#construction estimating errors and solutions

Explore tagged Tumblr posts

Text

How Accurate Is a Construction Cost Estimating Service Today?

Accuracy in construction cost estimating is a critical factor that directly impacts project success. With the rising complexity of modern construction projects and fluctuating market conditions, many stakeholders wonder: just how accurate is a construction cost estimating service today? This article explores the factors affecting estimating accuracy, common challenges, and how today’s technologies and best practices improve estimate reliability.

Factors Influencing Estimating Accuracy

Several elements influence the precision of a construction cost estimate:

Project Scope Definition The level of design detail strongly affects accuracy. Early-stage or conceptual estimates tend to be less precise due to limited drawings or specifications. As project plans mature, estimators can provide more detailed and reliable figures.

Data Quality and Sources Accurate cost estimating depends on up-to-date pricing data for materials, labor, and equipment. Using outdated or regionally irrelevant data can cause discrepancies. Reliable estimating services constantly update their cost databases to reflect current market rates.

Estimator Experience and Methodology Experienced estimators apply proven methodologies, industry standards, and risk assessment techniques. Their expertise in interpreting plans and anticipating challenges leads to better accuracy compared to automated or less experienced approaches.

Complexity and Project Type Simple projects with straightforward design and well-known materials are easier to estimate accurately. Complex projects—such as large commercial buildings or industrial facilities—introduce more variables that increase uncertainty.

Use of Technology Advanced estimating software and Building Information Modeling (BIM) integration help improve accuracy by automating quantity takeoffs and linking design changes directly to cost updates. This reduces manual errors and speeds up estimate revisions.

Common Accuracy Ranges

Accuracy is often expressed as a range or percentage variance from the actual project cost. Typical accuracy levels vary by estimate type and project stage:

Preliminary or conceptual estimates: ±15% to ±30%

Schematic design estimates: ±10% to ±20%

Detailed or bid estimates: ±5% to ±10%

It’s important to understand that no estimate can guarantee 100% accuracy due to unforeseen factors like weather, labor strikes, or supply chain disruptions.

How Estimating Services Improve Accuracy

Regularly updating cost databases: Reflecting current prices reduces pricing errors.

Conducting detailed quantity takeoffs: Precise measurement reduces scope gaps.

Collaborating with subcontractors and suppliers: Incorporating real bids enhances reliability.

Applying risk management contingencies: Buffers prepare budgets for uncertainties.

Leveraging technology: Automated tools reduce manual calculation mistakes.

Why Accuracy Matters

Accurate construction cost estimates contribute to better budget control, more effective bidding, and fewer costly change orders. They provide confidence to owners, contractors, and investors, enabling informed decision-making and smoother project delivery.

FAQs

What causes inaccuracies in construction cost estimates? Inaccuracies often stem from incomplete project information, outdated cost data, unexpected site conditions, and design changes during construction.

Can technology guarantee 100% accurate estimates? No technology can fully eliminate uncertainty, but it significantly improves accuracy by reducing human errors and increasing data integration.

How often should estimates be updated during a project? Estimates should be updated at key project milestones, such as after design revisions or major scope changes, to maintain accuracy.

Conclusion

While no construction cost estimating service can provide perfect accuracy, modern practices and technologies have greatly improved estimate reliability. Understanding the factors that influence accuracy helps stakeholders set realistic expectations and plan contingencies effectively. Ultimately, partnering with a skilled estimating service reduces financial risks and supports successful project outcomes.

#how accurate are construction cost estimates today#factors affecting construction estimating accuracy#technology in construction estimating services#typical accuracy range for construction estimates#how to improve accuracy of construction estimates#impact of project scope on estimate accuracy#role of estimator experience in accuracy#BIM for construction cost estimating#construction estimating errors and solutions#updating cost data for accuracy#risks in construction cost estimating#best practices for construction estimating accuracy#difference between conceptual and detailed estimates#importance of detailed quantity takeoffs#how subcontractor bids improve estimates#construction change orders and estimate accuracy#managing contingencies in construction estimates#estimating accuracy for commercial projects#challenges in industrial construction estimates#impact of design changes on cost estimates#technology tools for estimators#how often to update construction estimates#common causes of estimate inaccuracies#estimating small vs large construction projects#improving bidding accuracy with estimating#cost estimating software benefits#role of experience in construction estimating#how to reduce cost overruns with accurate estimates#using data analytics in construction estimating#what is a reliable construction cost estimate

0 notes

Text

Discover the Charm of the Best Hardwood Flooring Contractor Near Elmwood Park

Elmwood Park, with its blend of suburban tranquility and city-edge sophistication, is home to many beautiful residences. As homeowners seek to enhance the charm, warmth, and value of their properties, one feature consistently stands out—hardwood flooring. Classic, durable, and endlessly stylish, hardwood floors bring elegance to any space. But to truly capture their beauty, expert craftsmanship is essential. That’s where finding the best hardwood flooring contractor near Elmwood Park becomes vital.

In this article, we’ll dive deep into what makes a hardwood flooring contractor truly exceptional, how to identify the best in the Elmwood Park area, and why hiring the right professional can make all the difference in transforming your home.

1. The Lasting Appeal of Hardwood Flooring

Hardwood flooring has stood the test of time—and for good reason.

Timeless Aesthetic

Hardwood floors are versatile. Whether your home leans toward traditional architecture or modern minimalism, hardwood blends in beautifully. From rich walnut to sleek maple, the colors, textures, and finishes can be tailored to reflect your personal taste.

Unmatched Durability

When installed and maintained properly, hardwood floors can last decades—even generations. Unlike other flooring options, they can be sanded and refinished multiple times, refreshing their appearance without needing full replacement.

Boost in Home Value

Buyers love hardwood. In real estate, homes with hardwood flooring often command higher prices and sell faster. Investing in quality flooring and expert installation pays off.

2. Why the Right Contractor Matters

Even the finest hardwood materials can be ruined by poor installation. On the flip side, an experienced contractor can make mid-range materials look luxurious. The craftsmanship of the contractor defines how your floors feel, function, and last.

Precision Installation

Professional contractors ensure tight seams, seamless transitions, and even surfaces. They use precision tools and techniques to minimize gapping, creaking, or warping over time.

Customized Solutions

The best hardwood flooring contractors near Elmwood Park consider your home's unique layout, your lifestyle, and your design preferences. They recommend finishes, wood types, and patterns to match your needs.

Longevity and Maintenance

Top contractors also advise you on maintenance, offer warranties, and ensure the flooring is sealed and protected for long-term use—especially critical in a climate like Illinois'.

3. Qualities of the Best Hardwood Flooring Contractor Near Elmwood Park

Here’s what separates the best from the rest:

1. Local Reputation

A contractor who has worked in Elmwood Park and nearby neighborhoods understands the styles and construction challenges of homes in the area. They have references, online reviews, and community trust.

2. Proven Experience

Years of hands-on experience mean fewer errors and more creative solutions. Look for contractors with portfolios showcasing various project styles.

3. Certified and Insured

The best contractors are fully licensed, bonded, and insured. Many are certified by industry organizations like the National Wood Flooring Association (NWFA) or are Bona Certified Craftsmen.

4. Transparency

A top-tier professional will offer written estimates, explain the scope of work clearly, and provide timelines. They don’t upsell unnecessarily and educate homeowners along the way.

5. Portfolio and Samples

Seeing is believing. Reliable contractors will gladly show samples, completed projects, and even arrange site visits to past work.

4. Services Offered by Top Contractors

The best hardwood flooring contractors near Elmwood Park typically provide a range of services, including:

New Installation

This includes subfloor preparation, layout design, and final installation using either nail-down, glue-down, or floating methods.

Refinishing

Sanding, staining, and sealing old hardwood floors to restore their former glory—or to give them a whole new look.

Repairs

Fixing scratches, water damage, or warped planks without replacing the entire floor.

Custom Work

Creating herringbone or chevron patterns, inlays, and medallions for a unique design element.

Consultations

Helping clients select wood types, finishes, stains, and even advise on furniture pads and cleaning routines.

5. Top Wood Species Offered Near Elmwood Park

The best contractors usually work with a variety of wood species. Popular choices include:

Red Oak: Affordable, durable, and easy to stain.

White Oak: Stronger than red oak with a modern grain.

Maple: Light-colored and smooth-grained for contemporary spaces.

Hickory: Dense and rustic—ideal for active households.

Walnut: Deep, rich brown hues for luxury aesthetics.

Exotics (like Brazilian Cherry or Acacia): For a bold, unique statement.

Each type has its pros and cons, and the best contractors will help you choose based on your needs, budget, and home’s humidity levels.

6. Understanding the Installation Process

To appreciate the value a great contractor brings, it helps to understand what’s involved in the process:

Step 1: Site Evaluation

This includes measuring moisture levels, inspecting the subfloor, and evaluating room layout.

Step 2: Material Delivery and Acclimation

Wood needs time to adjust to the environment—usually 3-7 days in your home.

Step 3: Subfloor Preparation

Smoothing, cleaning, and repairing the base to prevent future issues.

Step 4: Layout Planning

Aligning boards to ensure symmetry, minimizing waste, and planning transitions.

Step 5: Installation

Method depends on wood type—nail-down, glue-down, or floating.

Step 6: Sanding and Finishing (for site-finished)

If you choose unfinished wood, the contractor will sand and apply stains or sealers on-site.

Step 7: Clean-Up and Final Inspection

Ensuring dust is removed and the finish is flawless.

7. Choosing the Right Contractor: Questions to Ask

Before hiring anyone, ask these important questions:

How long have you been installing hardwood flooring near Elmwood Park?

Can I see your portfolio or visit a past project?

Are you licensed and insured?

Do you offer a warranty? If so, what does it cover?

What brands or wood suppliers do you work with?

Do you use dustless sanding equipment?

How do you handle project delays or issues?

Do you offer free estimates and consultations?

8. Signs You’ve Found the Best Contractor

You’ll know you’ve found a top hardwood flooring contractor when:

They answer questions thoroughly and patiently.

Their past clients rave about them.

They offer solutions—not just sales pitches.

They arrive on time, respect your space, and communicate clearly.

Remember: your contractor will be working in your home for days or even weeks—professionalism is key.

9. Budgeting for Hardwood Flooring

Costs Involved:

Materials: $3–$15 per square foot, depending on wood species.

Labor: $3–$10 per square foot.

Additional Services: Removal of old flooring, subfloor repair, or custom staining.

How to Save Without Sacrificing Quality:

Choose domestic over exotic woods.

Consider engineered wood in less visible areas.

Get quotes from at least three reputable contractors.

Look for bundled packages or seasonal discounts.

10. Maintaining Your Hardwood Floors

Once your new floor is installed, proper care will help it last:

Use a microfiber mop and hardwood floor cleaner (no vinegar or harsh chemicals).

Add rugs in high-traffic areas.

Use felt pads under furniture.

Clean spills immediately.

Avoid walking in high heels or cleats indoors.

Schedule professional maintenance every few years.

11. Local Favorites: Contractors Serving Elmwood Park

While this article is not meant to endorse specific businesses, local homeowners often report high satisfaction with:

Artisan Wood Flooring Specialists

Windy City Hardwood

Urban Grain Flooring Co.

Parkside Custom Floors

Always verify their credentials and read current reviews.

Conclusion: Bring Out the Charm in Your Home

Your floors are one of the first things guests notice. Hardwood adds elegance, warmth, and character—but only when installed with care and expertise. Choosing the best hardwood flooring contractor near Elmwood Park ensures your investment will pay off for decades.

Whether you’re updating a century-old bungalow or finishing a brand-new build, trust in the hands of a skilled local professional. Discover the charm, quality, and craftsmanship that only the best can deliver—and step into a home you’ll fall in love with all over again.

youtube

#Best Hardwood Flooring Contractor Near Elmwood Park#Best Hardwood Flooring#Best Hardwood Flooring Contractor#Hardwood Flooring Contractor#Hardwood Flooring#Flooring#Elmwood Park#Youtube

2 notes

·

View notes

Text

Trimble SysQue vs MSuite in BIM

Both Trimble SysQue and MSUITE play crucial roles in the modern BIM (Building Information Modeling) ecosystem. While they are designed for distinct purposes, they often complement each other in streamlining workflows for MEP (Mechanical, Electrical, Plumbing) contractors and construction professionals. Let’s talk about both the tools individaully.

What is Trimble SysQue?

Trimble SysQue is primarily a Revit-based solution that enhances the BIM modeling services process by enabling the creation of fabrication-ready designs. Its strength lies in its precision and accuracy, achieved through the integration of manufacturer-specific data into BIM models. This ensures that every component designed using SysQue matches real-world specifications, making it ideal for prefabrication workflows. For example, when designing ductwork or piping systems, SysQue allows users to specify dimensions, materials, and components directly sourced from manufacturers. This level of detail not only reduces errors during construction but also ensures compatibility during the prefabrication and installation phases. SysQue is particularly useful for teams focused on creating detailed designs within Autodesk Revit, as it seamlessly integrates into this widely used platform.

How Trimble SysQue Enhances Revit Workflows for Fabrication-Ready Models

Trimble SysQue is a powerful tool that enhances Revit workflows, specifically tailored for the fabrication-ready MEP modeling (Mechanical, Electrical, and Plumbing) systems. It allows users to directly create and manage fabrication-level models within Revit, streamlining the transition from design to fabrication. Here’s how SysQue integrates with Revit and the advantages it offers for precise modeling:

Seamless Integration with Revit

Embedded within Revit: SysQue works directly inside the Revit environment, allowing users to build fabrication-ready models using the same familiar interface. It integrates with the existing Revit MEP tools, allowing for the inclusion of accurate fabrication data and shop drawings without leaving the platform. No Need for Separate Software: Traditionally, fabricators may have to switch between Revit for design and another platform for fabrication-level details. SysQue eliminates this need, making it possible to complete everything within Revit. This minimizes errors and improves collaboration between design and fabrication teams.

Accurate, Fabrication-Level Models

Data-Rich Models: SysQue generates models with detailed, fabrication-level data (e.g., sizes, materials, and specific fittings). These models are ready for fabrication, eliminating the need for additional conversions or adjustments before fabrication begins. Pre-configured Families and Components: SysQue includes a Revit family creation for manufacturer-specific components and parts that are pre-configured for fabrication. This ensures that the models are precise and compliant with industry standards.

Real-Time Coordination and Clash Detection

Automatic Clash Detection: SysQue enhances Revit’s clash detection capabilities by ensuring that the model is fully coordinated. This helps avoid conflicts between MEP systems and other building elements (e.g., structural or architectural components) early in the design process. Improved Collaboration: Teams can work more efficiently together, as SysQue’s data-rich models reduce errors and facilitate clearer communication between architects, engineers, and fabricators.

Material and Quantity Takeoff

Accurate Material Quantities: SysQue allows users to perform detailed quantity takeoffs directly within Revit. This is crucial for estimating the material requirements and ensuring that everything needed for fabrication is accounted for. Cost Estimation: With detailed material data, SysQue enables more accurate cost estimation, helping fabricators and contractors avoid costly errors and delays during the construction process.

Enhanced Workflow Efficiency

Eliminates Errors from Manual Conversion: Without SysQue, manual adjustments or conversions from design to fabrication models can lead to errors. SysQue streamlines this process by directly generating fabrication-level models, which improves workflow efficiency. Automation of Tasks: SysQue automates repetitive tasks such as component placement, reducing the time spent on manual drawing and ensuring consistency in the models.

Compliance and Standardization

Industry Standards Compliance: SysQue ensures that all components comply with fabrication and installation standards, reducing the risk of mistakes during the fabrication and installation phases. It supports various regional codes and standards, making it adaptable to different geographical locations. Template-Based Modeling: The use of predefined templates for different systems (HVAC, plumbing, electrical) ensures that models are consistent and meet the required specifications, making them easier to hand over to the fabrication team.

Improved Project Timelines

Accelerates Design to Fabrication: With SysQue, the time it takes to convert a design into a fabrication-ready model is significantly reduced, speeding up the overall project timeline. This allows teams to begin fabrication earlier, helping to meet tight deadlines.

Real-World Data and Material Tracking

Manufacturer-Specific Components: SysQue includes manufacturer-specific data for piping, ducting, and electrical systems. This ensures that every component is accurate and compatible with real-world products, making the transition to fabrication smooth and precise. Efficient Material Tracking: SysQue’s integration with Revit also ensures accurate tracking of materials, facilitating better inventory management and reducing waste.

A Step-by-Step Guide to Creating Fabrication-Ready BIM Models with SysQue

Creating fabrication-ready BIM models with SysQue involves leveraging the power of Autodesk Revit along with SysQue’s specialized tools for MEP (Mechanical, Electrical, and Plumbing) systems. SysQue allows for the detailed modeling of MEP systems, making the BIM model ready for fabrication. Here’s a step-by-step guide for new users:

1. Set Up Revit and SysQue

Install Autodesk Revit: Ensure you have Autodesk Revit installed, as SysQue integrates with it. You’ll need a licensed version of Revit (preferably 2024 or newer).

Install SysQue: Download and install SysQue from the SysQue website. Follow the installation instructions provided by Trimble.

2. Configure Project Settings

Set Units and Scale: In Revit, go to Manage > Project Units to configure the units (typically inches or millimeters, depending on your region).

Define Worksets: Set up worksets to organize your model, which helps with collaborative work and managing large-scale projects.

3. Set Up SysQue Content

SysQue comes with a library of manufacturer-specific MEP components. To ensure fabrication readiness, you’ll want to set up this library.

Load SysQue Families: Open the SysQue content manager, and load the families (like ductwork, piping, and other MEP systems) into your Revit project. These are detailed families that will allow you to model components with fabrication-level precision.

4. Begin Modeling with SysQue Tools

Model Piping and Ductwork: Use SysQue tools within Revit to start placing detailed piping and duct systems.

Piping: In the SysQue ribbon, choose the appropriate pipe type (e.g., copper, steel, plastic), then place and route pipes according to your system layout.

Ductwork: Similarly, place ducts and fittings, making sure to use SysQue’s tools for fabrication-level detailing. These tools allow you to specify fittings, offsets, and connections that are fabrication-ready.

5. Use MEP Detailing Tools

Routing Preferences: Set your routing preferences for different systems to match your design and fabrication requirements. SysQue allows you to customize the fitting types, installation methods, and other preferences for MEP systems.

Create Fabrication-Ready Components: SysQue provides detailed components, so when you place a fitting or a piece of equipment, it will have the exact dimensions and details needed for fabrication.

Ensure you set up the correct connector types (flanged, threaded, etc.) and pipe/material schedules to ensure accurate modeling.

6. Collaboration and Coordination

Coordinate Systems with Other Disciplines: Use the coordination tools in Revit to check for clashes between your MEP systems and the architectural or structural models.

Use Clash Detection: Run clash detection in Revit to make sure your systems are properly coordinated. SysQue integrates with Revit’s native clash detection, allowing for the identification of interferences early in the process.

7. Generate Fabrication Documentation

Fabrication Drawings: Once your model is complete, you can generate fabrication-ready drawings directly within Revit using SysQue’s templates and tools.

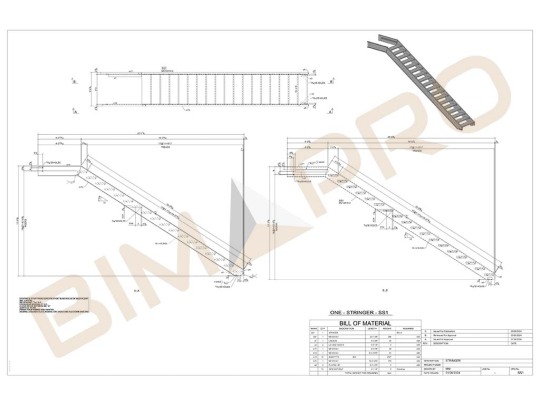

Bill of Materials (BOM): SysQue can automatically generate a BOM for all the components in your model, helping with procurement and material ordering.

8. Export to Fabrication Software

Export to FabShop: SysQue allows you to export your model to a fabrication software (like Trimble’s FabShop) for detailed fabrication. This software supports CNC (Computer Numerical Control) machines to create the components accurately.

Export to Other Formats: You can also export your model to other fabrication-friendly formats like DXF or IFC.

9. Review and Quality Control

Review the Model: Before sending the model to fabrication, ensure all components are properly detailed, with accurate dimensions, materials, and connections.

Verify Fabrication Specifications: Ensure that all fabrication specifications, such as insulation, material type, and fitting requirements, are correctly applied to the model.

10. Finalizing the Fabrication Model

Final Review and Export: Once all elements have been checked and the model is confirmed to be fabrication-ready, finalize the model by exporting it to the fabrication shop for production.

What is MSUITE?

MSUITE is a cloud-based software platform built to improve collaboration, communication, and the overall management of construction projects. It integrates several aspects of construction management, including BIM (Building Information Modeling), project documentation, daily logs, field reports, and more, all in one unified platform.

The platform provides tools for both contractors and construction managers to ensure that every phase of the project— from design to completion—runs smoothly and efficiently. MSUITE is particularly useful for companies looking to manage large-scale projects that require real-time data sharing, accurate reporting, and enhanced collaboration.

What are MSUITE's Role in BIM?

MSUITE plays a crucial role in enhancing real-time collaboration in construction through its comprehensive suite of cloud-based tools designed specifically for Building Information Modeling (BIM) projects. These tools provide seamless communication, coordination, and data sharing across teams, stakeholders, and project phases. Here are some key collaboration features and their benefits for project teams:

1. Centralized Project Data

MSUITE integrates all project data in a centralized platform, ensuring that every team member works with the latest information. With BIM models, drawings, schedules, and project documents stored in a single cloud repository, teams can avoid confusion and discrepancies caused by outdated or inconsistent data. This ensures that every decision is made based on real-time insights, improving accuracy and reducing rework.

2. Real-Time Communication Tools

MSUITE offers tools that allow project teams to communicate instantly, sharing messages, notes, and even markups directly on BIM models. This feature streamlines the approval process, reduces response time, and helps resolve issues promptly. With instant updates, architects, engineers, contractors, and other stakeholders can stay on the same page throughout the project lifecycle.

3. Document Control and Versioning

MSUITE ensures that project documents and BIM models are continuously updated and versioned automatically. As design changes are made or issues arise, teams can track revisions in real-time, ensuring everyone has access to the most current documents and models. This level of control mitigates the risk of using outdated information, enhancing collaboration between design and construction teams.

4. Task Management and Workflow Automation

Through MSUITE, project teams can assign tasks, track progress, and automate workflows. These capabilities ensure that each task is completed on time, and dependencies are met. Automated notifications keep teams informed of deadlines and project milestones, reducing delays and improving overall efficiency.

5. Collaborative BIM Viewing and Markups

MSUITE allows users to interact with 3D BIM models directly in the platform, making it easier for stakeholders to visualize the project. Team members can leave comments, suggestions, or questions directly on the models, creating a more interactive and transparent design process. This feature fosters real-time collaboration between designers, engineers, and contractors, resulting in fewer misunderstandings and better alignment of objectives.

6. Mobile Access

MSUITE’s mobile app ensures that project teams can access and update project information from anywhere, whether in the field or the office. This on-the-go access improves collaboration by allowing team members to view BIM models, communicate, and share files in real time, regardless of location. The ability to make instant updates is especially useful during site inspections or meetings with clients.

How MSUITE Enhances Productivity in MEP Fabrication Shops?

MSUITE plays a critical role in enhancing productivity within MEP (Mechanical, Electrical, and Plumbing) fabrication shops by streamlining workflows and improving tracking processes. The mobile field applications provided by MSUITE enable real-time access to project data, which ensures that fabrication teams have up-to-date schedules, task lists, and blueprints right at their fingertips. This reduces delays and ensures that fabrication work proceeds smoothly, with no need for workers to wait for updated information or clarifications.

Moreover, MSUITE’s issue tracking and resolution features are particularly beneficial in fabrication shops, where errors or delays can lead to costly rework. Field workers can immediately capture and report issues directly from the job site, attaching photos and notes for a complete record. This allows project managers to track and resolve problems quickly, ensuring minimal downtime and keeping fabrication on schedule.

The solution also facilitates better communication and collaboration between fabrication teams and the broader project team. MSUITE’s instant messaging and document-sharing capabilities help bridge the gap between shop floor workers and office teams, ensuring everyone is aligned and informed about project progress. This improved communication helps mitigate miscommunication issues that often lead to delays or mistakes in fabrication.

Additionally, MSUITE simplifies time tracking and labor reporting in fabrication shops, providing a streamlined approach that eliminates manual entry and improves accuracy. Accurate tracking of labor and equipment hours allows for better resource management, reducing inefficiencies.

Finally, MSUITE’s document management system ensures that fabrication workers always have access to the latest plans, blueprints, and specifications. This reduces the risk of errors caused by outdated documentation, helping teams to work more efficiently and ensuring that the fabricated components meet the required specifications.

Trimble SysQue vs MSUITE: Understanding the Key Differences and Use Cases

Trimble SysQue and MSUITE are both popular software solutions used in the Building Information Modeling (BIM) space, specifically for the mechanical, electrical, and plumbing (MEP) sectors. While both tools cater to MEP professionals, they each have unique strengths and are suited to different use cases. Here’s a comparative analysis of the two:

1. Purpose & Focus

Trimble SysQue:

SysQue is focused on MEP detailing and fabrication within the BIM process. It integrates with Revit to provide detailed fabrication-ready models for MEP systems, enabling contractors to generate shop drawings, bills of materials, and other data necessary for prefabrication.

Primary Use Case: Ideal for MEP contractors who need to streamline the transition from design to fabrication, making it easier to create accurate and detailed models for construction

MSUITE:

MSUITE is a comprehensive solution for MEP contractors that focuses on fabrication, field layout, and project management. It connects with various BIM platforms (like Revit) and provides tools for fabrication, prefab, and field coordination, helping contractors manage the entire lifecycle of a project.

Primary Use Case: Suited for companies that need a full project lifecycle solution—from design and fabrication to installation and project tracking.

2. Features & Functionality

Trimble SysQue:

Integration with Revit: SysQue is built to seamlessly integrate with Revit, providing a robust platform for adding detailed MEP components like ductwork, piping, and electrical systems.

Fabrication Details: SysQue provides precise detailing and generates fabrication-ready models, facilitating the move from design to real-world fabrication and installation.

Tools for Prefabrication: SysQue focuses heavily on prefabrication, with tools that automate the creation of fabrication-ready models, helping to reduce errors during construction.

3D Visualization: Provides 3D visualization of MEP systems, helping teams to resolve clashes and improve coordination.

MSUITE:

Fabrication and Field Layout: MSUITE provides tools not only for fabrication but also for field layout and installation, giving users access to prefabrication, as-built tracking, and project management.

Collaboration Features: MSUITE has strong collaboration features that enable better communication between contractors, fabricators, and field crews.

Integration Across Platforms: MSUITE integrates with Revit, AutoCAD, and other industry-standard tools to help create a unified workflow across the project lifecycle.

Real-Time Data: Offers real-time data syncing for field teams and contractors, which improves BIM coordination and ensures that everyone is on the same page.

3. Collaboration & Workflow

Trimble SysQue:

SysQue excels in workflows related to detailed fabrication and prefab, making it ideal for teams involved in detailed shop drawings and precise construction requirements.

It primarily supports collaboration among designers and fabricators, streamlining the process from design to construction.

MSUITE:

MSUITE offers a more holistic view of project management, supporting collaboration across various stages of the project. Its features like real-time field data syncing and project tracking are more beneficial for larger teams working in multiple phases.

It’s designed for use by contractors, fabricators, and field teams, which ensures that everyone can work together efficiently on all aspects of the project.

4. Usability

Trimble SysQue:

SysQue’s interface is designed for advanced users with experience in Revit and fabrication processes. It requires some expertise to maximize its potential, especially for teams who are integrating it into existing workflows.

The learning curve may be steep for those new to fabrication or Revit.

MSUITE:

MSUITE offers a user-friendly interface with a focus on ease of use across multiple stages of the project. Its tools are designed to be accessible for both field teams and project managers, making it less technical than SysQue in some areas.

MSUITE might be more approachable for contractors who are not deeply involved in the intricate details of fabrication.

5. Integration & Compatibility

Trimble SysQue:

SysQue integrates primarily with Revit and works well within the Trimble ecosystem, allowing smooth data transfer between different software tools for fabrication.

It’s best for teams already using Revit as their primary design tool.

MSUITE:

MSUITE offers broader compatibility with a variety of BIM tools, including Revit, AutoCAD, and other popular MEP software, making it a more flexible solution for contractors working across different platforms.

Its compatibility across the project lifecycle (design, fabrication, and fieldwork) makes it a more versatile option for MEP contractors.

6. Target Audience

Trimble SysQue:

Best suited for MEP contractors who are heavily focused on fabrication and prefabrication and who need precise, fabrication-ready models for installation.

MSUITE:

Ideal for MEP contractors looking for a comprehensive solution that covers all stages of a project—from design through fabrication to installation and project management.

7. Cost

Trimble SysQue:

SysQue is typically sold as part of the Trimble product and may require additional licensing for full functionality, making it a bit more expensive for smaller contractors or firms just starting to implement BIM solutions.

MSUITE:

MSUITE is also a premium solution, but its pricing can vary based on the features and the number of users involved in the project lifecycle. Like SysQue, MSUITE’s cost can be substantial for smaller companies.

Conclusion

When comparing Trimble SysQue and MSuite, both tools offer significant advantages tailored to the needs of the construction and BIM in Construction industry, but they serve different purposes. SysQue excels in providing accurate, data-rich Revit modeling services with enhanced detailing for MEP systems, making it an excellent choice for engineers and BIM professionals focused on precision and constructability. On the other hand, MSuite shines as a productivity and project management tool, offering streamlined workflows, tracking fabrication processes, and connecting field and shop operations.

Choosing between the two depends on your project requirements. If your priority is creating detailed BIM models with fabrication-ready data, SysQue is a strong contender. However, if you need to improve productivity, monitor workflows, and integrate data across teams, MSuite provides unparalleled efficiency. In some cases, leveraging both tools can create a comprehensive ecosystem that bridges detailed modeling with optimized project execution.

#Revitmodelingservices#BIMmodelingservices#MSuiteBIMSoftware#TrimbleBIMsoftware#ScantoBIMservices#TrimbleSysQueandMSUITE

1 note

·

View note

Text

Planning and estimating construction projects are crucial to their success. There are many complex processes involved. As part of this process, construction takeoffs are essential. Construction takeoffs are itemized and quantified lists of the materials, labor, and other resources required for construction projects.

Construction takeoffs are essential to project estimation, planning, and success in general. They give a thorough analysis of the necessary labor, materials, and resources, allowing for precise cost estimation and efficient project management. With enhanced accuracy and time savings, the process has been further streamlined with the introduction of digital takeoff tools and BIM-based solutions.

Importance of Construction Takeoffs

Accurate project estimation

Accurate project estimation is built on the foundation of construction takeoffs. Takeoffs give project stakeholders a thorough grasp of the project scope and associated costs by estimating the materials, equipment, and labor required. Realistic timetables and budgets can be created with the use of this information.

Enhanced project planning

A crucial aspect of project planning is takeoffs. Construction teams may create accurate project timetables, manage resources wisely, and spot potential bottlenecks or areas that need extra care with a full assessment of the available resources. This degree of planning ensures that the construction process runs more smoothly and helps to avoid delays and expensive change orders.

Improved communication and collaboration

Communication among project stakeholders is standardized by construction takeoffs. Takeoffs allow for simple and clear communication between architects, contractors, suppliers, and other team members by quantifying and clarifying requirements. This promotes teamwork and increases overall project efficiency by cutting down on ambiguity and errors.

Methods for Construction Takeoffs

Manual takeoffs

Traditional manual takeoffs entail looking at blueprints, plans, and specifications to manually calculate the amount of resources and materials needed. Even though it takes a lot of time and is prone to mistakes, this method is still employed occasionally, especially for smaller projects or when digital versions of certain details are not available.

Digital takeoff software

The building sector has undergone a change since the introduction of digital takeoff software. By eliminating laborious computations and lowering human error, these software solutions allow users to electronically measure quantities directly from digital designs. Software for digital takeoffs streamlines the process by providing features like annotation tools, automatic measurements, and simple cooperation.

3D modeling and BIM

The building sector has undergone a change since the introduction of digital takeoff software. By eliminating laborious computations and lowering human error, these software solutions allow users to electronically measure quantities directly from digital designs. Software for digital takeoffs streamlines the process by providing features like annotation tools, automatic measurements, and simple cooperation.

Read more

3 notes

·

View notes

Text

"...So we decided to combine the two. A war machine cannot function without both parts, in my estimation. My lead programmer, Avanti Tynshu, was in full agreement. Chief Mechanic Garsad was only opposed on the grounds that it may achieve a desire to slaughter its 'masters'. I assured him that not only would self-destruct measures would be in place just in case, but that the Non-Troll-Persona (NTP, a fitting descriptor for what is neither truly AI nor sole biotechnological growth) would be restrained in terms of intelligence."

"An artificial intelligence depends on the skills of its programmer, and in many instances is woefully insufficient. "AI" has been used by layfolk as a solution for anything, but in realistic terms it is impossible to give something enough intelligence in such a small area that it could feasibly operate at war. Military drones operate with AI, and their tactics are brutally simple. You don't need a lot of effort to program something to detonate a massive bomb wherever the target is. These machines, our Legionnaires, have to operate with more finesse. Therefore, in partnership with an unnamed party (withheld for their security), we are developing the NTP project to allow for tactical thinking and decision-making without the need for a server the size of a building."

"There are, of course, rumors of similar things out there. Constructs gone wild with their personalities. I cannot speak as to their design, if real, but NTPs are designed to be simple and below sapience. There will be limits placed on their capacity to, for lack of a better term, feel. This will prevent unneeded complications and serve as a barrier to full scale rebellion."

"I am no philosopher, but I have to pause to wonder at the implications of this. Would this be considered a sort of Flowers for Algernon scenario? Could these NTPs achieve the full emotional range without these blocks? This is a question for someone else. I feel that the true error would be to even seek these answers. Even so, when using NTPs, it is recommended to treat them less as tools and more as trusted servants. Being 'kind' is a cheap price for ensuring that even their limited feelings do not drift towards antipathy for whom they are forced to serve."

"All that written, it still remains to be seen what the final result is. For all I am aware at this time, the result could be something entirely unremarkable. Such is the nature of this work."

Xrumon Arigah, Treatise on War Machines (Unreleased)

2 notes

·

View notes

Text

In the ever-evolving Australian construction industry builders and developers are under constant pressure to deliver projects on time and within budget. But achieving this goal often depends on having accurate and timely Construction Estimating. This is where Outsource Estimating Services become a smart solution especially for companies working across Victoria and other parts of Australia.

#Outsource Estimating Services#Outsource Estimating#estimating services#construction estimating services#australia#melbourne#brisbane#construction estimator#construction estimating software

1 note

·

View note

Text

Pipe Crusher Market Share, Industry Size, Opportunity, Analysis, Forecast 2033

According to a recent study by Fact.MR, a market research and competitive intelligence provider, the global pipe crusher market is projected to reach USD 1.34 billion by 2033, with a compound annual growth rate (CAGR) of 5.1% over the next decade.

A pipe crusher, also known as a pipe shredder or pipe granulator, is an industrial machine designed to break down pipes into smaller pieces. These machines are widely used in recycling facilities, construction sites, and other sectors where pipes need to be processed for recycling or disposal. Pipe crushers are essential for effective waste management, facilitating the efficient processing and disposal of pipes.

For more insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=8593

Pipe crushers are instrumental in reducing the volume of waste material, which facilitates more efficient transportation and storage. Effective waste management, including the use of pipe crushers, helps mitigate the environmental impact of waste disposal.

Automation in pipe crushers offers significant advantages, particularly in enhancing operational efficiency. Automated systems streamline the crushing process by minimizing manual intervention and reducing human error. Automated feeding systems ensure that pipes are continuously and smoothly loaded into the crusher, resulting in uninterrupted operation. This leads to increased throughput, reduced downtime, and improved overall productivity.

Key Takeaways from Market Study

The global pipe crusher market is valued at US$ 817.64 million in 2023.

Worldwide demand for pipe crushers is projected to increase at a CAGR of 5.1% from 2023 to 2033.

The global market is estimated to reach US$ 1.34 billion by the end of 2033.

The market in the United Kingdom is projected to rise at a 4.2% CAGR through 2033.

India’s pipe crusher market is set to expand at a CAGR of 3% during the forecast period.

Increasing number of natural gas and crude oil pipelines, as well as growing usage of horizontal drilling for oil & gas production, will drive the demand growth for pipe crushers, says a Fact.MR analyst.

Market Competition

Pipe crusher manufacturers are increasingly forming strategic alliances and partnerships to leverage complementary strengths, enter new markets, and enhance their product offerings. These collaborations are driving the development of innovative solutions and broadening market reach.

For instance, in September 2022, FLSmidth acquired TK Mining to strengthen its position as a leading global provider of mining technology and services. TK Mining is renowned for its comprehensive solutions in material handling, mine systems, mineral processing, and related services.

Key Companies

Aceretech Machinery

ELANT

Franklin Miller Inc

Fulcrum Technology

GENIUS MACHINERY CO., LTD.

Net Plasmak

NICETY

Rothenberger

Wiscon Envirotech Inc.

Zhangjiagang Huade Machinery

Key Segments of Pipe Crusher Industry Research

By Type:

Shredders

Single Shaft

Single Motor

Double Motor

Double Shaft

Single Motor

Double Motor

Granulators

By Rotor Diameter:

Up to 400 mm

401 to 600 mm

601 to 800 mm

Above 800 mm

By Number of Blades:

Up to 15

18 to 24

Above 24

By Main Drive:

20 to 60 HP (15 to 45 KW)

60 to 100 HP (45 to 75 KW)

100 to 150 HP (75 to 110 KW)

150 to 200 HP (110 to 150 KW)

By Capacity:

Up to 400 Kg/Hr

401 to 1,200 Kg/Hr

1,201 to 1,600 Kg/Hr

Above 1,600 Kg/Hr

By Region:

North America

Latin America

Europe

Asia Pacific

Middle East & Africa

More Valuable Insights on Offer Fact.MR, in its new offering, presents an unbiased analysis of the global pipe crusher market, presenting historical demand data for 2018 to 2022 and forecast statistics for 2023 to 2033.

The study divulges essential insights into the market based on type (shredders (single shaft (single motor, dual motor), dual shaft (single motor, dual motor)), granulators), rotor diameter (mm) (up to 400 mm, 401 to 600 mm, 601 to 800 mm, above 800 mm), number of blades (up to 15, 18 to 24, above 24), main drive (20 to 60 HP (15 to 45 KW), 60 to 100 HP ( 45 to 75 KW), 100 to 150 HP (75 to 110 KW), 150 to 200 HP (110 to 150 KW)), and capacity (Kg/Hr) (up to 400 kg/hr, 401 to 1,200 kg/hr, 1,201 to 1,600 kg/hr, above 1,600 kg/hr), across five major regions of the world.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭: US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Revolutionize Your Construction Workflow with BIM Design Build

Building Information Modeling (BIM) Design Build Services offer a comprehensive solution for architecture, engineering, and construction projects. With enhanced accuracy in the design-build process, visualization of aesthetics and space planning, and parametric modeling for seamless updates, BIM enables project teams to streamline workflows and reduce costly errors. Advanced capabilities such as 3D geometry creation, 2D drawing accuracy, cost estimation, and energy analysis ensure efficient collaboration across all project phases. These services empower stakeholders to make data-driven decisions and deliver sustainable, high-quality outcomes.

You can take your project from concept to completion with confidence.

Visit: https://www.tejjy.com/our-services/bim-consulting-services/

0 notes

Text

Leveraging AI in Construction: How Companies Stay Ahead of Schedule and Under Budget

The construction industry, often associated with its time-consuming and labor-intensive procedures, has much to gain with the implementation of AI. You can deploy AI in construction to automate repetitive tasks, reduce human error, and streamline vast datasets to power better decision-making. This is essential in an industry where time and budgets are always limited.

In addition to speeding up operations, AI in construction has a lot more to offer than meets the eye. AI transforms construction into intelligent building models that prioritize resource efficiency and sustainability throughout their operational processes. As you explore the countless ways AI can transform construction, you will realize that the potential is not only exciting but also limitless.

The Role of AI in Project Management

Construction management for a project is a complex and intricate process requiring careful planning and execution. AI can become your collaborator in dealing with complexity by offering tools and solutions to sustain management efforts in a project. Through AI algorithms, you can automate schedules, streamline resource management, and predict areas where things will be problematic before things occur.

Among the most significant strengths AI brings to project management is its processing and analyze data at a quick pace. Through AI, you will learn from past projects, predict potential risks, and fine-tune strategies in alignment with this evaluation. This sophisticated approach ensures every project stays in tandem and is completed within the specified dates at a low chance of bearing costly delays.

How AI Improves Construction Site Safety

Safety is the first item on the agenda in a construction area, and AI provides advanced methods to improve it. You can use AI technologies to minimize the chances for accidents and maintain a secure area for employees at all levels. Monitoring the activity of employees, from recognizing hazards to implementing safety protocols, AI’s function in safety is substantial and comprehensive.

AI-powered surveillance cameras are able to continuously monitor worksites in real-time without interruption and detect unsafe behaviors and report them to the site managers in real-time. This progressive system allows you to address safety hazards before accidents occur. Furthermore, AI can analyze data from wearables worn by workers and unveil insights about their state of fatigue and alert their employers to hazards.

Predictive Analytics: Staying On Schedule

It is very important in the construction business to stay ahead of time in order to achieve successful projects, and AI-powered predictive analytics can prove to be a boon in this matter. Historical data and live-project statistics can be analyzed by AI to provide estimations regarding the time in the project and enable you to predict and rectify possible hurdles in time.

Predictive analytics can identify patterns and trends that may not immediately occur to human managers. For instance, AI can examine weather reports to identify ways in which bad weather can cause delay in projects and suggest plans to mitigate this. Staying current with these variables allows you to reschedule in advance and stay ahead of projects.

Cost Control: AI and Your Spending Habits

Cost management is one of the essential elements in any construction project, and AI can provide you with the tool to achieve this successfully. Through the use of AI in cost management operations, you can have better budget control in any given project, minimize waste, and achieve maximum return on investment.

Their algorithms can examine project data to determine cost-saving areas like minimizing usage of materials or lowering labor expenditures. By offering insights in this aspect, AI assists you in making sound choices and keeping costs under control. Moreover, AI can continuously monitor performance in monetary terms in real-time and let you know when budget overflows are possible to help you apply corrective actions at the earliest moment.

AI Technologies Transforming the Construction Industry

The construction industry is in the midst of a technology revolution, and at the epicentre of this revolution is AI. As you learn more about AI technologies, their uses are various and widespread and range from design and planning through execution to maintenance.

Drones: AI-powered drones can inspect areas under construction and transmit real-time data related to area conditions and progress. These are insights that are invaluable to managers eager to take timely and informed decisions.

Robotics: Robots with AI capability can automate repetitive and labor-intensive operations like brickwork or welding with greater efficiency and accuracy. This not only accelerates the process of construction but also minimizes the chances of human error.

Building Information Modeling (BIM): BIM systems with AI enable the preparation of intricate 3D models of construction works. These models enhance planning, coordination, and collaboration among various parties involved in a project.

IoT Devices: IoT devices with AI integration have the capability to monitor various aspects of a construction site continuously, from equipment performance to environmental factors. This data is useful in operational streamlining and provision for site safety.

By embracing these AI technologies, you are at the forefront of innovative building and opening the door to more sustainability and efficiency.

Pros and Cons of Construction with AI

Though AI has various advantages in construction, its use is accompanied by numerous challenges and disadvantages to factor in. Understanding these disadvantages will help you avoid them and benefit more from AI applications.

One key challenge is integration with legacy systems and processes through AI. Construction business enterprises will have legacy systems installed, and integration with AI may require huge investments in technologically upgrading and training employees. But if you approach this in a phased model and determine your best areas for AI applications, then you can eliminate these obstacles in a step-by-step approach.

Future Forecast: The Industry Shift in AI Transformation

As AI continues to progress, its application in the construction industry will also progress with time. Keeping up with trends in the future will enable you to stay ahead and capitalize on future opportunities.

Augmented Reality (AR): The integration of AI and AR will revolutionize design and planning processes in a way that the project can be seen in real-time and adjusted right away.

AI and Sustainability: As sustainability concerns continue to grow, AI will play an integral part in prompting sustainable construction methods. By minimizing waste and maximizing the use of resources, AI can help mitigate the environmental effects of projects.

Integration with Blockchain: The integration of blockchain with AI will enhance the transparency and accountability of the construction processes through better processes, such as procurement and contract management.

Future Robots: Future AI-powered robots will have the capability to conduct more complicated tasks and will further automate a construction yard to enhance efficiency.

By embracing these trends, you prepare to lead in a fast-paced industry in constant flux, redefining excellence and innovation at every level.

Embracing AI to Thrive in Construction

In short, AI is not only a technology but a strategic tool to ultimately gain success in the construction industry. By employing AI to enhance project management, safety, cost minimization, and adoption of innovative technologies, you will position yourself in the midst of the industry revolution.

During your AI journey, consider that successful implementation is based on effective planning, investment, and continuous improvement. Overcoming the challenge and embracing future trends lays the foundation for long-term sustainability and success.

0 notes

Text

Drone Survey: Revolutionizing Land and Aerial Mapping

In recent years, drone surveys have emerged as a groundbreaking solution in the fields of land surveying, construction, agriculture, and environmental monitoring. Using unmanned aerial vehicles (UAVs), drone surveys provide accurate, high-resolution data in a fraction of the time compared to traditional methods. With advancements in drone technology and data processing software, this modern surveying method is transforming how professionals capture, analyze, and interpret spatial information.

What is a Drone Survey?

A drone survey involves the use of UAVs equipped with high-definition cameras, LiDAR sensors, or multispectral imaging tools to capture aerial data of a particular area. These drones fly over the designated location, collecting thousands of geotagged images, which are then processed to generate 2D maps, 3D models, topographic maps, and volumetric calculations.

Unlike ground-based surveys, drones can cover large or hard-to-reach areas quickly and with minimal human intervention, making them ideal for remote, dangerous, or large-scale sites.

Benefits of Drone Surveys

Accuracy and Detail: Drones capture high-resolution imagery and data, ensuring precision and reducing human error. When combined with GPS and ground control points, they can achieve survey-grade accuracy.

Speed and Efficiency: A drone survey can be completed in hours, compared to days or weeks with traditional surveying methods. This rapid data collection speeds up project timelines and reduces labor costs.

Cost-Effective: By cutting down on man-hours, equipment needs, and delays, drone surveys offer a more economical solution for many industries.

Safety: Drones reduce the need for surveyors to physically access hazardous or unstable terrain, improving safety on site.

Applications Across Industries

Construction and Civil Engineering: Site planning, progress monitoring, volume calculations, and quality control.

Agriculture: Crop health monitoring, soil analysis, and yield estimation using multispectral imaging.

Mining and Quarrying: Stockpile measurement, site inspection, and environmental compliance.

Real Estate and Urban Planning: 3D mapping, land development planning, and promotional visuals.

Disaster Management: Assessing flood impact, damage analysis, and recovery planning.

Conclusion

Drone Survey Delhi is a game-changer in data collection and analysis. Its ability to deliver fast, accurate, and cost-effective results makes it an essential tool for modern surveyors and project managers. As technology continues to evolve, drone surveys will become even more integral to industries that rely on precise mapping and spatial data.

0 notes

Text

Groundwater Consulting in Costa Rica: Sustainable Solutions for Water Access and Management

Access to clean, reliable water is essential for agriculture, construction, tourism, and community development in Costa Rica. With increasing environmental challenges and growing demand for sustainable water solutions, groundwater consulting in Costa Rica has become a vital service for landowners, developers, and government agencies.

At Pura Vida Drilling, we specialize in delivering professional groundwater consulting services that help identify, evaluate, and manage underground water sources with accuracy and environmental responsibility.

What Is Groundwater Consulting?

Groundwater consulting involves technical and scientific assessments to locate, measure, and protect groundwater resources. This process is critical for ensuring long-term water availability while minimizing environmental impact. Services typically include:

Hydrogeological studies

Site assessments

Water quality testing

Well design and permitting support

Resource sustainability planning

Why Groundwater Consulting Matters in Costa Rica

Costa Rica’s diverse geography—ranging from coastal plains to volcanic mountains—makes groundwater exploration a complex task. A professional groundwater consultant can help:

Identify viable aquifers for domestic, agricultural, or industrial use.

Prevent costly drilling errors by conducting detailed surveys.

Ensure compliance with Costa Rican water regulations.

Assess water quality for safe consumption or irrigation.

Support eco-friendly development through sustainable water use planning.

Our Groundwater Consulting Process

At Pura Vida Drilling, our groundwater consulting services are grounded in scientific precision and local expertise. Here’s how we work:

Initial Site Evaluation We visit your site to understand your water needs, assess the environment, and collect preliminary data.

Hydrogeological Survey Our experts conduct in-depth studies using geophysical methods to locate underground water sources and determine their potential.

Water Quality & Quantity Analysis We test samples to ensure the groundwater meets health and usage standards and estimate long-term availability.

Well Planning & Development Support We guide you through the well design and permitting process, helping you comply with MINAE and other national water authorities.

Monitoring & Sustainable Use Post-drilling, we offer monitoring solutions to help you maintain safe and responsible water use over time.

Who Needs Groundwater Consulting in Costa Rica?

Groundwater consulting is ideal for:

Farmers and agribusinesses needing reliable irrigation sources.

Eco-lodges and resorts building in remote areas.

Municipal projects requiring water infrastructure development.

Property developers looking to ensure water access before construction.

Homeowners in rural areas needing private wells.

Why Choose Pura Vida Drilling?

Local Expertise: We understand the geology and water systems unique to Costa Rica.

Full-Service Solutions: From exploration to well construction, we handle it all.

Environmental Focus: We promote sustainable practices that protect natural resources.

Compliance-Ready: We help you navigate the permitting and regulatory landscape with ease.

Conclusion

Investing in groundwater consulting in Costa Rica is more than just planning a well—it’s about securing your future access to clean, dependable water. Whether you are developing land, growing crops, or managing a tourism project, professional consulting ensures that your groundwater usage is efficient, legal, and sustainable.

If you’re looking for trusted experts to guide your groundwater exploration or water resource management, Pura Vida Drilling is here to help—from first surveys to final well installation.

0 notes

Text

How a Construction Cost Estimating Service Helps in Risk Management

Risk management is a fundamental aspect of any construction project, as unforeseen challenges can lead to cost overruns, delays, and financial losses. One of the most effective ways to mitigate these risks is through a reliable construction cost estimating service. Accurate cost estimation allows contractors, project managers, and stakeholders to anticipate potential risks, allocate resources wisely, and ensure the financial stability of a project. This article explores how construction cost estimating services contribute to effective risk management and enhance project success.

Understanding Risk in Construction Projects

Construction projects involve multiple uncertainties, from fluctuating material costs to unexpected site conditions. Some of the common risks include:

Financial Risks: Cost overruns due to inaccurate estimates, inflation, or unexpected expenses.

Project Delays: Scheduling issues arising from unforeseen circumstances such as labor shortages or material delivery delays.

Legal and Compliance Risks: Issues related to permits, regulations, and contractual obligations.

Design Changes: Modifications made during the project lifecycle that impact costs and timelines.

Safety and Environmental Risks: Accidents, weather conditions, and environmental regulations affecting project execution.

A well-structured construction cost estimating service helps in identifying, assessing, and mitigating these risks before they escalate into costly problems.

Key Ways Construction Cost Estimating Services Help in Risk Management

1. Enhancing Budget Accuracy

Accurate cost estimates form the foundation of financial planning in construction projects. A reliable estimating service considers material costs, labor expenses, equipment needs, and contingency funds, ensuring that the project budget is realistic. By reducing budget uncertainties, contractors can avoid unexpected financial strain and ensure smoother project execution.

2. Identifying Potential Cost Overruns

A detailed cost estimate highlights potential cost overruns before the project begins. By analyzing past project data and industry trends, an estimating service can pinpoint areas where costs are likely to exceed initial expectations. This proactive approach allows project managers to allocate contingency funds appropriately and prevent financial shortfalls.

3. Facilitating Better Resource Allocation

Efficient resource allocation is crucial for minimizing risks in construction projects. A comprehensive cost estimate helps contractors determine the right amount of materials, labor, and equipment required for each phase of construction. This prevents shortages, reduces waste, and ensures that resources are used optimally.

4. Minimizing Schedule Delays

Delays in construction projects often lead to increased costs and client dissatisfaction. A precise cost estimate incorporates realistic timelines and accounts for potential disruptions such as weather delays, labor shortages, or supply chain issues. This foresight allows project managers to implement contingency plans and minimize schedule disruptions.

5. Supporting Contract Negotiations

A construction cost estimating service provides valuable data that strengthens contract negotiations with suppliers, subcontractors, and clients. By having a well-documented cost breakdown, contractors can negotiate better pricing, prevent disputes, and establish clear financial expectations before the project starts.

6. Mitigating Market Fluctuation Risks

The construction industry is highly susceptible to market fluctuations, including changes in material costs and labor rates. Cost estimating services use predictive analytics and historical data to assess these fluctuations and incorporate them into the project budget. This helps contractors prepare for potential price hikes and avoid last-minute financial setbacks.

7. Ensuring Regulatory Compliance

Legal and regulatory compliance is a critical aspect of risk management in construction. An experienced estimating service considers permit costs, environmental impact fees, safety regulations, and other legal expenses to ensure full compliance with local and national laws. This reduces the risk of fines, project delays, and legal disputes.

8. Providing Contingency Planning

Unexpected expenses are inevitable in construction projects. A cost estimating service factors in contingency budgets to cover unforeseen costs such as design modifications, equipment failures, or sudden labor shortages. Having a contingency plan in place ensures that unexpected challenges do not derail the project’s financial stability.

9. Reducing the Risk of Design Errors

Inaccurate estimates can lead to design errors that require costly rework. Construction cost estimating services utilize advanced tools such as Building Information Modeling (BIM) to detect design inconsistencies before construction begins. Identifying potential errors early in the planning stage prevents costly modifications during execution.

10. Enhancing Decision-Making with Data Analytics

Modern cost estimating services leverage big data analytics and AI-driven tools to provide data-backed insights for better decision-making. By analyzing previous project costs, labor productivity rates, and material price trends, estimators can offer more precise forecasts, helping project managers make informed financial and operational decisions.

The Role of Technology in Risk Management Through Cost Estimating

Technological advancements have further improved the risk management capabilities of construction cost estimating services. Some key innovations include:

AI and Machine Learning: These technologies analyze vast amounts of historical data to identify potential risks and predict cost trends.

Cloud-Based Estimating Software: Enables real-time collaboration, ensuring that all stakeholders have access to up-to-date cost data.

BIM Integration: Enhances accuracy by providing detailed visual representations of the project, reducing design-related risks.

Drones and Remote Sensing: Provide accurate site data, reducing uncertainties related to site conditions and topography.

By integrating these technologies, construction firms can improve estimate accuracy, reduce human errors, and enhance overall risk management strategies.

Conclusion

A reliable construction cost estimating service is a critical tool for risk management in construction projects. By providing accurate cost assessments, identifying potential financial risks, and incorporating contingency planning, these services help contractors avoid costly overruns and delays. Additionally, leveraging modern technology enhances the precision and effectiveness of estimating, making it an indispensable asset for successful project execution. Investing in a professional cost estimating service not only improves financial stability but also ensures that construction projects are completed efficiently, safely, and within budget.

#construction cost estimating service#risk management in construction#accurate cost estimation#cost overrun prevention#construction budgeting#financial risk mitigation#project delays solutions#construction project planning#estimating software#AI in cost estimating#BIM technology#cost estimation accuracy#resource allocation in construction#predictive analytics in estimating#market fluctuations in construction#contract negotiation strategies#contingency planning#regulatory compliance in construction#reducing design errors#construction project efficiency#data-driven estimating#cloud-based estimating tools#subcontractor cost estimation#supplier cost management#construction legal risks#unexpected expenses in construction#estimating service benefits#modern construction estimating#AI-driven construction forecasting#improving construction cost control

0 notes

Text

Why Should You Work with a Remodeling Contractor?

Home renovations are exciting and overwhelming at the same time. You need to select materials, manage timelines, and juggle multiple trades and permits. It makes the entire process complex with several moving parts. That’s where remodeling contractors Overland Park become helpful and essential, making the journey convenient with their expertise, efficiency, and peace of mind. Professional project management The significant advantage of hiring a contractor is that you don’t have to oversee the project from start to finish. Contractors take charge and coordinate with plumbers, painters, specialists, electricians, and installers to make the renovations happen in the correct sequence. Without them, even a small error can cost expensive delays and rework. Experienced contractors from the best remodeling companies Overland Park save you time and unnecessary stress. Access to reliable trades and materials Finding trustworthy trade experts can be hard. This is where a remodeling contractor offers a network of skilled professionals who are excellent at their job. Furthermore, they help source materials at a competitive price and understand how to avoid materials that won’t look good or last longer. You also benefit from their insider knowledge, leading to better workmanship and long-term value. Expertise and code compliance Remodeling involves structural change, upgrades, and electrical and plumbing work that must meet local building codes and safety standards. A licensed contractor understands the requirements and ensures your project remains compliant from start to finish. Moreover, it helps avoid costly fines, failed inspections, and redos, protecting you legally if you decide to sell the property in the future. Accurate budgeting and cost control Many homeowners underestimate the remodeling costs and spend over their budget. A good contractor offers realistic cost estimates, helping you prioritize savings and reliable furnishing. Moreover, you can avoid hidden expenses and last-minute surprises with an expert contractor. Time efficiency and reduced stress DIY and hiring multiple workers can lead to scams, miscommunications, and unnecessary project delays. That’s when you must onboard a remodeling contractor to manage schedules, solve complex renovation problems, and keep the project on track. Additionally, a professional can oversee the process, reducing your mental burden and routine disruption. About KC Home Solutions: If you are still looking for a remodeling contractor or company for outdoor living construction Prairie Village, KC Home Solutions is a renowned firm. It always offers a customized plan for your lifestyle and goals. You can rely on its team to efficiently undertake and complete your bathroom, bedroom, and kitchen remodeling. To get more details, visit https://kchomesolutions.com/ Original Source: https://bit.ly/3IoCiMP

0 notes

Text

Revit for Structural Engineering

In the realm of modern construction, Building Information Modeling (BIM) has become the cornerstone for efficient and precise project execution. Among the tools available, Autodesk Revit stands out as a game-changer for structural engineering. This comprehensive software enables engineers and designers to create advanced models and documentation, bridging the gap between design intent and construction reality. Let’s dive into Revit for structural engineering and how it facilitates seamless workflows from design to fabrication.

Advanced Structural Modeling and Documentation in BIM

Revit provides structural engineers with a sophisticated BIM environment to develop highly accurate design intent models and structural drawings. These models are the foundation for engineers and detailers to create more precise models tailored for fabrication and installation. By integrating all aspects of a project within a single platform, Revit empowers teams to:

Streamline design intent modeling.

Facilitate coordination between structural and architectural elements.

Deliver information-rich documentation for stakeholders.

Revit allows engineers to visualize the entire lifecycle of a structure, from early conceptual designs to the final stages of fabrication and installation. The software’s ability to integrate diverse data sets ensures a smooth transition between project phases, ultimately leading to a more cohesive and coordinated construction process.

Concurrent Creation of Structural Physical Model and Analystical Model

One of the standout features of Revit is its ability to generate physical and analytical models simultaneously.

Physical Model: Serves as the representation of the structure for coordination and documentation. This model ensures that structural elements align with architectural and MEP components, reducing clashes and misalignments.

Analytical Model: Supports structural analysis and design. Engineers can add structural loads, load combinations, and boundary conditions directly to this model, enabling accurate simulations and evaluations.

This dual modeling approach enhances the efficiency of structural workflows and ensures that engineers can make data-driven decisions with ease. The ability to maintain consistency between the physical and analytical models eliminates redundancy and reduces the likelihood of errors during the design and analysis phases.