#What are the Key Components of Solar Panels?

Explore tagged Tumblr posts

Text

What are the Key Components of Solar Panels?

A conventional components of solar panels, including a layer of silicon cells, a sturdy metal frame, a protective glass enclosure, and a network of interconnected wiring that facilitates the smooth flow of electric current generated by the silicon cells. Silicon, despite being a nonmetallic element, possesses remarkable conductive properties, allowing it to capture and convert sunlight into electrical energy. This remarkable phenomenon is attributed to the “photovoltaic effect,” which serves as the fundamental principle underpinning solar panel technology.

In essence, when sunlight strikes a silicon cell, it triggers the movement of electrons within the cell, setting in motion an electric current. This process enables the solar panel to harness the sun’s radiant energy and transform it into a readily usable form of electricity. Remarkably, this energy generation continues as long as the sun is shining, making solar panels a dependable and sustainable source of power. Furthermore, even on overcast days when sunlight is diffused by cloud cover, solar panels are still capable of generating electricity, thanks to the sun’s persistent ability to penetrate the cloud layers. A few years ago, coal, wood, and biomass were the primary sources of energy, while renewable energy played a secondary role. However, today, renewable energy sources such as solar energy, hydroelectric power, and wind power have replaced traditional sources. Solar energy, in particular, stands out as a cost-free and environmentally friendly energy source harnessed from sunlight. Solar photovoltaic (PV) modules, commonly known as solar panels, play a pivotal role in converting sunlight into electricity during daylight hours. In this comprehensive article, we will delve into the solar panel parts and components. In a subsequent piece, we will explore the installation process of solar panels.

Solar Panel Parts And Components

A solar PV module, or solar panel, is a complex assembly comprising nine essential components of solar panels, each of which plays a crucial role. Let’s explore these components one by one:

Solar Cells: At the core of every solar panel lie solar cells, which serve as the fundamental building blocks. Thousands of these cells are meticulously connected to form a solar panel. The assembly process involves soldering, encapsulation, mounting on a sturdy metal frame, and thorough testing. The efficiency of a solar panel is directly linked to the efficiency of its solar cells. Both the cost and performance of these solar cells significantly influence the overall effectiveness of the panel. Notably, solar cell efficiencies have steadily improved over the past decade. Various materials used in their production yield differing efficiencies. Even within the same technology, different companies may achieve varying conversion efficiencies. Two common types of solar cells are monocrystalline and polycrystalline solar cells.

Solar Glass: Another critical solar installation components is the solar glass, which serves as the outermost layer of the solar panel. This glass must possess both strength and reflectivity for optimal panel performance. Its primary function is to shield the solar cells from adverse weather conditions, dust, and dirt. Typically, tempered glass with a thickness ranging from 3mm to 4mm is recommended.

EVA (Ethylene Vinyl Acetate): EVA is a highly transparent plastic layer used to encapsulate the solar cells. It forms a protective, laminated coating atop the cells, holding them together securely. This material must exhibit durability and tolerance to withstand extreme temperature and humidity conditions.

Back Sheet: The back sheet, located at the rear of the panel, serves a dual purpose by providing mechanical protection and electrical insulation. It essentially serves as a protective covering.

Aluminum Frame: The aluminum frame is a critical structural pv panel component that imparts strength to the solar panel. It is advisable to use a frame constructed from a strong yet lightweight solar panel raw material. The frame should be rigid and capable of withstanding harsh environmental conditions, including high winds and external forces. Typically, aluminum frames come in two varieties: silver and anodized black.

Junction Box: Positioned at the rear of the panel, the junction box serves as the central point where cables interconnect with the solar panel.

Interconnectors: Interconnectors facilitate the connection of solar panels to one another. These solar panel parts must exhibit exceptional weather resistance while enabling secure connections.

Silicon Glue: Silicon glue stands as the most commonly employed adhesive within a solar panel. Its robust bonding properties, along with resistance to chemicals, moisture, and adverse weather conditions, make it the preferred choice for affixing components. Notably, silicon is also the predominant semiconductor material.

Inverter: After the solar panels capture DC electricity, the next step is to channel it through a solar inverter. Your home’s grid and appliances operate on alternating current (AC) electricity. Consequently, the inverter plays a crucial role in transforming the DC electricity harvested from your panels into AC electricity, making it usable. There are two prevalent types of inverters: string inverters and microinverters. String inverters are typically affixed to the side of your residence, where they consolidate all the electricity generated by your solar system. On the other hand, microinverters are compact devices attached to the underside of each individual solar panel, allowing for the direct conversion of DC to AC power at the panel level. At GST, we offer both inverter systems. To determine which inverter system best suits your needs, we recommend consulting with your solar adviser for more information.

Conclusion

Investing in a solar panel system constitutes a significant financial commitment. Therefore, it is advisable to prioritize high-quality solar plant components. Most solar panels come with a 25-year warranty, underscoring the importance of assessing the quality and understanding the function of each constituent part. Prospective buyers should equip themselves with knowledge about the various solar panel parts and components involved in solar panel fabrication, their roles, and overall functionality to make informed decisions and avoid substandard components.

#Components of Solar Panels#What are the Key Components of Solar Panels?#solar panel parts and components

0 notes

Text

The Difference Between Low, Medium, and High Voltage Switchgear

Switchgear plays a critical role in the generation, transmission, and distribution of electrical power. It ensures safe and efficient operation by controlling, protecting, and isolating electrical circuits and equipment. But not all switchgear is created equal — low, medium, and high voltage switchgear are designed for different voltage levels and applications.

Understanding the differences between these types is crucial for electrical engineers, electricians, project managers, and anyone involved in power systems. In this article, we break down what sets them apart in terms of voltage range, components, applications, design, and safety considerations.

What is Switchgear?

Before diving into the differences, let’s clarify what switchgear is.

Switchgear refers to the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential for de-energizing equipment for maintenance and for clearing faults in the power system.

Classification by Voltage Level

Low Voltage Switchgear (LV)

Voltage Range:

Up to 1,000V AC (typically 400V/690V in 3-phase systems)

Key Components:

Miniature Circuit Breakers (MCBs)

Molded Case Circuit Breakers (MCCBs)

Residual Current Devices (RCDs)

Contactors and relays

Busbars, metering, control panels

Applications:

Residential and commercial buildings

Data centers and office spaces

Light industrial automation

Control panels and motor control centers (MCCs)

Characteristics:

Compact and easy to install

High frequency of operation

Relatively simple maintenance

Often enclosed in modular panels

Standards:

IEC 61439

NEC (National Electrical Code)

Medium Voltage Switchgear (MV)

Voltage Range:

1kV to 36kV (sometimes up to 72.5kV)

Key Components:

Vacuum circuit breakers (VCBs)

SF₆ (sulfur hexafluoride) insulated switchgear

Current and voltage transformers (CTs, VTs)

Protective relays

Grounding switches

Applications:

Electrical substations

Large factories and industrial plants

Railways and airports

Renewable energy farms (wind/solar)

Characteristics:

Higher insulation and safety requirements

More robust protection systems

Often installed indoors or in compact outdoor enclosures

May use gas-insulated or air-insulated designs

Standards:

IEC 62271–200

IEEE C37 series

High Voltage Switchgear (HV)

Voltage Range:

Above 36kV (commonly 66kV, 132kV, 220kV, up to 765kV)

Key Components:

SF₆ circuit breakers

Air blast or oil circuit breakers (older systems)

Gas-insulated switchgear (GIS)

Disconnectors and earthing switches

High-end protection relays and SCADA integration

Applications:

National and regional power transmission networks

Power generation plants

Interconnecting large substations

Critical infrastructure (e.g., large data centers, airports)

Characteristics:

Complex installation and high-cost infrastructure

Requires rigorous safety procedures and specialized training

Often installed outdoors or in GIS (Gas Insulated Switchgear) format

Includes extensive monitoring and automation

Standards:

IEC 62271–100 (HV circuit breakers)

IEEE C37.06

ANSI C37 series

Safety Considerations

Always follow local electrical codes, use personal protective equipment (PPE), and conduct routine maintenance regardless of switchgear type.

Conclusion

Choosing the right switchgear type is critical for ensuring safe and efficient power distribution. Whether you’re designing a residential panel or a high-voltage substation, knowing the difference between low, medium, and high voltage switchgear helps you make informed decisions about equipment, safety, and performance.

Mastering this knowledge isn’t just good practice — it’s essential for anyone serious about a career in the electrical field.

10 notes

·

View notes

Text

Why Solar Earthing is Essential for Your Solar Panel System

When you think about solar power, you probably picture sleek solar panels soaking up the sun, cutting down electricity costs, and promoting clean energy. But there’s one crucial element that often goes unnoticed—solar earthing. This unsung hero ensures your solar installation runs safely and efficiently for years.

In this blog, we’ll explore what solar earthing is, why it’s essential, and how it benefits both large solar power plants and smaller solar setups.

What is Solar Earthing?

Solar earthing, also called grounding, is the process of connecting your solar panel system to the earth using conductive materials like copper or galvanized steel. The goal? To safeguard your system and everyone around it from electrical faults or lightning strikes.

Solar panel systems generate electricity, and with that comes the risk of faults due to factors like harsh weather, aging equipment, or unexpected electrical surges. A well-planned earthing system safely directs any stray or excess current into the ground, preventing hazards.

Why is Solar Earthing Important?

1. Ensures Safety for Users and Equipment

Solar systems operate with high electrical loads. Without proper earthing, an electrical fault can lead to dangerous shocks, fires, or damage to your system. A solid grounding setup protects your investment and ensures safety for all.

2. Boosts Efficiency in Solar Power Plants

For large-scale solar power plants, even a minor electrical fault can lead to substantial losses. Solar earthing stabilizes voltage levels, preventing disruptions and maintaining optimal efficiency.

3. Meets Regulatory Standards

Many countries have strict regulations requiring proper solar earthing for installations. Compliance not only helps avoid legal penalties but also guarantees a longer-lasting and safer system.

How Does Solar Earthing Work?

A solar panel system consists of several key components, including:

Solar panels

Inverters

Batteries (for off-grid systems)

Mounting structures

A proper earthing setup connects all these components to the ground using a network of conductors. If an electrical fault or lightning strike occurs, the current safely disperses into the ground instead of damaging the system or posing risks.

Different Types of Solar Earthing

The type of earthing method depends on the size and type of the solar installation. Here are three commonly used methods:

1. Plate Earthing

A metal plate, typically copper or galvanized iron, is buried underground and connected to the system. This is a common method for small-scale residential solar panel setups.

2. Rod Earthing

Metal rods are driven deep into the ground to ensure effective grounding. This method is ideal for larger solar power plants due to its efficiency and ability to handle higher electrical loads.

3. Strip Earthing

Conductive metal strips are laid underground to create a broad earthing network. This method is used for installations requiring a larger grounding surface area.

Key Benefits of Proper Solar Earthing

Enhances the Lifespan of Solar Installations A well-grounded system protects against electrical surges, reducing wear and tear and extending the life of your solar panels.

Improves System Reliability By keeping voltage levels stable, solar earthing ensures uninterrupted performance—even during extreme weather conditions.

Reduces Maintenance Costs A properly earthed system lowers the risk of electrical damage, minimizing costly repairs and replacements.

Provides Peace of Mind Knowing that your solar system is safeguarded from electrical hazards lets you enjoy clean, renewable energy without worry.

Earthing in Large Solar Power Plants

For utility-scale solar power plants, effective earthing is even more critical. These expansive installations require robust earthing systems, often incorporating advanced techniques like lightning arresters, to handle high electrical loads and unpredictable environmental factors.

Challenges in Solar Earthing

Despite its importance, solar earthing faces a few challenges:

Poor Soil Conductivity – In areas where the soil doesn’t conduct electricity well, additional measures like moisture-retaining compounds may be needed.

Corrosion of Earthing Components – Over time, earthing rods and plates may corrode, especially in humid regions. Regular maintenance helps prevent this.

Incorrect Installation – Faulty installation can compromise safety and efficiency. Always rely on experienced professionals to set up your system.

Best Practices for Effective Solar Earthing

Use High-Quality Materials – Opt for durable conductors like copper or galvanized steel for long-term reliability.

Schedule Regular Inspections – Routine maintenance helps catch potential issues early and keeps your system running smoothly.

Follow Local Regulations – Adhering to safety and compliance guidelines ensures your solar installation meets industry standards.

Final Thoughts

While solar earthing may not be the most talked-about aspect of solar energy, it’s one of the most vital. Whether you’re installing a small residential system or a large solar power plant, proper grounding is key to ensuring safety, efficiency, and long-term performance.

By investing in a reliable earthing setup, you’re not just protecting your solar panels you’re ensuring a secure and hassle-free switch to clean energy.

#solar earthing#solar panels for home#best solar panel in india#solar energy#solar panel installation#solar panel system#rooftop solar panels

3 notes

·

View notes

Text

Energy Independence with On-Grid Inverters: Fact or Fiction?

In an era of rising energy costs and environmental concerns, the term “energy independence” has gained significant traction. For many, the idea of generating their own electricity and reducing reliance on traditional power grids is both appealing and financially advantageous. On-grid inverters, a critical component of grid-connected solar systems, often come up in conversations about energy independence. But can they truly deliver on this promise? Let’s explore whether energy independence with on-grid inverters is fact or fiction.

What Are On-Grid Inverters?

On-grid inverters, also known as grid-tied inverters, are designed to convert the direct current (DC) electricity generated by solar panels into alternating current (AC) electricity for use in homes or businesses. These systems are connected to the utility grid, allowing users to draw power from the grid when their solar generation is insufficient and feed excess electricity back into it when production exceeds demand.

The Promise of Energy Independence

Energy independence implies the ability to generate and use your own electricity without relying on external sources, such as the utility grid. While on-grid inverters offer numerous benefits, achieving complete energy independence with these systems is a nuanced concept. Here are some key factors to consider:

1. Dependency on the Utility Grid

By design, on-grid inverters are tied to the utility grid. This connection enables users to draw electricity when solar production is low, such as during nighttime or cloudy days. While this ensures a continuous power supply, it also means that users remain partially dependent on the grid, making complete energy independence unattainable.

2. Net Metering Programs

Many regions offer net metering, allowing on-grid system owners to feed surplus electricity into the grid and receive credits or compensation. While this arrangement reduces energy costs and optimizes solar utilization, it reinforces the reliance on the grid for balancing energy supply and demand.

3. No Backup During Outages

A significant limitation of on-grid inverters is their inability to operate during power outages. For safety reasons, these systems automatically shut down when the grid goes offline, leaving users without electricity even if their solar panels are generating power. This contrasts with off-grid systems, which are designed to function independently.

The Role of Battery Storage

The integration of battery storage with on-grid systems can bridge the gap between reliance and independence. By storing excess solar energy, batteries enable users to power their homes or businesses during periods of low solar generation or grid outages. However, this hybrid approach comes with higher initial costs and additional maintenance requirements, which may not be feasible for everyone.

Advantages of On-Grid Inverters

Despite their limitations in achieving full energy independence, on-grid inverters offer several compelling benefits:

Cost-Effectiveness: On-grid systems are typically more affordable than off-grid setups due to the absence of battery storage. Lower initial investment and maintenance costs make them accessible to a broader audience.

Efficient Energy Utilization: By feeding excess solar power into the grid, on-grid systems minimize waste and contribute to the broader energy infrastructure.

Environmental Impact: Using solar energy reduces reliance on fossil fuels, lowering carbon footprints and promoting sustainability.

Scalability: On-grid systems can be easily scaled to meet growing energy needs, making them a flexible option for residential and commercial applications.

Is Energy Independence a Fiction?

While on-grid inverters cannot deliver complete energy independence in the traditional sense, they do empower users to generate a significant portion of their electricity and reduce reliance on utility providers. For those seeking a balance between sustainability and cost-effectiveness, on-grid systems are an excellent solution.

#On-Grid Inverter#Solar On Grid Inverter#Grid Tie Inverter#Solar Grid Tie Inverter#Best On grid Inverter#5kW On Grid Inverter#3kW On Grid Inverter

2 notes

·

View notes

Text

What is a DC Load Bank?

In the world of electrical engineering and testing, the term "DC load bank" might not be one you encounter every day, but its importance is monumental, especially in industries relying on direct current (DC) power systems. This article will delve into what a DC load bank is, its applications, and why they are essential for ensuring the reliability and efficiency of power systems. Welcome to an exploration of the unsung hero in power testing—EMAX Load Bank's specialty.

Understanding DC Load Banks

A DC load bank is a device designed to simulate electrical loads on a power source, specifically one that provides direct current. This simulation is crucial for testing and validating the performance and reliability of DC power systems, such as batteries, power supplies, and photovoltaic (solar) systems. By applying a controlled load, a DC load bank helps in determining how well a power source can handle real-world conditions and perform under various scenarios.

Components of a DC Load Bank

A typical DC load bank comprises several key components:

Resistive Elements: These are the primary components that dissipate power in the form of heat. They simulate the electrical load.

Control Systems: These allow for the adjustment and regulation of the load applied to the power source. Advanced control systems enable precise load management.

Cooling Systems: Since resistive elements generate heat, efficient cooling mechanisms (fans or liquid cooling) are essential to maintain safe operating temperatures.

Measurement Instruments: These instruments monitor voltage, current, and other relevant parameters to provide accurate data during testing.

Applications of DC Load Banks

Battery Testing

Batteries are at the heart of many DC power systems, from small-scale applications like consumer electronics to large-scale uses such as backup power systems and electric vehicles. DC load banks are used to perform discharge testing on batteries, ensuring they can deliver the required power over their expected lifespan. This testing is crucial for identifying potential issues and ensuring reliability.

Power Supply Validation

Power supplies need to be reliable and efficient, especially in critical applications like data centers, telecommunications, and industrial automation. DC load banks test these power supplies under different loads to verify their performance, efficiency, and stability. This process helps in identifying any weaknesses that might lead to failures or inefficiencies in real-world conditions.

Renewable Energy Systems

With the rise of renewable energy, particularly solar power, ensuring the reliability and efficiency of photovoltaic systems is paramount. DC load banks test these systems by simulating various load conditions, helping in the optimization and verification of solar panels and their associated power electronics.

Electric Vehicle Testing

Electric vehicles (EVs) rely heavily on DC power systems for propulsion and auxiliary functions. DC load banks play a critical role in testing EV batteries and power electronics, ensuring they can meet the demanding conditions of real-world driving. This testing is essential for safety, performance, and the overall user experience of EVs.

Why DC Load Banks are Essential

Ensuring Reliability

The primary purpose of a DC load bank is to ensure the reliability of power systems. By simulating real-world conditions, these devices help identify potential issues before they cause failures. This proactive approach to testing can prevent costly downtime and improve the overall dependability of power systems.

Enhancing Efficiency

Efficiency is a key consideration in any power system. DC load banks help in optimizing the performance of power sources, ensuring they operate at peak efficiency under various conditions. This optimization can lead to significant cost savings over time, especially in large-scale applications like industrial plants or renewable energy farms.

Safety Assurance

Safety is paramount in any electrical system. DC load banks help in identifying and mitigating risks by testing power sources under controlled conditions. This testing can reveal potential safety issues, such as overheating or overloading, allowing for corrective measures to be taken before real-world deployment.

Supporting Innovation

As technology advances, so do the demands on power systems. DC load banks support innovation by providing a reliable means of testing new power sources and technologies. This support is crucial for the development of next-generation batteries, power supplies, and renewable energy systems.

EMAX Load Bank: Leading the Way

In the realm of DC load banks, EMAX Load Bank stands out as a leader, providing cutting-edge solutions for a wide range of applications. EMAX Load Bank's products are designed with precision and reliability in mind, ensuring that they meet the rigorous demands of modern power systems.

Advanced Features

EMAX Load Bank offers advanced features that set their products apart:

Precision Control: EMAX Load Bank's control systems allow for precise load management, ensuring accurate testing and validation.

Robust Construction: Built to withstand demanding conditions, EMAX Load Bank's products are durable and reliable.

Comprehensive Monitoring: With state-of-the-art measurement instruments, EMAX Load Bank provides comprehensive data for analysis and optimization.

Commitment to Quality

EMAX Load Bank is committed to quality and innovation, continuously improving their products to meet the evolving needs of the industry. Their dedication to excellence ensures that customers receive the best possible solutions for their testing and validation needs.

Conclusion

DC load banks are essential tools in the world of electrical engineering, providing critical support for the testing and validation of DC power systems. From battery testing to renewable energy systems, these devices play a vital role in ensuring reliability, efficiency, and safety. EMAX Load Bank, with its advanced features and commitment to quality, leads the way in providing top-notch DC load bank solutions.

As technology continues to advance and the demand for reliable power systems grows, the importance of DC load banks will only increase. Whether you're in the field of renewable energy, electric vehicles, or industrial power systems, understanding and utilizing DC load banks is key to ensuring success and innovation in your endeavors.

2 notes

·

View notes

Text

Acoustic Emission Testing: A Comprehensive Overview

In the realm of Non-destructive Testing (NDT), where technology meets precision, one method stands out as a symphony of innovation, Acoustic Emission Testing (AET).

Humans have used sound for quality control and defect detection for centuries, with 'ping' testing being used for pottery.

In the 1860s, indium was accidentally discovered, emitting a squeaking sound due to bending forces.

What is Acoustic Emission Testing?

In the realm of Non-destructive Testing, one method that stands out for its unique capabilities is Acoustic Emission Testing.

This technique, often referred to as AE testing, plays a pivotal role in assessing the structural integrity of materials and components without causing any damage.

Acoustic Emission Process

Acoustic Emission Testing is the detection and analysis of high-frequency sound waves that are generated by materials and structures under stress or undergoing changes.

These emissions, often beyond the range of human hearing, are captured by sensitive sensors and then interpreted to gain valuable insights into the structural behavior of the object being tested.

Principles Behind AET

At the core of acoustic emission testing lies the principle that when a material undergoes deformation, cracking, or any structural change, it releases stress-energy in the form of acoustic emissions.

Highly sensitive sensors are able to detect these emissions as transient elastic waves that travel through the material.

Acoustic Emission Testing Equipment

Acoustic Emission Testing has emerged as a valuable Non-destructive Testing Technique for assessing the structural integrity of materials and components.

Central to the success of AET is the sophisticated equipment used to capture and interpret the elusive acoustic emissions.

In this article, we will delve into the world of acoustic emission testing equipment, its key components, and how these tools contribute to accurate and insightful analysis.

Applications of Acoustic Emission Testing

Acoustic Emission Testing has emerged as a versatile Non-destructive Testing Technique that finds applications in a diverse range of industries

1. Alternative Power Industries

Industries involved in alternative power sources, such as wind and solar energy, rely on Acoustic Emission Testing to monitor the structural health of components like turbine blades and solar panels.

2. Automobile Industry

In the fast-paced automobile industry, where safety is paramount, Acoustic Emission Testing is employed to assess the structural integrity of vehicle components.

Read More, Acoustic Emission Testing: A Comprehensive Overview

8 notes

·

View notes

Text

Understanding the Basics of Solar Permit Design and Plan Sets

As the adoption of solar energy continues to grow, so does the need for comprehensive and accurate solar permit designs and plan sets. These documents ensure that solar installations meet all local regulations and building codes, facilitating a smooth and efficient approval process. In this blog, we will delve into the basics of solar permit design and plan sets, exploring their importance, components, and the benefits they provide to solar installers and property owners.

Introduction: The Role of Solar Permit Designs and Plan Sets

Solar energy systems must comply with numerous local building codes and regulations. A well-prepared permit design and plan set ensures that the solar installation process adheres to these standards, avoiding potential delays and complications. Understanding the fundamentals of these documents is essential for anyone involved in the solar industry, from installers to property owners.

What Are Solar Permit Designs and Plan Sets?

Solar permit designs and plan sets are detailed documents that outline the specifications and layout of a solar energy system. They are submitted to local building departments as part of the permitting process to obtain approval for the installation. These documents include everything from the system’s electrical design to structural details, ensuring that the installation is safe, efficient, and compliant with all relevant codes.

Key Components of a Solar Permit Design and Plan Set

Site Plan

Overview of the property layout

Placement of solar panels, inverters, and other components

Accessibility considerations for maintenance and emergency services

Electrical Plan

Detailed electrical wiring diagram

Specifications of electrical components, such as inverters and junction boxes

Connection to the existing electrical system and grid

Structural Plan

Load calculations for mounting systems

Roof or ground mounting details

Engineering assessments to ensure structural integrity

Safety and Compliance

Adherence to local building codes and safety standards

Fire safety measures, including clearances and pathways

Signage and labeling requirements

The Importance of Accurate and Comprehensive Plan Sets

Accurate and comprehensive plan sets are essential for several reasons:

Read More: https://vishtik.com/understanding-the-basics-of-solar-permit-design-and-plan-sets/

1 note

·

View note

Text

[ID: the first google search result for "what are solar panels made of". the result reads:

By weight, the typical crystalline silicon solar panel is made of about 76% glass, 10% plastic polymer, 8% aluminum, 5% silicon, 1% copper, and less than 0.1% silver and other metals, according to the Institute for Sustainable Futures.19 Oct 2022]

the key component is doped high purity silicon. that's the part that turns light into electricity. there's a bunch of glass and other stuff to support that silicon but any heavy metals that might be in them (arnt even guaranteed to be there) make up less than 0.1% of the panel.

and if you take a gander here

https://www.epa.gov/hw/end-life-solar-panels-regulations-and-management#:~:text=Hazardous%20waste%20testing%20on%20solar,the%20environment%20at%20high%20levels

specifically in this part:

Thin-film solar cells contain thin layers of semiconductor material, such as cadmium telluride (CdTe) or copper indium gallium diselenide (CIGS), layered on a supporting material such as glass, plastic, or metal. CdTe is the second-most common PV material after silicon, and cells can be made using low-cost manufacturing processes, but their efficiencies aren't as high as silicon solar PV.

you see the heavy metals arnt an inherit part of solar panels but rather an alternative to silicon, and a less efficient one. also not the most common type of panel. you can very much have an efficient long lasting solar panel where the most harmful component is plastic.

95K notes

·

View notes

Text

Solar Power for Factories and Industries: Benefits, ROI, and Setup Guide

Introduction

India’s industrial sector is among the largest consumers of electricity, contributing to over 50% of the nation’s power demand. With fluctuating tariffs, carbon mandates, and rising operational costs, factory owners and plant heads are under pressure to find cost-effective, sustainable energy solutions.

Enter industrial solar systems in India — no longer a trend but a strategic investment.

If you’re exploring solar for factories, this guide covers everything: benefits, financial returns, types of installations, and a practical setup checklist tailored for Indian industries in 2025.

What is an Industrial Solar Power System?

An industrial solar system refers to large-scale photovoltaic (PV) installations designed to meet the high energy demands of manufacturing plants, processing units, warehouses, and other heavy-duty operations.

Key Components:

Solar Panels (Typically 500W+ Mono PERC)

String or Central Inverters

Mounting Structures (Roof/Ground/Canopy)

Monitoring Systems

Net Metering Setup

Common System Sizes:

50 kW — 500 kW (Medium-scale units)

500 kW — 2 MW (Large industrial installations)

2 MW+ (Utility-scale for captive use)

Why Solar for Factories Makes Business Sense in 2025?

1. Massive Electricity Cost Reduction

Industrial tariffs in states like Maharashtra, Gujarat, and Tamil Nadu range from ₹7–₹10/kWh. Solar power can reduce this to ₹3–₹4/kWh.

Annual Savings Example: A 500 kW solar system can generate ~7 lakh units/year, saving ₹50–₹60 lakhs annually.

2. Fixed Power Costs for 25+ Years

With solar, your factory locks in a fixed per-unit cost, eliminating exposure to utility tariff hikes.

3. High Return on Investment (ROI)

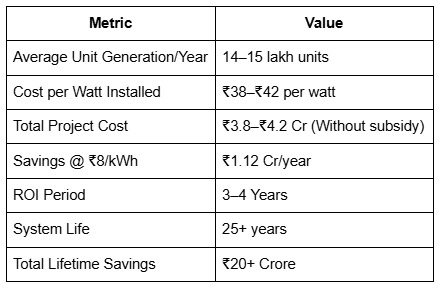

Most industrial solar projects deliver ROI within 3–4 years, followed by 20+ years of free electricity.

4. Accelerated Depreciation Tax Benefits

Under the Income Tax Act:

40% accelerated depreciation for solar assets

Significant upfront tax savings in Year 1

5. Improved ESG Scores & Green Certifications

Switching to solar helps industries comply with:

Carbon neutrality targets

ISO 14001 standards

BEE star rating improvements

Corporate sustainability reporting

6. Reliable Power Supply

Grid-connected systems with net metering reduce dependency on unstable grid power and costly diesel generators.

Calculating the ROI of an Industrial Solar System in India

✅ Important: Factors like roof space, plant operating hours, DISCOM policies, and state net metering rules affect exact ROI.

Types of Solar Installations for Factories

1. Rooftop Solar Systems

Uses idle roof space

Ideal for factories with concrete or metal sheet roofs

No land cost

2. Ground-Mounted Systems

Suitable for factories with surplus land

More scalable (2 MW+ projects)

Easier for O&M (operations and maintenance)

3. Solar Carport & Canopy Structures

Dual-use: Shade + Power

Ideal for parking lots, loading bays

Boosts space utilization

4. Hybrid Solar + Battery Storage

Combines solar with lithium batteries

Ensures power continuity during outages

Reduces diesel generator dependency

Chapter 5: Step-by-Step Setup Guide for Industrial Solar Installation

Step 1: Energy Audit & Feasibility Study

Evaluate total monthly consumption (kWh)

Analyze roof/land area

Consider operating load patterns (day/night)

Step 2: System Sizing & Technical Proposal

Determine optimal system size (e.g., 500 kW, 1 MW)

Load design simulation (PV Syst, Helioscope)

Financial modeling and ROI forecasting

Step 3: Vendor Selection (EPC Partner)

Choose experienced solar EPC companies in India

Verify MNRE/ALMM certification

Review past industrial case studies

The Grew Solar, for example, specializes in high-efficiency EPC delivery with 100% ALMM-compliant modules and in-house engineering.

Step 4: Approvals & Net Metering

Submit application to DISCOM

Follow state-specific net metering process

Grid synchronization documentation

Step 5: Procurement & Installation

Order Tier-1 panels, inverters, structures

Install mounting frames and cable routing

Commission and test the system

Step 6: Monitoring & Maintenance Setup

Install SCADA or remote monitoring systems

Offer AMC (Annual Maintenance Contract)

Train in-house facility managers

State-wise Net Metering and Policies for Industrial Users

Choosing the Right Solar Partner for Your Factory

What to Look for in a Solar EPC Company:

Experience with 500 kW+ industrial systems

MNRE, ALMM, ISO-certified vendor

Proven commercial ROI projections

In-house O&M and remote monitoring services

Post-sales support & AMC coverage

Why Choose The Grew Solar:

Over 25+ large-scale projects completed

Customized solutions for rooftops and ground-mounts

Complete project lifecycle support

Tier-1 components + intelligent monitoring dashboards

Excellent Google reviews & case studies

📞 Contact The Grew Solar today for a free energy audit and proposal tailored to your factory needs.

Solar Financing Options for Industries

CAPEX Model

Client owns the system

Full savings retained

Eligible for depreciation benefits

OPEX / PPA Model

Third-party investor owns the system

Factory pays per-unit consumed

Zero upfront cost

Loan-Based Model

Bank or NBFC funds the CAPEX

EMIs structured to offset with monthly savings

Performance Monitoring and Maintenance

Real-Time Monitoring Benefits:

View daily/monthly generation

Detect inverter errors instantly

Analyze performance ratio (PR)

AMC Services Include:

Monthly inspections

Panel cleaning

Inverter firmware updates

Fault rectification

The Grew Solar offers AI-based analytics for plant performance to maximize output across 25+ years.

Chapter 10: FAQs on Solar for Industrial Use

Q1: Can factories run entirely on solar power? Yes, especially if load patterns align with solar generation (daytime-heavy).

Q2: How much roof space is needed per kW? Approximately 90–100 sq. ft. per kW on RCC; 75–80 sq. ft. on metal roofs.

Q3: What is the lifespan of an industrial solar plant? 25+ years for panels, 10–12 years for inverters.

Q4: Can I claim carbon credits for going solar? Yes. Solar generation can offset Scope 2 emissions, and carbon credits can be monetized.

Conclusion

Solar energy is no longer just an eco-friendly initiative — it’s a bottom-line game-changer for factories and industrial units across India. Whether your goal is cutting power bills, ensuring energy security, or achieving ESG targets, industrial solar delivers massive value in 2025 and beyond.

And the first step? Partnering with a solar company that understands your operational complexity and energy needs.

👉 The Grew Solar is your trusted partner for large-scale industrial solar systems in India. 📞 Contact us today for a no-obligation feasibility audit and proposal.

0 notes

Text

True RMS Power Analyzers: Accurate Measurement for Real-World Electrical Signals

Modern electrical systems are rarely perfect. They’re filled with variable loads, nonlinear devices, and distorted waveforms that make accurate power measurement a challenge. Whether you’re troubleshooting a motor, analyzing energy efficiency, or testing power supplies, precise readings are essential for effective decision-making. Enter the True RMS (Root Mean Square) power analyzer—a specialized instrument designed to provide accurate power measurements even when the electrical waveform is far from a perfect sine wave. In this blog, we’ll explore what True RMS means, how these analyzers work, and why they’re indispensable for real-world electrical analysis.

What Does “True RMS” Mean?

Root Mean Square (RMS) is a mathematical way to express the effective value of an alternating current or voltage. It represents the equivalent DC value that would deliver the same energy to a load.

True RMS analyzers calculate this value by sampling the entire waveform, including all of its distortions and variations. In contrast, average-responding meters assume the waveform is a pure sine wave—which leads to inaccurate readings when harmonics, noise, or non-sinusoidal loads are involved.

Why True RMS Power Analyzers Matter

1. Accurate Measurements in Nonlinear Environments

Today’s electrical environments include devices like variable frequency drives (VFDs), LED lighting, computers, and inverters—all of which draw current in irregular patterns. True RMS analyzers account for these distortions, delivering reliable measurements.

2. Correct Power and Energy Analysis

When power quality matters, especially in systems with distorted waveforms, only a True RMS analyzer can provide accurate real power (kW), apparent power (kVA), reactive power (kVAR), and energy consumption (kWh).

3. Reliable Diagnostics and Troubleshooting

In facilities where unexpected shutdowns or component failures occur, True RMS measurements help pinpoint voltage sags, surges, or current anomalies—issues that might go unnoticed with simpler tools.

4. Supports Regulatory Compliance

Power quality standards (like IEEE 519 or EN 50160) require precise harmonic and waveform analysis. True RMS analyzers are built to meet these standards, making them essential for audits and certification processes.

Key Features of True RMS Power Analyzers

When selecting a True RMS power analyzer, look for the following features:

Multi-phase measurement capability (single-phase, split-phase, three-phase)

High sampling rate for capturing complex waveforms

Harmonic analysis up to the 50th order or higher

Real-time monitoring with data logging

Graphical display for waveform visualization

Connectivity options (USB, Ethernet, Bluetooth, or Wi-Fi)

Compliance with international power quality standards

Common Applications

True RMS power analyzers are used across industries to improve performance, troubleshoot issues, and ensure electrical safety:

Industrial Facilities: Analyze motor drives, lighting systems, and HVAC power consumption

R&D Labs: Test power electronics, inverters, and prototypes under dynamic conditions

Data Centers: Maintain stable power for sensitive IT infrastructure

Utilities: Monitor distribution systems and detect waveform distortion

Renewable Energy: Evaluate solar inverters and battery systems under variable loads

Leading True RMS Power Analyzer Models

Some of the most trusted options on the market include:

Fluke 435-II – Rugged, portable, and ideal for power quality analysis and energy studies

Yokogawa WT5000 – Laboratory-grade accuracy for high-end R&D

Hioki PW3198 – Excellent for troubleshooting and harmonic detection in field settings

Chauvin Arnoux PEL Series – Compact True RMS loggers for panel or equipment mounting

Keysight IntegraVision PA2200 – Combines oscilloscope-like visibility with True RMS accuracy

Final Thoughts

In the real world, electrical signals are messy. True RMS power analyzers cut through the noise—literally and figuratively—by offering precise, dependable measurements that account for every waveform irregularity. Whether you're conducting routine system checks, detailed energy audits, or in-depth R&D testing, a True RMS analyzer is the tool you can trust to get the data right.

0 notes

Text

Finding the Right Solar Power Installers in Sydney: Your Guide to Smart Solar Solutions in Australia

With electricity prices continuing to rise and sustainability becoming a growing priority, more Australian households and businesses are turning to solar energy as a smart, long-term investment. Choosing the right solar power installers Sydney is key to maximising the benefits of solar energy — from cost savings to environmental impact. Whether you're a homeowner looking to cut bills or a business aiming for sustainable operations, this guide will help you make informed decisions about the best solar solutions available.

In this article, we’ll explore how to choose reliable solar power installers, evaluate the best solar panels in Australia, and why companies like Energy Australia solar panels and Smart Commercial Solar are leading the shift towards smarter energy systems.

Why Go Solar in Sydney?

Sydney enjoys an average of 6 to 7 hours of sunlight per day, making it an ideal location for solar energy generation. By installing a solar system, you can:

Significantly reduce or eliminate your electricity bills

Protect yourself against future energy price hikes

Reduce your carbon footprint and contribute to a greener planet

Increase the value of your property

Access government incentives and rebates

To unlock these benefits, working with experienced and certified solar power installers Sydney is essential.

Choosing the Right Solar Power Installers

Whether you’re upgrading your current system or installing solar for the first time, selecting reputable solar power installers ensures your system is efficient, safe, and designed to meet your specific energy needs. Here are some tips for choosing a reliable installer:

1. Certification and Accreditation

Look for Clean Energy Council (CEC)-accredited installers. This ensures your installer meets national quality and safety standards.

2. Local Expertise

Opt for solar power installers Sydney who understand the local climate, energy policies, and network infrastructure.

3. Transparent Pricing

The best installers provide detailed quotes, explain system specifications, and help you calculate return on investment.

4. Warranty and Aftercare

Ensure you receive product warranties on the panels and inverters, as well as workmanship guarantees from the installer.

5. Custom System Design

Good installers tailor the system size, panel placement, and inverter selection based on your roof layout, energy usage, and future goals.

Energy Australia Solar Panels: A Trusted Provider

Energy Australia solar panels are backed by one of the country's leading energy retailers. Their solar systems are known for:

Quality components from leading manufacturers

Seamless integration with battery storage systems

Transparent installation and maintenance services

Flexible payment plans and energy buy-back options

For customers seeking bundled solutions — such as electricity plans combined with solar — Energy Australia is a popular choice that brings trust and convenience under one roof.

What Are the Best Solar Panels in Australia?

With many brands on the market, choosing the best solar panels in Australia depends on performance, durability, warranty, and price. Leading brands include:

SunPower – Known for premium efficiency and longevity

LG Solar – High-quality panels with excellent warranties

Jinko Solar – Affordable and reliable for residential use

Trina Solar – Popular for commercial installations

Q CELLS – Great value and strong Australian support network

Look for panels that are Tier 1 rated, have at least a 25-year performance warranty, and are supported by reputable Australian distributors.

The Rise of Solar Smart Systems

Technology is changing the way we generate and manage solar energy. A solar smart system uses intelligent features like:

Real-time energy monitoring via apps

Automatic optimisation based on weather conditions

Integration with home automation systems

Smart battery storage that shifts usage to peak hours

These systems allow you to track savings, identify issues early, and maximise your solar ROI. If you're serious about efficiency, ask your installer about solar smart options.

Smart Commercial Solar: A Business Energy Solution

Businesses across Sydney and Australia are rapidly investing in commercial solar. Smart Commercial Solar is a leading provider in this space, offering tailored solar solutions for offices, warehouses, schools, and industrial sites.

Their commercial offerings include:

Large-scale solar panel systems with custom design

Detailed energy usage analysis and savings forecasts

Finance options including power purchase agreements (PPAs)

Battery storage and smart grid integration

Ongoing system monitoring and performance reporting

Investing in Smart Commercial Solar not only cuts operating costs but also positions your business as a sustainability leader.

Final Thoughts

Whether you’re a homeowner or business operator, installing solar is one of the smartest financial and environmental decisions you can make. By choosing reliable solar power installers Sydney, using trusted brands like Energy Australia solar panels, and embracing solar smart technologies, you can future-proof your energy needs while reducing your carbon footprint.

Sydney offers ideal conditions and excellent rebates to make the switch. And with access to some of the best solar panels in Australia, there’s no better time to invest in renewable energy. For large-scale projects, Smart Commercial Solar provides scalable, intelligent solutions to take your business to the next level of sustainability.

Make the smart move — go solar today.

#solar power installers sydney#solar power installers#energy australia solar panels#best solar panels in australia#solar smart#smart commercial solar

0 notes

Text

Best Inverter for Home – Yukinova’s Smart Energy Solution

Need for Reliable Home Inverters

With increasing electricity demand and frequent power outages, homeowners are turning to smarter solutions to ensure uninterrupted power supply. Choosing the best inverter for home is no longer optional — it’s essential. Whether for daily backup or maximizing solar energy usage, a high-quality inverter can make a huge difference in comfort, convenience, and energy savings.

Yukinova brings to the market a line of hybrid solar inverters that redefine home energy solutions with advanced features and unmatched efficiency.

Why Yukinova Offers the Best Inverter for Home

Yukinova’s all-in-one hybrid solar inverters are designed for modern households that prioritize reliability and sustainability. These inverters combine three key components — inverter, solar charge controller, and battery management system — in one compact unit, reducing installation hassle while maximizing performance.

Here’s what makes Yukinova stand out as the best inverter for home:

Smart Energy Control: Manage grid, battery, and solar power intelligently.

Maximum Solar Utilization: Convert more sunlight into usable power.

High Efficiency: Reduce energy loss and cut down on electricity bills.

Space-Saving Design: Sleek and compact, suitable for homes of all sizes.

Yukinova Hybrid Inverter Range

Yukinova offers a range of inverter capacities to suit different household needs:

2 KVA Online Hybrid Inverter (24VDC) Ideal for small homes and shops with moderate power requirements. Compact yet powerful.

3 KVA Online Hybrid Inverter (24VDC) Designed for growing families or homes with slightly higher energy usage. Delivers consistent performance.

5 KVA Online Hybrid Inverter (48VDC) Best for large homes, villas, or small businesses. Handles heavy loads with ease and efficiency.

Every model ensures smooth operation, advanced safety features, and full compatibility with solar panels.

Key Benefits of Choosing Yukinova

Yukinova’s hybrid inverters aren’t just machines — they are smart energy partners. Here’s what you gain:

Uninterrupted Power: Instant backup during outages ensures comfort and safety.

Lower Energy Bills: Efficient solar use means reduced dependency on the grid.

Durability: Built to last with robust protection against overload, overvoltage, and short circuits.

Future-Ready Design: Easily integrates into new or existing solar setups.

These benefits are why Yukinova continues to be rated among the best inverter for home solutions by satisfied customers across India.

Conclusion: Power Your Home with Confidence

Investing in the best inverter for home is a smart move for any household seeking energy independence, cost savings, and sustainability. Yukinova’s hybrid solar inverters bring together innovation, reliability, and user-friendly design to offer unmatched value. Whether you’re setting up a new solar power system or upgrading an older one, Yukinova delivers the performance and peace of mind your home deserves.

ORIGNAL SOURCE :- https://lithiumionbatterysupplier.blogspot.com/2025/06/best-inverter-for-home-yukinovas-smart.html

0 notes

Text

Go Off-Grid and Save: Why Solar Bore Pumps Are the Future of Water Access

In today’s world, sustainability and self-sufficiency are more important than ever—especially when it comes to water supply in rural and remote areas. That’s why more Australians are turning to solar bore pumps as a smart, eco-friendly solution. At Water Bore Pump, we provide reliable, high-performance solar pumping systems that help you access groundwater without relying on the grid.

What Are Solar Bore Pumps?

Solar bore pumps use solar panels to power an electric pump that draws water from underground bores. They are ideal for off-grid properties, farms, livestock watering, and remote irrigation systems—offering a clean, low-maintenance, and cost-effective alternative to diesel or mains-powered pumps.

Key Advantages of Going Solar

🌞 Energy Independence: No reliance on mains electricity or fuel

💰 Lower Running Costs: Once installed, your water is pumped for free using solar power

🛠️ Minimal Maintenance: Fewer moving parts mean fewer breakdowns

🌱 Environmentally Friendly: Reduce your carbon footprint with zero-emission pumping

🚜 Perfect for Remote Areas: Ideal for farms, stations, and properties far from the grid

Why Choose Water Bore Pump?

At Water Bore Pump, we don’t just sell pumps—we provide end-to-end solutions. Our team helps you select the right system based on your bore depth, water demand, and location. We supply only high-quality, durable components designed to perform in harsh Australian conditions.

When you shop with us, you get:

Expert advice from bore water specialists

Proven systems from trusted brands

Nationwide delivery and support

Competitive pricing on complete solar pump kits

Ready to Pump Water the Smarter Way?

Join the growing number of Australians switching to solar-powered water solutions. Explore our full range of solar bore pumps at Water Bore Pump and take control of your water supply—sustainably and affordably.

Name - Water Bore Pump

Phone No. - 1300727042

Website - https://www.waterborepump.com.au/solar-water-bore-pumps.html

0 notes

Text

Ice Cream Cart Price Guide – Find the Best Deal for Your Budget

If you’ve been thinking about launching a mobile dessert business, or adding to your vending lineup, an ice cream cart could be an inexpensive, fun way to get rolling. But, before you jump into things, you’re likely wondering, well, the most important question: “How much is an ice cream cart?”

In this guide, we’ll break down ice cream cart prices, what factors affect them, and how to find the perfect cart for your budget and business goals.

💡 Why Choose an Ice Cream Cart?

Whether you’re launching a solo venture or adding to a fleet, ice cream push carts and bicycle ice cream carts are smart investments. They're:

Compact & Mobile – Take your business anywhere: parks, fairs, beaches, or city sidewalks

Low Overhead – Skip the rent and high startup costs of a traditional shop

Customizable – Add your branding, storage, and equipment tailored to your menu

Great ROI – High-margin treats meet impulse buying—especially in warm weather

💰 Ice Cream Cart Price Range: What to Expect

At AllStar Carts, we offer high-quality, U.S.-built carts that match a variety of budgets.

TypePrice Range (USD)Best ForBasic Push Cart$2,500 – $3,800New businesses, events, low volumeBicycle Ice Cream Cart$4,000 – $5,500Mobile vendors, city use, deliveryCustom-Built Cream Cart$6,000 – $8,000+Established brands, franchise, large events

These prices include essential features like cold storage, umbrella mounts, wheels, and stainless-steel construction. Add-ons like branding, sinks, solar panels, or dry storage can raise the total, but also increase convenience and professionalism.

🚲 Push or Pedal? Choosing the Right Ice Cream Cart

When comparing ice carts for sale, consider how and where you’ll be using your cart:

🔹 Ice Cream Push Carts

Ideal for: Static locations, events, sidewalks

Advantages: Lower cost, easier to maneuver in small spaces

Best for: Fairs, farmers markets, catering, walk-up spots

🔹 Bicycle Ice Cream Carts

Ideal for: Covering longer distances or routes

Advantages: Built-in mobility, eye-catching marketing

Best for: Urban vending, mobile advertising, residential areas

Want flexibility? Some carts can switch between push and pedal setups!

🔍 What Affects Ice Cream Cart Prices?

Several key factors impact the final ice cream cart price:

Cart Type: Push carts are generally more affordable than pedal-powered models

Storage Type: Cold plates, dry ice, or mechanical refrigeration add cost

Customizations: Logos, paint colors, sneeze guards, and menu boards

Utilities: Sinks, water tanks, or solar panels for off-grid use

Build Quality: AllStar Carts are made in the USA with heavy-duty stainless steel

As highlighted in this business startup guide on ice cream carts, a well-equipped cart can boost visibility and customer trust—helping you earn more, faster.

🛒 Buy From a Trusted U.S. Manufacturer

When you buy from AllStar Carts, you’re getting:

✅ Customizable carts with food-grade stainless steel

✅ Expert-built designs made for years of use

✅ Nationwide shipping and responsive service

✅ A partner that helps you succeed—not just a seller

Looking for more options? We also offer hot dog carts and food vending trailers for a complete mobile food solution.

❓ FAQs About Ice Cream Cart Pricing

How much is a basic ice cream push cart?

A quality entry-level cart typically ranges from $2,500 to $3,800, depending on size and features.

Do bicycle ice cream carts cost more?

Yes, because of added structure and components. Expect prices between $4,000 and $5,500 for a fully equipped mobile model.

Can I customize my cart?

Absolutely! We offer full customization including branding, colors, sink systems, and refrigeration upgrades.

Is financing available?

While AllStar Carts doesn’t offer direct financing, many customers use business loans, leasing programs, or local small business grants.

How long does delivery take?

Production and delivery typically take 2–4 weeks, depending on your custom features and order volume.

✅ Quick Summary

Ice cream cart prices range from $2,500 to $8,000+ based on cart type, features, and customization. Whether you're looking for a simple push cart or a premium bicycle ice cream cart, AllStar Carts provides durable, made-in-USA options to help you launch and grow your mobile vending business.

#IceCreamCart#IceCreamCartsForSale#BicycleIceCreamCart#IceCreamPushCart#MobileIceCreamBusiness#CreamCarts#IceCartsForSale#SmallBusinessUSA#StreetFoodBusiness#MobileVending#FoodCartStartup#VendorLife#EntrepreneurshipJourney#StartABusiness#AllStarCarts#MadeInUSA#CustomFoodCarts#FoodVendorEquipment#CartBusiness

0 notes

Text

Why Accurate Solar Quotes Depend on the Right Software

Getting a solar quote should be simple, right? In theory, yes—but in practice, it can get messy fast.

Think about it: every solar customer wants to know three things—how much it’ll cost, how much they’ll save, and what the system will look like on their property. As a solar professional, it’s your job to answer those questions quickly and accurately.

But when your quoting process involves jumping between spreadsheets, outdated price lists, and manual drawings, the risk of errors skyrockets.

That’s where the right software comes in.

In today’s fast-moving solar industry, accuracy isn’t just about looking good on paper. It’s about building trust, winning deals, and keeping projects on budget.

This blog dives into why precise quoting matters and how the right solar software makes all the difference, from the first click to the final signature.

Introduction: The Impact of Inaccurate Quoting

We’ve all seen it happen: a quote goes out with optimistic numbers, but once the actual system design is done, the cost jumps up. Maybe the roof layout wasn’t factored in properly, or the labor cost was underestimated. Now you’re left either absorbing the difference or renegotiating with a confused and frustrated customer.

Inaccurate quoting doesn’t just hurt your margins—it damages your credibility. It leads to mistrust, project delays, and in worst cases, cancelled installations. In a market where word-of-mouth and online reviews matter more than ever, you simply can’t afford to get it wrong.

This is why more solar companies are turning to purpose-built quoting software. With the right tools, you don’t just quote—you present a realistic, customized plan that’s ready to go.

Key Features of Solar Quoting Software

So, what makes solar quoting software actually good? At its core, it should help you work smarter, faster, and more accurately. Here are some must-have features:

1. Accurate System Sizing

Good software helps you calculate the system size based on the customer’s roof dimensions, shading, orientation, and energy usage. No more over-promising or under-delivering.

2. Real-Time Pricing

Your quote is only as accurate as your price data. The right platform pulls from real-time or customizable price databases so you can quote labor, panels, inverters, and BOS components accurately every time.

3. Incentive & Tax Credit Integration

Whether it’s the federal solar tax credit or local rebates, good quoting tools automatically calculate applicable incentives so customers get a clear picture of net cost and ROI.

4. Visual Proposals

It’s one thing to say the system will work. It’s another to show it with a layout, performance estimate, and professional-looking proposal. Visuals build trust and close deals.

5. Financing Options

Many homeowners and businesses rely on loans or leases. Software that integrates financing lets you showcase different payment plans and monthly savings in a few clicks.

The goal? A quoting system that removes guesswork and replaces it with confidence.

Linking Design, Costing, and Proposals

Here’s the thing: quoting doesn’t happen in a vacuum. It’s part of a bigger workflow that starts with site assessment and ends with installation.

When design, costing, and proposals aren’t linked, mistakes happen. You might design a beautiful layout, but if your quote doesn’t match the panel count or include the right inverter model, the numbers fall apart. Similarly, if you change the design later but forget to update the quote, your profit margin could disappear.

That’s why integration matters.

Modern solar software platforms connect design tools with pricing engines and proposal templates. Update one piece of the puzzle—say, you switch to higher-efficiency panels—and everything else updates automatically. It keeps your team aligned and your quotes consistent.

Improving Customer Trust with Transparent Quotes

Let’s be real: nobody likes vague estimates. Customers want transparency—they want to understand why they’re paying a certain amount, what they’re getting, and how it all benefits them.

With the right quoting software, you can give them just that.

Breakdowns of system components, lifetime energy production graphs, and savings forecasts help customers feel informed rather than overwhelmed. And when you can answer their “what if” questions on the spot—thanks to dynamic quoting tools—you’re no longer just a salesperson. You’re a trusted advisor.

Clear quotes lead to confident buyers. And confident buyers sign faster.

Best Tools for Accurate Commercial Solar Quotes

While residential quoting can be complex, commercial solar quotes are a whole different ballgame. You’re dealing with larger systems, custom configurations, multi-meter setups, and often more involved financial modeling.

Here are some tools that excel in the commercial quoting space:

ARKA 360 – A powerful all-in-one platform that combines design, accurate quoting, and dynamic proposals under one roof. ARKA 360 is built to streamline commercial and residential workflows, cutting down quote time while enhancing accuracy.

Aurora Solar – Offers detailed 3D modeling, shading analysis, and integrated financial modeling, ideal for complex commercial sites.

Helioscope – Known for its engineering-grade simulations and large-scale design capabilities. Great for utility and C&I scale projects.

SolarGraf – User-friendly and quick, with a strong emphasis on proposal generation.

For commercial projects, accuracy is non-negotiable. These tools provide the scalability and flexibility needed to handle large bids with confidence.

Conclusion: Accuracy Begins with the Right Software

At the end of the day, solar quoting isn’t just about numbers—it’s about trust, professionalism, and efficiency. An inaccurate quote can cost you a deal. But the right quote, delivered at the right time, can close it on the spot.

The best solar companies are investing in smarter quoting tools not just to look better, but to be better. Better at planning, presenting, and delivering solar solutions that meet real customer needs.

From reducing human error to improving proposal speed and clarity, quoting software has become the backbone of successful solar sales teams. Whether you’re a solo installer or managing multi-million-dollar commercial projects, the message is clear:

Accuracy doesn’t happen by accident. It happens with the right software.

1 note

·

View note

Text

Leading Solar Cable Manufacturers in India: Ambica Cables Shining Bright

As India accelerates its transition to clean energy, the demand for solar cables manufacturers in india—the lifelines of solar power systems—has surged dramatically. Solar cables must withstand extreme environmental conditions while maintaining efficiency and safety. In this fast-growing sector, Ambica Cables has emerged as a reliable and innovative manufacturer of high-quality solar cables.

What Are Solar Cables?

Solar cables are specialized wires designed to connect solar panels with other electrical components in a photovoltaic (PV) system. These cables are expected to perform efficiently under intense UV radiation, high temperatures, and in open-air installations. Key properties include:

UV and weather resistance

Flame retardant properties

High flexibility and thermal stability

Low conductor resistance for better efficiency

Ambica Cables: Powering Solar Solutions

Ambica Cables, with years of experience in the wire and cable industry, has developed a strong presence in the solar cable segment. Their products meet national and international standards, ensuring safety and performance in both residential and commercial installations.

Why Choose Ambica Cables?

High-Quality Conductors: Made from 99.97% pure electrolytic copper or tinned copper, ensuring low transmission losses.

Double Insulated for Safety: Solar cables from Ambica are insulated with cross-linked polymers (XLPE) for durability and resistance to harsh weather.

TUV/IEC Compliant: Cables comply with stringent international standards for solar applications.

RoHS & Eco-Friendly: Free from harmful substances, aligning with sustainable energy goals.

Long Service Life: Designed for more than 25 years of operation under outdoor conditions.

Ambica Cables’ solar products are widely used in:

Rooftop solar installations

Solar farms and large-scale PV systems

Off-grid solar applications

Industrial and commercial solar systems

Final Word

As the solar energy sector expands, so does the need for robust, efficient, and durable wiring solutions. Ambica Cables stands tall among India’s top solar cable manufacturers in india, offering cost-effective, quality-assured products that help power a greener future. Whether you're building a small rooftop system or a large solar park, Ambica delivers the trust you need—wire by wire.

Visit:- https://www.ambicacables.com/solar-cable.html

0 notes