#Three Phase transformer

Explore tagged Tumblr posts

Text

Delivering Reliable Power: Tirupati Transformer High-Efficiency Distribution Transformers Built for India’s Energy Needs

India’s energy landscape is evolving rapidly. With growing urbanization, increased industrial activity, and a surge in renewable energy adoption, the demand for efficient and reliable power Three Phase distribution transformer has never been greater. At the heart of this transformation lies the unsung hero of the power sector: the Distribution transformer.

At Tirupati Transformers, we understand the critical role transformers play in delivering uninterrupted, energy-efficient power across India’s cities, towns, and rural communities. Our high-efficiency distribution transformers are designed not only to meet current energy demands but also to align with the nation’s future goals for sustainability and grid modernization.

⚙️ Built for Indian Conditions:

Tirupati Transformers are engineered specifically for India’s diverse climate, voltage fluctuations, and load conditions. Whether it's the scorching summers of Rajasthan or the heavy monsoons in the Northeast, our units are tested for durability and performance in all environments.

High short-circuit strength Enhanced cooling systems Moisture-resistant insulation Anti-corrosive coatings

⚡ Energy Efficiency That Saves More:

Distribution losses are a major concern in India's power sector. Tirupati addresses this with star-rated energy-efficient transformers that comply with the latest Bureau of Energy Efficiency (BEE) guidelines. Our designs significantly reduce core and copper losses, helping utilities and industrial clients cut operational costs while conserving energy.

Key Efficiency Features:

CRGO & Amorphous metal cores Low-loss design complying with IS1180 Part-1 & IEC standards Aluminum and copper wound options Optional OLTC (On-Load Tap Changer) for voltage optimization

🏭 Supporting India’s Industrial Growth:

From state utilities and rural electrification programs to smart city projects and private Industrial transformer zones, Tirupati Transformers power critical infrastructure across the nation. With capacities ranging from 100 kVA to 2500 kVA, we offer a wide portfolio to suit every scale and sector.

Our transformers are widely used in:

Power distribution utilities (DISCOMs) Solar and wind energy farms Railways and metro projects Commercial buildings and industrial parks

✅ Quality You Can Trust:

At Tirupati Transformers, quality is not an option—it’s our promise. Our transformers go through rigorous testing at every stage of manufacturing. With ISO-certified processes and fully equipped testing labs, we ensure each unit delivers peak performance from day one.

Certifications & Standards:

ISO 9001:2015 BIS certification NABL-accredited testing Compliance with BEE, IS, and IEC standards

🌱 Powering a Sustainable Future:

As India moves toward its renewable energy goals and energy access for all, Tirupati Transformers is proud to contribute solutions that are both economically and environmentally responsible. Our focus on innovation and energy efficiency plays a vital role in reducing the nation’s carbon footprint.

🔋 Partner with Tirupati for Smarter Power Distribution:

With over 12 years of experience, a pan-India presence, and a track record of excellence, Tirupati Transformers is a trusted name in energy solutions. Whether you're a utility provider, a project developer, or an industrial client, we deliver transformers that are robust, reliable, and ready for the future.

Let’s power progress—efficiently, reliably, and sustainably.

📞 Contact Us Today:

To learn more about our products or to request a quote, visit: www.tirupatitransformers.com or email us at [email protected].

#Three Phase transformer#Three Phase distribution transformer#Distribution transformer#Industrial transformer#Three Phase industrial transformer#Solar transformer#Three phase solar transformer#OLTC solar transformer#OLTC distribution transformer#Three phase OLTC transformer

2 notes

·

View notes

Text

Top Three Phase Transformer: Types, Uses, and Features

Unlock the potential of Three Phase Transformer technology with Trio Transformer, a name you can rely on. Learn about the leading types—Core, Shell, and Autotransformers—tailored for diverse energy needs. Perfect for everything from factories to power stations, they deliver consistent and efficient performance. Built with advanced features, these transformers offer durability, safety, and optimal functionality.

0 notes

Text

High-Quality Three Phase Isolation Transformer in Thane – AG Power Systems

Looking for a reliable Three Phase Isolation Transformer in Thane? AG Power Systems, established in 1998, is a trusted name in exporting and trading high-performance electrical solutions. Our transformers are known for their compact design, low maintenance, and long-term reliability. Backed by skilled professionals and a commitment to quality, we deliver consistent and efficient solutions to meet varied industrial needs. Choose AG Power Systems in Thane for proven performance and unmatched service.

0 notes

Text

Discover the ECT-IM3 single-phase current transformer (100A–1000A) with 5A output, compact design, and easy bus bar mounting for industrial applications.

#current transformers#3 phase current transformer#Current Transformer#Three Phase Current Transformer

0 notes

Text

Efficient Power with Three-Phase Distribution3 phase transformer manufacturers in hyderabad

This system offers higher efficiency, balanced loads, and stable voltage levels, making it an essential component of modern power infrastructure. The use of three-phase transformers plays a key role in ensuring seamless power delivery, reducing losses, and maintaining operational efficiency.

Understanding Three-Phase Power Distribution

A three-phase power system consists of three alternating currents (AC) that are 120 degrees out of phase with each other. This configuration allows for a continuous and balanced power supply, making it more efficient than single-phase systems. The system is widely used in industrial plants, commercial buildings, and utility grids due to its reliability and cost-effectiveness.

Types of Three-Phase Transformer Connections

Star (Wye) Connection: This configuration provides a neutral point, allowing for both high and low voltage applications. It is commonly used for power transmission and distribution.

Delta Connection: This setup does not have a neutral wire and is mainly used in industrial applications where high power is required.

To ensure a smooth and efficient power supply, businesses rely on trusted 3 phase transformer manufacturers in hyderabad and 3 phase transformer suppliers in hyderabad to provide high-performance solutions.

Advantages of Three-Phase Distribution

Improved Efficiency

High-quality three phase transformers in hyderabad play a crucial role in maintaining this efficiency.

Higher Power Capacity

Three-phase power distribution can handle larger loads, making it ideal for heavy-duty applications such as industrial machinery, manufacturing plants, and power grids. Businesses work closely with 3 phase distribution transformer manufacturers in hyderabad and three phase distribution transformer suppliers in hyderabad to meet their energy demands.

Balanced Load Distribution

The three-phase system distributes power evenly across all three conductors, minimizing fluctuations and reducing the risk of equipment damage. Reliable 3 phase transformer distributors in hyderabad provide quality transformers that ensure stable power distribution.

Increased Reliability and Stability

This makes three phase transformers in hyderabad a preferred choice for critical applications in industries, hospitals, and commercial buildings.

Applications of Three-Phase Distribution

Three-phase distribution is used across various industries, including:

Commercial Buildings: Office complexes, shopping malls, and hospitals use three phase transformers in hyderabad for lighting, HVAC systems, and elevators.

Power Transmission and Distribution: Utility companies rely on 3 phase distribution transformer manufacturers in hyderabad to provide efficient power transmission over long distances.

Renewable Energy Systems: Solar and wind energy installations require best three phase transformer manufacturers in hyderabad to convert generated electricity into usable power.

Selecting the Right Three-Phase Transformer Supplier

When choosing a three phase transformers in hyderabad, it is essential to work with the best three phase transformer suppliers in hyderabad who offer high-quality, durable, and efficient products. Factors to consider include:

Transformer capacity and power rating

Energy efficiency and performance

Compliance with industry standards

Reputation of the manufacturer or supplier

Companies like KPEL Transformers are among the leading 3 phase transformer distributors in hyderabad, offering reliable and cost-effective solutions for diverse power distribution needs. Businesses must partner with trusted 3 phase transformer manufacturers in hyderabad, 3 phase transformer suppliers in hyderabad, and 3 phase transformer dealers in hyderabad to ensure seamless and efficient power management. For high-quality three phase transformers in hyderabad, KPEL Transformers remains a top choice among 3 phase distribution transformer manufacturers in hyderabad, providing innovative and reliable solutions for various applications.

0 notes

Text

The T-203H Handheld TTR Tester Three-Phase Transformer Turns Ratio Tester is a compact and high-precision testing device designed to accurately measure the turns ratio of three-phase transformers. This portable and user-friendly tester ensures that transformers are operating within the specified parameters, providing reliable and precise testing for both distribution and power transformers. The T-203H has been successfully used in the transformer turns ratio testing project in the Philippines, proving its efficiency and accuracy in real-world applications.

Key Features:

Three-Phase Transformer Testing: The T-203H is designed to test three-phase transformers, allowing for simultaneous testing of all three phases. This capability ensures that the turns ratio for all phases is checked, providing a complete assessment of the transformer's performance.

Handheld and Portable Design: The T-203H is a handheld tester, making it highly portable and easy to use in the field. Its lightweight design allows technicians to carry it to different testing sites, making it ideal for on-site transformer inspections and maintenance.

Accurate Turns Ratio Measurement: The T-203H provides precise measurement of the transformer turns ratio (TTR), ensuring that the transformer is operating within its rated specifications. This helps prevent performance issues such as voltage imbalances, efficiency losses, and potential transformer failures.

Wide Testing Range: With a broad measurement range, the T-203H is suitable for testing a wide variety of transformers, from low to high voltage. It can be used for small distribution transformers as well as large power transformers, making it a versatile tool for various applications.

Easy-to-Use Interface: The tester features a simple and intuitive interface with a digital display, making it easy for technicians to quickly set up and perform tests. The straightforward design allows for fast data reading and minimal setup time, improving the efficiency of testing operations.

Efficient Testing Process: The T-203H offers quick and efficient testing, saving time during transformer inspections and preventing extended downtime. Its automatic measurement functions make the testing process smooth and reliable, providing immediate results.

Applications: The T-203H is ideal for use in transformer maintenance, quality control, and commissioning. It is used by utilities, electrical service providers, and transformer manufacturers for turns ratio testing to ensure that transformers are properly set up and functioning correctly.

Applications in the Philippines: The T-203H was successfully employed in the transformer turns ratio testing project in the Philippines, where it was used to test various transformers in power distribution and industrial applications. The device proved its reliability in providing accurate measurements, helping the project team assess and ensure the proper functioning of transformers. Its portability and ease of use made it an essential tool for on-site testing in remote locations, contributing to the project's overall success.

The T-203H Handheld TTR Tester Three-Phase Transformer Turns Ratio Tester is a high-precision, portable solution for accurate and reliable transformer testing. With its ability to test three-phase transformers, handheld design, and accurate turns ratio measurements, it is an essential tool for transformer maintenance and diagnostics. The T-203H has proven its value in real-world applications, including the transformer testing project in the Philippines, where it helped ensure the optimal performance and safety of transformers. Whether used for routine inspections, preventive maintenance, or commissioning, the T-203H delivers quick and precise testing, making it an indispensable asset for electrical professionals.

For detailed information, please refer to the relevant links on the official website:https://www.gfuvegroup.com/power-transformer-test/three-phase-handheld-transformer-turns-ratio-meter.html

#power transformer#Power Transformer Test#Handheld TTR Tester Three-Phase Transformer Turns Ratio Tester

1 note

·

View note

Text

Three-Phase Distribution Transformers: Powering Efficient Energy Distribution

Three-phase distribution transformers are essential components in electrical distribution systems, designed to step down high voltage from transmission lines to lower voltages suitable for industrial, commercial, and residential use. Known for their efficiency and reliability, these transformers play a crucial role in ensuring a steady and safe supply of electricity to various end-users.

Key Features of Three-Phase Distribution Transformers

High Efficiency: Reduces energy losses during power conversion, ensuring optimal performance.

Durable Design: Built to withstand environmental conditions and operate reliably under varying load conditions.

Compact Construction: Space-efficient design for easy installation in urban, industrial, or remote locations.

Cooling Mechanisms: Includes oil-immersed or air-cooled systems for effective heat dissipation.

Customizable Ratings: Available in various voltage and power capacities to suit specific applications.

Components of a Three-Phase Distribution Transformer

Core: Made from high-quality silicon steel to minimize core losses.

Windings: Copper or aluminum windings designed for excellent conductivity and thermal stability.

Tank: Protects internal components and contains insulating oil for cooling and insulation.

Bushings: Facilitates safe electrical connections for the input (high voltage) and output (low voltage) sides.

Tap Changer: Adjusts voltage levels to maintain stability in varying load conditions.

Applications of Three-Phase Distribution Transformers

Industrial Power Distribution: Supplies power to factories and industrial complexes.

Commercial Buildings: Powers shopping malls, office buildings, and other commercial establishments.

Residential Areas: Provides electricity to housing colonies and apartment complexes.

Infrastructure Projects: Supports utilities in airports, railways, and metro systems.

Renewable Energy Systems: Integrates solar or wind energy into the grid by converting voltage levels.

Advantages of Three-Phase Distribution Transformers

Cost-Effective: Requires fewer materials and less space compared to multiple single-phase units.

Enhanced Reliability: Ensures a stable and consistent power supply, even during high demand.

Energy Efficiency: Minimizes energy losses, leading to lower operational costs.

Scalability: Easily adaptable for expanding electrical networks.

Ease of Installation: Simplified setup process for both indoor and outdoor applications.

Why Choose Danish Pvt Ltd for Three-Phase Distribution Transformers?

Danish Pvt Ltd is a trusted name in the manufacturing of high-performance three-phase distribution transformers. Our products are engineered for durability, efficiency, and reliability, meeting the diverse needs of industries and utilities.

What We Offer:

High-Quality Materials: Premium-grade cores and windings ensure long-lasting performance.

Advanced Technology: Cutting-edge manufacturing processes for superior efficiency.

Custom Solutions: Transformers tailored to specific voltage and capacity requirements.

Global Standards Compliance: Adherence to ISO, IEC, and other international quality certifications.

After-Sales Support: Comprehensive service, including maintenance, troubleshooting, and upgrades.

Conclusion

Three-phase distribution transformers are indispensable for modern power systems, providing efficient and reliable electricity distribution to a wide range of applications. At Danish Pvt Ltd, we pride ourselves on delivering top-quality transformers that ensure safety, efficiency, and long-term performance.

0 notes

Text

Kanyaka is the best three phase distribution transformer suppliers and distributors in hyderabad and are available for both indoor and outdoor applications.

#three phase distribution transformer manufacturers in hyderabad#three phase distribution transformer suppliers in hyderabad#3 phase transformers in hyderabad#3 phase transformer manufacturers in hyderabad#3 phase distribution transformer manufacturers in hyderabad#3 phase transformer suppliers in hyderabad

0 notes

Text

Affordable & Efficient: Best Three-Phase Transformer Prices

Get the best deals on three-phase transformers with Trio Transformer! We provide cost-effective and high-performance solutions tailored to your power requirements. Enjoy reliable quality at competitive prices.

0 notes

Text

Why Choosing a Three Phase Isolation Transformer in Thane is Crucial for Industrial Safety

Especially in industrial zones like Thane, where high-power equipment is the norm, the right transformer can significantly impact operational efficiency and safety standards.

What is a Three Phase Isolation Transformer?

A Three Phase Isolation Transformer is a special type of transformer designed to decouple two circuits. Unlike standard transformers, it isolates the primary and secondary windings to ensure no direct path for electrical current, which helps protect sensitive equipment from electrical spikes, noise, and surges. In an industrial setting, this means safer operations, longer equipment lifespan, and fewer maintenance issues.

Why Is It Crucial in Thane’s Industrial Sector?

Thane is one of Maharashtra’s fastest-growing industrial hubs. With sectors ranging from manufacturing to pharmaceuticals, consistent and clean power supply is a necessity. Here’s why choosing a Three Phase Isolation Transformer in Thane is a critical safety decision:

1. Electrical Safety

Isolation transformers reduce the risk of electric shock by isolating the load from the power source. In industries handling high-voltage machinery, this isolation is vital for worker safety and compliance with regulatory norms.

2. Protection Against Voltage Surges

Thane often experiences voltage fluctuations due to its high energy demands. A Three Phase Isolation Transformer helps manage these surges, thereby protecting valuable industrial machinery from sudden breakdowns or damages.

3. Improved Power Quality

These transformers filter out electrical noise, ensuring stable and clean power supply. This is especially crucial for industries using sensitive electronic equipment or automated systems.

4. Compliance with Safety Standards

Adopting Three Phase Isolation Transformers in Thane ensures that businesses comply with BIS, ISO, and other safety standards, which are mandatory for certain sectors like healthcare, manufacturing, and heavy engineering.

Key Factors to Consider Before Choosing One

When selecting a Three Phase Isolation Transformer in Thane, it’s important to consider:

Power Rating: Ensure the transformer matches your load requirements.

Insulation Class: Higher insulation offers better protection but comes at a higher cost.

Build Quality: Durable and high-quality transformers last longer and require less maintenance.

Manufacturer Support: Choose local, reputed vendors who offer service guarantees and quick support.

Tradeoffs and Challenges

While the benefits are clear, industries must also consider the tradeoffs:

Cost vs Quality: Premium transformers offer better efficiency and safety but may be more expensive.

Size Constraints: Larger units require more space, which may not be available in every industrial unit.

Initial Setup: Installation and configuration may need specialized labor, which can increase upfront costs.

Still, the long-term benefits in safety, compliance, and machine life outweigh these challenges.

Environmental & Long-term Impact

Incorporating a Three Phase Isolation Transformer in Thane not only safeguards operations but also supports sustainability. Efficient energy usage, reduced downtime, and minimized repair requirements contribute to lower carbon footprints and long-term cost savings.

Conclusion

For industries in Thane, ensuring operational safety, equipment longevity, and regulatory compliance hinges on selecting the right Three Phase Isolation Transformer. With a strategic investment in high-quality isolation transformers, businesses can enhance their productivity, reduce risks, and maintain consistent performance, all while protecting their workforce and infrastructure.

Top 5 FAQs about Three Phase Isolation Transformer in Thane

1. What is the primary function of a Three Phase Isolation Transformer in Thane industries? It isolates electrical equipment from the power source to protect against surges, spikes, and electrical noise, ensuring safer operations.

2. Why is an isolation transformer necessary for industrial units in Thane? Due to Thane’s heavy industrial load and voltage fluctuations, an isolation transformer ensures voltage stability and equipment protection.

3. How does a Three Phase Isolation Transformer enhance safety? By providing galvanic isolation, it eliminates the path for electrical shock and protects workers and equipment from electrical hazards.

4. Can a Three Phase Isolation Transformer reduce downtime in industries? Yes, by protecting machines from voltage irregularities and surges, it minimizes the chances of breakdowns and reduces maintenance needs.

5. Where can I find the best Three Phase Isolation Transformer in Thane? Trusted suppliers like AG Power Systems in Thane offer durable, efficient, and ISO-compliant transformers for industrial use.

0 notes

Text

The Role of Current Transformers in Power Monitoring and Energy Efficiency

In today’s energy-conscious world, monitoring and managing power consumption is critical. Businesses and industries are increasingly focused on improving energy efficiency to reduce costs and meet sustainability goals. One essential component in this process is the current transformer (CT). These devices play a pivotal role in power monitoring systems, enabling accurate energy measurement and safe operation. Curious about how they make a difference? Let’s dive into their key functions and benefits.

What Are Current Transformers?

Current transformers are specialized electrical devices designed to measure high currents in power systems by producing a lower, proportional current that monitoring equipment can safely process. Essentially, they step down large current levels to manageable values, allowing for precise measurement and control without the risk of damage to sensitive equipment.

Key Functions of Current Transformers in Power Monitoring

1. Accurate Measurement of Current Flow

Monitoring power systems would be nearly impossible without accurate current measurement.

Ensures precision in data collection: Current transformers provide highly accurate readings, which are critical for tracking energy usage, identifying inefficiencies, and maintaining system reliability.

Prevents equipment overloads: By constantly measuring current flow, CTs help detect unusual spikes that could indicate a problem, protecting equipment from damage.

2. Safety in High-Voltage Systems

Handling large electrical currents directly can be dangerous. Current transformers make power monitoring much safer.

Isolates measurement equipment from high voltages: CTs reduce the risk of electric shocks by allowing instruments to measure current indirectly.

Reduces the chance of equipment failure: The lower current output protects devices from potential overloads.

Benefits of Current Transformers in Energy Efficiency

3. Facilitating Energy Management

Current transformers are integral to effective energy management systems.

Supports detailed energy usage analysis: With accurate current measurements, businesses can identify peak consumption times, detect wastage, and implement strategies to reduce power usage.

Helps optimize load balancing: Properly balanced electrical loads improve efficiency and reduce wear on system components.

4. Supporting Demand-Side Management

In industrial and commercial settings, managing power demand is crucial to avoid penalties and optimize costs.

Helps control peak demand charges: By monitoring real-time current flow, companies can adjust operations to avoid exceeding peak thresholds set by utility providers.

Enables dynamic adjustments: Data from CTs can be integrated into automated systems that adjust loads based on consumption patterns.

5. Cost Savings and Sustainability

Reducing energy consumption not only cuts costs but also contributes to sustainability initiatives.

Lowers operational expenses: Identifying inefficiencies through precise power monitoring leads to targeted actions that minimize unnecessary energy use.

Reduces carbon footprint: Efficient power use directly correlates to lower emissions, making CTs an essential tool for eco-friendly operations.

Common Applications of Current Transformers

Current transformers are used in a variety of settings, including:

Industrial plants: For machinery and equipment energy monitoring.

Commercial buildings: To manage HVAC systems, lighting, and overall consumption.

Utility substations: For grid-level current measurement and protection.

Renewable energy systems: To track power generated by solar panels or wind turbines.

Conclusion

In summary, current transformers are indispensable in power monitoring and energy management, providing the accuracy, safety, and insights needed to optimize electrical systems. From reducing costs to enhancing sustainability, their benefits extend across industries. Companies looking for reliable, high-performance current transformers should consider trusted providers like Eastron Europe. With a reputation for quality and innovation, we offer advanced CT solutions that empower businesses to harness energy efficiency effectively. Ready to take control of your power systems? Start with the right tools and transform your energy management today!

#current transformers#split core current transformer#3 phase current transformer#Current Transformer#Three Phase Current Transformer#Eastron europe

0 notes

Text

Installing And Maintaining Three-Phase Transformers

Meticulous planning and attention to detail are necessary to achieve maximum performance and safety while installing a three-phase transformer. This blog offers a concise guide to assist you through the entire installation process, from preparing for pre-installation and assembling the required equipment to mounting the transformer and installing the necessary electrical connections. We’ll also go over how to test and commission the transformer to make sure it runs effectively, as well as important safety measures that need to be taken. You will also receive useful maintenance advice tips to assist you in maintaining the best possible condition for your transformer, guaranteeing its long-term dependability and efficiency. This book provides the information and understanding you need for a successful installation, regardless of your level of experience in installing transformers.

Pre-installation preparation

When installing a three-phase transformer, safety must always come first. To prevent accidental energization, start by shutting off all power sources and adhering to lockout/tagout protocols. To provide a safe working environment and protect against electrical risks, this step is absolutely essential. The installation location should next be carefully inspected to ensure that it has enough room, good ventilation, and is easily accessible for future maintenance. The location of the transformer must allow it to be installed without creating any operational or safety risks. To make sure the transformer you are installing satisfies these standards, you should also check the electrical specifications and requirements of your application. This includes determining the voltage ratings, load capacity, and system compatibility. By verifying these specifications, you can be confident that the transformer will work properly and effectively in your electrical system and avoid any potential mismatches that can cause problems or harm. These preliminary actions lay the groundwork for a safe and effective transformer installation.

Mounting the transformer

Installing the transformer correctly requires appropriate positioning and securing. Start by setting up the transformer on a mounting platform or flat, sturdy surface. To avoid any instability or vibrations that might impair the transformer’s performance and durability, make sure the surface is level and stable. After positioning the transformer, secure it in accordance with the manufacturer’s instructions by using the proper bolts and brackets. To keep the transformer securely in place, this entails choosing the right kind and size of fasteners and making sure they are fastened correctly. In addition to guaranteeing the transformer operates safely, this meticulous attention to placement and securing also makes future maintenance and inspections easier.

Electrical connections

Make sure that the input voltage satisfies the transformer’s requirements before making any primary connections to guarantee compatibility and correct operation. After confirmation, establish the primary connections using appropriate cables and connectors, making sure that every connection is tight and adequately insulated to avoid electrical risks and guarantee effective functioning. Make sure you have verified the secondary voltage requirements for secondary connections before moving ahead. This step is essential to prevent mismatches that might harm the connected equipment or the transformer. The secondary connections should then be connected in accordance with the manufacturer’s wiring schematic. Ensuring that the connections are completed accurately and safely requires careful adherence to the manufacturer’s instructions. For the transformer to operate safely and effectively, possible problems must be avoided and dependable performance must be ensured by paying attention to these elements in both the primary and secondary connections.

Grounding and bonding

An effective bonding and grounding system is essential to a three-phase transformer’s safe functioning. By carefully directing any stray electrical currents into the earth, grounding the transformer reduces the risk of an electrical fire and improves general safety. It is imperative that you take this action to safeguard the transformer and any attached equipment from any potential electrical problems. Furthermore, by connecting the transformer’s entire metal structure to the ground, any possible variations that can result in hazardous electrical faults are eliminated. To do this, every metallic component must be safely connected to a single grounding point. You may provide a stable and safe electrical environment, lower the danger of electrical shock and equipment damage, and guarantee safety standard compliance with proper grounding and bonding.

Testing and commissioning

Make sure that every connection and component is visually inspected before powering on the transformer. Keep an eye out for any indications of damage, loose connections, or incorrect installation that can jeopardize performance or safety. In order to avoid any problems during operation, it is essential to make sure that every component is intact and placed appropriately. After the inspection is over, turn the transformer on gradually. Keep a watchful eye out for any unusual vibrations, sounds, or temperature increases throughout this procedure since these hints might point to underlying issues. Early detection of these irregularities enables prompt remedial action, limiting additional harm. Apply the load progressively once the transformer has successfully been energized to evaluate its performance under operating conditions. This step ensures dependable operation by confirming that the transformer can safely carry the anticipated load. Gradual load testing ensures that the transformer is prepared for continuous operation under real-world conditions by pointing out any flaws or inefficiencies.

Maintenance tips for three-phase transformers

For three-phase transformers to operate dependably and last a long time, regular maintenance is essential. Following a planned maintenance schedule might help you avoid problems and get more use out of your equipment.

Scheduled inspections

To begin, check transformers on a regular basis for physical deterioration, corrosion, or overheating. Frequent visual inspections assist in spotting issues early. It is important to do routine oil analysis on transformers that contain oil. This examination keeps an eye on the insulation’s quality and assists in identifying any problems before they become more significant ones.

Cleaning and ventilation

It’s critical to keep the area around the transformer clean. Debris and dust can obstruct insulation and cooling, causing inefficiency or damage. To keep the transformer surfaces clear of impurities, clean them on a regular basis. In addition, efficient heat dissipation during operation depends on adequate ventilation. To avoid overheating, make sure there is enough ventilation around the transformer.

Monitoring temperature and load

Keep an eye on transformer temperatures to identify any overheating symptoms, since they might point to more serious issues. In order to avoid putting undue strain on a single winding, load balancing is also very important. Make sure that the load is equally distributed over all stages. Inequitable loading may cause components to fail and wear out too soon.

Electrical testing

Periodically check the integrity of the transformer’s insulation by conducting dielectric tests. These tests aid in the early detection of any malfunctions before they become serious. Furthermore, confirm that the transformer maintains output within reasonable bounds by checking the voltage regulation. An uninterrupted supply of power to connected devices is contingent upon proper voltage management.

Repairs and upgrades

Take quick action to resolve any identified problems to stop more harm and reduce downtime. To increase overall performance and efficiency, think about making improvements like upgrading cooling systems or retrofitting with more energy-efficient components. Improvements and repairs may extend the transformer’s lifespan and improve its performance.

Training and documentation

To guarantee that employees performing transformer maintenance adhere to correct protocols and safety standards, you need to offer them thorough training. Keep thorough records of all maintenance operations as well, including dates, conclusions, and remedial measures. Tracking the transformer’s performance and dependability over time requires accurate documentation.

You can minimize the chance of unplanned breakdowns and maximize the performance of your three-phase transformer by adhering to these maintenance recommendations, which will guarantee the transformer’s continuous dependability and efficiency.

To maximise three-phase transformer performance, efficiency, and longevity, it is not only essential to select the right three-phase transformer for your needs, but it is also essential to implement proper installation and routine maintenance. You can maximize the dependability of your electrical power distribution system, minimize downtime, and ensure safe operation by adhering to this thorough guidance and putting good maintenance methods into practice. To get the best outcomes, always put safety first, follow product instructions, and abide by industry standards. Take into consideration Miracle Electronics, a well-known three phase transformer manufacturer in India recognized for their dependable and effective solutions, if you’re looking for premium three-phase transformers. Their dedication to quality guarantees that your transformer installations and upkeep endeavours are bolstered by top-notch products and expertise.

Resources Read more

0 notes

Text

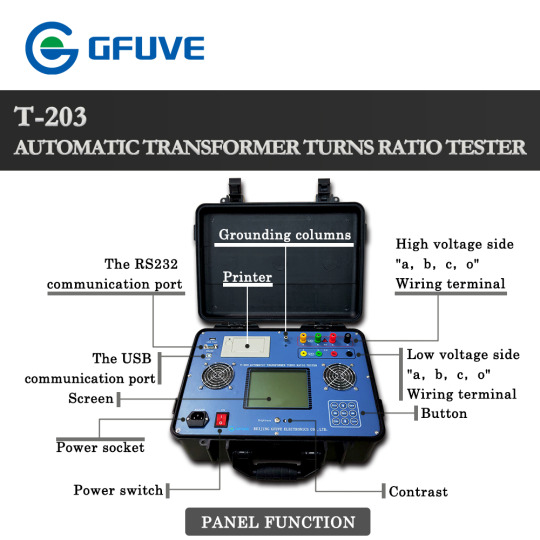

T-203 AUTOMATIC THREE PHASE TRANSFORMER TURNS RATIO TESTER

In power transformer Finished product production process, before the new installation of the transformer in operation, according to the national ministry of preventive test procedures, require the operation of transformer turn ratio or voltage ratio test, to check the correctness of the transformer turn ratio tap-changer of transformer whether inter turn short circuit transformer whether can run parallel. T-203 automatic transformer turns ratio tester adopts three-phase power supply output voltage, the test speed Instrument to adopt advanced technology for A/D, wide range range; High speed single chip microcomputer as the core digital processor, the test fast; English menu display, comprehensively improve the humanization and intelligent, instrument optional RS232 serial and USB connect with computer on line, to realize the remote control of the instrument and intelligent analysis of the data A three phase transformation ratio test, the test speed quickly, High accuracy and Perfect protection function.

FEATURES ■ Can be a variety of single-phase three-phase transformer and Z type and so on commonly used than wide test range and error calculation; ■ Three-phase power supply test instrument. Can be set up AC160V / 10 v test voltage. Have a larger output current, load ability. High test speed; ■ High low voltage reverse connect protection function, the short circuit of transformer Inter turn short circuit protection function; ■ Automatic conversion, without artificial calculation, to avoid the problems of variable than non integer input, a higher precision; ■ Large screen LCD menu, not to drop the electric clock and date display, memory 100 test data, in order to you at any time to view and print; ■ Instrument with communication interface, data management software is optional USB storage.

APPLICATION ■ Power plant; ■ Universities; ■ Research institutes; ■ Electrical testing center; ■ Voltage transformer factory; ■ Transformer manufacturers; ■ Railway electrical department; ■ ISO17025 Electrical laboratory; ■ Electricity power bureau & power company; ■ Power engineering commissioning company; ■ Electrical Department of industrial and mining enterprises;

1 note

·

View note

Text

yearning drunk!husband ushijima wakatoshi.

NOTE. contains a bit of alcohol content—though nothing too explicit or anything concerning <33

It always started the same way—kind of like an inside joke that grew wings, feathers, a tab, and Ushijima’s name on the reservation list.

Ushijima never initiated going out drinking with his Schweiden Adlers teammates. In fact, he rarely said anything about it at all. It was always someone else who mentioned it after a game. Always someone else who slung an arm over his shoulder and declared, “C’mon, Ushiwaka, we have to celebrate,” even though Ushijima had never once expressed interest in alcohol, bar food, or drunken conversations.

Still, he always went.

Because it’d be rude if he didn’t at least stay for a few minutes, he thinks.

Sometimes he showed up in his team windbreaker, sometimes in a long, dark gray coat that made him look like a trench-wearing monument of silence. And he never said no, even when the clamor of celebration was already grating at the edges of his patience.

Tonight was one of those nights.

They’d won by the skin of their teeth—an overtime set against a grueling opponent, the kind of match that made even the benchwarmers feel like champions by the end. So of course Heiwajima had started the round-up in the locker room. Hoshiumi had shouted over everyone about their lucky bar down the street, and within twenty minutes, the entire team had found themselves in their regular private suite.

Ushijima sat at the end of the table, his back straight, a glass in front of him filled with alcohol he didn’t particularly like. His teammates were loud and loose and chaotic—laughing at Sokolov trying to arm-wrestle the bar’s bouncer, clapping every time someone dropped a fork, and yelling across the table in at least three different languages.

“A thousand yen says he’ll ask about his wife in twenty minutes,” Hoshiumi said quietly, leaning toward their captain, Hirugami Fukurou.

“You’re giving him way too much credit,” Romero replied, fondly grinning. “He gets wistful around minute twelve.”

“He gets wistful the moment he sits down.”

Ushijima was unmoved. He stared at his drink, took a single sip, and let it rest in his hand. He didn’t participate in the yelling, the toasts, or the story someone was animatedly telling about a missed serve from three seasons ago. He just existed—quietly, stoically—as a satellite to the chaos.

Except, of course, they all knew he was waiting.

He always was.

There was a pattern to the transformation. First, he’d sit there like stone. Then he’d blink a little more slowly. His brows would draw together—not in anger, but in vague confusion, like he was lost in a thought he couldn’t solve. His fingers would move against his glass, not to drink but to fidget, just a little.

And then…

“Has anyone seen my phone?” Ushijima asked, barely louder than the buzz of conversation.

Hoshiumi slid it across the table immediately. “Right here, Ushiwaka. Sorry! We took a few pictures here and there.”

“Thank you.”

He looked down at the screen. It was still lit with the last message from you from earlier that day: Good luck, baby. Don’t forget to stretch your left shoulder. He’d never replied—he never did, not when he was already in headspace—but now, he stared at it like it was the only thing tethering him to reality.

“You want to text her?” Hoshiumi asks, lightly teasing, which Ushijima didn’t catch onto.

Ushijima didn’t answer. He opened the thread and typed a few letters. Deleted them. Typed something else. Backspaced. Then just stared.

And then finally: “She hasn’t replied.”

His teammates laughed.

“There it is!”

“It’s only been seventeen minutes! I win!”

“No, you cheated. I said ten, and he didn’t even check his phone until minute twelve!”

“Shh, shh, look at him—he’s pouting.”

“Wait, is this the pout phase? I thought that came after the silent brooding phase.”

“Technically we’re entering pout-brood overlap. It’s a dangerous time.”

Ushijima didn’t argue. He simply set the phone down again and folded his hands in front of him. Kageyama leaned over.

“You want me to call her for you, Ushijima-san?”

Ah, yes. Kageyama was too nice for his own good. Trying to enhance his socialization and trying to lessen his awkwardness with his teammates when the conversation didn’t revolve around volleyball.

Ushijima nodded. Just once. Immediately. “Yes.”

...

“Amazing! He’s not even trying to hide it.”

“Can you imagine being that in love?”

“He just wants his wife. Look at him. He’s a whole sad poem in one sitting.”

“She’s gonna get here, and he’s gonna light up like a lantern.”

“May this love run me over.”

Kageyama stood and walked a few paces away from the table, already dialing your number. Meanwhile, the others watched Ushijima sip his drink again—not because he wanted it, but because it gave his hands something to do. His eyes were glued to the screen even though no new notifications had appeared.

Romero leaned in conspiratorially to Hirugami. “Do you think she talks to him in, like, soft tones? Calls him ‘baby’ and stuff?”

“I think so,” he shrugs. “I think they’re sweet like that.”

“Aw, young love.”

The teasing continued, but it softened. Because underneath the jokes and the laughs was a sort of awe.

Their teammate—so serious, so focused, so unreadable on court—was completely and utterly soft when it came to his wife. Not in a loud way. Not in any way that could be easily teased, really. It was quiet. Heavy. Real.

When Kageyama returned, he had a pleased expression. “She’s on her way. Said she just got off work and is driving over.”

Ushijima gave another slow blink.

“Thank you.”

Kageyama nods. Somehow they manage to have conversations even if they just continue nodding to each other.

As soon as Kageyama said it, his phone buzzed with a new message. He didn’t even need to open it. He could tell by the way his entire body relaxed by a single, barely noticeable degree.

Sorry, hun. Just got off work. Are you okay?

He replied.

I’m okay. I miss you.

And then he set the phone down and folded his hands again, this time with more calm. More certainty. You were coming. That was all he needed to know.

The others noticed the shift immediately.

“He smiled.”

“No, he didn’t.”

“He did! Don’t argue with me; I saw it. It was micro. But it counted.”

“He’s already halfway out the door with his heart.”

“Watch, the second she walks through that door, he’ll go full puppy mode.”

Sure enough, fifteen minutes later, the door opened. A gust of cold air followed you inside, along with the soft jingle of the bar’s entrance bell. You spotted them easily—your eyes landing on Ushijima before anything else. And his entire body seemed to change shape.

He stood up—not quickly, but instantly, with a kind of gravity no one else in the room had.

You smiled as you approached, slipping out of your coat and brushing off the cold that nipped your nose softly. “Hi, love,” you greeted softly. “You ready to go?”

“Yes,” Ushijima said, already reaching for his jacket.

As he shrugged it on, you turned to the table. “Hope he wasn’t too much trouble?”

Hoshiumi leaned on the table with a grin. “[Name], your husband is the definition of ‘not trouble.’ We’re just grateful you came to collect him before he sighed himself into the carpet.”

“Tell them what he said!” someone shouted.

“He asked if anyone had seen his phone like it was a national emergency.”

“And he didn’t pout—he brooded. Like a man out of a romantic novel.”

“I think I did,” Ushijima just nodded at their comments about him.

He then stood by quietly, waiting for you to finish your goodbyes. When you looped your arm through his, he leaned ever so slightly toward you.

As they left, Romero raised his glass.

“To [Name]’s husband,” he declared. The table cheered.

Outside, as you two walked toward the car, you glanced up at him, fingers tightening around his arm.

“You really okay?” you asked.

He hummed. Then, in that low, steady voice only you ever got to hear, it softened—

“I missed you,” he said again. “They were loud. I wanted to see you very much.”

You smiled and gave his arm a firm, loving squeeze. “Well. I’m here now.”

And... yeah.

That’s what he’s been wanting to hear all night.

SEUMYO © 2025. PLEASE DO NOT REPOST, PLAGIARIZE, MODIFY OR TRANSLATE.

#‹𝟹 𓏲🗒️ꜝֶָ֢ ʾʾ#ushijima x reader#ushijima x y/n#ushijima x you#ushijima fluff#ushijima oneshot#haikyuu x reader#haikyuu fluff#haikyuu oneshot#hq x reader#hq fluff#hq oneshot#haikyuu ushijima#hq ushijima#ushijima wakatoshi#hq wakatoshi#haikyuu wakatoshi#haikyuu ushiwaka

4K notes

·

View notes

Text

Voltek Transformers: Leading the Way in Three Phase Distribution Transformers

Introduction:

Three phase distribution transformers are critical components in the electrical power distribution network. They are designed to step down the high voltage from power lines to a lower voltage that can be safely used in residential, commercial, and industrial applications. Among the various manufacturers in the market, Voltek Transformers stands out for its commitment to quality, innovation, and customer satisfaction. This article delves into the features, benefits, and applications of three phase distribution transformers by Voltek Transformers, recognized as one of the best three phase transformer manufacturers in Andhra Pradesh.

Overview of Three Phase Distribution Transformers:

A three phase distribution transformer is an electrical device that converts electrical energy from one voltage level to another in a three phase system. These transformers are essential for distributing electricity efficiently from the power generation stations to end users. The three phase system is preferred over single phase systems because it provides a more consistent and balanced power load, making it ideal for high-demand applications.

Voltek Transformers: Commitment to Excellence:

Voltek Transformers has established itself as a leader in the manufacturing of high-quality three phase distribution transformers. The company’s products are known for their durability, efficiency, and reliability. Voltek’s transformers are designed to meet international standards, ensuring they are suitable for a wide range of applications and environments. They are widely recognized among three phase transformer distributors in Telangana and three phase transformer dealers in Hyderabad.

Critical Role in Power Distribution:

Three phase distribution transformers are critical components in the electrical power distribution network. They are designed to step down the high voltage from power lines to a lower voltage that can be safely used in residential, commercial, and industrial applications. Among the various manufacturers in the market, Voltek Transformers stands out for its commitment to quality, innovation, and customer satisfaction. Recognized as one of the best three phase transformer manufacturers in Andhra Pradesh, Voltek Transformers has established itself as a leader in the manufacturing of high-quality three phase distribution transformers.

Applications across Various Sectors:

In residential applications, Voltek’s transformers step down high voltage from power lines to a safer, usable level for households. Commercial buildings, such as offices, malls, and schools, benefit from stable and reliable power for lighting, heating, and cooling systems. Industrial facilities, which often require large amounts of power for machinery and equipment, find that Voltek’s transformers deliver power efficiently and reliably. With the increasing adoption of renewable energy sources like wind and solar, Voltek’s transformers play a crucial role in converting and distributing generated power to the grid. In urban markets, Voltek is a prominent name as one of the top three phase transformer dealers in Hyderabad and three phase transformer traders in Hyderabad, ensuring that customers receive prompt and efficient service.

Conclusion:

Voltek Transformers has built a reputation for excellence in the field of three phase distribution transformers. Their commitment to high-quality manufacturing, innovative design, and customer-focused solutions makes their transformers a preferred choice for various applications. Whether it’s for residential, commercial, or industrial use, Voltek’s three phase distribution transformers provide reliable, efficient, and sustainable power distribution, ensuring the seamless operation of electrical systems. Their strong presence among the best three phase transformer manufacturers in Andhra Pradesh, three phase transformer distributors in Telangana, and three phase transformer dealers in Hyderabad further underscores their leadership in the industry.

0 notes

Text

Servo Voltage Stabilizer for Constant Voltage Regulation

The main purpose of a Servo Voltage Stabilizer is to provide constant voltage regulation for electrical equipment, protecting them from voltage fluctuations. These stabilizers ensure smooth operation and prevent potential damage to devices. They monitor and adjust voltage levels, providing stable power supply and saving energy. There are different types of servo voltage stabilizers available for various applications, such as single phase, three phase, AVR, digital, microcontroller-based, and industrial stabilizers. Spectron Stabilizer, a manufacturing branch of India Techno Systems, offers top-quality servo voltage stabilizers that are essential for maintaining the longevity and performance of electronic devices.

We manufacture the following types of Servo Voltage Stabilizer:

1. Single-phase servo voltage stabilizer

2. Three-phase servo voltage stabilizer

3. Industrial servo voltage stabilizer

4. Automatic servo voltage stabilizer

5. Manual servo voltage stabilizer

6. Digital servo voltage stabilizer

7. Oil-cooled servo voltage stabilizer

8. Air-cooled servo voltage stabilizer

9. Wall-mounted servo voltage stabilizer

10. Rack-mounted servo voltage stabilizer

Each of them is of the best quality and follows strict safety standards. They are available in a range of 1 KVA to 5000 KVA in both single-phase and three-phase. Give us a query at [email protected] and we would be happy to help you.

#servo voltage stabilizer#servo voltage stabilizer manufacturer#isolation transformer#three phase servo voltage stabilizer#servo voltage manufacturer

0 notes