#Timber Construction Connectors

Explore tagged Tumblr posts

Text

Kids' woodworking Day

"This is actually fun!"

We recently invited some students from a local school and the children of our staff to participate in our Kids' Woodworking Day event. The students worked alongside our team of expert carpenters to create a special project. During a break, they walked into our timber frame connector and the "ohhh!"s and "ahhh!"s were audible. Our staff explained that there are many career paths within the world of woodworking - from crafting smaller projects like the ones the students were working on, to building big timber frame structures.

As we wrapped up our time together, one of the girls proclaimed, "I could do this all day long!" Another student said, "This is actually fun!"

Our team enjoys inspiring the next generation of carpenters and experts in the construction industry. We provide real opportunities for career growth and professional development. If you'd like to join our team, carpenters can send their resumes to [email protected] or review our Preconstruction Manager opening here - https://northgroupconsultants.com/jobs/#/jobs/321

#construction company#construction#now hiring#hiring#construction industry#carpentry#woodworking#carpenter

2 notes

·

View notes

Text

Global Timber Connectors Market Key Drivers, Challenges by 2025-2032

Global Timber Connectors Market is experiencing steady growth, valued at USD 453 million in 2024 and projected to reach USD 654 million by 2032, expanding at a CAGR of 4.70% during the forecast period (2025-2032). This upward trajectory is driven by rising demand in construction sectors, particularly in residential and commercial building applications, along with infrastructure development projects worldwide.

Timber connectors are critical components in modern timber construction, providing structural stability and enhancing load-bearing capacity. Their adoption is accelerating due to the growing preference for sustainable and cost-effective wood-based construction solutions. Governments and industry bodies are increasingly promoting timber as a renewable building material, further stimulating market growth.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293180/global-timber-connectors-market-2025-2032-824

Market Overview & Regional Analysis

North America leads the timber connectors market, accounting for over 35% of global consumption, supported by well-established construction industries and stringent building codes requiring reliable timber framing systems. The region's focus on sustainable construction practices and the rehabilitation of aging infrastructure creates consistent demand.

Europe follows closely, with Germany and Scandinavia being key markets due to their advanced timber construction technologies and environmental regulations favoring wood-based building materials. Meanwhile, Asia-Pacific is emerging as the fastest-growing region, propelled by rapid urbanization and increasing investments in residential construction across China, Japan, and Southeast Asia.

Key Market Drivers and Opportunities

The market is primarily driven by the global construction industry's expansion, particularly the growing popularity of timber frame construction in both residential and commercial sectors. Lightweight wood structures are gaining preference over traditional materials because they offer faster construction times, better seismic performance, and lower carbon footprints.

Significant opportunities exist in the development of innovative connector designs that enhance installation efficiency and structural performance. The increasing adoption of engineered wood products like cross-laminated timber (CLT) and glue-laminated timber (glulam) presents new avenues for specialized connector systems. Additionally, post-pandemic infrastructure stimulus packages in various countries are expected to boost demand for timber construction components.

Challenges & Restraints

The timber connectors market faces several challenges, including competition from alternative building materials such as steel and concrete, which remain dominant in certain construction applications. Fluctuations in lumber prices and supply chain disruptions can impact market stability, while skilled labor shortages in timber construction may hinder adoption rates.

Regulatory hurdles and varying building codes across regions pose additional challenges for manufacturers. Furthermore, concerns about long-term durability in high-moisture environments and the need for proper installation techniques present technical barriers that the industry must address.

Market Segmentation by Type

3-way Connectors

4-way Connectors

Other

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/293180/global-timber-connectors-market-2025-2032-824

Market Segmentation by Application

Residential Building

Commercial Building

Infrastructure

Market Segmentation and Key Players

Pryda

Simpson Strong Tie

MiTek

Timberplates

Connext Post and Beam

Knapp GmbH

Report Scope

This comprehensive report analyzes the global timber connectors market from 2024 to 2032, providing detailed insights into:

Market size and growth projections

Detailed segmentation by type, application, and region

Competitive landscape and market share analysis

The report also includes in-depth profiles of major industry players, covering:

Company overview and product portfolios

Production capabilities and market strategies

Financial performance and recent developments

Our research methodology combines primary interviews with industry experts, market surveys, and thorough analysis of industry trends to provide accurate and actionable insights.

Get Full Report Here: https://www.24chemicalresearch.com/reports/293180/global-timber-connectors-market-2025-2032-824

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

0 notes

Text

Selecting the Right Connection Methods for Your Commercial Roof Trusses

When it comes to commercial construction, the strength and durability of a building largely depend on the roof structure. Roof trusses are a critical component, and selecting the right connection methods is essential to ensure safety, cost-efficiency, and longevity. In commercial buildings—where load demands, span requirements, and building codes are stringent—the method used to connect trusses can make or break your project’s success.

Whether you're building a retail center, warehouse, or multi-story office complex, choosing the right connection method for your commercial roof trusses is just as important as the truss design itself. Let’s explore the best practices, available methods, and expert considerations to help you make the right choice.

Why Truss Connection Methods Matter

Connection methods serve as the glue that holds the entire roof structure together. These connections:

Transfer loads between truss components

Ensure stability during construction and throughout the life of the building

Facilitate quick and safe installation

Comply with engineering and code standards

Inadequate or improperly selected connection systems can lead to structural failure, increased costs, and project delays. Therefore, understanding your options and the factors that influence your choice is crucial.

Types of Connection Methods for Commercial Roof Trusses

Choosing the best connection method depends on several factors such as truss material, building type, load requirements, and budget. Below are the most commonly used connection methods in commercial applications:

1. Metal Plate Connectors

Metal plate connectors, also known as truss plates or nail plates, are the most widely used method for wooden roof trusses. These plates are pressed into the wood at truss joints, providing a high-strength bond.

Advantages:

Fast installation

Cost-effective

Consistent and reliable

Best Used For: Large-scale commercial buildings using pre-engineered wood trusses.

2. Bolted Connections

Bolted connections involve fastening truss members using heavy-duty bolts, often accompanied by washers and steel plates. This method is common in both timber and steel trusses.

Advantages:

High load-bearing capacity

Reusable for temporary structures

Easy to inspect and maintain

Best Used For: Warehouses, bridges, and buildings requiring high structural integrity.

3. Welded Connections

Welding is typically used in steel trusses, offering a strong and permanent bond between members.

Advantages:

Superior strength

Minimal visible joint hardware

Excellent performance under dynamic loads

Best Used For: Industrial buildings and large-span commercial structures with steel framing.

4. Screwed or Lag-Bolt Connections

Lag bolts or screws are used for timber trusses where a metal plate might not be ideal, such as in exposed truss applications for aesthetic purposes.

Advantages:

Strong mechanical fastening

Good for custom or decorative applications

Best Used For: Retail or hospitality buildings with visible wooden trusses.

Factors to Consider When Selecting a Truss Connection Method

Selecting the right connection method is more than just matching materials—it involves engineering insight, code compliance, and practical feasibility. Here’s what to keep in mind:

1. Material Compatibility

The method must align with the material used—wood, steel, or engineered composites. For instance, a welded connection is great for steel but unsuitable for wood.

2. Load Requirements

Commercial buildings face varying live and dead loads depending on occupancy, roof type, and geographic location. The connection must handle both vertical and lateral forces.

3. Building Type and Design

Complex roof designs or wide-span buildings may require hybrid connection systems to accommodate architectural and structural demands.

4. Installation Environment

Will the trusses be preassembled offsite or installed onsite? Some connection types are better suited for factory assembly, while others accommodate field adjustments.

5. Code and Inspection Requirements

Always ensure compliance with local building codes, especially in areas prone to seismic or high wind activity. Each connection method must also be easy to inspect.

Ensuring Proper Installation with Expert Help

Improper installation of truss connections can compromise the structural integrity of the entire roof. To avoid this, always work with experienced professionals who understand the nuances of commercial roof truss systems.

A qualified provider will:

Conduct accurate load calculations

Select materials and connectors appropriate to your region and building type

Ensure all components meet local codes

Provide pre-engineered solutions that streamline installation

At Structural Wood Corporation, our team has decades of experience designing and fabricating custom roof truss systems that meet demanding commercial requirements. We can help you choose and install the right connections for your project, ensuring durability, compliance, and cost-efficiency.

Common Mistakes to Avoid

Here are a few costly mistakes to steer clear of when selecting connection methods:

Ignoring environmental conditions: Failing to factor in wind, snow, and seismic loads.

Overlooking long-term maintenance: Some connectors require ongoing checks, especially in corrosive environments.

Mixing incompatible materials: Using connectors that react poorly with truss materials can lead to deterioration over time.

Choosing aesthetics over performance: While it’s tempting to go with a more visually appealing method, structural integrity should always come first.

Future-Proofing Your Truss System

With commercial buildings evolving to meet new environmental and technological standards, the truss connection method should also accommodate future upgrades, such as:

Renewable energy systems (e.g., solar panels)

Rooftop HVAC systems

Reconfiguration of internal layouts

Make sure your roof truss system and its connectors are adaptable to changes in use or equipment without compromising structural integrity.

Final Thoughts

Selecting the right connection method for your commercial roof trusses isn’t a one-size-fits-all decision. It involves a careful balance of structural requirements, environmental conditions, budget, and aesthetic considerations. By understanding the available connection types and working with industry professionals, you can ensure a safe, efficient, and future-ready commercial roof system.

Have questions about your specific project? Reach out to our experienced team via our Contact Page. We’re happy to guide you through the process and help you select the ideal connection method for your roof trusses.

1 note

·

View note

Text

Prefabricated Wood I-Joists

Prefabricated wood I-joists are used throughout the world and are well accepted by the construction industry. Prefabricated wood I-joists are high-strength, cost-effective, and versatile building elements for floor, roof wall framing in residential and commercial construction. Product lines are manufactured in many sizes, using a number of component materials to obtain a wide variety of engineering design properties.

Prefabricated wood I-joists are specialized products, manufactured with specially designed equipment. Expertise in adhesives, wood products, manufacturing, and quality assurance are necessary for the fabrication of high-quality prefabricated wood I-joists. Prefabricated wood I-joists utilize the geometry of the I-shaped cross-section and high-strength components to maximize the strength and stiffness of the wood fiber. Flanges are manufactured from sawn lumber or structural composite lumber, whereas webs typically consist of plywood or oriented strand board.

The design of the prefabricated wood I-joist efficiently utilizes and optimizes the wood fibers. The flanges (the top and bottom of the assembled member) are designed to resist bending forces and to add stiffness to the product. The web section is designed to withstand the shear forces in the joist. Adhesive applied in the rout of each flange creates a durable exterior structural joint.

An I-shaped cross-section, as opposed to a solid rectangular cross-section, requires additional considerations. Due to its particular shape, the prefabricated wood I-joist requires special examination for and interior reaction capacity, shear capacity, deflection, connector compatibility, vertical load transfer at points of bearings, web holes, and floor and roof performance.

The unique manufacturing techniques and the variety of materials that are utilized result in design values that are typically proprietary to each manufacturer. Prefabricated wood I-joists are tested and qualified under ASTM Standard D-5055 and are recognized in evaluation reports issued by one or more of the model building code evaluation service organizations. Unique

Open Web Joists

Firring Timbers

I-Joists

Chipboard Flooring

Concrete Formwork Timber Beam

Engineered Timber I-Joist

3-1/2-in x 11 7/8-in LPI 42 Plu

LVIL Factory Outlet Formwork Ma

Open Web Joists

Firring Timbers

I-Joists

Chipboard Flooring

Concrete Formwork Timber Beam

Engineered Timber I-Joist

3-1/2-in x 11 7/8-in LPI 42 Plu

LVIL Factory Outlet Formwork Ma

0 notes

Text

Elevate Your Exteriors with WPC Outdoor Wall Panels

When it comes to contemporary building and design, the never-ending search for aesthetics combined with durability is a constant. One material that has garnered a lot of attention is WPC. For this reason, WPC exterior wall panels are famous for their brilliant performance and attractiveness. If you are thinking of renovating your outdoor area, here are the reasons you need to think about WPC outside wall panels

Advantages of WPC Outdoor Wall Panels

Lasts Long :- There is one reason why homeowners and builders prefer WPC panels, and that is because they are extremely durable. One difference from normal wood is that WPC doesn’t rot, decay, or allow insects to infest it. This property makes WPC perfect for outdoor applications where exposure to sun and rainfall might be an issue. Regardless of the weather conditions including heat or heavy rains, WPC will still look the same.

Easy to Take Care :- In order for ordinary varieties of timber to remain attractive, they need frequent staining, sealing, and maintenance. This isn’t true with WPC panels, however, since these require very little airy attention. In most cases just washing them with soap and water is sufficient enough to ensure cleanliness. Thus less money spent on maintenance leads to savings after some time lapses.

Eco-Friendly :- In today’s environmentally conscious world, building materials must be sustainable. WPC is an eco-friendly option because it utilizes recycled wood fibers and plastic thereby reducing the demand for virgin materials. Besides, WPC panels are recyclable at the end of their lifespan thereby enhancing the circular economy.

Aesthetic Versatility :- Available in many colors, textures, and finishes, WPC outdoor wall panels can bring about beauty, particularly by highlighting the property’s outer appearance. In case you desire rustic appeal with grains made of wood or modern looks characterized by seamlessness there exists a variety of panels suitable for your expectations.

Easy Setup :- WPC boards have been prepared for fairly simple shaping and assembling. When compared to wood planks, they can be chopped, bored, and secured into place using similar procedures but do not suffer from any splitting or bending in shape. Several WPC panels are sold with connectors that guarantee an unbroken and secure connection which cuts down on the installation time as well as labor expenses.

Water and UV Resistance :- Contrary to other types of timber, WPC exterior wall cladding has built-in protection against different types of water and exposure to sunlight. This plays a key role in avoiding bending movement, degree of moisture changes, or even color loss leaving your outdoor wall panels looking good for a long time while keeping their basic framework intact.

Applications of WPC Outdoor Wall Panels

If you want to give some new life to your home, then you can use these modern WPC panels that will not only make the house look beautiful but also natural.

The buildings used for commerce such as offices, shops, and hotels can be more attractive and long-lasting if these panels are used.

WPC louver manufacturers in India provide a perfect choice in parks, playgrounds, and other areas that are open to the public because they have qualities like safety, beauty, and durability all at the same time.

Create fences that are long-lasting and good-looking so as to provide both protection and safety while still being stylish.

Conclusion

WPC outdoor wall panels are a great revolution in the building materials sector offering an unmatched combination of beauty, durability, and sustainability. If you are a homeowner seeking to upgrade your outdoor spaces or a builder in search of dependable and flexible materials, then Makmore a WPC supplier in Bangalore is here to help. Embrace the future of construction and design by installing WPC outdoor wall panels on your exteriors and creating long-lasting beautiful masterpieces.

#wpc louvers suppliers near me#wpc louvers manufacturers in india#louvers for exterior wall#wpc exterior wall cladding#wpc outdoor wall panel#wpc decking manufacturers in india#wpc supplier in bangalore#wpc decking suppliers in india#wpc deck flooring near me#wpc exterior wall panels#wpc gate panels

0 notes

Text

What qualifies as a safety anchorage point for a personal fall arrest system?

Working at heights always involves some risk, but with proper safety equipment and anchorage points, the risks can be significantly reduced. Personal fall protection systems are a crucial part of fall protection for workers whose jobs involve working above the ground. However, for these systems to be effective, the anchorage point itself must meet certain criteria to safely arrest a fall.

The anchorage point that a fall arrest system attaches to needs to be able to withstand substantial impact and force. In a fall scenario, the arrested worker's full body weight will be placed on the anchorage point, which could range from 150-310 pounds on average. Therefore, any approved anchorage point must be rated to withstand a minimum of 5,000 pounds of force or 2 times the expected impact load.

Static lines and vertically suspended lifelines are common anchorage options for fall arrest systems. Anchorages formed of structural steel members, sound roofing materials, and wood members over 5 inches thick are generally sufficient if they meet strength requirements. Pre-engineered anchor points known as fall arrester blocks can also serve as compliant anchorage points. These portable blocks distribute energy across their structure during a fall impact.

For horizontal lifelines, additional criteria come into play. These require termination anchorages at both ends able to withstand twice the maximum arrest force along the lifeline. They also need to be securely attached to an anchorage capable of withstanding similar forces from two directions. Horizontal lifelines are common anchorage solutions for larger work areas requiring movement, like bridge construction. In all cases, occupiers need to verify the rated strength of any anchorage option and not exceed its limits.

Anchorage connectors like carabiners must also be rated for a minimum of 5,000 pounds to ensure they don't fail under any fall forces. Using connectors with ratings lower than the strength of the approved anchorage point could compromise fall protection. Connectors should always feature self-locking mechanisms and be compatible with the other components of the fall arrest system, including lanyards and harnesses.

Building surfaces like concrete, steel, timber, and masonry can generally qualify as anchorage points if structurally sound. However, attaching lanyards or lifelines to relatively small or moveable objects is unsafe and should be avoided. Gas pipes, vents, drainpipes, lighting fixtures, and other utilities cannot sustain heavy impact loads and are not approved as anchorage points for fall arrest systems. Surfaces like glass, gyprock, or wood paneling are also insufficient.

Portable fall arrester blocks provide flexibility when permanent structural anchorages are not present. These engineered blocks distribute and absorb forces to keep workers securely protected during falls. Having at least two such blocks on hand enables multiple attachment points and backup anchorages for changing work positions. Well-maintained blocks incorporate lightweight designs for easy transport and setup at varying work locations. Any anchorage point connecting a personal fall arrest system like lanyards or horizontal lifelines must be specifically rated to withstand a minimum impact force of 5,000 pounds. Rigid, load-bearing surfaces from structures can suffice but require assessment. Prefabricated fall arrester blocks provide versatility as approved temporary anchorage solutions at heights. The regular inspection ensures adequate safety anchorage points remain available for effective fall protection systems.

0 notes

Text

From Definition to Deployment: Navigating Formwork Fittings and Their Practical Usage and Benefits

In the intricate realm of construction, the selection and utilisation of formwork fittings stand as a critical determinant of project success. This blog takes a comprehensive journey from understanding the definition and practical deployment of formwork fittings to exploring the numerous benefits associated with these structural components, with a spotlight on Padmavati Engineering's expertise.

Formwork fittings are essential components used in the construction industry for creating temporary moulds or frameworks that support freshly poured concrete until it hardens and gains sufficient strength to stand on its own. This process, known as formwork, ensures the accuracy, stability, and safety of concrete structures during construction. Navigating formwork fittings involves understanding their definition, practical usage, and the benefits they bring to the construction process.

1.Definition of Formwork Fittings:

The specialised tools and equipment known as formwork fittings are used in combination with formwork systems. They are sometimes referred to as formwork accessories or components. Formwork panels, beams, braces, and other components can be assembled, aligned, and connected correctly to generate the necessary concrete shape with the help of these fittings. They guarantee that the structure of the formwork is safe, sturdy, and able to endure the pressure that the wet concrete exerts.

Formwork fittings are indispensable components in construction, providing the necessary support and structure for shaping concrete during the building process. The choice of materials, such as steel, aluminium, and timber, influences the durability, weight, and reusability of these fittings. Padmavati Engineering, a respected player in the industry, offers a diverse array of formwork solutions tailored to meet the distinctive demands of various construction projects.

2 .Practical Usage of Formwork Fittings:

Construction sites must be as efficient as possible, and the usefulness of utilising formwork fittings in this regard. The fittings from Padmavati Engineering are easy to assemble and disassemble because of their user-friendly features, which greatly improve workflow efficiency. Since time is of the essence in the construction industry, these fixtures are essential to completing projects on schedule.

1. Formwork Clamps: These clamps are used to connect and secure formwork panels, beams, or other elements together. They provide stability and prevent any movement during concrete pouring.

2. Formwork Connectors: These connectors are used to join formwork panels or beams at different angles or intersections, allowing the creation of complex shapes and structures.

3. Formwork Anchors: Anchors are used to fix formwork to the ground or existing structures, providing additional stability and preventing any shifting or displacement.

4. Formwork Brackets: Brackets are used to support and align vertical or horizontal formwork elements, maintaining their position and preventing sagging or deformation.

5. Formwork Ties: Ties are used to hold opposite formwork panels together. They create a tight bond, ensuring the concrete does not leak or spill during pouring.

6. Formwork Wedges: Wedges are used to level formwork elements and provide horizontal adjustments. They help in achieving precise alignment and maintaining the desired form.

3.Safety and Compliance:

At Padmavati Engineering, we strongly believe that safety is an essential component of construction and cannot be compromised. explains how their formwork fittings ensure a safe working environment on construction sites by meeting and even exceeding international safety standards. One of the main features of Padmavati Engineering's products is safety, which is incorporated into the design concept.

4. Padmavati Engineering's Commitment:

The success of building projects depends critically on maintaining a high level of proficiency with the materials and solutions used. Formwork fittings that meet the strictest industry standards are particularly important to Padmavati Engineering, a reputable company recognized for its unwavering commitment to quality and innovative methods. Whether the requirements are simple or complex in terms of architecture or engineering, Padmavati Engineering guarantees the delivery of trustworthy and painstakingly designed solutions, guaranteeing constant precision and dependability in all facets of their business operations.

5.Benefits of Formwork Fittings:

Formwork fittings play an important function in construction projects, in addition to their structural relevance. They have a number of advantages, including cost-effectiveness, efficiency, and sustainability. This blog explores how these fittings contribute to these qualities. Furthermore, Padmavati Engineering's solutions augment these benefits with their diversity and adaptability, making them an important asset in a variety of building projects.

Properly installed formwork fittings enhance the stability and structural integrity of the formwork system, reducing the risk of accidents and structural failures during concrete pouring.

Fittings enable precise alignment and positioning of formwork elements, ensuring accuracy in the shape and dimensions of the final concrete structure.

Many formwork fittings are designed for multiple uses, allowing them to be dismantled, reassembled, and reused on different construction projects. This reusability reduces material waste and lowers overall project costs.

Formwork fittings come in various sizes, shapes, and designs, enabling their use in diverse construction applications. They can be adapted to different formwork systems, accommodating complex architectural designs and structures.

Formwork fittings simplify the assembly and disassembly process, saving time and labour. They facilitate efficient concrete pouring, accelerating the overall construction schedule.

Conclusion:

As the construction industry continues to evolve, the importance of formwork fittings becomes more pronounced. From defining the basics to exploring the benefits, this blog sheds light on the integral role these fittings play in shaping successful construction projects. With Padmavati Engineering as a trusted partner, navigating the complexities of formwork fittings becomes not just a journey but a streamlined and dependable process, ensuring the success of your construction ventures.

In summary, formwork fittings are integral components of the formwork system, offering practical usage benefits such as increased safety, precise alignment, reusability, flexibility, and improved construction speed. By understanding their functions and incorporating them effectively, construction professionals can navigate formwork processes with ease, ultimately leading to the successful completion of concrete structures.

0 notes

Link

The global Timber Construction Connectors market size is expected to be worth around US$ 6.13 billion by 2030, according to a new report by Vision Research Reports.

The global Timber Construction Connectors market size was valued at US$ 760.0 million in 2020 and is anticipated to grow at a CAGR of 14.9% during forecast period 2021 to 2030

0 notes

Text

Global Timber Construction Connectors Market Size, Share, Growth Report, Related Trends, Statistics Analysis 2021 to 2027

Global Timber Construction Connectors Market

The global Timber Construction Connectors market was valued at USD 838.3 million in 2020 which expected to reach USD 2140 million by 2027 at a CAGR 13.9% from 2020-2027.

Traditional structural timber connections are classified into two forms: dowel types and metal connectors. They differ in how forces are transferred between connected members. Metal fasteners have minimal to no fire resistance and can easily transfer and absorb heat. One frequent workaround is to use plasterboard as fire protection. The metal connectors you use have a significant impact on the structural stability of a structure or project. After all, even the strongest component is only as good as the connector utilized; once the connector fails, it's just a matter of time before the entire structure collapses.

Get Sample Copy of this Report @ https://qualiketresearch.com/request-sample/Timber-Construction-Connectors-Market/request-sample

Market Drivers

The need for timber construction is expected to expand in the next years as the demand for sustainable structures rises. The socio-ecological benefits of green structures, as well as the development of Mass Engineered Timber (MET) products, are likely to drive up demand for timber construction in the future years. Timber construction has numerous advantages, including lower CO2 emissions and carbon usage, as well as biophilic design.

Market Restraints

In the construction industry, health and safety has long been a major issue. Working at heights, in restricted spaces, underground, and in close proximity to falling objects, handling loads manually, handling dangerous substances, and exposure to live electric cables are all tasks that construction workers must perform. Although the construction business employs only 6% of the workforce in the United States, it is responsible for about 20% of all fatalities, accounting for the highest number of fatalities of any other industry. Hazards to one's health and safety have a detrimental impact on the building sector, serving as a market restraint.

COVID-19 Impact on the Timber Construction Connectors Market

The suspension of construction activities in 2020 to stop the spread of the COVID-19 outbreak has had a significant impact on Timber Construction Connectors activities, limiting demand for connectors. Supply chain disruption and the cessation of trade operations around the world identified as the other major reasons impeding market growth.

Market Segmentation

The Global Timber Construction Connectors Market is segmented into By Product such as Timber to Timber, Timber to Masonry, and Timber to Steel. Timber to Timber segment has largest market share during the forecast period.

Regional Analysis

Global Timber Construction Connectors Market is segmented into five regions such as North America, Latin America, Europe, Asia Pacific, and Middle East & Africa. Europe dominated the Timber Construction Connectors market. This can be attributed to the country's high penetration of wood-based dwellings and the growing trend toward environmentally friendly constructions. The German government launched the Housing Construction Campaign in an attempt to address the country's escalating housing prices and scarcity. This is intended to help the building industry thrive and support demand for timber connections.

Key Players

Various key players are listed in this report such as Taurus India Limited, Simpson Strong Tie Co., Inc., MITEK INC., Timberplates, Knapp GmbH, Eurotec GmbH, MTC Solutions, BPC Fixings (The Vista Group), Globus Industries and among others.

Market Taxonomy

By Product

Timber to Timber

Timber to Masonry

Timber to Steel

By Region

North America

Latin America

Europe

China

Asia Pacific

Middle East & Africa

Browse Full Research Report @ https://qualiketresearch.com/reports-details/Timber-Construction-Connectors-Market

About Us

QualiKet Research is a leading Market Research and Competitive Intelligence partner helping leaders across the world to develop robust strategy and stay ahead for evolution by providing actionable insights about ever changing market scenario, competition and customers. QualiKet Research is dedicated to enhancing the ability of faster decision making by providing timely and scalable intelligence. We use different intelligence tools to come up with evidence that showcases the threats and opportunities which helps our clients outperform their competition.

Contact Person:

Vishal Thakur

Research Support Specialist

QualiKet Research

6060 N Central Expy #500, TX 75204, U.S.A

Email: [email protected]

Website: https://qualiketresearch.com

#Timber Construction Connectors Market size#Timber Construction Connectors Market Share#Timber Construction Connectors Market Trend#Timber Construction Connectors Market Growth#Timber Construction Connectors Market Application

0 notes

Link

A Timber Construction Connectors is actually a steel device, employed in conjunction with a bolt, that be part of timber in serious construction.

0 notes

Text

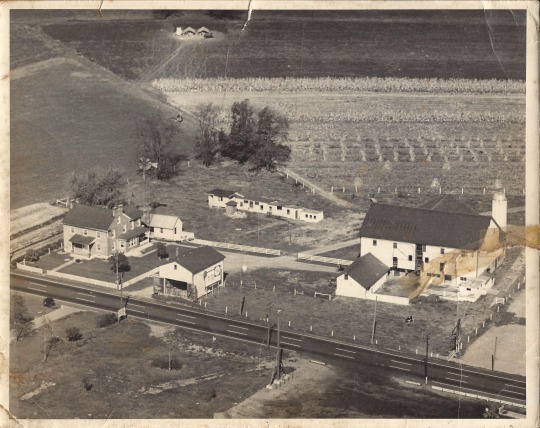

Adaptive Reuse Farmstead

An old farmstead sat vacant for about 15 years in Lancaster County, PA and our owners saw potential.

At that point, no farmer was going to put the extensive resources into the property that it would need to become functional again and the township didn't want a big corporation to destroy the buildings/property.

So we gave the historic farmhouse (& barn) new life by adapting it to serve as our headquarters for our construction company.

The farmhouse is office space, the in-law's quarters (black building on the right) is the timber frame conference room & more office space, and the timber frame connector serves as the reception area and open meeting space.

This shows how versatile timber framing can be and how you can blend old world craftsmanship with modern design features. We also love that it's given our team a biophilic space to work in and was a sustainable way to construct our building!

#biophilicdesign#timberframe#timberframing#adaptivereuse#custombuilders#postandbeam#construction company#timber frame#timber framing#post and beam#adaptive reuse

1 note

·

View note

Text

20-Year-Old Decks: Repair or Replace?

Softwood decks can keep going quite a while, contingent upon how well they're constructed, yet it's normal for decks of cedar, pine, or redwood to hold up for 10 to 20 years, so, all in all they start to crumble in manners that range from unattractive and badly arranged to absolutely perilous. "I've seen decks assembled two years back that we were unable to do anything with," says Phil Brown, proprietor of Archadeck of Central Connecticut in Wallingford, "and decks constructed 50 years go where the edge was totally fine." You can go to website to find best decks for your home.

Deck proprietors can now and again just manage the cost of fixes, which regularly implies supplanting the deck sheets and railings. The exact opposite thing they need to hear is that they need to supplant everything. Yet, once in a while there's no decision. Bombing siding or windows may look terrible or spill, yet a weak deck can fall. Somebody harmed in a deck breakdown—6,500 individuals have been since 2003, as per a Chicago Tribune story two years back—can sue the mortgage holder for harms. The Atlanta law office Kalka and Baer even promotes deck breakdown suit as one of its claims to fame. Also, in the event that somebody sues, that would immediately turn into the deck contractual worker's risk.

What's Obvious, and What Isn't?

Exposure around deck breakdowns has incited numerous regions to straighten out deck development guidelines before grants are given. "Today, "they're enthusiastic about strong things down," says Lou Pagnutti, whose Decks Unique in Commack, NY, has been building decks on Long Island for quite a long time. All things considered, on Long Island, which is loaded with homes worked over the most recent fifty years, Pagnutti gauges that about a large portion of his deck calls include a solicitation to supplant the sheets and rails on a current structure, i.e., a re-deck. "We examine the understructure," he says, which regularly includes eliminating deck sheets. "In the event that it's risky, we supplant it."

The value distinction between supplanting decking and rails versus modifying from the beginning is frequently huge. Cost is "consistently an intense inquiry," says Bryan Miller, leader of Outback Deck in Woodstock, Georgia. For example, if a mortgage holder simply needs new connectors and deck sheets on a 12-by-15 foot wood deck, that may be "a $3,000 to $4,000 gig." Tear the entire thing down—demo, dumpster rental, pull away, new timber—"that could undoubtedly be $9000 or $10,000, perhaps $12,000 or $15,000 or more on the off chance that they need a lot better quality item, similar to a Brazilian hardwood and costly rails."

Mill operator says Outback Deck will "do a significant fix, if it's a youthful enough deck that we feel certain" can be re-planked and another rail framework added without bargaining the security and solidness of the structure. "Youthful" signifies five to eight years of age.

Checking Five Criteria

"The vast majority will ask: what amount is it going to cost and when would it be able to be finished," Miller says. "What we cannot deny is that we need to think about it in an unexpected way."

The Atlanta organization adheres to the book, utilizing a six-page deck assessment structure from the North American Deck and Rail Association (NADRA). The examination centers around five explicit regions, three of them, Miller says, having to do with "purposes of association with the help presents or on the house." That is, present on balance, present on band, and band-to-house. Also, the investigation takes a gander at step and guardrail associations. The thought is to decide whether the deck is "coming up short"— crumbled yet at the same time sound—or really in danger of breakdown. That data, when decided, is enlarged with "photographs of decks in disappointment and decks in breakdown," Miller says. "We talk about the significance of understanding the idea of the current structure and why it should be supplanted."

Contrasting Deck and Frame Lifespan

Outback Decks isn't restricted on guideline to "rescuing" a more seasoned deck. Yet, the organization has created frameworks that steer it away from circumstances that contain risk for the manufacturer. NADRA chief VP, Mike Beaudry, gauges that about portion of the 50 million U.S. decks are at any rate 20 years of age. Respectable deckbuilders must have a technique for evaluating the usable existence of a deck, and an arrangement for deciding when its protected to fix rathere than supplant it.

At the point when California contractual worker Andrew York, proprietor of Pro Deck Construction, gets a call about fixing a deck, frequently it's "20 years of age and the redwood is exhausted. It's seen its life." The state of the casing, York says, will decide if the deck can be rescued. On the off chance that the outlining material isn't pressure-treated, and if it's unpainted, for the most part it's an act of futility.

York state that when he goes to an employment where "they simply need to do the decking rather than the whole casing, I clarify that there are 5 to 10 years of life in the casing, that the new deck will cost X and keep going anyway long, and that they can substitute the casing for X considerably more and it will last the life of the decking." If they're hoping to set aside cash, York says, they will go with simply supplanting the decking, yet "I ensure that it's perceived that we are simply doing the decking segment so we are not capable if this deck comes up short. I make that unmistakable in the extent of work."

Re-outlining includes "a beautiful huge cost distinction" because of different pieces of the territory being at high danger for fire. At Pro Deck Construction, a standard deck plan needs to meet the San Diego County fire code, which includes utilization of weighty lumber outlining on the hypothesis that "greater outlining individuals are more slow to light." For York, such circumstances become an occasion to recommend steel outlining, which he assesses 10% of substitution clients pick to utilize.

1 note

·

View note

Photo

7-story Wood Office Building in Zurich, Shigeru Ban

In the centre of Zurich, not far from the main railway station, a spectacular office building has recently begun to demonstrate the potential of wood as construction material. Shigeru Ban designed this new seven-story building with its visible wood construction as an addition to the headquarters of the Tamedia publishing company. The structure was to permit an assembly process similar to building blocks and feature a comprehensible load-bearing system. Wood elements were to remain exposed. To realize these architectural preconditions by using glue-laminated wood in premium quality for visible application and locking pin connections milled with extraordinary precision comprised a great challenge for all partners involved.One of Shigeru Ban’s aims was to build the structure in its entirety of wood, similar to traditional Japanese timber buildings. Not only columns and beams, but also joint connections consist predominantly of wood: instead of screws, nails or steel connectors, special dowels made of beech plywood serve for load transmission and reinforcement of construction components. The load-bearing structure with its full-height columns, beam pairs and girders with oval cross-section was created as a precise, CNC milled construction kit and assembled on-site similar to a three-dimensional puzzle. Planning and realization of this ambitious project were a great challenge for the timber engineers and builders.

8 notes

·

View notes

Text

Timber Construction Connectors Market 2020 Strong Development By Key Players, Research Analysis and Forecasts to 2027

Most recent Study on Industrial Growth of Global Timber Construction Connectors Market 2020-2027. A point by point study gathered to offer Latest knowledge about intense highlights of the Timber Construction Connectors market. The report contains distinctive market expectations identified with CAGR, income, production, Consumption, market size, gross margin, cost and other considerable elements.

While highlighting the key driving and guiding powers for this market, the report additionally offers a total investigation of things to come patterns and advancements of the market. It additionally looks at the role of the main market players associated with the business including their financial summary, corporate review and SWOT investigation.

Get Sample Copy of this Report: https://www.globalinforeports.com/request-sample/1082131

Top players Included:

MiTek, Simpson Strong Tie, Connext Post and Beam, Pryda, Timberplates, Knapp GmbH

Global Timber Construction Connectors Market Key Segments: On the Grounds of Type:

3-way Connectors

4-way Connectors

Other

On the Grounds of Application:

Infrastructure

Residential Building

Commercial Building

Leading Regions:

North America, Asia-Pacific, UK, Europe, Central & South America, Middle East & Africa

Get More Discount: https://www.globalinforeports.com/check-discount/1082131

The Timber Construction Connectors inquire about report is an important source of information for business strategists. It provides the Timber Construction Connectors outline with development examination, historical and futuristic cost income request and supply information. The exploration examination gives an elaborative depiction of the worth chain and distributor investigation.

This report gives a comprehensive analysis:

Key market sections and sub-sections.

Advancing business sector patterns and elements.

Changing market interest situations.

Measuring market openings through market estimating and market forecasting.

Following current patterns/openings/challenges.

Competitive Analysis.

Opportunity mapping in terms of technological developments.

For More Enquiry Click at: https://www.globalinforeports.com/send-an-enquiry/1082131

Customization of this Report: This Timber Construction Connectors report could be customized to the customer's requirements. Please contact our sales professional ([email protected]), we will ensure you obtain the report which works for your needs.

0 notes

Text

Route Review: Railriders Cycling: Oregon Coast

Railriders Cycling: Oregon Coast runs three routes along the renowned beauty of the Tillamook County shoreline, running on tracks of the Port of Tillamook Bay Railroad and sharing space with the Oregon Coast Scenic Railroad. The three routes currently on offer form one of three operations in the Northwest established by Kim and Anita Metlen, the pioneers of organized railbiking in Oregon and Washington. I rode the two routes described below on June 20th and 21st, 2019, although I unfortunately didn’t have time to schedule the Wheeler South route into my travel plans.

Vitals

Phone: 541-786-6165

Email: [email protected]

Website: https://ocrailriders.com/

Check-in Locations

Bay City to Tillamook: 5400 Hayes Oyster Drive, Bay City, OR

Wheeler North and South: 130 Marine Drive, Wheeler, OR

The Routes

The Wheeler North and South routes both start at a turnoff of in the north end of Wheeler, just as Highway 101 enters town. The 9-mile (14.5 km) round-trip Wheeler North route runs out of town along a vineyard and past dairy pastures before running on a trestle over the Nehalem River and then through ferny Northwestern forest.

As noted in the introduction, I was unfortunately unable (or too absent-minded?) to fit the 10-mile (16 km) round-trip Wheeler South route into my travel plans. However, as I describe in greater detail in the Travel Notes below, my bicycle ride down the coast took me along the tracks where it was easy to appreciate the views offered along the Nehalem Bay. I’ll have to return to the area to ride this route.

The Bay City route also starts starts along Highway 101, 17 miles (27 km) to the south of Wheeler and just north of Tillamook. The 12-mile (19 km) round-trip ride commences by what I took to be the world’s largest mound of oyster shells (see the intro photo above), but when describing it to my Connecticut coast born and bred mother, she made it sound as if 3-story heaps of blue point shells were round every corner in Bridgeport and Norwalk. The route offers a mix of Tillamook Bay views and open farmland, crossing many bridges and trestles over wildlife filled bogs, all under the hills of the Northern Oregon Coast Range.

As noted above, the three routes described here are part of a larger family of railbike tours founded by Kim and Anita Metlen, who deserve great admiration for the work they’ve done to promote cycling and recreation in the Northwest.

The routes stand out from others I’ve pedalled in that the line is still formally active and under the jurisdiction of the Federal Railroad Administration. While the line doesn’t currently handle freight in the vicinity of the railbike operations, the railbikes do share track with the Oregon Coast Scenic Railroad, subjecting the railbikes to federal safety regulations that treat them as inspection vehicles. The result is that riders wear safety vests and Railrider Cycling staff members are trained to operate safely in the manner of railroad maintenance workers. Given that I was riding my bicycle between the routes in northwestern drizzle, I was already wearing a high-vis raincoat and qualified to ride directly without an additional vest.

The line was originally constructed between 1906 and 1911 by the Pacific Railway and Navigation Company (PRN) to carry timber and agricultural products over the Northern Oregon Coast Range to Portland. Given the arduousness of maintaining a railroad in sopping coastal terrain, the line was dubbed Punk Rotten Nasty (PRN) by its workers. It was taken over by the Southern Pacific Railroad in 1916, and then the Port of Tillamook Bay Railroad as a shortline in 1990. Major storms in 1990, 1996 and 2007 segmented the line and mostly cut it off from the national network, although it has not been formerly decommissioned from future revenue service and a portion of the port operations, far from the segment used by the railbikes, still serves at least one lumber yard.

The Oregon Coast Scenic Railroad has been running excursion trains on the line since 2003. Raiilriders Cycling: Oregon Coast began the Bay City railbike route in 2016, and then expanded to the Wheeler North route in 2018 and the Wheeler South route in 2019.

The Vehicles

While all of the Railriders Cycling sites use a variant of the Railriders aluminum-framed and polyurethane-wheeled concept, the four-seat vehicles at Raiilriders Cycling: Oregon Coast regularly undergo creative re-engineering to ensure maximum performance and reliability. I rode the Wheeler North route with site manager Nate Bell (with Tara, half of the lovely couple running the three routes), who described his work in the engineering and economics of preventing wheel and hub wear, shaft flexion, and other concepts familiar to my work in railroad operations. Nate has been involved in the construction of all Railcyclers railbikes and told me that the “railbikes are ever-evolving, it’s the fun part about making them!”.

To my view, the quality of vehicle hardware was found in the seats, seat belts, and use of proven components such as Shimano chain tensioners.

Travel Notes

I pedalled the sites described above as part of a rail and cycling journey through the Northwest, reaching the coast after several days of enjoying the bikey-beery offerings of Portland. The obvious way to reach the coastal railbiking sites is by car, but I did find another option readers might enjoy. I picked up a folding bicycle in Portland, which I took on the Northwest Point bus to Cannon Beach, and then rode the 18 miles (30 km) to Wheeler to pedal the railbikes. Conveniently, both the seat and bike reservation can purchased through the Amtrak app on a smart phone. The Salmonberry Saloon in Wheeler offers fresh, local seafood and views of the Nehalem River.

After railbiking in Wheeler, I continued cycling south on the coast for another 17 (27 km) miles to Bay City to spend the night before railbiking there. I stayed in a cabin at the the Sheltered Nook, which I found on AirBnB and highly recommend. After leaving Bay City the next day, it was a short 5.5 mile (8.8 km) ride to Tillamook where I caught the NW Connector bus (bike rack on the front and space aboard) back to Portland.

Here is the beauty of riding a folding bike along the Oregon Coast:

I hope that it’s apparent to any reader of this blog that, in addition to the post-apocalyptic attraction of pedalling carts along former economically critical infrastructure, I find pleasure and diversion in mobility. To that end, I offer this photo of progressive Portland, where urban mobility hits its resonant frequency in the point convergence of an aerial tramway, streetcar, bikeshare dock, and parking for about 400 bicycles. (and I took the photo from a pedestrian bridge alongside an outdoor, urban elevator where a scootershare was carelessly left in the way)...(and the blue thing in the upper left is a crane for loading and unloading barges on the Willamette River)...

#railbike#railbikes#railbiking#ocrailriders#tillamook#tillamookcounty#portoftillamookbayrailroad#oregon#oregoncoast#oregoncoastscenicrailroad#wheeleroregon#baycityoregon#highway101#nehalemriver#nehalembay#tillamookoregon#tillamookbay#oysters#northernoregoncoastrange#portlandoregon

7 notes

·

View notes

Text

What is Hurricane Strapping?

When Hurricane Irma arrived in a couple of islands a few years back, a lot of roofs stayed put, reason being they had been fastened with hurricane straps.

This should suffice to assure you that installing a hurricane strap in your house is the need of the hour and must not be delayed. Though it is not certain that your roof will successfully brace a Category 5 storm, a hurricane strap is nevertheless a useful and inexpensive addition to your house’s existing components that you just cannot overlook.

Based on where you reside, chances are these straps may already be comprising the building code. And if they don’t, new constructions may have to be done to install the straps and allow them to pass the inspection and meet the code requirements. The roofs of older houses in all probability will be lacking hurricane straps. For these, the straps can be retrofitted to further strengthen and safeguard the aging edifices.

In hurricane strapping, a connector is placed between a wooden roof and the house below to attach the two firmly. The most common hurricane straps are built with galvanized or stainless steel with the goal to safeguard physical structures from turbulent weather conditions such as storms and excessive rain. Properties lying in a coastal area in particular should not be devoid of them. Hurricane straps are known by other names too like hurricane ties, hurricane brackets, hurricane anchors, hurricane clips, and hurricane strips.

Hurricane strapping in Florida

Florida, a state situated adjacent to the sea in the southeast of the United States, is quite susceptible to storm devastation, the two recent hurricanes being a case in point. And post Hurricane Andrew in 1992, the building code of Florida was revised, necessitating all new constructions (even those made of timber and concrete) to feature hurricane ties. There is every possibility that houses built prior to this period may not be equipped with hurricane straps and the solution lies in retrofitting.

Because hurricane straps are required to meet the area’s building code and certain technical specifications, their installation becomes the prerogative of experts. And even if you move into a house that already has hurricane straps fitted in it, you will still have to get them inspected to ensure nothing is amiss.

Different types of hurricane straps

Do not have this notion that hurricane straps come in just one form. Hurricane straps have multiple variants designed for different sections including timber connectors, rafter connectors, multipurpose straps, rafter/purlin clips, mending plates, truss anchors, moment connectors, twist ties and purlin braces.

So while timber connectors help in connecting beams, purlins, wall plates, floor plates, rafters, and studs firmly to the main structure, rafter connectors assist in forming a stronger bond between rafters and ridge boards.

When your house has every required hurricane strap, only then can you think of continuing to have a roof over your head, come hell or high water.

However, if all the precautions taken by you fail to prevent your roof or house from sustaining damage on being pounded by a fierce storm, you will be required to file an insurance claim and for a faster settlement and a bigger reward, you can avail public adjusting services that have helped many a policyholder draw maximum benefits from their coverage.

0 notes