#VisionSystems

Explore tagged Tumblr posts

Text

InGaAs Image Sensors Market Drivers Include Rising Demand for Infrared Industrial Vision Systems

Introduction

Rising automation, stricter quality standards, and the quest for reliable low-light inspection are propelling the InGaAs Image Sensors Market toward unprecedented growth. Made from indium-gallium-arsenide, these sensors capture visible-to-short-wave-infrared (SWIR) wavelengths, making them indispensable for modern industrial vision systems that must see beyond what silicon-based detectors can perceive. The market is expected to grow significantly as manufacturers intensify investments in photonics-enabled production lines.

1. Industrial Vision Systems Lead Demand

The strongest driver is the integration of SWIR cameras into production-floor machine-vision systems. Silicon detectors become ineffective above 1 µm, leaving inspection gaps in semiconductor wafer probing, electrolyte checks in lithium-ion batteries, and mixed-plastic sorting. In contrast, InGaAs arrays can detect moisture, organic compounds, and silicon defects through protective coatings, enabling complete, non-destructive in-line inspection. As automation expands, factories demand sensors that offer high-speed imaging and reliability under harsh operational conditions.

2. Process-Automation Economics: Why Infrared Pays for Itself

SWIR-enabled imaging reduces false rejects and rework by revealing invisible contaminants or layer thickness variations. Automotive paint shops can minimize scrap by identifying solvent pockets, while pharmaceutical production lines using InGaAs systems achieve quick return on investment due to improved defect detection. These gains help justify the higher upfront costs of InGaAs-based solutions, especially in high-volume or high-value manufacturing sectors.

3. Low-Light Advantages and Spectral Selectivity

Unlike thermal detectors that require emitted heat, InGaAs sensors operate in the reflective SWIR band (0.9–1.7 µm), providing high-contrast imaging even under low-light conditions. These sensors can work with invisible, eye-safe LED illumination, making them ideal for around-the-clock inspection. Narrow-band filtering enables detection of specific materials like epoxy, moisture, or sugars, enhancing precision without redesigning hardware, which makes InGaAs a versatile tool across industries.

4. Falling Costs and Technological Breakthroughs

Three major advances are driving costs down:

Improved manufacturing yields – Modern fabrication techniques have increased sensor yields, reducing per-unit cost.

Wafer-level packaging – Integration of micro-optics and signal processing at the wafer level lowers assembly complexity.

Flexible integration – Open firmware and modular architecture allow OEMs to customize performance without incurring licensing costs.

As a result, the total cost of deploying InGaAs-based vision systems is dropping, encouraging broader adoption even in mid-sized industrial operations.

5. Regulatory, Safety, and Sustainability Catalysts

Government regulations now push for non-contact, accurate inspection across industries like food safety, battery production, and chemical handling. InGaAs image sensors meet regulatory expectations for material detection and quality control. They also contribute to sustainability goals by enhancing combustion control in furnaces and kilns, reducing energy consumption and greenhouse gas emissions across industrial operations.

6. Regional Hotspots

Asia-Pacific: Strong manufacturing infrastructure and government subsidies are boosting domestic production and deployment of SWIR systems.

North America: Military and defense applications are accelerating InGaAs sensor demand for field-deployable systems and night-vision solutions.

Europe: Environmental compliance and industrial innovation are encouraging adoption in recycling and automation-focused sectors.

Each region is witnessing demand driven by a unique combination of policy, infrastructure, and sectoral focus.

7. Competitive Landscape

The market is currently dominated by a mix of global and regional players. Larger firms specialize in high-performance, large-format sensors for aerospace and defense, while smaller firms focus on cost-efficient solutions for industrial applications. New entrants are leveraging AI-enabled on-sensor analytics and compact form factors to address emerging use cases like portable diagnostics and mobile inspection.

8. Looking Ahead: What the Drivers Mean for Future Demand

The combination of regulatory mandates, improving economics, and performance advantages makes InGaAs image sensors increasingly attractive across industries. Demand is expanding not only in factory settings but also in outdoor, mobile, and autonomous systems. These sensors are expected to play a central role in future smart manufacturing and automated quality assurance systems.

Conclusion: Setting the Stage for Trends in Night-Vision and Surveillance

While industrial inspection remains a powerful catalyst, the capabilities of InGaAs sensors in low-light and covert environments point toward major growth in night-vision and surveillance applications. In the next article, we explore how these sectors are shaping innovation in sensor design, ruggedization, and real-time data processing.

#InGaAsImageSensors#InfraredImaging#IndustrialVision#SWIR#MachineVision#SmartManufacturing#SensorTechnology#AutomationSolutions#VisionSystems

0 notes

Text

Warehouse Robotics Market Analysis

Meticulous Research®, a leading global market research company, published a report titled ‘Warehouse Robotics Market—Global Opportunity Analysis and Industry Forecast (2025-2032)’. According to this latest publication, the warehouse robotics market is expected to reach $15.1 billion by 2032, at a CAGR of 14.4% from 2025 to 2032.

The warehouse robotics market is expanding primarily due to a greater emphasis on optimizing warehouse operations for faster product delivery, the increased use of autonomous mobile robots (AMRs), and the growing popularity of e-commerce shopping platforms. However, the market's growth may be limited by the high expenses associated with warehouse setup and infrastructure development. At the same time, major breakthroughs in robotics, artificial intelligence (AI), and machine learning technologies are projected to open up new growth potential for enterprises in this field. Nonetheless, the security threats associated with linked autonomous robots remain a significant challenge that may impede market expansion.

This market is divided into product types, functions, payload capacity, and end users. It also covers competitive analyses at the regional and national levels. Autonomous mobile robots are expected to be the most popular product category in 2025, accounting for more than 29% of the market. This is due to rising demand for warehouse automation, increasing expansion in the e-commerce sector, and the need for efficient AMRs to increase productivity. The move for customized AMRs built to handle fragile or specific sorts of commodities reinforces this segment's leadership.

Geographically, the Asia-Pacific region is expected to dominate the warehouse robots market with a 52.7% share by 2025. This region is home to major robotics manufacturers such as Daifuku, FANUC, Hikrobot, and Omron, and their presence helps to strengthen the region's market position significantly. Furthermore, the region's growth is driven by a thriving e-commerce industry, a focus on operational efficiency, and the usage of robotics in industries such as semiconductors, electronics, and automobiles.

Key Players

Some of the major players studied in this report are Daifuku Co., Ltd. (Japan), KUKA AG (Germany), ABB Ltd. (Switzerland), FUNUC Corporation (Japan), Toyota Material Handling India Pvt. Ltd.(India), Omron Corporation (Japan), Honeywell International Inc. (U.S.), Yaskawa Electric Corporation (Japan), Onward Robotics (U.S.), Zebra Technologies Corporation (U.S.), Hikrobot Co., Ltd. (China), SSI SCHÄFER - Fritz Schäfer GmbH (Germany), Onward Robotics (U.S.), TGW Logistics Group (Austria), and Addverb Technologies Limited. (India).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=6027

Key Questions Answered in the Report-

What is the value of revenue generated by the sale of warehouse robotics?

At what rate is the global demand for warehouse robotics projected to grow for the next five to seven years?

What is the historical market size and growth rate for the warehouse robotics market?

What are the major factors impacting the growth of this market at global and regional levels?

What are the major opportunities for existing players and new entrants in the market?

Which product type, function, payload capacity, and end user segments create major traction in this market?

What are the key geographical trends in this market? Which regions/countries are expected to offer significant growth opportunities for the manufacturers operating in the warehouse

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

Robotic Inspection: The Future of Quality Assurance with Dynalog Inc.

In today’s fast-paced and highly competitive industrial landscape, quality assurance has become more crucial than ever. Whether you're in automotive manufacturing, aerospace, electronics, or any other high-precision industry, ensuring product quality is no longer just a competitive edge—it's a necessity.

Enter Robotic Inspection—an advanced solution reshaping how manufacturers conduct quality control. At the forefront of this innovation is Dynalog Inc., a leading provider of robotic calibration and guidance systems that are helping industries embrace automation with confidence.

What is Robotic Inspection?

Robotic Inspection refers to the use of automated robotic systems equipped with sensors, cameras, and AI-powered software to examine products, parts, or assemblies for defects, dimensional accuracy, or inconsistencies. These systems can detect flaws with incredible speed and accuracy, often surpassing what the human eye or manual inspection tools can achieve.

Instead of relying solely on human inspectors, manufacturers are integrating robotic systems that work tirelessly, consistently, and with precision—day in and day out.

Why Robotic Inspection is Changing the Game

Traditionally, inspection processes have been time-consuming, error-prone, and highly dependent on the skill level of individual inspectors. But with Robotic Inspection systems, companies can benefit from:

Higher Accuracy: Robots don’t get tired or distracted. When paired with advanced vision systems and sensors, they can detect microscopic flaws or misalignments.

Increased Speed: Robotic systems perform inspections in real-time, significantly reducing cycle times and production delays.

Repeatability: Robotic inspection ensures consistent quality across every single part, eliminating variability.

Reduced Labor Costs: While robots do require an initial investment, they can reduce ongoing labor costs and human errors.

Data Collection & Analysis: These systems can be integrated with smart software to collect inspection data, allowing for real-time analysis and continuous improvement.

Dynalog Inc.: Pioneering Robotic Inspection Solutions

Dynalog Inc. has built a reputation as a leader in the field of robotic measurement, calibration, and inspection. For years, Dynalog has supported manufacturers worldwide in their journey toward smarter, more efficient automation. Their Robotic Inspection solutions combine cutting-edge hardware and software to deliver high-performance, plug-and-play systems for industrial environments.

Let’s take a closer look at what sets Dynalog apart:

1. Advanced Robot Calibration Technology

Calibration is key to ensuring a robot performs accurate inspections. Dynalog’s calibration systems ensure that every robotic arm is perfectly aligned with its intended path, reducing positional errors and improving inspection reliability. Their TCP (Tool Center Point) Calibration ensures that the robot knows exactly where the tool is located in 3D space—critical for high-precision inspection tasks.

2. Vision-Integrated Inspection Systems

Dynalog offers systems that incorporate advanced vision technologies—both 2D and 3D—to allow robots to “see” and evaluate parts in real-time. Whether it’s detecting cosmetic flaws, measuring part dimensions, or verifying part presence, these systems operate with remarkable speed and precision.

3. Seamless Integration

One of Dynalog’s strengths is the flexibility of their solutions. Their Robotic Inspection systems are compatible with major robot brands and can be integrated into existing production lines with minimal disruption.

4. Real-Time Error Correction

Through dynamic feedback and compensation mechanisms, Dynalog’s solutions allow robots to self-correct and adapt during inspections. This ensures minimal downtime and improved overall productivity.

Industries Benefiting from Robotic Inspection

While almost every industry can benefit from robotic inspection, some sectors are leading the adoption curve:

Automotive: Ensuring fit, finish, and safety-critical components are defect-free.

Aerospace: Verifying the dimensional accuracy of complex components where failure is not an option.

Electronics: Detecting micro-defects and component misplacements.

Medical Devices: Maintaining ultra-high precision standards for life-saving equipment.

Looking Ahead: The Future of Inspection is Robotic

With the growing demand for smart factories and Industry 4.0 initiatives, Robotic Inspection is poised to become a standard part of modern manufacturing. As technologies like AI, machine learning, and IoT continue to evolve, robotic systems will become even smarter, more intuitive, and capable of making real-time decisions on the factory floor.

Dynalog Inc. is committed to staying ahead of the curve, constantly innovating to meet the demands of tomorrow’s manufacturers.

Ready to Upgrade Your Quality Assurance?

If you're looking to improve your quality inspection processes, reduce costs, and stay competitive, it’s time to explore what Dynalog’s Robotic Inspection Systems can do for your business.

#RoboticInspection#Dynalog#IndustrialAutomation#RobotCalibration#QualityControl#SmartManufacturing#FactoryAutomation#MachineVision#InspectionAutomation#TCPcalibration#RoboticQualityAssurance#Industry40#AutomatedInspection#VisionSystems#ManufacturingInnovation

0 notes

Text

Top 1 botlle inspection System in 2025 -Optomech

Imagine inspecting 11,000 bottles per hour with microscopic accuracy—all without human intervention. That’s the power of Machine Vision Inspection!

🔬 AI-driven defect analysis for unmatched precision ⚡ Ultra-fast processing keeps up with high-speed lines 📊 Automated data logging for compliance and tracking

The BIS-XL system ensures zero-defect manufacturing, helping companies meet the highest quality standards effortlessly.

Are you still relying on manual inspections in 2025? Let’s talk about automation!

Contact us:

Visit: https://www.optomech.in/bottle-inspection-system/

cantact us : 91+ 8106733649

Contact us for Demo Feel free To Ask

#BottleInspection#MachineVision#InspectionSystem#Automation#ManufacturingExcellence#QualityAssurance#FoodSafety#PharmaInspection#BeverageIndustry#IndustrialAutomation#NonDestructiveTesting#VisionSystems#Optomech

0 notes

Text

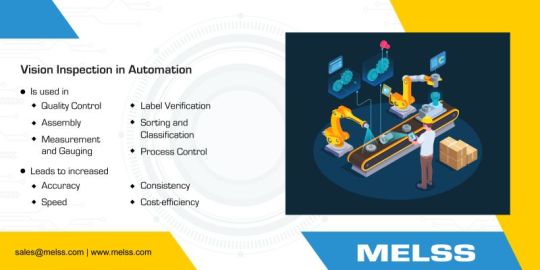

Is Vision Inspection a part of your Automation strategy? Vision inspection technologies such as cameras, imaging sensors and software are used in automated systems to capture and process images or videos in real time, inspect, analyse and assess products or processes for defects, measurement, verification and quality control. Actuators and Robotics enhance the utility of Vision Systems to sort, reject, or rework defective items after inspection. For increased accuracy, consistency, speed and cost-efficiency, vision inspection is used in the automation of: - Quality Control - Assembly - Measurement and Gauging - Sorting and Classification - Label Verification - Process Control For Industrial Automation solutions using the right vision inspection techniques, contact us. More Info: https://zurl.co/hp73q

0 notes

Text

Find the Best Automotive Camera manufacturers Brands for Your Vehicle with CK Vision

When it comes to finding the best automotive camera for your vehicle, trust CK Vision to deliver the best services.CK Vision cameras are easy to install and user-friendly. Our brand is known for advanced technology and high image quality and you can drive with peace of mind on the road. Contact us to get the top modules.

Visit Website: https://www.cameramanufacturer.com/

0 notes

Photo

On way to complete successful 11 years in the Vision Industry, 15+ vision equipments in market dedicated to printing, packaging and phone manufacturing industry and achieve countless happy customers. #anniversarycelebration #11years #visioninspection #visionsystems #printingindustry #packagingindustry #qualitycontrol #qualityinspection (at Jiangsu) https://www.instagram.com/p/CFd9_2MnY5N/?igshid=r2zcnuvuo95l

#anniversarycelebration#11years#visioninspection#visionsystems#printingindustry#packagingindustry#qualitycontrol#qualityinspection

0 notes

Link

Machine vision (MV) is the technology and methods used to provide imaging-based automatic inspection and analysis for such applications as automatic inspection, process control, and robot guidance, usually in industry. Machine vision is a term encompassing a large number of technologies, software and hardware products, integrated systems, actions, methods, and expertise.

#CloudVisionSystem#VisionSystem#machinevisionintegrator#visioninspectionsystems#machinevisioninspection#machinevisionsystem#parts counting machine

1 note

·

View note

Text

New Pin

Credit - A Machine Vision Company

0 notes

Photo

These vision software designs provide a user-friendly solution for high speed production.www.integrationautomation.com #automationsolutions #visionsystems#systemintegration

0 notes

Text

Robotic Weeding Machines Market Size, Status and Forecast 2020-2026: CARRE, DeereCompany, FPoulsenEngineering

The global research report titled “Robotic Weeding Machines Market” has recently been published by The Research Insights which helps to provide guidelines for the businesses. It has been aggregated based on different key pillars of businesses such as drivers, restraints, and global opportunities. This Robotic Weeding Machines Market research report has been compiled by using primary and secondary research techniques. Finally, researchers direct their focus on some significant points to give a gist about investment, profit margin, and revenue.

(Get Impressive Discount)

Download a Sample Copy of This Report(including full TOC, Tables and Figures):

https://www.theresearchinsights.com/request_sample.php?id=369810&mode=Arundhati

The report presents the market competitive landscape and a corresponding detailed analysis of the major vendor/key players in the market. Top Companies in the Global Robotic Weeding Machines Market: CARRE, DeereCompany, FPoulsenEngineering, NaioTechnologie

This report segments the global Robotic Weeding Machines Market based on Types are:

Vehicle-As-A-Platform

ControlModules

VisionSystem

Other

Based on Application, the Global Robotic Weeding Machines Market is segmented into:

AnimalHusbandry

CommercialLawn

Other

Buy Exclusive Report @:

https://www.theresearchinsights.com/checkout?id=369810&mode=Arundhati

Regional analysis of Global Robotic Weeding Machines Market:

Geographically, the global Robotic Weeding Machines Market has been fragmented into several regions such as North America, Latin America, Asia-Pacific, Africa, and Europe based on the productivity of several companies. Every segment along with its sub-segments is analyzed in the research report. The competitive landscape of the market has been elaborated by studying numerous factors such as top manufacturers, prices, and revenue.

The information on the global Robotic Weeding Machines Market is accessible to readers in a logical chapter-wise format. Driving and restraining factors have been listed in this research report, which helps to understand positive and negative aspects in front of the businesses.

Access Full Report information with TOC, here:

https://www.theresearchinsights.com/reports/Robotic-Weeding-Machines-Market-Status-and-Trend-Analysis-20172026-COVID19-Version-369810?mode=Arundhati

What are the market factors that are explained in the report?

-Key Strategic Developments: The Robotic Weeding Machines Market study also includes the key strategic developments of the market, comprising R&D, new product launch, M&A, agreements, collaborations, partnerships, joint ventures, and regional growth of the leading competitors operating in the market on a global and regional scale.

-Key Market Features: The Robotic Weeding Machines Market report evaluated key market features, including revenue, price, capacity, capacity utilization rate, gross, production, production rate, consumption, import/export, supply/demand, cost, market share, CAGR, and gross margin. In addition, the study offers a comprehensive study of the key market dynamics and their latest trends, along with pertinent market segments and sub-segments.

-Analytical Tools: The Global Robotic Weeding Machines Market report includes the accurately studied and assessed data of the key industry players and their scope in the market using several analytical tools. The analytical tools such as Porter’s five forces analysis, SWOT analysis, feasibility study, and investment return analysis have been used to analyze the key players' growth in the market.

Customization of the Report: This report can be customized as per your needs for additional data up to 3 companies or countries or 40 analyst hours.

About us:

The Research Insights – A global leader in analytics, research, and advisory that can assist you to renovate your business and modify your approach. With us, you will learn to take decisions intrepidly. We make sense of drawbacks, opportunities, circumstances, estimations, and information using our experienced skills and verified methodologies. Our research reports will give you an exceptional experience of innovative solutions and outcomes. We have effectively steered businesses all over the world with our market research reports and are outstandingly positioned to lead digital transformations. Thus, we craft greater value for clients by presenting advanced opportunities in the global market.

Contact us:

Robin

Sales manager

Contact number: +91-996-067-0000

https://www.theresearchinsights.com

0 notes

Photo

Stallion Group is the Authorized Distributor and Diamond Partner for Datalogic in India and the Middle East. Through Datalogic, Vision Systems and Sensors can be used in Food Beverage, Pharma and FMCG industries.

📌 Datalogic technology detects object presence,safeguards workers with light curtains,assures product quality with vision sensors,and identifies items using lasermarking.Food and product safety are assured by fixed industrial and handheld barcode readers,scanners,and mobile computers that track itemsthrough the manufacturing process and on to distribution.

For more information about this, please contact Stallion Group. https://www.stallionglobal.com/ #StallionGroup #datalogic #visionsystems #sensors #authorized #distributor #diamond #partner #fmcg #pharma #foodbeverage #india #uae #qatar #oman #middleeast

0 notes

Text

PCBs, used ubiquitously in all equipment from automobiles to cell phones, are composed of many components, such as diodes, transistors, capacitors, and integrated circuits. They perform designated tasks as defined by the application - whether it is battery and engine performance, an arithmetic and logic unit, and so on. #FunctionalTesting of a PCB involves many parameters to be checked and an #AutomatedTestEquipment is ideal for this. Application-specific PCBs in various shapes and sizes need to be handled for testing with dexterity, speed, and accuracy. #Robots are best suited to #PickAndPlace the #PCBs for testing and they also perform certain tests such as visual inspection. We provide solutions using robots and #VisionSystems to integrate with ATEs to perform testing of PCBs. For More Info: https://zurl.co/5i5D

0 notes

Video

Machine Vision System for Demo visit | www.bibus.in | #industrialautomation #manufacturing #makeinindia #microscan #visionsystem #bibusindia

0 notes

Text

0 notes

Link

#machinevision#machinevisioninspection#machinevisionsystem#Visionsysteminspection#machinevisionsystemintegrators#machinevisionsolutionsforprint#machinevisionsoftwarecompanies#machinevisionintegrator#visioninspectionsystemmanufacturers#VisionSystem#CloudVisionSystem#surfacedefectinspection#automatedvisioninspection#automationmachinemanufacturerinbangalore#Surface Defects Detection

0 notes