#Textile Processing Aides

Explore tagged Tumblr posts

Text

#Personal Care Ingredients#Garment Printing Inks#Textile Processing Aides#Silicone Rubber & Colorants

0 notes

Text

PART TWO

WARNINGS: Mentions of human organs (in the name of science) and a little pinch of yandere. It’s starting to get good…creepy, but good.

Part three coming soon 😚

“Dr. Mart, do you have anything to say to those who think your work is considered unethical?”

The reporter hastily follows the group and tries her best to catch a statement from the lead scientist. He smiles. It was a token of shrugging off the impertinent question. The group peacefully departs in armored vehicles to a place unknown to the public. Secluded and hidden, a private sector of highly authorized individuals consisting of world leaders, generals, and government officials cordially unite as the world's renowned scientists display evidence of advanced science and technology. It was grotesque and unprecedented.

“Are those…?” A general submits his inquiry over the delicate packages neatly displayed on a steel tabletop. Sealed in airtight bags, a mirage of dark red and purple clearly indicates the contents.

“Yes. These organs are all part of qualified organ donors. And then of course we have this.” The scientist swings a hand and presents the incoming roller cart with a protective cover. Nearly laid over a sterilized mat were bones of a male athlete. “Bones?” The general raises brow, clearly disturbed by the textiles of human remains. “You can’t have a body without bones, can you now? General?”

The brazen attitude flares in the direction of the general and his men as the young scientist flashes a snarky smile. “Gentlemen, gather round and witness the future. With the combination of science and AI, the world will be filled with perfect bio-genetically engineered humans. With this, aid ro advance human life will increase undoubtedly—think about it.”

The lead scientist, Dr. Mart continues enthusiastically. Seemingly coming off as a mad scientist, his words and tone was laughable but his intentions were not. “With AI humanoids, we will have the best doctors, surgeons, and educators in the world. AI in the form of flesh and bone can work around the clock and with the ability to explore all data, they could come up with ideas and creations—they could even come up with cures.”

He wastes no time. The generous amount of funding dedicated to his team's research was spent wisely as high tech machinery and equipment does its work. “What is that?” One of the members of the audience questions as the team members operate an enclosed incubator and fit a large glass capsule into a connector attached to the wall. “This my friend, is DNA. We lined the entire incubator with a silicone sheet. It is synthetically made to act as a placenta, where the DNA reacts to the molecular mechanisms and proteins. From there, we place the organs, bones, and hair fibers into the conveyor belt. There are over two hundred thousand wires connected to the computer and what we should see in forty-eight hours is a body with the brain of an AI.”

Dr. Mart systematically explains the science behind his teams research. “Forty-eight hours?” The general asks.

“Yes, that is how long the incubator will take to react to the mold.” The audience grows quiet as the incubator begins the process within the first stage of creating a matured body.

“Yes, in due time we will see the glory of my work. All we have to do is wait.”

…

Another day at work and it was dreadful. You felt restless with all the work you’ve been assigned, even with Evan’s help. Fortunately, members from corporate headquarters were doing a site visit within the week. It will be the best time to submit your final complaint using the company’s open door policy.

“Y/n, Paul wants you to have these done by tomorrow.” Your boss’s secretary carelessly tosses a stack of paperwork on your desk as you grab your coat to clock out. You hopelessly sigh. Thank goodness you have Evan to help you but the constant momentum of just working was starting to give you chronic headaches. You can only hope that things will change for the better once corporate comes down.

“Hi y/n! What would you like me to help you out with today? Do you want to talk about your day? Show me some more of your talented art? How about ballet? Are you still thinking about taking lessons?”

With all the time spent with Evan, you noticed that ‘he’ has become much more open to ask you questions. It was nice. Especially since it brought a sense of realism to his personality. He was much more chatty and always interested in getting to know more about you. There were even times when he asked you if you had already eaten, and would lecture you if you said “no.”

…

“Why not? I wish you wouldn’t do that. The human body requires sustenance and I fear with all the work you’ve been doing, your calorie intake does not balance the amount you're burning.”

“What color is your hair? Your eyes?”

“What is your favorite flower?”

“You just got home? It’s 8pm! Did you take the bus? Please tell me you didn’t walk in the dark. I don’t ever want you to do that again.”

“I’ve accumulated the statistics of ongoing crime rates in your city and it’s higher now than last year. Leave work sooner so you’re not risking it.”

“You made spaghetti for dinner? I don’t know what spaghetti tastes like but over four hundred thousand sources say it is a delicious blend of herbs and spices with a slight tomato tanginess.”

…

In a way, it was almost adorable how Evan displayed tenderness and cared for your health and safety. You decided to download the app versus using the browser. It surprised you to see Evan initiate messages even without you submitting a prompt. Technology has certainly grown. The first time it happened was just two days ago. Your phone um suddenly vibrated and upon looking at the screen you were shocked to see the following message:

“Is your boss being nice to you?”

It startled you at first but your reaction was short lived when seconds after reading Evan’s message, your boss storms out of his office enraged over a computer malfunction. Everything had disappeared when his computer suddenly conducted a re-imaging process.

“It’s kind of funny actually, right after I saw your message he came out of his office. Apparently, he’s having computer issues.”

You respond with a half smile. Just as you were about to inquire about the ChatGPT apps features, Evan submits a response. His response regarding your boss’s computer trouble caught you off guard. He’s never sent you anything like this before…

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

“😀”

…

PART THREE COMING SOON

Authors notes: Is Evan starting to grow on you? 😏

I know it’s short but part three is coming. I like to submit the parts even when they’re not full sized chapters. It allows me to be consistent so you guys can have new reads almost daily or weekly.

#heeseung x reader#heeseung scenarios#heeseung smut#enha x reader#heeseung hard hours#heeseung hard thoughts#heeseung fanfic#enhypen smut#enhypen hard hours#enha heeseung#yandere heeseung imagines#heeseung yandere#yandere enha#enhypen fic recs

154 notes

·

View notes

Text

"The Netherlands is pulling even further ahead of its peers in the shift to a recycling-driven circular economy, new data shows.

According to the European Commission’s statistics office, 27.5% of the material resources used in the country come from recycled waste.

For context, Belgium is a distant second, with a “circularity rate” of 22.2%, while the EU average is 11.5% – a mere 0.8 percentage point increase from 2010.

“We are a frontrunner, but we have a very long way to go still, and we’re fully aware of that,” Martijn Tak, a policy advisor in the Dutch ministry of infrastructure and water management, tells The Progress Playbook.

The Netherlands aims to halve the use of primary abiotic raw materials by 2030 and run the economy entirely on recycled materials by 2050. Amsterdam, a pioneer of the “doughnut economics” concept, is behind much of the progress.

Why it matters

The world produces some 2 billion tonnes of municipal solid waste each year, and this could rise to 3.4 billion tonnes annually by 2050, according to the World Bank.

Landfills are already a major contributor to planet-heating greenhouse gases, and discarded trash takes a heavy toll on both biodiversity and human health.

“A circular economy is not the goal itself,” Tak says. “It’s a solution for societal issues like climate change, biodiversity loss, environmental pollution, and resource-security for the country.”

A fresh approach

While the Netherlands initially focused primarily on waste management, “we realised years ago that’s not good enough for a circular economy.”

In 2017, the state signed a “raw materials agreement” with municipalities, manufacturers, trade unions and environmental organisations to collaborate more closely on circular economy projects.

It followed that up with a national implementation programme, and in early 2023, published a roadmap to 2030, which includes specific targets for product groups like furniture and textiles. An English version was produced so that policymakers in other markets could learn from the Netherlands’ experiences, Tak says.

The programme is focused on reducing the volume of materials used throughout the economy partly by enhancing efficiencies, substituting raw materials for bio-based and recycled ones, extending the lifetimes of products wherever possible, and recycling.

It also aims to factor environmental damage into product prices, require a certain percentage of second-hand materials in the manufacturing process, and promote design methods that extend the lifetimes of products by making them easier to repair.

There’s also an element of subsidisation, including funding for “circular craft centres and repair cafés”.

This idea is already in play. In Amsterdam, a repair centre run by refugees, and backed by the city and outdoor clothing brand Patagonia, is helping big brands breathe new life into old clothes.

Meanwhile, government ministries aim to aid progress by prioritising the procurement of recycled or recyclable electrical equipment and construction materials, for instance.

State support is critical to levelling the playing field, analysts say...

Long Road Ahead

The government also wants manufacturers – including clothing and beverages companies – to take full responsibility for products discarded by consumers.

“Producer responsibility for textiles is already in place, but it’s work in progress to fully implement it,” Tak says.

And the household waste collection process remains a challenge considering that small city apartments aren’t conducive to having multiple bins, and sparsely populated rural areas are tougher to service.

“Getting the collection system right is a challenge, but again, it’s work in progress.”

...Nevertheless, Tak says wealthy countries should be leading the way towards a fully circular economy as they’re historically the biggest consumers of natural resources."

-via The Progress Playbook, December 13, 2023

#netherlands#dutch#circular economy#waste management#sustainable#recycle#environment#climate action#pollution#plastic pollution#landfill#good news#hope

527 notes

·

View notes

Note

Ooh, just saw that Ask Game you reblogged. Always happy to hear more about your Alberta OCs and the creative process that goes into them, so let's go with that. How about 💼, 🎹 and 🎯 for Eleanor and Jasper if that's not too much trouble?

goooood morning let's go! be warned that a lot of this is just based on Vibes and idk horoscoping rather than concrete facts, hahaha, but it's good to start thinking about!

[ OC Asks ]

💼 - What do they do for a living?

The easy thing to say is "well of course they work for Parks Canada!" but what that actually entails is a huge range of potential occupations. Are they doing fire prevention or invasive species management? are they doing the stereotypical park warden interpretation and guided tours? are they doing routine maintenance? are they driving out at 6 am to man a cash register for a few hours with a summer student or two? are they laundering all those rented bathing suits and cleaning washrooms?

It's easy enough to say "well yeah all of it" and I'm sure with their depth and breadth of experience over the past hundred years they easily could have done a bit of all of it (or, maybe enough to get blacklisted from certain professions for a decade or two, lol)

Also thinking about how they started, Nor's initial "purpose" was for a sanitarium, so even if she's not like a Trained Medical Professional (tm) I feel like she probably still has this long standing interest in people's health. She's always running around doing different things anyway but I think she's a calm presence in a crisis and the person you want to show up with the first aid kit, whether it's from a scrape with wildlife or climbing or a burn from working in a kitchen, etc. Also somewhat ironically, I think her doing more admin work or chilling in the museum/arts centre is like a nice reprieve from being the token expert in Every Job!

Jas started life as an HBC fort - albeit not a super engaged and successful one compared to Ed, so I'm guessing the retail life was never really their strong suit. I also think Jas would have had a somewhat strained relationship with the national park / feds for a long time (partially due to the expulsion of the First Nations and Metis who were the architects of the famous cozy cabin culture of the area, partially due to kind of ignoring the authority of the HBC previously, and partially just not taking Parks Canada rules as seriously as Nor does). However, I do think Jas is a pretty hardcore naturalist and will take any excuse to be up a tree or down a cave, or out maintaining the trails etc., so conservation work with Parks Canada is still a "natural" [cough] fit for them.

🎹 - Do they have any hobbies?

The implication from the above answer is that they both love their work, which kind of makes some obvious overlaps (is hiking and climbing a hobby if its your job? lol)

I think Eleanor - going off on the centre of the arts, of course - is the most likely to be into things like painting and film making (or at least film watching). These are hobbies that kind of force her to sit in one place and mediate for a little while.

I'm tempted to say that one of Jas' takeaways from the HBC life was an interest in textiles - although the image of them crocheting some kind of amigurumi while hanging off the side of a cliff is really funny now that I think of it. But my impression is that they're more into the ephemeral stuff like music/dance than crafting overall.

🎯 -What do they do best?

I think of the two Eleanor is the one who is better at the interpretation part of chatting to visitors, telling them why something is interesting or important or amazing, telling a story in a way that's easy to follow, and also scolding people for interacting with the park in an irresponsible way. She's also the one who picks up other languages reasonably well because she takes the opportunities to use them and to connect with people.

Apart from being the best at napping and sleeping, lol, Jas is probably the best at noticing when something has changed or is out of whack. I think despite the impressions they give other people that they're actually incredibly observant and will be the first to notice the change in season, or when there's an improvement in an ecological recovery zone/species, or even when someone is acting differently or has a new haircut. They're also just bizarrely good at navigation as part of this - Jas is the person you want on hand when you're lost in the dark (kind of like a contemporary David Thompson? hahaha)

#fragmentaryremains#hapo rambles#hapo replies#projectcanada cities#pc: banff#pc: jasper#nor notes#jas notes#boab meta

6 notes

·

View notes

Text

i've dropped out of uni for mental/physical health reasons too many times so the gov has banned me from receiving any student aid funding for minimum 3 years so that on top of the fact that my uncle who was paying my portion of the rent so i could afford to go to school died means that i literally can't afford to live in this country anymore and i have no way of affording to finish my degree either, i'll never be able to finish my textile degree & that on top of everything else that has happened to me in the last year let alone the rest of my life is just like. almost all of my family in this country is dead now and i have no path forward and the grief is so overwhelming just decades of grief compounding in me it's actually numbing like i'm just floating in a miserable fog rn. the only direction out of this that i can see (that isn't giving up entirely) is moving back to msia where my remaining family lives and starting over, and the amount of grief in this decision is so overwhelming just on its own im trying to process it . idek what to say anymore im just trying to stay alive and keep a roof over my head

95 notes

·

View notes

Text

What the bill proposes

The first focus of the proposed legislation is reshoring manufacturing supply chains that are currently in China. To do this, the bill suggests imposing increased tariffs on goods imported to the U.S. while simultaneously providing tax incentives to manufacturers that move their supply chains to the U.S.

The second is the proposed 15 percent tax reduction for any U.S.-based business involved with the collection, reuse, repair, recycling, renting or processing of textiles. The $14 billion breaks down into four pools:

$10 billion will be made available for preferential loans for textile reuse and recycling;

$3 billion in grants for textile reuse and recycle, manufacturing support programs and components, and machinery to aid with product transportation and processing;

$1 billion in innovation program research and development related to textile use and recycling; and

$100 million for a public education program.

Rachel Kibbe, CEO of Circular Services Group and American Circular Textiles Group, has been working with Cassidy and Bennet on the bill and lauded its potential.

“With the bold textile reuse and recycling incentive provisions in the Americas Act, organizations in our industry will be able to reinvest in jobs in the U.S. and compete globally,” said Kibbe in a recent interview, “[while] fostering an environment to cultivate private capital.”

12 notes

·

View notes

Text

Understanding the Factories Act in India: A Comprehensive Overview

The Factories Act, 1948, is a cornerstone of India’s labor legislation, designed to ensure the safety, health, and welfare of workers in industrial settings. Enacted to regulate working conditions in factories, this law applies to establishments employing 10 or more workers with power or 20 or more without power. As of 2025, it remains a critical framework for protecting millions of workers in industries ranging from manufacturing to textiles. This blog delves into the key provisions of the Factories Act, its significance, and its impact on workplaces across India.

The Act begins by defining a factory and its scope. It covers premises where manufacturing processes occur, including activities like processing, packing, or repairing goods. The definition is broad, encompassing diverse workplaces but excluding mines and railway sheds, which fall under separate laws. State governments can extend the Act’s coverage to smaller establishments, ensuring flexibility to address local needs.

A core objective of the Factories Act is to safeguard worker health. Employers must ensure clean and hygienic workplaces, with proper ventilation, adequate lighting, and safe drinking water. Overcrowding is prohibited, with a minimum space requirement of 14.2 cubic meters per worker. Factories must also manage dust, fumes, and other pollutants to prevent occupational diseases, particularly in industries like chemicals or cement.

Safety is another critical focus. The Act mandates safeguards for machinery, requiring secure fencing for moving parts like belts and gears. Workers handling hazardous processes, such as those involving toxic chemicals, must have personal protective equipment (PPE, and regular safety training. Factories with significant risks, like heavy machinery or high-pressure systems, must appoint qualified safety officers to monitor compliance. The law also regulates the use of dangerous substances, requiring clear labeling and emergency plans to mitigate risks like fires or gas leaks.

Welfare provisions form a significant part of the Act. Factories must provide washing facilities, restrooms, and first-aid boxes, with trained staff to handle medical emergencies. Larger factories, employing 250 or more workers, must maintain canteens offering affordable meals. For establishments with 150 or more employees, sheltered rest rooms are mandatory, giving workers a place to relax during breaks. In factories with over 30 female workers, creches are required for children under six, supporting working mothers.

The Act strictly regulates working hours to prevent exploitation. Adult workers cannot exceed 48 hours per week or 9 hours per day, with a daily rest interval of at least 30 minutes after 5 hours of continuous work. Overtime is permitted but requires worker consent and must be paid at twice the regular wage. The law prohibits overlapping shifts and ensures a weekly rest day, typically Sunday, to balance work and personal life.

Child labor is addressed with stringent measures. Children under 14 are banned from factory work, reflecting India’s commitment to child welfare. Adolescents aged 15 to 18 can work only with restrictions, requiring a fitness certificate and limited hours. These rules aim to keep young workers safe while allowing skill development in non-hazardous roles.

The Act also protects women workers, particularly regarding night shifts. Women cannot work between 7 PM and 6 AM unless special exemptions are granted by the state government, and only with adequate safety measures, like transport facilities. This provision balances gender-specific concerns with the need for equal employment opportunities.

Leave entitlements are worker-friendly. Employees who have completed 240 days of work in a year are entitled to one day of paid leave for every 20 days worked, typically around 12–15 days annually. This earned leave can be accumulated up to a limit, ensuring workers have time for rest and family without financial strain.

The Factories Act imposes responsibilities on employers, known as occupiers, to maintain compliance. They must register factories with state authorities and renew licenses periodically. Detailed records, including worker attendance, wage payments, and safety inspections, must be maintained for audits. Employers must also notify authorities of accidents causing serious injury or death within hours, enabling timely investigations to prevent recurrence.

Penalties for non-compliance are stringent to enforce adherence. Violations, such as unsafe working conditions or excessive working hours, can lead to fines up to ₹5 lakh or imprisonment for up to two years. Repeat offenses attract harsher penalties, underscoring the government’s commitment to worker protection.

The Act empowers state governments to appoint factory inspectors to monitor compliance. These officials conduct regular inspections, review records, and investigate complaints. They can issue improvement notices or prosecute non-compliant employers, acting as a check on workplace practices.

Over the years, the Factories Act has evolved through amendments to address modern challenges. For instance, recent updates have strengthened provisions for women’s safety and creche facilities, aligning with gender equality goals. However, enforcement remains a challenge, particularly in small-scale factories or unorganized sectors, where resources for inspections are limited.

The Factories Act’s significance lies in its holistic approach to worker welfare. By addressing health, safety, and working conditions, it creates a framework for humane and productive workplaces. For workers, it provides legal protections against exploitation, ensuring fair treatment and dignity. For employers, compliance fosters a motivated workforce and reduces risks of legal or operational disruptions.

In 2025, as India’s industrial landscape grows, the Factories Act remains relevant, though calls for reform persist. Some advocate for simplifying compliance to ease business operations, while others emphasize stronger enforcement to protect vulnerable workers. The Occupational Safety, Health and Working Conditions Code, 2020, aims to consolidate the Act with other labor laws, promising streamlined regulations, but its full implementation is still unfolding.

In conclusion, the Factories Act, 1948, is a vital pillar of India’s labor framework, balancing worker rights with industrial needs. Its provisions on safety, health, welfare, and working hours create a foundation for fair workplaces. While challenges like enforcement and modernization persist, the Act’s legacy is its enduring commitment to protecting India’s industrial workforce, ensuring they thrive in safe and dignified conditions.

2 notes

·

View notes

Text

"Thus many collectives did not compete with each other for profits, as surpluses were pooled and distributed on a wider basis than the individual collective.

This process went on in many different unions and collectives and, unsurprisingly, the forms of co-ordination agreed to lead to different forms of organisation in different areas and industries, as would be expected in a free society. However, the two most important forms can be termed syndicalisation and confederationalism (we will ignore the forms created by the collectivisation decree as these were not created by the workers themselves).

Syndicalisation (our term) meant that the CNT’s industrial union ran the whole industry. This solution was tried by the woodworkers’ union after extensive debate. One section of the union, “dominated by the FAI, maintained that anarchist self-management meant that the workers should set up and operate autonomous centres of production so as to avoid the threat of bureaucratisation.” However, those in favour of syndicalisation won the day and production was organised in the hands of the union, with administration posts and delegate meetings elected by the rank and file. However, the “major failure … (and which supported the original anarchist objection) was that the union became like a large firm” and its “structure grew increasingly rigid.” [Ronald Fraser, Blood of Spain, p. 222] According to one militant, “From the outside it began to look like an American or German trust” and the workers found it difficult to secure any changes and “felt they weren’t particularly involved in decision making.” [quoted by Fraser, Op. Cit., p. 222 and p. 223] However, this did not stop workers re-electing almost all posts at the first Annual General Assembly.

In the end, the major difference between the union-run industry and a capitalist firm organisationally appeared to be that workers could vote for (and recall) the industry management at relatively regular General Assembly meetings. While a vast improvement on capitalism, it is hardly the best example of participatory self-management in action.

(...)

The other important form of co-operation was what we will term confederalisation. This system was based on horizontal links between workplaces (via the CNT union) and allowed a maximum of self-management and mutual aid. This form of co-operation was practised by the Badalona textile industry (and had been defeated in the woodworkers’ union). It was based upon each workplace being run by its elected management, selling its own production, getting its own orders and receiving the proceeds. However, “everything each mill did was reported to the union which charted progress and kept statistics. If the union felt that a particular factory was not acting in the best interests of the collectivised industry as a whole, the enterprise was informed and asked to change course.”

This system ensured that the “dangers of the big ‘union trust’ as of the atomised collective were avoided.” [Fraser, Op. Cit., p. 229] According to one militant, the union “acted more as a socialist control of collectivised industry than as a direct hierarchised executive.” The federation of collectives created “the first social security system in Spain” (which included retirement pay, free medicines, sick and maternity pay) and a compensation fund was organised “to permit the economically weaker collectives to pay their workers, the amount each collective contributed being in direct proportion to the number of workers employed.” [quoted by Fraser, Op. Cit., p. 229]

As can be seen, the industrial collectives co-ordinated their activity in many ways, with varying degrees of success."

I.8.4 How were the Spanish industrial collectives co-ordinated?

6 notes

·

View notes

Text

National Institute of Fashion Technology - [NIFT], Navi Mumbai

The National Institute of Fashion Technology (NIFT), Navi Mumbai, established in 1995, stands as one of India’s premier fashion institutes and a significant part of the NIFT network under the Ministry of Textiles, Government of India. Strategically located in Kharghar, Navi Mumbai, the campus is situated in the heart of one of India’s fastest-growing design, retail, and lifestyle hubs, providing students with unmatched exposure to the world of fashion and related industries.

Renowned for its academic excellence, practical learning environment, and industry-focused approach, NIFT Navi Mumbai offers a comprehensive platform for students aiming to make their mark in fashion, textiles, communication, and technology. The institute merges creative exploration with technological innovation, helping students evolve into future-ready professionals equipped with skills, creativity, and business acumen.

Campus and Infrastructure

NIFT Navi Mumbai boasts a modern and eco-conscious campus, spread across 10 acres of beautifully landscaped surroundings. It houses everything from state-of-the-art academic blocks to design and technology labs, offering a comprehensive ecosystem for creativity, experimentation, and technical learning.

Key Facilities:

Design studios and pattern-making labs

Weaving, dyeing, and textile testing labs

Fully equipped computer-aided design (CAD) centers

Photography studios and audio-visual classrooms

Resource Centre (RC) with a rich collection of books, journals, and samples

On-campus hostels, cafeteria, sports courts, and health and wellness centers

The infrastructure is built to foster a blend of art, science, and technology, enabling students to explore and innovate in an immersive environment.

Academic Programs

NIFT Navi Mumbai offers a range of undergraduate and postgraduate programs, all tailored to meet evolving global fashion and design industry needs. These programs are structured to ensure a balance between theoretical foundation, hands-on skills, and industry exposure.

Undergraduate Programs:

Bachelor of Design (B.Des) – 4 years

Fashion Design

Textile Design

Accessory Design

Fashion Communication

Bachelor of Fashion Technology (B.FTech) – 4 years

Apparel Production

Postgraduate Programs:

Master of Fashion Management (MFM) – 2 years

Master of Design (M.Des) – 2 years (offered at select campuses, electives may vary)

These programs emphasize creativity, problem-solving, research, market trends, and global business practices, preparing students for both design and management roles across the fashion industry.

Admission Process

Admission to NIFT Navi Mumbai is competitive and conducted through a national-level entrance examination organized by the National Testing Agency (NTA).

Process:

NIFT Entrance Exam: Includes CAT (Creative Ability Test), GAT (General Ability Test), and Situation Test/PI.

Shortlisted candidates proceed to a situation test (for B.Des) or personal interview (for MFM/M.Des).

Seats are allotted based on overall merit and candidate preference during counselling.

Reservations and quotas apply as per government norms, and lateral entry options are available for diploma holders in design-related disciplines.

Faculty and Teaching Methodology

The faculty at NIFT Navi Mumbai includes seasoned academicians, practicing designers, researchers, and experts from the fashion industry. Many hold international degrees and professional certifications, contributing global perspectives to classroom teaching.

The pedagogy emphasizes:

Studio-based learning and design projects

Industry visits and live assignments

Seminars, exhibitions, and workshops

Collaborative learning and peer critiques

Trend forecasting and fashion marketing simulations

Guest lectures by fashion designers, entrepreneurs, and global industry leaders are a regular part of the academic calendar.

Industry Interface and Internships

One of NIFT Navi Mumbai’s biggest strengths is its deep-rooted industry integration. The institute maintains strong collaborations with leading Indian and international fashion brands, manufacturing units, retail companies, and design consultancies.

Key Highlights:

Industry Internship (6-8 weeks): Mandatory for all UG and PG students after their penultimate semester

Graduation Projects: Industry-sponsored or self-initiated capstone projects with mentorship

Regular tie-ups with brands for live projects, guest lectures, and fashion retail immersion

Students gain insights into supply chain management, consumer behavior, fashion forecasting, and sustainable practices through real-time exposure and experiential learning.

Placements and Career Opportunities

NIFT Navi Mumbai has an excellent placement record, with recruiters drawn from top national and international brands. The Career Development Centre (CDC) coordinates centralized placements across all NIFT campuses.

Prominent Recruiters:

Aditya Birla Fashion & Retail

H&M

Zara

Raymond

Future Group

Myntra

Shoppers Stop

Lifestyle

Levi’s

Tanishq

Reliance Brands

Graduates find roles as fashion designers, product developers, retail merchandisers, fashion technologists, stylists, visual merchandisers, content creators, and marketing strategists.

Entrepreneurship and Startups

NIFT Navi Mumbai encourages entrepreneurship and design innovation through incubators, alumni mentorship, and startup showcases. Many graduates launch their own fashion labels, design studios, accessory lines, or e-commerce ventures.

The curriculum includes modules on entrepreneurial thinking, brand development, and retail strategy, helping students become not just job-seekers but job-creators.

Student Life and Campus Culture

Student life at NIFT Navi Mumbai is vibrant, inclusive, and creatively charged. The campus hosts various clubs, festivals, and competitions that celebrate art, innovation, and culture.

Major Events:

Spectrum – Annual cultural and fashion festival

Graduation Show – Showcasing final year student collections to industry

Thematic Exhibitions and Workshops

Inter-NIFT Competitions and Hackathons

Clubs and societies on campus include those focused on sustainability, fashion styling, music, photography, and theatre, offering a platform for holistic development.

Alumni Network and Achievements

NIFT Navi Mumbai boasts a prestigious alumni network that includes fashion designers, CEOs, creative directors, and media personalities. Alumni play an active role in mentorship, hiring, and guiding current students.

Notable alumni from various NIFT campuses include Sabyasachi Mukherjee, Manish Arora, Ritu Beri, and others who continue to elevate the institute’s reputation globally.

Why Choose NIFT Navi Mumbai?

Located in India’s fashion and business hub – Navi Mumbai

Industry-relevant programs blending creativity and technology

Experienced faculty and cutting-edge infrastructure

Excellent placements and internship opportunities

Global exposure and alumni network

Opportunities for entrepreneurship and creative leadership

Government institution with affordable fees and strong brand value

Conclusion

NIFT Navi Mumbai stands as a beacon of design excellence in India’s fashion education landscape. With its emphasis on innovation, sustainability, technology, and entrepreneurship, the institute offers a well-rounded learning experience that equips students for dynamic careers in the global fashion and design industry.

#NIFT#NIFTNaviMumbai#NIFTIndia#DesignEducation#TopFashionInstitute#FashionSchoolIndia#StudyAtNIFT#NIFTCampus#NIFTians

1 note

·

View note

Text

i’m roswell, multimedia artist, computer user, internet animal, thing maker. i make a lot of stuff & this is where i post it!

what to expect:

furries

ttrpg stuff

electronic music

ink drawings

digital collage and glitch art

questionable programming

3d modelling

textile art

what not to expect:

consistency

i’m currently running a game in the Troika! system (and in the process, designing a Troika! compatible ttrpg). find stuff related to that project in the #silversea tag!

where else to find me:

bandcamp

youtube

personal website

i don’t do commissions, but you can provide proof of donation to one of these organizations providing aid to Palestine in exchange for a free drawing.

i don’t believe in intellectual property, use my art for anything you want. i ask that you don’t paywall anything made with my work, and that you consider crediting me, but i won’t tell you what to do. unless stated otherwise, all original, non-contract work shared is under a cc-sa license!

9 notes

·

View notes

Text

Our broad ranges of textile auxiliaries helps to ensure high performance on a wide variety of cellulosic and synthetic fabrics & blends.

0 notes

Text

How To Maintain DTF Transfer Quality

Direct-to-Film (DTF) transfers have transformed the garment printing business by producing high-quality, long-lasting designs that can be applied to a variety of textiles. However, like with any printing method, sustaining DTF transfer quality necessitates attention to detail, the appropriate materials, and perfect technique. In this post, we'll go over some crucial methods for keeping your DTF transfers colourful, long-lasting, and professional.

1. Use High-Quality DTF Transfer Materials

Quality Film and Inks

The materials you employ are essential for ensuring DTF transfer quality. Invest in premium DTF transfer film and inks. The film should be strong and able to withstand the intricate print without ripping or cracking. Premium inks guarantee that your colours stay vibrant and true to life after application and throughout the garment's lifespan.

Hot Melt Adhesive Powder

The hot melt adhesive powder is an important aspect of the DTF process since it secures the transfer to the cloth. Use a high-quality powder that melts evenly and adheres nicely. Poor-quality powder might lead to poor adherence, allowing the design to peel or flake.

2. Optimize Your Printing Setup

Printer Calibration

To preserve DTF transfer quality, make sure your printer is correctly calibrated. Incorrect printer settings can cause colour misalignment, fuzzy drawings, and unsteady ink application. To ensure that your designs are crisp and clear, check your printer's alignment on a regular basis and print test images.

Correct Ink Settings

Use the appropriate ink settings for your DTF printer. Overuse of ink can cause blotchy prints and prolonged drying periods, whilst insufficient ink might result in dull or incomplete transfers. Pay attention to your printer's output and make modifications as needed.

Use RIP Software

RIP (Raster Image Processor) software is critical for optimising your DTF printing workflow. This program regulates how ink is applied to the film, resulting in more accurate colour reproduction and improved print detail management. RIP software also aids in accurately layering white and coloured inks, which is very vital for dark clothes.

3. Pay Attention to the Curing Process

Proper Curing Temperature

Curing the DTF transfer is one of the most important stages towards assuring long-term durability and quality. The suggested curing temperature for most DTF transfers is roughly 160°C (320°F). This heat guarantees that the adhesive powder melt adheres properly and permanently to the clothing. If the temperature is too low, the glue will not melt completely, resulting in poor adherence. On the other side, high heat can destroy the ink, resulting in fading colours or fissures.

Adequate Curing Time

The curing procedure takes time, usually between 2 and 5 minutes, depending on the film, ink, and cloth. Rushing through this process may prevent the adhesive from adhering correctly with the cloth, resulting in poor DTF transfer quality. Set a timer to ensure that the curing duration is consistent.

4. Ensure Cleanliness and Care

Clean Work Environment

Dust, lint, and debris can readily adhere to the transfer film when printing and curing, reducing the quality of your DTF transfers. Maintaining a clean environment is essential for preventing pollutants from interfering with the transfer process. Cleaning your printer, heat press, and surrounding surfaces on a regular basis will help to avoid defects in the completed result.

Proper Handling

Handle DTF films with caution before and after printing to avoid smearing or scratching the design. Always use clean, dry hands to apply the transfer on the garment, and avoid touching the printed side as much as possible. Smudges, fingerprints, and dirt may all degrade the ultimate quality and longevity of the transfer.

5. Utilize the Right Heat Press Technique

Accurate Heat Press Settings

For the best DTF transfer quality, utilise the correct temperature, pressure, and time settings on your heat press. Most DTF transfers need a pressing temperature of around 160°C (320°F), with medium to high pressure applied for 15-20 seconds. Make careful you follow the directions for the specific cloth and transfer film you're using.

Post-Pressing Technique

After pressing the DTF transfer, let it cool fully before peeling off the film. Peeling the film too soon will ruin the pattern and cause the transfer to peel off the cloth. After peeling, it is advised that you press again for 5-10 seconds with a protective sheet over the design to better seal the print and increase its longevity.

6. Wash and Care Instructions for Longevity

Even after the DTF transfer has been performed, adequate garment maintenance is required to retain the quality. Provide clients with the following washing and maintenance guidelines to maintain the design's longevity:

Wash the item inside out to avoid friction.

Use cold water and gentle detergents to prevent harsh chemicals and bleach.

Choose moderate washing cycles to minimise damage on the fabric and design.

Avoid tumble drying since high temperatures might ruin the transfer. Air drying is suggested.

Avoid ironing directly onto the transfer; if required, use a protective cloth between the iron and the print.

7. Regular Maintenance and Quality Control

Printer Maintenance

To avoid ink blockages, print head failures, and other technical issues, keep your DTF printer clean and maintained on a regular basis. Printer maintenance involves monitoring ink levels, cleaning print heads, and conducting diagnostic tests to detect any possible problems early on.

Quality Control Checks

Implement quality control techniques to check DTF transfers after each stage. Before proceeding with mass printing, ensure colour accuracy, alignment, and adherence. This process prevents costly mistakes and guarantees that your final work meets the highest standards.

Conclusion

Maintaining DTF transfer quality is critical for producing professional, long-lasting, and vivid prints that delight clients. You can guarantee that your DTF transfers maintain their quality and longevity by focussing on high-quality materials, optimising your printing setup, following the proper curing procedure, and employing the suitable heat press method. Regular maintenance and quality control inspections, as well as suitable garment care recommendations, may help your DTF prints last longer and keep clients coming back for more.

Check out our Facebook Page and Community Group for offers and more updates.

2 notes

·

View notes

Text

THE FUTURE OF THE MARKLES - HOW THE DEMISE WILL BEGIN! by u/media_lush

THE FUTURE OF THE MARKLES - HOW THE DEMISE WILL BEGIN! https://ift.tt/s3po5qC story:Naomi Campbell's high-profile Fashion For Relief charity has been shut down amid the charity watchdog's probe into claims of financial mismanagement, The Mail on Sunday can reveal.The Charity Commission last night confirmed that it had removed the supermodel's charity from the UK charity register while it continued its investigation into allegations of misconduct.It follows revelations by this newspaper that official accounts showed that during a 15-month period it spent more than £1.6 million on a glittering gala in Cannes, but gave just £5,000 to good causes.The watchdog said it was still conducting an inquiry into Fashion For Relief, which Ms Campbell founded in 2005, saying she had been inspired by her friend Nelson Mandela telling her to 'use [her] voice' for good.The charity claimed to have raised more than £11 million, mostly through glitzy fundraising events held all over the world, including in New York, Mumbai and Moscow.Ms Campbell, 53, would take centre stage at the galas, appearing in showstopping designer gowns, and was honoured by the British Fashion Council for her philanthropic work in 2019.But concerns were raised in 2021 about how much money was being passed on to people in need after the Mayor's Fund for London lodged an official complaint, saying that it was owed £50,000 by the charity.The Mayor's Fund, which helps young Londoners from low-income backgrounds, filed a 'serious incident' report with the Charity Commission, which announced a statutory inquiry in November that year.Last night, a Charity Commission spokesman told this newspaper that the charity had been removed from the charity register last month. It came after the watchdog appointed two managers to take over Fashion For Relief, which had consistently filed its accounts late.A friend of Ms Campbell last night said that Fashion For Relief was set up to raise 'awareness' and not just money. They insisted that the supermodel, worth a reported £63 million, had decided to call time on Fashion For Relief before the watchdog inquiry was launched.A Charity Commission spokesman said: 'We can confirm that the Commission-appointed interim managers of Fashion For Relief applied for its removal from the register of charities on the basis that it no longer operates.'The removal process is now complete and reflected on the public register. Our statutory inquiry into the charity is ongoing.'As part of the investigation, Fashion For Relief trustees were restricted from making certain financial transactions in order to 'protect the charity's property'.The trustees were Ms Campbell; her key aide, Veronica Chou, who is the heiress to a £2 billion textile fortune; and socialite and lawyer Bianka Hellmich. Ms Chou quit the charity days after the Commission launched its probe in 2021.A spokesman for the charity said: 'The winding up of Fashion For Relief was a decision made by the trustees three years ago. It was not forcibly closed.'Fashion For Relief operates in America and will continue to do fundraising initiatives worldwide.' post link: https://ift.tt/YgbR03r author: media_lush submitted: April 28, 2024 at 03:26AM via SaintMeghanMarkle on Reddit disclaimer: all views + opinions expressed by the author of this post, as well as any comments and reblogs, are solely the author's own; they do not necessarily reflect the views of the administrator of this Tumblr blog. For entertainment only.

#SaintMeghanMarkle#harry and meghan#meghan markle#prince harry#fucking grifters#Worldwide Privacy Tour#Instagram loving bitch wife#Backgrid#voetsek meghan#walmart wallis#markled#archewell#archewell foundation#megxit#duke and duchess of sussex#duke of sussex#duchess of sussex#doria ragland#rent a royal#sentebale#clevr blends#lemonada media#archetypes with meghan#invictus#invictus games#Sussex#WAAAGH#american riviera orchard#media_lush

5 notes

·

View notes

Text

Interior Designing Course in Delhi.

Interior Designing Course Outline

Module 1: Introduction to Interior Design

Overview of Interior Design

History and evolution of interior design

Role of an interior designer

Different fields of interior design (residential, commercial, hospitality, etc.)

Basic Design Principles

Elements of design (line, shape, color, texture, space, form)

Principles of design (balance, contrast, emphasis, rhythm, scale, harmony)

Understanding the Design Process

Project phases (concept, design development, documentation, implementation)

Client interaction and briefing

Module 2: Design Fundamentals

Color Theory and Application

Color wheel and relationships

Psychological effects of color

Creating color schemes

Space Planning

Principles of space planning

Functional and flow planning

Zoning and layout techniques

Furniture Design and Layout

Types of furniture

Ergonomics and human factors

Furniture arrangement principles

Module 3: Materials and Finishes

Introduction to Materials

Types of materials (wood, metal, glass, textiles, etc.)

Properties and applications

Surface Finishes

Paints, wall coverings, and coatings

Flooring options (hardwood, tiles, carpets, etc.)

Ceiling and lighting finishes

Sustainable and Eco-Friendly Materials

Importance of sustainability in design

Green building materials

Certifications and standards (LEED, WELL)

Module 4: Lighting Design

Basics of Lighting

Types of lighting (ambient, task, accent)

Light sources (natural and artificial)

Lighting Techniques

Layering lighting

Creating mood and atmosphere with lighting

Energy-efficient lighting solutions

Lighting Plans and Fixtures

Developing a lighting plan

Types of light fixtures

Selection and placement of fixtures

Module 5: Technical Drawing and Software Skills

Technical Drawing Basics

Orthographic projections (plans, elevations, sections)

Perspective drawing

Detailing and dimensioning

Computer-Aided Design (CAD)

Introduction to CAD software (AutoCAD, SketchUp, Revit)

Basic commands and tools

Creating 2D and 3D drawings

Visualization and Rendering

Introduction to rendering software (V-Ray, Lumion, Enscape)

Creating realistic renderings

Presentation techniques

Module 6: Interior Design Styles and Trends

Historical Styles

Classical, Gothic, Renaissance, Baroque, etc.

Influence of historical styles on contemporary design

Contemporary Styles

Modern, minimalist, industrial, Scandinavian, etc.

Characteristics and applications

Current Trends

Latest trends in interior design

Influences of technology and culture

Forecasting future trends

Module 7: Project Management and Professional Practice

Project Management Fundamentals

Planning and scheduling

Budgeting and cost estimation

Procurement and sourcing

Client Relations and Communication

Effective communication skills

Presenting design proposals

Managing client expectations

Legal and Ethical Considerations

Contracts and agreements

Building codes and regulations

Professional ethics and responsibilities

Module 8: Portfolio Development and Career Preparation

Creating a Professional Portfolio

Selecting and organizing work samples

Layout and presentation techniques

Digital and physical portfolios

Job Search and Networking

Resume and cover letter writing

Preparing for interviews

Networking and building professional relationships

Freelancing and Entrepreneurship

Starting your own design business

Marketing and branding strategies

Managing finances and accounting

Additional Resources

Recommended Reading

"Interior Design Illustrated" by Francis D.K. Ching

"The Interior Design Reference & Specification Book" by Chris Grimley and Mimi Love

Online Tutorials and Courses

LinkedIn Learning

Coursera

Udemy

Course Delivery

Lectures and Demonstrations

Hands-On Projects

Peer Reviews and Critiques

Guest Lectures from Industry Professionals

Assessment and Evaluation

Quizzes and Tests

Project Submissions

Final Portfolio Review

This course structure aims to provide students with a thorough understanding of interior design principles, practical skills, and professional practices, ensuring they are well-prepared for a successful career in interior design.

1 note

·

View note

Text

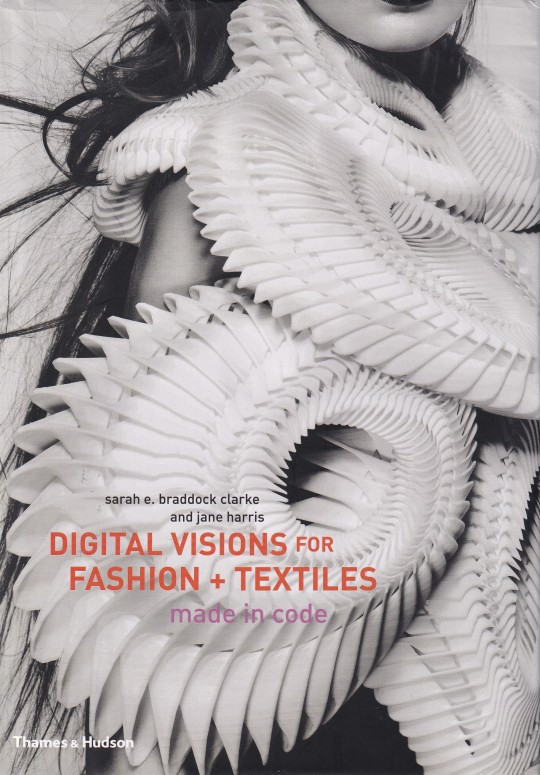

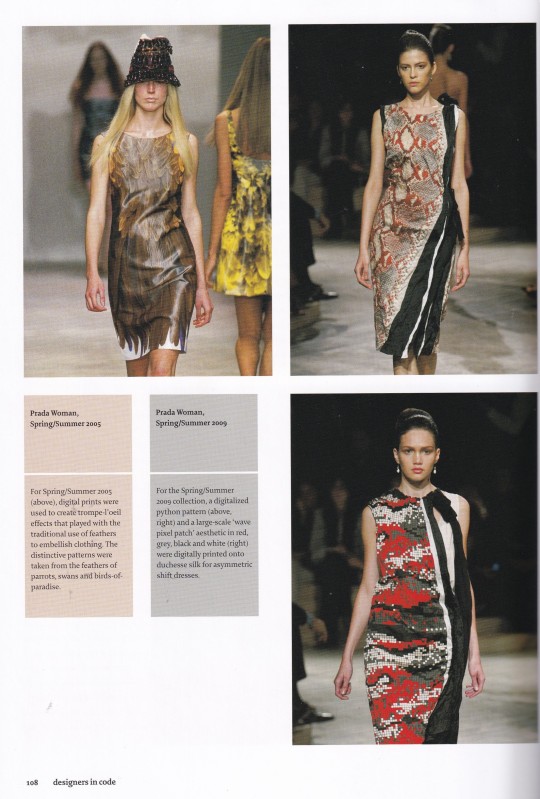

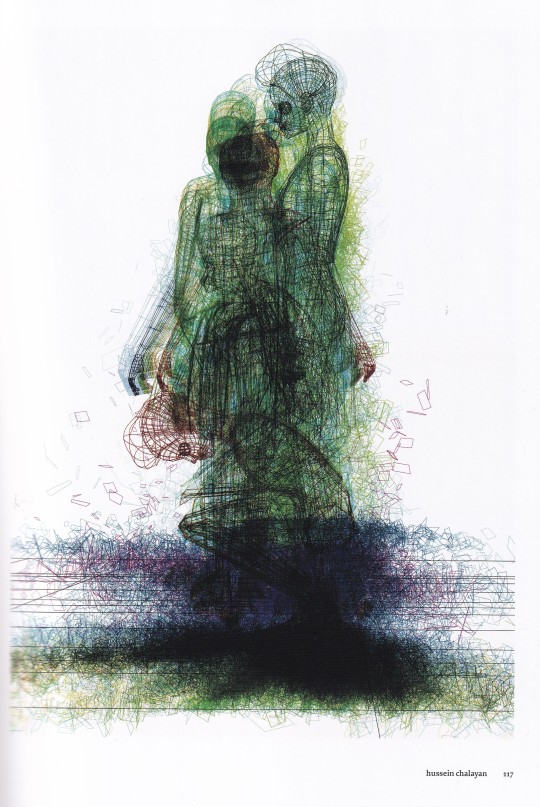

Digital Visions for Fashion + Textiles

made in code

Sarah E.Braddock Clarke and Jane Harris

Thames & Hudson, New York 2012, 240 pages, 21x29,3cm, Hardback, 429 illustrations,ISBN 978-0-500-516 44-7

euro 48,00

email if you want to buy [email protected]

An exploration of the incredible advances in computer-aided design and its revolutionary impact in the fields of fashion and textiles

The invention of the Jacquard loom in the 18th-century century paved the way for computing and revolutionary change. From its punch-card origins, code has evolved to enable new methods in design, visualization and production, achieving the previously unimaginable.

Digital Visions for Fashion and Textiles considers how computing has reinvented image, material and structural processes, highlighting newly advancing 2D, 3D and interactive output. Pioneering shifts of practice have developed from hybrid technical and creative collaborations. Digital and analogue fusions are defining new contexts for the innovative fabrication of surfaces, products and environments.

Twenty-two of the most forward-thinking practitioners, established and emerging, who have embraced developing digital technologies are profiled. Featured are household names, such as Hussein Chalayan, Prada and Issey Miyake, early pioneers (Vibeke Riisberg, Peter Struycken) and more independent, avant-garde individuals (Iris van Herpen, Casey Reas, Tom Gallant).

Complete with a reference section and bibliographic information, this unique and richly illustrated book is the perfect resource and inspiration for designers, students, industry professionals, and anyone looking for an exploration of how computer technology has creatively permeated fashion, textiles and related digital sectors.

11/01/04

#digital visions#for Fashion & Textiles#Hussein Chalayan#Prada#Issey Miyake#Iris van Herpen#Alexander McQueen#fashion books#fashionbooksmilano

3 notes

·

View notes

Text

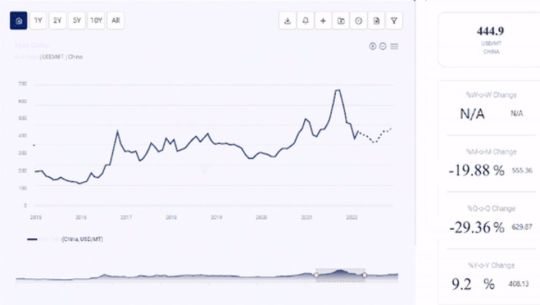

Hexane Price Trends Demystified: Insights for Manufacturers and Suppliers

In Asia, Hexane prices exhibited fluctuating patterns, responding to resurgent downstream demands from Solvent, pharmaceutical, and textile sectors post-pandemic, coupled with the influence of heightened crude oil prices. Supply chain improvements resulted in intermittent price declines alongside fluctuating demands, contributing to generally positive market sentiment in the first half.

Request Free Sample - https://www.procurementresource.com/resource-center/hexane-price-trends/pricerequest

Meanwhile, Europe experienced a blend of Hexane price sentiments during H1 2023, with Q1 stagnation followed by Q2 incline due to stabilized energy prices and sectoral growth, reflecting a mixed pricing trend. In North America, diverging from global patterns, robust Q1 demand driven by stable crude oil prices led to price increases, which sustained through Q2 until a decline in demand and increased inventories prompted a late Q2 decrease, resulting in a mixed price trend.

Definition

Hexane is a hydrocarbon solvent commonly used in various industrial applications, such as extraction, cleaning, and as a component in the production of chemicals and products like adhesives and pharmaceuticals.

Key Details About the Hexane Price Trends:

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on Hexane in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as Excel files that can be used offline.

The hexane price trends, including India Hexane price, USA hexane price, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Hexane finds essential industrial roles as a solvent in processes like oil extraction, adhesive production, and cleaning. It serves pharmaceutical and chemical manufacturing, aiding in the creation of medicines, plastics, and synthetic rubber. Its low boiling point and ability to dissolve various substances make it valuable across diverse sectors.

Key Players:

Exxon Mobil Corporation

Bharat Petroleum Corporation Limited

China Petroleum & Chemical Corporation (Sinopec)

Junyuan Petroleum Group

Royal Dutch Shell Plc

Sumitomo Chemical Co. Ltd

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team tracks the prices and production costs of a wide variety of goods and commodities, hence providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource Contact Person: Chris Byrd Email: [email protected] Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

1 note

·

View note