#SustainableEngineering

Explore tagged Tumblr posts

Text

Internal Combustion Engine

Introduction

For than a century, internal combustion engine (ICEs) have served as the foundation of contemporary transportation. More than 250 million vehicles in the US are powered by internal combustion engines (ICEs), which are renowned for their durability, fuel economy, and mechanical dependability. Globally, internal combustion engines (ICEs) have transformed transportation and power generation, changing everything from freight trucks to industrial equipment, and from small cars to airplanes. However, in the era of resource depletion, climate change, and carbon-neutral policies, ICEs are increasingly being scrutinized. The increasing popularity of electric vehicles (EVs) and sustainable fuels is putting the traditional internal combustion engine at a turning point. This blog discusses ICE classifications, components, operating principles, benefits, drawbacks, applications, and the evolving role of ICEs in a green energy future.

An internal combustion engine: what is it?

One kind of heat engine is an internal combustion engine, where fuel is burned inside a closed space. It converts the chemical energy of the fuel directly into mechanical energy, which drives machinery or propels an automobile ahead. Compared to external combustion engines (such as steam engines), internal combustion engines (ICEs) burn fuel inside the engine block, resulting in a more compact design and higher energy conversion efficiency.

Internal Combustion Engine Classifications

The ignition and combustion processes are the primary classification criteria for ICEs.

Engines with continuous combustion

These engines are constantly fed fuel and oxidizers, which create a steady flame. Among the examples are:

Gas-powered turbines

Jet Engine

They are known for their quick operations and consistent output, and they are mostly used in industrial and aviation environments.

Internal Combustion Engine Classifications

The ignition and combustion processes are the primary classification criteria for ICEs.

1. Engines with continuous combustion

These engines are constantly fed fuel and oxidizers, which create a steady flame. Among the examples are:

Gas-powered turbines

Jet Engine

They are renowned for their quick operations and consistent output, and they are mostly used in industrial and aviation environments.

2. Intermittent Combustion Engines (Reciprocating Engines)

Reciprocating engines, or intermittent combustion engines

These engines ignite a fuel and air mixture using timed cycles. There are two primary kinds:

In gasoline-powered spark-ignition engines, a spark plug is used to ignite the engine after compression.

Compression-ignition diesel engines start by heating compressed air and then injecting fuel.

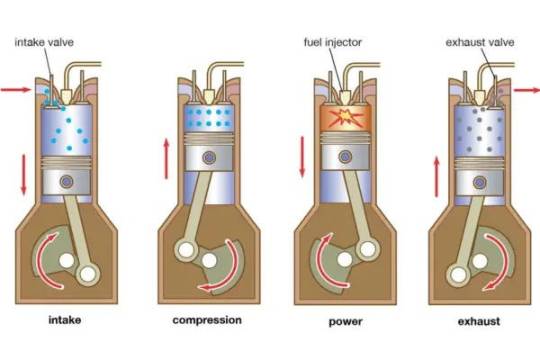

Working Principle of ICEs

The basic concept is that a piston is moved by mechanical energy created when fuel burns in a cylinder. Most internal combustion engines use a four-stroke cycle, which includes the following steps, to accomplish this:

1. Stroke of Intake

The air-fuel mixture (or just air in diesel engines) enters the combustion chamber at the beginning of the intake stroke as the piston falls and the intake valve opens.

2. Stroke by Compression

The piston then moves upward during the compression stroke, compressing the air-fuel mixture. Combustion is then started by a spark plug in gasoline engines or a fuel injector in diesel engines.

3. The Stroke of Power

Then, as the power stroke starts, the ignited air-fuel mixture pushes the piston downward, creating mechanical work that turns the crankshaft.

4. Stroke of Exhaustion

Consequently, during the exhaust stroke, the piston pushes the burned gasses out through the open exhaust valve. 🔁 With only one power stroke every two crankshaft revolutions, this cycle is continuously repeated in four-stroke ICEs.

Key Components of an Internal Combustion Engine

Understanding ICE anatomy helps grasp its function better:

ComponentFunctionCylinder HeadThe cylinder head contains the camshafts, injectors, spark plugs, and valves.Engine BlockContains pistons, crankshaft, and cylinders. Facilitates coolant flow.PistonA piston moves up and down within the cylinder to transmit force.CrankshaftConverts piston motion into rotary power.Combustion ChamberWhere fuel and air combine and ignite is the combustion chamber.

Internal Combustion Engine Benefits

Despite EVs’ growing popularity, ICEs still offer some important advantages: 🔧 Mature Technology: After decades of development, ICEs are incredibly reliable. 🛞 Its excellent power-to-weight ratio makes it ideal for mobile applications. 🏎️ Fast Start-Up: There is no waiting time, in contrast to steam engines. 💡 Fuel Types: Uses gasoline, diesel, natural gas, biodiesel, and ethanol. ⚙️ Compact Design: Easily integrated into a variety of vehicle sizes. 🔁 Reduced Maintenance: Routine upkeep is simple and available.

Disadvantages of Internal Combustion Engines

As stricter emission norms and environmental mandates take effect, the shortcomings of ICEs are becoming more apparent. 🌍 Environmental Impact: High emissions of CO₂ and NOx. 🧯Limited Fuel Sources: Reliant on fossil fuels. 💸 Fuel Price Fluctuations: Diesel and gasoline prices are unpredictable. 📢 Noise and Vibration: Greater than those of electric motors. 🔩 Energy Loss: Only around 25–30% of the fuel’s energy is converted into motion, with the remainder lost as heat.

Real-World Applications of ICEs

ICEs remain dominant in several sectors:

ApplicationEngine TypeExamplesAutomotiveGasoline & DieselCars, SUVs, MotorcyclesHeavy TransportDieselTrucks, Buses, LocomotivesMarineDiesel & Gas TurbinesCargo Ships, Patrol BoatsAviationJet Engines & TurbinesAirliners, DronesIndustrialStationary Gas EnginesGenerators, Pumps

Future of Internal Combustion Engines

The ICE sector is developing quickly as net-zero targets get near. ICEs are becoming cleaner, more effective devices rather than going extinct.

1. Electrification and Hybridization

Electric motors are added to plug-in hybrids, full hybrids, and mild hybrids to improve overall efficiency, which increases mileage and lowers pollution.

2. Alternative Fuels Hydrogen: No emissions from the tailpipe.

In contrast to fossil fuels, renewable resources are used to produce biofuels. Designers create carbon-neutral synthetic fuels to be carbon neutral.

3. Engine Control Units (ECUs) Driven by AI

In order to increase economy, advanced ECUs use machine learning to optimize combustion settings.

4. Materials for Lightweight Engines

Furthermore, the use of carbon fiber, ceramics, and magnesium alloys not only improves performance but also significantly decreases weight.

5. Turbocharging and Engine Downsizing

Smaller displacement engines may use less gasoline and produce the same amount of power when equipped with turbochargers.

FAQs About Internal Combustion Engines❓

What is the main difference between spark-ignition and compression-ignition engines?

Spark-ignition engines (gasoline) use a spark plug for ignition, while compression-ignition engines (diesel) ignite fuel due to high-pressure heat.

Will there be a ban on internal combustion engines?

By 2035–2040, many nations, particularly the EU and California, intend to phase out ICE-only automobiles. Authorities might still permit clean-fuel ICEs and hybrids, however.

Are ICEs more efficient than electric motors?

No. Electric motors are up to 90% efficient, while most ICEs operate around 25–30% thermal efficiency. However, ICEs offer longer range and fueling flexibility.

Can internal combustion engines run on hydrogen?

Indeed. Although infrastructure and safety issues still exist, specially designed internal combustion engines (ICEs) can run on hydrogen fuel and emit water vapor as exhaust.

What is the future of ICE in India?

India is investing in E20 fuel, hybrid vehicles, and biofuels to extend ICE lifespan while gradually adopting EVs.

Conclusion

Internal combustion engines have powered the modern world for more than a century. From Henry Ford’s Model T to modern turbocharged hybrids, internal combustion engines (ICEs) represent the advancement of engineering. ICEs will continue to be useful even though the future is moving toward electric transportation, particularly in areas without EV infrastructure or in industries like aviation and maritime. Decarbonization, not demonization, is the true objective. ICEs can still help create a greener future through hybridization, cleaner fuels, and smarter systems. In the long run, the way ICE technology coexists with future mobility solutions will largely depend on our willingness to embrace innovation. Moreover, prioritizing efficiency and committing to sustainability will be essential as we collectively advance toward a cleaner and more sustainable future. 📢 Want to learn more about ICEs or electrification strategies? Visit dorleco.com or email us at [email protected] for VCU solutions, CAN displays, CAN Keypads ,Engineering Software Service provider and Engineering Staffing Services and more.

#DorleControls#InternalCombustionEngine#FutureOfMobility#SustainableEngineering#VCUSolutions#CANDashboard#EVSoftware#AutomotiveTechnology#HybridVehicles#GreenMobility#EngineeringServices#ICEFuture#Biofuels#Electrification#HydrogenFuel#CleanTech

0 notes

Text

💡 Choose sustainability and innovation with trusted MEP Engineers in Ontario.

We bring clarity and performance to every system we design. 🌍 Eco-conscious and high-performing solutions built to last for decades. 📞 Contact us now:

0 notes

Text

Efficient Heat Exchanger Design: Enhancing Energy Efficiency and Sustainability

Discover how innovative heat exchanger designs enhance energy efficiency, reduce operational costs, and promote sustainability across industries.

https://emmfg.com/efficient-heat-exchanger-design-enhancing-energy-efficiency-and-sustainability/

#HeatExchangerDesign#EnergyEfficiency#SustainableEngineering#IndustrialInnovation#HVACSystems#WasteHeatRecovery#ThermalPerformance#GreenTechnology

1 note

·

View note

Text

Data-Driven Sustainability: A New Era for Engineering Projects

If you’re an engineering business that deals with design, production, or operations, you’re sitting on a goldmine of valuable data. Every project, process, and product generates digital footprints, drawings, material usage, site reports, machine logs, quality inspections, and so much more.

But here’s a reality check: over 70% of that data goes unused. Not because it's unimportant, but because it's unorganized, scattered, or simply overlooked.

Now think about that. What if all that valuable information could actually help you make faster decisions, reduce errors, save costs, and complete projects ahead of schedule?

That’s where Data Analytics Services come into play—not as a trend, but as a powerful engine to modernize your engineering workflow and unlock exponential growth.

Why Engineering Data Feels So Hard to Manage (And Why That’s a Problem)

It’s ironic, right? Engineering is a field driven by precision and planning. But when it comes to managing data, many firms still operate in chaos:

Blueprints in emails

BOMs in Excel sheets

Field data stored offline

Reports buried in legacy software

Zero real-time collaboration or visibility

As a result, engineers and decision-makers end up wasting time searching for info, repeating errors, and making reactive choices instead of proactive moves.

And the impact? Higher costs. Delayed deliveries. Lower quality. Lost opportunities.

What’s worse, it’s easy to miss that this is even happening. You’re so busy running projects, that the data problems get brushed under the rug… until they snowball into something bigger.

The Shift: From Data Overload to Data Intelligence

Imagine having a 360° view of your operations—real-time dashboards, instant access to every design update, machine status, resource utilization, and predictive insights.

That’s not a future dream. That’s what engineering companies are achieving today by investing in modern Data Analytics Services.

Here’s how the transformation looks when data is managed right:

✅ Quick design iterations using historical analysis

✅ Predictive maintenance to reduce downtime

✅ Optimized resource planning to avoid over- or underutilization

✅ Improved product quality by identifying flaws early

✅ Faster project delivery through live dashboards and automation

✅ Data-driven decisions instead of gut feeling

When engineering meets analytics, you don’t just build better—you build smarter.

What’s Holding You Back from That Transformation?

Let’s be real, most engineering firms want to modernize. They know the potential. But the roadblocks often sound like this:

"We have too much legacy data." "We don’t have the time to change systems." "We’re not sure where to start."

That’s exactly why tailored Data Analytics Services exist, to help you make the shift without disrupting your operations. Whether you’re dealing with complex design systems, scattered teams, or traditional infrastructure, the right partner can bring it all together, without the stress.

At AQe Digital, we specialize in solving these very challenges. We help engineering firms modernize their data strategy, using AI, automation, cloud, and deep industry knowledge, to create systems that work for your team, not against it.

Want to See What the Top Engineering Performers Are Doing Differently?

They’re not working harder — they’re working smarter with data.

We’ve uncovered how top engineering leaders are solving big challenges and driving sustainability by managing their data the right way. From product design to civil and industrial projects, this blog will open your eyes to what’s really working behind the scenes.

👉 How Engineering Data Management Drives Sustainability in Large-Scale Projects, see what you might be missing.

Don’t get left behind.

#EngineeringData#DataDrivenEngineering#SmartManufacturing#EngineeringAnalytics#DigitalTransformation#IndustrialInnovation#DataStrategy#AIinEngineering#SustainableEngineering#ModernEngineering

1 note

·

View note

Text

Why hydrogen fuel cell stack technologies matter for green energy

By Dipak Tukaram Warude

When we talk about the future of clean energy, hydrogen often enters the conversation. Not always front and center, but it's there — quiet, promising, a bit misunderstood. As the world races toward carbon neutrality, hydrogen fuel cells are stepping into the spotlight. And at the heart of these fuel cells is something very precise, very engineered: the fuel cell stack.

At Innovative Filtrex Techno Engineering India Private Limited, we’ve had the opportunity to contribute to hydrogen-related technologies through advanced filtration and membrane solutions. And though filtration is just one piece, understanding the fuel cell stack itself helps us design systems that support, protect, and improve these critical energy devices.

What Is a Hydrogen Fuel Cell Stack?

A hydrogen fuel cell stack is essentially a series of individual fuel cells arranged together to generate usable electrical power. Each fuel cell converts chemical energy from hydrogen and oxygen into electricity through an electrochemical reaction — with water and heat as the only byproducts.

One cell doesn’t produce much power. But when you stack hundreds together, you get a unit capable of powering anything from a forklift to a passenger car, or even a building.

Each cell typically contains:

An anode and cathode

A proton exchange membrane (PEM)

Catalyst layers

Gas diffusion layers

Bipolar plates to connect cells and manage fluid flow

And all of these parts need to function in harmony — if one cell fails or fouls, the stack’s efficiency drops.

Why Stacks Are the Heart of Fuel Cell Systems

The stack is where energy is made — literally. It's the engine of the system. Everything else (fuel supply, humidification, thermal management, power electronics) is there to support or manage what happens inside the stack.

Because of this, stack durability and efficiency are critical. If the membrane fouls from contaminants, or if fluid flows unevenly, performance suffers. That’s why filtration and purification — from gas filtration to water quality control — are so crucial. And that's where we at Innovative Filtrex step in.

Use Cases of Fuel Cell Stacks Today

Fuel cells aren't science fiction anymore. They’re powering real applications — quietly, cleanly.

Public transportation: Cities like Tokyo and Seoul have buses running entirely on hydrogen.

Material handling: Warehouses across North America use hydrogen-powered forklifts for zero-emission operations.

Backup power systems: Telecom towers and hospitals in remote regions rely on hydrogen fuel cells as reliable off-grid power.

Automotive sector: Global carmakers have introduced hydrogen fuel cell electric vehicles (FCEVs) to complement battery EVs.

And this is just the beginning. India, too, is laying down the groundwork for hydrogen infrastructure. With initiatives like the National Green Hydrogen Mission, there's growing interest — and we expect fuel cell adoption to accelerate across mobility, industry, and even residential sectors.

Challenges That Still Exist

It’s not all smooth sailing yet. Hydrogen storage and distribution remain costly. Fuel cell stacks, while cleaner, are also more complex than conventional engines or even batteries.

Cost of materials like platinum catalysts

Durability of membranes under cycling conditions

Purity requirements of hydrogen and oxygen streams

Thermal and water management within the stack

But the direction is clear. Governments are funding pilot projects. Industry leaders are investing in R&D. And innovation is speeding up — making stacks more efficient, compact, and affordable.

The Role of Filtration in Stack Longevity

One of the biggest threats to a fuel cell stack is contamination. Microscopic particulates, trace sulfur compounds, or even droplets of oil from a compressor can degrade the membrane or poison the catalyst.

That’s why high-purity gas and liquid filtration systems are essential. At Innovative Filtrex Techno Engineering India Private Limited, we’ve developed specialty filters capable of removing ultrafine particulates and aerosols from gas lines feeding the fuel cell. We also provide pre-treatment systems for water used in humidification — preventing scale or microbial growth that could interfere with stack performance.

Filtration may not be visible inside the stack, but it plays a quiet role in extending its life and maintaining consistent performance.

Representing Innovation on a Global Platform

We’re proud to share that Innovative Filtrex Techno Engineering India Private Limited, based in India, has been nominated for the 2025 Go Global Awards, hosted by the International Trade Council. This November, in London, we’ll join peers from across the world — businesses driving change, solving industrial challenges, and shaping the future.

This event isn’t just about recognition. It’s a place where ideas flow as freely as hydrogen should. A space to collaborate, challenge, and discover. We’re excited to share what we’re learning — and to learn from the best minds tackling today’s energy problems.

Final Thoughts

Hydrogen fuel cell stacks represent one of the cleanest energy generation technologies we have today. They're not perfect. But they’re promising. And if we solve the right problems — from purification to scaling — they could power a significant chunk of our future.

It's a complex field, sure. But it’s also exciting. At Innovative Filtrex, we’re not just watching from the sidelines. We’re contributing, one filter at a time.

Because sometimes, the cleanest energy starts with the cleanest process.

#HydrogenFuelCells#FuelCellStacks#CleanEnergy#GreenHydrogen#EnergyTransition#FiltrationTechnology#HydrogenEconomy#InnovativeFiltrex#MadeInIndia#GoGlobalAwards#InternationalTradeCouncil#London2025#ZeroEmissions#SustainableEngineering#FutureOfEnergy#FuelCellFiltration

1 note

·

View note

Text

Discover a world of innovation, growth, and hands-on experience at Native Engineering. We are offering exciting internship opportunities across multiple domains, designed to give you real-world exposure and practical skills in a collaborative environment.

Available Internship Programs:

Human Resource Internship

Data Analytics Internship

Web Development Internship

Cloud Computing Internship

Electric Vehicle Internship

Electronics Internship

Why Join Us?

Work on impactful, real-time projects

Learn from industry experts and mentors

Build your portfolio with cutting-edge tools and technologies

Be part of a team that values sustainability, inclusivity, and innovation

Apply Now and Start Your Journey: https://nativeengineeringin.wordpress.com/2025/06/23/building-a-smarter-india-native-engineerings-collaborative-approach-to-sustainable-urban-infrastructure/

Don't miss this opportunity to turn your skills into success. Explore your future with Native Engineering today.

#NativeEngineering#EngineeringInternship#TechCareers#InternshipOpportunity#WebDevelopmentInternship#CloudComputingInternship#EVInternship#ElectronicsInternship#HRInternship#DataAnalyticsInternship#FutureEngineers#CareerGrowth#STEMInternships#SustainableEngineering#JoinOurTeam

0 notes

Text

💧➡️ Moving Forward: The Rise of Dewatering Conveyors in Industry

Efficiency meets flow in the evolving world of dewatering conveyors—critical machinery that powers cleaner, faster, and more sustainable material handling across industries.

📊 Market Snapshot

2024: USD 0.33 billion

2025: USD 0.34 billion

2033 (Projected): USD 0.38 billion

CAGR (2025–2033): 📉 1.6% steady, smart growth

⚙️ By Type:

Automatic: Fully integrated systems for continuous, high-volume dewatering

Semi-Automatic: Flexible options for controlled, semi-manual operations

🏭 By Application:

Mining: For separation of solids and liquids in mineral processing

Food Industry: Hygienic, efficient moisture removal from produce or packaged goods

Industrial: Vital in wastewater treatment, sludge handling, and by-product recovery

Others: Custom-fit for chemical, pharma, and agriculture operations

🌍 Key Players Driving Innovation:

Jwala Engineering (India)

Cox and Plant Ltd. (U.K)

Accelor Food Tech Pvt Ltd (India)

Brain Industries (Australia)

Driver Southall, Syspal, CABE Engineering (U.K)

FoodeQ Engineering, Sormac (Netherlands)

Fenner Conveyors (India)

🔧 Why It Matters: In a world focused on cleaner production and resource optimization, dewatering conveyors offer: ✅ Reduced waste volume ✅ Enhanced product quality ✅ Streamlined processing

This tech isn’t just part of the system—it is the system driving sustainability and throughput in industrial workflows.

🔗 Dive deeper into the market: Full Report Here

#IndustrialMachinery#FoodProcessingTech#MiningEquipment#DewateringSolutions#EngineeringInnovation#CleanTech#MaterialHandling#SmartManufacturing#ConveyorSystems#IndustrialDesign#TumblrIndustry#Automation#SustainableEngineering#DewateringConveyorMarket

1 note

·

View note

Text

🔧💡 Engineering Consultancy Excellence in Abu Dhabi – Das And Partners

Looking for expert Engineering Consultancy in Abu Dhabi? Das And Partners offers customized solutions and cutting-edge technology to bring your projects to life! 🚧🏗️

#EngineeringConsultancyAbuDhabi#BestEngineeringServices#DAPConsultancy#AbuDhabiProjects#Innovation#SustainableEngineering#ConstructionSolutions#ProjectManagement#QualityEngineering

0 notes

Text

Why Choose Electric Vehicle Engineering? | ASTI Academy Discover how a career in Electric Vehicle Engineering can put you in the driver’s seat of tomorrow’s sustainable transport revolution. Learn the key reasons why this is a smart choice for future-ready professionals.

Read now and take your first step toward a green, high-tech career

#EVEngineering#SustainableEngineering#ElectricVehicles#CareerInEV#ASTIAcademy#StudyInUAE#CleanEnergyCareers

0 notes

Text

"High Temperature Insulation Materials: Powering Efficiency and Safety in Extreme Environments – 2025 Spotlight"

High temperature insulation materials are critical components in industries that operate under extreme heat—such as aerospace, metallurgy, power generation, and petrochemicals. These advanced materials, including ceramic fibers, aerogels, and insulating firebricks, are engineered to withstand temperatures exceeding 1000°C while minimizing heat loss, boosting energy efficiency, and enhancing operational safety. In 2025, with a strong push for energy conservation and sustainability, demand for lightweight, eco-friendly, and high-performance insulation solutions is at an all-time high. Innovations are also focusing on recyclable and low-carbon insulation alternatives that align with global green mandates. These materials not only protect equipment and personnel but also play a key role in reducing emissions across high-heat industries.

#HighTempInsulation#ThermalProtection#EnergyEfficiency2025#IndustrialInnovation#HeatResistance#SustainableEngineering#AdvancedMaterials#GreenIndustry#AerospaceTech#SmartManufacturing

0 notes

Text

Mechanical Projects

Introduction

All Services Global Pvt. Ltd. (ASG) has established itself as a leader in integrated facility management, offering a comprehensive suite of services tailored to meet the diverse needs of its clients. Among its extensive offerings, ASG's Mechanical Projects division stands out for delivering turnkey solutions that encompass the installation and maintenance of critical mechanical systems. AmbitionBox+3All Service Global+3All Service Global+3

Comprehensive Mechanical Solutions

ASG's Mechanical Projects division specializes in a wide array of services, ensuring that clients receive holistic solutions for their mechanical infrastructure needs. The team's expertise includes:

Hydraulic Works: Designing and implementing efficient hydraulic systems that optimize fluid power applications across various industries.

Firefighting Systems: Installing state-of-the-art fire suppression and detection systems to safeguard assets and personnel.

Plumbing Services: Providing robust plumbing solutions that ensure reliable water distribution and waste management.

Pump and Boiler Mechanisms: Maintaining and servicing pumps and boilers to guarantee optimal performance and energy efficiency.

Generators and Diesel Pumps: Offering installation and upkeep of generators and diesel pumps to ensure uninterrupted power supply during critical operations.

Experienced and Dedicated Team

A key factor in ASG's success is its team of seasoned professionals. With decades of collective experience, the staff possesses the technical acumen and practical knowledge required to handle mechanical projects of varying complexities. Their commitment to excellence ensures that each project is executed with precision, adhering to the highest industry standards. All Service Global+1All Service Global+1

Client-Centric Approach

Understanding that each client has unique requirements, ASG adopts a collaborative approach to project execution. By engaging clients throughout the project lifecycle, from initial consultation to final implementation, ASG ensures that solutions are tailored to meet specific operational needs and objectives. This client-centric philosophy fosters strong partnerships and results in outcomes that consistently exceed expectations. All Service Global

Commitment to Quality and Compliance

ASG's dedication to quality is evident in its adherence to stringent industry regulations and standards. The company employs robust quality control measures and continuous improvement practices to deliver services that not only meet but often surpass client expectations. Furthermore, ASG's compliance with statutory and governmental norms underscores its commitment to ethical and responsible business practices. All Service Global

Sustainable and Innovative Practices

In line with global trends emphasizing sustainability, ASG integrates eco-friendly practices into its mechanical projects. By utilizing energy-efficient systems and environmentally responsible materials, the company contributes to reducing the carbon footprint of its projects. Additionally, ASG stays abreast of technological advancements, incorporating innovative solutions that enhance system performance and longevity. All Service Global

Proven Track Record

Over the years, ASG has successfully completed numerous mechanical projects across various sectors, earning a reputation for reliability and excellence. The company's portfolio showcases a diverse range of projects, each reflecting ASG's ability to deliver customized solutions that address complex mechanical challenges.

Conclusion

All Services Global Pvt. Ltd.'s Mechanical Projects division exemplifies the company's overarching commitment to delivering integrated, high-quality facility management solutions. Through a combination of technical expertise, client-focused strategies, and a dedication to sustainability, ASG continues to set benchmarks in the mechanical services industry. For organizations seeking reliable and comprehensive mechanical project solutions, ASG stands as a trusted partner poised to deliver excellence at every stage

For more information or to request a consultation, visit their website: https://allservicesglobal.com

To stay updated with the latest posts, follow us on social media:

📸 Instagram

📘 Facebook

🐦 Twitter (X)

🔗 Linkedin

📌 Pinterest

🧵 Thread

🥁 Tumblr

❗ Reddit

Contact: ALL SERVICES GLOBAL +91-22 4063 7777 / +91- 22 4063 7788 https://allservicesglobal.com/

Digital Partner:

TVM INFO SOLUTIONS PVT LTD

Contact: TVM Info Solutions Pvt. Ltd.

+91- 90045 90039

Follow us on Social Media

🌐 Website

📸 Instagram

📘 Facebook

🔗 Linkedin

▶️ Youtube

0 notes

Text

Eco-Friendly Solutions in Heavy Equipment Repair: Trends & Innovations

Discover how the heavy equipment repair industry is going green. This blog dives into the latest eco-friendly trends and innovations making machinery maintenance more sustainable than ever. Read more here- https://wacoequipmentrepair.com/eco-friendly-solutions-in-heavy-equipment-repair-trends-innovations/

#EcoFriendlyRepair#SustainableMachinery#GreenConstruction#HeavyEquipmentRepair#CleanTech#EnvironmentallyFriendly#RepairInnovation#GreenTechnology#SustainableEngineering#HeavyMachineryMaintenance#EquipmentUpgrades#LowEmissionSolutions

0 notes

Text

Ash handling is crucial in industries like power generation and cement production, requiring efficient systems to manage large volumes while minimizing wear and energy consumption. Two primary pneumatic conveying methods—dense phase and lean phase—offer distinct advantages. Dense phase systems operate at low velocity and high pressure, moving ash in compact slugs, reducing wear, and enhancing energy efficiency. In contrast, lean phase systems use high velocity and low pressure, keeping ash suspended in the air stream but causing more equipment wear. While dense phase is ideal for abrasive or fragile materials, lean phase suits lighter, non-abrasive ones. Selecting the right system depends on material properties, energy efficiency, and infrastructure constraints.

#AshHandling#PneumaticConveying#DensePhase#LeanPhase#IndustrialAutomation#MaterialHandling#EnergyEfficiency#BulkMaterialHandling#PowerPlantOperations#CementIndustry#ConveyingSystems#AshConveying#IndustrialProcessing#BulkHandling#EngineeringSolutions#EfficientTransport#IndustrialEquipment#ManufacturingProcess#SustainableEngineering#PlantMaintenance#IndustrialEfficiency#PowderHandling#AirConveying#SystemOptimization#HeavyIndustry#OperationalExcellence

0 notes

Text

The construction industry is embracing green building technologies to reduce environmental impact while enhancing efficiency and sustainability.

#top college of technology in trichy#quality engineering and technical education.#krct the top college of technology in trichy#best college of technology in trichy#training and engineering placement#the top college of technology in trichy krct#GreenBuilding#SustainableEngineering#EcoFriendlyTech#SmartConstruction#RenewableEnergy#GreenArchitecture#SustainableLiving#EcoConstruction#SustainableDevelopment

0 notes

Text

Civil engineering firms in Adelaide

When it comes to civil engineering firms in Adelaide, Eight Blocks stands out as a trusted name, offering innovative solutions and exceptional service. With years of experience, the company has built a reputation for delivering high-quality engineering services tailored to meet diverse construction needs. Whether it’s infrastructure development, residential projects, or commercial construction, Eight Blocks ensures excellence in every aspect of civil engineering.

As one of the leading civil engineering firms in Adelaide, Eight Blocks takes pride in its commitment to precision, efficiency, and sustainability. The company specializes in a wide range of engineering services, from structural design to site development. With a team of skilled professionals, Eight Blocks ensures that every project is completed with the highest standards of safety and quality. Clients rely on their expertise for complex engineering challenges, making them a go-to choice for civil engineering solutions in Adelaide.

With the growing demand for reliable civil engineering firms in Adelaide, Eight Blocks continues to set benchmarks in the industry. The company works closely with architects, contractors, and developers to provide seamless engineering support. Their attention to detail and customer-centric approach make them a preferred choice among businesses and individuals looking for dependable engineering solutions. From road construction to large-scale commercial buildings, Eight Blocks has played a key role in shaping Adelaide’s urban landscape.

The success of Eight Blocks among civil engineering firms in Adelaide lies in its ability to blend technology with expertise. Using advanced engineering tools and modern construction techniques, the company ensures that projects are completed efficiently and cost-effectively. Whether it’s land development, drainage systems, or structural planning, their team works diligently to deliver outstanding results. Their expertise extends across various sectors, making them a well-rounded choice for engineering services.

Clients searching for reliable civil engineering firms in Adelaide trust Eight Blocks for their professionalism and technical excellence. The company follows strict quality control measures, ensuring that all projects adhere to industry standards and regulations. Their approach is based on sustainability and innovation, helping clients achieve long-lasting and environmentally friendly engineering solutions. From concept to completion, Eight Blocks remains dedicated to delivering results that exceed expectations.

For those looking for reliable civil engineering firms in Adelaide, Eight Blocks remains a top choice. Their dedication to quality, sustainability, and efficiency makes them a preferred partner for engineering projects of all sizes. Whether it’s designing robust structures or planning efficient drainage systems, Eight Blocks ensures that every project is executed with precision and professionalism. Their expertise and customer-focused service set them apart as one of Adelaide’s premier engineering firms.

As the demand for expert civil engineering firms in Adelaide continues to grow, Eight Blocks remains at the forefront of the industry. Their commitment to innovation, reliability, and excellence makes them a leader in civil engineering solutions. By working closely with clients and stakeholders, they ensure that every project is completed successfully, meeting both functional and aesthetic requirements. For high-quality engineering services in Adelaide, Eight Blocks is the name to trust.

#CivilEngineering#StructuralEngineering#ConstructionIndustry#EngineeringSolutions#InfrastructureDevelopment#BuildingDesign#UrbanPlanning#SiteDevelopment#SustainableEngineering#ProjectManagement

0 notes

Text

Erosion Corrosion in Titanium Alloys: A Reflection on Current Engineering Challenges

Introduction With industries rapidly advancing, the demand for durable and corrosion-resistant materials has never been greater. A recent study published in IgMin Research highlights the erosion-corrosion behavior of commercially pure titanium and Ti-6Al-4V alloy in sodium chloride solutions (Read More). This research underscores the importance of materials science in addressing modern engineering challenges, particularly in aerospace, marine, and industrial applications.

Key Findings: Understanding Titanium’s Durability

✔ Corrosion Resistance in Saline Environments

The study found that both commercially pure titanium and Ti-6Al-4V alloy performed well in solids-free saline water, maintaining high durability even at high impingement velocities.

✔ Impact of Suspended Solids on Erosion

When suspended sand particles were introduced, both materials suffered significant degradation, showcasing the impact of harsh environmental conditions on material performance.

Ti-6Al-4V alloy demonstrated slightly superior resistance, making it a preferred choice for extreme applications.

✔ Industrial Relevance

These findings are critical for industries relying on titanium alloys, including:

Aerospace Engineering: Where lightweight and corrosion-resistant materials are essential.

Marine Engineering: As seawater exposure accelerates material wear and degradation.

Biomedical Applications: For implant materials requiring long-term stability in bodily fluids.

Current Scenario in Materials Science & Engineering

The demand for stronger, more corrosion-resistant materials continues to drive global research efforts. Recent advancements in nano-coatings, self-healing materials, and AI-driven material selection are shaping the future of sustainable engineering solutions.

🔹 Smart Coatings & Protective Layers – Innovations in self-healing coatings aim to extend material lifespan in extreme conditions.

🔹 Green Manufacturing – Industries are shifting towards eco-friendly, recyclable materials to reduce environmental impact.

🔹 AI & Machine Learning in Material Design – Researchers are utilizing AI-powered simulations to predict material behaviors and optimize industrial applications.

Contribute to Cutting-Edge Materials Science Research

As materials engineering evolves, researchers can contribute valuable insights by publishing in leading open-access platforms like IgMin Research.

📌 If you are currently engaged in research, please consider visiting our journal's website.

#MaterialsScience#CorrosionResistance#TitaniumAlloys#EngineeringInnovation#ErosionCorrosion#SustainableEngineering#ResearchPublication#IgMinResearch

0 notes