#cmu block retaining wall

Explore tagged Tumblr posts

Text

Welcome to Acton Precast Concrete Limited wholesaler for concrete large retaining wall blocks! At Acton Precast, we take pride in providing top-quality products to meet all your landscaping needs.

#interlocking large concrete retaining wall blocks#interlocking concrete retaining wall#concrete wall retaining wall#cmu block retaining wall#block concrete retaining wall

0 notes

Text

Introduction In architectural drafting and construction, understanding the dimensions, scaling, and standardization of Concrete Masonry Units (CMUs) is crucial for accurate design, documentation, and execution. This guide presents an in-depth overview of CMU block sizes, scale usage in CAD, and ASTM specification references to help architects, engineers, and builders make informed decisions. CMU Block Sizes: Nominal vs. Actual Dimensions CMU sizes are commonly described in nominal dimensions (which include mortar joints) and actual dimensions (which are the true physical measurements of the unit). CMU SizeNominal Dimensions (D x H x L)Actual Dimensions (D x H x L)4" CMU (Full Block)4" x 8" x 16"3 ⅝" x 7 ⅝" x 15 ⅝"4" CMU (Half Block)4" x 8" x 8"3 ⅝" x 7 ⅝" x 7 ⅝"6" CMU (Full Block)6" x 8" x 16"5 ⅝" x 7 ⅝" x 15 ⅝"6" CMU (Half Block)6" x 8" x 8"5 ⅝" x 7 ⅝" x 7 ⅝"8" CMU (Full Block)8" x 8" x 16"7 ⅝" x 7 ⅝" x 15 ⅝"8" CMU (Half Block)8" x 8" x 8"7 ⅝" x 7 ⅝" x 7 ⅝"10" CMU (Full Block)10" x 8" x 16"9 ⅝" x 7 ⅝" x 15 ⅝"10" CMU (Half Block)10" x 8" x 8"9 ⅝" x 7 ⅝" x 7 ⅝"12" CMU (Full Block)12" x 8" x 16"11 ⅝" x 7 ⅝" x 15 ⅝"12" CMU (Half Block)12" x 8" x 8"11 ⅝" x 7 ⅝" x 7 ⅝" Common Uses by Size - 8" x 8" x 16": Most commonly used for load-bearing and structural walls. - 12" x 8" x 16": Ideal for retaining or foundation walls. - 4" x 8" x 16": Used for veneers and non-load-bearing partitions. Understanding CAD Scale Factors When working in CAD, all elements are typically drawn at a 1:1 scale in Model Space. Scale factors are applied in Paper Space to correctly print drawings to scale. For example: Drawing ScaleScale Factor1/32" = 1'-0"3841/16" = 1'-0"1921/8" = 1'-0"961/4" = 1'-0"481/2" = 1'-0"241" = 1'-0"12 Scale factor = Inverse of the drawing scale multiplied by 12 (inches per foot). These factors ensure that objects appear correctly sized on printed sheets. ASTM Specifications for CMUs ASTM International sets the standard for concrete block manufacturing to ensure quality and uniformity. Below is a list of relevant ASTM codes: ASTM DesignationCMU TypeASTM C55Concrete BrickASTM C73Calcium Silicate Face BrickASTM C90Load Bearing Concrete Masonry UnitsASTM C139Catch Basins and Manhole CMUsASTM C744Prefaced Concrete and Calcium Silicate UnitsASTM C936Solid Interlocking Concrete Paving UnitsASTM C1372Segmental Retaining Wall Units CMUs must meet these ASTM standards to be approved for construction use. ASTM C90 is the most referenced for conventional building blocks. Estimated Weight of CMU Blocks by Size CMU TypeNominal Size (inches)Estimated Weight (kg)4" × 8" × 16" BlockSmall block10–12 kg6" × 8" × 16" BlockMedium block14–18 kg8" × 8" × 16" BlockStandard block18–22 kg10" × 8" × 16" BlockHeavy block24–27 kg12" × 8" × 16" BlockExtra large block28–32 kg Factors Affecting CMU Weight by Material Type Material TypeDescriptionImpact on WeightStandard Concrete (cement + sand + gravel)Commonly used in structural and industrial applicationsMedium to high weightLightweight Concrete (e.g., volcanic ash or pumice)Used for non-load bearing walls or upper floors to reduce dead load20–30% lighter than standardHigh-Density Concrete (with metal or dense aggregates)Used for radiation shielding or specialty constructionVery heavy (35+ kg per block) Weight Variability and Material Impact It’s essential to note that the weight of a CMU block varies based on the material composition. While traditional concrete blocks made from cement, sand, and gravel provide a standard density suitable for most applications, lightweight alternatives using pumice or volcanic ash can reduce block weight by up to 30%, making them ideal for upper-level construction or thermal insulation. On the other hand, high-density concrete blocks, often infused with metallic aggregates, can weigh well over 35 kg per unit and are typically used for special cases like radiation shielding or military infrastructure. Because of this variability, it's always best to consult manufacturer specifications to confirm the actual weight of CMU blocks, especially when weight plays a critical role in structural design, transportation logistics, or installation methods. Conclusion Understanding CMU block dimensions, CAD scaling practices, and manufacturing standards is vital for ensuring accuracy, efficiency, and compliance in architectural and construction projects. Always verify the correct block size and ASTM standard for your application, and consult local building codes or a licensed engineer before beginning work. https://archup.net/types-of-concrete-building-units-used-in-construction/ https://archup.net/the-5-best-soundproof-drywall-products-top-rated-picks-full-buying-guide/ Stay tuned to our platform for more technical deep-dives designed for forward-thinking architects and builders. Read the full article

0 notes

Text

The Versatility of Concrete Blocks and Pavers in Modern Landscaping

Understanding Concrete Blocks

Concrete blocks, often referred to as concrete masonry units (CMUs), are prefabricated building materials made from a mixture of cement, water, and aggregates. Their durability, strength, and versatility make them suitable for various applications, including walls, foundations, and landscaping projects.

Benefits of Using Concrete Blocks

One of the primary advantages of concrete blocks is their ability to withstand extreme weather conditions. They are resistant to rot, insects, and fire, making them an excellent choice for both structural and decorative projects. Moreover, concrete blocks come in a variety of sizes, shapes, mortar and brick and textures, allowing for limitless design possibilities in residential landscaping.

In landscaping, concrete blocks can be used to create raised garden beds, flower planters, and retaining walls. Their sturdy nature ensures that the made structures can support plants while controlling soil erosion effectively. Additionally, they can also serve as a base for support walls in prettily designed outdoor kitchens.

The Aesthetic Appeal of Fireplace Stone Pavers

While concrete blocks serve as practical building solutions, pavers, particularly fireplace stone pavers concrete, add an elegant touch to outdoor living spaces. These pavers not only enhance the aesthetic appeal but are also engineered for high performance and longevity.

Why Choose Fireplace Stone Pavers?

Fireplace stone pavers specifically designed for patios and paths are both visually appealing and functional. Their natural stone-like appearance complements various styles, whether traditional, rustic, or modern. Homeowners can arrange these pavers in patterns that suit their specific tastes, seamlessly blending the hardscape with the surrounding nature.

One of the standout features of fireplace stone pavers concrete is their installation versatility. They can be laid out on gravel or sand beds, laid down quickly, and easily adjusted if required. This flexibility is particularly advantageous for DIY enthusiasts or homeowners looking to engage with contractors to complete an outdoor fireplace or patio project.

These pavers come in an array of colors, textures, and sizes, providing ample opportunity for creativity. Whether creating a focal point around a fire pit or designing a cozy nook for family gatherings, fireplace stone pavers concrete can elevate outdoor living experiences.

Combining Concrete Blocks and Pavers in Landscaping

A landscape that combines concrete blocks and pavers can create a cohesive and functional outdoor space. By utilizing concrete blocks for structural elements and fireplace stone pavers for pathways and patios, homeowners can design spaces that are both practical and inviting.

One popular application of this combination is in the construction of outdoor kitchens. Concrete blocks can be used to build the structure of the kitchen, while pavers can create a surrounding area for seating, dining, and leisure. This synergy helps in managing wear and tear due to foot traffic while adding value to the home.

Furthermore, using these materials collectively helps in easier maintenance. For example, if a specific area needs repair or replacement, addressing either the blocks or the pavers is straightforward without affecting the overall design.

0 notes

Text

Masonry Cost estimator in Miami-Dade County

When planning a construction project in Miami-Dade County, using a masonry cost estimator is essential for understanding the costs involved. Masonry work often plays a critical role in the durability and aesthetics of the structure. Whether you’re building a new home, adding a patio, or repairing a retaining wall, understanding masonry costs can help you budget effectively and avoid unexpected expenses. This guide provides a detailed overview of masonry costs in Miami-Dade County, factors influencing these costs, and how to get the best estimates for your project.

Understanding Masonry Costs in Miami-Dade County

Masonry costs vary depending on the type of project, materials used, and labor requirements. On average, homeowners in Miami-Dade County can expect to pay between $10 and $25 per square foot for standard masonry work. For more specialized projects, such as decorative stone or intricate brickwork, costs can range from $30 to $50 per square foot.

Common Masonry Projects and Costs

Brick Walls: $15 to $30 per square foot

Concrete Block Walls (CMU): $10 to $20 per square foot

Stone Veneer: $20 to $45 per square foot

Retaining Walls: $25 to $50 per square foot

Outdoor Patios: $12 to $35 per square foot

Factors Affecting Masonry Costs

Several factors can influence the overall cost of your masonry project:

Material Choice:

Brick: Durable and classic but moderately expensive.

Concrete: Cost-effective and versatile.

Natural Stone: Premium aesthetic appeal but higher cost.

Stucco: Affordable and weather-resistant.

Labor Costs: Labor rates in Miami-Dade County are influenced by the region’s competitive market and demand for skilled masons. Expect to pay between $50 and $100 per hour for experienced masons.

Project Complexity: Complex designs, curves, or custom patterns increase labor hours and costs.

Permits and Inspections: Local regulations may require permits for certain masonry projects, adding between $150 and $500 to your budget.

Site Preparation: Uneven or obstructed work areas can increase costs by requiring additional preparation, such as excavation or grading.

Cost-Saving Tips for Masonry Projects

Choose Standard Designs: Opt for simple layouts to minimize labor time.

Source Materials Locally: Reduce transportation costs by purchasing materials from local suppliers.

Combine Projects: Bundle multiple masonry tasks into one project to take advantage of economies of scale.

Hire Experienced Contractors: Skilled professionals may charge more but can work efficiently, reducing overall labor hours.

Why Use a Masonry Cost Estimator?

A masonry cost estimator simplifies the budgeting process by providing a detailed breakdown of costs for materials, labor, and other expenses. This tool is particularly useful for comparing quotes from contractors and ensuring transparency in pricing.

Benefits of Using a Masonry Cost Estimator:

Accurate project budgeting

Easy comparison of material costs

Identification of potential cost overruns

Estimate Florida Consulting: Your Partner in Masonry Cost Estimation

At Estimate Florida Consulting, we specialize in providing accurate and detailed cost estimates for masonry projects in Miami-Dade County. Our experienced team uses advanced tools and local market knowledge to deliver reliable estimates tailored to your project’s unique needs.

Our Services Include:

Comprehensive cost breakdowns

Material and labor cost analysis

Guidance on local regulations and permits

Get Your Masonry Project Started Today!

Planning a masonry project in Miami-Dade County? Contact Estimate Florida Consulting at 561-530-2845 for a free consultation and accurate cost estimate. Let us help you achieve your construction goals while staying within budget. Our Masonry Cost Estimator in Miami-Dade County ensures transparency and precision, helping you make informed decisions.

FAQs About Masonry Cost Estimation in Miami-Dade County

1. How much does masonry work typically cost per square foot in Miami-Dade County?

Masonry work in Miami-Dade County typically costs between $10 and $25 per square foot. For specialized projects, such as decorative stone or intricate brickwork, the cost can range from $30 to $50 per square foot.

2. What factors influence masonry costs the most?

Key factors include material choice (brick, concrete, stone, or stucco), labor rates, project complexity, required permits, and site preparation needs.

3. How can I save money on my masonry project?

You can save by choosing standard designs, sourcing materials locally, combining multiple projects, and hiring experienced contractors who work efficiently.

4. Do I need a permit for masonry work in Miami-Dade County?

Yes, many masonry projects require permits. Permit costs typically range from $150 to $500, depending on the project scope and local regulations.

5. Why should I use a masonry cost estimator?

A masonry cost estimator provides an accurate breakdown of materials, labor, and other costs, helping you budget effectively and avoid surprises.

6. How do I choose the best masonry contractor in Miami-Dade County?

Look for contractors with experience, positive reviews, and transparent pricing. Request multiple quotes to compare costs and services.

0 notes

Text

Hollow Concrete Block Manufacturer in Mumbai – High-Quality Solutions by Ultrablocks

When it comes to building construction, choosing the right materials is essential for ensuring durability, strength, and cost-efficiency. One of the most widely used building materials in the construction industry today is the hollow concrete block. As a trusted hollow concrete block manufacturer in Mumbai, Ultrablocks is committed to providing high-quality products that meet the demands of modern construction projects.

What are Hollow Concrete Blocks?

Hollow concrete blocks, also known as concrete masonry units (CMUs), are precast blocks made from a mixture of cement, aggregates, and water. They are designed with hollow cores, which offer numerous advantages over solid concrete blocks. The core cavities reduce the weight of the blocks, making them easier to handle and transport, while also providing better insulation properties.

Benefits of Choosing Hollow Concrete Blocks

Cost-Effectiveness: Due to their reduced weight and use of less material, hollow concrete blocks are more affordable compared to solid blocks. This cost efficiency can significantly reduce the overall expenses of a construction project.

Lightweight and Easy to Handle: Hollow blocks are easier to transport and lay, which can speed up the construction process and reduce labor costs.

Thermal Insulation: The hollow cores create pockets of air, providing better thermal insulation and making buildings more energy-efficient.

Sound Insulation: The design of hollow blocks helps in reducing sound transmission, making them a good choice for residential and commercial buildings where noise control is important.

Versatility: Hollow concrete blocks are suitable for a variety of applications, including walls, partitions, and even landscaping, offering flexibility in construction projects.

Why Choose Ultrablocks as Your Hollow Concrete Block Manufacturer in Mumbai?

Ultrablocks stands out as a reliable provider of hollow concrete blocks in Mumbai. Here’s why we are the preferred choice for builders and contractors:

Superior Quality: We ensure that our blocks are manufactured using the highest quality raw materials and modern production techniques. Our quality control measures ensure that each block meets industry standards for strength, durability, and consistency.

Wide Range of Sizes and Specifications: We offer a diverse selection of hollow concrete blocks to cater to the unique needs of different projects. Whether you need blocks for structural walls, partitioning, or specific architectural requirements, we have the right products for you.

Eco-Friendly Production: At Ultrablocks, we prioritize sustainability by using environmentally friendly manufacturing processes. Our blocks are designed to minimize waste and maximize energy efficiency.

Customization Options: We understand that every construction project is unique. That’s why we provide customizable solutions to meet specific project requirements, including block size and design specifications.

Timely Delivery: We know how important timelines are in construction projects. Our efficient production and delivery systems ensure that your order is delivered on time, helping you stay on schedule.

Applications of Hollow Concrete Blocks

Hollow concrete blocks are ideal for a wide range of applications, including:

Residential Construction: Used for building exterior and interior walls, partitions, and facades.

Commercial Structures: Perfect for constructing office buildings, malls, and retail stores due to their durability and cost-effectiveness.

Industrial Facilities: Used for partition walls and enclosures in factories and warehouses.

Landscaping Projects: Ideal for creating garden walls, retaining walls, and decorative elements.

Soundproof Walls: Effective for soundproofing rooms in residential complexes, hotels, and other establishments.

Why Ultrablocks is the Best Choice in Mumbai

With years of experience and a reputation for excellence, Ultrablocks has cemented its position as a top hollow concrete block manufacturer in Mumbai. Our commitment to quality, customer satisfaction, and timely service has made us a preferred supplier among builders and contractors.

Conclusion

For reliable, high-quality hollow concrete blocks in Mumbai, Ultrablocks is the trusted name in the industry. Our dedication to manufacturing durable and efficient building materials ensures that your construction projects are successful and cost-effective.

Contact Ultrablocks today for your hollow concrete block requirements and discover how we can support your next construction project with the best products on the market.

0 notes

Text

Top Cement Block Wall Manufacturers and Suppliers in India: SRG Infratech

When it comes to construction, quality materials are the cornerstone of any successful project. In India, SRG Infratech stands out as a leading name among Top Cement Block Wall Manufacturers and Suppliers in India. Known for their commitment to excellence, SRG Infratech offers a wide range of cement blocks that cater to various construction needs. Whether you're building a residential property, a commercial space, or an industrial complex, SRG Infratech provides the durability and reliability you require.

Why Choose Cement Blocks for Construction?

Cement blocks, also known as concrete masonry units (CMUs), are a popular choice in the construction industry for several reasons:

Durability: Cement blocks are incredibly strong and can withstand harsh weather conditions, making them ideal for both interior and exterior walls.

Fire Resistance: These blocks are non-combustible, adding an extra layer of safety to any structure.

Thermal Insulation: Cement blocks offer excellent thermal insulation properties, helping to maintain comfortable indoor temperatures and reducing energy costs.

Sound Insulation: They also provide effective sound insulation, which is beneficial for buildings in noisy environments.

Eco-Friendly: Cement blocks are made from natural materials and can be recycled, making them a sustainable choice for environmentally conscious builders.

SRG Infratech: A Leader in Cement Block Wall Manufacturing

SRG Infratech has established itself as a top manufacturer and supplier of cement blocks in India. Here's what sets them apart from the competition:

Quality Assurance: SRG Infratech adheres to stringent quality control measures to ensure that every cement block meets the highest standards. Their products are tested for strength, durability, and uniformity.

Advanced Technology: The company employs state-of-the-art manufacturing technology to produce cement blocks that are not only strong but also dimensionally accurate. This precision makes construction easier and more efficient.

Variety of Products: SRG Infratech offers a wide range of cement blocks, including solid blocks, hollow blocks, and interlocking blocks. This variety allows builders to choose the right type of block for their specific needs.

Sustainable Practices: The company is committed to sustainability. They use eco-friendly manufacturing processes and materials, ensuring that their products have a minimal environmental impact.

Customer Service: SRG Infratech prides itself on excellent customer service. They offer comprehensive support to clients, from selecting the right products to providing technical guidance during construction.

Applications of SRG Infratech Cement Blocks

SRG Infratech cement blocks are versatile and can be used in a variety of construction applications:

Residential Buildings: Whether you're constructing a single-family home or a multi-story apartment complex, SRG Infratech's cement blocks provide the strength and durability needed for long-lasting structures.

Commercial Buildings: From office spaces to retail outlets, these cement blocks are perfect for creating sturdy and safe commercial environments.

Industrial Structures: For warehouses, factories, and other industrial buildings, the robustness of SRG Infratech's cement blocks ensures that these structures can handle heavy loads and rough usage.

Boundary Walls: Cement blocks are ideal for constructing boundary walls that are both secure and aesthetically pleasing.

Landscaping: They can also be used in landscaping projects to create retaining walls, garden beds, and other features.

Conclusion

Choosing the right materials is crucial for the success of any construction project, and SRG Infratech's cement blocks offer an unbeatable combination of quality, durability, and sustainability. As one of the top cement block wall manufacturers and suppliers in India, SRG Infratech continues to set the standard in the industry. When you choose SRG Infratech, you're investing in the future of your construction projects.

For more information about SRG Infratech and their range of cement block products, visit their website or contact their customer service team. Build with confidence, build with SRG Infratech.

0 notes

Text

Timeless Craftsmanship in Masonry Styles

Have you ever walked into a building and marveled at the intricate masonry that stands the test of time? At Hirschi Masonry, we take pride in showcasing our expertise across diverse masonry styles, each telling its own story of craftsmanship history and architectural legacy. Whether you're a construction professional, history buff, homeowner, builder, or architecture enthusiast, understanding these styles can elevate your appreciation and application in various projects. In this blog post, we'll explore different masonry styles, their historical significance, and how Hirschi Masonry can bring these timeless techniques to your next project.

The Legacy of Masonry Craftsmanship

Masonry has been a fundamental element of construction for centuries. From the pyramids of Egypt to modern skyscrapers, the art of masonry continues to evolve while preserving its rich heritage.

Ancient Beginnings

The earliest examples of masonry can be traced back to ancient civilizations. The Egyptians used stone blocks to construct the iconic pyramids, demonstrating early mastery of masonry techniques. These ancient builders set the foundation for future generations to build upon.

Medieval Marvels

During the medieval period, Europe saw the rise of Gothic architecture, characterized by intricate stonework and towering cathedrals. The masons of this era perfected techniques such as ribbed vaulting and flying buttresses, leaving a lasting impact on architectural history.

Renaissance Revival

The Renaissance brought a renewed interest in classical architecture. Masons of this period drew inspiration from ancient Rome and Greece, incorporating elements like columns and arches into their designs. This era marked a significant evolution in masonry craftsmanship.

Diverse Masonry Techniques

Masonry is not a one-size-fits-all trade. Various techniques have been developed over the years, each offering unique benefits and aesthetic appeal.

Brick Masonry

Brick masonry is one of the most common and versatile styles. It involves laying bricks in a specific pattern, bonded together with mortar. Brick masonry is valued for its durability, fire resistance, and timeless appearance.

Stone Masonry

Stone masonry uses natural stones to create structures with a distinct and elegant look. There are two main types:

Ashlar Masonry

Ashlar masonry involves using precisely cut stones laid in a uniform pattern. This technique is often seen in high-end constructions due to its refined and polished finish.

Rubble Masonry

Rubble masonry, on the other hand, employs irregularly shaped stones, creating a more rustic and organic appearance. This style is commonly used in retaining walls and garden features.

Concrete Masonry

Concrete masonry units (CMUs) are popular in modern construction. These blocks come in various shapes and sizes, offering flexibility in design. Concrete masonry is known for its strength and energy efficiency.

Historical Significance of Masonry Styles

The beauty of masonry lies not only in its aesthetic appeal but also in the stories it tells. Each style reflects the cultural, technological, and artistic influences of its time.

Colonial Architecture

Colonial architecture in America often featured brick and stone masonry. These materials were readily available and provided the durability needed for homes and public buildings. Colonial masonry remains a cherished part of America's architectural heritage.

Victorian Elegance

The Victorian era saw an explosion of ornate masonry work. Intricate brick patterns, decorative stone carvings, and elaborate facades defined this period. Masons of this time demonstrated unparalleled skill and creativity.

Modern Minimalism

In the 20th century, masonry took on a more minimalist approach. Clean lines, simple forms, and the use of new materials like concrete became prevalent. Modern masonry focuses on functionality and efficiency while maintaining an elegant aesthetic.

Masonry in Home Renovation

For homeowners looking to renovate, incorporating masonry can add both value and character to a property.

Enhancing Curb Appeal

A well-crafted masonry facade can significantly boost a home's curb appeal. Whether it's a brick driveway, stone pathway, or a feature wall, masonry provides a timeless look that never goes out of style.

Interior Accents

Masonry is not limited to exterior applications. Exposed brick walls, stone fireplaces, and tiled kitchen backsplashes are popular interior design trends. These elements add texture and warmth to living spaces.

Durable Solutions

Masonry materials are known for their longevity and resistance to weathering. Choosing masonry for renovation projects ensures a lasting investment that requires minimal maintenance.

Hirschi Masonry's Approach to Craftsmanship

At Hirschi Masonry, we pride ourselves on our commitment to quality and attention to detail. Our team of skilled masons brings years of experience and a passion for preserving and innovating masonry traditions.

Expert Curation

We carefully select the best materials for each project, ensuring that every brick, stone, or block meets our high standards. Our expert curation guarantees that your masonry work will stand the test of time.

Precision and Skill

Our masons are masters of their craft, employing traditional techniques with modern precision. From intricate stone carvings to seamless bricklaying, we deliver exceptional results that exceed expectations.

Personalized Service

We understand that each project is unique. That's why we offer personalized consultations to understand your vision and tailor our services to meet your specific needs. Your satisfaction is our top priority.

Masonry Projects That Inspire

Hirschi Masonry has been a part of many inspiring projects, each showcasing our dedication to excellence and creativity.

Historical Restorations

We've had the privilege of restoring historic buildings, preserving their original charm while enhancing their structural integrity. Our work ensures that these architectural treasures can be enjoyed for generations to come.

Contemporary Designs

From sleek office buildings to modern homes, our contemporary masonry projects highlight the versatility of our skills. We blend traditional craftsmanship with innovative design to create stunning results.

Community Landmarks

Our contributions to community landmarks, such as public parks and cultural centers, reflect our commitment to enhancing the spaces where people live, work, and play. We take pride in being a part of projects that bring communities together.

Building a Legacy with Hirschi Masonry

Masonry is more than just construction; it's an art form that connects us to our past and shapes our future.

Educating Future Generations

We believe in passing down the knowledge and skills of masonry to future generations. Through apprenticeships and training programs, we ensure that the legacy of masonry craftsmanship continues.

Sustainable Practices

At Hirschi Masonry, we are committed to sustainability. We use environmentally friendly materials and practices to minimize our impact on the planet. Our goal is to build structures that are both beautiful and sustainable.

Community Engagement

We actively engage with our community, supporting local initiatives and events. Our involvement goes beyond construction; we strive to make a positive impact in the lives of those around us.

The Future of Masonry

The future of masonry is bright, with new technologies and techniques constantly emerging.

Innovation in Materials

Advancements in materials science are leading to the development of stronger, lighter, and more sustainable masonry products. These innovations open up new possibilities for design and construction.

Digital Tools

Digital tools, such as 3D modeling and augmented reality, are revolutionizing the way we approach masonry projects. These technologies allow for greater precision and creativity in design.

Continued Tradition

While we embrace innovation, we remain committed to the traditions that have defined masonry for centuries. The combination of old and new ensures that the art of masonry will continue to thrive.

Understanding the different masonry styles and their historical significance enriches our appreciation of this timeless craft. Whether you're a construction professional, an architecture enthusiast, or a homeowner looking to renovate, Hirschi Masonry offers the expertise and passion to bring your vision to life. Explore the rich legacy of masonry with us and see how we can transform your projects with our skilled craftsmanship. If you're ready to begin your masonry journey, contact Hirschi Masonry today to learn more about our services and how we can help you create something truly remarkable.

0 notes

Text

retaining walls or wall for out of house

lego shaped real concrete blocks - Google Search

these are great for heavy highway and other and you du yo see them a lot. most lock wit steel whcih is useless and ou son said it and daughter. you want to glue them wiht a fusing material and they dont ever and i is dangerous. true though if it all falls it is a catastrophe. deadly. well part of it too. so better to seal it an use tie backs wicn they needed her not many a few in hte middle higigght

these are huge. our are about normal csized cmu and no gaps no have them and inside, and see throug no only opened on the bottm like legos. and they clip together with perssur fit and on teh sides the middl lateral and thats it have r 13 are about 10k psi. and can be used to build a five story apartment compelx. once set they fuse. you need to sawcut to get tem off. and you can buy them wiht inslation. n parge on plaster not drywall tape no sanding a all. tappreotre it coat and then finish an done. nice too. hard and smooth.

we shall puot them in our areas fire rated lighwieht solid and fuse and fast. we do make a panel too. and it is 8 or 12 inches wide and various size usually 8 foot long and four high and it has cells in it. and inslation. fuses an locks in wiht teh next verticl edge and only a edge to female tyope and part of the block only. no metal or steel it is a waste of time. we use this now here. bugs and we need the sprayer.

tons need it

Thor Freya

Zues Hera

Olympus

0 notes

Text

Brick vs Block: Which Construction Material Is Right for You?

Introduction

Choosing the right construction material is a crucial decision for builders and contractors. Concrete bricks and blocks are two popular choices, each with its own set of advantages and applications.

In this blog, we will compare these two construction materials to help builders make informed decisions that align with their project requirements. Additionally, we'll explore the importance of selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers.

Concrete Bricks:

Concrete bricks are widely used in construction due to their versatility and aesthetic appeal. Here are some key benefits and applications of concrete bricks:

1. Aesthetics: Concrete bricks come in a variety of colors and textures, making them an excellent choice for projects that prioritize aesthetics. They can be used to create visually appealing facades, accent walls, and even decorative elements within a structure.

2. Precision: Concrete bricks are manufactured to precise dimensions, ensuring uniformity and ease of installation. This precision makes them ideal for intricate brickwork patterns and designs.

3. Durability: Concrete bricks are known for their strength and durability, making them suitable for load-bearing applications. They can withstand harsh weather conditions, which is essential for structures exposed to the elements.

4. Thermal Insulation: Concrete bricks offer good thermal insulation properties, helping to regulate indoor temperature and reduce energy consumption. This makes them a popular choice for residential construction.

5. Soundproofing: Due to their density, concrete bricks also provide effective soundproofing, which is valuable in reducing noise transfer between rooms or from the outside.

Applications of Concrete Bricks:

Residential homes

Commercial buildings

Retaining walls

Fireplaces

Garden walls

Decorative features

Concrete Blocks:

Concrete blocks, often referred to as cinder blocks or concrete masonry units (CMUs), have their own unique advantages and applications:

1. Structural Strength: Concrete blocks are favored for their structural strength and load-bearing capacity. They are commonly used in the construction of foundations, retaining walls, and other structural elements.

2. Cost-Efficiency: Concrete blocks are generally more cost-effective than bricks. Their larger size means fewer blocks are needed to cover a given area, reducing material and labor costs.

3. Speed of Construction: Due to their size, concrete blocks can be laid quickly, speeding up the construction process. This efficiency is particularly beneficial for large-scale projects.

4. Fire Resistance: Concrete blocks offer excellent fire resistance, which is a critical factor in building safety. They can withstand high temperatures and provide valuable fire protection.

5. Minimal Maintenance: Concrete blocks require minimal maintenance over the years, making them a low-maintenance option for long-lasting structures.

Applications of Concrete Blocks:

Foundations

Basement walls

Retaining walls

Commercial buildings

Industrial facilities

Warehouses

Selecting Reliable Concrete Brick and Block Making Machine Manufacturers

In addition to choosing the right construction material, it's essential to consider the machinery and equipment used in the manufacturing process. High-quality concrete bricks and blocks depend on the reliability of the production equipment. Here's why selecting trustworthy Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is crucial

1. Product Quality: Reliable manufacturers produce machines that meet industry standards, ensuring the consistent production of top-quality bricks and blocks.

2. Efficiency: Modern brick and block making machines offer improved efficiency and output. Investing in machinery from reputable manufacturers can lead to increased productivity and reduced production costs.

3. Support and Service: Established manufacturers often provide comprehensive support and maintenance services for their equipment, minimizing downtime and optimizing machine performance.

4. Innovation: Leading manufacturers invest in research and development, resulting in innovative features and technologies that can enhance the quality and efficiency of brick and block production.

5. Compliance: Ensure that the machinery you purchase complies with safety and environmental regulations in your region.

Conclusion

Both materials have their strengths and applications. Concrete bricks offer versatility and aesthetics, while concrete blocks provide structural strength and cost-efficiency. The choice between these two construction materials depends on your project's specific needs.

Additionally, selecting reliable Concrete Brick Making Machine manufacturers and Concrete Block Making Machine manufacturers is essential to ensure the consistent production of high-quality building materials. By carefully considering both the construction material and the machinery used in production, builders and contractors can make informed decisions that lead to successful and durable construction projects. Whether it's the material or the machinery, quality, and reliability are key to building a solid foundation for any construction venture.

Benny Enterprises is the best option for your best brick-making machine and block-making machine manufacturers we are also well known for being the best Fly ash brick making machine manufacturers, Automatic Fly ash brick making machine Manufacturers and many more.

Contact us for further…

#Concrete Block Making Machine#Construction Business#Concrete block making machine manufacturers#Concrete Brick Making Machine manufacturers#Automatic Fly ash brick making machine Manufacturers

0 notes

Text

The Best Way To Build a Wall

As premiere landscape designers in San Diego, we at Juniper Landscape Company pride ourselves on using only the best materials to build walls for our clients. We know that you want a beautiful, durable wall that will offer you years of service with low maintenance costs. Our goal as your San Diego Landscape Designer is to give you the wall you want! With that in mind, we use several proven products to help you build the walls you want on your property.

· We design and install block masonry walls using CMU block (https://www.rcpblock.com/). We have found this block to be one of the best in the industry for durability and hard wear in all weather conditions.

· We also use products from Keystone Walls (https://www.keystonewalls.com/), which offers beautiful options for finishing. These are some of our clients’ most popular wall choices, and we are proud to be Keystone recommended contractors in the San Diego area.

· In addition, we offer Allen block walls (https://allanblock.com/), segmental walls (https://www.orco.com/), and Belgard products (https://www.belgard.com/products/retaining-walls). As a client, you have a wide range of choice when it comes to the material we use for your walls, and we will help you understand the benefits and costs of each choice.

· When it comes to finishing your new walls, we can offer you options such as stucco (http://www.lahabrastucco.com/), flagstone (https://www.krcrock.com/), stone (https://www.southwestboulder.com/), stone veneer (http://www.eldoradostone.com/) and tile (https://www.arizonatile.com/). We want your new wall to look exactly the way you want and to enhance the beauty of your landscape design.

For years, we have offered our services as your landscape designer for San Diego. Juniper Landscape Company works with you to ensure that your wall project, whether it is a decorative or a retaining wall, is aesthetically pleasing and easy to maintain, giving you years of function and beauty. Call us today to discuss your next project.

1 note

·

View note

Text

Masonry Contractor in Lawrence, IN

We handle commercial and residential masonry repair and installation, focusing on quality craftsmanship and total customer satisfaction. We have been offering various masonry services to the Lawrence and Indianapolis areas for over a decade. Brick repair, brick and stucco mailbox repair, chimney repair, retaining wall repair, concrete repairs, fireplace repairs, cast stone repairs, and stucco repairs are all part of this service. To mention a few, we also build and engineer walls, CMU walls, brick walls, stone borders, outdoor fireplaces, outdoor kitchens, stone patios, and outdoor grills.

Visit us: https://jallenmasonrylawrence.com

#masonry contractor in Lawrence IN#Flat Stone Patio in LawrenceIN#Retaining Wall Installation in LawrenceIN#chimney repair in LawrenceIN#Brick Masonry in LawrenceIN#Hardscaping in LawrenceIN#Stone Landscaping in LawrenceIN#Concrete Contractor in LawrenceIN#Stucco Repair in LawrenceIN#Brick Mailboxe in LawrenceIN#residential masonry contractors near me#commercial masonry contractors in LawrenceIN#outdoor kitchen in LawrenceIN

1 note

·

View note

Text

Introduction In architectural drafting and construction, understanding the dimensions, scaling, and standardization of Concrete Masonry Units (CMUs) is crucial for accurate design, documentation, and execution. This guide presents an in-depth overview of CMU block sizes, scale usage in CAD, and ASTM specification references to help architects, engineers, and builders make informed decisions. CMU Block Sizes: Nominal vs. Actual Dimensions CMU sizes are commonly described in nominal dimensions (which include mortar joints) and actual dimensions (which are the true physical measurements of the unit). CMU SizeNominal Dimensions (D x H x L)Actual Dimensions (D x H x L)4" CMU (Full Block)4" x 8" x 16"3 ⅝" x 7 ⅝" x 15 ⅝"4" CMU (Half Block)4" x 8" x 8"3 ⅝" x 7 ⅝" x 7 ⅝"6" CMU (Full Block)6" x 8" x 16"5 ⅝" x 7 ⅝" x 15 ⅝"6" CMU (Half Block)6" x 8" x 8"5 ⅝" x 7 ⅝" x 7 ⅝"8" CMU (Full Block)8" x 8" x 16"7 ⅝" x 7 ⅝" x 15 ⅝"8" CMU (Half Block)8" x 8" x 8"7 ⅝" x 7 ⅝" x 7 ⅝"10" CMU (Full Block)10" x 8" x 16"9 ⅝" x 7 ⅝" x 15 ⅝"10" CMU (Half Block)10" x 8" x 8"9 ⅝" x 7 ⅝" x 7 ⅝"12" CMU (Full Block)12" x 8" x 16"11 ⅝" x 7 ⅝" x 15 ⅝"12" CMU (Half Block)12" x 8" x 8"11 ⅝" x 7 ⅝" x 7 ⅝" Common Uses by Size - 8" x 8" x 16": Most commonly used for load-bearing and structural walls. - 12" x 8" x 16": Ideal for retaining or foundation walls. - 4" x 8" x 16": Used for veneers and non-load-bearing partitions. Understanding CAD Scale Factors When working in CAD, all elements are typically drawn at a 1:1 scale in Model Space. Scale factors are applied in Paper Space to correctly print drawings to scale. For example: Drawing ScaleScale Factor1/32" = 1'-0"3841/16" = 1'-0"1921/8" = 1'-0"961/4" = 1'-0"481/2" = 1'-0"241" = 1'-0"12 Scale factor = Inverse of the drawing scale multiplied by 12 (inches per foot). These factors ensure that objects appear correctly sized on printed sheets. ASTM Specifications for CMUs ASTM International sets the standard for concrete block manufacturing to ensure quality and uniformity. Below is a list of relevant ASTM codes: ASTM DesignationCMU TypeASTM C55Concrete BrickASTM C73Calcium Silicate Face BrickASTM C90Load Bearing Concrete Masonry UnitsASTM C139Catch Basins and Manhole CMUsASTM C744Prefaced Concrete and Calcium Silicate UnitsASTM C936Solid Interlocking Concrete Paving UnitsASTM C1372Segmental Retaining Wall Units CMUs must meet these ASTM standards to be approved for construction use. ASTM C90 is the most referenced for conventional building blocks. Estimated Weight of CMU Blocks by Size CMU TypeNominal Size (inches)Estimated Weight (kg)4" × 8" × 16" BlockSmall block10–12 kg6" × 8" × 16" BlockMedium block14–18 kg8" × 8" × 16" BlockStandard block18–22 kg10" × 8" × 16" BlockHeavy block24–27 kg12" × 8" × 16" BlockExtra large block28–32 kg Factors Affecting CMU Weight by Material Type Material TypeDescriptionImpact on WeightStandard Concrete (cement + sand + gravel)Commonly used in structural and industrial applicationsMedium to high weightLightweight Concrete (e.g., volcanic ash or pumice)Used for non-load bearing walls or upper floors to reduce dead load20–30% lighter than standardHigh-Density Concrete (with metal or dense aggregates)Used for radiation shielding or specialty constructionVery heavy (35+ kg per block) Weight Variability and Material Impact It’s essential to note that the weight of a CMU block varies based on the material composition. While traditional concrete blocks made from cement, sand, and gravel provide a standard density suitable for most applications, lightweight alternatives using pumice or volcanic ash can reduce block weight by up to 30%, making them ideal for upper-level construction or thermal insulation. On the other hand, high-density concrete blocks, often infused with metallic aggregates, can weigh well over 35 kg per unit and are typically used for special cases like radiation shielding or military infrastructure. Because of this variability, it's always best to consult manufacturer specifications to confirm the actual weight of CMU blocks, especially when weight plays a critical role in structural design, transportation logistics, or installation methods. Conclusion Understanding CMU block dimensions, CAD scaling practices, and manufacturing standards is vital for ensuring accuracy, efficiency, and compliance in architectural and construction projects. Always verify the correct block size and ASTM standard for your application, and consult local building codes or a licensed engineer before beginning work. https://archup.net/types-of-concrete-building-units-used-in-construction/ https://archup.net/the-5-best-soundproof-drywall-products-top-rated-picks-full-buying-guide/ Stay tuned to our platform for more technical deep-dives designed for forward-thinking architects and builders. Read the full article

0 notes

Link

Written by R. Ann Parris on The Prepper Journal.

Some holiday weekend, head out to the ‘burbs” or stroll through some campgrounds or a public park. Your nose will pick up a couple very distinctive smells: Wood smoke and charcoal grills. Charcoal and wood fire scents carry far and linger long, presenting a pretty significant cue that people are nearby.

They also regularly offer really lovely wisps and plumes visible above rooftops, retaining walls, hedges, and woods depending on fuel source, weather, and skill. Even relatively small grills can pump enough to home in on once scents have us in the neighborhood.

We may very well want to avoid those telltales in some disasters, and there are plenty of other reasons low-and-no-smoke cooking backups are a must-have for preppers.

They apply to “normal” outage-based disasters and world-shaking events, and to beginners, apartment dwellers, and “soft” climate dwellers as well as the old hats who are already familiar with the numbingly, back-achingly incredulous amount of wood it takes to cook daily and keep even a tight, well-insulated home warm.

The backup methods I’ll list commonly use less fuel or completely different fuels than our primary systems. That diversity and efficiency helps our resources last longer and keeps us cooking when resupply isn’t available.

If we already count on wood or propane for winter heat or cooking, using alternatives now can lower our current burden, giving us the ability to stockpile more. (Or some extra cash and time!)

Many of us try to avoid pine and unseasoned wood in chimneys, especially brick that can’t be taken apart for easier access. Nonflammable, cleaner-burning and tabletop methods help limit buildup.

There are also scenarios where an injury or illness limits our usual labor, there are reasons to stay hunkered down inside, limit noise, and as such our most-efficient tools go down and our production slows; that or something like a flood or mudslide limits our access.

If we can cook and warm spaces without wood, we can horde that “now” precious commodity against greater need.

Or, we may not have a massive woodpile (yet), or a fireplace or woodstove of either species. We may not have a functioning chimney, or our chimney may develop a problem during a crisis. Backups for our backups keep us plodding forward.

*Liquid-gas fuels share some of the wood-charcoal factors, and have some new ones of their own.

Many of us live places where it gets pretty hot. Whatever the fuel used, heating the house unnecessarily just isn’t conducive for easing the stresses and burdens of an already difficult time – whether the crisis is widespread or only affecting us.

On the other hand, outdoor cooking gets old fast for those of us with seasonally or perennially dusty-windy conditions. That’s how it goes with picking oak catkins and maple spinners out of food, and dealing with flies and mosquitoes.

Grilling outside in a pounding rainstorm or frigid winds also kind of sucks – and can take forever – but then again it’s not usually a great idea to use charcoal grills inside.

Slight Consolation: Food you’ve suffered for in cold weather tastes better. (Muggy/hot weather, not so much.)

Options we can use indoors and under screened porches and pop-up pavilions check a big, big box.

There’s also the *other* rule of threes that some of us ascribe to: three ways to reach and accomplish any task. It’s not always possible (or practical), but in the case of alternative cooking methods, we can check that box, too, easily and with very little outlay in time or money.

Most of the methods below use things already in the home, very basic “everybody everywhere” tools, and outright trash/recycling that costs nothing but time. Some don’t even take up extra space.

The internet abounds with options for DIY’ing these and making them more efficient or portable, so I’m not going to reinvent the wheel on that front.

*I am not affiliated with any of the links provided, nor do I always agree with the authors (or even have any idea what else they post) – they’re the simplest, easiest, or most expedient versions that popped when I wanted an example.

Minimal-Smoke Cookers

Propane/Butane Stoves & Grills – There’s not a safe DIY for these and there’s potentially competition with preppers’ primary fuels or generators, but they’re pretty handy and inexpensive, so I don’t want to ignore them.

Rocket Stoves – I love these things. They take small kindling and sticks or trash wood and turn it into a high-efficiency, high-temperature burn. There’s a variation for everyone – balcony, porch, or backyard; homes, RVs, vehicle kits, or bag-portable.

Super easy DIY’s use CMU block, or a paint can, #10 can, or tall baked-beans or spaghetti-sauce cans and increasingly smaller cans. Other builds involve buckets, ammo cans, large terra cotta pots, cement, and sand. They’re not quite as super-easy or super-fast builds, but some variants further increase efficiency by burning the wood gas that’s generated from burning most woods.

Some of the store-bought versions have an added bonus: They’ll charge small devices or battery packs.

They can put off a fair bit of smoke, but they do it quickly and then stash away. They use wood, but we can fuel them with pruners and busted-up furniture and boards instead of axes and campfire/stove logs.

They’re not a simmer-beans or bake-bread oven/stove. It’s too fast and hot of a burn. They specialize in fast-cook foods and quickly bringing foods/water up to a boil to use with…

WonderBag/Wonder Boxes – Purchased or DIY, bag or box version http://www.instructables.com/id/How-to-Make-a-Wonder-Box-CookerCooler/, these function like a thermal cooker https://delishably.com/cooking-equipment/Thermal-Cooker.

They allow us to use a short “burn” time to heat food or water to boiling, then retain the heat, turning preexisting pots into non-electric slow cookers or crock pots.

Solar Cookers – DIY for solar ovens abound, from the simple glass over a tire with a pot inside, to some pretty complicated tilts, cuts and hinges. They’re done with pizza boxes and aluminum foil, vehicle reflectors, polished scrap metal, and mirrors. You can spend as little or as much as you fancy, ordering in or building.

I find them limited to mid-late spring through autumn, but I can protect them from pests pretty easily and they’re great for not heating the house or burning fuels in summertime, as are…

Steeping Jars – These are basically small-scale solar cookers. It’s as simple as pouring dehydrated veggies, grains, or pre-soaked beans in any ol’ jar, adding the needed water, and hanging/setting it in a bright spot.

Dark paint or fabric on jars, reflectors, and added insulation like a larger jar or aquarium can increase efficiency, reducing cook time and extending the weather they’re useful in.

*Don’t forget to brew sun tea & coffee.

Water Bags & Camp Showers – Getting the sun to give us a head start or completely handle heating water for us decreases resource and time expenditure. We can use anything, purpose-made, painted/covered garden sprayers, or regular ol’ jugs.

The warmed water can be used for wash-ups or for soaking and cooking freeze-dried foods, Lipton-Knorr-Rice-a-Roni sides, or our own noodles and rice.

The sun is free (when it’s there), compared to other resources – whether it’s propane, charcoal, or self-cut wood – and there’s little wear on parts compared to hydro or wind power. Even if the sun only warms that water, it’s reducing wait time and resource use.

*Keep a pot of water on a conventional oven, arctic brick stove, space heater, or woodstove, or on, under, or beside a grill and while a rocket stove burns out to accomplish the same ready-to-use pre-warming – even now. It’s even handier in winter, increasing heat radiation and serving as a heat sink.

DIY Candles – The upcoming methods call for a candle or alcohol stove. Those heat sources are interchangeable. (Differing flame heights will require adjustments.) We can also create our own.

With cotton mop strands, cord, or “real” wicks, olive oil can fuel lamps (https://www.littlehouseliving.com/olive-oil-candles.html). *Small citronella burners are really nice alternatives to open jars if we’ll have our lamps in and out of service for a while during an outage or long-term disaster.

We can sink wicks into shortening, too, in jars or the original tubs, creating another simple (and surprisingly long lasting) cooking method out of multi-functional storage items.

We use candles and mini-stoves in a grill, or set them up campfire/tailgate style with a grate over a terra-cotta pot, bricks, or some cans (fill them with water – sturdier + pre-warmed/boiled water).

Smells from candle, oil, and fuel-brick stoves and ovens will carry to nearby neighbors (so will cooking foods) but they dissipate even faster than quick-burn rocket stoves. The traces are even more contained when used indoors.

Clay Pot Heaters/Cookers – These are pretty easy to find for DIY – using as much hardware as you like, or kept streamlined and simple – or as prettied-up ready-to-use purchases.

They can be effective on their own, most usually to slowly warm foods like a slow cooker, but if they get plopped in a grill or oven (crack the door), the efficiency goes up and food will heat faster and more evenly.

*That goes for any of the methods that will fit. Be mindful of flame size and fumes.

Candle Ovens – We can buy a HERC oven (multiple recipes/examples: http://prepared-housewives.com/baking-with-the-herc-oven/) or DIY our own. It’s just rigging clusters of taper or pillar candles, DIY candles/lamps, or a whole slew of votives or tea lights on a drip-safe surface inside an oven, and cooking or baking at 200-300-degrees on the grate above.

*Hood/tent foods in full-size ovens (and campfire grates) with an overturned bowl or larger pan. It’ll hold heat closer to the food, speeding things up and cooking more evenly.

Can Stoves – These are super easy, super effective spinoffs of Sterno stoves and the military, camping, and emergency solid-fuel stoves that abound.

They can be done with greatest simplicity with just two types of can openers, or we can go to town with tin snips to increase ease or rig cross-bar “grills” at the top.

Backing up Backups

Increasing redundancy in our disaster cooking increases our ability to weather absolutely any storm. That makes these guys a prepper must-have in my book.

Some methods also significantly reduce our observable footprint, which may end up a major benefit, and some are reasonable alternatives to heating up our kitchens even now. Most of these have easy, inexpensive DIY options, allowing everyone to build extra resiliency into their disaster plans.

Follow The Prepper Journal on Facebook!

The post Prepper Must-Have: Minimal-Smoke Cooking Backups appeared first on The Prepper Journal.

from The Prepper Journal Don't forget to visit the store and pick up some gear at The COR Outfitters. How prepared are you for emergencies? #SurvivalFirestarter #SurvivalBugOutBackpack #PrepperSurvivalPack #SHTFGear #SHTFBag

16 notes

·

View notes

Text

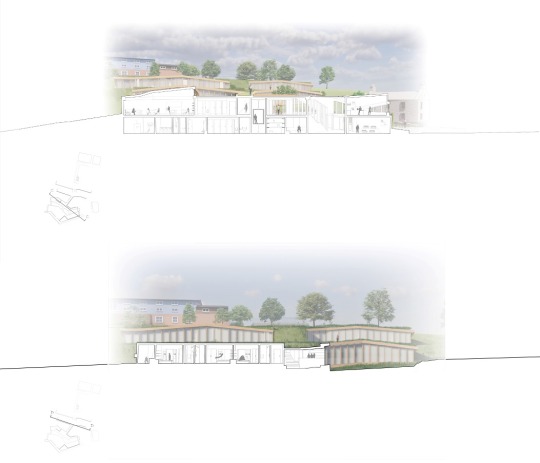

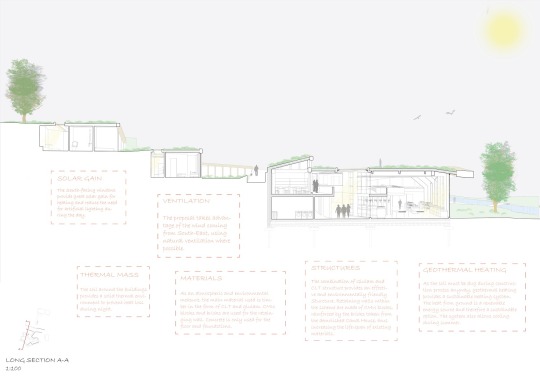

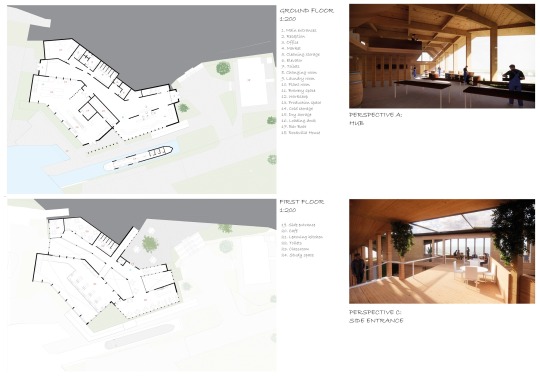

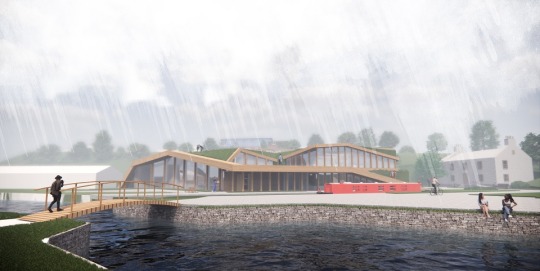

Jere Suominen, MSA Stage 3 Prize 2022, Highly Commended

The tools and technology for creating environmentally sustainable buildings already exist. This design seeks to implement these methods in a creative and playful way, connecting the technology with architecture and design in order to create a sustainable and thought-provoking ensemble. Instead of using a green roof for the sake of technology, the design aims to utilize the creative potential of it by practically turning the top of the building and surrounding areas into a public park for everyone to use – whether a user of the building or just a pedestrian navigating through the site. Or, instead of using a skylight just to get light into a space, it is also being used as a part of a rainwater harvesting system. The main idea driving the design was to create a sense of hierarchy, where nature is prioritized over built environment. This idea is communicated through materiality, structural choices, and other design aspects such as the building form and orientation. The design thus attempts to celebrate the local biodiversity and promote the environmental sustainability surrounding the project

FORM, ORIENTATION, PLACEMENT

The orientation and form of the proposal are designed to minimize its operational energy. As the building creates a landscape of its own, the design forms a sort of stepping along the hill, which allows the design to maximize the solar gain through large South-facing openings. This also means a minimal need for artificial lighting during the day. In fact, most spaces are specifically designed to discourage that by using the natural light in playful ways to create comfortable interior atmospheres. The building is embedded into the hillside and using the combined thermal mass of a green roof and the soil around the building it creates a thermal ‘pocket’ to lower heating or cooling requirements depending on the time of year.

LANDSCAPE

Due to the nature of the site and the design aspirations, landscape plays a massive part in the design. The building has been designed to be part of the landscape, allowing people to walk over it through designated paths. Entering the site from North-side provides a view of a specifically designed park with plenty of greenery, glancing at Glasgow city centre in the background. The building itself, however, is not visible until walking down the path and revealing the openings fitted into the landscape. This design aspect is intended to contribute to the visitors’ sense of hierarchy between built environment and nature. In order to modify the challenging slope to fit this design in, a ”cut and fill” approach is used to minimize the soil wasted during construction and digging, thus lowering the carbon footprint. This means that the soil cut out of the landscape to fit the building in, is reused somewhere else on the site.

MATERIALITY

Foundations: Environmentally problematic concrete must be used for the foundations due to the soil condition after digging on the site. However, the nearest supplier is right along the canal, cutting transportation costs and emissions to absolute minimum.

Glass façade: The specifically designed three-glazed window system provides an extremely efficient thermal performance while still allowing a lot of natural light into the interior spaces

Green roof: Local vegetation is used for the green roof. This is an attempt to bring back the biodiversity of the site, which is inevitably lost due to the construction process.

Retaining wall: The bricks are reused from the demolished Canal House in order to lengthen the life span of the deconstructed materials. The CMU blocks are locally produced to cut carbon emissions of transportation

WATER USAGE:

Water is an important element in this proposal. The green roof offers an incredible potential for a larger scale rainwater harvesting, and the skylights proposed use water for aesthetical and heating purposes. The drainage system is carefully laid out throughout the building and because of the slopy site, gravity essentially guides the all the collected rainwater into the same place for further reusage. The skylights always have a slight amount of water on top of them, which creates an interesting interior atmosphere, but additionally further strengthens the idea of making the building itself a part of the landscape when walking over it. The skylight then creates an illusion of a small river or a stream that is crossed when walking on the path on top of the building, connecting visitors with nature.

CONCLUSION:

I hope that this piece of work encourages the viewers to challenge the ideas we have about the limitations of sustainable building methods and materials. The climate change will inevitably force the building typologies to adapt, and the way we view the construction industry as a whole. However, this change also sparks new innovations, sustainable materials and methods of construction. Architecture has the potential - and arguably, the obligation - to implement these innovations into our built environments in a way, that makes cities better places to inhabit.

More on Jere's Instagram

0 notes

Text

The Use of CMUs in Retaining Wall Engineering

Concrete masonry retaining walls are the best looking and longest lasting of all retaining walls. This is because CMUs come in such a wide variety of textures and colors. The aesthetic scope of the blocks enables the engineering of beautiful, enduring retaining walls.

What is a CMU?

A CMU is a concrete masonry unit, commonly known as a cinder block. It is standard rectangular cast concrete block made of cement, aggregate and sand. These blocks are stacked to create the retaining wall. These bricks are easy to install. They’re fireproof, durable and require little to no maintenance.

Reinforced steel bars that are integrated into the CMUs add strength. This improves the wall’s weight-bearing capacity.

Concrete blocks come in various sizes and shapes making it possible to engineer retaining walls to suit the landscape.

CMU walls are built upon a poured concrete foundation. The blocks are cemented onto the foundation and then onto one another. Staggered vertical joints give the retaining wall added strength. Cap blocks finish the top of the wall.

The advantages of CMU blocks for retaining walls

Lightweight – because the blocks are hollow, they’re light and easy to install

Reinforced – steel reinforcing bars offer extra strength to an already strong wall. Concrete is poured into the holes that contain the rebar, creating a solid and durable wall.

Water resistant – Concrete blocks are ideal in high humidity areas as they are water resistant

Cost effective – CMU blocks are relatively cheap

Versatile – concrete blocks come in a variety of colors and shapes. This means that you can match the wall with the surrounding environment or the existing building. Pigments can be added to the block and mortar so you can blend the colors or choose to go with a sharp contrast.

Easy maintenance – CMUs are strong and easy to maintain. All they need is an occasional wash.

Improve your outdoor living along with the value of your property with a block retaining wall. We specialize in engineering beautiful retaining walls that should last a lifetime. Give us a call.

0 notes

Text

Nate Dalesio clads his Upstate New York family house in corkboard panels

Architect Nate Dalesio has completed a cork-covered home for himself and his young family in Upstate New York, reusing the existing foundations but replacing almost the entire building.

Dalesio, who also runs the architectural firm Multitude Studio from his home, overhauled the house originally built in 1937 in South Salem, New York. The abandoned property needed to be almost entirely razed in order to make it habitable.

The Cork Haven house replaces an earlier building that had fallen into disrepair

"The framing at the roof and floors, and the CMU at the exterior walls was consumed by rot and mold, and the entire house had to be leveled down to the top of foundation and built anew," said Dalesio.

"The existing footprint was entirely retained while targeted expansions have been used to enlarge the living spaces and bedrooms."

Nate Dalesio's chose to clad the replacement house in cork

The single-storey residence is laid out in a T-shaped plan, with one arm containing the public areas and kitchen, while the other accommodates three bedrooms and two bathrooms.

The completed house encompasses 2,500 square feet (232 square metres).

Vaulted ceilings create extra space inside. Photo by Meg Matyia

Because of the site's slope, the home's entry porch is reached via a flight of stairs. Inside, a small vestibule with large, built-in storage cabinets and a powder room is separated from the kitchen by a countertop – creating sightlines between the two areas.

The interiors features wide-plank white oak floorboards and white-painted walls. Pitched ceilings that follow the roof profiles give the rooms a spacious feeling, and plenty of skylights help brighten the living spaces.

Skylights bring additional light into the living areas. Photo by Meg Matyia

"Vaulted ceilings throughout the home create surprisingly spacious volumes that belie the modest footprint, and white oak panelling and floors bring warmth to contrast the crisp and sculptural white walls," said the architect.

At the back of the home, sliding glass doors open out onto a patio.

Read:

Contaminar Arquitetos designs concrete and cork school in Portugal

Dalesio designed the building's exterior to relate to the area's agricultural structures and barns, but using a more contemporary and minimal aesthetic.

The previous house on the site had a tin roof and wooden plank siding, which were swapped for black corrugated metal and corkboard.

White oak flooring and panelling create a light, minimal interior

The cork offers an additional layer of insulation, according to the architect, helping to lower the home's heating energy consumption.

"A modest budget of $150 per square foot was stretched to invest in highly insulated walls, roofs, floors, and windows to minimize utility bills, and the exterior cladding doubles as a continuous layer of corkboard insulation," Dalesio said.

The building's exterior is intended to echo the area's agricultural structures and barns, but with a more contemporary aesthetic

Cork is a useful building material, as it naturally resists humidity and mildew. It's also light and offers the potential to be recycled after use.

Other projects that incorporcate the material include a home in the Italian countryside by LCA Architetti, and an English countryside residence that Matthew Barnett Howland built using of monolithic cork blocks and was shortlisted for the 2021 Stirling Prize.

The photography is by Nate Dalesio, unless indicated otherwise.

The post Nate Dalesio clads his Upstate New York family house in corkboard panels appeared first on Dezeen.

0 notes