#Wireless RTU

Explore tagged Tumblr posts

Text

Battery-operated Remote Terminal Units Market Research, Size, Share, Analysis, Overview and Regional Outlook Study 2017 – 2032

The market for Remote Terminal Units (RTUs) that are battery-operated allows them to function in isolated or off-grid regions where access to a reliable power supply is restricted. RTUs are electronic devices used to monitor and manage remote equipment and processes in many different industries, such as oil and gas, water and wastewater management, power distribution, and telecommunications. Here is a summary of the market for battery-operated RTUs, including information on demand:

Market Overview: Due to a number of circumstances, the market for battery-operated RTUs has been expanding. The need for battery-operated RTUs has been fueled by the necessity for remote monitoring and control capabilities in various industries, particularly in places with weak power infrastructure. These devices enable efficient monitoring and control of remote assets without the requirement for a continual external power source thanks to their dependable and autonomous operation.

Demand Drivers:

1. Real-time monitoring and control of assets: situated in remote or isolating locations are necessary in many businesses. Without the requirement for a sizable power infrastructure or reliance on cable connections, battery-operated RTUs allow for effective data gathering, monitoring, and control of these assets.

2. Applications Off-Grid: In off-grid applications where access to a dependable power supply is restricted or nonexistent, battery-operated RTUs are widely used. Examples include remote water pumping stations in rural areas, environmental monitoring stations, remote weather monitoring stations, and remote oil and gas wellheads.

3. Emergency and Temporary Installations: Whereas immediate deployment is necessary, battery-powered RTUs are also used in emergency and temporary installations. When catastrophe recovery, building projects, or temporary infrastructure installations are taking place, these machines can instantly provide remote monitoring and control capabilities.

4. Environmental Monitoring: Data collection from remote weather stations, air quality sensors, and water quality sensors are all important aspects of environmental monitoring that battery-operated RTUs play a key role in. Continuous monitoring is made possible in remote or environmentally delicate locations by these equipment.

5. IoT Connectivity: The need for battery-operated RTUs has increased as the Internet of Things (IoT) is becoming more widely used in a variety of businesses. These devices are essential parts of IoT networks because they provide seamless data transmission, communication, and control between remote assets and central management systems.

Here are some of the key benefits for Stakeholders:

Remote Monitoring and Control

Flexibility and Mobility

Cost-Effective Deployment

Resilience to Power Outages

Integration with IoT and Smart Grids

Increased Data Accessibility

Environmental Monitoring and Compliance

Rapid Deployment for Emergency Response

Redundancy and Reliability

Scalability and Future-Proofing

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/battery-operated-remote-terminal-units-market/10333/

Market Segmentations:

Global Battery-operated Remote Terminal Units Market: By Company • SIEMENS • SENECA • Omniflex • King Pigeon Communication Co.,Limited • Servelec Group • TEKBOX • Micro Sensor Co., Ltd. • Hitachi Group • Remsdaq Ltd Global Battery-operated Remote Terminal Units Market: By Type • GPRS • GSM • Modular • Others Global Battery-operated Remote Terminal Units Market: By Application • Power Industry • Government and Utilities • Industrial Global Battery-operated Remote Terminal Units Market: Regional Analysis The regional analysis of the global Battery-operated Remote Terminal Units market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Battery-operated Remote Terminal Units market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Battery-operated Remote Terminal Units in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Battery-operated Remote Terminal Units in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: TheAsia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Battery-operated Remote Terminal Units in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Battery-operated Remote Terminal Units in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/battery-operated-remote-terminal-units-market/10333/

Reasons to Purchase Battery-operated Remote Terminal Units Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Battery-operated Remote Terminal Units#RTU Market#Remote Monitoring#Wireless RTU#Industrial Automation#Battery-powered RTU#IoT (Internet of Things)#Energy Efficiency#Data Collection#Telemetry#Remote Control#Battery-powered Sensors#SCADA (Supervisory Control and Data Acquisition)#Energy Management#Off-grid Applications#Renewable Energy#Battery Technology#Remote Sensing#Communication Protocols#Edge Computing#Connectivity Solutions#Remote Data Acquisition#Condition Monitoring#Asset Management.

0 notes

Text

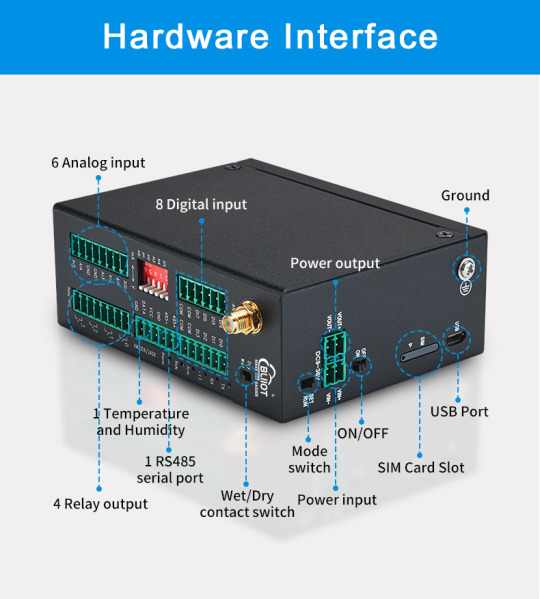

4G 8 DIN 6 AIN 4 DO Industrial Remote Control for Smart Factory

S272 is a 4G RTU with IIoT data acquisition, remote monitoring and control, SMS alarm functions, it is widely used in remote data acquisition and monitoring of various industries, such as smart grid, smart transportation, industrial automation, smart building, firefighting, public safety, environmental protection, meteorology, digital medical, agriculture, forestry, water, coal mining, petrochemical and other fields.

8 digital input, 4 relay output, 6 analog input and 1 temperature&humidity input;

1 RS485 serial port, Modbus RTU (Master/Slave), can expand multiple Modbus Slave devices, Max. 320 data points;

Embedded TCP/IP stack, supporting Modbus RTU, Modbus TCP and transparent transmission;

Built-in powerful telephone and SMS alarm function, regular reporting, abnormal upper and lower limit alarm;

Local logic control of the device, linking relay outputs based on monitoring of digital input and analog value thresholds;

Anti-dropout mechanism to ensure the device always online and it comes with data retransmission function;

Support remote configuration, remote management and remote restart by SMS;

Built-in powerful timer function, support timed automatic reporting, timed daily SMS, timed online, timed offline, timed restart, timed execution relay output, etc.;

0 notes

Text

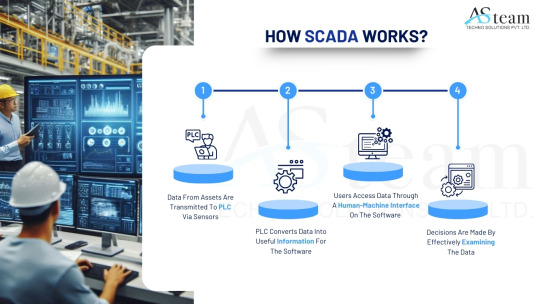

How SCADA Works?

Supervisory Control and Data Acquisition (SCADA) systems are critical in managing and monitoring industrial processes across various industries, including manufacturing, utilities, transportation, and energy.

Field Devices

At the process level, field devices like sensors, meters, and actuators are used to monitor variables like voltage, flow, temperature, and pressure. These gadgets collect information and carry out system-directed operations.

Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs)

The SCADA software and the field devices are connected by RTUs and PLCs. After gathering information from the sensors, they transmit it to the control center. Additionally, the SCADA system may send them orders to modify settings or control actuators.

Communication Infrastructure

Strong communication networks are necessary for SCADA to transmit data between the control center and field equipment. This infrastructure can be wireless (such as satellite, radio, and cellular networks) or wired (such as Ethernet and fiber optics).

Centralized Control Station

SCADA software, which analyzes data, creates visualizations, and gives operators tools to monitor and manage operations, is housed in the control station.

Human-Machine Interface (HMI)

The SCADA system's user interface is called the HMI. Operators can engage with the system and make well-informed decisions because to its graphical depictions of processes, warnings, and trends.

#automation#SCADA#PLC#HMI#Automation#Technology#business and industry sectors#business#industrial automation#soft starter#software#software engineering

3 notes

·

View notes

Text

0 notes

Text

Designing a Basic SCADA System: A Foundational Guide

Introduction

SCADA (Supervisory Control and Data Acquisition) systems in industrial automation serve a vital purpose in monitoring and controlling processes. From manufacturing, energy management, water treatment, to infrastructure, SCADA systems offer a single platform for data collection, visualization, and control. Designing a basic SCADA system entails knowing its most important components and how they cooperate to facilitate smooth operations.

Key Components of a SCADA System

A well-structured SCADA system includes several core components:

Remote Terminal Units (RTUs) or PLCs: These collect real-time data from sensors and field devices.

Communication Infrastructure: Data from field devices is transmitted to the central system via wired or wireless communication protocols.

SCADA Software: Installed on central servers or PCs, it processes the incoming data, provides visualization through HMI screens, and allows operators to control processes remotely.

Human Machine Interface (HMI): It is the interface that presents data, alarms, and controls in an interactive form.

Steps involved in designing a basic SCADA System

Define System Requirements: Identify the process to be monitored, the number of data points, and control level needed.

Choose Hardware Components: Select suitable PLCs or RTUs, sensors, and network devices according to the needs of the process.

Develop Communication Architecture: Develop an efficient communication network through appropriate protocols (such as Modbus, Ethernet/IP, or wireless systems).

Program and Configure the System: Develop control logic in PLCs and program SCADA software to interact with field devices.

Test and Validate: Test conditions to ensure data collection, alarms, and control functionality.

Deploy and Maintain: Install the system on-site and schedule periodic updates and maintenance.

Learning SCADA Design with Real-Time Exposure

Learning how to develop a SCADA system is a skill that is best acquired in a lab-based training setup. A PLC SCADA Course in Nashik provides the future automation experts a chance to practice on live equipment and industrial-standard projects. Centers like VIATA, in the center of Nashik, have a reputation for combining theoretical knowledge with lab application.

VIATA is headed by an industrialist with more than 20 years of experience in automation. The institute's strategy involves training in Stepper & Servo Motors, Drive Technologies, DCS, and IIoT, all of which are essential for SCADA system design. Students get exposure to HMI configuration, AC motor drives, VFDs, and control panel engineering, so the training is applicable to both fresh graduates and experienced professionals.

Why opt for a PLC SCADA Course in Nashik?

Live Industrial Projects: Learners are exposed to real systems, equipping them for the challenges of the industry.

Best Automation Experts: Training experts with field experience impart real-world perspectives to the class.

Balanced Curriculum: From initial PLC logic to advanced SCADA interfaces, all aspects of control system development are included.

Guaranteed Placement Support: With career guidance and focused interview skills training, students are assisted in making the transition into the workforce.

Conclusion:

Creating a simple SCADA system isn't only about knowing software and hardware, but also real-life integration of these tools within an industrial environment. To gain a good foundation in automation, taking a hands-on PLC SCADA Course in Nashik provides the ideal combination of theory and practice. Under the tutelage of experts and real-time learning facilities such as those provided by VIATA, students are imparted the necessary skills to thrive in contemporary automation jobs.

0 notes

Text

0 notes

Text

Solar SCADA

Suryalog Solar SCADA is a reliable and sustainable IoT bases system for solar power plants. It has ground mount products like SCADA and RTU loggers, WMS, PPC, and ground mount Accessories. Suryalog Solar SCADA is leading with cutting-edge technologies in Ground mount solar power plants. Suryalog has a highly solar-experienced team in Hardware, Software, and Service. Solar SCADA has functionalities for monitoring, management, and maintenance activity. Solar SCADA is working with all types of input, and output ports to collect data from various types of devices in solar. Suryalog SCADA is compatible with All types of communication systems it works with wired as well as wireless solutions over a long distance.

0 notes

Text

Power substation automation Market - Forecast(2024 - 2030)

Power Substation Automation Market Overview

Request Sample Report :

Growth is supported by member states’ policies to meet the bloc’s 2030 renewable energy target. Substation Automation Systems (SAS) through SCADA Systems, Programmable logic controllers (PLCs) and Remote Terminal Units (RTUs) provide protection, control, automation, monitoring, and communication capabilities as a part of a comprehensive substation control and monitoring solution. To improve the system’s overall efficiency and productivity, a substation automation system automates some repetitive, laborious, and error-prone operations such as those related to protective relay and load tap changers. With the rising demand for smart cities and smart grids, the market is analyzed to grow at significant rate during forecast period 2022–2027.

Report Coverage

The report: “Power Substation Automation Market — Forecast (2022–2027)”, by IndustryARC covers an in-depth analysis of the following segments of the Power Substation Automation market

By Type: Transmission Substation Automation, Distribution Substation automation and collector/tie line substation automation)

By Module: Hardware, SCADA, communication network technology

By Stage: Retrofit & New construction

By End User: Utilities & Industrial

By Geography: North America (U.S, Canada, Mexico), South America (Brazil, Argentina and others), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC (China, Japan India, SK, Aus and Others), and RoW (Middle east and Africa)

Inquiry Before Buying :

Key Takeaways

While the accessible potential for deployment of wireless connectivity in substation automation is high, the acceptance of the technology is afflicted by myriad set anxieties and worries close to the wireless technology, one among which is the lack of interoperability

Approximately 83% of the end-users across substation automation regarded interoperability as major concern.

Accomplishment of interoperability would necessitate a construction of full fledged architecture with software based systems, in which disparate standards can be applied.

Being connected to a substation and retrieving vital information from remote devices has always been a challenge for system designers. Not all the substations are of the same size or importance. Many substations are in remote areas where communication could be the biggest challenge when it comes to monitoring a substation.

Power Substation Automation Market, By Region, 2021

For More Details on This Report — Request for Sample

Power Substation Automation Market Segment Analysis — By Application

Utilities dominated the Power Substation Automation Market with a value share of approximately 78% in 2021. The significant investments in the sector are contributing to the market growth rate. The U.S. Department of Energy (DOE) announced more than US$30 million in federal funding, matched by more than US$35 million in private sector funds. In 2021, USDA announced to invest US$598 million to improve, modernize rural electric infrastructure. With the implementation of smart grids, both utilities and consumers expect the energy market to work more efficiently and more cost-effectively. Unlike traditional grid management, smart grids provide operators with the opportunity to monitor remotely substations and grid assets in real-time data. They add distributed automation features, and enable predictive maintenance. Traditional grid management, which involved primary substation assets such as circuit breakers and transformers, is very limited by its communication protocols. The traditional grid management structure requires a dedicated link between the substation control system and a regional control centre. As such, traditional grid management can no longer meet the increasing demand for flexibility, stricter operating and environmental regulations, and the larger number of stakeholders in a deregulated industry. Transitioning to smart grid management will provide an infrastructure that supports multiple distributed energy resources, digital substations and smart grid technology. This combination which will help manage the demand of energy, reduce costs for both energy suppliers and consumers and save energy in the long-term contributing to a healthier environment.

Power Substation Automation Market Segment Analysis — By End User

A transmission substation connects two or more transmission lines, and can range from simple to complex. A transmission station may have transformers to convert between two transmission voltages, voltage control/power factor correction devices such as capacitors, reactors or static VAR compensators and equipment such as phase shifting transformers to control power flow between two adjacent power systems. The global transmission type substation automation market was around $11.06bn in 2021 and is estimated to reach $15.74 billion by 2027, growing at a CAGR of 6.24%. This is the majority substation type in the overall substation automation market. A distribution substation transfers power from the transmission system to the distribution system of an area. In some situations it is uneconomical to directly connect electricity consumers to the main transmission network, unless they use large amounts of power, so the distribution station reduces voltage to a level suitable for local distribution. The downtown areas of large cities feature complicated distribution substations, with high-voltage switching, and switching and backup systems on the low-voltage side. In addition to transforming voltage, distribution substations also isolate faults in either the transmission or distribution systems.

Schedule A Call :

Power Substation Automation Market Segment Analysis — By Geography

North America dominated the Power Substation Automation Market with a value share of approximately 39% in 2021. The investments and the government plans are the major factors contributing to the growth in the region. The Smart Grid Investment Grant (SGIG) program aimed to accelerate the modernization of the nation’s electric transmission and distribution systems. The program selected projects electricity providers across the nation with plans to upgrade their systems. With regard to industries such as utilities, renewable energy, and oil and gas, the United States has emerged as the world’s most potential market for substation-related projects. To increase the reliability and capacity of transmission and distribution networks, utilities in the United States are investing heavily in replacing, upgrading, and extending new and existing transmission and distribution infrastructure.

Power Substation Automation Market Drivers

Industry 4.0 and Increase in adoption of substation automation across Utilities and Industries

Industry 4.0 revolution creates smart automation in the phase of industrialization. Increasing demand for machines in the manufacturing sector is set to push the process automation market to new heights. Implementation of process automation in industries results in many benefits such as productivity gains, improved team performance, enhanced managerial reporting, error reduction, cost reduction, and higher quality. The growing need to achieve process optimization in lesser time in the industrial operations coupled with various government initiatives to adopt automation is driving the process automation market. The modernization of smart power grids, integration of renewable energy sources and criticality of energy availability, drive the increasing demand to monitor power-related information from the edge. Smart monitoring enables businesses to control and protect their facilities and energy assets. Along with the increasing investments in power industry it is also observed that the key players in oil and gas and utility sector are planning for the upgradation of the substations which is expected to drive the power substation automation market. With the Industry 4.0 standards being evolved , it is not only the Engineering aspect of the Power Generation, Transmission or Distribution, but also the running plants which are getting ready for the future.

Increase in Technology Developments and Digitization Requirements

The advanced developments in wireless technology have opened up new ways for this market with improved quality and increase in production, which is further expected to fuel the demand for substation automation. The data-hungry digital economy requires highly efficient power networks. The demand for high-quality and reliable energy systems grows across industries as digitization continues to change world. Substation automation systems are used by companies where power availability is critical, and energy control and monitoring is a necessity. The demand for substation automation solutions has evolved. With multi-touch technologies such as PLC, DCS, MES, and SCADA, automation equipment has become more sophisticated, carrying out more complex actions at a low operating cost. Also, coupled with the advancements in sensor technology, these technologies have started the era of smart manufacturing, resulting in business process improvement.

Buy Now :

Power Substation Automation Market Challenges

Lack of skilled workforce and substation automation needs monitoring

According to Paradox of Automation, the more well-organized and efficient an automated system, the more crucial the human contribution of the operators. Hence, training the workforce with the skills required for the industry process automation is a strategic concern in the growth and development outlook of this sector. Having a knowledgeable and well-staffed local team on hand to help with process automation issues is absolutely necessary for proper functioning. The substation automation transformation trend is accelerating the miniaturization of technology and the pace of integrating industrial applications with electronics. A major challenge to the OEMs is to enhance the receptiveness of education and training systems to these fluctuations in skill requirements and to enhance the access to training and skills development. Ultimately, the growth of substation automation depends on the availability of relevant labor force and how productive they are, which solely rests on the skills they possess and how effectively those skills are implemented.

Power Substation Automation Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Power Substation Automation market. In 2021, the market of Power Substation Automation market has been consolidated by the top players

Hitachi

GE

Siemens

Schneider Electric

Mitsubishi Electric

Eaton

Cisco

S&C Electric

SEL

Honeywell

Recent Developments

In June 2021, ABB has joined forces with Swiss utility Axpo to develop modular green hydrogen production plants in Italy. The two companies will apply their complementary skills to achieve affordable green hydrogen, with ABB harnessing its automation, electrification, and digital leadership in industrial operations and Axpo’s experience as an established energy provider.

In December 2020, Siemens Smart Infrastructure launched its new PowerLink CM, a condition monitoring solution for high-voltage AC and DC transmission lines

Related Reports

Water Meter Market — Forecast(2021–2026) Report Code: AIR 0142

Heat Flow Meters Market — Forecast(2021–2026) Report Code: ESR 0306

For more Automation and Instrumentation Market related reports, please click here

0 notes

Text

A SCADA system is composed of interconnected components that work together to monitor and control industrial processes effectively. At its core is the Supervisory Controller, which acts as the central computer, managing data exchanges between Human-Machine Interfaces (HMIs), Programmable Logic Controllers (PLCs), and Remote Terminal Units (RTUs). PLCs are microcomputers that collect and process data from sensors and other input devices, performing critical tasks like performance monitoring, equipment runtime calculations, and generating alarms for anomalies. RTUs, another type of microcomputer, are rugged and wireless, ideal for capturing data from remote locations. The HMI provides operators with a user-friendly interface, visualizing SCADA data through maps, icons, charts, and dashboards for real-time system monitoring. Additional components include Intelligent Electronic Devices (IEDs), which enhance system capabilities, and communication systems that enable data transfer via cables, radio, or the Internet. SCADA systems also rely on programming languages, such as C, to create operational diagrams and process maps, ensuring seamless control and decision-making.

0 notes

Text

Data Concentrator can Receive the data on Wireless Bridge/ Network, Convert Wireless Signal into RS-485/ TCP-IP Format, Point to Communication, Easily connected to SCADA and RTU Panel

0 notes

Text

Resilient for Demanding Industrial Settings

Engineered to withstand demanding conditions, SR500 4g industrial router routers feature:

- Rugged enclosures to resist vibration, shock and extreme temperatures from -40°C to 75°C

- IP30 rating to prevent dust and moisture ingress

- DIN rail or desktop mounting for secure installation

- Redundant cellular and WiFi prevents downtime from network outages

Powerful Cellular and WiFi Connectivity

The SR500 line supports:

- 4G LTE CAT4 providing up to 150Mbps down/50Mbps up for high-bandwidth applications

- Optional 1.8GHz private LTE with 1000m range for campus and industrial park coverage

- 802.11b/g/n WiFi with internal or external antennas for local wireless access

This enables combining long-range cellular and short-range WiFi in one router.

Advanced Networking Features

SR500 routers provide:

- 2 x 10/100Mbps Ethernet ports for wired connectivity

- Extensive VPN protocols like IPsec, OpenVPN, GRE for secure remote communications

- SD-WAN capabilities to optimize performance across multiple links

- TR-069 and SNMP management for auto-configuration and monitoring

Tailored for Industrial IoT Projects

Typical applications include:

- Connecting PLCs, RTUs, sensors, meters and other assets to cloud platforms

- Enabling public WiFi and smart city services like traffic control and surveillance

- First responder networks with cellular and failover WiFi

- Deploying SD-WAN to combine multiple network links

- Adding cellular connectivity to sites without wired internet access

Customizable Linux Platform

The SR500 runs OpenWrt Linux allowing full customization. Development guides help tailor routers to specific use cases.

Centralized Management for Scalability

Star Device Manager (Star Cloud) enables managing entire networks of routers for simplified provisioning and monitoring. With industrial-grade reliability, the SR500 series provides connectivity assurance for critical industrial IoT.

1 note

·

View note

Text

4G wireless remote network fault monitoring terminal RTU5028E can be used for disconnection and power failure network fault monitoring, applicable to the state monitoring of server rooms, base stations, laboratories, network cameras, servers, etc.. It can automatically determine the cause of failure of 7 network devices, distinguish whether the network device failure is caused by network failure or power failure, and can automatically or manually restart the device remotely to solve the failure problem, which greatly improves the efficiency of network equipment operation and maintenance.

1.Multi-way real-time monitoring of network disconnection + power failure + network cable failure; 2.Supports simultaneous monitoring of 7 network devices, including WiFi devices; 3.Automatically determine whether a network device failure is caused by a network or a power outage; 4.Automatic or manual remote reboot of the device to solve problems quickly; 5.Built-in 4G and Ethernet communication method; 6.Support BLIIoT Cloud and SCADA and other monitoring centers;

1 note

·

View note

Text

Honeywell TC500A-N Commercial Thermostat Wireless AHU^RTU_PartsHnC

The Honeywell TC500A-N is a wireless communication thermostat designed to seamlessly integrate with commercial HVAC systems like air handling units (AHUs) and rooftop units (RTUs). This advanced thermostat acts as the brain of your heating and cooling, offering precise temperature control and flexible configuration options. Whether you manage a conventional or heat pump system, the TC500A-N adapts to your needs. It supports modulating heating and cooling, ensuring efficient operation and optimal comfort. Plus, its intuitive user interface simplifies adjustments for occupants and facility managers alike. But the benefits extend beyond basic control.

#wirelessthermostat#TC500A-N#Honeywell#PartsHnC#PartsHnCBuzz#HVACParts#FurnaceParts#AirConditionerParts

0 notes

Text

Data Concentrator

Data Concentrator can Receive the data on Wireless Bridge/ Network, Convert Wireless Signal into RS-485/ TCP-IP Format, Point to Communication, Easily connected to SCADA and RTU Panel

0 notes

Text

Intelligent Remote Terminal Unit (RTU) Market - Forecast and Analysis, 2023-2027

Originally published on Technavio: Intelligent Remote Terminal Unit (RTU) Market by Deployment, Type and Geography- Forecast and Analysis 2023-2027

The Intelligent Remote Terminal Unit (RTU) Market is the focus of thorough analysis, centering on deployment methods, types, and geographical factors, with a forecast spanning from 2023 to 2027. This research provides valuable insights into the factors driving market growth and shaping the adoption of intelligent RTUs across different regions.

One crucial aspect of the analysis is the examination of various deployment methods within the intelligent RTU market. These methods may include on-premises deployments, cloud-based solutions, and hybrid approaches. Understanding the advantages and challenges of each deployment method is essential for predicting market trends and identifying opportunities for growth and innovation.

Furthermore, the study explores the different types of intelligent RTUs available in the market. These may include wired RTUs, wireless RTUs, and hybrid RTUs, each offering unique functionalities suited to specific applications and environments. The forecast delves into the adoption trends of these RTU types, providing insights into the factors influencing market demand and growth trajectories.

Geographically, the analysis covers key regions including North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. Each region presents unique opportunities and challenges for the intelligent RTU market, influenced by factors such as regulatory frameworks, technological advancements, and infrastructure development. The forecast examines regional trends in market size, growth prospects, and competitive landscape, offering valuable insights for stakeholders seeking to expand their presence in specific geographic markets.

The intelligent RTU market is driven by factors such as the growing need for real-time monitoring and control in various industries, including oil and gas, utilities, transportation, and manufacturing. Factors such as the increasing adoption of Industrial Internet of Things (IIoT) technologies, the demand for energy efficiency, and the need for predictive maintenance solutions contribute to market growth. The analysis explores how these factors shape market dynamics and drive innovation in intelligent RTU technologies.

To Learn deeper into this report , View Sample PDF

In conclusion, the intelligent RTU market analysis for the period 2023-2027 provides a comprehensive overview of deployment methods, types, and geographical dynamics. By understanding the factors influencing market trends and growth opportunities, stakeholders can make informed decisions to capitalize on emerging opportunities and drive business success in the rapidly evolving landscape of intelligent RTUs.

For more information please contact.

0 notes

Text

BLIIoT Smart Meter Remote Reading Solution

Background

The smart meter remote reading system is a new IoT technology designed to improve the integrated billing management of water meters and electricity meters. The automatic meter reading method of the intelligent meter reading system can replace the traditional manual meter reading. The smart water meter remote meter reading system can use wired technology or wireless technology to report and collect users' water and electricity data in real time, achieving remote monitoring, centralized data storage and unified management.

Smart Meter Remote Reading Solution

The smart meter remote meter reading system is divided into comprehensive application layer, data management layer and data collection layer. The principle of the data collection layer is to collect data from each meter through transmission media (such as RS485 interface, power supply, 4G,Ethernet, etc.). According to the meter reading task of the management center, the data of each meter is automatically collected through Remote Monitoring RTU S475.

The concentrator RTU S475 can transmit data to the data server via Ethernet or GPRS. The data server is a smart meter remote reading system that can perform data processing, classification, and screening, saving manual work.

Advantage

1.RTU S475 connects to the smart meter through RS485 or RS232 interface, and uploads data through Ethernet or 4G.

2. RTU S475 supports Modbus RTU, Modbus TCP and MQTT protocols, and supports active reporting mode and polling mode.

3. RTU S475 can be connected to Alibaba Cloud, Huawei Cloud, BaRe Cloud, SCADA and third-party cloud platforms.

4. Users can receive and monitor real-time water meter data through the cloud or SCADA large screen

In Conclusion

To sum up, Remote Monitoring RTU S475 plays a key role in remote reading of smart water, electricity and gas meters. Its application not only improves the efficiency of public utility management, but also provides feasibility and convenience for the scientific utilization of resources.

More information about BLIIoT Remote Monitoring RTU S475: https://www.bliiot.com/remote-terminal-units-p00178p1.html

0 notes