#conveyingsystem

Explore tagged Tumblr posts

Text

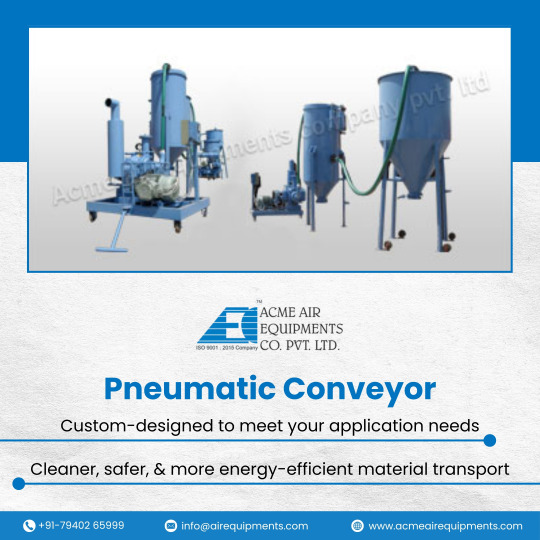

Moving materials the clean way. Acme’s Lean Phase Pneumatic Conveying System transports dry bulk materials efficiently, using air or gas pressure to ensure a clean, spillage-free process—even over long distances.

For more details, visit- https://www.acmeairequipments.com/product/pneumatic-conveying-system/

#acmeairequipment#pneumaticconveyor#pneumaticconveyingsystem#conveyingsystem#chemicalindustry#fertilizerindustry#foodindustry#pharmaceuticalindustry

0 notes

Text

ENHANCING EFFICIENCY AND SAFETY: THE MECHANICS OF INDUSTRIAL LIME HANDLING SYSTEMS.. Check out our latest blog post, where we discuss how Industrial lime conveying system, a versatile chemical compound with applications spanning construction, water treatment, and manufacturing, requires efficient and secure handling within industrial settings. Click the below link to read the full article now!

READ MORE: https://blog.vgprocess.com/uncategorized/lime-conveying-systems-enhancing-efficiency-and-safety/

Company Website : https://vgprocess.com/multiple-effect-evaporators/

#vgprocess#equipment#material#manufacturer#socialmediamarketing#materialhandling#suppliers#safety#risk#enviornment#future#minimizeaccident#pneumatic#mncl#limehandling#industriallime#conveyingsystem#chemical#compound#watertreatment#manufacturing#industrialsettings#coalhandlingp#researchreport#reports#research#mee#pneumaticknocker#Secure#panindia

0 notes

Text

Handling PET Flakes with Precision Using Lean Phase Conveying Systems Efficient PET flakes conveying is critical in recycling plants where used PET bottles are transformed into fibres. Macawber Engineering’s lean phase conveying system offers a robust solution for PET flakes handling, addressing challenges like low bulk density, irregular shape, and flow inconsistencies. The system uses a lean phase pneumatic conveying setup, including a rotary airlock valve and Roots Blower, to transfer flakes from feed hoppers to inline dryers and extruder hoppers.

Smart features such as T-type diverter valves and PLC-SCADA integration allow precise material routing with minimal downtime. Designed for reliability, the system ensures cleaner operation, reduced fines, and seamless flow in even complex recycling layouts. This PET recycling conveying system includes components like diverter valves, bag filters, and bin vent filters, all customized for the unique properties of PET flakes.

Optimize plastic recycling with our high-performance conveying system for plastic flakes, built for automation, durability, and efficiency.

#PETRecycling#PlasticRecycling#MaterialHandling#PneumaticConveying#LeanPhaseConveying#ConveyingSystems#PETFlakesHandling#PneumaticTransfer#IndustrialAutomation#RecyclingTechnology#BulkMaterialHandling#RotaryAirlockValve#DiverterValve#EngineeringSolutions#SmartManufacturing#macawberindia

0 notes

Text

Safety Considerations for Operating Lean Phase Conveying Systems

Lean phase conveying systems offer efficient material transport but demand meticulous safety measures. Prochem, a leader in industrial safety, emphasizes key precautions. Prioritize equipment inspection, ensuring airlock integrity to prevent leaks. Implement proper grounding to neutralize static electricity risks. Regular staff training on emergency procedures is imperative.

#ProchemSafety#ConveyingSystems#SafetyFirst#EquipmentMaintenance#OperatorTraining#RiskMitigation#SystemInspection#Efficiency#PersonnelSafety

0 notes

Text

KHK Racks are used to convert the rotational motion into linear motion. A gear rack has straight teeth cut and cylindrical gear meshing with the rack. There are many applications where the rack is stationary and the pinion move. And in some applications, the pinion is rotated on fix axis and the rack moves. Rack and pinion are used in applications like lifting mechanisms, conveying systems, horizontal movement, positioning mechanisms and many more.

SEIMITSU is an authorized distributor of KHK

To know more: https://www.seimitsu.in/KHK-CP-Rack-Pinions.html

Email Id: [email protected]

Call: +91 9028121211

0 notes

Text

Types Of Pneumatic Conveyors

A pneumatic conveying system is used to transport bulk materials safely, efficiently, and with lesser equipment. There are three types of pneumatic conveyors based on the type of material that they can move and their airflow source. Read on to see an in-depth analysis of the different types of pneumatic conveyor systems.

#pneumaticconveyors#pneumaticconveyingsystem#conveyingsystem#conveyors#machines#industry#blog#article

0 notes

Link

Most common problems for belt conveyors and solutions to resolve these problems. Do you face these problems for belt conveyor? if yes, get the perfect belt conveyor solution over here.

0 notes

Photo

#MerryChristmas #HappyNewYear2020 #Luxme #materialhandling #innovation #conveyors #conveyingsystems #technology #foodsafety #foodprocessing #engineering #bulksolids #manufacturing #quality #processengineering #processtechnology #tech #bulkhandling #solidshandling #hygiene #2k20

1 note

·

View note

Text

CONSTRUCTION COMPANY'S ARE YOU PAYING TOO MUCH TAX ON YOUR BUSINESS?

FREE Estimates, MAXIMUM Refund, FAST E-Filing & REFERRAL Bonuses!!!

Find Out The 7 Biggest Legal Tax Loopholes For Real Estate Investor's In The New Tax Law!!!

HAND IT OFF TO THE EXPERTS!!!

We Provide Tax Planning & Bookkeeping Services...For More Details Email: [email protected] or call/text #OZSRI to: 832-235-4962

Book a FREE Consultation/Copy & Paste URL:

https://eddiejenkins353.lpages.co/kbttaxservices for a FREE ESTIMATE!!!

5909(C) Scott St. Houston, TX 77021

#GeneralRequirement #ExistingConditions

#Concrete #Masonry #Metals #Wood #Plastics #ThermalProtection #MoistureProtection #Doors #Windows #Finishes #Specialties #Equipment #Furnishings #SpecialConstruction

#ConveyingSystems #Mechanical #Plumbing

#Electrical

0 notes

Text

For over two decades, Acme Air Equipments Company Pvt. Ltd. has been at the forefront of manufacturing excellence, delivering premium-quality Twin and Tri-Lobe Roots Blowers, Gas Boosters, Conveying Systems, and Dust Collection Systems. Our customer-centric solutions are designed to meet your specific application needs with precision and reliability.

For more details, visit- https://www.acmeairequipments.com/

#AcmeAirEquipments#DustCollectionSystem#TriLobeRootsBlower#GasBoosters#ConveyingSystems#TwinLobeRootsBlowers

0 notes

Text

THE FUTURE OF MATERIAL HANDLING: Pneumatic Conveying System.. Check out our latest blog post, where we discuss how The technology’s capacity to handle a wide range of materials in an efficient and safe manner makes it the ideal solution for numerous industries, from food processing to pharmaceuticals and beyond. With a blast of air, you can unlock a world of possibilities, improve productivity and drive profits!,

Click the below link to read the full article now!

READ MORE: https://blog.vgprocess.com/.../the-future-of-material.../

Company Website : https://vgprocess.com/pneumatic-conveying-system/

#vgprocess#equipment#Manufacturing#manufacturer#socialmediamarketing#motor#suppliers#storagebox#storagesolutions#storageboxmurah#future#materialhandling#pneumatic#vendors#conveyingsystem#industrialengineering#efficiencyimprovement#costsavings#engineeringgoods#multipleeffectevaporator#system#instadaily#india#panindia#vadodara#ourvadodara#profits#simplifiedproject#indsutry#costreduction

0 notes

Text

The steel industry relies on precise powder handling for processes like recycling, conveying, and dosing. Macawber India’s Pneumatic Conveyor For Steel ensures efficient transfer of materials such as iron ore, lime, and coke dust in pellet, sinter, and blast furnace plants. Boost your steel plant efficiency with advanced pneumatic conveying solutions!

#SteelIndustry#PneumaticConveying#MacawberIndia#IndustrialSolutions#SteelManufacturing#BulkMaterialHandling#MaterialHandling#PowderHandling#EngineeringSolutions#ProcessOptimization#DensePhaseConveying#IndustrialAutomation#ManufacturingExcellence#ConveyingSystems#SteelProduction#EfficiencyMatters#InnovativeEngineering#SteelPlants#SmartManufacturing#BulkPowders#IndustrialInnovation#OperationalExcellence#SteelProcess#PlantEngineering#ManufacturingTech#ProcessEngineering

0 notes

Photo

Types Of Pneumatic Conveyors

There are three types of pneumatic conveyors, which are defined according to the type of material they can move as well as the source of their airflow.

1. Dilute Phase Pneumatic Conveyors

It utilizes high-velocity, low-pressure streams of air that fluidize fine particles. The material is pushed by a screw feeder directly inside the conveying line and then sent through an air mover at high speeds.

2. Dense Phase Pneumatic Conveyors

This type of conveyor uses low velocity and high pressure and is suitable for products that are prone to breaking. The material is first loaded into a pressure vessel, from where it’s forced into the conveying line by high pressure and moved to its destination.

3. Semi Dense Phase Pneumatic Conveyors

It’s essentially a middle point between the two other systems and thus offers the qualities of both types. They have an air mover and are pressurized, so they can move bulk material at a slightly higher speed while still protecting it.

For detailed information about the pneumatic conveying system, read on: Types And Advantages Of Pneumatic Conveyors.

#pneumaticconveyorsystem#pneumaticconveyors#conveyingsystem#conveyors#watertreatmentplant#industry#machinery#machines

0 notes

Link

Conveying System is very important part of any industry. Good quality Conveying System can reduce your human efforts and can save time. Let's know about How to Choose Conveying System for any Industry?

0 notes

Photo

Get better results with #Luxme #materialhandling equipment. From tubular chain #conveyors to lump breakers and automatic bag openers, we offer you complete #solidshandling systems. Learn more here www.luxme.com #technology #engineering #manufacturing #conveyingsystems #innovation #tech #foodprocessing #sanitary #materialhandlingequipment #equipment #foodmanufacturing #foodindustry #foodsafety #foodproduction

0 notes

Text

Ash handling is crucial in industries like power generation and cement production, requiring efficient systems to manage large volumes while minimizing wear and energy consumption. Two primary pneumatic conveying methods—dense phase and lean phase—offer distinct advantages. Dense phase systems operate at low velocity and high pressure, moving ash in compact slugs, reducing wear, and enhancing energy efficiency. In contrast, lean phase systems use high velocity and low pressure, keeping ash suspended in the air stream but causing more equipment wear. While dense phase is ideal for abrasive or fragile materials, lean phase suits lighter, non-abrasive ones. Selecting the right system depends on material properties, energy efficiency, and infrastructure constraints.

#AshHandling#PneumaticConveying#DensePhase#LeanPhase#IndustrialAutomation#MaterialHandling#EnergyEfficiency#BulkMaterialHandling#PowerPlantOperations#CementIndustry#ConveyingSystems#AshConveying#IndustrialProcessing#BulkHandling#EngineeringSolutions#EfficientTransport#IndustrialEquipment#ManufacturingProcess#SustainableEngineering#PlantMaintenance#IndustrialEfficiency#PowderHandling#AirConveying#SystemOptimization#HeavyIndustry#OperationalExcellence

0 notes