#Ceramic PCB

Explore tagged Tumblr posts

Text

J-Cube Technologies Inc.

J-Cube Technologies Inc. is an organization that specializes in the production of printed circuit boards (PCBs).

Our company is based in Montreal, Canada, and has been active in the industry for over a decade. Through our success in Asian infrastructure development and the expansion of our engineering and technical manufacturing expertise, we have grown to be a world-class provider of comprehensive and reliable electronic solutions.

#jcubetech#jcubetechca#J-Cube Technologies Inc#metal pcb#metal core pcb manufacturer#metal core printed circuit board#aluminum core pcb#mcpcb#LED MPCB#Ceramic PCB#mcpcb manufacturer#Quick turn mpcb#pcb core#Printed Circuit Board#Analog circuit#Bare board#Blind via#Component#Dip Trace#Schematic Capture#Library Pane#Schematic Pane

2 notes

·

View notes

Text

What is ceramic pcb board

Ceramic pcb boards are actually made of electronic ceramics as the basic material and can be made in various shapes. Among them, the characteristics of high temperature resistance and high electrical insulation of ceramic circuit boards are the most prominent. The advantages of low dielectric constant and dielectric loss, high thermal conductivity, good chemical stability, and similar thermal expansion coefficient to components are also very significant.

Different types of ceramic pcb

Ceramic PCB is widely used in power electronics, electronic packaging, hybrid microelectronics and multi-chip modules due to its excellent thermal conductivity and air tightness. But not everyone is clear about the classification. Many manufacturers think ceramic PCBs are expensive and fragile as soon as they hear about ceramic PCBs. Yes, this is indeed a shortcoming of ceramic PCBs, but not all ceramic PCBs are like this. Today we will tell you about the different types of ceramic PCBs.

Al2O3 ceramic PCB

Al2O3 ceramic PCB ( alumina ceramic PCB) refers to various ceramic PCBs with Al2O3 as the main raw material and an Al2O3 content of more than 75%. It has a rich source of raw materials, with advantages of low price, high mechanical strength and hardness, good insulation performance, good heat shock resistance, good chemical resistance, high dimensional accuracy, and good adhesion to metals. It is a ceramic substrate material with good comprehensive performance. Currently used Al2O3 ceramic substrates, the content of Al2O3 accounts for 85% to 99.5%. Among them, 96% Al2O3 ceramic PCB is widely used in the production of thick film circuit substrates and chip devices. The thermal conductivity of Al2O3 at room temperature is 29W/(m·K), which is close to the thermal conductivity of steel; with the increase of Al2O3 content, the electrical insulation performance and thermal conductivity of Al2O3 ceramic PCB will increase, but At the same time, it will also lead to an increase in the firing temperature, an increase in energy consumption, a large loss of kiln furniture, and an increase in manufacturing costs.

SiC ceramic PCB

The thermal conductivity of SiC ceramic PCB is very high, 100~490W/(m·K) at room temperature, and it is related to the purity of SiC crystals. The higher the purity, the greater the thermal conductivity; the oxidation resistance is good, and the decomposition temperature is above 2500℃, it can still be used at 1600℃ in an oxidizing atmosphere; the coefficient of thermal expansion is also low, and it is close to Si, with good electrical insulation performance; SiC has a Mohs hardness of 9.75, second only to diamond and cubic BN, and has high mechanical strength. SiC ceramics have strong covalent bond characteristics and are difficult to sinter. Usually, a small amount of boron or aluminum oxide is added as a sintering aid to increase the density. Experiments show that beryllium, boron, aluminum and their compounds are the most effective additives, which can make SiC ceramics denser than 98%.

BeO ceramic PCB

BeO has a brazine structure, in which oxygen ions are arranged in a hexagonal close-packed manner to form a hexagonal lattice. The general oxide is usually an ionic compound, but BeO has a strong covalent bond and an average molecular weight of only 12. Because of its good electrical properties, luminescence and photochemical properties, high mechanical strength, low dielectric loss, etc, it become one of the materials that people pay attention to.

AlN ceramic PCB

AlN ceramic PCB (aluminum nitride ceramic) is a new type of high thermal conductivity ceramic packaging material. It has been extensively studied in the 1990s and gradually developed. It is currently generally considered to be a promising electronic ceramic packaging PCB. AlN material has high thermal conductivity, excellent dielectric properties, high electrical insulation strength, stable chemical properties, strong corrosion resistance, and good mechanical properties. In particular, its thermal expansion coefficient matches with silicon, which makes it an ideal semiconductor packaging substrate materials and have been widely used in integrated circuits, microwave power devices, millimeter-wave packaging, high-temperature electronic packaging and other fields.

Ceramic PCB for IGBT Module

IGBT stands for insulated-gate bipolar transistor. It is a bipolar transistor with an insulated gate terminal. The IGBT combines, in a single device, a control input with a MOS structure and a bipolar power transistor that acts as an output switch. IGBTs Ceramic PCB are suitable for high-voltage, high-current applications. They are designed to drive high-power applications with a low-power input.

IGBT, or Insulated Gate Bipolar Transistor, is a BJT transistor with a MOS Gate, or we can say an IGBT module is the combination of a BJT and a MOS Gate. An IGBT chip is small in size, but it can control electrical energy transmission and achieve 100,000 times of current switch at ultra-high voltages of 650 million V in only 1 second.

IGBT modules have been applied in automotive, industrial, aerospace, consumer electronics, and many other industries for many years. But how to optimize the thermal dissipation of an IGBT package so the module can work at a higher power? If thermal can dissipate more quickly, the IGBT module can have more advanced applications. For this purpose, engineers are using ceramic PCBs for IGBT packaging.

Ceramic PCBs dissipate thermal from IGBT chip to the outer packaging

You may ask, how much thermal does an IGBT module generate when it works? It is equal to the heat generated by 100 electric furnaces. So much thermal has to be dissipated immediately from the IGBT chip and leads to the application of ceramic PCBs.

How does a ceramic PCB protect the IGBT module from the heat? In an IGBT module, a ceramic PCB is placed under the IGBT chip, or we can say that the chip is assembled on the ceramic circuit board. The ceramic PCB connects and supports the chip and dissipates thermal quickly from it to the outer packaging. In this way, the chip is protected from the influence of thermal.

Why Ceramic PCBs can be used for IGBT thermal dissipation

There are alumina (Al₂O₃) PCBs, aluminum nitride (AlN) PCBs, and silicon nitride (Si₃N₄) PCBs used for thermal dissipation of IGBT modules.

Why ceramic PCBs can dissipate thermal effectively for the IGBT module? Because ceramic materials have good properties of thermal dissipation and electrical insulation. Unlike aluminum substrate PCBs, ceramic PCBs do not use an insulation layer that hinders thermal dissipation. During the ceramic PCB manufacturing process, the copper-clad is directly bonded onto the ceramic substrate at high temperatures under high pressures. Then the circuit layer is manufactured by the photoresist coating method. When the circuit board is manufactured, the IGBT and other components are mounted on the board. Ceramic materials have ultra-high insulation and can withstand breakdown voltage up to 20KV/mm. The thermal conductivity of alumina PCBs is 15-35W/mK, aluminum nitride PCB 170-230W/mK, and silicon nitride PCB 80+W/mK. On the contrary, an aluminum PCB has thermal dissipation of only 1-12W/mK.

If you’re interested in our products, pls kindly email to Sandy: [email protected]

1 note

·

View note

Text

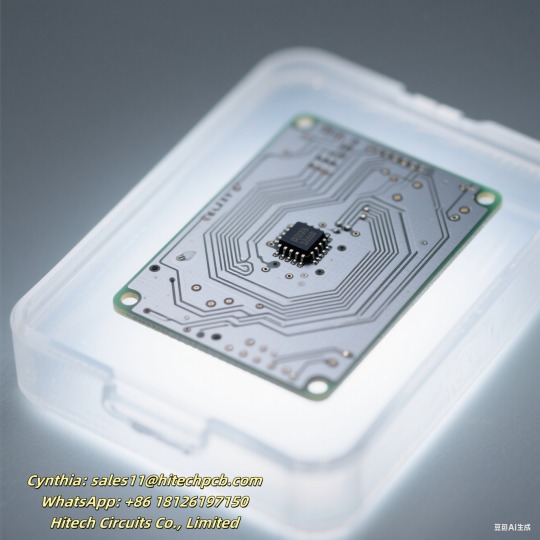

One-stop PCB assembly service and PCB manufacturing supplier -- Hitechpcba

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

5 notes

·

View notes

Text

4. Our Competitive Advantages, excellent PCBA manufacturer - Hitech Circuits from China

What sets us apart from other PCBA suppliers? Here are the key advantages we bring to the table:

Advanced Manufacturing Capabilities: Equipped with state-of-the-art SMT (Surface Mount Technology) lines, automated inspection systems, and cleanroom facilities, we can handle complex PCBA projects with high precision and efficiency. Whether you need small-batch prototypes or large-scale production, we have the capacity to deliver on time.

Strict Quality Control: Our quality control process is comprehensive, covering every stage of production. We utilize Automated Optical Inspection (AOI), X-ray inspection, and functional testing to detect and rectify any defects before shipment. This ensures that you receive PCBA with zero compromises on quality.

Flexible Customization: We work closely with you to understand your specific requirements. From design optimization to component selection, our team of experts provides valuable insights to help you achieve the best results. Whether you need a unique form factor, specific materials, or specialized testing, we can tailor our solutions to fit your needs.

Cost-Effective Solutions: We strive to offer competitive pricing without sacrificing quality. By optimizing our supply chain, streamlining production processes, and leveraging economies of scale, we can provide cost-effective PCBA solutions that help you maximize your profit margins.

Timely Delivery: We understand the importance of meeting deadlines in the electronics industry. Our efficient production planning and robust supply chain management ensure that your PCBA orders are delivered on time, every time. This helps you stay on schedule with your product launches and meet market demands.

Whether you're a startup launching a new product or an established company looking to optimize your supply chain, we have the expertise and resources to support your goals. Contact us today to discuss your PCBA requirements and discover how we can help you achieve excellence in your electronic devices. Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

0 notes

Text

High-Performance Ceramic PCB Solutions – Bestpcbs

Bestpcbs offers premium Ceramic PCB solutions known for exceptional thermal conductivity, electrical insulation, and durability. Ideal for high-power and high-frequency applications, our ceramic PCBs ensure reliable performance in extreme environments. Whether for LED, aerospace, or medical devices, trust Bestpcbs for advanced, long-lasting ceramic circuit board technology engineered to meet your most demanding requirements.

0 notes

Text

Ceramic PCB Special PCB with Big Function and Use made by Hitech Circuits

We are a professional ceramic pcb manufacturer, supplier from China, we mainly supply high quality Alumina (Al2O3) Ceramic PCB, Aluminum Nitride (AIN) Ceramic PCB board and IGBT Ceramic PCB. Our ceramic printed circuit boards features of high pressure, high insulation, high temperature, and high reliable and minor volume electronic products, Hitech is your best choice for ceramic PCB boards and needs.

Pls send PCB files to [email protected] to get a quote now!

What is ceramic pcb board

Ceramic pcb boards are actually made of electronic ceramics as the basic material and can be made in various shapes. Among them, the characteristics of high temperature resistance and high electrical insulation of ceramic circuit boards are the most prominent. The advantages of low dielectric constant and dielectric loss, high thermal conductivity, good chemical stability, and similar thermal expansion coefficient to components are also very significant.

Different types of ceramic pcb

Ceramic PCB is widely used in power electronics, electronic packaging, hybrid microelectronics and multi-chip modules due to its excellent thermal conductivity and air tightness. But not everyone is clear about the classification. Many manufacturers think ceramic PCBs are expensive and fragile as soon as they hear about ceramic PCBs. Yes, this is indeed a shortcoming of ceramic PCBs, but not all ceramic PCBs are like this. Today we will tell you about the different types of ceramic PCBs.

Al2O3 ceramic PCB

Al2O3 ceramic PCB ( alumina ceramic PCB) refers to various ceramic PCBs with Al2O3 as the main raw material and an Al2O3 content of more than 75%. It has a rich source of raw materials, with advantages of low price, high mechanical strength and hardness, good insulation performance, good heat shock resistance, good chemical resistance, high dimensional accuracy, and good adhesion to metals. It is a ceramic substrate material with good comprehensive performance. Currently used Al2O3 ceramic substrates, the content of Al2O3 accounts for 85% to 99.5%. Among them, 96% Al2O3 ceramic PCB is widely used in the production of thick film circuit substrates and chip devices. The thermal conductivity of Al2O3 at room temperature is 29W/(m·K), which is close to the thermal conductivity of steel; with the increase of Al2O3 content, the electrical insulation performance and thermal conductivity of Al2O3 ceramic PCB will increase, but At the same time, it will also lead to an increase in the firing temperature, an increase in energy consumption, a large loss of kiln furniture, and an increase in manufacturing costs.

SiC ceramic PCB

The thermal conductivity of SiC ceramic PCB is very high, 100~490W/(m·K) at room temperature, and it is related to the purity of SiC crystals. The higher the purity, the greater the thermal conductivity; the oxidation resistance is good, and the decomposition temperature is above 2500℃, it can still be used at 1600℃ in an oxidizing atmosphere; the coefficient of thermal expansion is also low, and it is close to Si, with good electrical insulation performance; SiC has a Mohs hardness of 9.75, second only to diamond and cubic BN, and has high mechanical strength. SiC ceramics have strong covalent bond characteristics and are difficult to sinter. Usually, a small amount of boron or aluminum oxide is added as a sintering aid to increase the density. Experiments show that beryllium, boron, aluminum and their compounds are the most effective additives, which can make SiC ceramics denser than 98%.

BeO ceramic PCB

BeO has a brazine structure, in which oxygen ions are arranged in a hexagonal close-packed manner to form a hexagonal lattice. The general oxide is usually an ionic compound, but BeO has a strong covalent bond and an average molecular weight of only 12. Because of its good electrical properties, luminescence and photochemical properties, high mechanical strength, low dielectric loss, etc, it become one of the materials that people pay attention to.

AlN ceramic PCB

AlN ceramic PCB (aluminum nitride ceramic) is a new type of high thermal conductivity ceramic packaging material. It has been extensively studied in the 1990s and gradually developed. It is currently generally considered to be a promising electronic ceramic packaging PCB. AlN material has high thermal conductivity, excellent dielectric properties, high electrical insulation strength, stable chemical properties, strong corrosion resistance, and good mechanical properties. In particular, its thermal expansion coefficient matches with silicon, which makes it an ideal semiconductor packaging substrate materials and have been widely used in integrated circuits, microwave power devices, millimeter-wave packaging, high-temperature electronic packaging and other fields.

Ceramic PCB for IGBT Module

IGBT stands for insulated-gate bipolar transistor. It is a bipolar transistor with an insulated gate terminal. The IGBT combines, in a single device, a control input with a MOS structure and a bipolar power transistor that acts as an output switch. IGBTs Ceramic PCB are suitable for high-voltage, high-current applications. They are designed to drive high-power applications with a low-power input.

IGBT, or Insulated Gate Bipolar Transistor, is a BJT transistor with a MOS Gate, or we can say an IGBT module is the combination of a BJT and a MOS Gate. An IGBT chip is small in size, but it can control electrical energy transmission and achieve 100,000 times of current switch at ultra-high voltages of 650 million V in only 1 second.

IGBT modules have been applied in automotive, industrial, aerospace, consumer electronics, and many other industries for many years. But how to optimize the thermal dissipation of an IGBT package so the module can work at a higher power? If thermal can dissipate more quickly, the IGBT module can have more advanced applications. For this purpose, engineers are using ceramic PCBs for IGBT packaging.

Ceramic PCBs dissipate thermal from IGBT chip to the outer packaging

You may ask, how much thermal does an IGBT module generate when it works? It is equal to the heat generated by 100 electric furnaces. So much thermal has to be dissipated immediately from the IGBT chip and leads to the application of ceramic PCBs.

How does a ceramic PCB protect the IGBT module from the heat? In an IGBT module, a ceramic PCB is placed under the IGBT chip, or we can say that the chip is assembled on the ceramic circuit board. The ceramic PCB connects and supports the chip and dissipates thermal quickly from it to the outer packaging. In this way, the chip is protected from the influence of thermal.

Why Ceramic PCBs can be used for IGBT thermal dissipation

There are alumina (Al₂O₃) PCBs, aluminum nitride (AlN) PCBs, and silicon nitride (Si₃N₄) PCBs used for thermal dissipation of IGBT modules.

Why ceramic PCBs can dissipate thermal effectively for the IGBT module? Because ceramic materials have good properties of thermal dissipation and electrical insulation. Unlike aluminum substrate PCBs, ceramic PCBs do not use an insulation layer that hinders thermal dissipation. During the ceramic PCB manufacturing process, the copper-clad is directly bonded onto the ceramic substrate at high temperatures under high pressures. Then the circuit layer is manufactured by the photoresist coating method. When the circuit board is manufactured, the IGBT and other components are mounted on the board. Ceramic materials have ultra-high insulation and can withstand breakdown voltage up to 20KV/mm. The thermal conductivity of alumina PCBs is 15-35W/mK, aluminum nitride PCB 170-230W/mK, and silicon nitride PCB 80+W/mK. On the contrary, an aluminum PCB has thermal dissipation of only 1-12W/mK.

Usages and applications of ceramic printed circuit boards

Ceramic printed circuit boards have a wide range of applications and can be used in the LED field, solar panel components, high-power power semiconductor modules, semiconductor refrigerators, electronic heaters, power control circuits, power hybrid circuits, smart power components, high-frequency switching power supplies , solid state relays, automotive electronics, communications, aerospace and military electronic components.

Advantages of ceramic PCB boards

Higher thermal conductivity

More matching thermal expansion coefficient

Stronger and lower resistance metal film

The solderability of the substrate is good, and the use temperature is high

Good insulation

Low high frequency loss

High-density assembly is possible

It does not contain organic ingredients, is resistant to cosmic rays, has high reliability in aerospace and has a long service life

The copper layer does not contain an oxide layer and can be used for a long time in a reducing atmosphere

Disadvantages of ceramic pcb boards

1. Fragile This is one of the most important shortcomings. At present, only small-area ceramic printed circuit boards can be produced.

2. Expensive There are more and more requirements for electronic products. Ceramic circuit boards only meet the requirements of some relatively high-end products, and low-end products will not be used at all.

0 notes

Text

Ceramic Printed Circuit Manufacturing Processes and Technologies

Ceramic printed circuit board manufacturing processes can be categorised into four types: HTCC, LTCC, DBC and DPC.

The HTCC (High Temperature Co-fired Ceramic) process requires temperatures higher than 1300°C, but is quite expensive due to the choice of electrodes;

LTCC (Low Temperature Co-fired Ceramics) requires calcination at temperatures around 850°C but produces less accurate circuits with lower thermal conductivity in the final product;

DBC (Direct Bonded Ceramics) requires the formation of an alloy between the copper foil and the ceramic, and the calcination temperature must be tightly controlled in the 1065-1085°C temperature range. Since the thickness of the copper foil in the DBC method cannot be less than 3oz, the ratio between trace width and depth is limited in this type of ceramic printed circuit board.

DPC (direct plated ceramic) preparation methods include vacuum plating, wet plating, exposure plating, etching, and other processes, making the product relatively expensive. In addition, DPC ceramic circuit boards require laser cutting, which cannot be accurately processed by conventional drilling, milling, or punching machines, and thus laser cutting provides more precise bond strength and trace width.

Hitech Circuits is a trustworthy Ceramic PCB manufacturer in China. If you have related PCB needs, please feel free to contact Us.

1 note

·

View note

Text

Viasion PCB: Your Trusted Partner for High-Quality Custom and Advanced PCBs

In today’s fast-paced electronics industry, choosing the right PCB manufacturer can make all the difference. Whether you're working on a new tech innovation or scaling an existing product, the quality, precision, and reliability of your printed circuit boards are critical. That’s where Viasion Technology Co., Ltd. steps in—a proven leader in the PCB industry with over 15 years of experience delivering excellence.

Viasion offers comprehensive PCB manufacturing and assembly services to clients across the globe, including the United States. From custom PCB boards to complex blind vias printed circuit boards, their products serve various industries including automotive, telecom, medical devices, and consumer electronics.

Why Choose Viasion for Your PCB Needs?

Viasion is more than just a custom PCB manufacturer. Their expertise spans across a wide range of advanced PCB types including blind via PCBs, ceramic PCBs, flexible PCBs, and copper based PCBs—all manufactured in ISO-certified facilities with stringent quality control.

Here’s a closer look at what makes Viasion a preferred partner:

1. Advanced Blind Via PCB Capabilities

For high-density interconnect (HDI) designs, blind vias PCBs are essential. These vias connect outer layers to inner layers without passing through the entire board, saving space and improving signal integrity. As a trusted blind vias PCB manufacturer, Viasion delivers precise, reliable blind via PCBs ideal for compact, high-speed devices.

Their expert team uses laser drilling and advanced lamination techniques to ensure accuracy and consistency in every board. Whether you're prototyping or in full-scale production, Viasion provides solutions that meet your specific requirements.

2. Durable and High-Performance Ceramic PCBs

When it comes to thermal conductivity, high-frequency performance, and durability, ceramic PCBs stand out. Ideal for aerospace, LED lighting, and automotive applications, these boards handle extreme environments where standard PCBs may fail.

As an experienced ceramic PCB manufacturer, Viasion offers a variety of ceramic substrates, including alumina and aluminum nitride, ensuring optimal performance even in the most demanding conditions. Their ceramic PCBs are designed to offer low thermal expansion, excellent insulation, and high mechanical strength.

3. Cost-Effective and Efficient Copper Based PCBs

Copper based PCBs are essential for high-power electronics due to their superior heat dissipation capabilities. These are commonly used in power converters, industrial control systems, and automotive components.

Viasion manufactures copper based PCBs with excellent reliability and durability. Their manufacturing process ensures a strong bond between copper and insulating layers, resulting in high-performance boards ready for tough applications.

4. Fully Customizable PCB Manufacturing

Need something tailored to your specific project? Viasion is a specialist custom PCB manufacturer, delivering bespoke PCB solutions that match your design and functional requirements. Whether it's a custom PCB board for a wearable device or a multi-layer board for an IoT product, their engineering team works closely with you to bring your design to life.

You’ll get DFM (Design for Manufacturing) support, fast prototyping, and competitive pricing—all while maintaining the highest quality standards.

5. Reliable Flexible PCB Manufacturing

For applications where space, weight, and flexibility are crucial, flexible PCBs are the go-to solution. Used in devices like smartphones, cameras, and medical instruments, flexible PCB boards allow for bendable, compact designs.

Viasion is a trusted flexible PCB manufacturer, producing single-sided, double-sided, and multi-layer flex PCBs. Their flex PCB capabilities include fine-line spacing, tight tolerances, and advanced materials like polyimide for high heat resistance.

Their flexible circuits are tested for bend cycles, ensuring longevity and reliability even under constant motion and mechanical stress.

Applications Across Every Industry

Viasion serves a wide array of industries:

Medical Devices: Miniaturized flexible PCBs and ceramic PCBs for diagnostic tools and implants

Automotive: High-temperature copper based PCBs and custom PCBs for control units

Consumer Electronics: High-density blind via PCBs and flexible PCBs for wearables and mobile devices

Telecommunications: Multi-layer custom PCBs and blind vias printed circuit boards for routers and servers

Industrial Equipment: Rugged ceramic PCBs and copper based PCBs for control systems

No matter your industry, Viasion brings the technical expertise and manufacturing excellence needed to make your project a success.

Why U.S. Customers Trust Viasion

Even though Viasion is based in Shenzhen, China, their services are perfectly aligned for U.S. businesses. With fast international shipping, English-speaking support staff, and a focus on total customer satisfaction, Viasion delivers a seamless experience for customers in the United States.

Key benefits for U.S. clients include:

No minimum order quantity

Quick turnaround and prototyping

Full turnkey PCB assembly service

Competitive pricing without compromising quality

UL and ISO certified production processes

Get Started Today

Whether you need a custom PCB board, ceramic PCB, or a complex blind vias PCB, Viasion is equipped to deliver top-tier solutions tailored to your unique specifications. Their dedication to quality, innovation, and customer support makes them the go-to custom PCB manufacturer for companies across the USA and beyond.

👉 Visit www.viasionpcb.com to request a quote or reach out to their team at [email protected] for personalized support.

0 notes

Text

We are a professional ceramic pcb manufacturer, supplier from China, we mainly supply high quality Alumina (Al2O3) Ceramic PCB, Aluminum Nitride (AIN) Ceramic PCB board and IGBT Ceramic PCB. Our ceramic printed circuit boards features of high pressure, high insulation, high temperature, and high reliable and minor volume electronic products, Hitech is your best choice for ceramic PCB boards and needs.

0 notes

Text

Elevate Your Electronics with Hitech Circuits Co Limited

Experience seamless technology integration with Hitech Circuits Co Limited - your dependable partner for printed circuit board assembly. The PCBs we manufacture are meticulously assembled by our expert team to ensure a high level of precision and reliability. For top-notch PCB assembly, trust Hitech Circuits Co Limited, whether you are an electronics enthusiast or a business. We bring your ideas to life through advanced technology and unsurpassed expertise. Let us design and assemble your printed circuit boards to meet your specific needs.

0 notes

Text

PCB Assembly, PCB Manufacturing & Electronic Assembly service & electronics manufacturing company – Hitech Circuits Co., Limited

As leading one-stop PCB Assembly services provider in China, Hitech Group offers high quality, cost effective, express PCB board products and provides PCB manufacturing, electronics assembly manufacturing, components sourcing, Box build assembly and PCBA testing services for our customers.

For low volume PCB assembly projects, our quick turn PCB assembly delivery time goes from 8 hours to 48 hours when components are ready.

No matter you are an electrical engineer, a product designer, a system integrator or a maker looking for PCB fabrication and PCB assembly, or PCB manufacturing and assembly, or electronic assembly services (electronic PCB assembly) ,or a low cost PCB assembly house, Hitech Circuits PCB assembly team will be your perfect PCB assembly house in China.

What is PCB Assembly?

It’s the step in the manufacturing process in which you populate a blank board with the electronic components needed to make it into a functional printed circuit board. It’s these components that make a board into the circuit that enables an electronic product to function. PCB assembly typically takes place via one of two processes:

1. Surface-mount technology

SMT: SMT stands for “Surface Mount Technology“. The SMT components are very small sizes and comes in various packages like 0201, 0402, 0603, 1608 packages for resistors and capacitors. Similarly for Integrated circuits ICs we have SOIC, TSSOP, QFP and BGA.

The SMT components assembly is very difficult for human hands and can be time taking process so it is mostly done by automated pick and place machine.

2. Through-hole manufacturing

THT: THT stands for “Through hole Technology”. The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Why Choose Hitech Circuits PCB Assembly Manufacturer for Your PCB Assembly Projects?

There are several PCB manufacturers specializing in PCB assemblyservices. However, Hitech Circuits PCB Assembly stands out owing to the following:

Assistance in Material Procurement:

Technically, in PCB assembly services, the quality of parts is the responsibility of the OEM; however, we ease your job by assisting you to make the right selection. We can help you procure all your parts of the same type own a single part number, thanks to our supply chain and vendor network as well as experience. This saves time and cost that goes in ordering single parts as you plan.

Testing procedures:

We are very focused on quality and thus implement stringent testing procedures at each stage of the assembly and after completion.

Fast Turnaround Times:

Our well-equipped facility and the right tools enable us to complete your requirements well before time, and without compromising on the quality or functioning of the PCBs. For simple designs we revert in 24 to 48 hours.

Cost Effectiveness:

While PCB assembly is a cost-effective alternative, we go a step further and assure that the parts you list are of a good quality and suitable for your requirement. Also, you can control the part flow and replenish them as needed. This eliminates the need to buy extra stock and store it.

Quick Quote:

We offer a quick quote based on your BOM. All you need is a detailed BOM, Gerber files, your application requirement sheet, and quantity.

We’re not one to stand still, which is why we use the latest equipment and the finest minds to create your PCB projects. We’re constantly keeping our finger on the pulse of the latest trends. And as a result, we know how to deliver the highest standards of PCB assembly to meet all your requirements.

Our dedicated, friendly customer service team also means that we support you every step of the way. Offering our expert guidance to ensure a complete PCB project that you’re happy with.

Contact us today

No matter what your printed circuit board assemblyneeds are, we always aim to deliver efficient, dependable solutions. For more information about our services, do not hesitate to get in touch with us today for a no-obligation quote.

0 notes

Text

Advantages of ceramic PCB boards

Higher thermal conductivity

More matching thermal expansion coefficient

Stronger and lower resistance metal film

The solderability of the substrate is good, and the use temperature is high

Good insulation

Low high frequency loss

High-density assembly is possible

It does not contain organic ingredients, is resistant to cosmic rays, has high reliability in aerospace and has a long service life

The copper layer does not contain an oxide layer and can be used for a long time in a reducing atmosphere

0 notes

Text

2. Why PCBA Quality is Non-Negotiable, Hitech Circuits at your service.

The quality of PCBA directly impacts the performance, reliability, and lifespan of your electronic devices. A subpar PCBA can lead to frequent malfunctions, increased product returns, and damage to your brand reputation. On the contrary, a well-crafted PCBA ensures stable operation, reduces maintenance costs, and enhances customer satisfaction.

Our PCBA manufacturing process adheres to the highest industry standards. From material selection to final inspection, every step is meticulously monitored to guarantee that each assembly meets or exceeds your specifications. We use premium-grade PCBs, genuine electronic components, and advanced soldering techniques to ensure strong connections and optimal functionality.

Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

#pcb assembly#pcb manufacturer#pcba#led pcb#pcb#fr4#flexible pcb board#aluminum pcb#electronic#ceramic pcb#flex pcb

0 notes

Text

Ceramic PCB | High-Performance PCBs by BestPCBs

BestPCBs offers top-quality Ceramic PCBs designed for high thermal conductivity, durability, and excellent performance in demanding applications. Ideal for LED lighting, aerospace, and power electronics. Get reliable and efficient Ceramic PCBs today!

0 notes

Text

High-Performance Ceramic PCBs from China: Precision, Reliability, and Innovation

In the realm of advanced electronics, where high power density, extreme temperatures, and miniaturization are critical, ceramic PCBs (printed circuit boards) have emerged as a game-changing solution. Manufactured with cutting-edge technology in China, these PCBs combine superior material properties with cost-effective production, making them indispensable for industries pushing the boundaries of performance. Whether for aerospace, automotive, or next-gen telecommunications, ceramic PCBs made in China stand at the forefront of innovation, delivering unmatched quality and value. Pls send PCB files to [email protected] to get a quote now!

Why Ceramic PCBs?

Ceramic PCBs utilize substrates like alumina (Al₂O₃), aluminum nitride (AlN), or silicon nitride (Si₃N₄), offering unique advantages over traditional FR-4 or metal-core boards:

Exceptional Thermal Conductivity: Ranging from 24–320 W/m·K (depending on material), ceramic substrates efficiently dissipate heat from high-power components, preventing thermal failure.

High Electrical Insulation: Withstand voltages up to 15–25 kV/mm, ideal for high-frequency and high-voltage applications.

Thermal Stability: Operate reliably in extreme temperatures (-55°C to +850°C) without warping or degradation.

Chemical Resistance: Immune to moisture, acids, and corrosive environments.

Miniaturization Potential: Enable ultra-thin, high-density designs for compact devices.

China’s Edge in Ceramic PCB Manufacturing

China has solidified its position as a global leader in ceramic PCB production, driven by:

Advanced Material Expertise Chinese manufacturers master the synthesis and processing of advanced ceramics (e.g., AlN for ultra-high thermal conductivity), ensuring optimal performance for niche applications.

State-of-the-Art Fabrication Technologies

Thick-Film & Thin-Film Printing: Precision deposition of conductive traces (Au, Ag, Cu) for high-frequency circuits.

LTCC/HTCC (Low/High-Temperature Co-Fired Ceramics): Multi-layer designs with embedded components for RF and microwave systems.

Laser Machining: Micron-level accuracy for intricate circuit patterns and micro-vias.

Cost-Effective Scalability Leveraging automated production lines and economies of scale, Chinese suppliers deliver premium ceramic PCBs at competitive prices.

Global Compliance & Certifications Adherence to ISO, IPC, RoHS, and UL standards ensures compatibility with international markets.

Key Applications of Ceramic PCBs

Power Electronics

EV/HEV inverters, IGBT modules, and motor drives.

Solar power converters and wind turbine control systems.

LED Lighting High-power LED arrays for automotive headlights, stadium lighting, and UV sterilization.

Aerospace & Defense Radar systems, satellite communication modules, and avionics requiring radiation-hardened solutions.

5G & RF Devices Base station amplifiers, RF filters, and millimeter-wave circuits for ultra-fast data transmission.

Medical Equipment Implantable devices, MRI systems, and laser surgical tools demanding biocompatibility and precision.

Industrial Sensors High-temperature pressure sensors, gas detectors, and IoT edge devices.

Features of Premium Ceramic PCBs from China

Material Versatility

Alumina (Al₂O₃): Cost-effective, widely used for LED and power modules.

Aluminum Nitride (AlN): Ultra-high thermal conductivity (170–320 W/m·K) for high-frequency ICs.

Silicon Nitride (Si₃N₄): Exceptional mechanical strength for harsh environments.

Customization Capabilities

Layer count (1–10+ layers).

Surface finishes (ENIG, immersion tin, gold plating).

Thickness (0.25 mm to 2.5 mm).

Complex shapes and cutouts via laser or CNC machining.

Superior Signal Integrity Low dielectric loss and stable impedance control for high-speed digital and RF circuits.

Rigorous Quality Assurance

Automated Optical Inspection (AOI).

X-ray testing for layer alignment and via integrity.

Thermal shock and humidity resistance testing.

Why Partner with Chinese Ceramic PCB Suppliers?

End-to-End Solutions From design simulation and prototyping to mass production and certification support.

R&D Collaboration Work with engineers to optimize thermal management, material selection, and layout for your application.

Fast Turnaround Prototypes delivered in 5–7 days; bulk orders with flexible MOQs.

Sustainable Practices Eco-friendly production processes and recyclable material options.

Global Logistics Network Seamless export to Europe, North America, and Asia with full documentation support.

Conclusion

As industries evolve toward higher efficiency, smaller form factors, and extreme operational demands, ceramic PCBs made in China offer a future-proof solution. Combining advanced material science, precision engineering, and cost competitiveness, Chinese manufacturers are redefining the possibilities for next-generation electronics.

Whether you’re developing cutting-edge 5G infrastructure, electric vehicle systems, or life-saving medical devices, partnering with a trusted Chinese ceramic PCB supplier ensures your products achieve peak performance, reliability, and market success.

0 notes

Text

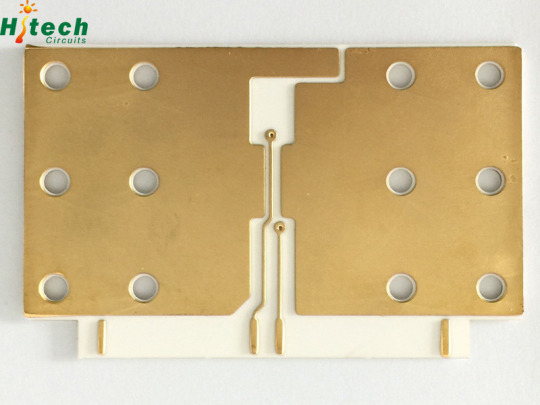

Alumina (AL2O3)Ceramic PCB

Layer Count: 1 layer

Unit Size: 55mm *130mm

Board Thickness:2.0mm

Surface Finish:gold plating

Solder Mask: White

0 notes