#WeighingSystem

Explore tagged Tumblr posts

Text

Türünün En İyisi: %1-%2 Toleranslı Tartımlı Granül Debimetresi!

Un değirmeni ve tahıl işleme tesisleriniz için maksimum verim, minimum sapma! Maselmak Flowbalancer, %1-%2 tolerans aralığıyla çalışan yüksek hassasiyetli tartımlı granül debimetresi ile ürün akışını anlık izleyin, kontrolü elinizde tutun. ✔️ Kolay arayüz ✔️ Hızlı tepki süresi ✔️ Endüstriyel dayanıklılık

Top Precision Flowmeter: ±1-2% Tolerated Accuracy!

Maximum efficiency, minimum deviation for your flour mill and grain processing lines! Track and control your product flow with Maselmak Flowbalancer – a high-precision weighing flowmeter with ±1-2% tolerated accuracy. ✔️ User-friendly interface ✔️ Fast response time ✔️ Industrial-grade durability

#Maselmak#Flowmeter#WeighingSystem#GrainProcessing#FlourMillTechnology#AutomationSolutions#IndustrialAutomation#FlowControl#PrecisionEngineering#Debimetre#UnDeğirmeni#Otomasyon#EndüstriyelÇözümler#TartımlıSistem#TahılTeknolojileri#MakineSanayi

0 notes

Text

Checkweighers are essential in the food and manufacturing industries for ensuring correct packaging amounts of food and beverages. This guide highlights their benefits and key elements to know.

0 notes

Text

Advanced Silo Weighing System for Precise Inventory Management

A silo weighing system is a technology used to measure the weight of materials stored in a silo or other types of storage containers. This system is commonly employed in industries such as agriculture, manufacturing, and logistics where accurate monitoring of inventory and material usage is crucial.

The key components of a silo weighing system typically include load cells, which are sensors that measure the force exerted by the material within the silo. These load cells are strategically placed under the legs or supports of the silo to accurately gauge the weight.

Load Cells: Load cells are installed at various points beneath the silo to support its weight. These cells convert the force exerted by the material into an electrical signal. Signal Processing Unit: The electrical signals from the load cells are transmitted to a signal processing unit. This unit processes the signals to calculate the total weight of the material in the silo.

Display and Control Unit: The calculated weight data is then displayed on a control unit, often equipped with a digital display. This unit may also include controls for calibration, data logging, and other relevant functions.

#SiloWeighingSystem#WeighingSystem#LoadCell#LoadCells#SingleEndedShearBeamLoadCell#DoubleEndedShearBeamLoadCell#WeightMeasurement#UniversalLoadCell#WeighModules#CompressionLoadCell#SinglePointLoadCell#ShearBeamLoadCell#BeamLoadCell#SensomaticLoadCell#BallTypeLoadCell#TypesofLoadCells#Sensotech

0 notes

Text

The versatile 15" touchscreen weighing controller from Essae is specially designed to facilitate your desired features and can be customised to suit your specifications. The user-friendly controller equips you with better control and ensures better security with strategic user privilege settings.

Talk to our team today! 🌐https://bit.ly/32AyGA8

#weighingsystem#realtimemonitoring#efficientweighing#IWTweighingcontroller#machinery#protectingyourprofits#India#essaedigitronics#robustperformance#streamlinedoperations#elevateyourperformance#uncompromisingaccuracy

0 notes

Text

Looking to enhance your industrial batching process? This article explains precision batching systems in depth, highlighting their major components like load cells, control systems, and feeding mechanisms. Learn how they work together to deliver reliable, accurate, and efficient material handling, helping industries meet production goals with minimum waste.

#PrecisionBatching#BatchingSystems#IndustrialAutomation#MaterialHandling#ProcessEngineering#ManufacturingSolutions#EngineeringInnovation#AutomationTechnology#IndustrialEquipment#SmartManufacturing#PowderHandling#WeighingSystems#LoadCells#ProcessControl#BulkMaterialHandling#IndustrialBatching#EngineeringSolutions#MacawberIndia#AutomationSystems#ManufacturingTechnology

0 notes

Text

Transforming Production Processes with Weighing and Batching Automation

Today, in the highly competitive world of manufacturing, accuracy and productivity are the keys that unlock success. 2002 is when Accord become the leading turnkey electrical and automation solution provider. As one of the leaders in such an experience in making industrial processes more possible and engaging through advanced weighing and batching automation systems, let’s analyze how such innovations transform production workflows and unlock unparalleled value for manufacturers.

Streamlining Industrial Processes Through Precision Weighing

Foundation of an Efficient Production System Proper measurement and consistent material handling form the basis of any production system. With modern manufacturing facilities under strict pressure to maintain high-quality output while keeping productivity maximum, advanced weighing systems equipped with PLC automation panels have become a most effective tool in this regard.

It has been realized that with accuracy weighing technologies, the waste material can be minimized up to 30% and also improve the consistency of the products. These systems employ state-of-the-art load cells as well as advanced control algorithms to ensure accurate measurements right down to the smallest quantities, particularly critical in Food Beverages Automation, as the precision of all ingredients directly affects the quality of the product.

How Automation Reduces Errors in Batching Operations

Human mistakes in manual batching processes can cause major quality problems of the products and wastage of materials. Weighing and Batching Automation Systems can virtually ensure manufacturing does not have to worry about these issues any longer. Our automated solution involves various verification steps and real-time monitoring for each batch to meet exact specifications.

Smart sensors and advanced control systems enable integration of:

Continuous flow monitoring

Real-time adjustment of feeding mechanisms

Automatic documentation of batch parameters

Instant alerts on any deviations

One of our success stories recently happened in implementing a Rice Fortification System that achieved 99.9% accuracy in nutrient addition, showing just how precise modern automation solutions can be.

Key Benefits of Modern Weighing and Batching Systems

The benefits of introducing automated weighing and batching systems go far beyond mere accuracy improvements. Based on our accumulated experience working with different industries, we have identified the following significant transformative benefits:

Improved Product Consistency

The modern batching system controls each batch to precision levels, thereby meeting specifications exactly in terms of composition. Product variations can be very critical in some industries, and this is significantly reduced with proper batching.

Increased Efficiency

The manufacturers can achieve higher throughput rates with reduced labor costs by automating the weighing and batching processes. Our MCC Panels Automation Services ensure seamless integration of multiple process controls, which optimize overall plant efficiency.

Improved Resource Management

The automated system delivers better data on material usage, thereby helping in improved inventory management and waste reduction. Data-driven approaches help a manufacturer make supply chain optimizations and reduce the cost of operating.

Compliance and Traceability

Modern batching systems record each operation in great detail, which will aid in the attainment of regulatory compliance and also quality control.

Smart Technologies Integration into Advanced Material Handling

Smart manufacturing is going to be the way forward. For the intelligent automation solution that can easily adjust to changes in production needs, our research team keeps on developing new innovations capable of augmenting the existing weighing and batching systems. Innovation examples;

Machine learning predictive maintenance algorithms

IoT sensors for real-time monitoring

Advanced analytics for process optimization

Cloud-based reporting and control systems

These smart technologies empower manufacturers to:

Predict and prevent equipment failures

Optimize batch sequences automatically

Reduce setup times between product changes

Enhance OEE

Choosing the Right Automation Solution for Your Industry Needs

The right automation solution involves careful consideration of factors unique to your industry and your production requirements. We understand that one size does not fit all at Accord. Our approach is therefore

Detailed Analysis

An initial proper in-depth analysis with respect to your current process for improvement and potential pitfalls involved

Custom Solution Design

Our engineering team develops the best solutions for you, fine-tuned to improve on what currently exists in your infrastructure while meeting your specific requirements

Implementation and Support

We thoroughly support all installation through commissioning, so your team is fully trained and comfortable with the new system.

Continuous Improvement

We don’t just install — we maintain ongoing relationships with our clients, gather feedback, and implement improvements based on real-world data of actual performance.

Conclusion

An important step ahead in manufacturing efficiency and quality control is weighed and batched automation of industrial processes. With the evolution of technology, possibilities for optimization and improvement grow exponentially. At Accord, we remain committed to our vision of merging corporate responsibility with technological excellence, developing solutions that do not just improve production processes but contribute to the greater benefit of society.

We have 18 years of experience developing innovative solutions and realize the challenges manufacturing organizations are facing in this current competitive environment. Our focus on the development of user-friendly robust systems designed to operate reliably in extreme operating environments, dedications to service for customers, and continuous improvement make us a trusted partner in industrial automation.

As we look to the future, we continue to invest in research and development, pushing the boundaries of what’s possible in industrial automation while maintaining our core values of respect, professionalism, and perseverance. Through our commitment to innovation and customer success, we help manufacturers achieve their production goals while preparing for the challenges of tomorrow.

#IndustrialAutomation#WeighingSystems#BatchingAutomation#SmartManufacturing#EfficiencyBoost#AccurateProduction#ProcessOptimization#InnovativeSolutions

0 notes

Text

Roller Weighing Scale

Tech Tip: Enhance your material handling efficiency with a Roller Weighing Scale. This versatile scale integrates seamlessly into conveyor systems, allowing for continuous and accurate weighing of items as they move along the production line. Ideal for industrial environments, it ensures precise weight measurements and helps maintain a smooth workflow.

Contact us for a free consultation today. 📞 +91-9824135305 | ✉️ [email protected] | 🌐 www.endeavourweigh.com/product/roller-weighing-scale/

#RollerWeighingScale#IndustrialWeighing#ConveyorWeighing#MaterialHandling#AccurateWeighing#WeighingSolutions#IndustrialEquipment#ProductionLine#ContinuousWeighing#EfficientWeighing#WeighingTechnology#AutomatedWeighing#WeighingSystems#IndustrialAutomation#PrecisionWeighing

0 notes

Text

#Display clarity meets #structural #integrity #Aluminum #Diecasting #frames provide corrosion-#free, high-#precision #support for weighing #terminals in #factories & #labs 🖥️Slim #profile 💪Rigid support 🌧️#Built for every #condition

📞 Goyal Inc 🌐 www.Incgoyal.com | 📧 [email protected] | 📱 +91 9811088250

www.incgoyal.com

www.x.com/goyal_inc

www.youtube.com/@GoyalInc

www.instagram.com/goyalinc

www.in.pinterest.com/goyalinc

www.facebook.com/incgoyal

www.threads.net/@goyalinc

#DisplayPanelFrame #IndustrialDesign #DiecastAluminum #WeighingSystems #GoyalInc #AutomationSupport #SmartFactory

3 notes

·

View notes

Text

Explain The Features Of Tank Weighing System!!

We are engaged in manufacturing, supplying, and exporting a commendable array of Tank Weighing System that is widely used to weigh liquid or solid material in an accurate manner. We are one the foremost Tank Weighing System Manufacturers and Tank Weighing System Suppliers in India.

Features:-

->No maintenance needed

->High-low-level audio-visual alarms

->Economical price

->Expandable control output to use as a batch controller

->Simple design allows easy load cell replacement

#TankWeighingSystem#WeighingSystem#TableTopWeighingScale#TopWeighingScale#WeighingScale#weighing#scale#weighingmachine#weighingscales#industrialscale#industrialweighing#weighbridge#Ahmedabad#Gujarat

0 notes

Text

We have created a video to help you understand load cells, their features, and applications. We manufacture load cells and other weighing-related equipment and machines. To explore our products further, please visit our website.

0 notes

Text

Load Cells for Aircraft Weighing System -Sensomatic Loadcell

Discover the heart of precision in aircraft weighing systems - Load Cells.

Understanding these vital components is key to ensuring accurate weight measurements. Dive into the world of Load Cells and unravel their role in aviation safety.

Exploring Load Cells for Aircraft Weighing Systems Load Cells play a crucial role in maintaining the balance and safety of aircraft.

Ever wondered how these devices ensure precise weight measurement?

Our latest guide unveils the mysteries, providing insights into the technology behind Load Cells and their significance in the aviation industry. Calibration Guide for Optimal Performance Achieving accurate measurements requires proper calibration. Follow our comprehensive calibration guide to enhance the performance of your Load Cells.

Learn the intricacies of calibration, ensuring your aircraft weighing system operates with utmost precision and reliability. Precision in Every Detail In the realm of aviation, precision is paramount.

Our focus on detail ensures that Load Cells deliver consistent and reliable results. Explore the technology that goes into crafting these precision instruments, setting the standard for accuracy in aircraft weight measurement.

#LoadCellsforAircraftWeighingSystem#SensomaticLoadcell#AircraftWeighingSystem#AircraftWeighingLoadcell#Loadcell#singleendedshearbeamloadcell#stypeloadcell#universalloadcell#beamloadcell#shearbeamloadcell#Sensomatic#sloadcell#sbeamloadcell#Aircraftweighing#weighingsystem

0 notes

Text

Goodscan GS210B Dimensioning,Weighing,Labor Scan,Picture-taking,Data/Pictures Storage and Upload,Providing Data Interface and Docking System.Improve productivity,efficiency and safety. Parcel Types:Regular,Irregular,Ultra-thin Boxes Items. Applications:Warehousing and Space Management. High speed parcel DWS.Ensure that you know the correct data for your parcel freight with fully automated dimensioning,weighing and barcode reading.Every parcel counts. Mob.:008617376826899 Email:[email protected] Web.:www.good-scan.com #dimensioningsystem #cubingsystem #weighingsystem #warehouseautomation

0 notes

Quote

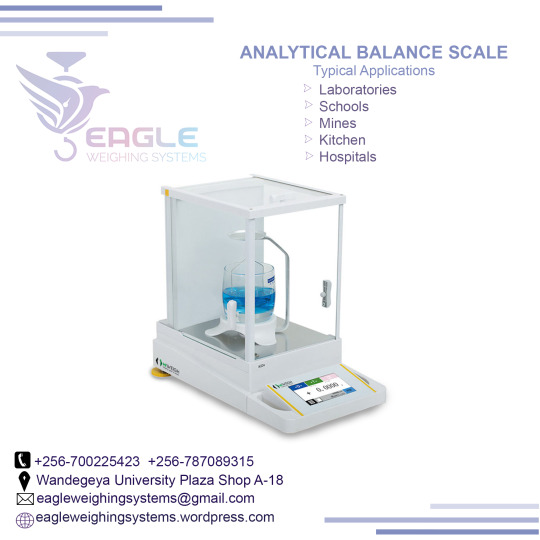

All Our Laboratory Weighing Scales are suitable for Laboratories, Production Control, Production Units, Medical Labs, Scientific Research Lab, Educational & College Projects.We are located at Wandegeya University Plaza Room A18 For more details please contact us on ; +256 700225423 +256 (0) 787089315 Or email us at:[email protected] http://www.revolvy.com/Eagleweighing https://www.linkedin.com/in/eagle-weighingsystems-854184157/ https://foursquare.com/user/564559909 https://eagleweighingsystems.tumblr.com/ https://www.facebook.com/How-to-buy-a-weighing-scale-in-Kampala-103630581384013/ https://www.facebook.com/Weighing-Scales-Near-Me-in-Kampala-Uganda-114133650339292/?modal=admin_todo_tour https://agency.sortlist.com/agency/eagle-weighing-scales-uganda-ltd/profile https://youtu.be/Xt0DcY4ZYB4 https://youtu.be/ZDCblNwq4-U https://youtu.be/ViJIgfmkA_s https://youtu.be/lIRZn-twEvo https://youtu.be/uoBR_75u70s https://youtu.be/W1sHg5SeCbA https://youtu.be/9ubb5umlTlo

0 notes

Link

#weighingautomation #weighingtechniques #weighingsystem #onboardweighing #wheelloader

0 notes

Text

ESTEK Load cell

Looking for Load cell? Get the best in class #LoadCell for your #Weighbridgeat best price. #Estek#EstekLoadcell Call - 7300093963 Know more - http://bit.ly/2DF78fJ #Equal #EqualOnline #TruckScale #Weighing#Weighingsolution #WeighingMachine#WeighingScale #Jaipur #India #Dharamkanta#WeighbridgeSolution #Weigh #Engineering#PostoftheDay #WeighingSystem #RoadWeighbridge#IndustrialSolution #IndustrialEquipments#WeighingIndustries #Loadcells #LoadcellSensor

0 notes

Text

Weighing Solution Expert

At Optima Weightech, we specialize in making machines and equipment for weighing. We've given a quick look at some of our popular products that are in high demand. Watch the video to find out more about them.

0 notes