Software Support for Energy Production Optimization

BLloTLink Protocol Conversion Software: Supports protocols like Modbus, MQTT, and OPC UA, enabling seamless integration with wind farm equipment, mainstream industrial SCADA systems, or cloud platforms (e.g., AWS IoT, Thingsboard) for data collection, analysis, and optimization.

BLRAT Remote Access: Facilitates remote monitoring and maintenance, reducing on-site maintenance costs and improving wind farm operational efficiency.

Real-Time Operating System: Supports Linux-RT-4.9.170, ensuring low-latency data processing for real-time turbine status monitoring.

Qt-5.12.5 GUI Tool: Enables the development of intuitive user interfaces for on-site personnel to monitor and operate the system.

Docker and Node-Red Support: Simplifies the rapid development of IoT applications for wind farm monitoring.

Typical Application Scenarios

Condition Monitoring: Collects data from sensors on vibration, temperature, and hydraulic pressure to analyze equipment health, predict maintenance needs, and extend equipment lifespan.

Energy Optimization: Leverages edge computing to analyze wind speed and power output, dynamically adjusting turbine angles or loads to maximize energy production efficiency.

Fault Diagnosis: Uses AI modules (e.g., Y31 AIN Modules) to detect abnormal vibrations or mechanical faults, providing early warnings to minimize downtime.

Cloud Integration: Uploads operational data to the cloud via 4G/WiFi for long-term trend analysis, optimizing the energy management strategy of the entire wind farm.

Customization and Scalability

Modular Design: Users can select different SOMs (e.g., SOM341: 16GB eMMC + 2GB DDR4) and IO boards (e.g., X23: 4 RS485 + 4 DI/DO) to meet specific monitoring requirements.

Development Support: Offers extensive development examples (e.g., Node-Red, MQTT, CAN) to accelerate the creation of customized monitoring applications.

Long-Term Support: Shenzhen Beilai provides customized R&D and long-term after-sales support to ensure continuous system optimization.

Practical Benefits

Enhanced Reliability: Real-time monitoring and predictive maintenance reduce wind turbine failure rates.

Optimized Energy Output: Data-driven adjustments to operational parameters improve power generation efficiency.

Reduced Operating Costs: Remote management and automated monitoring minimize manual intervention and maintenance costs.

Strong Environmental Adaptability: DIN35 rail mounting and rugged aluminum alloy casing suit the complex environments of wind farms.

Example Configuration

For wind farm monitoring, a recommended configuration is:

Model: BL342B-SOM341-X23-Y51-Y95

(1)Hardware: 3 Ethernet ports, 16GB eMMC, 2GB DDR4, 4 RS485, 4 DI/DO, 2 PT100 temperature sensors, 4 PWM outputs + pulse counters.

(2)Functions: Supports multi-device networking, temperature monitoring, wind speed measurement, and remote data transmission.

Software: Ubuntu 20.04 + BLloTLink + Node-Red for data collection, protocol conversion, and IoT application development.

Conclusion

The ARMxy BL340 series embedded industrial computer, with its high-performance hardware, flexible I/O configuration, robust software support, and industrial-grade reliability, provides an ideal solution for wind farm monitoring. It not only enables real-time management of wind turbines but also optimizes energy production through data analysis and remote maintenance, reducing operational costs. It is a core component for the intelligent operation of wind farms.

0 notes

Text

6 Things You Should Know to Elevate Your Embedded Linux Software Development

Getting started with embedded Linux development is now easier than ever. But to build a reliable, production-ready system, you need to go beyond the basics. Here are six critical areas to focus on to take your Linux-based embedded product to the next level.

1) Driver Development: Ensure Hardware Compatibility Before finalizing your hardware design, always verify whether Linux drivers are available for the components you choose. Most silicon vendors test their reference boards with Linux, so chances are drivers exist. But replacing parts to cut costs without checking driver availability can lead to time-consuming development efforts.

2) BSP Adaptation: Match Software to Hardware When working with a System-on-Module (SoM), you��ll need to tailor the BSP (Board Support Package) to your exact hardware setup. This involves configuring the Linux kernel and adjusting the device tree — a special file that describes the hardware layout. Learning to navigate device tree files (DTS) is essential, even if it seems complex at first.

3) Boot Time Optimization: Speed Up System Start Fast boot times matter in many industries — from automotive to consumer devices. By default, bootloaders and kernels aren’t optimized for speed. You’ll need to tweak U-Boot settings, delay non-critical driver loads, and streamline startup scripts to meet performance expectations.

4) Power Consumption: Build Energy-Efficient Products Battery-powered products demand smart power management. Standard Linux kernels often don’t use all the SoC’s power-saving features out of the box. Techniques like clock gating, power domains, and peripheral shutdowns require deep hardware-software collaboration to extend battery life.

5) Real-Time Requirements: Add Determinism If Needed Linux isn’t a real-time OS by default. For soft real-time tasks, standard Linux may suffice. But when you need hard real-time behavior, tools like Xenomai can be integrated — though they require careful driver and kernel-level modifications.

6) System Updates: Keep Your Product Secure & Up-To-Date Over-the-air (OTA) updates are essential today, but Linux doesn’t offer a one-size-fits-all solution. You’ll need to handle updates for the bootloader, kernel, and root file system, often using partitioning techniques like dual-image systems. Done right, it ensures system integrity even in cases of power loss during an update.

The Takeaway While Linux-based embedded systems are easier to launch than ever before, truly robust product development still requires thoughtful planning and technical know-how. The good news? If you know where to focus — like the six areas above — you can streamline development, reduce risks, and get to market faster.

✨ Need help optimizing your embedded Linux project? Silicon Signals specializes in building production-ready embedded systems on platforms like Toradex, NXP, and more.

📩 Get in touch to schedule a free consultation or request a custom demo.

🔗 www.siliconsignals.io

#embeddedtechnology#embeddedsoftware#embeddedsystems#androidbsp#linux kernel#android#linuxdebugging#aosp#iot development services#iotsolutions

0 notes

Text

Game-Changer for Compliance & Ethics Training: A Modern Approach

HR compliance training ensures that employees understand company policies, industry regulations, and legal requirements that govern workplace behavior. From ethical decision-making to workplace safety, corporate compliance training plays a pivotal role in risk management and legal protection. Organizations must invest in high-quality compliance courses to mitigate the risks associated with non-compliance.

Key Benefits of Compliance Training

Risk Mitigation – Annual compliance training minimizes legal liabilities and ensures that employees are aware of updated laws and company policies.

Workplace Safety – Safety and compliance training helps employees follow protocols that prevent workplace hazards.

Increased Employee Engagement – Ethics and compliance training builds a positive work culture, reducing unethical behavior and reinforcing company values.

Regulatory Adherence – Regulatory and compliance training keeps businesses aligned with industry-specific regulations, avoiding fines and penalties.

Enhanced Productivity – Well-informed employees contribute to smoother operations, reducing errors and compliance-related disruptions.

The Shift to Compliance Training Online

The digital era has given rise to compliance training online, making it easier for organizations to deliver flexible, engaging, and cost-effective training modules. Learning Management Systems (LMS) and other e-learning platforms allow businesses to conduct compliance officer training and HR compliance courses remotely, ensuring accessibility for all employees.

Advantages of Online Compliance Training

Flexibility – Employees can complete training at their own pace, minimizing work disruptions.

Cost-Effectiveness – Eliminates travel and venue costs associated with in-person training.

Customization – Training modules can be tailored to suit industry-specific requirements.

Interactive Elements – Multimedia content enhances engagement and knowledge retention.

Real-Time Tracking – Organizations can monitor progress and ensure completion of required courses.

The Role of Microlearning in Compliance Training

Microlearning compliance training has emerged as an innovative solution to overcome the challenges associated with traditional compliance education. By breaking down complex compliance topics into short, digestible learning modules, this approach improves engagement and knowledge retention.

Benefits of Compliance Microlearning

Short, Focused Lessons – Employees absorb information faster and retain it longer.

Convenient Access – A micro-learning platform for frontline employees allows staff to complete training on their mobile devices, even in the field.

Higher Engagement – Gamification and interactive elements make learning more enjoyable.

Frequent Reinforcement – Regular training refreshers help keep compliance top-of-mind for employees.

Implementing a Microlearning Compliance Training Solution

Organizations looking to enhance their corporate compliance microlearning strategies must adopt the right tools and methodologies. A robust compliance microlearning solution ensures effective knowledge transfer and regulatory adherence.

Steps to Implement a Successful Microlearning Program

Identify Training Needs – Conduct an assessment to determine the key compliance areas requiring attention.

Choose the Right Platform – Select a microlearning tool for frontline staff that supports interactive and mobile-friendly learning.

Develop Engaging Content – Incorporate videos, quizzes, and real-life scenarios to make training effective.

Ensure Accessibility – Make compliance courses available across multiple devices for ease of access.

Monitor & Evaluate – Use LMS Training analytics to track employee progress and adjust content as needed.

Compliance Training for Different Industries

Compliance requirements vary across industries, making it essential for organizations to offer customized training programs. Below are some industry-specific compliance training solutions:

1. HR Compliance Training

HR compliance courses cover essential workplace regulations, including anti-harassment training, equal employment opportunity policies, and workplace ethics. These programs ensure that HR professionals are equipped to handle compliance challenges effectively.

2. Environmental Compliance Training

Companies in manufacturing, construction, and energy sectors must adhere to environmental laws and sustainability practices. Environmental compliance training educates employees on waste management, emissions control, and conservation efforts.

3. Safety Compliance Training

Industries such as healthcare, transportation, and construction require rigorous safety compliance training to reduce workplace accidents. This includes OSHA compliance, hazard communication, and emergency response training.

4. Financial Regulatory and Compliance Training

Banks, insurance companies, and financial institutions must comply with stringent regulations such as GDPR, HIPAA, and anti-money laundering laws. Regular compliance and training programs help employees stay updated on evolving financial regulations.

The Future of Compliance Training: AI and Automation

The evolution of compliance training does not stop at microlearning. Advanced technologies like artificial intelligence (AI) and automation are revolutionizing training for compliance by providing personalized learning experiences.

Emerging Trends in Compliance Training

AI-Powered Learning Paths – AI-driven systems analyze employee performance and tailor training content to address individual weaknesses.

Automated Compliance Tracking – Ensures employees complete their yearly compliance training on time, reducing administrative burden.

Virtual Reality (VR) Training – Creates immersive compliance scenarios for hands-on learning experiences.

Data-Driven Decision-Making – Predictive analytics help companies identify compliance risks before they escalate.

Choosing the Right Compliance Training Platform

Organizations must invest in a reliable training solution that aligns with their compliance needs. A robust LMS training system should offer:

Scalability – Ability to accommodate growing workforce needs.

Customizable Modules – Adaptability to industry-specific regulations.

Real-Time Reporting – Tracking features to monitor training progress and completion rates.

User-Friendly Interface – Ensures seamless navigation for employees.

Conclusion: Embracing a New Era of Compliance Training

The shift from traditional training methods to compliance training online and microlearning solutions is a game-changer for organizations worldwide. By leveraging compliance microlearning, companies can enhance employee engagement, ensure regulatory adherence, and build a culture of ethical responsibility. Investing in the right microlearning platform and LMS training tools will enable businesses to stay ahead in an increasingly complex regulatory landscape.

Whether it’s HR compliance training, safety compliance training, or regulatory compliance education, modern digital learning solutions empower employees to stay informed and compliant. The future of compliance training is here, and businesses must embrace these innovations to drive success and sustainability.

#compliance training#compliance training online#compliance training for employees#compliance courses#hr compliance training#corporate compliance training#compliance officer training#hr compliance courses#environmental compliance training#staff compliance training#safety and compliance training#safety compliance training#annual compliance training#ethics and compliance training#training for compliance#regulatory and compliance training#compliance safety training#yearly compliance training#Compliance Microlearning#microlearning compliance training#corporate compliance microlearning#compliance microlearning solution#micro-learning platform for frontline employees#microlearning tool for frontline staff#microlearning platform#LmsTraining#training individual#on a job training#compliance and training

0 notes

Text

How to Choose the Right System on Module for Your Application

As technology evolves, choosing the right system on module (SoM) for your application can seem like a daunting task. With so many options available, it’s essential to understand your project’s needs and the features of different SoMs to ensure optimal performance. Whether you're building an IoT device, a medical tool, or an industrial machine, finding the right SoM can make or break your project. This blog post will guide you through the key considerations when selecting a system on module for your specific application.

#system in package#automotive electronics#car electronics#ev power module#wifi module#System On Module

1 note

·

View note

Text

AMD Kria K24 SOM Edge Tech

Innovation with AMD’s Kria K24 SOM

The most recent additions to the Kria lineup of adaptive System-on-Modules (SOMs) and development kits are the AMD Kria K24 System-on-Module (SOM) and KD240 Drives Starter Kit. The AMD Kria K24 SOM is aimed for cost-concerned industrial and commercial edge applications and provides power-efficient computation in a compact form factor. The K24 uses half the power1 of the bigger, connector-compatible Kria K26 SOM despite being half the size of a credit card thanks to advanced InFO (Integrated Fan-Out) packaging.

For powering electric motors and motor controllers used in compute-intensive digital signal processing (DSP) applications at the edge, the K24 SOM offers excellent determinism and low latency. Electric motor systems, robotics for industrial automation, power generation, elevators and trains, surgical robots, medical equipment like MRI beds, and EV charging stations are a few examples of important uses.

The products provide a smooth route to production deployment with the K24 SOM when used in conjunction with the KD240 Drives Starter Kit, a motor control-based development platform that is ready to use right out of the box. Users don’t need to be experts in FPGA programming to rapidly get up and running, accelerating time to market for motor control and DSP applications.

“The AMD Kria K24 SOM and KD240 development platform build on the breakthrough design experience introduced by the Kria SOM portfolio, offering solutions for robotics, control, vision AI, and DSP applications,” stated Hanneke Krekels, corporate vice president, Core Vertical Markets, AMD. “System developers must balance cutting costs with addressing the rising expectations for performance and power efficiency. For a quick time to market, the K24 SOM contains the essential parts of an embedded processing system on a single production-ready board while yet delivering outstanding performance per watt.

In many companies, robotic equipment that powers assembly lines and other machinery is powered by hundreds of motors. According to estimates, electric motors and motor-driven systems account for over 70% of all the electrical energy used globally by the industrial sector. Therefore, even a 1% increase in a drive system’s efficiency may have a big influence on operating costs and the environment.

Greg Needel, CEO of Rev Robotics, said: “The AMD Kria SOM portfolio has helped make reliable hardware for robotics and industrial edge applications accessible to the masses and we’re excited to see the portfolio extended with the new K24 SOM and KD240 Starter Kit.” “With Kria SOMs, we’re able to adapt to changing software and hardware requirements, simplify the development of even advanced control loop algorithms, and build really cool things for both commercial and STEM educational customers.”

Accelerated Design Cycles and Simplicated DSP Development

The K24 SOM has a specially created Zynq UltraScale+ MPSoC chip, and the accompanying KD240 starting kit is an FPGA-based motor control kit that costs less than $400. In contrast to previous processor-based control kits, the KD240 offers simple access for entry-level developers, allowing them to start at a more advanced stage in the design cycle.

The K24 SOM supports more design processes than any previous version and is certified for usage in industrial applications. Included in this are well-known design tools like Matlab Simulink and programming languages like Python, which has a broad ecosystem that supports the PYNQ framework. Additionally supported are Docker and Ubuntu. The AMD Vitis motor control libraries are also available to software developers, preserving compatibility for conventional development processes.

AMD launched the first App Store for edge apps with the Kria K26 SOM launch. With the release of the KD240 Starter Kit, AMD becomes the first company to provide pre-built motor control software, enabling customers to develop industrial solutions that are dependable, accessible, and equipped with cutting-edge security features.

For an improved ramp-up experience for developers, the KD240 is supported by an optional Motor Accessory Pack (MACCP), with more motor kits coming out in the future that may be ordered separately.

A Family of Scalable SOMs is available

By using Kria SOMs, developers may concentrate on offering unique, value-added functionality rather than spending time and resources on extensive design work around the chosen silicon device.

System architects may easily switch between the K24 and K26 SOM without changing boards thanks to connector compatibility, which allows power, performance, space, and cost to be balanced for systems that are energy-efficient.

K24 SOMs are designed for 10-year industrial lifecycles and are available in both commercial and industrial variants. The industrial-grade SOM incorporates ECC-protected LPDDR4 memory for high-reliability systems in addition to compatibility for wider temperature ranges.

Orders for the K24 SOM (commercial and industrial variants) and KD240 Drives Starter Kit may be made directly via the manufacturers’ website or through distributors all around the globe. The K24 industrial version is anticipated to launch in Q4, while the commercial version is already shipping.

0 notes

Text

Looking for a reliable solution to monitor industrial dust in real time?

Discover our advanced dust monitoring system powered by the Nuvoton MA35 processor. With support for PM1.0, PM2.5, PM10, and environmental sensors, it delivers accurate, real-time data even in harsh conditions.

✅ Multi-sensor support

✅ Real-time wired/wireless communication

✅ Ideal for smart environmental control

FET-MA35-S2 embedded system-on-module

0 notes

Text

Intelligent Pigging Service Market to Reach US$ 1.8 Bn by 2034: Key Drivers & Trends

The global intelligent pigging service market was valued at US$ 907.2 million in 2023, and it is expected to reach US$ 1.8 billion by the end of 2034, expanding at a compound annual growth rate (CAGR) of 6.7% during the forecast period from 2024 to 2034.

Introduction: Smart Pipeline Monitoring on the Rise

Intelligent pigging, also known as smart pigging, is a technique used primarily in the oil & gas sector to inspect pipelines internally without disrupting the flow of product. These tools—commonly referred to as “pigs”—leverage advanced sensor technologies to detect issues such as metal loss, corrosion, cracks, leaks, and geometry changes. Among the most used techniques are Magnetic Flux Leakage (MFL), Ultrasonic Testing (UT), and Caliper Pigging.

As the world grapples with increasing energy demands and the aging of oil & gas infrastructure, the adoption of intelligent pigging services is accelerating across key markets.

Rise in Focus on Pipeline Corrosion Control

Corrosion remains one of the biggest threats to pipeline systems. Factors such as water, oxygen, carbon dioxide (CO₂), hydrogen sulfide (H₂S), and microbial activity can significantly degrade pipeline integrity. If left undetected, corrosion can lead to metal loss, system failures, environmental hazards, and loss of life.

To address this, intelligent pigging tools are being widely employed to monitor internal pipeline conditions in real-time. These tools are capable of detecting early-stage corrosion, allowing pipeline operators to take corrective action before more serious damage occurs.

The industry’s focus on pipeline safety and reliability is driving the demand for these services. Intelligent pigs are equipped with sensors that quantify metal loss, assess wall thickness, and detect anomalies, thereby reducing the risk of unplanned downtime and catastrophic failure.

Investment in Oil & Gas Infrastructure

With the global energy demand on the rise, countries are stepping up investments in oil & gas infrastructure to ensure energy security. For instance, Vedanta, an India-based energy conglomerate, announced a US$ 4 billion investment to double its oil & gas output by 2027. Similarly, state-run Indian companies such as ONGC and Indian Oil Corporation plan to invest over US$ 143.6 billion in 2024–2025 across exploration, refining, petrochemicals, and pipeline infrastructure.

These investments naturally lead to increased demand for intelligent pigging services, as newly commissioned pipelines must undergo routine non-destructive inspection (NDI) to comply with safety and operational standards.

Technological Advancements Driving Market Dynamics

Modern intelligent pigging tools are evolving rapidly. Manufacturers are combining cleaning pig design with advanced sensor arrays, enabling multifunctional pigs that are easier to operate and more efficient.

Key innovations include:

System-on-Module (SoM) architectures for autonomous and remote inspections

High-resolution cameras and vision systems for visual validation

AI-powered data analytics for real-time pipeline health reports

Such innovations allow for predictive maintenance and significantly reduce manual inspections. These advancements are reshaping pipeline monitoring practices and transforming the industry into a more digitally connected and proactive ecosystem.

Regional Insights: Asia Pacific Leads the Way

Asia Pacific emerged as the dominant regional market in 2023 and is expected to retain this position through 2034. The rapid industrialization, strong investment in energy infrastructure, and initiatives by public sector undertakings in countries such as India, China, and Japan are fueling the demand.

In India, the government’s push for energy self-sufficiency has led to large-scale pipeline construction projects, especially in underserved and remote regions. This directly contributes to the expansion of the intelligent pigging services sector.

Competitive Landscape: Strategic Moves and Innovation

Key players such as LIN SCAN, T.D. Williamson, Inc., Baker Hughes, GE Vernova, NDT Global, and Shell Plc are focusing on expanding their product lines with multi-sensor pigs, enhanced digital data reporting, and partnership-based service delivery models.

For instance, in May 2024, ConocoPhillips entered a strategic agreement to acquire Marathon Oil, strengthening its position in upstream production and indirectly influencing downstream pipeline inspection needs. Likewise, partnerships such as the one between Artera Services and T.D. Williamson in 2022 demonstrate a shift toward integrated solutions.

Conclusion: A Market Poised for Predictive Integrity Management

The intelligent pigging service market is entering a new phase—driven not only by regulatory compliance but also by technological innovation and a heightened focus on predictive pipeline integrity. As energy infrastructure expands, especially in high-growth regions like Asia Pacific, the demand for intelligent pigging solutions will rise steadily.

With the fusion of AI, IoT, and real-time diagnostics, intelligent pigging is becoming an essential tool in ensuring the safe, sustainable, and efficient delivery of energy across the globe.

0 notes

Text

System on Module (SOM) Market Size, Share, By Type, Application, Top Key Players - Global Opportunity Analysis and Industry Forecast 2022-2030

Global “System on Module (SOM) Market” 2022 Reports give a Key study on the industry status of the System on Module (SOM) Manufacturer with the specific statistics, meaning, definition, SWOT Analysis, expert opinion, and recent development across the globe. The research report also covers the Market Size, Price, Sales, Revenue, Market share, Gross Margin, growth rate, and cost structure. The report aims to give an additional sample of the latest scenario, economic slowdown, and Covid-19 impact on overall Industry.

The System on Module (SOM) research report will also study market share for major stakeholders in their global capacity as transformers of the global scale. This qualitative and quantitative analysis will include key product offerings, key differentiators, revenue share, market size, market status, and strategies. The report will also cover key agreements, collaborations, and global partnership soon to change dynamics of the market on a global scale.

Click the link to get a free Sample Copy of the Report @ https://crediblemarkets.com/sample-request/system-on-module-som-market-80979?utm_source=Kaustubh&utm_medium=SatPR

By Market Verdors: Kontron Congatec MSC Technologies (Avnet) Advantech ADLink Portwell Eurotech SECO srl Technexion Phytec Axiomtek Aaeon Toradex EMAC Avalue Technology By Types: ARM Architecture x86 Architecture Power Architecture By Applications: Industrial Automation Medical Entertainment Transportation Test & Measurement

Some Point from Table of Content:

Global System on Module (SOM) Market Analysis, Key Company Profiles, Types, Applications and Forecast to 2030

1 System on Module (SOM) Market Definition and Overview

2 Research Method and Logic

3 Market Competition Analysis

4 Market Segment by Type, Historical Data and Market Forecasts

5 Market Segment by Application, Historical Data and Market Forecasts

6 Global System on Module (SOM) by Region, Historical Data and Market Forecasts

7 United State Market Size Analysis 2018-2030

8 Canada Market Size Analysis 2018-2030

9 Germany Market Size Analysis 2018-2030

10 UK Market Size Analysis 2018-2030

11 France Market Size Analysis 2018-2030

12 Italy Market Size Analysis 2018-2030

13 Spain Market Size Analysis 2018-2030

14 Russia Market Size Analysis 2018-2030

15 China Market Size Analysis 2018-2030

Direct Purchase this Market Research Report Now @ https://crediblemarkets.com/reports/purchase/system-on-module-som-market-80979?license_type=single_user;utm_source=Kaustubh&utm_medium=SatPR

16 Japan Market Size Analysis 2018-2030

17 South Korea Market Size Analysis 2018-2030

18 Australia Market Size Analysis 2018-2030

19 Thailand Market Size Analysis 2018-2030

20 Brazil Market Size Analysis 2018-2030

21 Argentina Market Size Analysis 2018-2030

22 Chile Market Size Analysis 2018-2030

23 South Africa Market Size Analysis 2018-2030

24 Egypt Market Size Analysis 2018-2030

25 UAE Market Size Analysis 2018-2030

26 Saudi Arabia Market Size Analysis 2018-2030

27 Market Dynamic Analysis and Development Suggestions

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country ➋ Key winning strategies followed by the competitors ➌ Who are the key competitors in this industry? ➍ What shall be the potential of this industry over the forecast tenure? ➎ What are the factors propelling the demand for the System on Module (SOM)? ➏ What are the opportunities that shall aid in significant proliferation of the market growth? ➐ What are the regional and country wise regulations that shall either hamper or boost the demand for System on Module (SOM)? ➑ How has the covid-19 impacted the growth of the market? ➒ Has the supply chain disruption caused changes in the entire value chain?

Contact Us

Credible Markets 99 Wall Street 2124 New York, NY 10005 Email: [email protected]

0 notes

Text

Single Board Computer Market Size, Share, Trends, Demand, Industry Growth and Competitive Outlook

Middle East and Africa Single Board Computer Market Segmentation, Processor Type (Arm Architecture, X86 Architecture, Other Architectures), Operating System (Windows, Linux, Android, and Others), Speed (2 to 4 GHz, 1.5 to 2 GHz, Below 1.5 GHz, and Others), Type (System-on-Chip (SoC) and System-on-Module (SoM)), Distribution Channel (Indirect Sales and Direct Sales), Connectivity (Wired and Wireless), Application (Industrial Automation, Consumer Electronics, Health Care, Automotive, Education and Research, Telecommunications and Others) - Industry Trends and Forecast to 2032

Middle East and Africa single board computer market size was valued at USD 171.91 million in 2024 and is projected to reach USD 223.54 million by 2032, with a CAGR of 3.4% during the forecast period of 2025 to 2032.

Middle East and Africa Single Board Computer Market report not only identifies the emerging trends along with major drivers, challenges and opportunities in the market but also analyses them efficiently. Moreover, this market report includes top to bottom analysis and evaluation of various market related factors that plays key role for better decision making. This market report focuses on the global key manufacturers to define, describe and analyze the market competition landscape via SWOT analysis. Middle East and Africa Single Board Computer Market research study presents actionable market insights with which sustainable and money-spinning business strategies can be created. Middle East and Africa Single Board Computer Market report assists define, describe and forecast the market by type, by application and by region.

Market definition in the Middle East and Africa Single Board Computer Market business report gives the scope of particular product with respect to the driving factors and restraints in the market. The report contains estimations of CAGR values which are quite significant and aids businesses to decide upon the investment value over the time period. Businesses can have an idea about complete background analysis of the industry which includes an assessment of the parental market. Likewise, this Middle East and Africa Single Board Computer Market report puts forth various strategies that are used by key players of the market.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Middle East and Africa Single Board Computer Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/middle-east-and-africa-single-board-computer-market

Middle East and Africa Single Board Computer Market Overview

**Segments**

- By Component: Processor, Memory, Storage, Others - By End-User: Industrial Automation, Aerospace and Defense, Transportation, Healthcare, Others - By Country: UAE, Saudi Arabia, South Africa, Egypt, Nigeria, Rest of Middle East and Africa

The Middle East and Africa single board computer market is segmented based on components, end-users, and countries. The component segment is further divided into processors, memory, storage, and others. Processors play a crucial role in determining the performance of single board computers, while memory and storage are essential for storing and accessing data efficiently. The end-user segment includes industrial automation, aerospace and defense, transportation, healthcare, and others. Each sector has unique requirements for single board computers, with industrial automation and aerospace and defense being the key contributors to market growth. geographically, the market is categorized into UAE, Saudi Arabia, South Africa, Egypt, Nigeria, and the rest of the Middle East and Africa.

**Market Players**

- Intel Corporation - Qualcomm Technologies, Inc. - Raspberry Pi Foundation - NXP Semiconductors - Advantech Co., Ltd. - Arduino - Fujitsu - Adlink Technology Inc. - Axiomtek Co., Ltd. - VersaLogic Corporation

Key players in the Middle East and Africa single board computer market include industry giants such as Intel Corporation and Qualcomm Technologies, Inc. These companies offer a wide range of single board computer solutions catering to various applications and industries. The Raspberry Pi Foundation is known for its affordable yet powerful single board computers that have gained popularity among hobbyists and educational institutions. NXP Semiconductors is another major player known for its cutting-edge technology and innovation in the single board computer market. Advantech Co., Ltd., Arduino, Fujitsu, Adlink Technology Inc., Axiomtek Co., Ltd., and VersaLogic Corporation are also significant contributors to the market, offering diverse product portfolios to meet the growing demand for single board computers in the region.

The Middle East and Africa single board computer market is witnessing robust growth driven by increasing demand for efficient computing solutions across various industries. Industrial automation is one of the leading end-users of single board computers in the region, utilizing these compact and powerful devices for controlling and monitoring manufacturing processes. The aerospace and defense sector also heavily relies on single board computers for critical applications such as unmanned aerial vehicles (UAVs) and radar systems. These industries require high-performance processors, ample memory, and reliable storage solutions to ensure seamless operations.

In terms of market players, Intel Corporation stands out as a dominant force in the Middle East and Africa single board computer market, offering a wide range of processors and chipsets that power these compact computing devices. Qualcomm Technologies, Inc. is another key player known for its expertise in wireless technologies, which are essential for communication and connectivity in single board computer applications. The Raspberry Pi Foundation has carved a niche for itself with its user-friendly and cost-effective single board computers, appealing to both enthusiasts and educational institutions looking to introduce students to computer programming and electronics.

NXP Semiconductors brings cutting-edge technology and innovation to the market, offering advanced solutions for industrial automation, transportation, and healthcare applications. Advantech Co., Ltd., Arduino, Fujitsu, Adlink Technology Inc., Axiomtek Co., Ltd., and VersaLogic Corporation also play significant roles in catering to the diverse needs of customers in the region. These market players continue to innovate and develop new features and solutions to meet the evolving requirements of industries such as healthcare, transportation, and defense.

The Middle East and Africa single board computer market is poised for continued growth, fueled by the increasing adoption of Internet of Things (IoT) devices, automation technologies, and artificial intelligence solutions across various sectors. As industries seek more efficient and reliable computing solutions, the demand for high-performance single board computers is expected to rise. Market players are likely to focus on product development, partnerships, and strategic alliances to gain a competitive edge and capitalize on emerging opportunities in the region. Overall, the outlook for the single board computer market in the Middle East and Africa looks promising, with technology advancements and industry-specific applications driving growth in the coming years.The Middle East and Africa single board computer market is experiencing notable growth due to the increasing demand for efficient computing solutions across various industries in the region. One of the prominent sectors leveraging single board computers is industrial automation, where these compact and powerful devices are utilized for controlling and monitoring manufacturing processes efficiently. The aerospace and defense industry also heavily relies on single board computers for critical applications such as unmanned aerial vehicles (UAVs) and radar systems, highlighting the need for high-performance processors, adequate memory, and reliable storage solutions to ensure seamless operations in these demanding environments.

Key market players in the Middle East and Africa single board computer market are driving innovation and offering a diverse range of products to cater to the evolving needs of customers in the region. Leading companies such as Intel Corporation and Qualcomm Technologies, Inc. are at the forefront, providing a wide array of solutions powered by advanced processors and wireless technologies essential for connectivity and communication in single board computer applications. The Raspberry Pi Foundation has carved a niche for itself with its user-friendly and cost-effective single board computers, appealing to hobbyists, educational institutions, and enthusiasts exploring computer programming and electronics.

NXP Semiconductors is also a significant player in the market, delivering cutting-edge technology and innovative solutions for industrial automation, transportation, and healthcare applications. Advantech Co., Ltd., Arduino, Fujitsu, Adlink Technology Inc., Axiomtek Co., Ltd., and VersaLogic Corporation contribute substantially by offering diverse product portfolios to meet the increasing demand for single board computers in the region. As the adoption of Internet of Things (IoT) devices, automation technologies, and artificial intelligence solutions continues to rise across various sectors, the demand for high-performance single board computers is expected to increase further.

Looking ahead, the Middle East and Africa single board computer market is poised for continued growth, driven by technological advancements and the specific requirements of industries seeking efficient and reliable computing solutions. Market players are likely to focus on continuous product development, strategic partnerships, and alliances to stay competitive and capitalize on emerging opportunities in the region. With a promising outlook, the single board computer market in the Middle East and Africa is expected to witness sustained growth in the coming years, supported by industry-specific applications and the increasing adoption of advanced technologies in various sectors.

The Middle East and Africa Single Board Computer Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/middle-east-and-africa-single-board-computer-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Key Influence of this Market:

Comprehensive assessment of all opportunities and risk in this Middle East and Africa Single Board Computer Market

This Market recent innovations and major events

Detailed study of business strategies for growth of the this Market-leading players

Conclusive study about the growth plot of the Middle East and Africa Single Board Computer Market for forthcoming years

In-depth understanding of this Middle East and Africa Single Board Computer Market particular drivers, constraints and major micro markets

Favourable impression inside vital technological and market latest trends striking this Market

To provide historical and forecast revenue of the market segments and sub-segments with respect to four main geographies and their countries- North America, Europe, Asia, and Rest of the World (ROW)

To provide country level analysis of the market with respect to the current market size and future prospective

Browse More Reports:

Asia-Pacific Medical Robots Market Global Steel Pipes Market Global Rechargeable Spinal Cord Stimulator (SCS) Systems Market Global Carrier Screening Market Asia-Pacific Breast Cancer Diagnostics Market Global Rotavator Market Global Cosmetic Packaging Market Global Cufflinks Market Global Building and Construction Plastic Fasteners Market Global Virtual Private Branch Exchange (PBX) Market Global Metal Nanoparticles Market Global Airborne Radars Market Middle East and Africa Wearable Devices in Sports Market Global Seed Treatment Nematicides Market Global Non-Woven Fabric Market Europe Point-of-Care (POC) Drug Abuse Testing Market Global Security Orchestration Market Global Catalyst Fertilizers for Nitrogenous Fertilizer Market Asia-Pacific Heparin Market Global Microcarrier Market Global Pentane Market Global Molecular Biology Kits and Reagent Market Europe Robotic Vacuum Cleaner Market Global Nerve Regeneration and Repair Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

0 notes

Text

FET-MA35-S2 SoM: A Multi-core Secure Industrial-grade Solution for EV Charging Pile TCU