#deethanizer

Explore tagged Tumblr posts

Text

Diving into Liquified Petroleum Gas (LPG): Safety, Regulations, Manufacturing Techniques, and Uses

Have you ever used a barbecue or cooked outdoors with a propane stove? If so, you've likely experienced the convenience and flexibility of Liquefied Petroleum Gas, or LPG. This convenient fuel packs a powerful punch, but what exactly is it? In this article, we'll delve into the world of LPG, examining its composition, production process, and its various applications in our lives. We'll also cover safety measures and address some common questions about this widely-used fuel option. Whether you're an experienced grill chef or simply interested in alternative energy sources, stick around for an in-depth look at LPG!

Introduction

Liquefied petroleum gas (LPG), also known as propane, is a flammable mixture of hydrocarbon gases like propane, butane, and others. It's produced during oil refining or extracted from natural gas wells. Made up of various hydrocarbons like butane and propane, LPG is a flammable gas obtained during oil and gas processing. Commonly stored in pressurized cylinders for homes, this versatile fuel also travels through pipelines for large-scale use. A major benefit of LPG is its clean burning nature. Unlike many fuels, LPG is sulfur-free, resulting in fewer emissions. This eco-friendly characteristic makes it popular in households for cooking and heating, as well as in industries for tasks like steam generation and raw material production. You'll also find LPG in common items like aerosols, barbecue grills, and portable heaters.

What makes LPG special is:

Convenient and Clean: Stored in pressurized cylinders for homes (think BBQ tanks!), LPG is a clean-burning fuel with minimal sulfur emissions, making it more eco-friendly than some alternatives.

Versatile Fuel: This gas powers a surprising range of things, from home cooktops and heaters to industrial processes like steam generation. Don't forget those fun summer barbecues!

Transportation: LPG can also be transported efficiently through pipelines for large-scale applications.

Raw Material: Beyond fuel, LPG serves as a key ingredient for producing ethylene, a building block for many plastics.

Aerosol Power: Even some spray cans get their propellant boost from LPG!

Manufacturing Processes

LPG primarily originates from two sources. Approximately 60% of it is derived from the extraction of natural gas and oil deposits from the earth, while the remaining 40% is generated through the refining of crude oil. Historically, LPG was disregarded and burned off as an undesired by-product during the production of other fuel sources. However, it is now acknowledged as a versatile, low-carbon fuel capable of delivering a significant amount of energy.

Natural gas processing initiates at the wellhead, where raw natural gas is extracted from producing wells. The composition of this raw natural gas is contingent upon various factors, including the type, depth, and location of underground deposits, as well as the geological characteristics of the area.

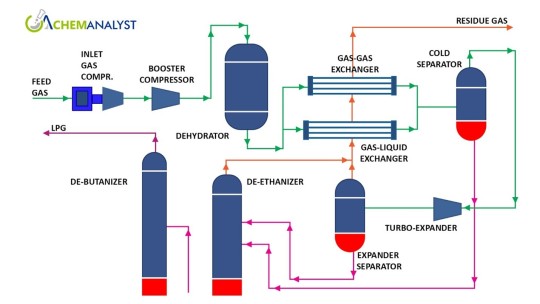

The conventional LPG extraction process involves the utilization of four columns. The initial step in extracting LPG from Natural Gas Liquids (NGL) is the DeEthanizer column. Within this column, methane and ethane are separated, with both components exiting the top of the column. Since there's no need to liquefy methane and ethane, particularly in small quantities, they remain in vapor phase, eliminating the necessity for an additional condenser.

The top product from the DeEthanizer, containing methane and ethane, serves as internal fuel for generating steam used in the column's reboiler. Heat is supplied to the column via forced circulation using a reboiler pump, ensuring efficient operation. Heavier hydrocarbons, excluding ethane, exit the column as a liquid bottom product, subsequently flowing into the DeButanizer column.

The DeButanizer column is chosen over the DePropanizer due to the composition of the bottom product from the DeEthanizer, containing small amounts of propane (2% of mass fraction) and butane (5% of mass fraction). Using smaller columns for subsequent extraction enhances economic efficiency and separation efficacy, requiring less duty for the reboiler.

Before entering the DeButanizer column, the bottom product from the DeEthanizer is depressurized from 26 to 17 bar and introduced into the DeButanizer as mixed-phase feed. Within the DeButanizer, this feed is fractionated into mixed propane and butane as overhead product and heavier hydrocarbons (C5+) as bottom product. The overhead product is fully condensed in the condenser through heat exchange with cooling water, with the resulting condensate collected in a reflux drum to prevent pump cavitation due to vapor phase.

The DePropanizer column separates propane as overhead product and butane as bottom product. The condensed overhead vapor is collected in the reflux drum, with a portion returned to the column as reflux via pump, and the remainder withdrawn as liquid propane product. Reboiler heat in the DePropanizer is supplied by a reboiler, aided by a reboiler circulation pump.

Nearly 100% propane and 99% butane can be recovered from the feed as overhead column product. The butane product, classified as field grade butane, is composed of 30% isobutane and 65% normal butane. This is further processed in a butane splitter to separate isobutane and normal butane.

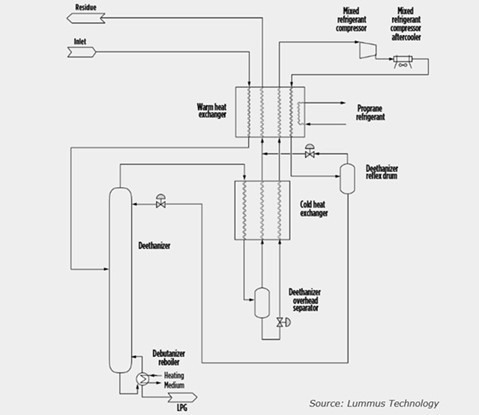

LUMMUS Technologies, one of the leading technology providers of LPG based in US, provides the IPOR (Iso-Pressure Open Refrigeration) Process for the manufacturing of LPG.

This process begins by cooling and partially condensing dry feed gas using a warm heat exchanger, where it interacts with cold process streams, propane refrigerant, and mixed refrigerant. The partially condensed feed gas then goes to the deethanizer for separating the bottom LPG liquid product. The deethanizer reboiler supplies the necessary heat for separation, while the cold reflux stream comes from the open-loop mixed refrigerant (MR) system.

The gas stream from the deethanizer overhead undergoes cooling and partial condensation in the cold heat exchanger. Then, it moves to the deethanizer overhead separator, where the separated liquid acts as the refrigerant for the open-loop MR cycle. The vapor left is residue gas, which gets heated in both the cold and warm heat exchangers.

After the deethanizer overhead separator, the MR liquid's pressure decreases, creating the lowest process temperature. This cold temperature partially condenses the overhead gas stream. Next, the MR stream is heated and vaporized through the cold and warm heat exchangers before going to the MR compressor. The compressed MR stream undergoes cooling and partial condensation again in the warm heat exchanger. The two-phase stream then goes to the deethanizer reflux drum, where the liquid part is used as reflux for the deethanizer column, thus completing the open loop of the MR cycle.

Any non-condensable vapors, mainly methane, along with the vapor from the deethanizer overhead separator, leave the process as part of the residue gas stream. For refinery off gas applications, a hydrogen purification plate-fin exchanger and a hydrogen separator are added after the warm heat exchanger to produce a hydrogen-rich product stream.

The following figure demonstrates the LPG production process:

Major Applications of Liquified Petroleum Gas (LPG)

Domestic

LPG is widely embraced for cooking in homes, with gas cooktops, ovens, and outdoor BBQs being popular choices. The allure of cooking with gas lies in its precise heat control, favored by both amateur cooks and seasoned chefs alike. Gas appliances offer instant adjustments, facilitating seamless transitions between cooking intensities. Furthermore, gas ovens stand out for their ability to maintain optimal moisture levels in food, preserving its succulence and natural flavors.

Commercial

Restaurants and other commercial hubs commonly rely on large industrial-sized gas cylinders. These cylinders ensure a steady and ample supply of gas for the high-volume demands of commercial kitchens and hospitality settings. By utilizing such industrial-scale equipment, establishments can efficiently manage their cooking operations and maintain optimal heating conditions, ensuring the comfort and satisfaction of their patrons. These gas cylinders play a vital role in supporting the smooth functioning of large-scale culinary and hospitality endeavors.

Heating

LPG serves as a versatile heating solution for both residential homes and commercial buildings. Its adaptability allows it to power an array of heating appliances, including space heaters, boilers, and fireplaces. This flexibility makes LPG an attractive choice for various heating needs, providing efficient warmth and comfort while offering the convenience of easy installation and operation. Whether it's warming a cozy living room or maintaining a comfortable temperature in a large office space, LPG stands as a reliable and versatile fuel option for heating application.

Fuel

LPG serves as a cleaner-burning alternative fuel suitable for powering cars, trucks, and buses. Its eco-friendly nature stems from emitting fewer pollutants compared to traditional gasoline or diesel, making it a greener choice for transportation. Beyond its environmental benefits, LPG also presents a cost-effective option, offering potential savings for vehicle owners and operators. By opting for LPG, drivers can enjoy reduced emissions while potentially cutting down on fuel expenses, contributing to both environmental sustainability and economic efficiency in the transportation sector.

Safety Regulations for LPG

LPG is a convenient and reliable fuel, but for the sake of safety it's important to handle and store it responsibly. Here's how to keep yourself and your surroundings safe:

Store it Right: Keep your LPG tanks in a well-ventilated space that's approved for such storage. This means away from anything that could spark a fire, like open flames, heaters, or even direct sunlight. Good airflow helps prevent gas buildup.

Handle with Care: When moving LPG cylinders, use proper lifting techniques to avoid hurting yourself. Always keep them upright and secure them to prevent them from falling over.

Be Leak-Wary: Regularly check for leaks in your tanks, pipes, and appliances. If you find one, clear the area immediately and don't use the LPG until the leak is fixed.

Plan for Emergencies: Have fire extinguishers readily available in LPG storage and usage areas.

Market Outlook

The LPG market is primarily propelled by its high caloric value, making it an efficient energy source for heating and cooking applications, often substituting for natural gas. Its clean-burning properties, characterized by minimal sulfur content, contribute to reduced emissions, driving demand, particularly in regions with strict environmental regulations. With approximately half of its usage allocated to heating and cooking, and the remainder split between automotive and industrial sectors, LPG showcases versatility across diverse applications. Its convenience of delivery, typically via trucks and storage in large tanks, ensures reliable access for residential and commercial users, while portable solutions like reusable gas canisters cater to on-the-go needs, further solidifying its market presence as a significant alternative to traditional fuels.

Liquified Petroleum Gas (LPG) Main Players

Significant players in the Global Liquified Petroleum Gas (LPG) market are IRPC Refinery, ExxonMobil, Indian Oil Corporation Limited, Saudi Aramco, JXTG Nippon Oil & Energy, GASCO, Reliance Petroleum Limited, Bharat Petroleum Corporation Limited, and Others.

Liquified Petroleum Gas (LPG) Market Challenges

The LPG industry market is also facing a few bumps. Here's a breakdown of the key hurdles:

Price Rollercoaster: LPG prices are like a thrill ride, prone to sharp swings due to factors like crude oil costs, political tensions, and imbalances between supply and demand. This volatility makes budgeting and planning an issue for both consumers and suppliers.

Supply Chain Snags: Disruptions in the supply chain, caused by natural disasters, political conflicts, or infrastructure breakdowns, can throw a wrench into getting LPG where it needs to go. Ensuring a smooth-running and reliable supply chain is vital to meeting market needs.

Alternative Energy on the Rise: LPG is facing growing competition from alternative energy sources like natural gas, electricity, and renewables. As consumer preferences shift, governments offer incentives, and technological advances for these alternatives, the demand for LPG could take a hit.

Conclusion:

Liquefied Petroleum Gas, or LPG, is a versatile fuel option gaining traffic due to its amazing properties. This flammable mixture, extracted from oil and gas wells, is primarily composed of carbon-based compounds like butane and propane. Stored in pressurized cylinders for household use, LPG can also be transported through pipelines for large-scale applications. One of LPG's biggest advantages is its clean burning nature. Unlike traditional fuels, LPG is virtually sulfur-free, resulting in significantly fewer emissions. This characteristic makes it an attractive alternative for both domestic and transportation sectors, driving the predicted growth of the LPG market. Furthermore, LPG's clean combustion paves the way for its potential substitution of more polluting fuels in the near future. With its eco-friendly profile and efficient burning properties, LPG is well-positioned to become a fuel of choice in the years to come.

0 notes

Text

snippet of Leif's next chapters

Chapter 38 ~ 40 (?): Breaking ties

With all the precautions he had taken, they still managed to catch up with him as he crossed the bridge. The smell of Osselt's incense stunk up the surroundings, no matter how strong the breeze, lost in the crowd. He peered into the water, from where Deethan's gaunt eyes watched for any of his movements, aware of the possibility of Leiftan falling into the river. The unfortunate mermaid had been slowly tearing herself apart since Lance's awakening and yet she still inissted to do as she was told. The same sick devotion that Erika had for that guard of idiots…

All the bonds he'd made, all the damage he'd seen from traveling from Eldarya… All that was gone when the bridge broke, the current had carried half of them away, the other half had been too coward to find an alternative to reach him.

He was alone alone on the other side of that fallen bridge, as he had always been. As he always would be.

That's why in the future Tsubomi will leave the north with him, so they can travel through Eldarya again, looking for at least one good thing brought by the war caused by Lance and Leif.

1 note

·

View note

Photo

#любимаяработа #амурскийгпз #агпз #тыжпереводчик #переводчикитожелюди #olgainguz #amur #svobodny #agpp #amurskygpp #ингузпушингуз #oprema #demethanizer #deethanizer #nrucolomn (у месту Амурский Гпз) https://www.instagram.com/p/B7GHYj3izSr/?igshid=1kekrq8n3suwe

#любимаяработа#амурскийгпз#��гпз#тыжпереводчик#переводчикитожелюди#olgainguz#amur#svobodny#agpp#amurskygpp#ингузпушингуз#oprema#demethanizer#deethanizer#nrucolomn

0 notes

Photo

favs i did for deethanes respawn album !

4 notes

·

View notes

Note

did you have a favored name for janus before his was officially revealed? if you did, why did you like it? ( i'm honestly still super pumped that one of the names in my top three ended up being canon )

yep! Ethan was my name of choice, partly because of the logos-ethos-pathos theory which i do love a lot, and partly because a feeling’s not a thing you own which, yes, has ethan as deceit’s name, and also has some of the loveliest deceit characterization in existence. it was also almost certainly the reason it took me several weeks to warm up to janus as the actual name because i kept going ‘no.... no....... deethan.....’

#asks#janus is firmly in my head now tho#although 'ethan' actually feels more right for afnatyo!deceit tbh#Anonymous

4 notes

·

View notes

Text

JE TOHLE NEJHEZČÍ OSTROV?! | Nintendo pátek - ANIMAL CROSSING: NEW HORIZONS | DeeThane A jak se ANIMAL CROSSING: NEW HORIZONS líbí vám? ANIMAL CROSSING: NEW HORIZONS: ... via YouTube https://www.youtube.com/watch?v=5SL-wzIvLhE

0 notes

Photo

From: My good boy on vacation in Austria @deethane

0 notes

Video

instagram

SHORT TWITCH CLIPS - Hacker??? 🤔🤔🤔 ➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖ Credit: DeeThane (twitch) ➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖ ❤️ Follow Renegad1stv on Instagram ❤️ 💎 YouTube channel in BIO 💎 ➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖ #renegad1s_tv #esl #twitchclips #reggie #Rainbowsixsiege #rainbowsixsiegememes #rainbowsixsiegememe #rainbowsixsiegeart #rainbowsixsiegecosplay #rainbowsixsiegeftw #rainbowsixsiegegame #rainbowsixsiegexboxone #rainbowsixsiegefunnymoments #rainbowsixsiegede #rainbowsixsiegeps4 #rainbowsixsiegeela #rainbowsixsiegeposter #rainbowsixsiegepc #rainbowsixsiegeranked #rainbowsixsiegememess #rainbowsixsiege1v5clutch #rainbowsixsiegeclips #rainbowsixsiegeitalia #rainbowsixsiegegameplay #rainbowsixsiegefanart #rainbowsixsiegeeliteskin #funny#r6siege #sixmajorparis #deethane https://www.instagram.com/p/BsiZDtVnWNj/?utm_source=ig_tumblr_share&igshid=1wh4dtgex3azt

#renegad1s_tv#esl#twitchclips#reggie#rainbowsixsiege#rainbowsixsiegememes#rainbowsixsiegememe#rainbowsixsiegeart#rainbowsixsiegecosplay#rainbowsixsiegeftw#rainbowsixsiegegame#rainbowsixsiegexboxone#rainbowsixsiegefunnymoments#rainbowsixsiegede#rainbowsixsiegeps4#rainbowsixsiegeela#rainbowsixsiegeposter#rainbowsixsiegepc#rainbowsixsiegeranked#rainbowsixsiegememess#rainbowsixsiege1v5clutch#rainbowsixsiegeclips#rainbowsixsiegeitalia#rainbowsixsiegegameplay#rainbowsixsiegefanart#rainbowsixsiegeeliteskin#funny#r6siege#sixmajorparis#deethane

0 notes

Text

Seven processes of petroleum refining

From crude oil to oil, there are many processes, and different processes will produce the same raw materials .

The basic routes from crude oil to oil are generally:

1 The crude oil is first divided into different straight-run distillates according to the boiling point requirements of different products, and then the non-ideal components in the distillate are removed according to the quality standards of the products;

2 Conversion by chemical reaction to produce the desired components, which in turn yields a range of qualified petroleum products.

The common processes for petroleum refining are atmospheric and vacuum distillation, catalytic cracking, delayed coking, hydrocracking, solvent deasphalting, hydrorefining, and catalytic reforming.

1) Atmospheric and vacuum distillation

Raw materials:

Crude oil, etc.

Product:

Naphtha, gas oil (gas oil), residual oil, asphalt, minus one line.

Basic concepts:

Atmospheric and vacuum distillation is a combination of atmospheric distillation and vacuum distillation. It is basically a physical process: the feedstock oil is divided into oils with different boiling points (called fractions) according to the evaporation capacity in the distillation tower. Some of these oils are blended. After adding the additive, it is delivered as a product, and a considerable part is the raw material of the subsequent processing device.

Atmospheric and vacuum distillation is the first process of oil processing in refinery, called primary processing of crude oil, including three processes: a. desalting and dehydration of crude oil; b. atmospheric distillation; c. vacuum distillation.

Production process:

Crude oil generally has salt and water, which can cause corrosion of equipment. Therefore, crude oil is first subjected to desalting and dehydration pretreatment before entering atmospheric and vacuum, usually by adding demulsifier and water.

Crude oil is formed into two parts through a flow meter, a heat exchange part, and a distillation tower. A part of the oil forms a top oil, passes through a cooler, a flow meter, and finally enters the tank area. This part is a chemical light oil (so-called naphtha); Forming the bottom oil, and then passing through the heat exchange part, entering the atmospheric pressure furnace and the atmospheric pressure tower to form three parts, a part of diesel oil, a part of wax oil, and a part of bottom oil; the remaining bottom oil is passed through a vacuum furnace, a vacuum tower Further processing, generating a minus line, wax oil, residual oil and asphalt.

The respective yields: naphtha (light gasoline or chemical light oil) accounted for about 1%, diesel accounted for about 20%, wax oil accounted for about 30%, residual oil and asphalt accounted for about 42%, and reduced one line accounted for about 5%. about.

The atmospheric and vacuum distillation process does not produce gasoline products, in which wax oil and residual oil enter the catalytic cracking process to produce gasoline, diesel, kerosene and other refined oil products; naphtha is directly sold by other small enterprises to produce solvent oil or to further processing in the next step. It is generally used to produce solvent oil or extract extract compounds by catalytic reforming;

Production equipment:

The atmospheric and vacuum distillation device is a distillation device for processing crude oil once, that is, a crude oil is fractionated into a processing device for components such as gasoline, kerosene, diesel oil, wax oil, and residual oil. Crude oil distillation generally includes two parts of atmospheric distillation and vacuum distillation.

Atmospheric distillation tower

The atmospheric distillation of crude oil is the distillation of crude oil at normal pressure (or slightly higher than normal pressure). The distillation equipment used is called crude oil atmospheric distillation column (or atmospheric pressure column).

The heavy oil component remaining under atmospheric distillation has a large molecular weight, a high boiling point, and is easily decomposed at a high temperature, which deteriorates the distilled product and produces coke, which destroys normal production. Therefore, in order to extract more light components, the boiling point range of the distilled feedstock oil is often lowered by lowering the distillation pressure. This distillation process under reduced pressure is called vacuum distillation.

Vacuum distillation tower

The vacuum distillation is a distillation process carried out under a negative pressure of less than 100 KPa. The core equipment for vacuum distillation is a vacuum tower and its vacuum system.

The vacuum pumping equipment of the vacuum tower is usually a steam injector (also called a steam suction pump) or a mechanical vacuum pump. Among them, the mechanical vacuum pump is only used in some dry vacuum distillation towers and vacuum towers of small refineries, and steam injectors are widely used.

(2) Catalytic cracking

Generally, crude oil obtained by atmospheric and vacuum distillation can be obtained from gasoline, kerosene and diesel oil, such as 10 to 40%, and the rest are heavy distillate and residual oil. If you want more light oils, you must reprocess the heavy and residual oils. Catalytic cracking is the most common production process for producing gasoline and diesel. Gasoline and diesel are mainly produced through this process. This is also the most important production link for general petroleum refining companies.

Raw materials:

Residual oil and wax oil are about 70%. Catalytic cracking is generally based on vacuum distillate oil and coking wax oil. However, with the increasing crude oil and the increasing demand for light oil, most of the refining and chemical enterprises have begun. The vacuum residue is added to the raw material, and even the atmospheric residue is directly used as a raw material for refining.

Product:

Gasoline, diesel, oil slurry (heavy distillate), liquid propylene, liquefied gas; each accounted for 42% of gasoline, diesel accounted for 21.5%, propylene accounted for 5.8%, liquefied gas accounted for 8%, and slurry accounted for 12%.

Basic concepts:

Catalytic cracking is the main process for processing heavy oil (such as residue) into light oil (gasoline, kerosene, diesel) in the presence of a catalyst. It is the main secondary processing method in the refining process. Belongs to the chemical processing process.

Production process:

The normal slag and the wax oil enter the riser, the settler and the regenerator through the feedstock buffer tank to form oil and gas, and enter the fractionation tower.

A part of the oil and gas enters the crude gasoline tower, the absorption tower, and the air compressor enters the condensed oil tank, passes through the re-absorption tower, the stabilization tower, and finally performs gasoline refining to produce gasoline.

A part of the oil and gas passes through the fractionation tower and enters the diesel stripper, and then the diesel is refined to produce diesel. A part of the oil and gas passes through the fractionation tower and enters the slurry circulation, and finally the oil slurry is produced.

A part of the oil and gas enters the liquid hydrocarbon buffer tank through the fractionation tower, and passes through the desulfurization adsorption tank, the sand filter tower, the water washing tank, the desulfurization alcohol extraction tower, the pre-alkaline washing tank, the amine liquid recovery unit, the desulfurization extraction tower, the buffer tower, and finally enters the liquid state. A hydrocarbon tank forms a liquefied gas.

A part of the oil and gas enters the depropanizer, reflux tower, deethanizer, propylene column, reflux tank through the liquid hydrocarbon buffer tank, and finally enters the spheroidal tank of the propylene zone to form liquid propylene.

The liquid propylene is further processed by the polypropylene workshop to produce polypropylene.

Production equipment:

Regenerator

The primary function of the regenerator is to burn off the coke on the coked catalyst to restore the activity of the catalyst while also providing the heat required for cracking. The regenerator consists of a casing, a cyclone, an air distributor, a secondary combustion chamber and a heat extractor.

Riser reactor

Straight pipe type: It is mostly used for high and low side-by-side anti-re-rear system. It is characterized by direct insertion from the bottom of the settler, simple structure and small pressure drop.

Folding type: mostly used for coaxial anti-re-system.

Settler

The function of the settler is to separate the reaction oil and gas from the riser and the catalyst. The oil and gas are separated from the entrained catalyst by the cyclone and then passed through the gas collection chamber to the fractionation system; the catalyst from the rapid separator falls down by gravity in the settler. , falling into the gas section.

Three machines

Main fan: Supply regenerative scorch air.

Air press: used to boost the rich gas from the fractionation system and then sent to the absorption stabilization system.

Supercharger: Supply the type IV reaction regeneration unit dense phase riser to adjust the catalyst circulation amount.

Three valve

Single-acting slide valve: In the type IV catalytic cracking unit, it is fully open during normal operation, closed in an emergency, and the two devices are disconnected to prevent backflow of the catalyst; the circulation of the two catalysts is adjusted in the riser catalytic cracking unit.

Double acting slide valve: installed between the regenerator outlet and the venting chimney, adjusting the pressure of the regenerator to maintain the pressure balance of the two devices.

Plug valve: The amount of circulation of the catalyst is adjusted in a coaxial catalytic cracking unit.

0 notes

Text

DeeThane - Uroboros (Official Music Video) | EP Uroboros

DeeThane – Uroboros (Official Music Video) | EP Uroboros

View On WordPress

0 notes

Video

youtube

DeeThane - Čas feat. Seven & Stewe & Ilona Maňasová (Official music vide...

0 notes

Photo

Moja ljubavi! Oprema buduće fabrike. Любовь моя! Оборудование будущего завода. My love! Equipment of future plant. #pravaljubav #oprema #demethanizer #deethanizer #nrucolomn #coldbox #substation #amur #amurskygpp #olgainguz #ясчастливыйкакникто #ольгаингуз #амурскаяобласть #амурскийгпз #любимаяработа #настоящаялюбовь #оборудование #деметанизатор #деэтанизатор #колоннавыделенияазота #подстанция #холодныйблок (у месту Амурский Гпз) https://www.instagram.com/p/B0he8FuJL2w/?igshid=x7ae09rld842

#pravaljubav#oprema#demethanizer#deethanizer#nrucolomn#coldbox#substation#amur#amurskygpp#olgainguz#ясчастливыйкакникто#ольгаингуз#амурскаяобласть#амурскийгпз#любимаяработа#настоящаялюбовь#оборудование#деметанизатор#деэтанизатор#колоннавыделенияазота#подстанция#холодныйблок

0 notes

Video

instagram

SHORT TWITCH CLIPS - easy 😏😏😏 ➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖ Credit: DeeThane (twitch) ➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖ ❤️ Follow Renegad1stv on Instagram ❤️ 💎 YouTube channel in BIO 💎 ➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖➖ #renegad1s_tv #esl #twitchclips #reggie #Rainbowsixsiege #rainbowsixsiegememes #rainbowsixsiegememe #rainbowsixsiegeart #rainbowsixsiegecosplay #rainbowsixsiegeftw #rainbowsixsiegegame #rainbowsixsiegexboxone #rainbowsixsiegefunnymoments #rainbowsixsiegede #rainbowsixsiegeps4 #rainbowsixsiegeela #rainbowsixsiegeposter #rainbowsixsiegepc #rainbowsixsiegeranked #rainbowsixsiegememess #rainbowsixsiege1v5clutch #rainbowsixsiegeclips #rainbowsixsiegeitalia #rainbowsixsiegegameplay #rainbowsixsiegefanart #rainbowsixsiegeeliteskin #funny#r6siege #sixmajorparis #deethane https://www.instagram.com/p/BrqD87ahStN/?utm_source=ig_tumblr_share&igshid=al7ue7sds2yx

#renegad1s_tv#esl#twitchclips#reggie#rainbowsixsiege#rainbowsixsiegememes#rainbowsixsiegememe#rainbowsixsiegeart#rainbowsixsiegecosplay#rainbowsixsiegeftw#rainbowsixsiegegame#rainbowsixsiegexboxone#rainbowsixsiegefunnymoments#rainbowsixsiegede#rainbowsixsiegeps4#rainbowsixsiegeela#rainbowsixsiegeposter#rainbowsixsiegepc#rainbowsixsiegeranked#rainbowsixsiegememess#rainbowsixsiege1v5clutch#rainbowsixsiegeclips#rainbowsixsiegeitalia#rainbowsixsiegegameplay#rainbowsixsiegefanart#rainbowsixsiegeeliteskin#funny#r6siege#sixmajorparis#deethane

0 notes

Text

catalytic cracking

Generally, crude oil obtained by atmospheric and vacuum distillation can be obtained from gasoline, kerosene and diesel oil, such as 10 to 40%, and the rest are heavy distillate and residual oil. If you want more light oils, you must reprocess the heavy and residual oils. Catalytic cracking is the most common production process for producing gasoline and diesel. Gasoline and diesel are mainly produced through this process. This is also the most important production link for general petroleum refining companies.

Raw material

Residual oil and wax oil are about 70%. Catalytic cracking is generally based on vacuum distillate oil and coking wax oil. However, with the increasing crude oil and the increasing demand for light oil, most of the refining and chemical enterprises have begun. The vacuum residue is added to the raw material, and even the atmospheric residue is directly used as a raw material for refining.

Product

Gasoline, diesel, oil slurry (heavy distillate), liquid propylene, liquefied gas; each accounted for 42% of gasoline, diesel accounted for 21.5%, propylene accounted for 5.8%, liquefied gas accounted for 8%, and slurry accounted for 12%.

Basic concepts

Catalytic cracking is the main process for processing heavy oil (such as residue) into light oil (gasoline, kerosene, diesel) in the presence of a catalyst. It is the main secondary processing method in the refining process. Belongs to the chemical processing process.

Production process

The normal slag and the wax oil enter the riser, the settler and the regenerator through the feedstock buffer tank to form oil and gas, and enter the fractionation tower.

A part of the oil and gas enters the crude gasoline tower, the absorption tower, and the air compressor enters the condensed oil tank, passes through the re-absorption tower, the stabilization tower, and finally performs gasoline refining to produce gasoline.

A part of the oil and gas passes through the fractionation tower and enters the diesel stripper, and then the diesel is refined to produce diesel. A part of the oil and gas passes through the fractionation tower and enters the slurry circulation, and finally the oil slurry is produced.

A part of the oil and gas enters the liquid hydrocarbon buffer tank through the fractionation tower, and passes through the desulfurization adsorption tank, the sand filter tower, the water washing tank, the desulfurization alcohol extraction tower, the pre-alkaline washing tank, the amine liquid recovery unit, the desulfurization extraction tower, the buffer tower, and finally enters the liquid state. A hydrocarbon tank forms a liquefied gas.

A part of the oil and gas enters the depropanizer, reflux tower, deethanizer, propylene column, reflux tank through the liquid hydrocarbon buffer tank, and finally enters the spheroidal tank of the propylene zone to form liquid propylene. The liquid propylene is further processed by the polypropylene workshop to produce polypropylene.

Production equipment

Regenerator

The primary function of the regenerator is to burn off the coke on the coked catalyst to restore the activity of the catalyst while also providing the heat required for cracking. The regenerator consists of a casing, a cyclone, an air distributor, a secondary combustion chamber and a heat extractor.

Riser reactor

Straight pipe type: It is mostly used for high and low side-by-side anti-re-rear system. It is characterized by direct insertion from the bottom of the settler, simple structure and small pressure drop.

Folding type: mostly used for coaxial anti-re-system.

Settler

The function of the settler is to separate the reaction oil and gas from the riser and the catalyst. The oil and gas are separated from the entrained catalyst by the cyclone and then passed through the gas collection chamber to the fractionation system; the catalyst from the rapid separator falls down by gravity in the settler. , falling into the gas section.

Three machines

Main fan: Supply regenerative scorch air.

Air press: used to boost the rich gas from the fractionation system and then sent to the absorption stabilization system.

Supercharger: Supply the type IV reaction regeneration unit dense phase riser to adjust the catalyst circulation amount.

Three valve

Single-acting slide valve: In the type IV catalytic cracking unit, it is fully open during normal operation, closed in an emergency, and the two devices are disconnected to prevent backflow of the catalyst; the circulation of the two catalysts is adjusted in the riser catalytic cracking unit.

Double acting slide valve: installed between the regenerator outlet and the venting chimney, adjusting the pressure of the regenerator to maintain the pressure balance of the two devices.

Plug valve: The amount of circulation of the catalyst is adjusted in a coaxial catalytic cracking unit

0 notes

Text

DeeThane - Randomák 2 | #ZG

DeeThane – Randomák 2 | #ZG

View On WordPress

0 notes

Text

DeeThane - Beast a Bestie | #ZG

DeeThane – Beast a Bestie | #ZG

View On WordPress

0 notes