#basf

Explore tagged Tumblr posts

Text

The distinctive livery of the N°90 M1 Procar highlights the curves of the Paul Ricard Circuit during an historic racing event held in conjunction with the 2017 1000Km Le Castellet.

#bmw#classic#vintage#classic car#bmw motorsport#classic and vintage bmw#bmw m1#bmw procar#bmw e26#basf

32 notes

·

View notes

Text

1983 BASF Video Cassettes ad

#basf#vhs#beta#video cassette#vice#1983#1980s#vintage ad#vintage ads#vintage advertising#vintage advertisement

117 notes

·

View notes

Text

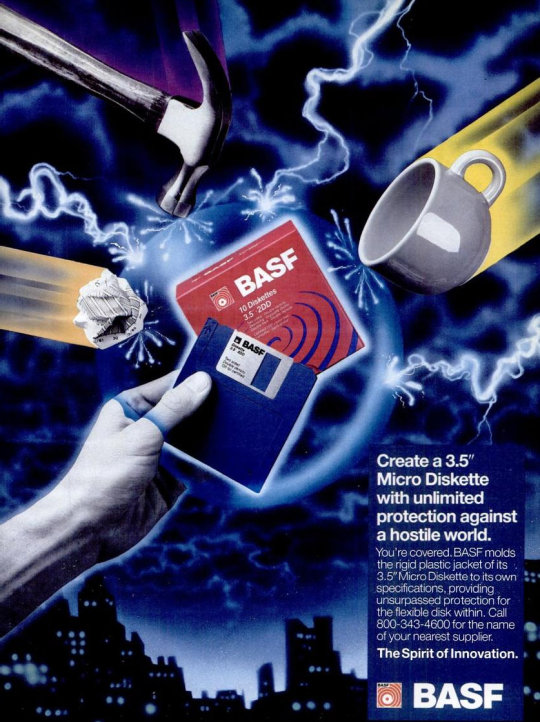

PC Mag - February 1989 BASF 3.5" Micro Diskette

226 notes

·

View notes

Text

#BASF#video tapes#VHS#VHSwave#1988#80s#1980s commercials#synthwave#vaporwave#T 120#T 160#extra quality#gif#my gifs

62 notes

·

View notes

Text

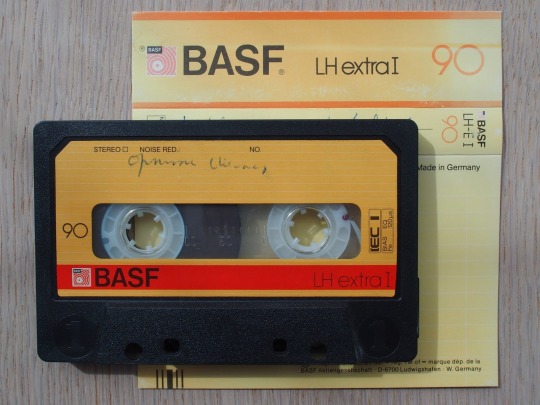

BASF Pro II Chrome

#cassette tape#cassette#audio tape#chrome#mix tape#80s ads#80s nostalgia#80s music#80s#retro style#retro#retro aesthetic#basf#chrome tape

11 notes

·

View notes

Text

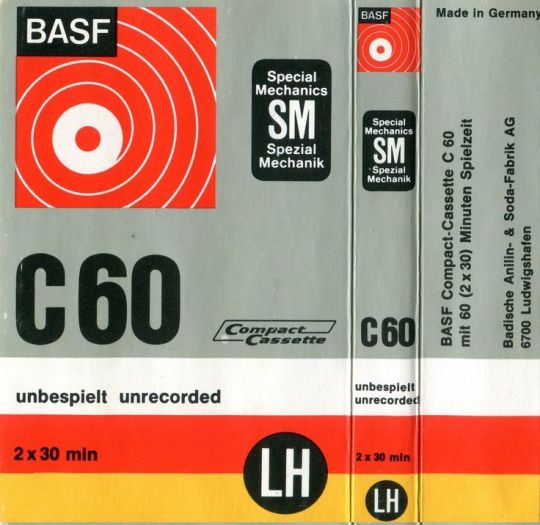

J-card for an BASF C60 blank cassette tape.

📸 source: Pinterest

25 notes

·

View notes

Text

ᴍᴀxɪᴍᴀ ᴅᴇsɪɢɴ | ɢᴇʀᴍᴀɴʏ (1991)

4 notes

·

View notes

Text

The workers are also protesting as the ‘Wage Agreement’ between the owners and workers is yet to be signed, reports a Moulvibazar correspondent quoting Raju Guala, president, Bangladesh Cha Sramik Union, (Tea plantation workers union ) Sylhet valley.

The workers are currently paid Tk 85 per day, but they are demanding Tk 200 at present, the correspondent said.

“The owners are delaying the wage agreement, which is detrimental to the tea laborers,” Raju Guala said. “The wage agreement is usually signed every two years, but it is already three years and there is no sign of the new agreement,” Guala added.

#strikes#bangladesh#desiblr#sylhet#basf#bangladesh anarcho syndicalist federation#tea workers#community building#practical anarchy#practical anarchism#anarchist society#practical#revolution#anarchism#daily posts#communism#anti capitalist#anti capitalism#late stage capitalism#organization#grassroots#grass roots#anarchists#libraries#leftism#social issues#economy#economics#climate change#climate crisis

4 notes

·

View notes

Text

45 Years Ago Today: May 17, 1980 - M1 Procar Series at Monaco: The #80 BASF M1 driven by Hans-Georg Bürger. More info on the 2-year run of the M1 procar series can be found in the following link https://classic-vintage-bmw.tumblr.com/procarinfo

#bmw#classic#vintage#classic car#bmw motorsport#bmw e26#bmw m1#bmw m1 procar#basf#monaco#classic and vintage bmw

22 notes

·

View notes

Text

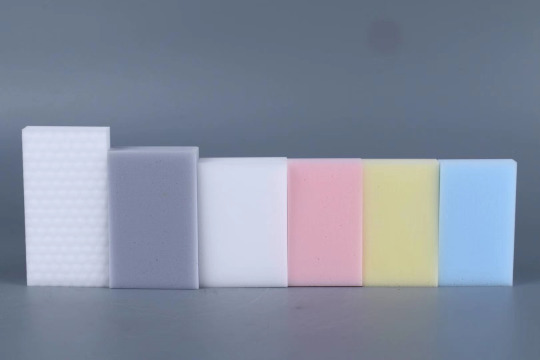

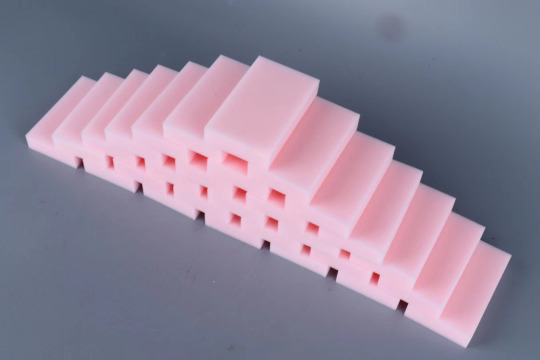

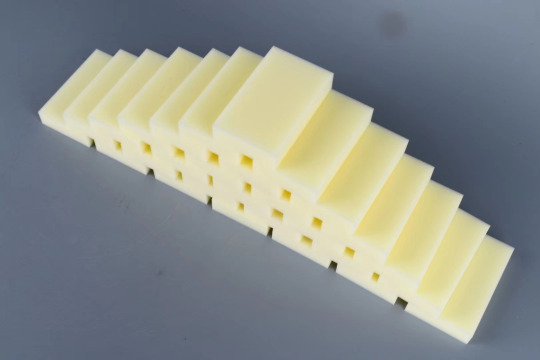

Nano Sponges Contain Formaldehyde Contamination?

Kitchen grease cleaning has always been a headache, and traditional cleaning sponges often need to be used with chemical cleaning agents, making cleaning stubborn stains time-consuming and laborious. In recent years, the new nano sponge has become popular because it is ideal for cleaning stubborn stains and does not require any chemical cleaning agents. So where does the cleaning superpower of the nano sponge come from?

A discreet and introverted "techie".

Nano sponges are known by the scientific name melamine foam, commonly known as magic wipe, high-tech sponge and so on. The main component of the nano sponge is a melamine resin foam, made from melamine and formaldehyde polymerisation. The melamine resin has a high porosity three-dimensional mesh structure, each "bubble hole" has at least 3 holes or 2 destructive surfaces, and most of the bubble prongs are shared by at least 3 structural units. The capillary openings in the sponge automatically absorb stains from the surface during the wiping process. Because of its comprehensive properties such as good sound absorption, flame retardancy and resistance to humidity and heat, nano sponges are widely used in the construction industry, electronic products, biological treatment processes and other fields. The nano sponge is also a good helper in household chores, with high grease removal capacity and high water efficiency (only 30-40% of the water used in traditional cleaning methods), making it a highly acclaimed cleaning tool.

Rumoured to be toxic?

While melamine and formaldehyde are both toxic chemicals when singled out, the synthetic amine resin is a stable substance that does not decompose into formaldehyde again. However, during the polymerisation of the two molecules, some of the unreacted free formaldehyde is present in the nano sponge. Therefore, manufacturers reduce the free formaldehyde content by improving the foaming process and maturing the formaldehyde removal process. In addition, formaldehyde itself is a water-soluble and chemically unstable substance and can be removed by placing it in a ventilated area or rinsing with water before use. If you buy a nano sponge from a qualified merchant, ventilate it for a period of time, rinse it and then use it, you can basically avoid the danger of formaldehyde!

Tips:

From a hygiene point of view, the spaces between the sponges can accumulate a lot of grease and food residue, which should be rinsed and dried after use.

Do not use the nano sponge on electrical products that are not suitable for contact with water.

Do not use bleach or hot water to disinfect the sponge as this will cause the sponge to yellow and deteriorate and will shorten its life.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

2 notes

·

View notes

Text

Plastic Compounds Market: Engineered Polymers Powering Modern Manufacturing

Plastics have evolved far beyond basic polymers. Today, plastic compounds—engineered blends of base resins with additives, fillers, and reinforcements—are transforming how industries approach strength, weight, sustainability, and cost efficiency. From under-the-hood car components and durable electrical housings to recyclable packaging and medical devices, plastic compounds deliver the performance characteristics modern manufacturing demands.

As sustainability regulations tighten and industries seek advanced alternatives to metals and ceramics, the Plastic Compounds Market is experiencing significant growth driven by innovation, application diversity, and value-added customization.

What Are Plastic Compounds?

Plastic compounds are customized formulations made by blending a base polymer (like polypropylene, polyethylene, ABS, or PVC) with a variety of performance-enhancing agents. These additives may include:

Fillers (e.g., glass fibers, talc, calcium carbonate) for strength and thermal resistance

Stabilizers to protect against heat and UV degradation

Plasticizers to improve flexibility

Colorants and pigments for aesthetics

Flame retardants, impact modifiers, and antimicrobial agents for specialized functions

The result is a material precisely engineered for a specific application or industry requirement—lighter than metal, more durable than traditional plastics, and often easier to process or recycle.

Market Overview: A Growing Global Opportunity

The global plastic compounds market was valued at USD 70.81 billion in 2024 and is projected to reach USD 97.27 billion by 2029, expanding at a CAGR of 6.6%. The surge is driven by several key factors:

Lightweighting in Automotive and Aerospace

OEMs are turning to reinforced plastic compounds to reduce vehicle weight, improve fuel efficiency, and meet emission standards—without compromising safety or durability.

Consumer Electronics Miniaturization

As devices shrink and become multifunctional, the need for strong, heat-resistant, and electrically insulated plastic compounds is rising sharply.

Infrastructure and Construction Growth

PVC and PE compounds are used in pipes, cables, window profiles, and insulation due to their long service life and ease of installation.

Sustainable Packaging

With growing bans on single-use plastics, the demand for biodegradable and recyclable compounds made from PLA, starch blends, and recycled PET is gaining momentum.

Medical and Healthcare Applications

Medical-grade plastic compounds offer biocompatibility, sterilization resistance, and regulatory compliance for devices, tubing, and drug delivery systems.

Key Segments by Resin and Application

By Resin Type:

Polypropylene (PP) Compounds – Widely used in automotive interiors, appliance housings, and furniture.

Polyvinyl Chloride (PVC) Compounds – Preferred for electrical, construction, and healthcare uses due to flame resistance and low cost.

Polyethylene (PE) Compounds – Used in flexible packaging, wires & cables, and agricultural films.

ABS and Polycarbonate Compounds – Known for high impact resistance, often used in consumer electronics and automotive exteriors.

By End-Use Industry:

Automotive & Transportation

Electrical & Electronics

Building & Construction

Packaging

Medical Devices

The customization flexibility of plastic compounds makes them relevant across all these sectors.

Leading Plastic Compound Manufacturers

Several global companies dominate the plastic compounds market by offering extensive R&D capabilities, global supply chains, and sustainable material portfolios:

BASF SE (Germany) – Offers high-performance plastic compounds with applications in automotive, packaging, and medical sectors.

LyondellBasell (Netherlands/USA) – Known for its polypropylene and polyethylene-based compounds with a focus on recyclability.

RTP Company (USA) – Specializes in customized thermoplastic compounds, including flame-retardant and conductive materials.

SABIC (Saudi Arabia) – Provides advanced engineering plastic compounds for electronics, construction, and mobility sectors.

Dow Inc. (USA) – Focuses on sustainable plastic compounds used in infrastructure, flexible packaging, and health industries.

These players are investing in circular economy models, bio-based materials, and closed-loop recycling systems to align with environmental mandates and customer expectations.

Download PDF Brochure to Get Deeper Insights :

The plastic compounds market is more than a subsegment of the polymer industry—it’s a driving force behind innovation, sustainability, and performance in global manufacturing. As industries seek smarter materials that balance cost, efficiency, and environmental impact, engineered plastic compounds provide the answer.

From lightweight car panels to recyclable food trays and medical-grade polymers, plastic compounds are quietly enabling the products of tomorrow. The companies and sectors that embrace their full potential today will be better positioned to lead in a resource-conscious, innovation-driven future.

#plastic compounds#polypropylene compounds#sustainable plastics#BASF#RTP Company#engineered polymers#recyclable materials#industrial plastics

0 notes

Text

바스프, 기능성소재 디자인 연구소 ‘크리에이션 센터’ 개소

한국바스프 안산공장, 제품 디자인부터 소재 개발, 해석 및 생산까지 올인원 솔루션 제공 가능 바스프 기능성소재 디자인 연구소 ‘크리에이션 센터’, 안산에 개소(image. 바스프) 글로벌 화학기업 바스프(BASF)는 6월 17일 경기도 안산에 그룹 내 다섯 번째 ‘크리에이션 센터(Creation Center)’를 개소했다. 한국바스프 안산공장 부지 내 위치한 크리에이션 센터는 고객이 바스프의 ���신적인 기능성소재를 경험하고 최첨단 디자인 솔루션을 공동 개발할 수 있도록 돕는 협업 공간으로 설계되었다. 바스프는 크리에이션 센터를 통해 제품 디자인 개발 초기 단계부터 소재에 대한 전문 지식과 컨설팅을 제공하고 공동 창작을 지원함으로써, 고객과의 관계를 더욱 강화하고 핵심 산업에서 혁신을 가속화할…

View On WordPress

0 notes

Text

📸 Audiochrome (BS)

3 notes

·

View notes