#anodizing software

Explore tagged Tumblr posts

Text

10 Key Advantages of Implementing Surface Finishing Software in Modern Manufacturing

The surface finishing industry is integral to manufacturing, ensuring that components are both high-performing and visually appealing. As demand grows and production scales, traditional tracking methods and manual systems begin to show their limitations. That’s where surface finishing software proves to be a game-changer — streamlining processes, enhancing visibility, and boosting accuracy across the board.

Here are the top 10 benefits manufacturers can gain by adopting surface finishing software:

1. Live Visibility Across the Shop Floor

Surface finishing processes include numerous stages, from pretreatment to final rinse. Knowing exactly where each load is at any given moment is critical. Specialized software built for surface finishing provides:

Real-time tracking of every job’s progress

Insights into delays, dwell times, and tank status

Instant updates to avoid communication gaps

This transparency ensures smoother coordination, faster response times, and fewer production mistakes.

2. Complete Digital Traceability

Traceability is no longer optional — it’s a requirement for both customers and regulatory compliance. Instead of relying on paper-based job travelers, surface finishing software enables:

Automatic, timestamped tracking of job history

Digital QA records

Surface area, operator, and inspection logs

These digital records improve audit readiness and accountability throughout the process.

3. Smart Surface Area Calculations

Accurate coating depends on precise surface area estimations. Surface finishing software supports:

Automated calculations for both standard and complex geometries

Integration of surface area data into job pricing, dosing, and QA routines

Consistent and predictable finishing quality

This not only reduces coating errors but also cuts down on chemical waste.

4. Flexible, Real-Time Scheduling

Unexpected changes — rush jobs, equipment issues, or part delays — are common in surface finishing. Software tools help manage this by:

Visualizing workflow capacity and identifying bottlenecks

Enabling drag-and-drop job rescheduling

Allowing immediate schedule adjustments with minimal disruption

This agility helps maintain productivity and avoid downtime.

5. Integrated Quality Assurance Workflows

Relying solely on manual QA increases the risk of missed defects. With finishing software, you can:

Customize QA checklists for each process

Record inspection results, measurements, and images

Automatically flag defects and assign rework

Built-in QA tools help enforce high standards consistently.

6. Optimized Load Management

Managing racking and processing loads efficiently is vital. Surface finishing software simplifies this by:

Digitally tracking loads throughout the process

Providing instant updates on tank availability and job status

Reducing manual errors and missed components

This improves throughput and labor efficiency.

7. Centralized Chemical Testing Controls

Chemical bath condition directly affects output quality. With software, you can:

Schedule and log chemical tests systematically

Monitor trends across tanks and time

Receive alerts for abnormal readings or overdue tests

This reduces unnecessary chemical consumption and extends bath life.

8. Detailed Cost Per Part Insights

Accurate cost management requires more than tracking labor or materials. Surface finishing software offers:

Cost-per-part calculations based on surface area, time, and chemical usage

Historical job data to support quoting and pricing

Visibility into profitability and resource allocation

These insights empower smarter pricing strategies and improved margins.

9. Unified Job and Process Management

Instead of juggling spreadsheets or whiteboards, surface finishing software centralizes operations via:

A single dashboard for job tracking, QA, and documentation

Consolidated load history and production data

Role-based access for shop floor teams, supervisors, and QA personnel

This fosters better team collaboration and standardized procedures.

10. Audit-Ready Compliance and Documentation

Maintaining certifications and meeting customer expectations requires meticulous records. Software solutions streamline this by:

Automatically generating and storing job documentation

Organizing QA forms and chemical logs for quick access

Ensuring alignment with compliance standards

This reduces audit stress and builds customer trust.

How PROPLATE™ Elevates Surface Finishing Operations

PROPLATE™ is built specifically for the surface finishing industry, incorporating decades of hands-on experience into one powerful platform. It offers features such as:

Real-time load tracking and job visibility

Accurate surface area and cost-per-part tools

Dynamic scheduling and QA management

Automated monitoring of chemical baths and compliance records

It’s compatible with desktops, tablets, and mobile devices — ensuring seamless integration into existing workflows and setting your operations up for long-term efficiency and scalability.

Final Thoughts

In today’s fast-paced manufacturing environment, surface finishing software is more than just an upgrade — it’s a necessity. By digitizing and streamlining complex finishing processes, manufacturers can maintain quality, adapt to changing demands, and improve operational control.

Looking to enhance traceability, efficiency, and compliance in your surface finishing workflow? Discover how PROPLATE™ can help you modernize your operations with confidence and precision.

#surface finishing software#metal surface finishing#proplate™#anodizing software#surface finishing industry#erp platforms

0 notes

Text

More CRT TV Research for Tenna Purposes

GO TO PART ONE

please use this information to hurt him. or do other things to him. also send me links

DISCLAIMER: I am not an expert, a few days ago I knew almost nothing about CRT tvs, some of this info might be wrong but luckily not a lot of people still know a ton about CRT tvs so the chances of somebody noticing an error are probably pretty slim.

Alright, onto electronics and wires and stuff. I'm a bit more comfortable in this realm. Slightly. My degree is still far more in the software realm than hardware but I'll do my best.

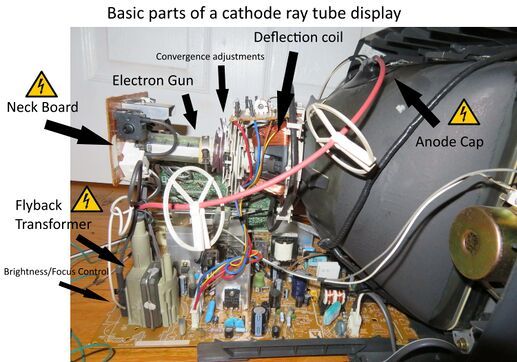

I put together this diagram showing the wiring that would make up a CRT tv. Keep in mind that I am super duper not an expert and this diagram is simplified, probably has multiple mistakes, and should not be considered a reliable reference for any real life work or repairs.

Signal flow shows the process of data getting from the antenna or other input onto the screen. Control flow shows where instructions for things like volume, brightness, channel etc. are sent. Power shows where electricity goes, anything connected to the high voltage would be extremely dangerous to mess with. And sync flow... I don't entirely understand tbh. It's something to do with making the image show up correctly onscreen.

The most dangerous wires to mess around with:

again, anything connected to high voltage. In particular, connected to the screen and whatnot is the anode, a suction cup responsible for delivering massive amounts of charge to the area behind the screen. Could easily deliver a shock strong enough to kill a human if not properly discharged (turning the tv off is not enough, the charge is stored). The effects on a darkner may be different though.

The flyback transformer and connected cables would also be very dangerous to mess with, still potentially lethal, though not quite as dangerous as touching the anode cap.

Less dangerous are the wires on the neck board (part of the CRT bit on the diagram) and the deflection coil wires (also part of the CRT bit on the diagram, but directly connected to the H/V sweep)

Any other power wires can still deliver a nasty shock but are much less dangerous.

The signal wires are generally pretty safe in terms of voltage.

Now, danger in terms of breaking the TV.

Fairly safe to mess with:

Wires that are plugged in, like composite cables, are very replaceable as they are not built into the TV

Breaking the buttons may make it difficult to interact with the TV, but all the core functionality would still remain, and it is my understanding that buttons are fairly easy to replace.

The infrared (IR) sensor for remote controls is also easy to fix, and even if it breaks you can likely use the buttons on the tv anyway

Messing with the micon/microcontroller can mess with the settings and such, but again, the core functionality of the TV is still there

Messing around with the speaker and connected wires can result in a buzzing noise or no sound at all, but is again pretty non-critical and repairable. Same with the wires connected to the audio amplifier.

A bit risky to mess with in terms of effects and repairability:

The jungle chip handles a lot of image related stuff. If messing with it doesn't cause the image to cut out entirely, it could cause the wrong colors to appear or other issues

Messing with some of the wires connected to video stuff could also cause issues like loss of color in the image

Messing with the vertical timebase could cause the image to turn into a horizontal line, messing with the horizontal timebase could cause no image or severe distortion.

Very risky to mess with:

Flyback transformer wires: can cause electrical arcing that damages the tv

Wire to the anode: Can cause sparks and arcing and again, potential damage to the tv.

Messing with the power supply wires could result in a blown fuse. I imagine finding the right kind of replacement fuse might be hard, or you might need to solder the new one on.

The wires that go to the neck board are sensitive in terms of voltage and messing with them can mess up the picture the tv shows

Messing with the deflection yoke could cause it to misalign and thus cause the picture to be distorted

Other things

TENNA'S "SIGHT"

The Panasonic TC-14S3R I found has something called the Contrast Auto Tracking System. Basically, it seems like it's possible for the tv to adjust contrast based on room brightness, so it seems that the TV has some sort of light sensor... or camera.

Doing a bit more research, apparently this would have been separate from the infrared sensor (for the remote) which is apparently usually located inside the tv.

Apparently some high-end CRTs had light sensors for brightness/contrast, which would have been on the outside of the TV. I'm not certain, but I think the small shiny black rectangle at the bottom left of this image of a CRT from ebay may be that light sensor.

Anyway, if anything were to be Tenna's eyes, it would probably be either a light sensor like this, or the infrared sensor, which would be located internally and much harder to access. Or maybe both of them together are his sight, and cutting off either one would make him partially blind.

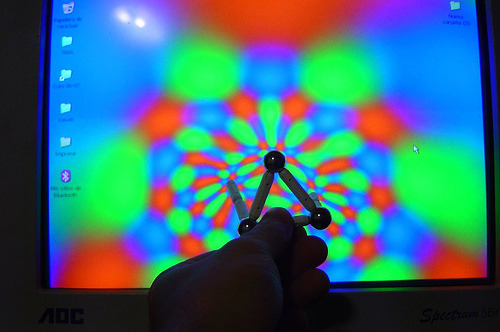

MAGNETS

Putting magnets up against a CRT screen messes with the electrons that create the image on the screen, as well as the iron mesh inside the tv (according to someone on reddit). Weaker magnets are unlikely to cause permanent damage, and temporary display issues can be fixed by degaussing, a process involving creating a controlled magnetic field to get all the magnetism and such for the TV back to normal. I believe some TVs will go through degaussing manually when turned off and on, or may have an option to run degaussing manually.

However, stronger magnets can cause permanent damage. Some external degaussing devices exist that can fix more severe damage, but some magnet damage simply cannot be repaired, permanently warping the image on the screen.

GO TO PART ONE

Anyway thanks for reading my posts have fun writing and drawing tv pain. Or tv sex. or both

Sources

CRT Torture: TV vs fun magnets, big magnet, and TOTALLY UNSAFE magnets

Vintage Panasonic TC14S3R Retro Portable 14” CRT Television Gaming SCART

What is this wire in a CRT TV?

Panasonic TC-14S3R User Manual

Degaussing TV: A Complete Guide to Enhancing CRT Image Quality

54 notes

·

View notes

Text

good morning, it is time for fanbot bio :))

i don’t have a ref sheet for them because. i can’t draw lmao BUT i have other character details

Songbird “Birdie”

Built in 1910 (115 years old as of 2025)

Height: 5’2”

Weight: 998 lbs

Made of: Anodized titanium mostly on the faceplates, copper, and gold alloy

Eyes: Blue

Hair: A wig made with brilliant warm colors, layered yellow, orange, and a little red

Backstory: Songbird, “Birdie” as their new friends call them, was built by a private inventor after receiving some parts from an old colleague out in San Diego. Mr. Burgeron, the inventor, did not yet know if he was to have a boy or a girl so he built Songbird as a blank slate to be customized when the baby arrived. Songbird was treated as nothing more than a piece of machinery by the adults of the house but was loved to death by Mr. Burgeron’s son. The Burgerons soon had a daughter and Songbird was fitted for female presenting parts. However, their daughter passed away at some point in her youth and Mr. Burgeron was devastated. Songbird, not understanding human mortality, would ask when they’d be fully finished for the little girl, but would never receive a kind answer. After a year of being made to do housework, Mr. Burgeron left Songbird in the laboratory of the house for ages, even after he passed and his family moved out. Songbird awoke one day to someone raiding the abandoned house (likely Phantom but I’m not sure yet). This started their journey out in the real world (the rest of this is still in development tbh, but they’re out there and they get fixed up eventually by. someone. maybe Walter Robotics idk)

Description: Songbird is a petit, colorful little bot originally dressed like a colorful old-timey nanny. Before being taken in and repaired, their dirty black dress has a few colorful petticoats underneath and they wear torn striped rainbow stockings. Their black hat has some damage to it. The points of highlight on their face shine with brilliant rainbow colors in the light. After repairs, the wear and tear on their chassis is repaired and they wear much more masculine clothing: black pants, a red shirt, rainbow bow tie, and they even get a new hat.

They’re very childlike in appearance and in character. They’re very naive most of the time even after all that’s happened to them. Due to dysphoria about their voice and legitimately broken speech software, they often go silent and rely on sign language to communicate. They suffer from many of the same issues as Rabbit does what with the hardware not matching the software. They’re very skittish at first but slowly open up a little bit more. Even after repairs, they tend to be very quiet and still use sign language most of the time. When pressed, they can and WILL stand up for themself. They have a monumental amount of love to give but not enough people to give it to.

#spg#steam powered giraffe#steam powered giraffe fanbot#fanbot#spg fanbot#here they are#come get y’all juice#been cooking with this one for a little bit#and yet#i still haven’t gotten their backstory down#oh well#there’s no rush#no art at this time

11 notes

·

View notes

Text

Agricultural Machinery Parts by Sand Casting or Investment Casting

Hansheng Machinery also houses a fully-equipped machining complex offering precision machining, fabrication and mechanical or welding assembly services. The equipment mix is regularly modified to ensure an ability to offer the turnkey finished metal components customers demand at that moment.

Machining parts/Agricultural Machinery Parts/casting parts

We can offer you investment casting parts, railway casting parts, railway parts, excavator machinery parts, mining machinery parts, engineering machinery, agricultural machinery parts, sand casting, bucket tooth, auto parts, stamping & forging, and valve parts. We are capability in manufacture non-standard metal machining.

1. Investment Casting Sand Casting/ Lost Wax Casting/Precision Casting/Gravity Casting/Stainless Steel Casting/Carbon Steel Casting/ Die Casting/Cookware Handle Casting/Pan Handle Casting/Home Hardware Casting;

2. Materials: Carbon Steel, Stainless Steel, Alloy Steel And Duplex Steel, Wcc, Wcb, Lcc, Color Metal etc;

3. Surface treatment: Heat treatment, machining, polishing, anodizing, hard anodizing, galvanized, enp, chrome plating, powder coating and painting;

4. Software for specification drawings: Pdf, auto CAD, solid work, proe;

5. Main production equipments: Wax injection, CNC-machine, heat treatment furnace;

6. Quality assurance in accordance with ISO9001: 2008, strict material inspection and exact dimension control, 100% quality control.

7. OEM order is welcome;

8. The parts can be made completely based on your specifications such as drawing, design, sample etc.

0 notes

Text

How to Select a Reliable Aluminum Die Casting Manufacturer in India

If you're handling sourcing in 2025, you’ve probably faced the crunch. Demand for aluminum parts is climbing fast – especially in sectors like automotive, aerospace, and consumer electronics. At the same time, reshoring efforts are throwing old supplier networks off balance. Choosing the right aluminum die casting manufacturer in India can streamline your supply chain, but the question is – how do you select a reliable manufacturer?

India’s die casting market reached approximately $3.77 billion in 2024. According to forecasts, the sector is projected to grow at around 5.13% annually through 2033, reaching $6.13 billion.

In this guide, we have presented the right questions that procurement professionals should ask and the key selection criteria while choosing the right aluminum die cast manufacturer in India.

Why India is a Competitive Aluminum Die Casting Hub

The manufacturing sector in India is gaining momentum, backed by initiatives like Make in India 2.0 and the National Manufacturing Mission. The Indian government has designed these programs to boost global competitiveness through:

Infrastructure development

Generous incentives

Streamlined compliance

Low labor rates and modern industrial zones in India offer a solid cost advantage to global sourcing teams. Widespread investments in ports, roads, and logistics corridors have strengthened the supply chain.

Meanwhile, Indian die casting facilities are now matching up to Chinese and European players in output and quality. According to research, India’s aluminum die casting market is projected to grow at a 4.85% CAGR between 2025 and 2033.

Core Criteria to Evaluate an Aluminum Die Casting Manufacturer

Choosing an aluminum die casting manufacturer isn't just about capacity. It's about consistency, compliance, and long-term capability. Here’s what procurement teams should look for:

1. Production Capacity

Can the supplier meet your forecasted demand without compromising lead times? They can should be able to scale from prototype to full production with predictable turnaround.

2. Certifications

Make sure the supplier is certified for quality assurance. Check for the following:

ISO 9001 certification

IATF 16949 certification

These standards reflect robust quality management systems. Always request current documentation before finalizing your procurement deal.

3. Tooling Expertise

Manufacturers having in-house die design and tool maintenance can reduce costs and minimize downtime. It also ensures tighter control over design iterations.

4. Material Sourcing

Ask if they use certified primary aluminum or recycled blends with traceable origins. Substandard inputs can impact the integrity of parts.

5. Quality Control Systems

From X-ray testing to coordinate measuring machines (CMM), top manufacturers implement multiple checks. Inspect their rejection rates and in-process inspection protocols.

6. Scalability

Can they ramp up production as your volumes increase? Flexibility is key for growing OEMs and Tier-1 suppliers.

Tech Capabilities Of Aluminum Die Casting Manufacturer in India

A reliable aluminum die casting manufacturer today is not just a casting shop. They’re a full-service engineering partner. Leading Indian suppliers offer:

In-house CAD and CAM design support

CNC machining

Leak and pressure testing

Post-casting surface treatments like anodizing or powder coating

Ask if they use simulation software like MAGMASOFT or AutoCAST to test die flow and solidification before tooling begins. That step alone can cut lead times and prevent costly design errors. The more tech they integrate, the fewer surprises downstream.

Choose Smarter, Not Just Cheaper – Partner with rivexa

Choosing the right aluminum die casting manufacturer in India is more than asking questions. It’s a strategic decision that defines the integrity of your supply chain. Ask the right questions, verify capabilities, and prioritize long-term reliability over short-term savings.

At rivexa, we’ve already done the groundwork, partnering with vetted suppliers in India who meet global standards. Let’s talk, and we’ll help you find a reliable sourcing partner in India.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the manufacturer HOW TO SET UP Connect the USB cable to your My Passport Ultra and to your Windows PC.Open My Passport Ultra and install WD Discovery from the drive. Equipped with USB-C technology, the My Passport Ultra portable drive offers an easy way to expand your storage with a modern metal design that complements your PC. It’s Windows 10-ready out of the box to seamlessly deliver plug-and-play storage, while password protection with hardware encryption helps enforce the security of your content. USB-C ready, USB 3.1 compatible Innovative style Automatic backup software Password protection Windows 10-ready USB-C ready, USB 3.1 compatible Featuring the latest in USB-C technology, the My Passport Ultra portable drive delivers quick and easy storage for your PC, while the included USB 3.1 adapter makes sure it’s compatible with older machines. Innovative style and function Fusing modern anodized metal and textures, the My Passport Ultra portable drive is available in silver and blue to seamlessly match your personal style and the latest computers. Get more out of WD Discovery Included WD Discovery software* makes it easy to back up your photos, videos and documents to the My Passport Ultra drive. To help preserve your online life, WD Discovery allows you to import your content from popular social media and cloud storage services, like Facebook, Dropbox and Google Drive. WD Discovery software can also be used to manage your drive settings like reformatting, LED control and more. *Internet activation required Easy-to-use auto backup software For your photos, videos or business documents, the WD Backup software included in WD Discovery makes it easy to help protect what’s important to you by automating your backup routine. Simply download WD Backup, plug in your drive and set your hourly, daily or monthly schedule. Password protection with 256-bit AES hardware encryption The WD Security function within WD Discovery helps keep your files private with a password you can choose, making it easy to enable password protection and 256-bit AES Hardware Encryption.

High capacity With up to 5TB** of capacity, you have plenty of room to keep your photos, videos, music and documents with you, wherever you go and in your control. **As used for storage capacity, one terabyte (TB) = one trillion bytes. Total accessible capacity varies depending on operating environment. Customer Reviews 4.3 out of 5 stars 10,322 — Trusted, portable storage with a modern, metal design Blazing-fast portable storage in a cool, durable design Capacity Up to 5TB Up to 2TB Auto Backup Software WD Backup software, Compatible with Apple Time Machine (requires reformatting) WD Backup software, Compatible with Apple Time Machine (requires reformatting) Password protection and hardware encryption Yes Yes Social Media/Cloud storage import with WD Discovery, import all photos, videos and files from social media and cloud storage with WD Discovery, import all photos, videos and files from social media and cloud storage Interface USB-C ready. USB 3.1 compatible. USB-C and USB 3.1 Gen 2 ready; USB 3.0, USB 2.0 and USB-A compatible Shock resistant - no data Built to withstand a 6.5-foot (1.98 meters) drop test Works with Windows Mac compatible (reformatting required) Windows Mac compatible (reformatting required)

Digital Storage Capacity: 5TB Form Factor: 2.5-inch | USB- Type C compatible|USB-C to USB-A adapter- compatible with older machines. Material: Metal Formatted NTFS and compatible with Windows | Can be reformatted for Mac or other operating systems. Software for device management and automatic backup with password protection- 256-bit AES hardware encryption Warranty: 3 Year Warranty [ad_2]

0 notes

Text

No. One top Solution for Precision Metalworking – ESSELL Machinery

Welcome to ESSELL, your trusted partner in advanced metal fabrication solutions. With years of expertise and innovation, ESSELL delivers a powerful portfolio of high-precision machines designed for cutting, bending, marking, welding, and shearing metal with excellence. We cater to industries like automotive, construction, aerospace, electricals, signage, kitchenware, and more.

Fiber Laser Cutting Machine – Precision at Light Speed

ESSELL’s Fiber Laser Cutting Machine is engineered for unmatched speed, precision, and energy efficiency. Built with cutting-edge fiber laser technology, it can easily cut stainless steel, carbon steel, aluminum, brass, and copper with smooth, burr-free edges.

Key Features:

Power options from 1kW to 12kW

Auto-focus laser head for variable thickness

High-speed linear motors and intelligent CNC control

Low maintenance with long laser life (100,000+ hours)

Nesting software for material optimization

Applications: Sheet metal components, signage, furniture, elevator panels, control boxes, and more.

CNC Bending Machine – Accuracy in Every Angle

Our CNC Bending Machines offer exceptional repeatability and power for precision bending tasks. Designed with servo or hydraulic systems, these machines allow complex multi-axis bending with ease.

Why Choose ESSELL Bending Machines?

CNC programmable control panel for easy operations

High torque output with synchronized hydraulic cylinders

Accurate back gauge system

Energy-efficient servo systems

Safety light curtains and anti-collision systems

Industries Served: Automotive parts, enclosure manufacturing, railways, architecture.

Fiber Laser Marking Machine – Permanent Marking, Zero Compromise

The Fiber Laser Marking Machine from ESSELL is the perfect solution for high-speed, high-contrast, and permanent engraving on metal and non-metal surfaces. Whether you want to mark logos, barcodes, batch numbers, or customized artwork—this machine does it all with incredible speed and clarity.

Benefits:

Maintenance-free operation

Extremely low running cost

Suitable for metals (SS, aluminum, copper), plastics, anodized materials

Optional rotary attachments for cylindrical parts

High-speed galvo scanning system

Applications: Tool marking, electronics, medical devices, hardware branding.

Fiber Laser Welding Machine – Clean Welds, Strong Joints

Our Fiber Laser Welding Machines bring speed and precision together for seamless welding applications. Ideal for sheet metal parts, the fiber laser welding system ensures minimal distortion and strong joints without the need for filler material in many cases.

Technical Advantages:

Up to 10x faster than traditional MIG/TIG welding

Cleaner finish with low heat input

Suitable for stainless steel, aluminum, copper, mild steel

2-in-1 and 3-in-1 options (welding, cleaning, cutting)

Perfect For: Metal fabrication, modular kitchen units, elevator panels, metal furniture, battery enclosures.

Sheet and Pipe Fiber Laser Cutting Machine – Dual Function, Double Efficiency

Our Sheet and Pipe Cutting Fiber Laser Machine provides unmatched flexibility by combining two machines in one. It allows easy switching between sheet metal and tube cutting without compromising accuracy.

Features:

Pneumatic/automatic chuck for pipe clamping

Rotary attachments for round, square, or elliptical pipes

Support for auto-loading pipe material (optional)

Easy-to-use interface for switching modes

High-speed operation with clean edge finish

Applications: Gym equipment, steel structures, pipelines, furniture, and more.

Shearing Machine – Clean Cuts, No Distortion

For fast and accurate straight cuts on metal sheets, ESSELL’s Shearing Machines are the ideal choice. These machines use precision-ground blades and rigid frames to ensure smooth, burr-free shearing with minimal distortion.

Features Include:

Hydraulic or mechanical drive systems

Adjustable rake angle for different thicknesses

Front and back gauge for easy length control

Heavy-duty construction for long machine life

Foot pedal operation with emergency stop

Used In: Steel service centers, fabrication shops, sheet metal production.

Why Choose ESSELL?

At ESSELL, we don’t just deliver machines—we provide complete industrial automation solutions. Our team of experts supports you from machine selection to installation, training, and after-sales service.

✅ Customization Available ✅ On-Site Installation & Demo ✅ Prompt After-Sales Support ✅ AMC & Maintenance Plans ✅ Industry 4.0 Ready Machines

Our goal is to help you maximize productivity, minimize errors, and stay ahead in a competitive market through reliable and cutting-edge equipment.

Let’s Build the Future of Metalworking Together

Thousands of businesses across India trust ESSELL for their fabrication needs. Whether you're setting up a new workshop or upgrading your production line, we are here to deliver technology that works for you.

📞 Contact Us Today 📲 Mobile: 9811765994 🌐 Website: www.essell.co 📧 Email: [email protected]

Youtube : https://www.youtube.com/@essellengineers PAN India Delivery & Service Support Google Map:- https://maps.app.goo.gl/D3THEbGRUZKTD55z8

ESSELL – Where Quality Meets Precision.

0 notes

Text

From Lab to Factory: PSA Market Grows With Industrial Standardization

The global Particle Size Analyzer Market was valued at USD 332.8 Mn in 2021 and is projected to reach USD 541.3 Mn by the end of 2031, growing at a CAGR of 5.2% from 2022 to 2031. Particle size analyzers (PSAs) play a critical role in quality control and product development across a variety of industries, including pharmaceuticals, mining, chemicals, food & beverages, and construction materials. The growing need to ensure product uniformity, performance, and safety is fueling demand for advanced particle size measurement technologies.

Market Drivers & Trends Several key factors are propelling market growth:

Increased adoption in pharmaceuticals and battery manufacturing is driving demand for PSAs to analyze powders, suspensions, and emulsions with high precision.

Technological advancements in techniques such as laser diffraction and nanoparticle tracking analysis (NTA) are enabling greater accuracy and faster analysis.

Booming lithium-ion battery market, especially due to electric vehicle (EV) proliferation, has created a need for precise control of cathode and anode material particle sizes.

Rise in nanotechnology awareness and applications has expanded PSA use in high-precision research and manufacturing.

In addition, regulatory compliance and the need for consistent product quality are driving companies to adopt particle size analysis as a standard practice.

Key Players and Industry Leaders The particle size analyzer industry is consolidated, with major players actively engaged in R&D, product innovation, and strategic partnerships to maintain their market position. Key companies include:

Anton Paar GmbH

Beckman Coulter, Inc

Bettersize Instruments Ltd.

Bühler Group

Fritsch GmbH

Horiba, Ltd.

Intertek Group plc

Mettler-Toledo International Inc.

Microtrac Retsch GmbH

Shimadzu Corporation

Sympatec GmbH

These players offer diverse portfolios spanning laser diffraction analyzers, DLS-based systems, and emerging technologies like NTA. Their market strategies include product expansion, mergers and acquisitions, and regional footprint enhancement.

Recent Developments

In February 2021, Horiba Ltd. established the HORIBA Institute for Particle Analysis in Japan to enhance development in airborne particle and nanomaterial analysis.

In June 2020, Fritsch GmbH launched the ANALYSETTE 22 NeXT Micro, a laser particle sizer with a wide measurement range (0.05–1500 µm), suitable for quality control and R&D.

Several companies are also integrating AI and automation into PSA devices for real-time monitoring and improved throughput.

Latest Market Trends

Nanoparticle Tracking Analysis (NTA) is gaining ground, especially in biotech and environmental science, due to its ability to detect nanoparticles in the 30–600 nm range.

Portable particle size analyzers are being developed for on-site analysis in sectors like mining and agriculture.

Integration with software platforms for real-time data analysis and remote monitoring is becoming common across manufacturing sectors.

The trend toward wet dispersion analysis continues due to its high accuracy in diverse liquid-based samples such as slurries and emulsions.

Market Opportunities

Rising pharmaceutical manufacturing in emerging markets, especially in India and China, presents a lucrative opportunity.

Increasing R&D in nanotechnology and biotechnology, backed by government and academic institutions, is creating demand for advanced PSA tools.

Growing investments in battery material R&D for energy storage and EVs will require reliable particle characterization solutions.

The use of PSAs in additive manufacturing (3D printing) for metal powders is also expanding rapidly.

Discover essential conclusions and data from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=15773

Future Outlook The particle size analyzer market is expected to witness consistent growth through 2031, driven by expanding applications in high-growth industries and technological enhancements. As precision and quality continue to be emphasized across global supply chains, the role of PSAs will become increasingly integral. Moreover, automation and AI integration will further streamline operations and make particle analysis more accessible and efficient.

Market Segmentation The market is segmented based on technology, dispersion type, and end-use industry:

By Technology:

Dynamic Image Analysis (DIA)

Static Image Analysis

Laser Diffraction

Dynamic Light Scattering (DLS)

Nanoparticle Tracking Analysis (NTA)

Others (e.g., Sieve Analysis, Centrifugal Sedimentation)

By Dispersion Type:

Wet Particle (most dominant and growing segment)

Dry Particle

Spray Particle

By End-use Industry:

Pharmaceutical

Food & Beverage

Building & Construction

Chemical

Metals & Mining

Agriculture & Forestry

Healthcare

Industrial

Others (e.g., Academia, Semiconductors)

Regional Insights Asia Pacific leads the global market with approximately 30% market share in 2021. Factors such as rapid industrialization, increasing R&D investments, and strong presence of manufacturing industries are driving this growth. China, India, Japan, and South Korea are key contributors.

North America follows closely, driven by a strong pharmaceutical base, rising demand for nanomaterials, and technological innovation. The U.S. remains a leader in high-end PSA adoption due to a large number of pharmaceutical, biotechnology, and electronics companies.

Europe also commands a substantial share, backed by environmental regulations and advancements in life sciences.

Frequently Asked Questions

1. What is the market size of the Particle Size Analyzer industry? In 2021, the global market was valued at US$ 332.8 Mn, and it is projected to grow to US$ 541.3 Mn by 2031.

2. What is driving the growth of the PSA market? The growth is primarily driven by rising demand in pharmaceuticals, battery production, nanotechnology, and R&D across various sectors.

3. Which technology is gaining significant traction in the market? Nanoparticle Tracking Analysis (NTA) is one of the fastest-growing technologies due to its precision and applicability in advanced materials research.

4. Who are the major players in the market? Prominent companies include Anton Paar, Horiba, Mettler-Toledo, Shimadzu, and Microtrac Retsch, among others.

5. Which region dominates the market? Asia Pacific is the leading region, supported by large-scale manufacturing, R&D investments, and increasing adoption across industries.

6. What are the key applications of particle size analyzers? They are used in drug formulation, battery material analysis, food processing, construction materials, metal powders for 3D printing, and more.

7. How are particle size analyzers used in the pharmaceutical industry? They help in analyzing API particle sizes, ensuring proper drug dissolution, bioavailability, and formulation stability.

0 notes

Text

Sheet Metal Fabrication in Bangalore: The Hub of Precision Engineering

Summary

Explore the growing demand for sheet metal works in Bangalore and discover how top fabrication companies in Bangalore deliver precision, quality, and reliability across industries with advanced manufacturing solutions.

Introduction

Bangalore, often celebrated as the Silicon Valley of India, is rapidly emerging as a powerhouse in industrial and manufacturing sectors. Among the many services that support the city's booming industries, sheet metal fabrication stands out as a core component of product development and engineering. From intricate enclosures to heavy-duty industrial parts, the demand for sheet metal works in Bangalore has grown significantly in recent years.

In this article, we explore the scope, strengths, and advantages of working with sheet metal fabrication companies in bangalore, and why this city is now one of India’s most reliable manufacturing destinations.

What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of transforming flat metal sheets into desired shapes and structures through techniques such as cutting, bending, welding, and assembling. It is a critical process in numerous industries, including:

Automotive and Aerospace

Electrical and Electronics

Construction and Infrastructure

Medical Devices

Consumer Appliances

Telecom and Energy Equipment

Precision and consistency are vital in sheet metal works, especially when dealing with mass production or custom prototyping.

Why Bangalore?

1. Industrial Infrastructure

Bangalore boasts advanced industrial zones such as Peenya Industrial Area, Bommasandra, and Electronic City that are home to a dense concentration of engineering and fabrication units. These hubs are equipped with the latest machinery and logistics systems, making Bangalore a manufacturing-ready city.

2. Skilled Workforce

The city benefits from a large pool of engineers, machine operators, and designers who specialize in CNC operations, CAD software, laser cutting, and mechanical fabrication. This ensures high accuracy in output and reduced turnaround times.

3. Tech Integration

Bangalore’s fabrication industry is quick to adopt emerging technologies such as automation, CNC machining, and laser-based systems. These innovations improve efficiency, reduce human error, and support high-volume production.

Services Offered by Fabrication Companies in Bangalore

Fabrication companies in Bangalore typically offer a wide range of services to meet the diverse needs of various sectors. Some of the key services include:

● CNC Laser Cutting

Using high-powered lasers, materials such as stainless steel, aluminum, and copper are cut with pinpoint accuracy. This allows for the creation of complex and clean-edged parts.

● CNC Bending & Forming

Precision press brake machines are used to bend and form sheets into desired shapes. This is essential for creating brackets, enclosures, chassis, and cabinets.

● MIG/TIG/Spot Welding

Welding is crucial in combining different components. Fabrication shops in Bangalore offer MIG, TIG, and spot welding for both heavy and thin-gauge metals.

● Punching & Stamping

CNC turret punching machines help in making holes, cutouts, and complex designs efficiently and accurately.

● Surface Finishing

To protect against corrosion and improve aesthetics, services like powder coating, anodizing, and galvanizing are offered.

● Prototyping & Assembly

Many sheet metal works in Bangalore also include prototyping services for startups and R&D teams. Full or partial assembly services are also available for ready-to-install products.

Industries Served

The versatility and precision of fabrication companies in Bangalore make them well-suited to serve a wide range of industries, such as:

Aerospace: Lightweight yet strong components with tight tolerances

Medical Devices: Sterile, corrosion-resistant equipment housings

Automotive: Customized body panels, brackets, and engine parts

Telecom: Enclosures, racks, and panels for networking equipment

Green Energy: Structures for solar panels, battery cabinets, and more

These companies often follow international quality standards such as ISO 9001, ISO 14001, and AS9100, depending on the industry.

Advantages of Choosing Fabrication Companies in Bangalore

Cost-Effective Production

Thanks to the competitive manufacturing ecosystem, fabrication services in Bangalore often come at a lower cost compared to other major cities without compromising on quality.

Fast Turnaround

Whether it's a prototype or a large batch order, turnaround times are kept short due to advanced scheduling systems, CNC automation, and a dedicated workforce.

Customization & Flexibility

Most sheet metal fabricators offer complete design-to-delivery solutions. Whether it’s a one-off design or a recurring production order, clients benefit from flexibility and tailored service.

Scalability

With a wide network of suppliers and sub-contractors, sheet metal works in Bangalore can scale production rapidly to meet growing business needs.

What to Look for in a Fabrication Partner?

When selecting a fabrication company, it’s important to consider:

Technical Capabilities: Does the shop have modern CNC and laser cutting equipment?

Quality Standards: Are they ISO-certified? Do they follow lean manufacturing practices?

Material Expertise: Can they work with multiple metals like SS, MS, GI, and aluminum?

Communication & Transparency: How well do they share project timelines, reports, and updates?

Delivery & Packaging: Can they ensure secure, on-time delivery with proper documentation?

Many companies also offer online quote portals where customers can upload CAD files and get instant estimates.

Future of Sheet Metal Works in Bangalore

With the rise of Industry 4.0, IoT integration, and smart manufacturing, Bangalore’s fabrication sector is set to become more digital and data-driven. Technologies like 3D printing, robotic welding, and AI-powered inspection systems are already being tested in forward-thinking fabrication workshops.

The increasing focus on electric vehicles, renewable energy, and medical technology is also expected to drive demand for precision sheet metal fabrication in the city.

Conclusion

Whether you're a startup needing a prototype or an OEM looking for a high-volume production partner, fabrication companies in Bangalore offer the technical know-how, flexibility, and reliability required to meet your goals. With a strong industrial foundation, skilled professionals, and cutting-edge technology, sheet metal works in Bangalore are setting benchmarks in quality and innovation.

So, if you’re looking for dependable and cost-effective sheet metal solutions, Bangalore might just be the perfect place to start.

FAQ

Q1. What services are commonly offered by sheet metal fabrication companies in Bangalore? Most fabrication companies in Bangalore offer CNC laser cutting, punching, bending, welding, powder coating, and custom prototyping for a variety of industries.

Q2.Why is Bangalore considered a hub for sheet metal works? Bangalore has advanced industrial zones, a highly skilled workforce, and access to the latest fabrication technologies, making it a prime location for precision sheet metal works.

Q3.Do fabrication companies in Bangalore handle custom or small-batch projects? Yes, many sheet metal fabricators in Bangalore specialize in both mass production and small-batch/custom fabrication for startups, R&D teams, and niche applications.

Q5.What industries rely on sheet metal works in Bangalore? Industries like aerospace, automotive, electronics, telecom, renewable energy, and medical devices frequently depend on Bangalore-based fabrication services.

Q6. Are Bangalore fabrication companies equipped with advanced technologies like CNC and laser cutting? Absolutely. Many fabrication companies in Bangalore use modern CNC machines, laser cutters, and automated welding systems to ensure precision and quality.

Q7. How do I get a quote from a fabrication company in Bangalore? Most companies offer online quote systems where you can upload CAD files and get pricing based on material, quantity, and specifications. Q8. What materials are typically used in sheet metal fabrication in Bangalore? Common materials include stainless steel (SS), mild steel (MS), aluminum, galvanized iron (GI), and sometimes copper or brass depending on the project.

#sheet metal fabricators in bangalore#heavy fabrication companies in bangalore#fabrication companies in bangalore#sheet metal works in bangalore

0 notes

Text

Reducing Errors and Waste in Surface Finishing with PROPLATE™

In the surface finishing industry, reducing errors and waste is crucial for maintaining efficiency, lowering costs, and ensuring high-quality metal surface coatings. Traditional methods often rely on manual processes, which can lead to inconsistencies, rework, and excessive material usage. With the advent of PROPLATE™, an advanced metal finishing software, businesses can now optimize their manufacturing process software, improve precision, and minimize waste.

The Challenges in Metal Surface Finishing

Metal surface finishing shops face various challenges, including inaccurate Chemical surface treatment measurements, inefficient scheduling, and high material wastage. Whether dealing with Barrel Plating, Rack Zinc Plating, anodizing software, or powder coating inventory, improper calculations and lack of real-time monitoring can result in costly errors.

Moreover, heat treatment services and manufacturing production software often require precise control over temperature, coating thickness, and material usage. Without an efficient production ERP system, tracking these parameters manually can lead to inconsistencies and compliance issues.

How PROPLATE™ Helps Reduce Errors

PROPLATE™ integrates advanced manufacturing ERP software with intelligent automation to reduce human errors. This best metal finishing software ensures precision in plating anodizing software applications, from chemical bath concentration control to accurate metal finishing technology calculations. By leveraging ERP software for manufacturing, businesses can improve their workflows, leading to reduced defects and better resource utilization.

Automated Calculations & Accurate Surface Area Measurement PROPLATE™ offers intelligent metal finishing shop software that calculates surface area accurately for Metal surface coatings. This feature helps reduce chemical overuse and ensures optimal coating thickness, minimizing the need for rework.

Real-time Monitoring & Quality Control With built-in job shop management software, businesses can track production in real time, identifying potential errors before they lead to major defects. This functionality ensures adherence to quality standards while reducing wastage of raw materials.

Optimized Scheduling & Workflow Management Jobshop ERP solutions provided by PROPLATE™ help businesses streamline scheduling, ensuring that every order follows an optimized path. This reduces bottlenecks and unnecessary delays in the manufacturing ERP system.

Chemical Test Analysis & Cost Control PROPLATE™ automates chemical surface treatment monitoring, ensuring that precise amounts of chemicals are used during the finishing process. This prevents excessive waste while maintaining compliance with environmental regulations.

Enhancing Efficiency with Manufacturing ERP SaaS

By integrating enterprise resource planning systems, PROPLATE™ serves as an all-in-one manufacturing improvement software that enhances operational efficiency. Its ERP solutions include features tailored for ERP software for metal finishing, making it the ideal choice for any metal finishing company looking to optimize production.

With ERP platforms specifically designed for manufacturing ERP SaaS, businesses gain access to advanced manufacturing management software that facilitates lean operations and minimizes resource wastage. The role of ERP in manufacturing industries is evident in the way PROPLATE™ digitizes and automates manual tasks, leading to improved accuracy and better decision-making.

Conclusion

For any metal finishing company, reducing errors and waste is key to maximizing profitability and ensuring sustainability. By leveraging PROPLATE™, businesses in the surface finishing industry can integrate manufacturing ERP software systems, improve quality control, and streamline operations. With its intelligent job shop software and manufacturing process software, PROPLATE™ is the ultimate solution for achieving efficiency and precision in metal surface finishing

#manufacturing erp software#metal finishing company#metal surface finishing#proplate™#surface finishing software#digital solutions#metal surface coatings#anodizing software

0 notes

Text

Redefining Home Cinema with Smart Technology

The Evolution of Home Entertainment

The way we experience movies at home has transformed dramatically over the past few decades. From the days of bulky VHS tapes to the era of streaming services, each advancement has brought convenience and quality closer together. Today, the pursuit of a theater-like experience at home has led to the development of sophisticated devices that prioritize both visual and auditory excellence. Among these, a standout 4K movie player has emerged, designed to deliver unparalleled picture and sound quality. This device, known as the Kaleidescape Strato V, represents a pinnacle in home entertainment technology, offering a seamless blend of high-fidelity playback and intuitive design. Its ability to store and play movies with lossless audio and Dolby Vision support sets it apart from conventional streaming boxes, making it a favorite among cinephiles who crave authenticity in their viewing experience.

Unpacking Premium Movie Playback

The essence of a great home cinema lies in its ability to replicate the magic of a commercial theater. This is where advanced movie players shine. With a sleek black anodized aluminum finish, this particular device not only performs exceptionally but also adds a touch of elegance to any setup. It supports 4K Ultra HD playback with bit rates up to 100 Mbps, ensuring that every frame is crisp and every color vibrant. The inclusion of Dolby Vision and HDR10 means that viewers can enjoy movies as directors intended, with dynamic contrast and vivid hues. Additionally, its 960GB solid-state drive can store approximately ten high-bitrate 4K movies, making it a standalone solution for those starting their digital collection. For those seeking to expand, the device can connect to larger servers, unlocking a vast library and multi-room playback capabilities. This scalability ensures that the system grows with the user’s needs, providing a future-proof investment in entertainment.

The Role of Smart Home Integration

A modern home cinema is not just about the screen and speakers; it’s about creating an immersive environment where every element works in harmony. Smart home technology has become a key player in this space, allowing users to control lighting, shades, and even seating with a single command. Voice assistants have revolutionized how we interact with our homes, offering hands-free control that enhances convenience. The cost of such advanced voice control systems, often referred to as the Josh AI price, varies depending on the complexity of the installation and the number of connected devices. These systems integrate seamlessly with premium movie players, enabling users to start a movie, dim the lights, and adjust the sound with a simple voice prompt. This level of integration transforms a living room into a cinematic sanctuary, where technology fades into the background, and the story on screen takes center stage.

Designing the Ultimate Viewing Experience

Creating a home theater that rivals professional setups requires careful consideration of both hardware and software. The movie player in question offers a streamlined interface optimized for navigating small libraries, with downloads completing in as little as ten minutes over gigabit Ethernet. Its compatibility with advanced control protocols allows it to sync with various home automation systems, ensuring a cohesive experience. The player’s lossless audio support, including formats like Dolby Atmos and DTS:X, delivers sound that envelops the viewer, from the subtlest whisper to the most explosive action sequence. For those investing in smart home technology, the ability to automate environmental settings enhances the experience further. While the upfront cost of such systems may seem significant, the value lies in their ability to deliver consistent, high-quality entertainment tailored to individual preferences.

Why Quality Matters in Home Cinema

In an age where streaming services dominate, the difference between compressed and lossless content is stark. Standard streaming often sacrifices quality for bandwidth, resulting in buffering or reduced detail. In contrast, downloading high-bitrate movies ensures flawless playback, free from interruptions. This commitment to quality is what drives enthusiasts to invest in premium systems. The movie player’s ability to upscale HD and SD content to 4K resolution means that even older films look stunning on modern displays. Coupled with smart home integration, where voice commands can fine-tune the ambiance, the result is an experience that feels bespoke. The cost of advanced voice control, while a consideration, is justified by the ease and precision it brings to managing complex setups, making every movie night feel like a special event.

The Future of Home Entertainment

As technology continues to evolve, the boundaries of what’s possible in home cinema expand. Devices like the 4K movie player discussed here are paving the way for a future where quality and convenience coexist effortlessly. Its recognition with prestigious design awards highlights its blend of form and function, appealing to both tech enthusiasts and aesthetes. Similarly, advancements in voice-activated smart home systems promise even greater personalization, with costs becoming more accessible as adoption grows. Together, these technologies are redefining what it means to watch a movie at home, turning passive viewing into an active, immersive experience. For those who value the art of filmmaking, investing in such systems is not just about entertainment—it’s about preserving the integrity of the cinematic vision in the comfort of one’s own space.

Find out more today, visit our site.

epic sound system price

epic extended warranty terra8

0 notes

Text

Hello, the poem got me thinking so here’s some fun trivia facts about Songbird!

They used to have wings but their inventor removed them. He intended to reattach them at some point but never did. However, he left the wiring active and exposed so Birdie’s back always feels kinda weird. It doesn’t always hurt, sometimes it just feels like a phantom sensation or a weird tingle. They don’t like it

They like to sing quite a bit when their speech software isn’t being weird but they’re very, VERY shy about it so they don’t sing for very many people.

They’re weirdly good at playing the recorder of all things. Other bots they meet think it’s both a blessing and a curse. A blessing because “yay, Birdie can play an instrument and does it well” but a curse in the sense of “oh god, of all things, why the fucking recorder?”

They get easily attached to people around them. They will follow you around like a sad lost puppy if they like you

They like dressing both masculinely and femininely but they tend to default to a more masculine look solely because that’s how they originally look when taking care of Mr. Burgeron’s son

They dream about their old kiddos all the time. They usually wake up with hydraulic fluid on their face when they do dream

They have limited weaponry as a last defensive resort should anything happen to the children they’re watching

Rabbit is their favorite SPG bot for. obvious reasons lol

When they change their look, they keep their brightly colored hair, but opt for a shorter wig

They were not awake or aware for the years they spent locked away. They were turned off by Mr. Burgeron until someone accidentally kicked their ‘on’ button

They love dolls and will do anything for a new one

They still don’t quite understand what happened to the Burgerons and their children but they have a limited understanding of the fact that they aren’t coming back

They do not like being left alone. At all. If you leave them alone, they will likely freak the fuck out after a few minutes

Heavily inspired by Spinel from Steven Universe for them, except they don’t go full vindictive like she does. They get mad but nowhere near as mad as Spinel does

They can read and they’re quite smart, but because of their childlike programming and disposition, they prefer children’s books

They know ten different languages: English, Spanish, ASL, BSL, French, Italian, Mandarin, Japanese, Korean, and Russian. They want to learn more of both spoken and signed languages

They’re built to look more like a doll than a standard automaton. The anodized titanium on their cheeks is in a circular pattern like the rosy cheeky painted/stitched on old dolls. They lowkey look like a puppet

Feel free to throw any additional questions at my inbox! Asks are on and I’d love to start getting them about Songbird or really any characters y’all have questions about

#steam powered giraffe fanbot#steam powered giraffe#spg#spg fanbot#fanbot#wow two posts?#right after each other?#what will twenty do next?

5 notes

·

View notes

Text

Metal Marking Machine Manufacturer, Exporter & Supplier in Ahmedabad | Divine Laser Technologies

The demand for accurate and permanent product marking has led industries to adopt advanced marking solutions. Among these, Metal Marking Machines have gained immense popularity for their ability to produce sharp, clear, and permanent marks on various metals. Divine Laser Technologies proudly stands as a leading Metal Marking Machine Manufacturer, Exporter & Supplier in Ahmedabad, delivering state-of-the-art marking systems to clients across industries.

At Divine Laser Technologies, we are committed to innovation, precision engineering, and customer satisfaction. Our extensive experience in developing Metal Marking Machines in Ahmedabad has helped us become a trusted name among manufacturers and exporters. Whether your industry requires Laser Metal Marking Machines, Metal Engraving Machines, or high-speed Industrial Marking Machines, our solutions offer unmatched performance and reliability.

Why Metal Marking Machines Are Essential

Metal Marking Machines play a crucial role in modern manufacturing. They provide permanent identification and traceability for products, which is vital for quality control, regulatory compliance, branding, and customer information. Whether marking serial numbers, batch codes, logos, barcodes, or QR codes, a reliable Laser Metal Marking Machine ensures high-precision results on metal surfaces.

Industries such as automotive, aerospace, electronics, medical devices, tools manufacturing, and jewelry rely heavily on Metal Engraving Machines to produce fine, accurate marks that withstand wear, corrosion, and harsh environments. As an Ahmedabad Marking Machine Manufacturer, Divine Laser Technologies offers an extensive range of machines designed for both small-scale workshops and large industrial production lines.

Our Range of Metal Marking Machines

At Divine Laser Technologies, we design and manufacture a comprehensive portfolio of Metal Marking Machines in Ahmedabad to cater to a wide range of industrial applications. Our offerings include:

Fiber Laser Metal Marking Machines: Our Fiber Laser Metal Marking Machines are ideal for marking metals such as stainless steel, aluminum, brass, copper, titanium, and more. These machines are known for:

High-speed marking with excellent accuracy

Low maintenance and long operational life

Energy efficiency and minimal operating costs

Ability to create intricate patterns, logos, and data codes

CO2 Laser Metal Engraving Machines: For marking coated metals, anodized aluminum, and certain plastics, our CO2 Laser Metal Engraving Machines deliver high-quality results. These machines provide a versatile solution for industries requiring both metal and non-metal marking capabilities.

Portable Industrial Marking Machines: We also manufacture Portable Industrial Marking Machines for on-site and mobile applications. These machines are lightweight, easy to operate, and perfect for large components, pipelines, or fieldwork.

Customized Metal Marking Machines: As an expert Ahmedabad Marking Machine Manufacturer, we understand that every customer has unique requirements. We offer customized Metal Marking Machines tailored to meet specific production needs, surface types, and marking designs.

Features and Benefits

When you choose a Metal Marking Machine from Divine Laser Technologies, you are investing in a solution packed with advanced features:

Precision and Clarity: Achieve sharp, permanent marks with consistent quality across production batches.

Speed and Efficiency: Our machines ensure rapid marking cycles, enhancing productivity.

Versatility: Compatible with a wide range of metals and alloys, offering flexibility in production.

Durability: Engineered for long service life with minimal maintenance requirements.

Software Integration: User-friendly software interfaces support automated marking and easy design modifications.

Environmentally Friendly: Laser-based machines require no inks, chemicals, or consumables, reducing waste and operational costs.

Industries We Serve

As a trusted Metal Marking Machine Manufacturer, Exporter & Supplier in Ahmedabad, Divine Laser Technologies serves a diverse client base across multiple sectors, including:

Automotive: Chassis numbers, engine parts, gear components

Aerospace: Component identification, part tracking

Electronics: PCB marking, component codes

Medical Devices: Surgical tools, implants, instruments

Tooling and Hardware: Drill bits, saw blades, wrenches

Jewelry: Fine engraving for branding and personalization

Defense: Marking weapons, ammunition, and equipment

Industrial Manufacturing: Serial numbers, logos, product details

Our Laser Metal Marking Machines are designed to handle the challenges of every industry, ensuring top-notch performance and adaptability.

Why Choose Divine Laser Technologies?

Proven Expertise: With years of experience as a leading Ahmedabad Marking Machine Manufacturer, we possess deep industry knowledge and technical expertise. Our engineering team is dedicated to delivering machines that meet the highest standards of performance and reliability.

Cutting-Edge Technology: We stay ahead of the curve by integrating the latest advancements in laser and marking technology. Our continuous investment in R&D allows us to provide clients with state-of-the-art Metal Marking Machines that drive business growth.

Tailored Solutions: We understand that different industries and applications require unique marking capabilities. That is why we offer customized machines and solutions that cater to your exact operational needs.

Quality and Compliance: All our machines are manufactured under strict quality control processes. Our products comply with international safety and quality standards, ensuring reliable and compliant marking for every industry.

Global Reach: As a prominent Metal Marking Machine Manufacturer, Exporter & Supplier in Ahmedabad, Divine Laser Technologies exports machines to markets across India and worldwide. Our robust distribution network ensures timely delivery and reliable service support.

Customer-Centric Approach: At Divine Laser Technologies, customer satisfaction is our top priority. We provide exceptional pre-sales consultation, installation support, operator training, and after-sales service, helping you achieve maximum return on investment.

The Future of Metal Marking with Divine Laser Technologies

In a competitive global market, product traceability and brand identity are critical factors that differentiate your offerings. With Divine Laser Technologies' advanced Laser Metal Marking Machines and Industrial Marking Machines, you gain a competitive edge through precision, consistency, and durability.

We continue to innovate and enhance our Metal Marking Machines in Ahmedabad, keeping pace with evolving industry trends and technological advancements. Our commitment to delivering high-quality marking solutions ensures that your business stays future-ready.

If you are looking for a reliable Metal Marking Machine Manufacturer, Exporter & Supplier in Ahmedabad, look no further than Divine Laser Technologies. Whether you need a standard Laser Metal Marking Machine, a precision Metal Engraving Machine, or a fully customized Industrial Marking Machine, we have the right solution for you.

Contact Us Divine Laser Technologies today to discuss your requirements, request a product demo, or get a personalized quote. Let us help you elevate your marketing capabilities and take your production to the next level.

For more information: https://www.lasermarkingmachine.info/

Call us: 8069220249

E-mail ID: [email protected]

Location: 10 Grand Vishala Odhav Ring Road Ahmedabad, Gujarat, (India)

#Metal Marking Machine#Metal Marking Machine in Ahmedabad#Laser Metal Marking Machine#Metal Engraving Machine#Industrial Marking Machine#Ahmedabad Marking Machine Manufacturer

0 notes

Text

How CNC Machining Services Work: An Overview

CNC machining is a cornerstone of modern manufacturing, offering high precision, speed, and flexibility for producing intricate parts and components. From aerospace to automotive, electronics to industrial machinery, CNC machining services are critical in fabricating parts that meet exact specifications. Whether you're a product designer or a manufacturing engineer, understanding how CNC machining works can help you leverage its benefits effectively.

What Is CNC Machining?

CNC machining is a subtractive manufacturing process where material is removed from a solid block—known as a blank or workpiece—using a variety of cutting tools. The process is controlled by pre-programmed computer software that dictates the movement of machines such as mills, lathes, routers, and grinders. Unlike manual machining, CNC systems operate with extraordinary precision and repeatability, making them ideal for high-tolerance, complex parts.

Key Components of CNC Machining Systems

Computer-Aided Design (CAD): Everything starts with a 3D model or a technical drawing of the desired part. Engineers or designers use CAD software to define dimensions, geometries, and tolerances.

Computer-Aided Manufacturing (CAM): The CAD file is then imported into CAM software, which generates a toolpath and converts the design into G-code—a programming language that CNC machines understand.

CNC Machine: The G-code is uploaded to the CNC machine, which follows the programmed instructions to execute precise movements and tool changes. Machines may be 3-axis, 4-axis, or even 5-axis, depending on the complexity of the part and the number of simultaneous movements required.

Cutting Tools: Depending on the material and design, different cutting tools are used, such as end mills, drills, or turning tools. The choice of tool affects surface finish, cutting speed, and overall efficiency.

Workholding: Fixtures and vises secure the workpiece in place during machining, ensuring stability and accuracy.

The CNC Machining Workflow

Here’s a simplified breakdown of the typical CNC machining process:

1. Design & Planning

The journey of custom CNC machined parts begins with a detailed design. Engineers define all technical requirements, including geometry, material selection, surface finish, and tolerance. This stage is crucial because the CAD model directly influences machining feasibility and cost.

2. Programming

CAM software interprets the CAD model to produce G-code. This code tells the CNC machine what actions to perform—movements along the X, Y, and Z axes, spindle speeds, feed rates, tool changes, and more.

3. Setup

A technician sets up the machine by loading the workpiece, installing the required tools, and configuring the machine based on the program. This step may also involve calibrating the tool offsets and checking initial positions.

4. Machining

Once everything is set up, the machine starts removing material as per the G-code instructions. The process could involve multiple operations such as drilling, milling, turning, or tapping. Multi-axis machines can produce complex geometries in a single setup, reducing lead time and improving precision.

5. Inspection & Quality Control

After machining, the part is inspected using precision measurement tools such as calipers, micrometers, or Coordinate Measuring Machines (CMM). This step ensures that the final product meets all specified dimensions and tolerances.

6. Finishing Operations

Depending on the application, post-machining processes like deburring, anodizing, or powder coating may be applied. These finishing steps enhance durability, corrosion resistance, or aesthetics.

Types of CNC Machining

There are several types of CNC machining processes, each suited for specific applications:

Milling: A rotating cutting tool moves along multiple axes to remove material.

Turning: The workpiece rotates while a stationary cutting tool shapes its exterior or interior.

Drilling: Straight holes are created using a rotating drill bit.

EDM (Electrical Discharge Machining): Material is removed using electrical sparks—ideal for hard materials or intricate cavities.

Grinding: A rotating wheel removes material to achieve high surface finish and tight tolerances.

Advantages of CNC Machining

Precision: CNC machines can achieve tolerances as tight as ±0.001 inches, ideal for high-performance industries.

Repeatability: Once programmed, the machine can produce thousands of identical parts with minimal variation.

Flexibility: CNC services can handle one-off prototypes or high-volume production runs.

Efficiency: Faster turnaround times and reduced manual labor.

Material Versatility: Supports a wide range of materials including metals (aluminum, steel, titanium), plastics (nylon, ABS, PEEK), and composites.

Applications of Custom CNC Machined Parts

Custom CNC machined parts are essential in industries where performance and reliability are non-negotiable:

Aerospace: Complex components such as turbine blades, housings, and brackets.

Medical Devices: Surgical instruments, prosthetics, and diagnostic equipment.

Automotive: Engine components, transmission parts, and custom performance mods.

Robotics & Automation: Gears, end-effectors, and structural parts.

Consumer Electronics: Housings, frames, and connectors.

At MS Machining, our team specializes in producing high-quality custom CNC machined parts tailored to exact client specifications. Whether you need prototypes or full-scale production, MS Machining delivers consistent quality with fast lead times.

Why Choose MS Machining?

When it comes to custom CNC machined parts, choosing the right partner can make all the difference. Here's what sets MS Machining apart:

State-of-the-Art Equipment: We operate a fleet of advanced 3-, 4-, and 5-axis CNC machines.

Experienced Technicians: Our machinists have years of hands-on experience across multiple industries.

Fast Turnaround: We streamline production timelines without compromising quality.

Material Expertise: From exotic alloys to engineering plastics, we handle diverse materials with precision.

Quality Assurance: Every part undergoes rigorous inspection to ensure it meets or exceeds your requirements.

Whether you're a startup developing your first prototype or a large enterprise needing scalable production, MS Machining is your trusted source for dependable CNC machining services.

The Future of CNC Machining

CNC machining is constantly evolving, with emerging technologies like AI, machine learning, and automation pushing the boundaries further. Predictive maintenance, adaptive toolpath optimization, and real-time quality monitoring are enhancing productivity and reliability. As industries continue to demand higher performance and customization, CNC machining will remain a foundational technology for manufacturing innovation.

Final Thoughts

CNC machining is more than just a fabrication method—it's a bridge between concept and reality. With its unparalleled accuracy, versatility, and efficiency, it enables manufacturers to produce everything from simple fixtures to complex aerospace components. Companies like MS Machining are at the forefront, delivering precision-crafted custom CNC machined parts that help bring ambitious designs to life.

Whether you're exploring rapid prototyping or full-scale manufacturing, understanding how CNC machining services work empowers you to make informed decisions and achieve superior results.

0 notes

Text

Closed Die Forging Open Spelter Sockets

1. Investment casting sand casting/ lost wax casting/precision casting/gravity casting/stainless steel casting/carbon steel casting/ die casting/cookware handle casting/pan handle casting/home hardware casting;

2. Materials: Carbon steel, stainless steel, alloy steel and duplex steel, wcc, wcb, lcc, color metal etc;

3. Surface treatment: Heat treatment, machining, polishing, anodizing, hard anodizing, galvanized, enp, chrome plating, powder coating and painting;

4. Software for specification drawings: Pdf, auto CAD, solid work, proe;

5. Main production equipments: Wax injection, CNC-machine, heat treatment furnace;

6. Quality assurance in accordance with ISO9001: 2008, strict material inspection and exact dimension control, 100% quality control.

7. OEM order is welcome;

8. The parts can be made completely based on your specifications such as drawing, design, sample etc.

0 notes