#WorkshopSetup

Explore tagged Tumblr posts

Text

Updating organization at the Adabench for the New Year This coming year, we wanted to update our storage and organization: with about 700 original designs, a couple dozen in progress, and thousands of items in the shop, it's hard to keep track of all the components and devboards we need to test various combinations. Historically, we've used double-sided totes

, which are good, but the double-sidedness is a bit annoying, or the little divider boxes for small breakouts

, and snap-top boxes for SMT components

But all these cases were sort of swimming around, and it was getting unwieldy. We're going to try to use the large IKEA ALEX drawers

- we like them cause they're wide and thin - and maybe use something like gridfinity

to make a flat storage surface so we can quickly find any PCB or part we need.

#organizationgoals#newyearupdate#storagesolutions#adabench#electronicsworkshop#ikeaalex#gridfinity#pcbdesign#electronicsorganization#diysetup#makerspace#storageideas#workspacegoals#creativesolutions#tidyworkspace#storagehacks#diyorganization#electronicsprojects#smallpartsstorage#modularstorage#ikeahack#makersgonnamake#storagetips#workshopsetup#designworkflow#electronicslab#tidyup#workspaceinspo#makerslife#organizedworkshop

18 notes

·

View notes

Text

Milwaukee PACKOUT Organizer: Rugged, Modular Storage for the Jobsite and Beyond

When you need tool storage that’s tough, portable, and totally customizable, the Milwaukee PACKOUT Organizer system delivers. Designed for professionals who demand jobsite durability and efficient organization, PACKOUT offers modular versatility unlike anything else on the market.

What Makes Milwaukee PACKOUT Stand Out?

Milwaukee’s PACKOUT system isn’t just storage—it’s a productivity solution. Key features include:

Modular design: Stack and connect toolboxes, totes, drawers, and organizers

Impact-resistant polymer construction: Built to survive drops, spills, and tough jobsite conditions

IP65 rated weather seal: Protects against water and debris

Customizable internal dividers: Configure for fasteners, hand tools, and accessories

Wide compatibility: Works seamlessly with all PACKOUT components

Popular PACKOUT Organizer Options

1. PACKOUT Compact Organizer (Model 48-22-8435)

5 removable bins for fasteners and small tools

Transparent lid keeps items visible

Reinforced latches and hinges

2. PACKOUT Large Tool Box (Model 48-22-8425)

Ideal base unit for heavy tools

Supports vertical stacking

Industrial-grade latches and handle

3. PACKOUT Rolling Tool Box (Model 48-22-8426)

All-terrain wheels and extendable handle

Transport an entire stack with ease

4. PACKOUT Drawer Tool Boxes

Available in 2-drawer and 3-drawer versions

Locking drawers for added security

Stay in place even when stacked

Benefits for Pros and DIYers

Stay organized: Spend less time searching, more time working

Expand over time: Add new components as your tool collection grows

Easy transport: From workshop to truck to jobsite

Custom foam inserts: Protect sensitive tools like meters or power heads

Who Uses Milwaukee PACKOUT?

Electricians: Organize wire nuts, meters, drivers, and more

Plumbers: Store pipe fittings, sealants, and PEX tools

HVAC techs: Keep tubing benders, analyzers, and screws in one place

Woodworkers: Separate router bits, sandpaper, clamps, and jigs

FAQ: Milwaukee PACKOUT Organizer

Q: Is PACKOUT waterproof?

A: PACKOUT components are IP65 rated��resistant to water and dust, but not submersible.

Q: Can I mount PACKOUT on walls or in vans?

A: Yes, Milwaukee offers a PACKOUT mounting plate and racking systems for shop or vehicle setups.

Q: Are PACKOUT boxes heavy?

A: No. Even when fully loaded, they’re designed for ergonomic handling and transport.

Q: Is PACKOUT compatible with other brands?

A: The locking system is proprietary to Milwaukee, but the open layout works well with non-Milwaukee tools.

Q: Where can I buy PACKOUT in the USA and Canada?

A: Tool Academy, Home Depot, and Amazon all offer full PACKOUT selections with fast shipping.

About the Author

As a trades professional and gear tester, I’ve used nearly every tool storage system out there. PACKOUT wins for durability, convenience, and expandability—it keeps my tools protected and ready at every jobsite.

#MilwaukeePACKOUT#PACKOUTOrganizer#MilwaukeeToolStorage#PACKOUTSystem#MilwaukeeStorage#PACKOUTSetup#MilwaukeePACKOUTLife#PACKOUTBuild#PACKOUTNation#PACKOUTCrush#ToolStorage#ToolboxGoals#ToolOrganization#WorkshopSetup#ToolLife#GarageOrganization#ProTools#ToolLover#WorkshopInspo#ToolJunkie#MilwaukeeToolsUSA#MilwaukeeToolsCanada#ToolStorageUSA#CanadianDIY#USAToolHeads#ToolTok#ToolTime#DIYToolHack#EverydayCarry#TradesmanLife

0 notes

Text

How to Select the Best Power Tools for Your Workshop

Read on: https://safatcotrading.com/how-to-select-the-best-power-tools-for-your-workshop/

0 notes

Text

The Hoists That Keep Our Shop Moving

In any fabrication or industrial environment, the equipment you choose isn’t just about specs, it’s about reliability, safety, and long-term performance. Over the years, we’ve used a range of hoists in our shop, some we’ve kept, some we’ve retired, and a few have become permanent fixtures in our day-to-day work.

Here are the hoists we rely on the most, along with our honest thoughts on each:

R&M Spacemaster SX Wire Rope Hoist

This has become one of our most trusted hoists. It's well-engineered, doesn’t require a lot of maintenance, and has a compact trolley design that fits seamlessly into our existing framework. The control is smooth, and load stability is top-notch. It's definitely earned its place.

CM Lodestar Electric Chain Hoist

CM’s Lodestar is a classic for a reason. We’ve used it for everything from lifting structural steel to positioning smaller assemblies. It’s rugged, parts are easy to find, and it just works. No frills, just dependable performance.

Harrington NER Electric Chain Hoist

Harrington brings some nice refinements, we especially like the dual speed and quiet operation. It’s a great option when precision is key or when working indoors where noise matters more.

Konecranes CLX Chain Hoist

We use this in tighter areas of the shop where space is limited. It’s small but strong and has a user-friendly interface. Konecranes does a great job blending power and ergonomics with this one.

Demag DCS Pro Chain Hoist

This hoist gives you a more refined lift , especially helpful for sensitive or more technical projects. The variable speed and quick-response controls are what make it stand out. We don't use it for everything, but for the right job, it's a game changer.

#fabricationlife#industrialequipment#hoists#overheadcrane#rmhoist#manufacturingtools#workshopsetup#heavylifting#shopgear#engineeringtools#cmhoist#harringtonhoists#konecranes#demaghoist#materialhandling#shoplife#toolreview#machineryblog

0 notes

Text

Choosing the Right Oil Drain Pan: A Must-Have for Maintenance and Clean Workspaces

Whether you’re managing a professional auto repair shop, running a busy manufacturing plant, or maintaining your own vehicle at home, an oil drain pan is one of the most essential tools in your workspace. Though it may seem like a basic item, choosing the right oil drain pan can significantly affect the efficiency, cleanliness, and safety of your maintenance routines.

In this guide, we’ll explore everything you need to know about oil drain pans—what they are, the different types available, key features to look for, and how they fit into the larger picture of industrial tools and equipment. We’ll also show you how to buy lubrication equipment online from trusted suppliers who offer reliable and durable solutions for your needs.

What is an Oil Drain Pan?

An oil drain pan is a specially designed container used to collect used engine oil during an oil change or lubrication service. Its primary function is to prevent spills and allow for the safe and easy transfer of oil for recycling or disposal. Drain pans come in various shapes, sizes, and materials depending on the specific use case—whether for automobiles, heavy machinery, or industrial lubrication systems.

Why You Need a Quality Oil Drain Pan

Many overlook the importance of a reliable oil drain pan, often settling for makeshift containers that can leak, spill, or be hard to handle. Here’s why investing in a quality oil drain pan is worth every penny:

Clean and Controlled Oil Changes: A good pan prevents messes, reduces cleanup time, and makes the oil change process seamless.

Safety First: Avoid dangerous spills that can lead to slips and falls.

Environmental Compliance: Proper collection and disposal of used oil is vital for meeting environmental regulations.

Durability: Quality pans last longer and resist damage from hot oil and chemical exposure.

Types of Oil Drain Pans

Not all oil drain pans are created equal. Here are some of the most commonly used types, each suited for different applications:

1. Basic Oil Drain Pans

These are simple pans with open tops and no additional features. Ideal for DIYers and small garages, they usually hold 5–10 quarts of oil and are made from durable plastic or metal.

2. Closed Oil Drain Containers

Featuring a sealed container with a pour spout and a large opening, these pans reduce the chance of spills when transporting oil for disposal. They are a favorite in automotive shops due to their portability and clean design.

3. Low-Profile Drain Pans

Used primarily in industrial settings or under heavy machinery, these pans can slide beneath low-clearance equipment. They are wide, flat, and often come with wheels for easy mobility.

4. Truck and Heavy-Duty Oil Drain Pans

For those working with large vehicles like trucks or agricultural equipment, high-capacity pans—often holding 20+ gallons—are available. These often come with features like built-in pumps, strainers, and reinforced structures to handle high volumes.

Key Features to Look For

When shopping for an oil drain pan, consider the following factors to ensure you’re investing in a tool that matches your needs:

1. Capacity

Choose a pan that holds more oil than your engine’s capacity to avoid overflow. Larger operations may need 15–25-gallon pans, while personal use might only require 5 quarts.

2. Material

High-density polyethylene (HDPE) is popular for its resistance to chemicals and hot fluids. Steel pans are highly durable and often used in industrial applications.

3. Portability

Handles, wheels, and pour spouts make transporting and disposing of oil easier, especially for those managing multiple maintenance bays.

4. Ease of Cleaning

Look for a smooth interior surface to prevent oil buildup. Some models also include filters or grates to catch debris before it settles in the pan.

5. Spill-Proof Design

Lids, seals, and secure caps help prevent oil from spilling during movement, ensuring a safer and cleaner workspace.

Integrating Oil Drain Pans into Industrial Maintenance

In larger operations, oil drain pans are just one component in a comprehensive lubrication and maintenance system. They are used in tandem with oil dispensers, pumps, filters, and meters—many of which are part of broader industrial tools and equipment portfolios.

From mobile drain carts to wall-mounted drain tanks, these setups help facilities stay organized and compliant with health and environmental standards. This is especially crucial in environments like power plants, manufacturing lines, and fleet maintenance garages where routine servicing is non-negotiable.

Where to Buy Oil Drain Pans and Lubrication Equipment

With so many options available, the easiest and most efficient way to get the right oil drain pan is to buy lubrication equipment online. Reputable online stores offer detailed product specifications, customer reviews, and a wider selection than most physical retailers.

When purchasing online, look for suppliers that specialize in industrial tools and equipment. They often provide technical support, volume pricing, and bulk ordering options for commercial clients. Brands that focus exclusively on lubrication technology typically offer better durability, ergonomic design, and accessories that enhance workflow.

Tips for Safe and Responsible Use

To get the most out of your oil drain pan, always follow these best practices:

Always wear gloves when handling used oil.

Dispose of oil properly at recycling centers or through your waste disposal contractor.

Clean the pan after each use to prolong its life.

Store in a cool, dry area to prevent degradation of materials.

Label and segregate oil types to avoid contamination.

Final Thoughts

An oil drain pan may seem like a simple tool, but it plays a vital role in keeping maintenance routines clean, safe, and efficient. From home garages to heavy-duty industrial operations, the right oil drain pan—combined with complementary industrial tools and equipment—makes all the difference in how smoothly your maintenance process runs.

If you're ready to upgrade your setup, don't settle for generic tools. Instead, buy lubrication equipment online from trusted suppliers who specialize in providing professional-grade solutions. With the right tools in your arsenal, every oil change becomes quicker, cleaner, and safer—for your workspace and the environment.

#OilDrainPan#IndustrialTools#CarMaintenance#AutoRepairTips#GarageTools#BuyToolsOnline#LubricationEquipment#WorkshopSetup#OilChangeTime#MechanicalTools#MechanicLife#VehicleDIY#ToolOrganization

0 notes

Text

Steps to Customize Your Milwaukee Packout Setup

Introduction

Customizing your Milwaukee Packout setup can transform your work efficiency, organization, and overall productivity. Whether you’re a professional tradesperson or a DIY enthusiast, a tailored Packout system ensures your tools are always within reach and well-organized. This guide will walk you through each step to create a setup that perfectly fits your needs.

What is Milwaukee Packout?

Milwaukee Packout is a modular storage system designed to provide customizable and portable tool organization solutions. With various components like tool boxes, organizers, and totes, the Packout system offers endless possibilities for creating a storage setup that suits your specific requirements.

Benefits of Customizing Your Milwaukee Packout

Customizing your Milwaukee Packout setup brings numerous benefits:

Efficiency: Quick access to tools saves time.

Organization: Keeps tools systematically arranged.

Portability: Easy to transport between job sites.

Protection: Provides secure storage to prevent tool damage.

Professionalism: A well-organized setup enhances your professional image.

Understanding the Components of Milwaukee Packout

Overview of the Components

Milwaukee Packout includes various components that can be mixed and matched to create a tailored storage solution.

Tool Boxes

Packout tool boxes come in different sizes, each designed to hold a variety of tools and accessories securely.

Organizers

Organizers feature compartments for small parts and tools, helping to keep everything in its place.

Totes and Bags

Packout totes and bags provide flexible storage options for larger tools and equipment, offering easy access and portability.

Steps to Plan Your Custom Milwaukee Packout Setup

Assessing Your Needs

Start by evaluating the types of tools you have and how often you use them. This assessment will help you determine the necessary components for your setup.

Planning Your Layout

Design a layout that maximizes space and accessibility. Consider the order in which you use your tools and arrange them accordingly.

Selecting the Right Components

Choose the Packout components that best fit your needs. Think about the size, type, and number of tools you need to store.

Tools and Accessories for Customizing Your Packout

Essential Tools

Basic tools like screwdrivers, pliers, and wrenches are necessary for assembling and customizing your Packout system.

Custom Inserts and Foam

Custom foam inserts can be cut to fit specific tools, providing extra protection and organization.

Labels and Stickers

Using labels and stickers helps to quickly identify tools and parts, enhancing overall organization.

Creating a Modular Setup

Benefits of Modularity

A modular setup allows you to easily adjust and expand your storage as your tool collection grows.

Examples of Modular Configurations

Consider configurations like stacked tool boxes for compact storage or side-by-side arrangements for easy access.

Organizing Your Tools Efficiently

Tool Categorization

Group similar tools together to streamline your workflow and make finding tools easier.

Accessibility and Convenience

Place frequently used tools in easily accessible locations to save time during tasks.

Maintaining Your Milwaukee Packout Setup

Regular Cleaning

Keep your Packout components clean to ensure they function properly and look professional.

Inspecting for Damage

Regularly check for any damage or wear and tear, and replace or repair components as needed.

Updating Your Setup

As your tool collection evolves, update your setup to accommodate new tools and improve organization.

Advanced Customization Tips

Adding Tech Features

Incorporate tech features like LED lighting or battery charging stations to enhance your setup.

Custom Paint and Finishes

Personalize your Packout with custom paint or finishes to make it uniquely yours.

Common Mistakes to Avoid

Overloading Components

Avoid overloading your Packout components, which can cause damage and reduce mobility.

Ignoring Weight Distribution

Ensure even weight distribution to maintain balance and prevent tipping.

Cost-Effective Customization Strategies

DIY Custom Inserts

Create your own custom inserts using foam or other materials for a budget-friendly solution.

Using Recycled Materials

Incorporate recycled materials to save money and reduce environmental impact.

Case Studies: Successful Milwaukee Packout Customizations

Electrician’s Setup

Explore how electricians customize their Packout setups to keep their tools organized and accessible.

Carpenter’s Setup

Learn from carpenters who have tailored their Packout systems for maximum efficiency and convenience.

Frequently Asked Questions About Milwaukee Packout

Q. How do I start customizing my Milwaukee Packout setup?

A. Begin by assessing your tools and planning a layout that fits your workflow. Select the appropriate Packout components and start organizing.

Q. What are the essential components of a Milwaukee Packout system?

A. Essential components include tool boxes, organizers, totes, and bags. Custom inserts and labels can further enhance organization.

Q. Can I expand my Packout setup over time?

A. Yes, the modular design of the Milwaukee Packout system allows you to add or rearrange components as your needs change.

Q. How can I ensure my tools are protected in the Packout system?

A. Use custom foam inserts and regularly inspect your Packout for damage to ensure your tools are secure and protected.

Q. What are some advanced customization options for my Packout setup?

A. Consider adding tech features like LED lighting or custom paint finishes to personalize your setup further.

Q. Is it possible to create a cost-effective Packout setup?

A. Yes, using DIY inserts and recycled materials can help reduce costs while still providing a customized storage solution.

Conclusion

Customizing your Milwaukee Packout setup can significantly improve your tool organization, efficiency, and overall work experience. By following the steps outlined in this guide, you can create a tailored setup that meets your specific needs and enhances your productivity. Keep your Packout system updated and maintained to ensure it continues to serve you well for years to come.

#MilwaukeePackout#ToolStorage#MilwaukeeTools#PackoutSystem#ToolOrganization#ModularStorage#WorkshopSetup#ToolBox#JobsiteReady#ToolLovers#OrganizedTools#StorageSolutions#ToolEnthusiast#EfficientWorkspaces#ToolManagement

0 notes

Text

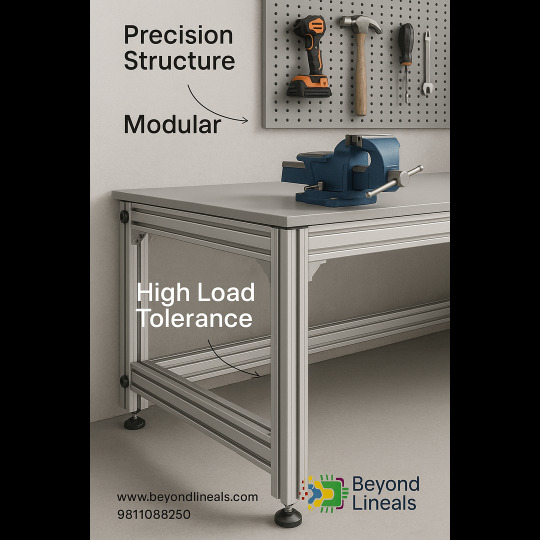

#Backbone of #Precision Our #extruded #aluminum #profiles keep your #workstations #sturdy & #modular With #easy #assembly & #unbeatable #strength-to-weight ratio they’re #trusted base in every #professional #setup 📌#Used in: #Modular #workbenches #mounting #arms #tool #storage ✅ High load-bearing strength ✅ Configurable and anodized finishes

www.beyondlineals.com

www.instagram.com/beyondlineals/

www.x.com/Beyondlineals

www.facebook.com/beyondlineals/

www.youtube.com/@BeyondLineals

www.threads.net/@beyondlineals

www.in.pinterest.com/Beyondlineals

📞 Beyond Lineals 🌐 www.beyondlineals.com | 📧 [email protected] | 📱 +91 9811088250

#ModularWorkbench #AluminumExtrusions #WorkshopSetup #BuiltForWork #HeavyDutySupport #SmartManufacturing #TSlotFrame #PrecisionEngineering #LabFurniture #StrongAndLight

2 notes

·

View notes

Photo

Hey guys, I found a free e-book on setting up a workshop in 13 Steps... https://bit.ly/SettingUpaWorkshop

1 note

·

View note

Photo

Machines are set up and I'm ready to plane some maple. New project - I'm making a computer desk. Since I got my second dust collector from @bucktoolsworkshop I can do this kind of work indoors. Wouldn't use it for sanding but that bag catches all the shavings from the planner. It's much quieter than I thought too! #dustcollection #dustcollector #workshop #workshoplife #woodshop #workshopsetup #planerthicknesser #maple #wood #furnituremaking #workbench (at Alexandria, Virginia) https://www.instagram.com/p/B4-KpXtgYW8/?igshid=gkk1iiohevpt

#dustcollection#dustcollector#workshop#workshoplife#woodshop#workshopsetup#planerthicknesser#maple#wood#furnituremaking#workbench

0 notes

Text

Ladyada's desk gets a scope cart

We've always wanted a portable scope cart

for our workspace to have our test equipment either by the desk for firmware work or at the soldering worktable for rework debugging. At our new office, we finally have space for one! We picked up this 'dental cart'

- It is not super fancy, but it is metal, and it came together fairly easily. We like the mini top shelf for the scope and the second shelf underneath for the power supply and electronic load. The drawer can hold leads or probes. We've locked it next to our desk so we have more desktop space, and it's easy to peek over as we bring up new boards like the metro RP2350

We'll also get the VGA output into our video streaming setup to show off signals we're working on.

#ladyada#scopecart#electronicsworkbench#testequipment#firmwaredevelopment#solderingstation#debuggingtools#workspaceorganization#dentalcart#oscilloscope#powersupply#electronicsload#makerspace#diyengineering#electronicsenthusiast#portablecart#workspacetools#hardwaredebugging#makersmovement#electronicsgear#workshopsetup#workspaceupgrade#debuggingstation#signalprocessing#vgaoutput#metroRP2350#techbench#hardwareprojects#videostreaming#electronicsprojects

12 notes

·

View notes

Photo

#TBT to my Envelope Addressing Session: Holiday edition 2017! This year it comes with new materials and something very useful that will help you TONS to create wonderful envelopes! Link to registration in profile or here: https://ift.tt/2ppyfE8 #calligraphyworkshop #workshopsetup https://ift.tt/2MRKYbW

0 notes

Text

Essential Power Tools for Beginners: What You Need to Get Started

Read on: https://safatcotrading.com/essential-power-tools-for-beginners-what-you-need-to-get-started/

0 notes