#Weld Defect Identification

Explore tagged Tumblr posts

Text

Radiography Test: Key Techniques and Benefits Explained

Radiography test is a non-destructive testing (NDT) method. It uses X-rays or gamma rays to examine the internal structure of materials. This technique is essential for detecting hidden flaws without causing damage, ensuring the integrity and safety of components. Radiography test is widely applied in industries such as manufacturing, construction, and aerospace to inspect welding, castings, and…

#Computed Radiography#Defect Detection#Digital radiography#Gamma-ray Testing#Industrial radiography#NDT Techniques#Non-Destructive Testing (NDT)#Radiographic Evaluation#Radiographic Examination#Radiographic Film Analysis#Radiographic Imaging#Radiographic Interpretation#Weld Defect Identification#Weld Inspection#Weld Integrity Testing#Weld Quality Assessment#Welding Inspection#X-ray Inspection

0 notes

Text

Ensuring Weld Quality: Advanced Ultrasonic Testing Methods

In the world of welding, ensuring the quality and integrity of welds is crucial. One of the most effective ways to inspect welds is through ultrasonic testing, which uses high-frequency sound waves to detect imperfections. This blog explores advanced ultrasonic testing methods for welding inspection, highlighting their benefits and applications in the UK.

Introduction to Ultrasonic Testing

Ultrasonic testing for welding involves high-frequency sound waves to detect flaws in welds. This non-destructive testing (NDT) method effectively identifies internal and surface defects without damaging the material.

Why Ultrasonic Testing for Welding?

Accuracy: Provides precise detection of internal flaws.

Non-Destructive: Does not damage the material being inspected.

Versatility: Suitable for a wide range of materials and thicknesses.

Advanced Ultrasonic Testing Techniques

Advanced ultrasonic testing techniques have revolutionised the NDT industry, providing unprecedented levels of accuracy and efficiency. Below are some of the most advanced testing techniques used in the industry:

1. Phased Array Ultrasonic Testing (PAUT)

PAUT is an advanced technique that uses different ultrasonic elements and electronic time delays to create a sweeping beam. This method provides a detailed image of the weld, allowing for precise identification of defects.

Benefits:

High-resolution and detailed images

Faster inspection times

Improved defect characterisation

2. Time-of-Flight Diffraction (TOFD)

TOFD is another complex ultrasonic testing method that uses the time taken by sound waves to travel and diffract around defects to detect and size flaws accurately.

Benefits:

High accuracy in defect sizing

Effective for detecting both surface and subsurface defects

Reduced operator dependency

3. Automated Ultrasonic Testing (AUT)

AUT involves automated systems that perform ultrasonic inspections. This method enhances the consistency and repeatability of inspections, making it ideal for large-scale projects.

Benefits:

Consistent and repeatable results

Increased inspection speed

Reduced human error

Applications of Ultrasonic Testing in the UK

Ultrasonic testing is widely used in the UK across different industries to provide safety and integrity to critical infrastructure. Here are some key applications of ultrasonic testing in the UK.

1. Oil and Gas Industry

In the UK, the oil and gas industry rely heavily on ultrasonic testing for welding to ensure the integrity of pipelines and other critical infrastructure. PAUT and TOFD are commonly used to inspect welds in pipelines, ensuring they are free from defects that could lead to failures.

2. Aerospace Industry

The aerospace industry requires the highest levels of safety and reliability. Ultrasonic testing methods are used extensively to inspect welds in aircraft components, ensuring they meet strict safety standards.

3. Construction and Infrastructure

Ultrasonic testing plays a crucial role in the construction industry, particularly for inspecting welds in bridges, buildings, and other structures.

Advantages of Advanced Ultrasonic Testing Methods

Check out the advantages of advanced ultrasonic testing methods over traditional approaches.

1. Enhanced Accuracy

Advanced ultrasonic testing methods provide higher accuracy in detecting and sizing defects than traditional methods.

2. Increased Efficiency

Automated and advanced techniques like PAUT and AUT significantly reduce inspection times while maintaining high levels of accuracy.

3. Comprehensive Reporting

These methods offer detailed and comprehensive reporting, providing clear images and data that can be used for further analysis and decision-making.

Conclusion

Adopting advanced ultrasonic testing for welding is essential for industries aiming to maintain high quality and safety standards.

Investing in these advanced techniques enhances inspection reliability and ensures compliance with stringent safety regulations. By leveraging the benefits of advanced ultrasonic testing, industries can achieve greater efficiency, accuracy, and overall project success.

9 notes

·

View notes

Text

Why Robot Accuracy Matters in Automation — and What Dynalog-US Does

In today's ever-evolving world of manufacturing, robot accuracy is not only a benefit, it is a necessity. In every manufacturing sector, whether it is automotive, aerospace, electronics, or medical device manufacturing, the level of robot accuracy can affect the bottom line. Errors, even as small as a millimeter, can lead to defective products, more rework, and loss of productivity due to downtime. This is where Dynalog-US can help, transforming industry views on robotic precision and system calibration.

What Is Robot Accuracy?

In its simplest form, robot accuracy refers to the robot's ability to reach a point in space, not just on the first attempt, but every time. It's not to be confused with repeatability, which just means hitting the same point each time, and not necessarily the correct point. For industries where correct reference of absolute positioning is required - welding, machining, or assembly, etc. - true robot accuracy is paramount.

To put it another way: If you have a robotic arm as a laborer assembling smartphones, a misalignment of 0.2 mm could result in malfunctioning buttons, cracked screens, or circuit boards that just do not work. In aggregate, this could lead to increased return rates, loss of brand reputation, and wasted materials.

Why Routine Calibration Can’t Do the Job

In many facilities, the use of default manufacturer settings or basic calibration is enough to get by in ensuring accuracy. However, modern robotics requires more than that. With regards to the working environment, payload being handled, attachment of the tool, and wear on the robot over time, robot positioning can and will be off.

This is the main reason that robot calibration and TCP (Tool center point) correction is now seen as a necessary step to ensure peak robotic performance. No one is more aware of this than Dynalog-US.

Dynalog-US: Setting the Standard for Robot Performance

With decades of experience in robotic inspection, calibration, and automation optimization, Dynalog-US has established themselves as a trusted name to industry clients laying on the line the ability to do their job well. Their specialty is the enhancement of robot performance, providing an array of calibration tools and methods that redefine accuracy.

One of offerings is robotic calibration systems, that enable automated and accurate identification and correction of robot parameters. Regardless of base frame calibration, tool centre point calibration, or the calibration of an entire robotic cell, Dynalog takes every step necessary to exert your robotic system to perform as advertised, every time.

The Benefits of Superior Accuracy

✅ Less Scrap and Rework

When precision is maximized, manufacturing errors are cut drastically. Parts are assembled correctly on the first try.

Bringing it All Home

From complex weld paths in the automotive sector, to the delicate assembly of microelectronics, along with many other applications, Dynalog's methods of calibration are making a real difference in industries all around the world. For example, automotive companies utilize systems from Dynalog to calibrate robotic arms on production lines for the precise location of each spot weld with micron to sub-micron accuracy.

Aerospace manufacturers can depend on Dynalog to maintain tight tolerances on mission-critical parts such as wing mounts and gear assemblies.

Medical device manufacturers use Dynalog's calibration technology to assemble tiny, intricate components with the utmost accuracy.

Regardless of the industry, robot accuracy has a direct impact on worker safety, compliance, and customer satisfaction- that's why companies choose Dynalog.

The Future of Robot Accuracy: Artificial Intelligence Meets Calibration

Dynalog is currently leading the charge in the realm of integrating artificial intelligence and machine learning into the calibration process of robots, which means that systems will not only be able to self-correct, but they will also have the ability to predict when a robots' accuracy might drift- before it becomes a problem. This predictive maintenance will arm companies with insight on when to service their robots, which in turn helps 'maximize' the lifespan and reliability of a robot.

Why Dynalog-US?

Years of Proven Experience: Dynalog is not only a subsidiary of Accu-Spec/US, with 60 years of field experience, Dynalog is a leader in robotic accuracy and system calibration.

Best in Class Hardware and Software: Its calibration software and hardware are some of the best and most advanced in the

#Robot Accuracy#Robotic Calibration#Dynalog-US#Robot TCP Calibration#Industrial Automation#Precision Robotics#Robotic Inspection Systems#Manufacturing Automation#Robot Performance Optimization#Robot Accuracy Solutions

0 notes

Text

Perform ISO Container Inspection using eAuditor ISO Container Inspection is the process of evaluating shipping containers to ensure they meet the International Organization for Standardization (ISO) standards, particularly for safety, structural integrity, and usability in global transport. These inspections help verify that containers are fit for cargo loading, international shipment, and storage, and are compliant with ISO 6346, ISO 1496, and CSC (Container Safety Convention) regulations. Performing an ISO Container Inspection using eAuditor ensures that shipping containers are systematically evaluated for structural integrity, regulatory compliance, and cargo readiness based on international standards such as ISO 6346, ISO 1496, and the Container Safety Convention (CSC). eAuditor streamlines this process by offering standardized digital checklists, photo documentation, automated reporting, and corrective action tracking, making container inspections faster, safer, and fully traceable. - Preparing for ISO Container Inspection Using eAuditor 1.1 Define Inspection Scope and Purpose - Determine inspection goals: - Pre-loading (Pre-trip Inspection): Ensure the container is fit before use - Post-unloading: Check for damage or contamination - Routine Safety Check: Verify structural soundness and compliance - Define scope: - Dry containers, reefers, tanks, open tops, or flat racks - Single inspection or fleet-wide audit 1.2 Collect Relevant Standards and Documents - Reference materials: - ISO 6346 for container coding and identification - ISO 1496 for container dimensions and structural safety - CSC plate requirements (Container Safety Convention) - Shipping line or port inspection protocols 1.3 Customize or Download eAuditor Checklist Use or adapt a checklist template in eAuditor to cover: - Visual and structural inspection points - Interior and exterior condition - CSC plate validation - Specialized equipment (e.g., reefer units) - Photo evidence sections - Fields for tagging container number, location, and inspector name - Conducting the ISO Container Inspection Using eAuditor 2.1 Start with Identification and Documentation - Record container type, size (e.g., 20ft, 40ft), and ISO code - Confirm CSC plate presence, legibility, and expiration date - Check the container number format against ISO 6346 (e.g., ABCU1234567) 2.2 Inspect the Container Exterior - Sidewalls: Check for dents, bulges, corrosion, holes - Roof panel: Inspect for cracks, water damage, and impact marks - Doors: - Seal integrity and gasket condition - Locking rods, handles, and hinges are operational and secure - Corner posts and castings: - Confirm no deformation or weld damage - Undercarriage: - Check cross members, gooseneck tunnel, and forklift pockets 2.3 Examine Interior Condition - Cleanliness: - Free from debris, residues, pests, and strong odors - Flooring: - No holes, rot, heavy staining, or oil contamination - Wall linings: - No delamination or moisture damage - Water tightness: - Perform a light test or verify gasket seals 2.4 Specialized Container Elements (if applicable) - Reefer Containers: - Unit condition, temperature display, and electrical cables - Drainage, ventilation, and insulation - Tank Containers: - Check manholes, valves, and the structural frame - Open-Top or Flat Rack: - Verify tarpaulin, lashings, and structural welds 2.5 Capture Findings in eAuditor - Mark each item as: - Compliant - Minor Defect - Major Defect - Not Applicable - Add comments for any defects - Take photos of damage or issues directly from the device - Use geotagging and timestamping for traceability 2.6 Collaborate with Teams in Real Time - Assign on-site corrections (e.g., cleaning, repairs) immediately - Tag repair or maintenance teams in comments - Use digital signatures to confirm inspection completion - Post-Inspection Actions and Reporting 3.1 Generate a Digital Container Inspection Report - Automatically compile a report with: - Container identification and inspection date - Defects categorized by severity - Photos and notes for each observation - Action items assigned and pending - Export as PDF, Excel, or secure web link 3.2 Create and Track Corrective Actions - For all major or safety-related defects: - Log an action in eAuditor’s Action Management system - Assign responsibility and set due dates - Monitor resolution with real-time updates and reminders 3.3 Analyze Inspection Trends - Use the eAuditor analytics dashboard to: - Identify commonly recurring container issues - Compare conditions by container type or supplier - Monitor the completion of corrective actions over time - Track inspection compliance across locations - Key Areas to Include in ISO Container Inspection Checklist - Container ID (as per ISO 6346) - CSC plate validation (legibility and date) - Door seals, locks, and hinges - Floorboards and internal cleanliness - Sidewalls, end walls, and roof integrity - Corner castings and understructure - Water tightness and odor presence - Refrigeration system checks (for reefers) - Tank container manholes and valves - Photos of damage, rust, or contamination - Benefits of Using eAuditor for ISO Container Inspection - Consistent inspections using digital, reusable checklists - Faster data entry via mobile or tablet - Photo and file attachment for evidence-based findings - Real-time collaboration and team visibility - Action tracking for defect resolution - Automated reporting for clients or internal records - Cloud-based history for audit trails and regulatory readiness Summary Conducting an ISO Container Inspection using eAuditor provides a reliable, digitized method to assess container safety, cleanliness, and regulatory conformity. With real-time inspection tools, image documentation, clause-based checklists, and instant corrective action workflows, eAuditor ensures that your container operations stay efficient, compliant, and ready for global shipment or internal use. Read the full article

0 notes

Text

Improving Inspection Efficiency with Industrial CR: Real-Time Results and Digital Archiving

In industries where safety, precision, and compliance are non-negotiable—such as aerospace, oil and gas, automotive, and manufacturing—non-destructive testing (NDT) plays a vital role in quality assurance. Among NDT techniques, Industrial Computed Radiography (CR) has emerged as a powerful alternative to traditional film-based radiography. It offers faster, safer, and more efficient inspection workflows—thanks in large part to real-time results and digital archiving capabilities.

This article explores how CR technology is revolutionizing industrial inspections by accelerating the process, improving data management, and enabling better defect traceability.

The Shift from Film to Digital: A Productivity Leap

Traditional radiographic testing (RT) using film has long been a standard method for detecting internal defects in welds, castings, and other critical components. However, film processing is time-consuming and involves chemicals, darkrooms, and physical storage—all of which slow down operations and increase costs.

Industrial Computed Radiography addresses these inefficiencies by replacing film with a phosphor imaging plate, which captures X-ray energy and stores it as a latent image. This image is then scanned, digitized, and processed using specialized software—eliminating the need for film processing altogether.

Real-Time Results: Faster Inspections, Faster Decisions

One of the biggest advantages of industrial CR is the speed of image acquisition and evaluation.

How it enhances inspection efficiency:

Immediate image capture: Inspectors can view the radiographic image within seconds of scanning the plate, enabling rapid defect identification.

On-the-spot retakes: If image quality is insufficient or a part needs re-inspection, it can be done instantly—no waiting for film to develop.

Quick feedback loops: Inspection teams can relay results to manufacturing or engineering teams in real time, minimizing downtime and accelerating decision-making.

This rapid feedback is especially valuable in high-stakes environments like pipeline construction or aircraft maintenance, where project delays or undetected flaws can lead to costly and hazardous outcomes.

Enhanced Image Quality and Analysis Tools

Digital images produced by CR systems are more versatile and analyzable than traditional film. With digital post-processing tools, inspectors can:

Adjust contrast and brightness

Zoom in for fine detail

Apply filters or annotations

Compare with baseline or historical images

These capabilities lead to more accurate defect detection, reducing the risk of false positives or overlooked discontinuities. Moreover, automated tools can flag anomalies, helping standardize results across operators and shifts.

Digital Archiving: Secure, Searchable, and Shareable

Another game-changer for industrial CR is its digital archiving capability. Unlike film-based systems that require large physical storage space and are prone to damage or loss, digital CR stores files in centralized, secure repositories.

Key benefits of digital archiving:

Instant retrieval: Locate inspection records by asset, date, operator, or part number in seconds.

Remote access: Engineers, auditors, or clients can access records from anywhere, improving collaboration and compliance reviews.

Data security and backup: Files can be encrypted, backed up, and stored redundantly to prevent data loss.

Traceability: Every inspection is logged, creating an auditable history that supports ISO, ASME, and API compliance.

For companies operating in highly regulated sectors, digital archiving reduces the burden of manual documentation and simplifies audit preparation.

Real-World Impact: Time, Cost, and Safety

By adopting industrial CR, organizations can experience:

Up to 50% faster inspection cycles

Lower operational costs (no film, chemicals, or darkrooms)

Improved safety by minimizing exposure time and handling

Reduced material rework through better defect visibility

The cumulative effect is a more streamlined, responsive, and scalable inspection program that aligns with lean manufacturing, Six Sigma, and Industry 4.0 principles.

Conclusion

Industrial computed radiography is not just a digital upgrade—it’s a transformation of how inspections are performed and managed. Through real-time imaging and digital archiving, CR empowers companies to detect flaws faster, store data smarter, and maintain full traceability throughout the asset lifecycle.

As industries continue to demand higher quality standards, faster turnaround times, and regulatory compliance, investing in industrial CR is a strategic move toward efficiency, accuracy, and long-term value.

0 notes

Text

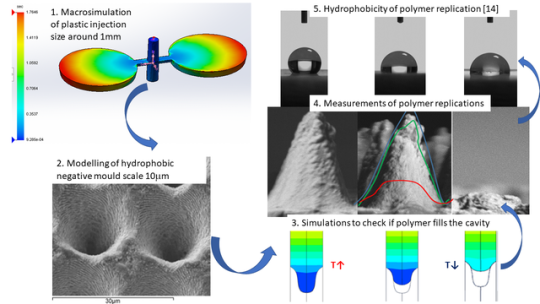

Optimize Your Mold Design with Plastic Flow Simulation

In today’s competitive manufacturing landscape, precision and efficiency are critical to success—especially in injection molding. Designing high-quality plastic parts isn't just about the mold—it’s about ensuring that the entire flow process is optimized from start to finish. This is where Plastic Flow Simulation becomes essential. At DDSPLM, we offer advanced Plastic Flow Simulation tools powered by Moldex3D and integrated with Siemens NX, enabling manufacturers to simulate, visualize, and refine mold filling behavior before committing to costly production.

What is Plastic Flow Simulation?

Plastic Flow Simulation is a virtual validation technique that replicates how molten plastic fills, packs, and cools inside a mold. Using simulation tools like Moldex3D or Simcenter, mold designers and engineers can visualize flow patterns, pressure distribution, air traps, weld lines, shrinkage, and more—before the tool is even manufactured. This technology empowers you to evaluate your design early in the product development cycle, significantly reducing the risk of defects, production delays, and costly rework.

Key Features of Plastic Flow Simulation

Flow Behavior Analysis

Weld Line and Air Trap Prediction

Cooling Analysis

Packing and Shrinkage Simulation

Fiber Orientation and Warpage Prediction

Gate and Runner Optimization

Material Database Integration

Benefits of Plastic Flow Simulation

Improved First-Time-Right Tooling

Faster Time-to-Market

Reduced Scrap and Rework

Better Part Quality and Strength

Lower Mold Trial Costs

Optimization of Cycle Time and Cooling Efficiency

Early Identification of Design Issues

Confidence in Complex Mold Designs

Why Choose DDSPLM?

DDSPLM is a leading digital solutions partner for product engineering and manufacturing organizations. Here's why companies across industries trust us:

💡 Domain Expertise – Over a decade of experience in PLM, CAD, CAE, and Simulation

🔧 Tailored Solutions – Customized toolkits and consulting for mold and tooling industries

🧩 Seamless Integration – Deep expertise in Siemens NX, Teamcenter, Moldex3D, and other platforms

📈 Proven Results – We’ve helped our clients reduce time-to-market by up to 30%

🤝 End-to-End Support – From concept design to manufacturing validation

Conclusion

Plastic Flow Simulation is no longer optional—it's a necessity for any organization involved in mold design and plastic part manufacturing. By leveraging DDSPLM’s simulation solutions, you gain a strategic advantage in delivering high-quality, defect-free parts while optimizing time, cost, and material usage.

0 notes

Text

Boosting Efficiency: The Power of AI in Automated Defect Detection

Introduction

In the contemporary Automated Manufacturing Defect Detection landscape, achieving efficiency and maintaining quality control are essential for success. Conventional methods of defect detection, which often depend on human inspection, tend to be labor-intensive and susceptible to inaccuracies. As industries aim for excellence, the integration of Artificial Intelligence (AI) in automated defect detection is proving to be transformative, greatly enhancing precision, speed, and cost efficiency.

The Limitations of Conventional Defect Detection

Manufacturers have historically depended on manual inspections or rudimentary automated systems to spot product defects. However, these approaches present several drawbacks:

Human Error: Even experienced inspectors may overlook minor defects, particularly in fast-paced production settings.

Inconsistency: Different inspectors may apply varying criteria for identifying defects, resulting in inconsistent quality control.

Time-Consuming: Manual inspections can hinder production flow and elevate labor expenses.

Limited Scalability: As production demands grow, relying exclusively on human inspectors becomes increasingly unfeasible.

These limitations underscore the necessity for AI-driven automated defect detection, which provides a more intelligent and dependable solution.

The Impact of AI on Defect Detection

1. Machine Learning and Computer Vision

AI-enhanced systems employ machine learning (ML) algorithms and computer vision technology to scrutinize product images and identify defects with remarkable accuracy. These systems can be trained on extensive datasets to detect even the most minor imperfections, such as cracks, scratches, or misalignments.

2. Real-Time Quality Control

In contrast to traditional techniques, AI can evaluate product quality instantaneously, facilitating the prompt identification and rectification of defects. This capability prevents defective items from progressing further along the production line, thereby minimizing waste and reducing rework expenses.

3. Self-Learning Abilities

A significant advantage of AI-driven defect detection is its capacity for ongoing learning and enhancement. As the system analyzes increasing amounts of data, it improves its precision, adjusting to emerging defect patterns and variations in manufacturing processes.

4. Improved Accuracy and Consistency

AI removes the inconsistencies that arise from human bias, guaranteeing a consistent quality standard. This results in greater customer satisfaction and a reduction in product recalls.

5. Integration with Advanced Manufacturing Systems

AI-based defect detection systems integrate effortlessly with Industry 4.0 technologies, including IoT devices and predictive maintenance solutions. This integration enables manufacturers to establish a connected and intelligent production line that optimizes efficiency.

Key Advantages of AI-Enhanced Automated Defect Detection

Boosted Productivity: AI can evaluate thousands of products each minute, significantly alleviating bottlenecks.

Cost Efficiency: Early detection of defects reduces material waste and the costs associated with rework.

Scalability: AI-driven systems can manage high production levels without sacrificing accuracy.

Enhanced Safety: In high-risk industries, AI can assess products without putting human workers in perilous situations.

Data-Driven Insights: AI offers critical insights into defect patterns, assisting manufacturers in refining their production processes.

Industries Benefiting from AI Defect Detection

AI-powered defect detection is revolutionizing various sectors, including:

Automotive: Detecting flaws in components, welding, and assembly processes.

Electronics: Ensuring that circuit boards and microchips adhere to stringent quality standards.

Pharmaceuticals: Identifying packaging mistakes and potential contamination issues.

Textiles: Evaluating fabric quality, stitching accuracy, and color uniformity.

The Future of AI in Manufacturing

As artificial intelligence technology progresses, the capabilities of automated defect detection are set to become increasingly sophisticated. Anticipated advancements may encompass:

Edge AI Processing: AI-enabled cameras that perform on-site defect analysis without relying on cloud services.

Augmented Reality (AR) Integration: Offering immediate visual feedback to human inspectors.

Enhanced Predictive Analytics: Recognizing defect patterns before they escalate into significant problems.

Conclusion

Automated defect detection powered by AI is transforming quality control in the manufacturing sector, improving efficiency, precision, and cost savings. By adopting AI technologies, manufacturers can decrease defects, lower operational expenses, and sustain a competitive advantage in the market.

As AI Globose Technology Solutions advances, its significance in smart manufacturing and Industry 4.0 will continue to strengthen. This is the opportune moment for industries to invest in AI-driven defect detection, setting the stage for a future characterized by impeccable production.

0 notes

Text

How Computed Radiography Enhances Imaging Precision in Industrial Applications

Computed Radiography (CR) is transforming industrial inspections by delivering high-resolution digital images with superior accuracy. Unlike traditional film radiography, CR offers enhanced image clarity, faster processing, and better defect detection in critical components. Industries like marine, oil & gas, and aerospace rely on Computed Radiography for weld inspections, corrosion monitoring, and structural assessments. Its ability to enhance imaging precision ensures early defect identification, reducing downtime and improving safety. With cost-effective, eco-friendly digital imaging, Computed Radiography is the preferred choice for non-destructive testing (NDT) in modern industrial applications.

0 notes

Text

Mastering Manufacturing Sourcing Services and Moldflow And Casting Analysis

Maintaining a lead in the always-changing field of manufacturing depends on this. Imagine launching a product only to find that the sourcing of materials and the quality of the mold flow are subpar. This can result in significant losses and setbacks. Fortunately, advancements in manufacturing sourcing services and moldflow and casting analysis have provided manufacturers with robust tools to ensure quality and efficiency.

The Importance of Manufacturing Sourcing Services

The Manufacturing sourcing services are the backbone of the production process. These services involve the identification and procurement of raw materials, components, and other necessary elements from reliable suppliers. Efficient sourcing can significantly impact the cost, quality, and time-to-market of a product. For example, a company that sources high-quality materials at competitive prices can pass these savings onto customers, gaining a competitive edge.

How Sourcing Services Drive Efficiency

One of the primary benefits of manufacturing sourcing services is the streamlined supply chain they create. By working with trusted suppliers, manufacturers can ensure a consistent flow of materials, reducing the risk of production delays. Additionally, these services often include rigorous vetting processes, ensuring that all sourced components meet stringent quality standards. This not only enhances product reliability but also builds customer trust.

The Role of Technology in Sourcing Services

Technology has revolutionized manufacturing sourcing services. Advanced software solutions now allow manufacturers to track and manage their supply chains with unprecedented accuracy. Real-time data analytics can identify potential disruptions before they occur, enabling proactive problem-solving. Moreover, digital platforms facilitate better communication between manufacturers and suppliers, ensuring that all parties are aligned and any issues are promptly addressed.

Understanding Moldflow And Casting Analysis

Moldflow and casting analysis are critical processes in manufacturing, particularly in industries reliant on plastic and metal components. These analyses use sophisticated simulation software to predict how materials will behave during the molding and casting processes. By understanding these behaviours, manufacturers can optimize their designs, reducing the risk of defects and improving overall product quality.

Benefits of Moldflow and Casting Analysis

Implementing moldflow and casting analysis offers several advantages. Firstly, it helps in identifying potential issues such as air traps, weld lines, and sink marks before actual production begins. This pre-emptive approach saves time and resources that would otherwise be spent on troubleshooting post-production problems. Secondly, these analyses enable manufacturers to refine their designs, ensuring that the final product meets all specifications and performance requirements.

Technological Advancements in Moldflow and Casting

The field of moldflow and casting analysis has seen significant technological advancements. Modern simulation software provides highly accurate predictions, allowing for detailed analysis of material flow and solidification. This level of precision helps in optimizing the entire manufacturing process, from mould design to production parameters. Furthermore, continuous advancements in computational power mean that these analyses can be performed faster and more accurately than ever before.

Integration of Sourcing Services with Moldflow and Casting Analysis

The synergy between manufacturing sourcing services and moldflow and casting analysis is undeniable. Effective sourcing ensures that high-quality materials are used in production, which is critical for the success of moldflow and casting processes. Conversely, insights gained from moldflow and casting analyses can inform sourcing decisions, ensuring that the selected materials are best suited for the intended applications.

Conclusion

In conclusion, mastering manufacturing sourcing services and moldflow and casting analysis is crucial for achieving excellence in manufacturing. These processes not only ensure high-quality products but also enhance efficiency and cost-effectiveness. For businesses looking to stay competitive in the fast-paced manufacturing landscape, leveraging these tools is essential. To explore more about these innovative solutions, visit feamax.com.

Blog Source Url: -

0 notes

Text

Revolutionize Your Material Testing with Integrated NDE Services' Portable Hardness Testing

In the realm of material testing, precision and reliability are paramount. Integrated NDE Services offers state-of-the-art portable hardness testing solutions, designed to meet the stringent demands of modern industry. Specializing in non-destructive testing (NDT), their innovative technology provides accurate hardness measurements without compromising the integrity of the tested materials.

Comprehensive Non-Destructive Testing (NDT) Solutions

Integrated NDE Services excels in a range of non-destructive testing methods, ensuring that materials and components meet the highest quality standards. Their portable hardness testers are an essential part of NDT testing, allowing for efficient on-site evaluations that are crucial for maintaining the safety and performance of critical components.

Advanced Portable Hardness Testing

The portable hardness testers from Integrated NDE Services are engineered for versatility and accuracy. These devices facilitate quick, reliable measurements across various hardness scales, making them indispensable for non-destructive inspection in diverse industrial applications. From manufacturing to aerospace, their equipment ensures materials meet specific hardness criteria without the need for destructive testing.

Positive Material Identification and NDT Inspection Services

Integrated NDE Services also offers Positive Material Identification (PMI), ensuring the right materials are used in production processes. This service is crucial for industries where material composition directly affects safety and performance. Complementing PMI, their NDT inspection services include ultrasonic testing NDT and visual inspection NDT, providing a comprehensive suite of solutions for thorough material evaluation.

Ultrasonic and Non-Destructive Weld Testing

Ultrasonic non-destructive testing (UT) is another area of expertise for Integrated NDE Services. UT is ideal for detecting internal flaws and ensuring the integrity of welds without causing damage. Their non-destructive weld testing services are essential for verifying the quality and durability of welded joints, critical in sectors such as construction and shipbuilding.

Visual Inspection and Broader NDT Services

Visual inspection NDT remains a fundamental part of Integrated NDE Services' offerings. This method allows for the immediate identification of surface defects and irregularities. Combined with their advanced portable hardness testing and ultrasonic testing capabilities, Integrated NDE Services provides a holistic approach to non-destructive testing services, ensuring comprehensive material and structural integrity assessments.

Why Choose Integrated NDE Services?

Choosing Integrated NDE Services means partnering with a leader in the field of non-destructive testing. Their portable hardness testing solutions are designed to deliver precise results quickly and efficiently, making them ideal for on-site inspections. Supported by a team of experts, they offer unparalleled service and support, ensuring clients maximize the benefits of their advanced testing technologies.

Conclusion

In the ever-evolving landscape of material testing, Integrated NDE Services stands out with its advanced portable hardness testing solutions. Specializing in non-destructive testing, including ultrasonic and visual inspection, they provide reliable and comprehensive testing services that meet the highest industry standards. Whether you need positive material identification, non-destructive weld testing, or a full suite of NDT inspection services, Integrated NDE Services is your trusted partner for ensuring material integrity and performance. Embrace the future of material testing with Integrated NDE Services and enhance your quality assurance processes with their cutting-edge technologies.

#non destructive testing#ndt testing#destructive testing#Positive Material Identification#"non destructive inspection#ndt inspection services#ultrasonic testing ndt#non destructive weld testing#ndt inspection#non destructive testing services#ultrasonic non destructive testing#visual inspection ndt#ultra sonic testing

0 notes

Text

Five Most Common Testing Methods in Non-Destructive Testing (NDT) by Geo Con Tech Group

Non-destructive testing (NDT) is an examination of components or workpieces for their quality and structure without causing damage or impairment. Regulated under the international standard DIN EN ISO 9712, NDT is widely utilized in various industrial sectors such as plant engineering, mechanical engineering, steel, power plant, and vehicle construction.

Geo Con Tech Group ensures that NDT adheres to a strict certification process to prevent personal injury and property damage. This process involves the identification and evaluation of discontinuities or imperfections, as the actual determination of a defect is governed by specific testing regulations.

The 5 Most Common Non-Destructive Testing (NDT) Methods

Visual Testing (VT) is the simplest and most widely used NDT method. It involves the direct inspection of a material or component to identify surface defects. This method often employs tools like magnifying glasses, mirrors, and borescopes to enhance visibility.

Ultrasonic Testing (UT) uses high-frequency sound waves to detect internal flaws in materials. The sound waves travel through the material and reflect back from any discontinuities, providing detailed information about the integrity of the component. This method is highly effective for detecting cracks, voids, and other internal defects.

Radiography Testing (RT) utilizes X-rays or gamma rays to produce images of the internal structure of a component. The resulting radiographs reveal any hidden flaws such as cracks, voids, or inclusions. RT is widely used in industries where the internal quality of materials is critical, like aerospace and construction.

Eddy Current Testing (ET) involves inducing electrical currents (eddy currents) in a conductive material and monitoring the interaction of these currents with the material. This method is particularly useful for detecting surface and near-surface defects in metals. ET is commonly used in the inspection of aircraft components and tubing.

Magnetic Particle Testing (MT) is used to detect surface and slightly subsurface discontinuities in ferromagnetic materials. It involves magnetizing the component and applying ferrous particles, which accumulate around any flaws, making them visible under appropriate lighting. This method is widely used in industries such as automotive, railways, and welding.

Who may perform non-destructive testing?

Standard-compliant testing necessitates a certified inspector who has attained one of three proficiency levels, based on their experience and training, for the specific testing method (VT, MT, PT, UT, RT).

Level 1: Authorized to conduct test procedures and document the results.

Level 2: In addition to conducting tests, they can also interpret and evaluate the results according to relevant standards and regulations.

Level 3: Beyond conducting and evaluating tests, they are qualified to choose appropriate testing procedures, draft procedure descriptions, and oversee the entire testing facility.

Geo Con Tech Group: Leading the Way in Non-Destructive Testing (NDT) in Chennai, India

Geo Con Tech Group stands at the forefront of Non-Destructive Testing (NDT) in Chennai, India, offering unparalleled expertise and adherence to international standards. NDT is crucial in various industrial sectors, including plant engineering, mechanical engineering, steel, power plant, and vehicle construction. Geo Con Tech Group ensures that all NDT processes comply with the international standard DIN EN ISO 9712, preventing personal injury and property damage by identifying and evaluating discontinuities or imperfections in materials and components

Why Geo Con Tech Group is the Best in NDT:

Comprehensive Testing Methods: Geo Con Tech Group utilizes the five most common NDT methods—Visual Testing (VT), Ultrasonic Testing (UT), Radiography Testing (RT), Eddy Current Testing (ET), and Magnetic Particle Testing (MT). Each method is meticulously applied to detect and analyze defects without damaging the test materials, ensuring the highest quality and safety standards.

Certified Inspectors: The company's NDT inspections are performed by certified professionals who have achieved various proficiency levels (Level 1, Level 2, and Level 3). These experts are not only trained to conduct and document test procedures but also evaluate results, select appropriate testing methods, and oversee the testing facility, ensuring accuracy and reliability.

State-of-the-Art Technology: Geo Con Tech Group employs advanced tools and technologies such as magnifying glasses, mirrors, borescopes, high-frequency sound waves, X-rays, gamma rays, and ferrous particles. This ensures that every test is conducted with precision, providing detailed insights into the integrity of materials and components.

Industry-Specific Solutions: The company’s extensive experience across various industries, including aerospace, automotive, railways, and construction, allows them to tailor their NDT services to meet specific industry needs. This targeted approach ensures optimal results and compliance with industry standards and regulations.

Commitment to Safety and Quality: Geo Con Tech Group's rigorous certification process and adherence to international standards reflect their commitment to safety and quality. By thoroughly identifying and evaluating material imperfections, they help prevent potential failures, ensuring the safety and reliability of industrial components.

Geo Con Tech Group's dedication to excellence in Non-Destructive Testing makes them the top choice for industries in Chennai and beyond. Their certified inspectors, advanced technologies, and industry-specific expertise ensure that they deliver reliable and accurate NDT services, maintaining the highest standards of safety and quality.

FAQ: Non-Destructive Testing (NDT) by Geo Con Tech Group

1. What is the most common NDT method used?

The most common Non-Destructive Testing (NDT) method used is Visual Testing (VT). VT involves the direct inspection of a material or component to identify surface defects using tools like magnifying glasses, mirrors, and borescopes. It is widely used due to its simplicity and effectiveness in detecting visible imperfections.

2. Who will do NDT testing in Chennai, India?

In Chennai, India, NDT testing is conducted by certified professionals from Geo Con Tech Group. These professionals have attained various proficiency levels (Level 1, Level 2, and Level 3) based on their experience and training. They are authorized to conduct test procedures, document results, evaluate findings according to standards, and oversee the entire testing facility.

3. How to contact an NDT testing company in Chennai, India?

To contact an NDT testing company like Geo Con Tech Group in Chennai, India, you can reach out through their official website or contact them directly via phone or email. Their customer service team will assist you in scheduling testing services, providing detailed information about their methods, and addressing any specific needs or inquiries you may have.

0 notes

Text

Nickel 200 Flanges Suppliers

INTRODUCTION :

Manilaxmi Industrial is a noticeable supplier and manufacturer of an expansive level of nickel 200 flanges. We are offering these flanges in different sizes, types, shapes, rules, etc. In addition, we give nickel 200 flanges at changed specifications, as shown by the mention of clients. These flanges are by and large critical in various industrial applications, considering their dumbfounding corrosion resistance. Nickel 200 is a pure alloy with high mechanical strength and limits over a wide range of temperatures. It offers stunning general corrosion resistance in key and acidic circumstances.

DESCRIPTION

Nickel 200 is a pure alloy known for its excellent mechanical strength and impressive corrosion resistance across a wide temperature range. This makes it ideal for various industrial applications. The flanges made from Nickel 200 are particularly valuable in harsh environments where both acidic and basic conditions prevail. At Manilaxmi Industrial, we produce Nickel 200 flanges that adhere to strict quality standards, ensuring their performance and reliability in demanding applications.

BENEFITS

Nickel 200 flanges offer numerous benefits, making them a preferred choice in multiple industries:

High Corrosion Resistance: Nickel 200 flanges exhibit outstanding resistance to corrosion, ensuring longevity even in aggressive environments.

Mechanical Strength: The high mechanical strength of Nickel 200 enables it to withstand significant pressure and stress.

Versatility: Suitable for a wide range of temperatures and environments, these flanges are incredibly versatile.

Durability: The inherent properties of Nickel 200 contribute to the durability and long service life of the flanges.

Quality Assurance: Manufactured using premium-quality raw materials and advanced technology, our flanges meet international standards, ensuring zero defects and optimal performance.

SPECIFICATION

Specification: ASTM B564 / ASME SB564

Dimension Standard: ANSI B 16.5, BS 1560, BS 10, IS 6392, B-2.1 NPT, API, DIN, JIS, MSS SP 44

Size: ½” NB to 12” NB

Class / Pressure: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, ASA 150#, ASA 300#, DIN ND 6,10,16,25,40

Equivalent Grades

STANDARD: UNS, WNR., AFNOR, EN, JIS, GOST, BS

Nickel 200: N02200, 2.4066, N-100M, Ni 99.2, NW 2200, НП-2, NA 11

Chemical Composition

Nickel 200C: 0.15 maxMn: 0.35 maxSi: 0.35 maxS: 0.01 maxCu: 0.25 maxFe: 0.40 maxNi: 99.0 min

Mechanical Properties

Density: 8.9 g/cm³

Melting Point: 1446°C (2635°F)

Tensile Strength: Psi – 67000, MPa – 462

Yield Strength (0.2% Offset): Psi – 21500, MPa – 148

Elongation: 45%

PRODUCT OVERVIEW

Manilaxmi Industrial offers a comprehensive range of Nickel 200 flanges, including:

Nickel 201 Threaded Flanges

Nickel 201 Slip-On Flanges

Nickel 201 Long Weld Neck Flanges

Nickel 201 Blind Flanges

Alloy 201 Ring Type Joint (RTJ) Flanges

Nickel 201 Weld Neck Flanges

These flanges are designed to cater to various industrial sectors, such as:

Power Plant Industry

Pharmaceuticals Industry

Oil and Gas Industry

Pulp and Paper Industry

Chemical Industry

Marine Applications

Condensers

Heat Exchangers

Our production process includes rigorous testing, such as hardness tests, mechanical tests, chemical tests, intergranular corrosion tests, and positive material identification tests, ensuring the highest quality of flanges.

CONCLUSION

Manilaxmi Industrial stands out as a leading manufacturer and supplier of Nickel 200 flanges, thanks to our commitment to quality and customer satisfaction. Our flanges are designed to meet the diverse needs of various industries, providing excellent corrosion resistance, mechanical strength, and durability. For high-quality Nickel 200 flanges, trust Manilaxmi Industrial to deliver products that meet your exact specifications and performance requirements.

For more information or to place an order, please contact us at:

Email: [email protected]

Phone: +91-7710800415

1 note

·

View note

Text

HEALTH AND SAFETY COURSES IN NELSPRUIT

LEADING TRAINING PROVIDER IN SOUTHERN AFRICA IN HEALTH AND SAFETY COURSES

Occupational Health and Safety Training Courses:

Safety Officer We cover the following Modules: Basic Principles of SHE OHS Legislation Technical Safety Aspects Occupational Health Environmental Management Management Systems

Hazard Identification and Risk Assessment We cover the following Modules: Requirements of Safety Preparing to Identify Hazards Identify Hazards Remedial and Follow up Action

Contractors Safety management We cover the following Modules: Contractors Safety Analysis Safety Policy Contractor qualification Procedure Contractor Legal Implications Control of Contractors Contractor Specific requirements General Safety Accident Recording Safety Policies

Incident Accident Investigation in the workplace We cover the following Modules: Legal and Organizational Requirements Gathering Information Completing Reports

Mines Health & Safety We cover the following Modules: Mines Health & Safety Act 29 of 1996

Oshas We cover the following Modules: Policies Identify and control Hazards Identify people and resources Prepare a statement of Responsibilities Schedule Inspections Developing Plans Developing training plans Developing plans to investigate accidents Develop a strategy to involve workers Evaluating your program Return to work program

Safety File How to draw up your own safety file.

She Rep We cover the following Modules: Identify Hazards Evaluate and report Hazards Preventative Measures & training Legislation Organizing OHS Information Welding, Scaffolding & Rigging Training Courses:

Basic rigging and slinging We cover the following modules in basic Rigging and slinging. Theory and Practical. Introduction Identify and selecting lifting equipment Different load requirements Unsafe and defective equipment Different Slings and Hooks etc. Planning Practical training.

Advanced rigging and slinging We cover the following modules in Advanced rigging. Lifting equipment Plan and prepare to lift a load Slings and Bolts Lifting and moving a load Maintaining and storing equipment Practical training

Working on Heights with fall arrest The following modules are covered in Working on heights. Theory and Practical training is done. Introduction Fall arrest equipment and regulations Inspect, assemble, and store fall arrest equipment select suitable anchor plants Use Fall arrest systems with a double Lanyard Pre-installed vertical and horizontal life lines Practical training

Scaffold erecting The Following modules are covered and both theory and practical training is done Types of access scaffolding Inspector roles and responsibilities Drawings Inspect and Handover Practical training

Scaffold inspecting The Following modules are covered and both theory and practical training is done. Types of access scaffolding Inspector roles and responsibilities Drawings Inspect and Handover Practical training . Please feel free to contact our offices for more details call/WhatsApp on{+27792721535}{+27739163400}

#training#machinery#safety#safetyofficer#health an safety#firefighter#firstaidtraining#first aid#forklift training

0 notes

Text

Perform OSHA Welding Safety Inspection using eAuditor OSHA Welding Safety refers to the set of standards and guidelines established by the Occupational Safety and Health Administration (OSHA) to protect workers involved in welding, cutting, and brazing operations. These activities present serious hazards such as fire, explosion, electric shock, toxic fumes, and eye or skin injuries. OSHA enforces safety requirements primarily under 29 CFR 1910 Subpart Q (for general industry) and 29 CFR 1926 Subpart J (for construction). Performing OSHA Welding Safety Inspection using eAuditor ensures a thorough evaluation of hot work environments, tools, materials, and protective measures to maintain worker safety, prevent fire and explosion hazards, and ensure full compliance with OSHA regulations (29 CFR 1910 Subpart Q and 29 CFR 1926 Subpart J). This inspection process enables real-time identification and resolution of risks associated with welding, cutting, and brazing activities. - Purpose of the Inspection Using eAuditor for OSHA Welding Safety Inspections helps organizations: - Identify unsafe welding practices and environmental conditions - Validate equipment functionality and worker compliance - Enforce PPE usage and hazard controls - Ensure alignment with OSHA standards for general industry and construction - Assign and track corrective actions digitally and efficiently - Key Inspection Areas in eAuditor Work Area and Environmental Conditions - Is the area clear of flammable or combustible materials? - Are fire-resistant blankets or shields in place where needed? - Is ventilation adequate, especially in enclosed or confined spaces? - Are warning signs posted around welding zones? - Are weather or environmental factors (wind, rain, heat) creating unsafe conditions? eAuditor Inputs: Checklist fields, photo documentation, environmental risk tagging Welding Equipment and Tool Safety - Are welding machines in good working condition? - Are power leads, electrode holders, torches, and hoses inspected and undamaged? - Have the gas cylinders been stored upright, capped, and secured? - Are regulators, flashback arrestors, and check valves functioning properly? - Proper insulation and grounding of electrical components. eAuditor Inputs: Pass/fail checks, condition status (e.g., "Service Needed"), image capture of defects Fire Prevention and Emergency Readiness - Is a fire extinguisher readily accessible and fully charged? - Assigning of trained fire watch when required by OSHA? - Shielding or removal flammable materials from the vicinity. - Is the hot work permit system in place and up to date? - Are emergency exits and egress paths unobstructed? eAuditor Inputs: Permit upload options, fire watch sign-in, and extinguisher condition logs Personal Protective Equipment (PPE) - Are workers wearing appropriate welding helmets and filter lenses? - Is PPE flame-resistant and in good condition (gloves, jackets, aprons)? - Are face shields and safety goggles used for grinding/chipping? - Are respirators provided and used in high-fume areas? - Rating of footwear for hot work protection. eAuditor Inputs: PPE compliance checklist, conditional fields for missing/inadequate PPE, photo logs Gas Cylinder Handling and Storage - Are cylinders properly labeled and segregated by gas type? - Are oxygen and fuel gas cylinders stored at least 20 feet apart or separated by a fire barrier? - Storage areas should be ventilated and away from heat sources. - Are valves closed and caps installed when not in use? - Are cylinders transported with carts, not rolled or dragged? eAuditor Inputs: Storage condition tagging, space verification, image documentation Worker Training and Competency - Have workers been trained in welding safety procedures? - Are MSDS/SDS for welding-related materials accessible? - Is training documented and current for each operator? - Are workers aware of confined space procedures if applicable? - Is a supervisor or qualified person overseeing welding operations? eAuditor Inputs: Signature confirmation, training record attachment, dropdown for qualification level Post-Welding Clean-Up and Monitoring - Is slag and scrap properly removed and stored? - Is the area rechecked for smoldering materials after welding ends? - Are tools and PPE stored safely after use? - Have all the gas valves and electrical controls been turned off. - Are final inspections conducted before vacating the site? eAuditor Inputs: Final inspection checklist, notes for corrective actions, end-of-shift sign-offs - Automation and Workflow Features in eAuditor - Real-Time Field Inspections: Use mobile devices to capture and report hazards on-site - Automated Hot Work Permit Management: Attach or link permits to inspection forms - Photo and Video Evidence: Document unsafe conditions or completed corrective actions - Corrective Action Assignment: Send alerts to responsible personnel with deadlines and priority levels - Cloud-Based Records: Maintain OSHA-compliant inspection logs accessible from any device Summary The OSHA Welding Safety Inspection in eAuditor empowers safety teams to proactively manage hazards, ensure worker protection, and maintain regulatory compliance during welding and cutting activities. By standardizing inspections, documenting field observations in real time, and managing permits and PPE use digitally, eAuditor streamlines OSHA compliance while promoting a culture of safety and accountability in welding operations. Read the full article

0 notes

Text

Sustainable Practices in Pipeline Integrity: Environmental Implications in the Intelligent Pigging Market

Intelligent Pigging: The Future of Pipeline Inspection and Maintenance Introduction to Pigging Technology Pigging refers to the process of using pipelines cleaning devices known as pigs to perform maintenance tasks inside pipelines. Traditionally, basic pigging devices known as dumb pigs were used mainly for cleaning purposes. However, over the last few decades, advanced intelligent pigging technology has emerged which allows for non-destructive testing of pipelines from inside. Types of Intelligent Pigging Systems There are several types of intelligent pigging systems available depending on the type of tests required: Geometry pigs use magnetic flux leakage or ultrasonic techniques to detect dents, corrosion and other defects on the outer surface of the pipeline. They can accurately measure wall thickness loss across the entire pipeline length. (177 words) Cleaning Pigs are used after geometry pigs to clean out accumulated debris and wax from the pipeline. Some advanced cleaning pigs even have scrapers and brushes attached to help remove scale. (80 words) Crack Detection Pigs use high-resolution ultrasonic testing to detect cracks, notch defects or other cracks in the pipe material, especially in areas with welds or previous repairs. This helps detect any impending failures at an early stage. (103 words) Metal Loss Pigs use technologies like eddy current to accurately measure metal loss corrosion both internally and externally. They provide detailed maps and quantification of corrosion rates across the pipeline. (95 words) Significance of Intelligent Pigging Intelligent pigging play a vital role in ensuring pipeline integrity and safety. Some of the key benefits of intelligent pigging include: (96 words) -Detection of defects that are otherwise undetectable during external inspections. This prevents catastrophic failures. -Accurate mapping and sizing of defects allows for planned repairs or re-routing of fluids to bypass severely corroded sections. (79 words) -Scheduled multiple inspections over the years allows monitoring of corrosion rates and planning long-term maintenance/replacement. (70 words) -Internal inspections eliminate need for excavations along the pipeline route which are costly and disruptive. (57 words) Future of Intelligent Pigging With continuous technology advances, future intelligent pigs are expected to have even higher resolution tools for micro-level defect detection. Some emerging areas include: (101 words) -Ultrasonic phased arrays for detection of minute cracks in welds. -Multiple technology pigs carrying a combination of tools for comprehensive multi-faceted inspections. -Sensors integrated pigs for real-time transmission of inspection data for quick analysis. -Use of machine learning and AI for automated defect identification and corrosion modeling. -Development of nano-bots or pigs smaller than 1mm that can enter pipelines as small as 1 inch in diameter. -Autonomous robotic crawlers for inspection of difficult sections like bends. (95 words) In conclusion, intelligent pigging is revolutionizing pipeline inspection by enabling high resolution internal examinations. With advancements, pigs will get more sophisticated to ensure zero failures in critical pipeline infrastructure transporting oil, gas and other fluids.

0 notes

Text

What is AI-based Visual Inspection and its Use cases ?

Visual checks form an essential part of quality management in almost every industrial and manufacturing process. However, the task requires dedicated employees and is repetitive when conducted manually. Technological innovation now means that it is possible to improve productivity and guarantee consistency, thanks to artificial intelligence. Today's forward-thinking manufacturers are deploying AI-based visual inspection to reduce errors and detect anomalies with impressive accuracy. Automated visual inspection techniques can help save your business time, effort, and money. Read on to discover how automatic visual evaluation and a deep learning approach can save significant time and effort.

What is Visual Inspection?

Visual inspection is a process of evaluating objects, materials, or systems using human eyes to identify defects, irregularities, or specific attributes. It is a fundamental quality control technique employed across various industries to ensure the accuracy, integrity, and compliance of products or processes. Visual inspection involves careful observation and assessment of visual cues such as color, shape, size, texture, and overall appearance to make informed judgments about the condition or quality of the subject under scrutiny. While traditionally a manual process, advancements in technology have led to the integration of automation and artificial intelligence, enhancing the precision, efficiency, and scope of visual inspection tasks.

What Is AI-Based Visual Inspection?

AI-based visual inspection refers to the integration of artificial intelligence (AI) and computer vision technologies in the process of inspecting and evaluating products or components visually. This approach enhances traditional visual inspection methods by utilizing advanced algorithms, machine learning, and deep learning techniques to analyze images or videos for defects, irregularities, or specific attributes. In AI-based visual inspection, high-definition cameras capture visual data, which is then processed and analyzed by AI algorithms. These algorithms can identify patterns, anomalies, or specific features that might be difficult to detect by human eyes alone. Through training on labeled datasets, the AI system learns to recognize different characteristics and make informed decisions about the quality or condition of the items being inspected.

The benefits of AI-based visual inspection include increased accuracy, consistency, and efficiency compared to manual inspections. It can handle large volumes of data quickly and perform inspections at a much higher speed. This technology is employed in various industries, such as manufacturing, quality control, automotive, electronics, healthcare, and more, to ensure products meet predetermined specifications and standards. AI-based visual inspection represents a significant advancement in quality control processes, leveraging the power of artificial intelligence to enhance accuracy and streamline inspection tasks.

Real-world applications of AI Visual inspection

AI-based visual inspection finds wide-ranging applications across various industries due to its accuracy, speed, and ability to detect subtle nuances that might escape human eyes. Some notable real-world applications include:

Product Defect Detection: AI-driven visual inspection automates the identification of defects in manufactured products. It's used to spot cosmetic issues, misalignments, faulty welds, or assembly errors, ensuring only high-quality items reach the market.

Damage Detection: The technology is leveraged to autonomously identify damage in equipment, structures, or buildings. It can swiftly spot surface cracks, dents, structural integrity issues, or even water damage, facilitating prompt maintenance and preventing further deterioration.

Corrosion Monitoring and Detection: In industries dealing with infrastructure, pipelines, storage tanks, and vessels, AI-powered visual inspection monitors corrosion levels. It aids in identifying the early stages of corrosion, allowing for proactive maintenance and minimizing risks.

Equipment Inventory Management: AI streamlines asset management by automatically tagging and recording equipment details. Visual inspection helps read and transcribe equipment tags, thereby cataloging them efficiently into a database, and simplifying inventory tracking.

Quality Assurance in Food Production: AI visual inspection is used to scrutinize food products for quality control. It can identify size, shape, color, and defect irregularities, ensuring only safe and high-quality items reach consumers.

Pharmaceutical Inspection: In pharmaceuticals, AI-based visual inspection ensures the integrity of medications by detecting imperfections in pills, capsules, or packaging, thus upholding stringent safety standards.

Agricultural Yield Estimation: AI-driven visual inspection assists in estimating crop yields by analyzing images of fields. This aids farmers in making informed decisions about resource allocation and harvesting times.

Security and Surveillance: The technology enhances security by autonomously monitoring areas for suspicious activity. It identifies unauthorized personnel, intrusions, or unusual behaviors in real-time, improving overall safety.

Automotive Manufacturing: AI-based visual inspection verifies the quality of automotive components during production, catching issues such as paint defects, misalignments, or faulty components before they escalate.

Medical Diagnostics: In medical imaging, AI-powered visual inspection aids in diagnosing diseases by analyzing medical images, identifying anomalies, and assisting medical professionals in making accurate decisions.

Retail Inventory Management: AI visual inspection can help in stock management by automatically counting items on shelves and comparing them to inventory records, reducing human error and ensuring accurate stock levels.

Advantages Of AI-Based Visual Inspection

Below are some common reasons you should choose automated visual inspection for quality testing.

Enhanced Precision: AI-powered visual inspection offers unparalleled accuracy in identifying even the minutest defects or irregularities, surpassing human visual capabilities.

Consistent Performance: Automated systems maintain a consistent level of performance regardless of factors like fatigue or external distractions, ensuring reliable and standardized results.

High-Speed Analysis: AI-based inspection processes data rapidly, enabling quick decision-making and efficient handling of large volumes of visual data in real time.

Cost-Efficiency: Once set up, AI visual inspection systems reduce labor costs and operational expenses by streamlining the inspection process and minimizing the need for extensive human involvement.

Risk Mitigation: By deploying AI in hazardous environments or situations, organizations can protect human workers from potential dangers while maintaining quality control.

Complex Pattern Recognition: AI algorithms excel at recognizing intricate patterns, making them suitable for tasks that involve analyzing intricate details, textures, or complex shapes.

Data-Driven Insights: The data generated by AI-based inspections can offer valuable insights into production processes, allowing for continuous improvement and optimization.

Reduced Error Rates: Automated inspections minimize human error, contributing to higher accuracy levels and reducing the risk of faulty products reaching consumers.

Scalability: AI inspection can be easily scaled up or down to meet varying production demands without compromising accuracy or efficiency.

Data Annotation for Visual Inspection AI

Data annotation is a fundamental process in the realm of computer vision, specifically for tasks involving visual inspection. In this context, data annotation refers to the meticulous labeling of images or videos with specific attributes, such as object boundaries, classifications, or semantic features. The need for data annotation in visual inspection using computer vision arises from several critical factors:

Training Machine Learning Models: Computer vision models, particularly those driven by machine learning algorithms, require substantial amounts of labeled data to learn and generalize from. By annotating images with accurate labels, the models can identify patterns, make informed decisions, and perform visual inspections with high precision.

Quality Control and Defect Detection: Visual inspection is often employed in quality control and defect detection scenarios. For instance, in manufacturing industries, products are visually inspected for defects, and these defects need to be precisely labeled for the model to recognize and classify them accurately.

Semantic Understanding: Data annotation facilitates semantic understanding. It enables the model to differentiate between objects, identify their positions, and understand their relationships within an image. This is crucial for applications like object counting, locating specific features, or measuring dimensions.

Complex Task Handling: Many visual inspection tasks involve intricate or subjective criteria that cannot be solely determined by automated algorithms. Human annotators with domain expertise can label such nuanced attributes effectively, ensuring the accuracy of the model's predictions.

Diverse Scenarios: Visual inspection occurs across a broad spectrum of industries, from healthcare and automotive to agriculture and electronics. Data annotation allows models to adapt to the unique attributes and variations of each domain, making it versatile for various applications.

Model Validation: Labeled data serves as a benchmark for evaluating model performance. With annotated data, the model's predictions can be compared to ground truth, allowing for continuous refinement and improvement of the algorithm.

Human-AI Collaboration: Data annotation promotes a symbiotic relationship between humans and AI. While automation can handle large volumes of data, human annotators are vital for refining complex or ambiguous cases, enhancing the model's accuracy.

Data annotation for visual inspection using computer vision is the cornerstone upon which accurate and reliable AI models are built. It bridges the gap between raw visual data and AI understanding, empowering machines to perform complex tasks with the precision and reliability required for critical applications.

Conclusion

In a world saturated with visual data, the significance of AI-powered visual inspection cannot be overstated. The transformational impact it brings to quality control, efficiency, and accuracy is reshaping industries at their core. What was once a manual and time-consuming process has evolved into a realm where machines, armed with advanced algorithms and deep learning, can scrutinize vast volumes of visual data swiftly and precisely.

At TagX, we recognize the immense potential of AI visual inspection and stand ready to guide you on this journey. Our expertise lies in translating this potential into reality by providing tailored data solutions for various applications of AI visual inspection. Our dedicated team brings years of experience in Data collection, curation, and data annotation, enabling businesses to harness the full potential of computer vision solutions. With TagX by your side, you can unlock the true power of visual data, scale your visual technologies, and achieve unparalleled accuracy in detection and analysis.

0 notes