#advanced pcb assembly

Explore tagged Tumblr posts

Text

Navigating the Future of Electronics with Rigid-Flex and Taconic PCB Manufacturers

Today’s Printed Circuit Boards (PCBs) are much more flexible and advanced than the first rigid versions. Compact devices with great capabilities and multiple features have earned popularity in the electronics industry, leading to the rise of Rigid-Flex PCBs and Taconic PCBs. The use of these technologies enables unique designs, improves how long the device works, and maintains good electricity flow. Rigid-flex PCB Manufacturers can move and also keep their form, similar to how rigid boards function. They particularly shine in high-speed or RF and microwave applications. Dependable and effective products rely greatly on what electronics do.

Rigid-Flex PCBs: Hybrid Structure with High Functionality

Rigid-Flex PCBs take attributes from both stiff and flexible PCBs and merge them into one board. As a result, rigid and flexible boards no longer need connectors and cables, letting us make assemblies that are lighter and more space-saving. You can find these boards in smartphones, medical devices used on patients, military systems and aerospace devices. They are suited for use in places that require resistance to vibration and bending due to machines. In manufacturing, various layers are made and bonded together using very accurate methods. Therefore, it is only experienced manufacturing companies that can keep products of constant quality and performance.

Key Advantages of Rigid-Flex PCB Manufacturers

Important benefits of using well-known Rigid-flex PCB Manufacturers are their excellent design aid and advanced methodologies. They depend on laser direct imaging for precise work and optical inspection that finds problems in the early stage. Tests using temperature fluctuation and electrical overload guarantee that the product will function in any extreme condition. Manufacturers typically boost efficiency by assisting with design changes that lower the number of components and simplify assembly. In addition, they guarantee that flexible circuit boards meet all IPC standards for quality. Because they are involved in developing products and moving them into mass production, they help make the process more efficient.

Taconic PCBs: High-Frequency Performance Excellence

Taconic PCB Manufacturers are produced from proprietary PTFE-based laminates designed by Taconic with low dielectric loss and thermal stability. These boards are the preferred option for RF, microwave, and high-speed digital designs. They are most prevalent in satellite communications, radar systems, 5G base stations, and aerospace communication modules. Taconic laminates have low signal attenuation and superior dimensional stability. They exhibit moisture resistance as well as heat tolerance, which makes them dependable in extreme working environments. Production using these laminates demands proficiency in drilling, plating, and multilayer bonding because of their special properties.

What to Expect from a Taconic PCB Manufacturers

The best Taconic PCB Manufacturers must possess extensive experience in working with high-frequency laminate material. It involves strict impedance control, surface preparation, and low-loss transmission line engineering. Cleanroom facilities, specially designed PTFE-compatible equipment, and precise lamination procedures are necessary for high-quality output. The producers may perform RF testing and thermal profiling to ensure circuit integrity. They also guide customers on stack-up selection as well as PCB layout according to end-use frequency requirements. By maintaining compliance with IPC and MIL-spec specifications, these companies ensure the critical applications' performance and safety.

Comparing Rigid-Flex and Taconic PCBs

Although both are sophisticated PCBs, Rigid-Flex and Taconic PCBs are for different technical applications. Rigid-Flex is prized for mechanical flexibility, whereas Taconic leads for signal transmission at high speeds. Rigid-Flex boards simplify systems and minimize space utilization in cramped enclosures, while Taconic boards maintain signal purity in communication networks. The components and manufacturing methods are quite different, as are the final-use applications. The two are chosen based on physical space, frequency range, and exposure to the environment. Designers will often talk to both varieties of manufacturers to match their circuit requirements with the appropriate solution.

Conclusion

As innovation speeds up in electronics, the need for Rigid-flex PCB Manufacturers and Taconic PCBs keeps increasing. Such technologies facilitate the development of lighter, faster, and more efficient devices across industries. With increasingly sophisticated design challenges, collaborating with an experienced manufacturer is crucial. BS Interconn Hong Kong Co., LIMITED differentiates itself by providing quality-oriented, customer-centric PCB manufacturing services. Whether you're creating a next-generation medical wearable or a state-of-the-art RF device, selecting a reliable Rigid-Flex or Taconic PCB producer guarantees that your product will outperform and outlast the competition.

#Rigid-flex PCB Manufacturers#Taconic PCB Manufacturers#flexible circuit boards#high-frequency PCB#RF PCB solutions#microwave PCBs#PTFE laminates#hybrid PCB design#aerospace PCB#medical device PCBs#5G PCB manufacturer#signal integrity PCB#low dielectric PCB#high-speed PCB#multilayer PCB assembly#IPC compliant PCBs#MIL-spec PCBs#advanced PCB manufacturing#Taconic laminate PCB#Rigid-Flex technology

1 note

·

View note

Note

How would one go about learning how to make something like the cactus?

Like prerequisites, older code, hardware stuff, etc.

The main prerequisites I can think of are being heavily interested in vintage computers, and having the drive to try and fail and then try again.

I started with building Grant Searle's design, borrowing from other working designs as I went. However, for the front panel? That's alot of time designing, learning, simulating in Logisim, and testing with physical logic gates to produce something 100% original and of my own design. I imagine most folks won't want to go to the trouble of designing an entire front panel state machine like I did.

The good news is that there are way more kits that can help teach the necessary skills than ever before! Most notably, Ben Eater's 6502 kit is a really great way to learn many of the things that I've put into practice here. He has a whole youtube video series associated with it, walking through concepts, construction, programming, etc. step by step. Even if you don't build one of his kits, watching them is an informative process. *I* learned alot, even after having built the Cactus.

If you're going the Z80 direction, the RC2014 series of kits can teach you plenty. There's also glitchworks kits in a few processor types, but those tend to be a bit more for the advanced user. There's the 1802 Membership Card but that's small and not really expandable. I could be here all day listing kits that can help teach and build up experience.

I should mention that I have a computer science degree in my back pocket, but learning logic gates or using assembly was only lightly touched on in the course of my studies. Most of the programming I do involved messing around in BASIC anyway.

I really didn't have a game plan for some of it, so alot of my learning process was trial and error. Alot of errors, in fact. Still making them, and learning from them. I also took the harder route to construction, since I didn't know how to use EDA tools for designing PCBs like KiCAD or Altium or Eagle (don't use Fritzing for the love of fuck).

Oh, one other thing I can recommend: reading through contemporary 1970s computing magazines like Byte (check the internet archive for back issues). There are all sorts of cool projects and ideas present that can really guide you. It doesn't hurt to have a copy of Don Lancaster's TTL Cookbook on hand (I think it's in PDF form online).

Finding a community to help you out is also a great idea. Even back in the 1970s, many folks who jump-started the home computer revolution had the Homebrew Computer Club to help them out. Community meetings to bounce ideas off of, and help one another through debugging are essential in my book -- you don't have to work in a vacuum. I've got a few places I've asked for help, most notably the Retrotech Crew discord server. I've had the benefit of friends who also have homebrewed designs like @techav, who have inspired me with their ideas, but helped me out with mine. In turn, as I've learned, I've been able to help out others.

Hopefully that answers your question. Keep 'em coming!

44 notes

·

View notes

Text

“1128–8-AL: The Sorcerer’s Spacer of Circuit Realms”

Chapter 1: The Sorting Hat of Hardware

The 1128–8-AL is no mere Muggle spacer. Forged from goblin-sourced aluminum and imbued with MIL-SPEC enchantments, this standoff operates under Class 1 precision — a mastery even Ravenclaw’s lost diadem would covet. Its core? A ±0.005" tolerance, sharper than the edge of Godric Gryffindor’s sword.

Why it outshines the common cauldrons:

Plastic Standoffs: Fragile as a Cornish Pixie’s teacup, their load capacity crumbles faster than a vanishing cabinet.

Steel Rivals: Clumsy as Hagrid’s motorcycle, their weight drags down assemblies like a Dementor’s embrace.

Chapter 2: The Triwizard Trials of 1128–8-AL

1. Defending the Chamber of Circuits (Aerospace): When avionics shudder like the Whomping Willow in a storm, the 1128–8-AL casts a Shield Charm. Mount it in satellites or fighter jets to withstand vibrations fiercer than a Blast-Ended Skrewt’s tantrum.

2. Healing at St. Mungo’s (Medical Devices): Inside MRI machines and surgical bots, this spacer channels precision gentler than a Skele-Gro potion. Survives sterilization harsher than a Hungarian Horntail’s breath.

The Marauder’s Map of Specs

Metric 1128–8-AL Muggle Alternatives Material Goblin-grade aluminum (MIL-DTL-55181) Troll-forged steel / Pixie-dust plastic Load Capacity 500 lbs (≈ a Hungarian Horntail) 200 lbs (≈ a flobberworm) Temperature Resistance -54°C to +121°C (Dementor-proof) Melts faster than a chocolate frog

The Dark Arts (Limitations)

No Portkey Function: Cannot teleport your PCB to Mars (yet).

Too Subtle for Slytherin: Lacks the flash of a Golden Snitch.

The Prophecy of Precision

Hogwarts 2.0 (Smart Factories): Paired with Arithmancy-grade AI, 1128–8-ALs predict assembly failures before Trelawney mutters “dire omens.”

Order of the Phoenix (Space Colonies): NASA seeks lunar-grade variants for Mars rovers — because even Martians need protection from Acromantula-sized vibrations.

Epilogue: A Spellbinding Choice To dismiss the 1128–8-AL is to let your circuits tumble like the Tower of Gringotts. As Dumbledore wisely said: “It does not do to dwell on poorly spaced assemblies, and forget to live.”

References

Advanced Runes of Hardware Standards (Ministry of Engineering, 2024)

The Tales of Beedle the Machinist (Ilvermorny Press)

Hogwarts: A History of Enchanted Assemblies (Weasleys’ Wizard Wheezes Editions)

1 note

·

View note

Text

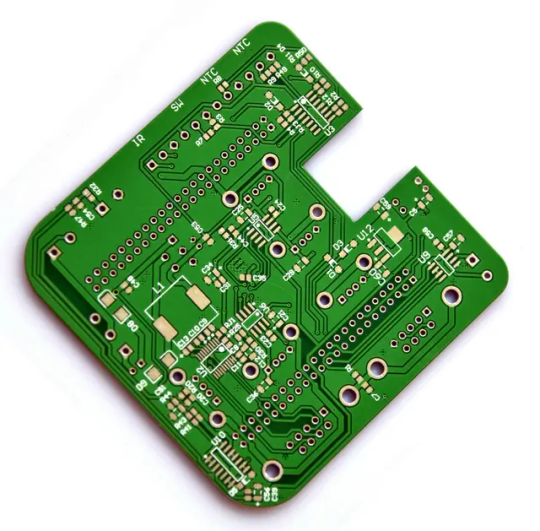

PCB Manufacturing-PCB Assembly-Hitech Circuits

Hitech Circuits is a lеаding PCB Manufacturing & PCB Assembly company with more than 20 years experience in the electronics manufacturing industry. We focus on PCB Design, PCB Layout, Circuit board fabrication, Turnkey PCB assembly, and electronic parts sourcing services.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

We offer a full range of Electronic manufacturing services.

-LED PCB

-Heavy Copper PCB

-Multilayer PCB

-HDI PCB

-Flexible PCB

-Rigid-Flex PCB

-High Speed PCB

-High Frequency PCB

-PCB Reverse Engineering

7 notes

·

View notes

Text

Understanding the Functionality of Samsung Refrigerator PCB Main Assembly

Samsung refrigerators have become essential appliances in modern households, offering innovative features and advanced technologies to ensure food preservation and convenience. The (Printed Circuit Board) PCB Main Assembly serves as the brain of the refrigerator, coordinating various functions and ensuring optimal performance.

Components of the Refrigerator PCB Main Assembly

The Refrigerator PCB Main Assembly consists of several essential components, each playing a crucial role in the refrigerator's operation.

Microcontroller: It is the central processing unit (CPU) and the computer performs programmed instructions to coordinate communication between the components.

Sensors: The ambient parameters (temperature, humidity, door status) supply critical information for regulation.

Relays: You control the flow of electricity to the compressor, fan motors, and defrost heater.

Capacitors: It will help you store the electrical energy and help to regulate voltage, and guarantee that the PCB is operating reliably.

Resistors: Protect sensitive components from harm by limiting the flow of electricity across certain circuits.

Diodes: Allow current to flow exclusively in one direction to avoid reverse polarity and safeguard components from damage.

Connectors: Facilitate electrical connections between the PCB and other refrigerator components to ensure seamless integration.

Working Principle PCB Main Assembly

The PCB Main Assembly operates on a set of programmed instructions that determine its behavior depending on sensor input and user command. The micro controller continuously monitors sensor input such as the reading of the temperature from the refrigerator compartment, and freezer. The microcontroller controls the transition of the compressor on, or off or the speed of the fan and also the defrost cycles based on the sensor data as to how to keep the temperature and humidity at the optimal level. In addition to the other refrigerator components, for example, display panel and user interface, the PCB Main Assembly provides feedback and enables users’’ interaction. The PCB Main Assembly incorporates safety features of overload protection and temperature sensors to protect the refrigerator from damage and to protect the user.

Communication Protocols

Data can be communicated to other components through microcontrollers by communication protocols like UART (Universal Asynchronous Receiver Transmitter), SPI (Serial Peripheral Interface), and I2C (Inter Integrated Circuit).

UART is used to transfer real-time data from a microcontroller to external devices like display panels and temperature sensors.

There is a power of communication SPI and I2C for the communication of integrated circuits associated with the PCB Main Assembly for efficient data transfer and synchronization between components.

Troubleshooting and Maintenance

Common issues with the Samsung Refrigerator PCB Main Assembly include sensor failures, relay malfunctions, and power supply issues, which can affect the refrigerator's performance.

To solve PCB Main Assembly problems, we can use diagnostic methods, like running self-tests and checking the error code.

The assembly can stay longer depending on the main, such as cleaning dust and debris from the PCB and securing appropriate ventilation.

The PCB Main Assembly is an important component of the Samsung refrigerator systems since it organizes several functions to contribute to the overall efficiency of the refrigerator and food preservation. Fore-knowledge of the PCB Main Assembly and the way it is constructed can assist users in likely managing problems in their fridges.

2 notes

·

View notes

Text

The Vital Role of Solder Paste Printers in Electronics Manufacturing

In the rapidly evolving world of electronics manufacturing, solder paste printers have become indispensable tools that enhance efficiency and precision in the assembly of printed circuit boards (PCBs). These machines automate the process of applying solder paste, a mixture of tiny solder balls and flux, to specific areas on a PCB, ensuring that components are securely attached during the soldering process.

What Makes Solder Paste Printers Essential?

Efficiency and Speed: One of the primary advantages of solder paste printers is their ability to significantly increase production speed. By automating the paste application, manufacturers can achieve higher throughput, which is crucial for meeting tight production schedules. This increased efficiency not only accelerates the assembly process but also allows for the scaling of production to meet growing demand.

Precision and Accuracy: Solder paste printers are designed to apply solder paste with high precision. This accuracy is vital in electronics manufacturing, where even the slightest misalignment can lead to defects and product failures. Advanced printers utilize sophisticated vision systems to ensure that the paste is applied exactly where it is needed, reducing the risk of errors.

Cost Reduction: Automating the solder paste application process leads to significant cost savings. By minimizing labor costs and reducing material waste, manufacturers can improve their profit margins. Additionally, the consistency provided by these machines helps to lower the rate of defects, further contributing to cost efficiency.

Quality Control: Modern solder paste printers often come equipped with advanced inspection systems that monitor the paste application in real time. This capability allows manufacturers to identify and address potential issues early in the production process, ensuring that only high-quality products reach the market.

Flexibility: Many solder paste printers are designed to handle a variety of PCB sizes and configurations. This adaptability is essential for manufacturers who need to respond quickly to changing product demands and market trends.

Innovations Shaping the Future

Recent innovations in solder paste printing technology, such as the integration of AI and IoT capabilities, are revolutionizing the industry. AI allows for data analysis that optimizes printing processes, while IoT connectivity enables remote monitoring and control. These advancements not only enhance efficiency but also contribute to the overall quality of electronic devices.

1 note

·

View note

Text

4 Crucial Things to Consider While Choosing LED PCB Manufacturer

LEDs have revolutionized lighting. At the heart of their brilliance, is the PCB assembly. Electing the right LED PCB assembly manufacturer can make or break your project. This ensures quality, performance, and ultimately, success. So, before you dive into the luminous world of LED PCBs, this article sheds some light on the key factors to consider when making your purchase:

1. Experience Matters: You should choose a manufacturer with proven expertise in LED PCB assembly. The company you choose should have a track record of successful projects similar to yours. Experience means they will understand your specific needs and deliver assemblies that meet or exceed your expectations.

2. Material Matters: The heart of your PCB is its materials. Go for manufacturers

who ensure high-quality FR4 or metal-core PCBs for optimal thermal management and longevity. They must adhere to industry standards for materials and components to guarantee reliability and safety.

3. Thermal Management: LEDs are designed to generate heat, so proper thermal management plays a crucial role. Look for manufacturers who offer solutions like aluminium heat sinks. Their expertise in thermal management can extend the lifespan of your LED PCB and prevent overheating issues.

4. Price is Not Everything: Though cost is important, its priority is not over quality.

The cheapest option might have hidden costs in the long run. Choose a manufacturer who offers budget-friendly pricing while maintaining high-quality standards and reliable service.

If you are looking for an LED PCB manufacturer near you you can count on Hitech Circuits Co., Limited. They have more than 20 years of experience in the electronics manufacturing industry. They have a talented design team who follow advanced manufacturing techniques.

These guidelines help you illuminate your path to finding the perfect LED PCB assembly manufacturer. Your choice has a direct impact on the performance, lifespan, and success of your project.

2 notes

·

View notes

Text

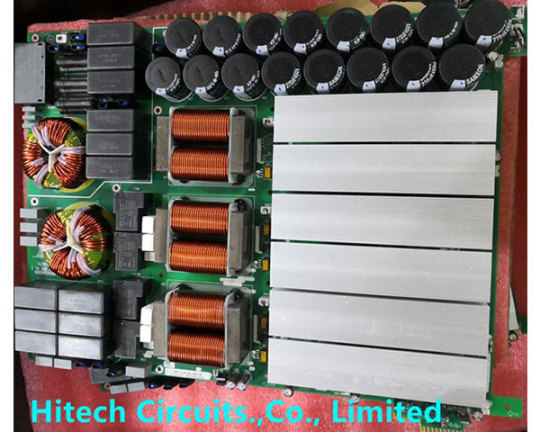

One-stop PCB assembly service and PCB manufacturing supplier -- Hitechpcba

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

5 notes

·

View notes

Text

High Volume PCB Assembly by Hitech Circuits Co., Limited in Shenzhen China

Your leading PCB High Volume PCB Assembly supplier in China

With 15 years of experience and high efficiency in PCB assembly and manufacturing, HITECH CIRCUITS is the perfect source for Big Batch PCB assembly on a limited budget. If you are looking for a large PCBA assembly within your budget, we will be your ideal choice. HITECH CIRCUITS has more than 15 years of experience in the OEM/PCBA manufacturing and assembly of printed circuit boards, advanced production technology and equipment, professional engineers and purchasing team to provide our partners with personalized and complete process solutions. HITECH CIRCUITS’s supply chain services deliver supply chain innovation on demand. We offer a bold, yet proven service solution designed to grow market share and profit. Our innovative approach to managing the supply chain offers a complete business model that delivers the talent and transformative tools necessary to create predictability, reliability, and responsiveness across your entire supply chain. Our practitioners are passionate about supply chains. We have spent a generation understanding, refining and building the best in intelligent supply chains. We provide talent on-demand with expertise in data analytics and strategic technologies that can help you predict, plan and respond more effectively.

Some designs require assemblies in small volume, maybe just prototypes, while others require them in high volume. At SMT house, High Volume, Large Volume, or Big Batch PCB Assembly always refers to printed board assembly projects with quantities more than 5K pieces. HitechPCB has the capability to offer high volume PCB assembly services to meet your requirements of high-quality, competitive price, on-time delivery and smooth communication in any manner of full turnkey, consigned and partial turnkey.

Also, if your business is involved in applications that require high-volume PCB assembly, the company to contact is HitechPCB, because we’re a complete turnkey solution for printed circuit boards assembly, we are ideally suited for bulk PCB assembly orders. Our state-of-the-art equipments, large facility and wide range of highly-qualified experts give us the capability of high-volume PCB assembly of up to 9,000,000.

We are also the perfect source if you’re looking for large-order PCB assembly on a budget. Because of our high level of efficiency and more than 10 years of experience with printed circuit board manufacturing and electronics assembly, we offer large printed circuit board orders at surprisingly competitive prices compared to other PCB manufacturers or PCB assembly companies.

Our large order PCB assembly process starts with a tested and practiced set of workflow guidelines for every phase of the process, from pre-order PCB design consultation with professional veteran engineers to PCB fabrication, components sourcing, PCB assembly, PCBA testing, PCBA inspection, PCBA packing and shipping all under the auspices of a highly-skilled production staff. You can be confident that no matter how many circuit boards you order, you will enjoy fast service, low prices and extremely high quality.

With our excellent after-sales service, 24 sales and technical support team, quick response service, we will be your best Big Batch PCB assembly manufacturer inChina. A wide variety of highly qualified experts

Why choose Hitechpcba Big Batch PCB Assembly

Compared to our competitors, Hitechpcba offers large printed circuit board orders at very competitive prices. The risky big batch PCB assembly process begins with a set of tried and tested workflow guidelines. From ordering PCB design to component procurement, manufacturing, testing, assembly, inspection, shipping and packaging. This is all under the guidance of our highly skilled production staff.

No matter how many boards you order, you'll love the fast response service, low cost, and surprisingly high quality.

Whether you are seeking for product designer, electrical engineer, system integrator, manufacturer, or big batch PCB manufacturing and assembly, low cost big batch PCB housing, electronic assembly services, Hitech Circuits PCB Assembly team will be your perfect choice for big batch PCB assembly plant inChina.

Finding Reliable High Volume PCB Assembly Supplier?

When your design passed the prototyping verification after optimization, DFM and DFT check, it’s time to find a manufacturer or a supplier who has ability to perform high volume PCB manufacturing and assembly for you. HITECH CIRCUITS is a one-stop PCB solution provider, no matter which your design stage is located, we always can help in PCB manufacturing, assembly and design. With both design and manufacturing knowledge, we can feedback some suggestions to modify or change your design on the basis of cost-down without sacrificing the quality and performance. What’s more, if choosing our full turnkey PCB assembly service, we will be responsible of BOM sourcing to reduce your workload. Our approach to conducting high volume printed circuit board assembly is founded on a commitment to the highest possible quality, based on IPC standards and our inner quality control processes. In spirit of those high assembly standards, HITECH CIRCUITS developed excellent high-volume assembly capabilities and manufacturing processes relied on our advanced assembly lines in dust-free workshop.

#PCB assembly #Electronic assembly #China PCB manufacturer

1 note

·

View note

Text

PCBA assembly manufacturing services China

PCBA assembly manufacturing services provides by Hitech provides, from PCBA sample to medium or mass production volume. Our professional SMT factory has advanced equipments help us to offer rich experience in various PCBA manufacturing.

Hitech Group provides PCBA assembly, from PCBA sample to medium MASS production volume. Our professional SMT factory has advanced equipments, such as the world-class stencil printing, SMT chip pick & place, solder reflow, and in-line testing and steel mesh manufacturing. AOI test machine and X-ray testing machines for quality check.

Here below is our main services for PCB assembly manfacturing: Please provice BOM, so we can check and quote electronic parts and assembly prices. Thanks.

Surface Mount Technology

Pin Through-hole Assembly

RoHS

Selective Wave Soldering

Conformal Coating

Complete box build assembly

Inspection Methods

PCBA manufacturing services - HiTech Circuits Co., Limited

#pcb china#pcb design#pcb fabrication#pcb factory#pcb board#pcb manufacturer#flex pcb#pcb supplier#touhou pcb#aluminum pcb

1 note

·

View note

Text

High Volume PCB Assembly With Accelerating Manufacturing Efficiency

In the fast-paced world of electronics, speed and efficiency are key factors that determine the success of a business. PCB Assembly, also known as PCBA, plays a crucial role in meeting the demands of industries like consumer electronics, automotive, telecommunications, and medical devices. This article explores the importance and benefits of high-volume PCBs and their various methods, including Through-Hole Assembly and Electronic PCB Assembly, in enhancing production processes and enabling rapid PCB Assembly.

The Significance of High Volume PCB Assembly

PCBA is a manufacturing process that involves the assembly of a large number of printed circuit boards with consistent quality and precision. As industries continue to grow and evolve, the demand for electronic products is increasing exponentially. Companies need to cater to this ever-growing demand efficiently and cost-effectively. Large-Scale PCB Assembly is the solution that allows them to achieve high production rates and economies of scale.

Understanding PCB Assembly Techniques

Through-Hole PCB Assembly:

Through-Hole PCB Assembly is a traditional assembly method that involves the insertion of electronic components through holes on the PCB. These components are then soldered onto the opposite side of the board, ensuring a sturdy connection. While Through-Hole Assembly is reliable and provides mechanical strength, it is more suitable for low- to medium-volume production due to the manual labor involved.

Surface Mount Technology (SMT) Assembly:

Surface Mount Technology Assembly is a more modern and widely used method for high volume PCB Assembly. SMT components are directly mounted onto the surface of the PCB, eliminating the need for drilling holes. This automation-friendly process significantly speeds up production, making it ideal for high volume manufacturing.

Advantages of High Volume PCB Assembly

Cost-Effectiveness:

One of the primary advantages of high-throughput PCB Assembly is the cost-effectiveness it offers. By automating the assembly process, companies can reduce labor costs, minimise material waste, and optimise production efficiency. The bulk purchasing of components for high volume production also allows for better deals and lower component costs.

Faster Time-to-Market:

With rapid PCB Assembly techniques, companies can significantly reduce the time-to-market for their products. This swift turnaround time enables businesses to capitalize on market trends, respond to customer demands faster, and stay ahead of the competition.

Consistent Quality:

Automated assembly processes in High Volume PCB Assembly ensure consistent and precise placement of components, leading to higher product quality. The use of advanced machinery and quality control measures minimizes human errors, resulting in more reliable electronic products.

Scalability:

As the demand for electronic products increases, Big Volume PCB Assembly provides the scalability needed to meet market requirements. By streamlining production processes, businesses can seamlessly scale their operations to accommodate higher volumes without compromising on quality.

Design Flexibility:

The adoption of High Volume PCB Assembly allows for greater design flexibility. Manufacturers can experiment with different board layouts and quickly iterate prototypes before committing to large-scale production, reducing the risk of costly errors.

Industrial PCB Assembly and Its Impact

The industrial sector has seen significant advancements in PCB technology. Industrial PCB Assembly caters to applications that demand ruggedness, reliability, and high performance. Industries like aerospace, automotive, and industrial automation rely heavily on electronic components to function seamlessly in challenging environments.

PCB Assembly in High Volume has revolutionized the industrial sector by providing sophisticated PCBs that can withstand extreme temperatures, vibrations, and corrosive conditions. This has not only improved product reliability but also extended the lifespan of critical equipment, reducing downtime and maintenance costs.

Ensuring Quality in Electronic PCB Assembly

Electronic PCB Assembly is at the heart of every electronic device. Ensuring the highest quality in this process is crucial to maintaining the integrity of the end product. Manufacturers achieve this by implementing strict quality control procedures, including:

Automated Optical Inspection (AOI):

AOI systems use advanced cameras to inspect the soldering and component placement on PCBs. They can detect defects and inconsistencies in real-time, ensuring that only flawless PCBs move forward in the assembly line.

X-ray Inspection:

X-ray inspection is used to examine hidden solder joints and identify any defects that may not be visible through standard inspection methods. This technique ensures the integrity of complex and miniaturized components.

Functional Testing:

Functional testing is performed on the assembled PCBs to verify their proper functioning as intended. This testing stage guarantees that the final products meet the required specifications.

Also Read: SMT PCB Assembly

Conclusion

High Volume PCB Assembly has become the backbone of the electronics industry, enabling manufacturers to meet growing demands efficiently and economically. Through-Hole PCB Assembly and Surface Mount Technology (SMT) Assembly cater to different production needs, offering unique advantages in various applications.

The continuous evolution of electronic devices calls for quicker time-to-market, superior quality, and scalability. High Volume PCB Assembly addresses these demands, making it an indispensable aspect of modern-day electronics manufacturing. As technology continues to advance, this essential process will undoubtedly play an even more significant role in shaping the future of the electronics industry.

Source: https://mefrontechnologies.medium.com/high-volume-pcb-assembly-with-accelerating-manufacturing-efficiency-4585ce00ab14

#pcb asse#pcb manufacturing#ems#ems manufacturing#manufacturing services#electronics industry#electronic engineering#ems company#ems solution

1 note

·

View note

Text

Innovative Solutions for Modern Industry: Your Trusted Partner in Automation and Conveyance Systems

In the rapidly evolving landscape of manufacturing and industrial automation, companies are constantly seeking reliable partners that can provide comprehensive solutions tailored to their specific needs. Whether it’s streamlining production lines, integrating advanced robotics, or ensuring efficient material handling, the right technology can significantly boost productivity and competitiveness. This article explores key aspects of modern industrial solutions, emphasizing the importance of quality equipment and expert services in driving operational excellence.

The Role of Belt Conveyor Systems in Modern Industry

Efficient material handling forms the backbone of manufacturing operations, enabling smooth movement of goods across various stages of production. A critical component in this process is the belt conveyor system. As a leading belt conveyor supplier Penang companies in the region benefit from a wide range of conveyor solutions designed to optimize workflow. These systems are engineered for durability, adaptability, and ease of maintenance, ensuring seamless integration into existing production lines.

Belt conveyors are versatile and can be customized to handle different types of materials, from lightweight components to heavy industrial loads. Their efficiency reduces manual labor, minimizes product damage, and accelerates throughput. Choosing the right conveyor system is vital for maintaining high productivity levels and ensuring safety standards are met.

Advanced Manufacturing with SMT PCB Machine & Conveyor Systems

Printed Circuit Boards (PCBs) are fundamental to electronic devices, and their production demands precision, speed, and reliability. Incorporating SMT PCB machine & conveyor systems into manufacturing processes enhances these aspects significantly. These machines automate the placement of electronic components onto PCBs, reducing errors and increasing output.

A well-designed conveyor system in SMT assembly lines ensures smooth transfer of PCBs between different stages of production, such as soldering, inspection, and testing. This integration not only boosts efficiency but also improves product quality, leading to fewer defects and higher customer satisfaction. Investing in high-quality SMT PCB machinery and conveyor solutions is a strategic move for electronic manufacturers aiming to stay competitive in a global market.

The Power of PLC Programming & Electrical Control Systems

Automation is impossible without sophisticated control systems, and PLC (Programmable Logic Controller) programming plays a pivotal role. PLCs are industrial computers used to control machinery and processes, enabling precise operation and real-time adjustments. PLc programming & electrical control system Electrical control systems, integrated with PLCs, provide the backbone for automated production lines, ensuring safety, consistency, and scalability.

Expertise in PLC programming and electrical control system design is essential for customizing solutions that meet specific operational requirements. Properly programmed PLCs can coordinate multiple machines and sensors, optimize cycle times, and facilitate troubleshooting. For industries seeking to enhance automation efficiency, investing in reliable control systems is a key step toward digital transformation.

Embracing Automation with Industrial Cobot & Robot Arm

The advent of collaborative robots (cobots) and robotic arms has revolutionized manufacturing processes worldwide. These intelligent machines work alongside human operators, performing repetitive or dangerous tasks with high precision. Industrial cobot & robot arm solutions increase productivity, reduce labor costs, and improve safety standards on the shop floor.

Implementing robotic automation requires careful planning and integration with existing systems. When properly deployed, cobots can handle tasks such as assembly, packaging, and material transfer, freeing up human workers for more complex and value-added activities. As technology advances, the accessibility and capabilities of industrial robots continue to expand, offering businesses a competitive edge in automation.

Why Choose the Right Partner for Industrial Solutions?

Partnering with a reputable supplier and service provider ensures that your automation and conveyance systems are tailored to your operational needs. From conveyor systems to robotics and control systems, selecting high-quality equipment and expert support can significantly impact your production efficiency.

In summary, embracing innovative solutions—such as belt conveyor systems, SMT PCB machinery, advanced PLC programming, and industrial cobots—enables industries to stay ahead in a competitive market. By focusing on reliable technology and professional services, businesses can achieve higher productivity, improved safety, and long-term operational success.

0 notes

Text

Automatic Laser Soldering Robot market : Size, Share Growth, SWOT Analysis, Key Players, Industry Trends and Regional Outlook

According to a new report from Intel Market Research, the global Automatic Laser Soldering Robot market was valued at USD 84 million in 2024 and is projected to reach USD 118 million by 2032, growing at a steady CAGR of 5.1% during the forecast period (2025–2032). This growth is driven by increasing demand for high-precision soldering in electronics manufacturing, the push for automation in production lines, and the environmental benefits of laser-based processes.

What is an Automatic Laser Soldering Robot?

Automatic Laser Soldering Robots represent a revolutionary approach to joining metal components using laser technology. Unlike traditional soldering methods that require physical contact, these systems utilize concentrated laser beams to precisely heat targeted areas without touching sensitive components. The process involves directing laser energy to melt solder wire or paste, creating flawless joints with micron-level accuracy.

These systems excel in applications requiring:

Micro-scale precision: Handling components as small as 0.1mm

Non-contact operation: Eliminating mechanical stress on delicate parts

Programmable workflows: Enabling rapid changeovers between product designs

📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/4525/automatic-laser-soldering-robot-2025-2032-915

Key Market Drivers

1. Explosive Growth in Miniature Electronics

The consumer electronics boom, particularly in smartphones, wearables, and IoT devices, demands soldering solutions capable of handling increasingly compact components. Laser soldering robots provide the necessary precision for:

PCB assembly with ultra-fine pitch components

Micro-BGA and QFN package soldering

Flexible circuit board applications

2. Sustainability Mandates in Manufacturing

With environmental regulations tightening globally, manufacturers are transitioning to laser soldering because it:

Reduces hazardous fume generation by 60-80% compared to conventional methods

Consumes 35% less energy per solder joint

Eliminates flux residue cleanup requirements

3. Advancements in Laser Technology

Recent breakthroughs in fiber laser and semiconductor laser systems have enhanced soldering capabilities through:

Higher energy efficiency (>30% conversion rates)

Improved beam quality (M² < 1.3)

Enhanced thermal control systems (±0.5°C stability)

Market Challenges

Despite strong growth prospects, several factors are restraining market expansion:

High initial investment: Entry-level systems start at $50,000, limiting SME adoption

Skill gap: Requires specialized training in laser optics and robotics programming

Material limitations: Certain reflective or heat-sensitive substrates require careful parameter tuning

Leading Applications

The technology is transforming production across multiple industries:

Consumer Electronics (42% market share): Smartphone cameras, microphone arrays

Automotive Electronics (28%): ADAS sensor assemblies, battery management systems

Medical Devices (18%): Implantable electronics, diagnostic equipment

Aerospace (12%): Avionics, satellite components

Regional Market Insights

Asia-Pacific: Dominates with 58% market share, driven by electronics manufacturing hubs in China, Japan, and South Korea

North America: Shows the fastest growth (6.2% CAGR) due to reshoring initiatives and automotive sector demand

Europe: Leads in medical and aerospace applications with stringent quality requirements

Emerging Markets: Southeast Asia and India experiencing increased adoption as global manufacturers diversify supply chains

Technology Trends

The industry is evolving through several key innovations:

Hybrid vision systems combining 2D/3D imaging with AI-based defect detection

Adaptive power control that automatically adjusts laser parameters based on thermal imaging feedback

Collaborative robotic arms enabling safe human-machine interaction in workcells

📘 Get Full Report Here: Automatic Laser Soldering Robot Market - View in Detailed Research Report

Competitive Landscape

The market features a mix of established automation providers and laser specialists, including:

Anewbest

Japan Unix

HORIUCHI ELECTRONICS

Wolf Produktionssysteme

Apollo Seiko

These companies are competing through:

Vertical integration of laser sources and robotic platforms

Development of proprietary solder alloys optimized for laser processes

Expansion of service networks for installation and maintenance

About Intel Market Research

Intel Market Research is a leading provider of strategic intelligence, offering actionable insights in industrial automation, advanced manufacturing, and technology markets. Our research capabilities include:

Real-time competitive benchmarking

Global technology adoption monitoring

Market entry strategy development

Over 350+ industrial reports annually

Trusted by Fortune 500 manufacturers, our insights empower decision-makers to optimize their production technologies.

🌐 Website: https://www.intelmarketresearch.com 📞 International: +1 (332) 2424 294 📞 Asia-Pacific: +91 9169164321 🔗 LinkedIn: Follow Us

0 notes

Text

Professional BGA Assembly for High-Density PCB Applications

Our BGA assembly services offer precise and reliable solutions for high-performance electronic devices. Using advanced equipment and X-ray inspection, we ensure accurate placement and soldering of ball grid array components. Ideal for compact, high-speed circuits like CPUs and GPUs, our BGA assembly process guarantees strong connections and long-term durability. Trust our experienced team to deliver quality, efficiency, and consistency in every project—from prototyping to full-scale production.

Read More : https://espcba.com/the-future-of-printed-circuit-board-manufacturing-trends-every-electronics-manufacturer-should-know/

0 notes

Text

In today’s competitive electronics manufacturing landscape, efficiency and precision are paramount. Pick-and-place machines, integral to the assembly process, offer unparalleled speed and accuracy in placing electronic components on printed circuit boards (PCBs). As technology evolves, these machines are continuously updated to meet the industry's rising demands.

At Sunway, we understand the critical role pick-and-place machines play in optimizing your production line. We offer a diverse selection of second-hand machines from top brands including Fuji, Juki, Hanwha, Siemens, YAMAHA, and Panasonic. Each of our refurbished machines has been meticulously tested and calibrated by professional engineers, ensuring they deliver peak performance and reliability.

Choosing our pre-owned pick-and-place machines means you can access advanced technology while benefiting from significant cost savings. Our machines provide an excellent balance of quality and value, allowing you to upgrade your production capabilities without exceeding your budget. Whether you're looking to enhance your existing setup or establish a new production line, our expert team is here to help you find the right machine for your needs.

Invest in efficiency, precision, and cost-effectiveness with Sunway’s range of high-quality second-hand pick-and-place machines. Contact us today to discover how we can support and elevate your SMT production process.

1 note

·

View note

Text

High-Performance PCB Assembly Services That Power Innovation

From idea to implementation, East/West Manufacturing Enterprises delivers world-class PCB Assembly Services designed to meet your most demanding project goals. Whether you're building consumer electronics, medical devices, or aerospace systems, our team ensures every board is built with precision and care.

We specialize in surface mount, through-hole, and mixed-technology assembly, backed by rigorous testing and inspection. Our advanced equipment and skilled technicians guarantee high-yield results—even for complex, multilayer designs.

Need quick-turn prototypes or full-scale production? We scale with your needs while keeping quality and delivery timelines front and center.

Power your next breakthrough with reliable PCB assembly from a trusted U.S. manufacturer.

0 notes