#TitaniumScrap

Explore tagged Tumblr posts

Text

Titanium made from lower-grade sponge or scrap has disadvantages: weaker mechanical properties, impurities, inconsistent composition, higher processing costs, environmental impact, limited applications, and long-term reliability concerns. Careful consideration of the material's source and quality is vital for optimal performance.

To obtain additional information, feel free to reach out to us via email at [email protected].

#KnowYourTitanium#Titanium#TitaniumSponge#TitaniumScrap#LowMechanicalProperties#HighImpurites#LowBiocompactibility#LowerGradeTitanium#NotMedicalTitaniumGrade#HorizonTitanium#StrongerTogether

0 notes

Photo

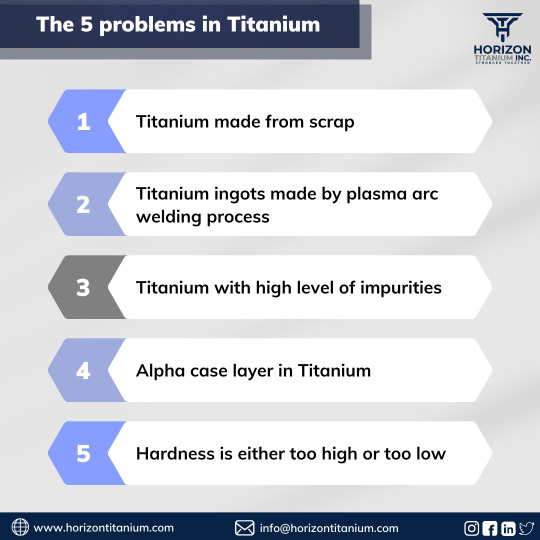

We have listed some of the problems you may need to take care of while purchasing Titanium. 1. Iron, oxygen, and tungsten carbide (added during the machining process) are heavily contaminated in titanium scrap and are challenging to remove while melting titanium scrap. 2. Titanium is highly reactive with oxygen and other gases. Titanium may react with atmospheric gases while welding compacted briquettes during the Titanium ingot manufacturing process. 3. Higher impurity content (Oxygen, Iron, Nitrogen) makes Titanium brittle and decreases its fatigue life & fracture toughness. 4. The alpha case is a brittle and hard layer that can readily break the material when the material is under sudden or repeating stress. 5. If the hardness of Titanium is high, the machining process becomes more complex, and tool life diminishes. When the hardness is low, the performance of the finished product weakens. There are a few more things you may want to know before deciding to buy Titanium rods/sheets for medical applications. To learn more about such problems, DM us or email us at [email protected].

#KnowYourTitanium#Titanium#Problems#TitaniumScrap#TitaniumWelding#Impurities#AlphaCase#Hardness#ELI#TitaniumRoundbar#TitaniumSheet#TitaniumImplant#MedicalImplants#OrthopedicImplant#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Photo

Titanium sponge which has low iron content can be used as a raw material for producing Titanium and Titanium alloy ingots. However, Titanium scraps are heavily contaminated with iron and oxygen and are difficult to use for Titanium ingot production, because there is no such process developed yet to remove those impurities from scrap. Therefore, the Titanium sponge is an ideal material for Titanium raw material production.

Stay connected for more updates. For more information, write us at [email protected]

#KnowYourTitanium#Titanium#TitaniumSponge#TitaniumScrap#Impurities#Mechanical#Metallurgy#Metals#Iron#Ilmenite#Rutile#Titanite#TitaniumBars#TitaniumRods#TitaniumSheets#TitaniumPlates#TitaniumPipes#TitaniumTubes#TitaniumWires#TitaniumImplants#MedicalImplants#Orthopaedic#OrthopaedicImplants#MedicalDevices#Aerospace#Chemical#oilandgasindustry#HorizonTitanium#StrongerTogether

0 notes