#cnc machine productivity

Explore tagged Tumblr posts

Text

Regular CNC Machine Servicing And Ready Availability Of CNC Spare Parts Are All You Need To Reduce Downtime And Improve Your CNC Machine Productivity.

0 notes

Text

GD Prototyping is a leading CNC machining company that provides one-stop services for businesses.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc precision machining#cnc metal machining#cnc metal fabrication#cnc metal process#cnc metal processing#cnc metal parts#metal machining#metal processing#metal products#prototype manufacturing#cnc manufacturing#cnc processing

2 notes

·

View notes

Link

#market research future#cnc machine products#cnc machine market revenue#cnc machine companies#cnc machine market trends

0 notes

Text

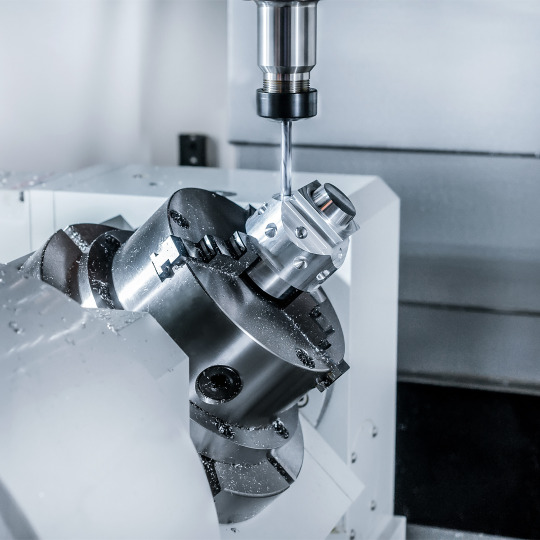

Maximizing Efficiency with the Best CNC Rotary Table for Precision Machining in 2025

In the competitive landscape of precision machining, efficiency is key to staying ahead. A CNC rotary table is an essential tool for manufacturers looking to optimize their CNC VMC machines in 2025. At Kuvam Technologies, we offer high-precision rotary tables, including 4th axis rotary tables and 5th axis rotary tables, designed to streamline production and enhance accuracy. Here’s how our rotary tables can transform your machining operations.

#rotary table#CNC rotary table#Precision machining#Hydraulic rotary table#Tilting rotary table#CNC machining#4th axis machining#5th axis machining#CNC machine components#Rotary table accuracy#CNC productivity

0 notes

Text

Precision CNC Machining Services in Bangalore Industry

Summary

Bangalore is emerging as a key hub for CNC machining, offering advanced technology, skilled talent, and diverse industry support. It excels in precision manufacturing, innovation, and global CNC machine exports.

Introduction

In the heart of India's technological hub, a quiet revolution is underway — one that is transforming the way parts are designed, manufactured, and assembled. Bangalore, traditionally known for its dominance in software and IT services, is rapidly becoming a powerhouse in precision manufacturing. At the center of this evolution lies CNC machining services in Bangalore, powering industries from aerospace to electronics with unparalleled precision and efficiency.

Whether you're a startup prototyping your next big innovation or a multinational looking for reliable large-scale production, CNC technology is likely part of your journey. In this blog, we explore why Bangalore is emerging as a go-to destination for CNC solutions and how CNC companies and manufacturers are shaping the city's industrial future.

What is CNC Machining?

CNC, or Computer Numerical Control, is a method of automating machine tools using computer programming. Unlike traditional manual machining, CNC machines follow a pre-programmed sequence of commands, ensuring high precision, repeatability, and speed. This technology is used to create complex components that meet strict dimensional tolerances, which is critical in sectors like aerospace, automotive, defense, and medical devices.

The rise of CNC machining in India reflects a global trend, but Bangalore stands out because of its rich ecosystem of tech talent, engineering expertise, and thriving startup culture.

Why CNC Machining Services in Bangalore Stand Out

1. Technological Synergy

Bangalore is uniquely positioned at the intersection of mechanical engineering and software development. The city's legacy in tech makes it easier for CNC companies to integrate software-driven innovations like CAD/CAM modeling, real-time monitoring, and AI-driven quality checks into their operations.

This synergy creates a smarter manufacturing environment. For instance, a CNC company in Bangalore might use machine learning algorithms to predict tool wear and minimize downtime — a significant value-add for clients demanding quick turnarounds and zero defects.

2. Access to Talent

With engineering colleges like IISc, RVCE, and PES University producing top-notch graduates, CNC machine manufacturers in Bangalore have access to a deep talent pool. This is vital in an industry that demands expertise not just in mechanical systems but also in programming, design, and electronics.

Moreover, the city's startup culture encourages constant experimentation and innovation. From developing new multi-axis CNC machines to creating custom automation systems, young engineers in Bangalore are pushing the envelope.

3. Diverse Industry Demand

The demand for CNC machining services in Bangalore comes from a broad range of industries:

Aerospace: High-precision components like turbine blades, engine parts, and structural supports.

Automotive: Parts like pistons, transmission housings, and gears.

Electronics: Housings, connectors, and precision mounts.

Medical Devices: Surgical instruments, orthopedic implants, and diagnostic equipment parts.

This diversity helps CNC companies in the region build specialized capabilities and stay ahead of global trends.

CNC Machine Manufacturers in Bangalore: Driving Industrial Growth

While service providers use CNC machines to deliver components to clients, the backbone of the ecosystem lies with the CNC machine manufacturers in Bangalore. These manufacturers are the ones designing and building the actual hardware — lathes, milling machines, routers, and grinders that run the CNC programs.

Innovations in Machine Design

Local manufacturers have embraced global standards in machine design. Many now offer:

5-axis machines for greater flexibility and precision

Automated tool changers to speed up production

Closed-loop control systems that monitor real-time performance

What’s more, many manufacturers now provide IoT-enabled machines that can be monitored remotely, a feature that is increasingly sought after by companies running smart factories.

Export and Global Reach

Several CNC machine manufacturers in Bangalore are not just serving the Indian market but also exporting their machines to Europe, Southeast Asia, and the Middle East. This speaks volumes about the quality and competitiveness of Bangalore-made machines.

Additionally, these manufacturers often offer turnkey solutions—from machine supply to installation, training, and after-sales service—making them highly attractive to both Indian and international clients.

Choosing the Right CNC Company in Bangalore

With so many players in the space, finding the right CNC company in Bangalore can feel overwhelming. Here are a few factors to consider:

1. Experience and Specialization

Different CNC companies specialize in different industries. Some are experts in automotive prototyping, while others excel in aerospace-grade components. Choosing a company that aligns with your industry requirements is crucial for success.

2. Technology Stack

Look for companies using the latest tools—high-speed machining centers, automated inspection systems, and modern CAM software. The use of cutting-edge technology directly impacts product quality, turnaround time, and cost-efficiency.

3. Certifications

ISO, AS9100, or IATF certifications indicate that a company follows stringent quality processes. These are especially important if your components require tight tolerances or regulatory compliance.

4. Client Feedback and Case Studies

Customer testimonials and real-world examples of past projects can give you a clearer picture of a company’s capabilities. Don’t hesitate to ask for references or visit their facility if possible.

The Future of CNC Machining in Bangalore

As industries continue to evolve, the role of CNC machining will only grow. Several trends are likely to shape the future of the industry in Bangalore:

Additive + Subtractive Manufacturing: Some CNC companies are combining traditional subtractive methods with 3D printing for hybrid manufacturing.

Green Machining: With sustainability becoming critical, companies are investing in energy-efficient machines and coolant recycling systems.

AI and Predictive Maintenance: AI algorithms will help anticipate failures and schedule maintenance, reducing costs and downtime.

Digital Twins and Simulation: Advanced simulation tools are enabling manufacturers to visualize machining processes before they begin, optimizing tool paths and reducing errors.

Bangalore’s mix of technical talent, industrial growth, and innovation culture ensures it will remain a key hub for CNC machining not just in India, but in the broader Asia-Pacific region.

Conclusion

Whether you're looking for high-precision components, custom machine design, or integrated automation systems, the CNC landscape in Bangalore offers everything you need. The convergence of software and hardware, backed by a robust talent ecosystem, makes this city a standout destination for manufacturing excellence.

So, if you’re in the market for CNC machining services in Bangalore, or looking to source from reliable CNC machine manufacturers in Bangalore, there's no better place to start your journey. From prototyping to production, a trusted CNC company in Bangalore can help bring your ideas to life with precision, speed, and innovation.

FAQ

1. What are CNC machining services, and how are they used in Bangalore? CNC (Computer Numerical Control) machining services involve the automated control of machining tools by a computer. In Bangalore, these services are widely used in industries like aerospace, automotive, electronics, and medical devices to produce precision parts and components.

2. Why is Bangalore a leading hub for CNC machining in India? Bangalore offers a unique combination of tech expertise, skilled engineering talent, and strong demand from diverse industries. The city's legacy in IT and manufacturing makes it an ideal environment for innovative and high-precision CNC solutions.

3. What industries rely on CNC machining services in Bangalore? CNC services in Bangalore cater to aerospace, automotive, medical devices, electronics, defense, and industrial automation sectors. Each industry requires high-precision components that CNC technology is well-suited to produce.

4. How do I choose the right CNC company in Bangalore? Look for a company with experience in your industry, modern CNC technology, relevant certifications (such as ISO or AS9100), and strong client feedback. Visiting the facility or reviewing case studies can also help evaluate their capabilities.

5. Who are the CNC machine manufacturers in Bangalore? Bangalore is home to several leading CNC machine manufacturers that design and build advanced machining equipment like 5-axis mills, automated lathes, and IoT-enabled machines. These manufacturers often serve both domestic and international markets.

6. Are CNC machines made in Bangalore exported to other countries? Yes. Many CNC machine manufacturers in Bangalore export their products to Europe, Southeast Asia, and the Middle East. These machines meet global standards and are often used in international smart factories and production lines.

0 notes

Text

I just had a mild mind-fuck when thinking about generative AI, social media, and the advancement of modern production technologies.

Generative AI is making it so that the cheapest way to access imagery and content is through something owned by corporations and governments. Along with the fact that most communication online is done through social media, that means that how we express ourselves and talk to each other is heavily regulated and monitored by the powerful.

However, with the advancements in Additive and Subtractive production technologies such as CNC machines and 3D Printers, the means of production of goods is becoming increasingly decentralized. You can make your own stuff if you want to. We are no longer quite as reliant on corporations and factories to acquire physical goods. A lot of people can just make things for themselves.

So, effectively, the whole dynamic of class structure is starting to flip. The rich are ceasing to own the means of production, as its becoming something the middle and lower class can access for themselves. However, the means of communication and self expression are increasingly being owned by the elites. Something that, until very recently, was basically impossible to regulate and control effectively.

THE ENTIRE DYNAMIC OF HOW THE WORLD WORKS IF FLIPPING, AND I DONT KNOW WHAT TO MAKE OF IT.

#AI#social media#socialism#class warfare#art#elite#elites#communication#means of production#3d printing#cnc machines#production#power dynamics

1 note

·

View note

Text

Engineered for Strength: Leading the Way in OEM CNC Machine Manufacturing

Precision, durability, and innovation—that’s what sets great off-road fabrication apart. In an industry where strength and reliability are non-negotiable, serious builders turn to trusted sources for components that won’t crack under pressure. That’s why choosing the right supplier is more than a purchase—it's a performance decision. For off-road enthusiasts, welders, and manufacturers alike, having access to high-grade parts from OEM CNC Machine Manufacturers is essential.

Off-road vehicles demand more than ordinary components. Whether it's for roll cages, suspension arms, or engine mounts, parts must be machined to exacting specifications. The best OEM CNC Machine Manufacturers don't just meet industry standards—they raise the bar. They produce components that are tested under real-world conditions, built with consistency, and delivered with performance in mind. These manufacturers don't mass-produce parts with guesswork—they precision-cut, engineer, and finish every unit to the highest degree.

The backbone of any serious off-road setup is the quality of its materials. That’s where Arrow Manufacturing Products come into play. Built for those who push their machines to the limit, these products are engineered to perform in extreme environments—from desert trails to rocky climbs. Every component is fabricated with attention to detail, tested for strength, and made for abuse. When you rely on Arrow Manufacturing Products, you're equipping your build with components designed for serious impact resistance and long-term use.

Customization is another key factor. Not every builder needs a cookie-cutter part. Off-road customization is personal, and so are the parts that go into each build. That’s why a strong supplier offers flexibility, precision engineering, and compatibility with a wide range of vehicle types. The goal isn't just to sell metal—it's to solve real-world off-road challenges with components that make sense on the trail and on the job.

From tube notching fixtures to tab kits, quality weld-on brackets to gussets that add reinforcement exactly where it's needed, everything is about functional design. Builders don’t have time to deal with parts that don’t fit or fail under stress. Quality parts reduce build times, lower long-term costs, and eliminate headaches.

At the end of the day, what matters most is trust. Trust in your build, trust in your components, and trust in the supplier that stands behind every cut, weld, and bolt. Choosing partners that deliver top-tier fabrication components is the difference between average and exceptional. Whether you're racing, crawling, or fabricating for clients, that choice starts with sourcing your parts from industry leaders who specialize in off-road-ready solutions.

Get it right the first time. Choose quality. Choose reliability. Choose parts that work as hard as you do.

0 notes

Text

Engineered Components Designed for Precision and Reliability

Explore a high-quality range of machined components built for durability and precision. The page highlights Suraj Brass Industries’ expertise in delivering CNC Turned Parts tailored to meet the complex needs of modern industries, ensuring consistent performance in every application.

0 notes

Text

CNC Machining for Rapid Prototyping | Fast & Accurate Prototypes

Transform your product ideas into real-world solutions with Rapid Prototyping CNC Machining services from Impel Concepts. Their precision and speed help bring your vision to life with accuracy and efficiency. Whether you’re developing a concept or refining a part, Impel Concepts delivers quality every step of the way. Trust them for fast turnarounds and professional-grade prototypes tailored to your specifications.

#rapid prototyping cnc machining#cnc production machining#FEA Analysis#Concept Rendering#cnc machining solutions#Prototype development

1 note

·

View note

Text

The Marvel of High - Precision Stainless - Steel Metal Washers

Hey there, Tumblr fam! Ever wondered about the unsung heroes of precision engineering? Let's talk about high - precision stainless - steel metal washers.

Our team dives deep into the world of micro - tolerances to create these little wonders. We start with the finest stainless - steel, a material renowned for its strength and resistance to rust and corrosion. But it's not just about the raw material; it's the process that makes our washers stand out.

Using state - of - the - art machinery and advanced machining techniques, we carve and shape each washer with an accuracy that's mind - blowing. These aren't your average washers you find in a hardware store. Our high - precision versions are designed for industries where even the slightest deviation can spell disaster, like aerospace, medical devices, and high - tech electronics.

Whether it's a washer for a delicate medical implant or a crucial component in a high - speed aircraft engine, we've got the skills and technology to deliver. So, the next time you see a complex machine working flawlessly, remember, there might just be one of our high - precision stainless - steel metal washers quietly doing its job, ensuring everything runs smoothly.

this Tumblr - style post capture the essence of what you want to convey about your washer processing? If you have any specific elements like a more personal touch or additional technical details, I can refine it further.

#cnc swiss#precision#machining#precision hardware products#precision machining#StainlessSteel#PrecisionMachining#MetalWashers

0 notes

Text

Premium CNC Machined Products

Upgrade your manufacturing with top-quality CNC machined products! Engineered for accuracy, durability, and performance. Get the best from a trusted CNC machine company.

https://middleeastcnc.com/

1 note

·

View note

Text

Metal CNC machining services

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc metal machining#cnc metal process#cnc metal fabrication#cnc metal parts#metal machining#metal products#metal cnc#cnc metal processing

2 notes

·

View notes

Link

#market research future#cnc machine products#cnc machine market revenue#cnc machine companies#cnc machine market trends

0 notes

Text

𝐂𝐍𝐂 𝐦𝐚𝐜𝐡𝐢𝐧𝐞 𝐟𝐨𝐫 𝐜𝐮𝐭𝐭𝐢𝐧𝐠 𝐠𝐫𝐨𝐨𝐯𝐞𝐬 𝐚𝐧𝐝 𝐜𝐡𝐚𝐦𝐟𝐞𝐫𝐢𝐧𝐠 𝐭𝐡𝐞 𝐞𝐧𝐝𝐬 𝐨𝐟 𝐢𝐝𝐥𝐞𝐫 𝐫𝐨𝐥𝐥𝐞𝐫 𝐬𝐡𝐚𝐟𝐭𝐬

we have successfully automated the CNC machining process for roller shafts precisely shaping flat ends, chamfers, and grooves with unmatched efficiency and accuracy. Visit now https://en.guderoller.com

0 notes

Text

#rapid prototype# If you are looking for rapid prototype supplier, we are here for you. Please drop me an email at your convenience [email protected], we will be happy to help! For more information, please visit https://www.sgproto.com/

0 notes

Text

Discover Premier CNC Machine Manufacturers in Canada: Excellence Today

Precision Engineering for Off-Road Innovation

When it comes to crafting high-performance components for rugged terrains, few can rival the expertise of CNC Machine Manufacturers in Canada. Leveraging state-of-the-art multi-axis machining centers, these specialists transform raw billets of aluminum, stainless steel, and titanium into parts that endure the harshest conditions. From shock-absorber mounts to skid-plate brackets, each piece is engineered with microscopic precision to guarantee perfect fitment and long-term reliability.

Advanced Materials and Cutting-Edge Techniques

The off-road arena demands materials that balance strength with weight savings. Leading providers invest heavily in additive-aided toolpath optimization and real-time thermal compensation to maximize tolerance control. By collaborating closely with OEMs, these experts push the boundaries of what’s possible—bringing you components designed for peak performance. Whether it’s flow-forming hollow shafts or micromilling intricate fin patterns, the focus remains unwavering: deliver parts that outperform and outlast.

Custom Solutions Tailored to Your Needs

No two off-road builds are the same. That’s why top-tier CNC Machine Manufacturers in Canada offer fully bespoke services, from initial design consultation through final prototype testing. Utilizing advanced CAD/CAM integration, they iterate rapidly, producing prototypes in days rather than weeks. Their ability to accommodate complex geometries and low-volume runs makes them the partner of choice for boutique fabricators and large-scale assemblers alike.

Commitment to Quality and Certification

Quality assurance is non-negotiable when lives and livelihoods depend on component integrity. Accredited shops adhere to rigorous ISO 9001 standards and routinely perform in-process inspections using CMMs, laser scanners, and dynamic balancing rigs. Traceability is maintained at every step, ensuring material certificates accompany each shipment. This meticulous approach minimizes rework and guarantees that every batch meets or exceeds stringent performance criteria.

Why Choose Arrow Manufacturing Expertise

While numerous shops claim precision, only a select few truly embody the ethos of Arrow Manufacturing Products. Their seasoned engineers bring decades of off-road experience, understanding the nuances of shock dynamics, torsional loads, and vibration damping. By marrying hands-on off-road knowledge with advanced machining capabilities, they deliver components that integrate seamlessly into your build, enhancing durability and drivability.

Sustainable Practices for a Greener Tomorrow

Environmental stewardship is at the forefront of modern manufacturing. Leading facilities implement closed-loop coolant systems, high-efficiency dust collection, and energy-optimized spindle drives to reduce waste and lower carbon footprints. They recycle or repurpose metal shavings and invest in renewable energy sources, reflecting a commitment that extends beyond the shop floor.

Your Partner in Off-Road Excellence

For builders and engineers who demand uncompromising quality, Arrow Manufacturing Products stands ready to exceed expectations. From prototype to production, their seamless workflow, stringent certifications, and focus on innovation ensure your off-road projects achieve unparalleled performance and reliability. When the trail gets tough, trust parts crafted by masters of precision to keep you moving forward.

0 notes