#TitaniumMetal

Explore tagged Tumblr posts

Text

Durable Titanium Plates: The Key to Success in Aerospace and Manufacturing

Titanium is one of the most sought-after materials in industries requiring strength, durability, and lightweight solutions. Titanium plates are especially crucial in sectors like aerospace and manufacturing, where performance, reliability, and precision are paramount. If you're looking for a material that offers superior strength-to-weight ratios and resistance to harsh environments, titanium plates from trusted suppliers like Accromet can be the solution your business needs.

In this article, we'll explore why titanium plates are essential for success in aerospace and manufacturing and how Accromet's products can help elevate your operations.

Why Choose Titanium Plates for Aerospace and Manufacturing?

Titanium is an extraordinary material with a unique combination of properties that make it ideal for industries that demand high performance, like aerospace and manufacturing. Here’s why titanium plates are indispensable:

1. Unmatched Strength-to-Weight Ratio

Titanium’s strength-to-weight ratio is significantly higher than that of steel and other metals. This makes titanium plates incredibly strong while remaining lightweight—an essential feature in industries like aerospace, where reducing weight is crucial for fuel efficiency and performance.

2. Corrosion Resistance

Whether exposed to sea water, acidic environments, or high-temperature conditions, titanium retains its integrity. This resistance makes it a prime material for aerospace components that are often exposed to harsh environmental conditions.

3. High-Temperature Performance

In aerospace and industrial manufacturing, materials need to withstand extreme temperatures. Titanium remains stable and performs well even in high heat, making it the perfect choice for components in engines, airframes, and other critical systems.

4. Biocompatibility

In some manufacturing applications, such as medical devices, titanium plates offer the advantage of biocompatibility. This property makes titanium ideal for use in implants and other medical applications where the material comes into direct contact with the body.

Titanium Plates in Aerospace: Ensuring Safety and Performance

The aerospace industry relies heavily on titanium plates due to their combination of lightweight properties and incredible strength. Airplanes, spacecraft, and satellites require materials that can withstand extreme pressure, temperature variations, and corrosion without compromising on safety. Here’s how titanium plays a critical role:

Engine Components: Titanium is often used in the construction of aircraft engines, where high strength and heat resistance are essential. Titanium’s ability to perform well at high temperatures makes it ideal for turbine blades, compressor blades, and other engine components.

Airframe and Structural Components: The aerospace industry demands materials that offer high tensile strength while minimizing weight. Titanium plates are widely used in airframes, landing gear, and fuselage sections, where they help improve fuel efficiency without sacrificing strength.

Exotic Metals in Aerospace: Beyond titanium, aerospace manufacturers are increasingly turning to exotic metals such as titanium alloys to meet demanding specifications. Titanium alloys offer enhanced strength and durability compared to pure titanium and are frequently used in critical aerospace components.

Titanium Plates in Manufacturing: Enhancing Durability and Precision

Titanium is not only crucial for aerospace but also plays a significant role in industrial manufacturing. From automotive to energy sectors, titanium plates contribute to the production of high-performance machinery and components. Some key benefits include:

Durability and Resistance to Wear: In high-stress manufacturing environments, titanium plates withstand wear and tear better than many other metals. Their resistance to fatigue and corrosion ensures long-lasting performance, even in the most demanding applications.

Precision Manufacturing: Titanium can be easily machined and fabricated into precise components for specialized applications. Whether it's creating parts for high-end automotive engines or precision tools, titanium’s versatility makes it indispensable for manufacturers who require accuracy and efficiency.

Cost-Efficiency in the Long Run: While titanium plates may have a higher initial cost compared to other metals, their durability, lightweight nature, and long lifespan make them a cost-effective solution in the long run. Fewer repairs and replacements mean reduced maintenance costs and enhanced productivity.

330 Stainless Sheet: A Complement to Titanium Plates

While titanium plates are invaluable in many applications, 330 stainless sheet is another material that complements titanium in certain manufacturing processes. 330 stainless steel is known for its exceptional resistance to oxidation and high-temperature strength, making it an excellent choice for components exposed to heat and pressure. Using a combination of titanium plates and 330 stainless sheet can optimize the performance of critical components, particularly in environments with high-temperature and corrosion challenges.

Q&A: Titanium Plates in Aerospace and Manufacturing

Q1: What makes titanium plates suitable for aerospace applications? A1: Titanium’s combination of strength, lightweight properties, and corrosion resistance makes it ideal for aerospace. Its ability to perform under extreme temperatures and pressure ensures the safety and efficiency of aircraft and spacecraft components.

Q2: How does titanium compare to other metals in manufacturing? A2: Titanium outperforms many metals in terms of durability, strength-to-weight ratio, and resistance to corrosion and high temperatures. While it can be more expensive initially, its long lifespan and high performance make it a cost-effective choice in the long run.

Q3: Can titanium plates be used in medical applications? A3: Yes, titanium is biocompatible, which makes it an excellent choice for medical implants, prosthetics, and other applications where direct contact with the human body is required.

Conclusion: Choose Accromet for High-Quality Titanium Plates

When it comes to sourcing titanium plates for aerospace, manufacturing, or other industrial applications, Accromet is a trusted name in the industry. Our titanium products are designed to meet the highest standards of quality, offering the durability, strength, and precision required for critical operations.

Whether you need titanium plates for aerospace engineering, automotive manufacturing, or medical devices, Accromet provides the reliable materials you need to ensure success. Reach out to us today to learn more about our titanium offerings and how they can enhance your operations.

#TitaniumPlates#AerospaceMaterials#ManufacturingSolutions#TitaniumMetal#ExoticMetals#TitaniumAlloys#Accromet#330StainlessSteel#IndustrialMaterials#HighPerformanceMaterials#CorrosionResistantMetals#DurableMetals#TitaniumForIndustry#TitaniumManufacturing#AerospaceTechnology#HeavyDutyMetals#PrecisionManufacturing#AdvancedMetals#MetalFabrication#MaterialScience

0 notes

Text

Top 5 High-Temperature Metals Used in Aerospace & Automotive Industries

The aerospace and automotive industries are some of the most demanding sectors when it comes to material performance. Components must endure extreme temperatures, pressure, and stress. High-temperature metals are engineered to withstand these harsh environments while maintaining strength, corrosion resistance, and durability. Here, we’ll explore the top 5 high-temperature metals used in these industries, highlighting their key properties and applications.

1. Inconel Alloys

Properties:

Temperature Resistance: Inconel alloys, such as Inconel 625 and Inconel 718, can withstand extreme temperatures ranging from 1,000°F to 2,000°F.

Corrosion Resistance: Excellent resistance to oxidation and corrosion, making it ideal for environments with high pressure and heat.

Applications: Used in aircraft engines, turbine blades, exhaust systems, and high-performance automotive parts.

Why it's Used: Inconel’s strength and resistance to oxidation and thermal fatigue make it a go-to choice for both aerospace and automotive engineers. It's essential for components like turbines and combustion chambers that must endure extreme conditions.

2. Titanium Alloys

Properties:

Temperature Resistance: Titanium alloys maintain their strength at high temperatures, typically up to 1,000°F.

Lightweight: Known for their low density, titanium alloys offer a significant weight advantage.

Corrosion Resistance: Resistant to both heat and corrosion, making them ideal for high-performance and long-lasting applications.

Applications: Titanium is frequently used in aerospace for components such as airframes, jet engines, and fasteners. In the automotive industry, it is found in high-performance parts like exhaust systems and engine components.

Why it's Used: Titanium alloys provide the perfect balance of high strength, low weight, and corrosion resistance, making them essential for parts that need to perform under intense heat and pressure while keeping the overall weight low.

3. Stainless Steel (High-Temperature Grades)

Properties:

Temperature Resistance: High-temperature grades like 309 and 310 stainless steel can withstand temperatures as high as 2,000°F.

Strength & Toughness: Excellent mechanical properties that retain strength at elevated temperatures.

Corrosion Resistance: Exceptional resistance to corrosion and scaling in high-temperature environments.

Applications: Stainless steel is used for exhaust systems, heat exchangers, and various structural components in both aerospace and automotive applications.

Why it's Used: Stainless steel’s versatility, high temperature tolerance, and resistance to rust make it an essential material for components that need to maintain structural integrity while facing high heat.

4. Hastelloy

Properties:

Temperature Resistance: Hastelloy alloys can perform at temperatures up to 2,000°F without losing their strength or structural integrity.

Corrosion Resistance: Outstanding resistance to corrosion, especially in highly reactive environments such as high-temperature gas turbines.

Applications: Common in the aerospace industry for components that operate under extreme heat and pressure, such as engine parts, combustion chambers, and exhaust systems.

Why it's Used: Hastelloy alloys are the material of choice for applications requiring both extreme heat resistance and corrosion protection, which is why they’re widely used in aerospace engines and other high-temperature sectors.

5. Tungsten Alloys

Properties:

Temperature Resistance: Tungsten can withstand temperatures up to 6,000°F, making it one of the most heat-resistant metals available.

Density & Strength: Tungsten is incredibly dense and strong, making it suitable for high-performance applications.

Corrosion Resistance: While tungsten is resistant to most forms of corrosion, it is typically alloyed with other metals for improved ductility and strength.

Applications: Tungsten is used in specialized aerospace applications such as rocket nozzles and aerospace shielding. In the automotive sector, it is used in high-performance engine components and braking systems.

Why it's Used: Tungsten’s unparalleled temperature resistance and strength at extreme conditions make it indispensable for parts that must endure the highest levels of heat and stress.

Conclusion:

If your company needs materials that can withstand extreme conditions in aerospace or automotive applications, reach out for a free consultation or to get material specifications for these high-temperature metals. Our experts can help you choose the right metal for your specific needs and guide you through the procurement process.

Whether you’re designing components for jet engines, turbines, or high-performance automotive parts, we have the right materials for the job. Contact us today to discuss how we can help you source the best high-temperature metals for your project!

0 notes

Text

Is Titanium Magnetic

Is Titanium Magnetic? Titanium, a popular metal renowned for its exceptional strength and lightweight properties, has long been a subject of fascination. One question that frequently arises is whether titanium possesses magnetic properties.

Contrary to popular belief, titanium is not inherently magnetic. In its pure form, titanium is classified as a non-magnetic metal. This means that it does not exhibit strong attraction or repulsion to magnets.

However, titanium can become weakly magnetic under certain conditions, such as in the presence of a strong magnetic field or when alloyed with certain elements.

#titaniummagneticmri#titaniummagneticmaterial#Istitaniumametal#titaniummagnets#titaniummetal#titaniumuses#titaniummagnetic#titaniummagneticproperties#titanium#magnetic

1 note

·

View note

Link

Titan Engineering Pte Ltd is the Titanium supplier Malaysia of CP titanium Grade 1,2,3,4 and titanium alloy Grade 5,6,12,23. We are the leading exporter and supplier of Titanium in Malaysia. Get the best offer from us for Titanium in Malaysia and Get high quality Titanium .

1 note

·

View note

Link

The ability to manipulate the basic properties at the atomic scale is the latest trend of modern technology Read more: https://www.99alternatives.com/article/is-titanium-magnetic.html #titaniummetal #titaniumprice #titaniumuses #usesoftitanium #titaniumsymbol...

0 notes

Text

Titanium Plates: The Perfect Material for Aerospace, Medical, and Industrial Use

Titanium plates have earned their place as one of the most essential materials in various industries, thanks to their remarkable properties. From the aerospace sector to medical applications and industrial use, titanium plates offer unmatched durability, strength, and corrosion resistance. In this article, we will explore why titanium plates are so highly regarded, and why they are an ideal material for industries in the USA and around the world.

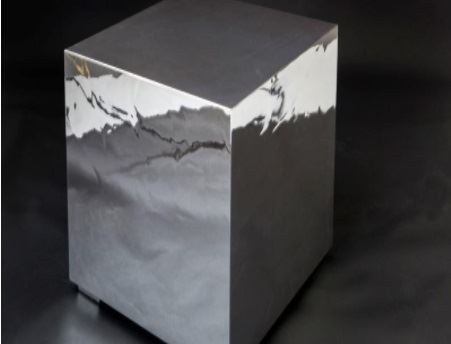

What Are Titanium Plates?

Titanium plates are flat sheets made from titanium, a lightweight yet strong metal that is highly resistant to corrosion, heat, and wear. The plates are often used in applications where strength, lightweight properties, and resistance to harsh environments are crucial. These plates can be manufactured in various thicknesses and grades, making them suitable for a wide range of industries, including aerospace, medical, and industrial sectors.

Key Properties of Titanium Plates

The appeal of titanium plates lies in their exceptional characteristics, including:

Strength and Durability: Titanium is known for its impressive strength-to-weight ratio, meaning it is incredibly strong yet lightweight.

Corrosion Resistance: Titanium is highly resistant to corrosion from many chemicals, saltwater, and extreme environments.

High-Temperature Performance: Titanium plates can withstand elevated temperatures, making them ideal for high-heat applications.

Biocompatibility: This is particularly important in medical applications, where titanium is used in implants and prosthetics due to its ability to integrate seamlessly with human tissue.

Non-Toxic: Unlike other metals, titanium is non-toxic and does not pose a risk of poisoning when used in medical or food-grade environments.

These unique properties make titanium plates an invaluable material across various industries, offering both reliability and performance.

Applications of Titanium Plates in Aerospace, Medical, and Industrial Sectors

1. Aerospace Industry

Titanium has long been a preferred material in the aerospace sector due to its strength, low weight, and resistance to high temperatures. Titanium plates are used in aircraft components, including engine parts, wings, and structural elements. The aerospace industry benefits from the material’s ability to withstand extreme conditions while maintaining structural integrity.

Lightweight Components: Titanium’s low density makes it ideal for weight-sensitive applications, such as aircraft fuselage and wing structures.

Engine Components: Titanium’s high-temperature resistance makes it perfect for engine parts like turbine blades, exhaust systems, and heat exchangers.

Corrosion Resistance: Aircraft parts exposed to harsh weather conditions, including saltwater environments, benefit from titanium’s corrosion resistance, ensuring longer service life.

As the aerospace industry continues to prioritize fuel efficiency and reliability, titanium plates remain a go-to material for designing lightweight yet strong aircraft components.

2. Medical Industry

The medical field relies heavily on titanium plates due to the material’s biocompatibility and strength. Titanium is widely used in medical implants, prosthetics, and surgical instruments.

Implants and Prosthetics: Titanium’s ability to integrate with human bone tissue makes it ideal for creating durable and long-lasting implants, such as dental implants, joint replacements, and bone screws.

Surgical Tools: Surgical instruments made from titanium plates offer strength and precision while minimizing the risk of allergic reactions.

Long-Lasting and Safe: Since titanium is non-toxic, it doesn’t cause rejection or complications when used inside the human body, making it a reliable material for permanent implants.

Titanium plates are also gaining popularity for creating customized prosthetics, ensuring that patients benefit from devices tailored to their specific needs.

3. Industrial Applications

In industrial settings, titanium plates are valued for their corrosion resistance, strength, and longevity. These plates are used in a variety of environments, from chemical processing to power plants and more.

Chemical Processing: Titanium’s resistance to corrosion from chemicals and acids makes it ideal for applications in harsh environments like chemical reactors, heat exchangers, and pipelines.

Marine Applications: Titanium plates are used in the construction of marine vessels and underwater equipment, where they must resist the corrosive effects of saltwater.

Power Generation: Titanium plates are utilized in heat exchangers, boilers, and other power generation systems where high strength and resistance to wear are crucial for long-term operation.

From power plants to petrochemical industries, titanium plates help improve operational efficiency by withstanding harsh conditions without degrading.

Why Choose Titanium Plates for Your Industry?

1. Cost-Effectiveness in the Long Run

While titanium may have a higher initial cost compared to other metals, its long lifespan and durability make it cost-effective in the long run. In aerospace, medical, and industrial sectors, where components must withstand extreme conditions, investing in titanium plates reduces maintenance costs and the need for replacements over time.

2. Enhanced Performance

The strength and lightweight properties of titanium improve the overall performance of equipment and components. In aerospace, for instance, reducing weight while maintaining strength leads to fuel savings and greater operational efficiency. In medical applications, titanium plates ensure long-term functionality of implants and prosthetics.

3. Customization and Precision

Titanium plates can be fabricated into custom shapes and sizes to meet the specific requirements of various applications. Whether you're designing an aerospace component or a medical implant, titanium can be shaped with high precision to match exact specifications, ensuring optimal performance.

Frequently Asked Questions (FAQs) about Titanium Plates

Q1: Are titanium plates suitable for high-temperature applications?

Yes, titanium plates have exceptional heat resistance and can withstand high temperatures, making them perfect for use in applications like aerospace engines and industrial heat exchangers.

Q2: How long do titanium implants last in the human body?

Titanium implants are known for their longevity, with some implants lasting a lifetime due to the material’s biocompatibility and strength. The exact lifespan depends on the specific implant and the patient's health.

Q3: Are titanium plates more expensive than other metals?

Yes, titanium plates generally cost more than other metals like steel or aluminum. However, their durability, resistance to corrosion, and long lifespan often justify the higher initial cost in the long term.

Q4: Can titanium plates be used in marine environments?

Absolutely. Titanium is highly resistant to corrosion from saltwater, making it an excellent material choice for marine applications such as shipbuilding and underwater equipment.

Conclusion: The Value of Titanium Plates Across Industries

From aerospace to medical and industrial applications, titanium plates are indispensable for ensuring reliability, performance, and longevity. Their unique combination of strength, lightness, corrosion resistance, and biocompatibility makes them the ideal choice for businesses looking to optimize their products and operations.

Call to Action: Interested in incorporating titanium plates into your business? Contact us today to explore our wide range of titanium products and find the perfect solution to enhance your operations and meet your industry’s needs.

#TitaniumPlates#TitaniumMetal#AerospaceMaterials#MedicalImplants#IndustrialMaterials#CorrosionResistance#BiocompatibleMaterials#AdvancedMaterials#MetalFabrication#ManufacturingSolutions#PrecisionEngineering#MaterialScience#HighPerformanceMaterials#MetalAlloys#TitaniumApplications#TitaniumIndustry#StrongAndLightweight#MarineApplications#ChemicalProcessing#DurableMaterials

0 notes

Text

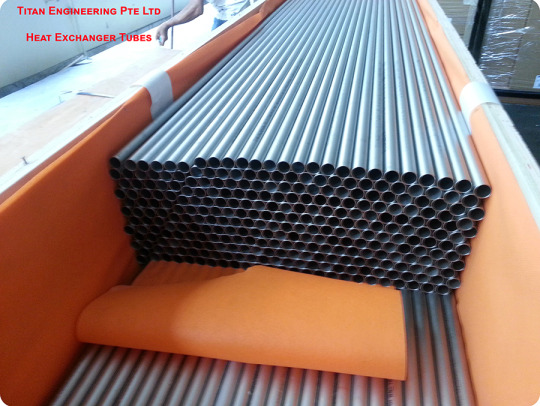

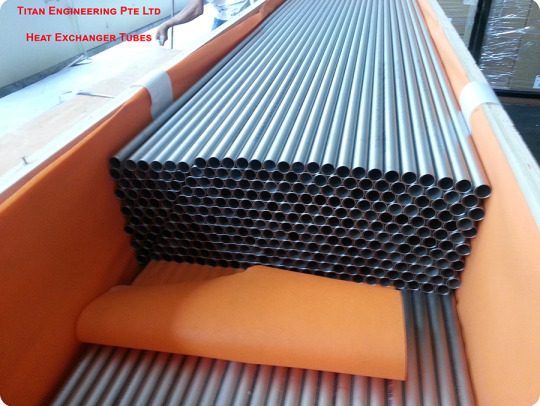

Heat Exchanger Tubes

TitaniumMetal is one of the leading manufacturers, Supplier and exporters of high quality Heat Exchanger Tubes, Stainless Steel 316Ti Round Bars, Inconel, Incoloy, 6Al4V titanium, Hastelloy, Steel 316Ti Round bar Supplier in Malaysia.

0 notes

Link

TitaniumMetal is one of the leading manufacturers, Supplier and exporters of high quality Stainless Steel 316Ti Round Bars, Inconel, Incoloy, 6Al4V titanium, Hastelloy, Steel 316Ti Round bar Supplier in Malaysia.

0 notes

Link

TitaniumMetal is one of the leading manufacturers, Supplier and exporters of high quality Stainless Steel 316Ti Round Bars, Inconel, Incoloy, 6Al4V titanium, Hastelloy, Steel 316Ti Round bar Supplier in Malaysia.

0 notes

Link

Titanium Malaysia is the Titanium supplier in Malaysia . We are the leading exporter and supplier of Titanium in Malaysia. Get the best offer from us for Titanium in Malaysia and Get high quality Titanium .

0 notes

Link

TitaniumMetal is one of the leading manufacturers, Supplier and exporters of high quality Heat Exchanger Tubes, Stainless Steel 316Ti Round Bars, Inconel, Incoloy, 6Al4V titanium, Hastelloy, Steel 316Ti Round bar Supplier in Malaysia.

0 notes

Link

TitaniumMetal is one of the leading manufacturers, Supplier and exporters of high quality Heat Exchanger Tubes, Stainless Steel 316Ti Round Bars, Inconel, Incoloy, 6Al4V titanium, Hastelloy, Steel 316Ti Round bar Supplier in Malaysia.

0 notes

Link

TitaniumMetal is one of the leading manufacturers, Supplier and exporters of high quality Heat Exchanger Tubes, Stainless Steel 316Ti Round Bars, Inconel, Incoloy, 6Al4V titanium, Hastelloy, Steel 316Ti Round bar Supplier in Malaysia.

0 notes

Link

TitaniumMetal is one of the leading manufacturers, Supplier and exporters of high quality Heat Exchanger Tubes, Stainless Steel 316Ti Round Bars, Inconel, Incoloy, 6Al4V titanium, Hastelloy, Steel 316Ti Round bar Supplier in Malaysia.

0 notes

Link

TitaniumMetal is one of the leading manufacturers, Supplier and exporters of high quality Heat Exchanger Tubes, Stainless Steel 316Ti Round Bars, Inconel, Incoloy, 6Al4V titanium, Hastelloy, Steel 316Ti Round bar Supplier in Malaysia.

0 notes

Link

CP Titanium plates are as per ASTM B265/ASTM SB265 available in both CP and Alloy grades in thickness ranging from 0.5mm to 100 mm thick. Titanium Plate is available in widths and lengths based on customers requirements.

0 notes