#digital-water-flow-meter-price-list

Explore tagged Tumblr posts

Text

Balancing Valve Price, Types & Working Principle – Best Supplier in Delhi

In HVAC systems, hydronic networks, and industrial pipelines, balancing valves are essential for ensuring equal flow distribution and energy efficiency. These valves are designed to maintain hydraulic balance by regulating fluid flow in heating, cooling, and water supply systems.

As a trusted balancing valve manufacturer and supplier in Delhi, Udhhyog offers a complete range of manual, automatic, and advanced balancing valves for industrial, commercial, and residential use.

This guide covers the types of balancing valves, their working principles, flow diagrams, and an updated price list to help you choose the right solution.

What is a Balancing Valve?

A balancing valve is a control valve used to distribute flow evenly across branches of a hydraulic system. By doing so, it maintains consistent temperature, pressure, and energy usage throughout the system.

It is commonly used in:

Chilled water systems

Heating and cooling loops

Hot water recirculation systems

District cooling networks

Balancing Valve Types

🔹 Manual Balancing Valve

Requires manual adjustment using a handwheel.

Ideal for simple or fixed-load systems.

🔹 Automatic Balancing Valve

Self-adjusts based on pressure fluctuations.

Maintains constant flow without manual intervention.

🔹 Pressure Independent Balancing Valve (PIBV)

Combines control and balancing in one unit.

Useful in dynamic systems with load variation.

🔹 Advanced Digital Balancing Valve

Features sensors, actuators, and flow meters.

Provides remote control and diagnostics.

Balancing Valve Diagram & Symbol

A balancing valve diagram illustrates its:

Inlet and outlet ports

Adjustable handle or actuator

Flow measurement points

Symbol:

The balancing valve symbol in engineering drawings includes:

A square box with two diagonal lines

Directional arrows to indicate flow

These symbols and diagrams are essential for system planning, installation, and maintenance.

Automatic Balancing Valve – Working Principle

The automatic balancing valve contains a diaphragm and spring that respond to pressure changes. When differential pressure increases, the diaphragm restricts flow. When pressure drops, it opens to allow more flow.

This ensures:

Constant flow rate regardless of upstream or downstream changes

Improved energy efficiency

Reduced maintenance

Related Valve Types

🔹 Balanced Bellows Safety Relief Valve

Uses bellows to isolate the spring chamber from back pressure.

Ideal for boilers, steam, and gas pipelines.

🔹 Balanced Plug Valve

Plug is pressure-balanced to reduce torque.

Used in chemical plants and high-pressure pipelines.

🔹 Balanced Safety Relief Valve

Maintains accurate opening pressure even with variable backpressure.

Common in compressor discharge lines and steam systems.

Advanced Balancing Valve Flow Chart

An advanced balancing valve flow chart includes:

Design flow rate

Presetting steps

Flow measurement using differential pressure

Adjustments for optimum flow

This is used in digital models and ensures accurate commissioning of HVAC systems.

Balancing Valve Price List – Delhi Market

Valve TypeSize (mm)Price Range (INR)Manual Balancing Valve15–50₹850 – ₹2,200Automatic Balancing Valve20–80₹2,500 – ₹6,500Pressure Independent Valve25–100₹4,500 – ₹10,000Digital Balancing Valve25–150₹15,000 – ₹35,000Balanced Bellows Relief Valve25–100₹6,000 – ₹15,000Balanced Plug Valve25–150₹8,000 – ₹18,000

📌 Note: Prices may vary based on brand, material (bronze, brass, SS), and pressure class.

Applications of Balancing Valves

🏢 HVAC systems in buildings

🏭 Industrial fluid and steam systems

🏥 Hospitals and laboratories

🏬 Shopping malls and multiplexes

🏠 High-rise residential projects

Why Choose Udhhyog – Best Balancing Valve Supplier in Delhi

🛠️ Complete Range of Solutions

From basic manual valves to advanced digital systems, we have everything.

🧪 Tested & Certified Products

All valves are pressure-tested and compliant with IS/ISO standards.

📦 Quick Availability & Bulk Supply

We deliver across Delhi, Haryana, Punjab, Uttar Pradesh, Jammu & Kashmir.

💬 Expert Support

We help you with valve selection, system design, and commissioning.

💰 Affordable Pricing

Get the best prices on high-quality balancing valves, direct from manufacturer.

Conclusion

Balancing valves are vital for maintaining energy efficiency and uniform performance in modern fluid systems. From manual to automatic, Udhhyog manufactures and supplies all types of valves to meet your specific requirements.

With a wide stock range, competitive pricing, and expert assistance, Udhhyog is your go-to balancing valve supplier in Delhi.

Contact Udhhyog Today

📞 Call or Visit Udhhyog for customized quotes, technical catalogs, and delivery information.

#BalancingValve#AutomaticBalancingValve#PressureIndependentValve#ValveSupplierDelhi#Udhhyog#HVACBalancing#IndustrialValves#BellowsReliefValve#BalancedPlugValve#BalancingValveDiagram

0 notes

Text

Balancing Valve Price, Types & Working Principle – Best Supplier in Delhi

In HVAC systems, hydronic networks, and industrial pipelines, balancing valves are essential for ensuring equal flow distribution and energy efficiency. These valves are designed to maintain hydraulic balance by regulating fluid flow in heating, cooling, and water supply systems.

As a trusted balancing valve manufacturer and supplier in Delhi, Udhhyog offers a complete range of manual, automatic, and advanced balancing valves for industrial, commercial, and residential use.

This guide covers the types of balancing valves, their working principles, flow diagrams, and an updated price list to help you choose the right solution.

What is a Balancing Valve?

A balancing valve is a control valve used to distribute flow evenly across branches of a hydraulic system. By doing so, it maintains consistent temperature, pressure, and energy usage throughout the system.

It is commonly used in:

Chilled water systems

Heating and cooling loops

Hot water recirculation systems

District cooling networks

Balancing Valve Types

🔹 Manual Balancing Valve

Requires manual adjustment using a handwheel.

Ideal for simple or fixed-load systems.

🔹 Automatic Balancing Valve

Self-adjusts based on pressure fluctuations.

Maintains constant flow without manual intervention.

🔹 Pressure Independent Balancing Valve (PIBV)

Combines control and balancing in one unit.

Useful in dynamic systems with load variation.

🔹 Advanced Digital Balancing Valve

Features sensors, actuators, and flow meters.

Provides remote control and diagnostics.

Balancing Valve Diagram & Symbol

A balancing valve diagram illustrates its:

Inlet and outlet ports

Adjustable handle or actuator

Flow measurement points

Symbol:

The balancing valve symbol in engineering drawings includes:

A square box with two diagonal lines

Directional arrows to indicate flow

These symbols and diagrams are essential for system planning, installation, and maintenance.

Automatic Balancing Valve – Working Principle

The automatic balancing valve contains a diaphragm and spring that respond to pressure changes. When differential pressure increases, the diaphragm restricts flow. When pressure drops, it opens to allow more flow.

This ensures:

Constant flow rate regardless of upstream or downstream changes

Improved energy efficiency

Reduced maintenance

Related Valve Types

🔹 Balanced Bellows Safety Relief Valve

Uses bellows to isolate the spring chamber from back pressure.

Ideal for boilers, steam, and gas pipelines.

🔹 Balanced Plug Valve

Plug is pressure-balanced to reduce torque.

Used in chemical plants and high-pressure pipelines.

🔹 Balanced Safety Relief Valve

Maintains accurate opening pressure even with variable backpressure.

Common in compressor discharge lines and steam systems.

Advanced Balancing Valve Flow Chart

An advanced balancing valve flow chart includes:

Design flow rate

Presetting steps

Flow measurement using differential pressure

Adjustments for optimum flow

This is used in digital models and ensures accurate commissioning of HVAC systems.

Balancing Valve Price List – Delhi Market

Valve TypeSize (mm)Price Range (INR)Manual Balancing Valve15–50₹850 – ₹2,200Automatic Balancing Valve20–80₹2,500 – ₹6,500Pressure Independent Valve25–100₹4,500 – ₹10,000Digital Balancing Valve25–150₹15,000 – ₹35,000Balanced Bellows Relief Valve25–100₹6,000 – ₹15,000Balanced Plug Valve25–150₹8,000 – ₹18,000

📌 Note: Prices may vary based on brand, material (bronze, brass, SS), and pressure class.

Applications of Balancing Valves

🏢 HVAC systems in buildings

🏭 Industrial fluid and steam systems

🏥 Hospitals and laboratories

🏬 Shopping malls and multiplexes

🏠 High-rise residential projects

Why Choose Udhhyog – Best Balancing Valve Supplier in Delhi

🛠️ Complete Range of Solutions

From basic manual valves to advanced digital systems, we have everything.

🧪 Tested & Certified Products

All valves are pressure-tested and compliant with IS/ISO standards.

📦 Quick Availability & Bulk Supply

We deliver across Delhi, Haryana, Punjab, Uttar Pradesh, Jammu & Kashmir.

💬 Expert Support

We help you with valve selection, system design, and commissioning.

💰 Affordable Pricing

Get the best prices on high-quality balancing valves, direct from manufacturer.

Conclusion

Balancing valves are vital for maintaining energy efficiency and uniform performance in modern fluid systems. From manual to automatic, Udhhyog manufactures and supplies all types of valves to meet your specific requirements.

With a wide stock range, competitive pricing, and expert assistance, Udhhyog is your go-to balancing valve supplier in Delhi.

Contact Udhhyog Today

📞 Call or Visit Udhhyog for customized quotes, technical catalogs, and delivery information.

#BalancingValve#AutomaticBalancingValve#PressureIndependentValve#ValveSupplierDelhi#Udhhyog#HVACBalancing#IndustrialValves#BellowsReliefValve#BalancedPlugValve#BalancingValveDiagram

1 note

·

View note

Text

Balancing Valve Price, Types & Working Principle – Best Supplier in Delhi

In HVAC systems, hydronic networks, and industrial pipelines, balancing valves are essential for ensuring equal flow distribution and energy efficiency. These valves are designed to maintain hydraulic balance by regulating fluid flow in heating, cooling, and water supply systems.

As a trusted balancing valve manufacturer and supplier in Delhi, Udhhyog offers a complete range of manual, automatic, and advanced balancing valves for industrial, commercial, and residential use.

This guide covers the types of balancing valves, their working principles, flow diagrams, and an updated price list to help you choose the right solution.

What is a Balancing Valve?

A balancing valve is a control valve used to distribute flow evenly across branches of a hydraulic system. By doing so, it maintains consistent temperature, pressure, and energy usage throughout the system.

It is commonly used in:

Chilled water systems

Heating and cooling loops

Hot water recirculation systems

District cooling networks

Balancing Valve Types

🔹 Manual Balancing Valve

Requires manual adjustment using a handwheel.

Ideal for simple or fixed-load systems.

🔹 Automatic Balancing Valve

Self-adjusts based on pressure fluctuations.

Maintains constant flow without manual intervention.

🔹 Pressure Independent Balancing Valve (PIBV)

Combines control and balancing in one unit.

Useful in dynamic systems with load variation.

🔹 Advanced Digital Balancing Valve

Features sensors, actuators, and flow meters.

Provides remote control and diagnostics.

Balancing Valve Diagram & Symbol

A balancing valve diagram illustrates its:

Inlet and outlet ports

Adjustable handle or actuator

Flow measurement points

Symbol:

The balancing valve symbol in engineering drawings includes:

A square box with two diagonal lines

Directional arrows to indicate flow

These symbols and diagrams are essential for system planning, installation, and maintenance.

Automatic Balancing Valve – Working Principle

The automatic balancing valve contains a diaphragm and spring that respond to pressure changes. When differential pressure increases, the diaphragm restricts flow. When pressure drops, it opens to allow more flow.

This ensures:

Constant flow rate regardless of upstream or downstream changes

Improved energy efficiency

Reduced maintenance

Related Valve Types

🔹 Balanced Bellows Safety Relief Valve

Uses bellows to isolate the spring chamber from back pressure.

Ideal for boilers, steam, and gas pipelines.

🔹 Balanced Plug Valve

Plug is pressure-balanced to reduce torque.

Used in chemical plants and high-pressure pipelines.

🔹 Balanced Safety Relief Valve

Maintains accurate opening pressure even with variable backpressure.

Common in compressor discharge lines and steam systems.

Advanced Balancing Valve Flow Chart

An advanced balancing valve flow chart includes:

Design flow rate

Presetting steps

Flow measurement using differential pressure

Adjustments for optimum flow

This is used in digital models and ensures accurate commissioning of HVAC systems.

Balancing Valve Price List – Delhi Market

Valve TypeSize (mm)Price Range (INR)Manual Balancing Valve15–50₹850 – ₹2,200Automatic Balancing Valve20–80₹2,500 – ₹6,500Pressure Independent Valve25–100₹4,500 – ₹10,000Digital Balancing Valve25–150₹15,000 – ₹35,000Balanced Bellows Relief Valve25–100₹6,000 – ₹15,000Balanced Plug Valve25–150₹8,000 – ₹18,000

📌 Note: Prices may vary based on brand, material (bronze, brass, SS), and pressure class.

Applications of Balancing Valves

🏢 HVAC systems in buildings

🏭 Industrial fluid and steam systems

🏥 Hospitals and laboratories

🏬 Shopping malls and multiplexes

🏠 High-rise residential projects

Why Choose Udhhyog – Best Balancing Valve Supplier in Delhi

🛠️ Complete Range of Solutions

From basic manual valves to advanced digital systems, we have everything.

🧪 Tested & Certified Products

All valves are pressure-tested and compliant with IS/ISO standards.

📦 Quick Availability & Bulk Supply

We deliver across Delhi, Haryana, Punjab, Uttar Pradesh, Jammu & Kashmir.

💬 Expert Support

We help you with valve selection, system design, and commissioning.

💰 Affordable Pricing

Get the best prices on high-quality balancing valves, direct from manufacturer.

Conclusion

Balancing valves are vital for maintaining energy efficiency and uniform performance in modern fluid systems. From manual to automatic, Udhhyog manufactures and supplies all types of valves to meet your specific requirements.

With a wide stock range, competitive pricing, and expert assistance, Udhhyog is your go-to balancing valve supplier in Delhi.

Contact Udhhyog Today

📞 Call or Visit Udhhyog for customized quotes, technical catalogs, and delivery information.

#BalancingValve#AutomaticBalancingValve#PressureIndependentValve#ValveSupplierDelhi#Udhhyog#HVACBalancing#IndustrialValves#BellowsReliefValve#BalancedPlugValve#BalancingValveDiagram

0 notes

Text

Best Flange Manufacturer in India | SS & MS Flanges Supplier

India is a major hub for high-quality industrial flanges, catering to industries like oil & gas, construction, power plants, and chemical processing. Top manufacturers provide ASME, ANSI, and ISO-certified flanges in stainless steel, mild steel, and alloy materials, ensuring durability and performance.

Best Flange Manufacturers in India

1. Rajveer Stainless & Alloys (Mumbai)

✅ Leading exporter of stainless steel flanges ✅ Wide range: Slip-on, weld neck, and threaded flanges ✅ ISO 9001:2015 & ASME-certified

2. Fit-Wel Industries LLP (Ahmedabad)

✅ Manufacturer of industrial and pipeline flanges ✅ Bulk orders & fast delivery across India ✅ Competitive pricing & customized solutions

3. Kiah Metallurgical India (Delhi)

✅ Stockist & exporter of carbon and alloy steel flanges ✅ Immediate dispatch for urgent orders ✅ Industry leader in high-pressure flanges

4. Steel Mart India (Chennai)

✅ Large inventory of mild steel & forged flanges ✅ Supply to oil & gas, refineries, and shipbuilding ✅ PED & API-certified manufacturer

Types of Flanges & Their Applications

Flange TypeDescriptionIndustry ApplicationsSlip-On FlangeSlides over the pipe & welded.Low-pressure pipelinesWeld Neck FlangeProvides high strength with long hub.Oil & gas, power plantsBlind FlangeSeals pipeline ends.Pressure testing & storage tanksThreaded FlangeScrews onto pipes, no welding needed.Small-diameter pipingSocket Weld FlangeWelded on one side for high pressure.High-pressure pipingLap Joint FlangeUsed with stub ends for easy removal.Maintenance-heavy applicationsLong Weld Neck FlangeExtended hub for high-temperature piping.Chemical & power plantsOrifice FlangeDesigned for flow measurement.Fluid control & metering

Why Choose Indian Flange Manufacturers?

Competitive Pricing – Affordable rates with bulk discounts.

Certified Quality – ASME, ANSI, API, ISO 9001, PED compliance.

Quick Turnaround – Large stock availability & fast shipping.

Customization Available – Special coatings, non-standard sizes & pressure ratings.

Global Supply – Exporting to USA, UK, UAE, Europe, and Asia.

Industries Using Flanges

Oil & Gas – Pipelines, refineries, and offshore platforms

Power Plants – Thermal, nuclear, and gas-based stations

Chemical & Petrochemical – High-pressure piping systems

Water Treatment – Wastewater management & desalination

Marine & Shipbuilding – Offshore drilling & ship pipelines

Food & Beverage – Hygienic-grade stainless steel flanges

SEO & Digital Marketing Strategy for Flange Manufacturers

Google My Business (GMB) Optimization – Boost local visibility & customer reach.

Backlink Building – List on TradeIndia, Justdial, IndiaMART & industry directories.

Schema Markup Implementation – Use FAQ & Product Schema for higher rankings.

Content Marketing – Publish industry blogs, case studies & guides.

Social Media & Ads – Promote products on LinkedIn, Facebook & Instagram.

FAQs

Q1: What materials are used for flanges in India?

A: Common materials include stainless steel (SS 304, SS 316), carbon steel, and mild steel (MS).

Q2: How to choose the right flange for industrial use?

A: Consider pipe size, pressure rating, material, and ASME/ANSI compliance before purchasing.

Q3: Are Indian flange manufacturers export-ready?

A: Yes, many Indian manufacturers export globally and meet international quality standards.

Q4: Can Indian manufacturers provide custom flanges?

A: Yes, they offer custom machining, special coatings, and unique sizes as per industry needs.

#FlangeManufacturer#FlangesIndia#IndustrialFlanges#SteelFlanges#PipingSolutions#OilAndGasIndustry#PetrochemicalIndustry#PipelineSolutions#EngineeringSupplies#MadeInIndia#StainlessSteelFlanges#CarbonSteelFlanges#ASMEFlanges#ANSIFlanges#IndustrialSupplier#FlangeExporters#B2BManufacturing#GMBOptimization#TradeIndia#Justdial#IndiaMART

1 note

·

View note

Text

Leading Pipe Flange Manufacturer in India | High-Quality & Certified

Pipe flanges play a crucial role in piping systems, allowing easy connection, maintenance, and pressure control. Indian manufacturers offer high-quality flanges made from stainless steel, carbon steel, and alloy materials that meet ASME, ANSI, API, and ISO standards for durability and efficiency.

Best Pipe Flange Manufacturers in India

1. Aashish Steel

✅ Specializes in stainless steel & duplex flanges ✅ Exports to 40+ countries ✅ Custom orders & bulk discounts

2. Petromat Oil & Gas Equipment Pvt. Ltd.

✅ Supplier of industrial & pipeline flanges ✅ Fast delivery across India & globally ✅ High-pressure & corrosion-resistant options

3. Rajendra Industrial Corporation

✅ Stockist of ASME, ANSI, API, and DIN flanges ✅ Immediate dispatch available ✅ Custom coatings & precision machining

4. Kiah Metallurgical India

✅ ISO 9001:2015 certified supplier ✅ Wide range of stainless steel, carbon steel & alloy flanges ✅ Competitive pricing with quick shipping

Types of Pipe Flanges & Their Applications

Flange TypeDescriptionCommon UsesSlip-On FlangeSlides over the pipe & welded.Low-pressure pipingWeld Neck FlangeHigh strength for extreme conditions.Oil & gas pipelinesBlind FlangeSeals pipe ends securely.Pressure testing & vesselsThreaded FlangeScrewed onto pipes without welding.Small-diameter pipingSocket Weld FlangeWelded only on one side.High-pressure pipelinesLap Joint FlangeWorks with stub ends for easy dismantling.Maintenance-heavy pipingLong Weld Neck FlangeExtended hub for high-temperature uses.Power plants & chemical industriesOrifice FlangeDesigned for flow measurement.Fluid control & metering

Why Choose Indian Pipe Flange Manufacturers?

Affordable Pricing – Cost-effective production with bulk discounts.

High-Quality Standards – ASME, ANSI, API, and ISO 9001-certified products.

Quick Delivery – Large stock availability with rapid dispatch.

Customization Options – Special sizes, coatings, and finishes as per requirements.

Global Supply Chain – Indian flanges are exported to USA, UK, UAE, Europe & Asia.

Industries That Use Pipe Flanges

Oil & Gas – Pipelines, refineries, offshore platforms

Power Plants – Steam, nuclear & gas-based plants

Chemical & Petrochemical – High-pressure processing

Water Treatment – Desalination, wastewater management

Marine & Shipbuilding – Offshore & ship piping

Food & Beverage – Hygienic & sanitary-grade piping

SEO & Digital Marketing Strategy for Flange Manufacturers

Google My Business (GMB) Optimization – Improves local search rankings.

Backlink Strategy – List on TradeIndia, Justdial, IndiaMART & industry blogs.

Schema Markup Implementation – Add FAQ & Product Schema for better SEO.

Content Marketing – Publish technical blogs, case studies & guides.

Social Media Engagement – Promote on LinkedIn, Facebook & Instagram.

FAQs

Q1: What is the best material for pipe flanges?

A: Stainless steel (SS 304, SS 316) offers corrosion resistance, while carbon steel is best for high-pressure applications.

Q2: How do I select the right pipe flange?

A: Consider pressure rating, pipe size, material, and compliance with industry standards before purchasing.

Q3: What certifications should a pipe flange manufacturer have?

A: Look for ASME, ANSI, API, ISO 9001, and PED certifications to ensure high quality.

Q4: Can Indian manufacturers provide custom pipe flanges?

A: Yes, leading manufacturers offer custom sizes, drilling, and coatings.

#PipeFlange#FlangeManufacturer#IndustrialFlanges#SteelFlanges#PipingSolutions#OilAndGasIndustry#PetrochemicalIndustry#PipelineSolutions#EngineeringSupplies#MadeInIndia#StainlessSteelFlanges#CarbonSteelFlanges#ASMEFlanges#ANSIFlanges#IndustrialSupplier#FlangeExporters#B2BManufacturing#GMBOptimization#TradeIndia#Justdial#IndiaMART

1 note

·

View note

Text

Best Flange Manufacturers in India | High-Quality Industrial Flanges

India is one of the leading manufacturers of industrial flanges, serving sectors like oil & gas, petrochemicals, construction, and power plants. Indian manufacturers offer cost-effective, high-quality, and durable flanges that meet global standards.

Top Flange Manufacturers in India

1. Aashish Steel

✅ Manufacturer of stainless steel and duplex steel flanges. ✅ Supplies globally with ISO 9001:2015 certification. ✅ Offers custom flange sizes and finishes.

2. Pioneer Forge India

✅ Specializes in high-pressure flanges for industrial applications. ✅ ANSI, ASME, and API-certified products. ✅ Fast production and delivery across India.

3. Chhajed Steel & Alloys

✅ Carbon steel and alloy steel flange manufacturer. ✅ Exporter to over 30+ countries. ✅ Provides bulk order discounts.

4. Petromat Oil & Gas Equipment Pvt. Ltd.

✅ Leading supplier of oil & gas industry flanges. ✅ Expertise in weld neck, slip-on, and blind flanges. ✅ Custom fabrication for specialized projects.

Types of Flanges & Their Applications

Flange TypeDescriptionCommon ApplicationsSlip-On FlangeSlides over the pipe and welded in place.Low-pressure piping systemsWeld Neck FlangeStrong weld connection for high-stress applications.Oil & gas pipelines, power plantsBlind FlangeSeals off a pipe end.High-pressure vessel systemsThreaded FlangeScrewed onto a pipe, no welding needed.Small-diameter pipelinesSocket Weld FlangeSocket fitting for high-pressure applications.Hydraulic & chemical industriesLap Joint FlangeWorks with stub-end fittings.Easy dismantling in piping systemsLong Weld Neck FlangeSimilar to weld neck with an extended hub.High-temperature applicationsOrifice FlangeUsed with orifice meters to measure flow rates.Fluid measurement systems

Factors to Consider When Choosing a Flange Manufacturer

Material Quality – Stainless steel, carbon steel, alloy steel.

Pressure Ratings – ANSI/ASME Class 150 to 2500.

Global Standards – ASME, ANSI, API, DIN, JIS compliance.

Customization – Sizes, drilling patterns, and surface coatings.

Supplier Reputation – ISO certification, industry experience.

Cost & Bulk Discounts – Compare multiple suppliers for best pricing.

Industries Using Flanges in India

Oil & Gas – Used in pipelines, refineries, and offshore platforms.

Power Generation – Steam, gas, and hydroelectric power plants.

Petrochemical & Chemical Processing – High-pressure chemical transport.

Water Treatment & Plumbing – Wastewater systems, desalination plants.

Shipbuilding & Marine – Offshore structures and vessel piping.

Food & Beverage – Hygienic flanges for processing plants.

SEO & Digital Marketing Strategies for Flange Businesses

Google My Business (GMB) Optimization – Improve local search rankings.

Industry Directories & Backlinks – List business on TradeIndia, Justdial, IndiaMART, ExportHub.

Schema Markup – Implement FAQ & Product Schema for SEO ranking.

Content Marketing – Publish technical blogs, case studies, and whitepapers.

Social Media Promotion – LinkedIn, Facebook & Instagram for B2B engagement.

FAQs

Q1: What are the most commonly used flange materials?

A: Stainless steel (SS 304, SS 316) for corrosion resistance, and carbon steel for cost-effective applications.

Q2: How do I select the right flange type?

A: Choose based on pressure rating, pipe compatibility, and industrial application needs.

Q3: What certifications should flange manufacturers have?

A: Look for ASME, ANSI, API, ISO 9001:2015, and PED certifications for quality assurance.

Q4: Can I get custom flanges for my project?

A: Yes, many manufacturers offer custom machining, coatings, and size modifications.

1 note

·

View note

Text

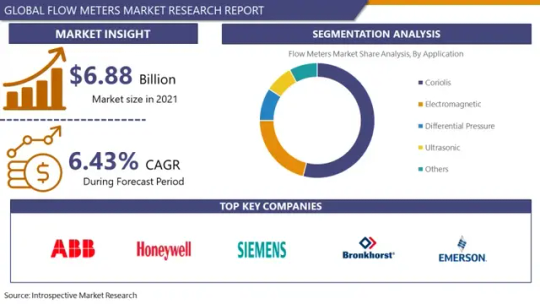

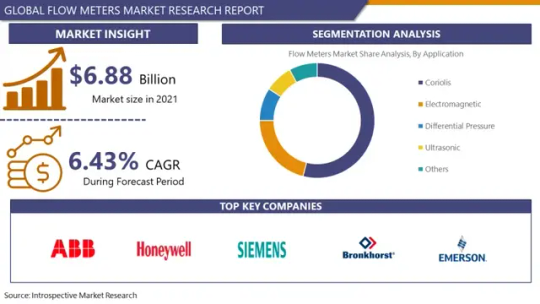

Flow Meters Market: Global Industry Analysis and Forecast 2023 – 2030

Global Flow Meters Market was valued at USD 6.88 Billion in 2021 and is expected to reach USD 10.64 Billion by the year 2028, at a CAGR of 6.43% .

Flowmeters is also known as flow sensors, are electronic devices that primarily measure or manage the flow rate of liquids and gasses within the pipes and tubes. The sensors are normally connected to the gauges to render their measurements; nevertheless, they can also be connected to computers and digital interfaces. In addition, they are also used in HVAC systems, medical devices, chemical factories, and septic systems. These meters can especially measure leaks, blockages, pipe bursts, and switching in the liquid concentration, due to any abomination or pollution. They measure the flow rate of a fluid, liquid, or gas when it passes through a confined transmission system. There are various principles of flow meters, such as orifice meters, venturi meters, rotameters, flow nozzles, and others.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15846

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Flow Meters Market include:

ABB Ltd, Siemens AG, Bronkhorst High-Tech BV, Honeywell International Inc., Emerson Electric Co., SICK AG, Omega Engineering Inc. (Spectris PLC), Christian Bürkert GmbH & Co. KG, TSI Incorporated, Keyence Corporation, Sensirion AG, Azbil Corporation, Endress+Hauser AG, KROHNE Messtechnik GmbH and Other major Players.

If You Have Any Query Flow Meters Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15846

Segmentation of Flow Meters Market:

By Technology

Coriolis

Electromagnetic

Differential Pressure

Ultrasonic

Others

By End-User

Oil & Gas

Water & Wastewater

Chemical & Petrochemical

Food & Beverage

Power Generation

Pulp & Paper

Other

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Flow Meters market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Flow Meters market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Flow Meters market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Flow Meters market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Flow Meters Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15846

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Email: [email protected]

#Flow Meters#Flow Meters Market#Flow Meters Market Size#Flow Meters Market Share#Flow Meters Market Growth#Flow Meters Market Trend#Flow Meters Market segment#Flow Meters Market Opportunity#Flow Meters Market Analysis 2023

0 notes

Text

Flow Meters Market: Global Industry Analysis and Forecast 2023 – 2030

Global Flow Meters Market was valued at USD 6.88 Billion in 2021 and is expected to reach USD 10.64 Billion by the year 2028, at a CAGR of 6.43% .

The flow meters market is witnessing robust growth propelled by increasing demand from various industries such as oil and gas, water and wastewater, chemicals, and pharmaceuticals. Flow meters play a critical role in measuring the flow rate of liquids or gases in pipelines, aiding in process optimization, efficiency enhancement, and regulatory compliance. With technological advancements, the market is experiencing a shift towards digital flow meters equipped with advanced features like remote monitoring, wireless connectivity, and data analytics capabilities.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15846

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Flow Meters Market include:

ABB Ltd, Siemens AG, Bronkhorst High-Tech BV, Honeywell International Inc., Emerson Electric Co., SICK AG, Omega Engineering Inc. (Spectris PLC), Christian Bürkert GmbH & Co. KG, TSI Incorporated, Keyence Corporation, Sensirion AG, Azbil Corporation, Endress+Hauser AG, KROHNE Messtechnik GmbH and Other major Players.

If You Have Any Query Flow Meters Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15846

Segmentation of Flow Meters Market:

By Technology

Coriolis

Electromagnetic

Differential Pressure

Ultrasonic

Others

By End-User

Oil & Gas

Water & Wastewater

Chemical & Petrochemical

Food & Beverage

Power Generation

Pulp & Paper

Other

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Flow Meters market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Flow Meters market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Flow Meters market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Flow Meters market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Flow Meters Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15846

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Email: [email protected]

#Flow Meters#Flow Meters Market#Flow Meters Market Size#Flow Meters Market Share#Flow Meters Market Growth#Flow Meters Market Trend#Flow Meters Market segment#Flow Meters Market Opportunity#Flow Meters Market Analysis 2023

0 notes

Text

Turbine Flow Meter

Turbine Flow Meter

https://www.facebook.com/CBROINDIA/posts/4824889960934817

Our Turbine Flow Meter are designed for the volumetric measurements of liquids & gases. The meters are rugged, reliable & precise instruments suitable for all industrial corrosive & Non – Corrosive Chemicals, Fuels, and Oil & Gases etc. The basic meter consists of a freely suspended bladed rotor positioned axially in the flow stream with the flowing fluid pushing against the blades. The rotational speed of the turbine is proportional to the velocity of the fluid & hence truly represents the volume of the fluid flowing through meter. The rotation of turbine rotor generates electrical pulses in the pick off attached to flow meter housing. The output pulses are amplified & converted to measure flow rate & integration. Turbine sensor with four/six digit batch controller with ICO Relay output contact offered to transfer. Preset qty. Of liquid from main storage tank with automatic flow shut off. We are a credible Manufacturer, Exporter and Supplier of Turbine Flow Meter in India. Applications : Water Diesel Petrol Vegetable Oil Hydraulic Oil Chemical (S.S. With Teflon coating) Milk plant. Gases

#Ultrasonic-btu-meter#Portable-ultrasonic-flow-meter#Clamp-on-ultrasonic-flow-meter#Ultrasonic-flow-meter#Heat-meter#BTU-METER#OVAL-GEAR-FLOW-METER#digital-water-flow-meter-price-list#digital-water-flow-meter-with-telemetry-system#digital-water-flow-meter-for-borewell#magnetic-flow-meter-with-totalizer#Digital-Water-Flow-Meter-manufacturers-in-India

1 note

·

View note

Text

InSinkErator Evolution Compact 3/4 HP Household Garbage Disposal

Product Description Reliance Controls THP103 AMWATT Appliance Load Tester / Plug-in Ammeter and Wattmeter. Gives instant accurate reading of wattage and amperage used by household appliances. Reads from 1-1875 watts. 26" cord. cULus listed. Since 1909, Reliance Controls Corporation has contributed more innovations that any other single manufacturer and has been awarded over 85 patents on manual transfer switches, time switches and accessories. Reliance Controls Corporation specializes in the manufacturing of a wide variety of electrical products. The primary product line consists of heavy duty time clocks and controls, generator accessories, transfer switches and transfer panels for portable generators. and inverters. And after over a century of innovation, Reliance Controls Corporation has built an enviable reputation for high quality, superior engineering and exceptional customer service.

Price: $19.00

Meter gives instant, accurate digital readout

Readout measures amps or watts used by common-cord connected household appliances (1.0 to 15.0 amps, 125 to 1,875 watts)

Long 26-inch cord reaches remote electrical outlets

Rugged, high-impact construction

Easy slide-switch action insantly converts between amps and watts

Product Description In-Sink-Erator Evolution Compact ¾ HP Food Waste DisposerPerfect for households with restricted cabinet space, the Evolution Compact; delivers the new standard in sound and grind performance in a compact size.InSinkErator’s powerful food waste disposers are the right choice when replacing an existing unit or designing a brand-new kitchen. You can choose between five Evolution models, including Evolution Septic Assist;, designed specifically for homes with septic systems. With an InSinkErator; food waste disposer in your kitchen, chicken bones, fruit rinds, coffee grounds and more can go right in the sink – where they’re virtually liquefied to safely flow into your sewage system or septic tank. You’ll enjoy a cleaner food preparation area, and less bagged garbage cluttering your home.In-Sink-Erator Evolution Compact ¾ HP Food Waste Disposer Features:; MultiGrind; Two grind stages let you quickly grind difficult food waste you wouldn’t put in a standard disposer, like celery and potato peels. ; SoundSeal; Makes the Evolution Compact; at least 40% quieter than standard disposers. ; 34.6-Ounce Stainless Steel Grind Chamber and Grind Component Handles more volume than standard disposers. ; ¾ Horsepower Dura-Drive; Induction Motor Gives you more horsepower than standard disposers. ; Quiet Collar; Sink Baffle Ensures quiet operation. In-Sink-Erator Evolution Compact ¾ HP Food Waste Disposer Specifications:; Type of Feed: Continuous; On/Off Control: Wall Switch; Motor: Single Phase; HP: ¾; Volts: 120; HZ: 60; RPM: 1725; Amp. (Avg. Load): 8.1; Time Rating: Intermittent; Lubrication: Permanently Lubricated Upper & Lower Bearings; Shipping Weight (Approx.): 19.5 lbs.; Unit Finish: Black Enamel Gray TEN-1706; Overall Height: 12-1/8"; MultiGrind Technology: GrindShear Ring;; Grind Chamber Capacity: 34.6 oz.; Motor Protection: Manual Reset Overload; Average Water Usage: ¼ Gallon Per Person Per Day; Average Electrical Usage : ½ KWH Per Month; Drain Connec

Price: $158.00

SoundSeal Technology which delivers quieter performance versus a standard disposer

MultiGrind Technology , with two-stage grind to quickly grind virtually any food waste

34.6 oz. Stainless steel grind chamber and grind components for longevity

¾ Horsepower Dura-Drive® Induction Motor; power cord not included

We Come To You 4-Year In-Home Limited Warranty

The post InSinkErator Evolution Compact ¾ HP Household Garbage Disposal appeared first on Top Seller Website.

from Top Seller Website https://topsellers.website/insinkerator-evolution-compact-3-4-hp-household-garbage-disposal/ from Top Sellers https://topsellerswebsite.tumblr.com/post/176377415253

0 notes

Text

Mass Flow Meter Control Market 2020- Revenue, Price and Gross Margin Research Report 2020

Industry Insight

The COVID-19 pandemic disruption is estimated to transform the Mass Flow Meter Control Market in the years to come drastically, and its after-effects will be persistently seen in the years ahead. The MRFR report on the Mass Flow Meter Control Market meticulously tracks the COVID-19 pandemic effect for the years ahead. Moreover, the precise analysis of drivers and restraints in a post-COVID-19 market offers a coherent understanding of future growth cues.

The take of global mass flow meter control market 2020 recorded by Market Research Future reveals that the market can hit 6% to the net worth amid the pandemic. The years of growth is calculated to be from 2017-2023.

Get Free Sample of Report @ https://www.marketresearchfuture.com/sample_request/4975

Top Market Players

The top players operating in the mass flow controller market are listed as Brooks (U.S.), Bronkhorst (the Netherlands), Teledyne Hastings (U.S.), Burkert (Germany), Sensirion (Switzerland), HORIBA (Japan), Sierra (U.S.), Alicat Scientific (U.K), and MKS (U.S.).

Top Impacting Factors

Mass flow controllers play a pivotal role in the fluid & gas processing as well as control application to measure and control the flow of liquids and gases. Mass flow controller market size is probable to nurture at a fast rate by 2023 owing to the demand for low flow rate controlling devices for precise measurements. The intensifying focus on microtechnology in sectors, such as science & engineering, has tinted the emphasis on the measurement of meager mass flow rates. Substantial developments in the laboratory & biomedical research sector that require gas flow measurement under controlled conditions show favoring nature towards the mass flow controller market growth for the future timeframe.

At the same time, the high level of accuracy and stability offered by mass flow controllers is also boosting the demand from the sectors such as oil & gas, food & beverage, chemical, and pharmaceutical industries. Other than this, the demand for mass flow controllers in the semiconductor industry for plasma etching and chemical vapor deposition processes will also fuel the mass flow controller market growth in the forecast period.

The worth of flow control in the semiconductor equipment, mainly in the manufacturing process, is paramount to capability, repeatability, and manufacturing of integrated circuits. Improvements in calibrations, diagnostics, and digital communication protocols have enhanced the capabilities of mass flow controllers, stressing the demand in the semiconductor industry. The versatile & reliable performance of these controllers fundamental to semiconductor process tools will also support the market growth in the foreseeable years. Furthermore, the escalating implementation of mass flow controllers in oil & gas and petrochemical industries for the measurement of gas flow is also highly supporting the high demand in the mass flow controller market.

Segmentation of Market: Mass Flow Controller

The study by MRFR also digs some segmentation of the global mass flow controller market, which has been done through connection type, flow measurement, material type, connectivity technology, application.

Among the connection type segment, the mass flow controller market has included direct and indirect.

Among the flow measurement segment, the market is further included low, medium, and high.

Among the material type segment, the market has included stainless steel and exotic alloys.

Among the connectivity technology segment, the market for the global mass flow controller has classified into Profibus, analog, Ethercat, RS-485, Modbus TCPIP, Ethernet, and others. The global mass flow controller market has a wide area of applications in industries of chemical, semiconductor, petroleum, food and beverages, water and waste treatment, and oil &gas.

Get Full Report @ https://www.marketresearchfuture.com/reports/mass-flow-controller-market-4975

Region-Wise Analysis

Region-wise, the study moves forward for analysis of the global mass flow controller market in various regions such as Asia-Pacific, North America, Europe, and the Rest of the World.

The North America region is led mainly by the U.S., is studied to scrutinize gains throughout the forecasted period in the mass flow controller market. This regional growth is mainly propelled by robust pharmaceutical and petrochemical industries in the U.S.

The Asia Pacific is also expected to acquire the prevalent share of the mass flow controller market during the forecast period. The mass flow controller market in the emerging countries of India, China, and Japan, are expected to inflate at the highest CAGR due to the escalating technological advances in medical and healthcare devices in support of the increasing population of these countries.

Electronics and semiconductor manufacturers in the European region are also escalating their production, which is again pressurizing the MFC manufacturers to boost their production. The mass flow controller market players are observing significant necessitate for ease of technology in MFCs, which will allow the system to be impervious or capable of autocorrecting the gas flowing throughout. These developments are likely to bolster the market in the coming years in the European region.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

Contact:

Market Research Future

+1 646 845 9312

Email: [email protected]

0 notes

Text

Top Flange Manufacturer in Delhi | SS & MS Flanges at Best Price

Delhi is home to top flange manufacturers supplying stainless steel (SS), mild steel (MS), and carbon steel flanges for industries like oil & gas, construction, power plants, and chemical processing. Manufacturers ensure ASME, ANSI, API, and ISO-certified products with customized solutions.

Best Flange Manufacturers in Delhi

1. Star Metal & Tubes

✅ Specialist in SS & MS flanges ✅ Bulk order discounts & fast shipping ✅ Custom machining available

2. Vinayak Metals

✅ ASME, ANSI, API-certified flanges ✅ Supplier for oil & gas, power, and construction industries ✅ Competitive pricing & international exports

3. Metcore Steel & Alloys

✅ ISO 9001-certified manufacturer ✅ Provides slip-on, weld neck, and blind flanges ✅ Custom sizes, coatings & pressure ratings

4. Riddhi Siddhi Metals

✅ Stockist of industrial flanges in Delhi ✅ Large inventory for immediate dispatch ✅ Offers heat-treated & corrosion-resistant options

Types of Flanges & Their Applications

Flange TypeDescriptionIndustry ApplicationsSlip-On FlangeSlides over the pipe & welded.Low-pressure pipelinesWeld Neck FlangeHigh-strength connection with long hub.Oil & gas, power plantsBlind FlangeSeals pipeline ends.Pressure testing & storage tanksThreaded FlangeScrewed onto pipes, no welding needed.Small-diameter pipingSocket Weld FlangeWelded on one side for strength.High-pressure applicationsLap Joint FlangeWorks with stub ends for easy removal.Maintenance-heavy pipingOrifice FlangeUsed for flow measurement.Fluid metering & industrial piping

Why Choose Flange Manufacturers in Delhi?

Affordable Prices – Direct manufacturer pricing & bulk discounts.

Certified Quality – ASME, ANSI, API, and ISO 9001-approved flanges.

Fast Turnaround – Stock availability with quick dispatch.

Custom Options – Special coatings, non-standard sizes, and pressure ratings.

Global Supply – Exporting to USA, UK, UAE, Europe, and Asia.

Industries Using Flanges in Delhi

Oil & Gas – Pipelines, refineries, offshore drilling

Power Plants – Thermal, hydro, and nuclear stations

Chemical & Petrochemical – Corrosion-resistant piping

Water Treatment – Desalination & wastewater projects

Shipbuilding & Marine – Offshore structures & vessels

Food & Beverage – Hygienic & stainless steel applications

SEO & Digital Marketing Strategy for Flange Manufacturers

Google My Business (GMB) Optimization – Improve local search rankings.

Backlink Building – List on TradeIndia, Justdial, IndiaMART & industry directories.

Schema Markup Implementation – Use FAQ & Product Schema for better SEO.

Content Marketing – Publish industry insights, technical blogs, and case studies.

Social Media & Ads – Promote on LinkedIn, Facebook & Instagram to reach buyers.

FAQs

Q1: What materials are commonly used for flanges?

A: Flanges are made from stainless steel (SS 304, SS 316), mild steel (MS), and carbon steel for different industrial needs.

Q2: How do I choose the right flange for my project?

A: Consider pipe size, pressure rating, material compatibility, and certification (ASME/ANSI/API) before purchasing.

Q3: Are Delhi-based flange manufacturers export-ready?

A: Yes, many manufacturers export globally and meet international quality standards.

Q4: Do manufacturers in Delhi offer custom flanges?

A: Yes, they provide custom machining, coatings, and non-standard dimensions.

#FlangeManufacturer#FlangesDelhi#IndustrialFlanges#SteelFlanges#PipingSolutions#OilAndGasIndustry#PetrochemicalIndustry#PipelineSolutions#EngineeringSupplies#MadeInIndia#StainlessSteelFlanges#CarbonSteelFlanges#ASMEFlanges#ANSIFlanges#IndustrialSupplier#FlangeExporters#B2BManufacturing#GMBOptimization#TradeIndia#Justdial#IndiaMART

1 note

·

View note

Text

Best Pipe Flange Manufacturer in India | Certified & Reliable

Pipe flanges are essential for connecting pipes, valves, and pumps in various industries, including oil & gas, power plants, and chemical processing. Indian manufacturers provide high-quality stainless steel, carbon steel, and alloy flanges with ASME, ANSI, and ISO certifications, ensuring durability and efficiency.

Top Pipe Flange Manufacturers in India

1. Aashish Steel

✅ Specializes in stainless steel, duplex, and super duplex flanges ✅ Exports to 40+ countries ✅ Custom machining and bulk order discounts

2. Petromat Oil & Gas Equipment Pvt. Ltd.

✅ Supplier of industrial & pipeline flanges ✅ Quick delivery across India & globally ✅ High-pressure & corrosion-resistant options

3. Rajendra Industrial Corporation

✅ Stockist of ASME, ANSI, API, and DIN flanges ✅ Immediate dispatch for urgent orders ✅ Custom coatings & specialized finishes

4. Kiah Metallurgical India

✅ ISO 9001:2015 certified supplier ✅ Wide range of SS, CS, and alloy flanges ✅ Competitive pricing with fast shipping

Types of Pipe Flanges & Their Uses

Flange TypeDescriptionApplicationSlip-On FlangeSlides over the pipe and is welded.Low-pressure pipingWeld Neck FlangeHigh strength for extreme conditions.Oil & gas pipelinesBlind FlangeCloses pipe ends securely.Pressure vessels, testing systemsThreaded FlangeScrewed onto pipes without welding.Small-diameter pipingSocket Weld FlangeSocket fitting for durability.High-pressure pipelinesLap Joint FlangeEasy to dismantle for maintenance.Piping with frequent disassemblyLong Weld Neck FlangeExtended hub for high-temp resistance.Power plants, chemical industriesOrifice FlangeUsed with orifice plates for flow measurement.Fluid control & metering

Why Choose Indian Pipe Flange Manufacturers?

Cost-Effective Pricing – Competitive rates compared to global suppliers.

High-Quality Standards – ASME, ANSI, API, and ISO 9001 certified products.

Fast Turnaround Time – Quick manufacturing & delivery across India and worldwide.

Customization Available – Tailored sizes, coatings, and finishes for specific needs.

Strong Export Network – Indian flanges are shipped to USA, UK, UAE, Europe, and Asia.

Industries That Rely on Pipe Flanges

Oil & Gas – Offshore platforms, pipelines, refineries

Power Plants – Steam, nuclear, and gas-based power stations

Chemical & Petrochemical – High-pressure and high-temperature applications

Water Treatment – Desalination plants and wastewater systems

Marine & Shipbuilding – Piping for offshore structures and ships

Food & Beverage – Hygienic-grade flanges for safe processing

SEO & Digital Marketing Strategy for Flange Manufacturers

Google My Business (GMB) Optimization – Improve local visibility in search results.

Backlink Strategy – Get listed on TradeIndia, Justdial, IndiaMART, and industry directories.

Schema Markup Implementation – Use FAQ & Product Schema for enhanced SEO.

Content Marketing – Publish technical blogs, case studies, and industry updates.

Social Media Presence – Engage with buyers on LinkedIn, Facebook, and Instagram.

FAQs

Q1: What is the most commonly used pipe flange?

A: Slip-on flanges are widely used for low-pressure piping systems due to their ease of installation and cost-effectiveness.

Q2: How do I choose the right flange material?

A: Stainless steel (SS 304, SS 316) is best for corrosion resistance, while carbon steel is ideal for high-pressure environments.

Q3: What certifications should a pipe flange manufacturer have?

A: Look for ASME, ANSI, API, ISO 9001, and PED certifications to ensure high-quality standards.

Q4: Can Indian manufacturers provide customized pipe flanges?

A: Yes, top manufacturers offer custom drilling, special coatings, and non-standard sizes based on project requirements.

#PipeFlange#FlangeManufacturer#IndustrialFlanges#SteelFlanges#PipingSolutions#OilAndGasIndustry#PetrochemicalIndustry#PipelineSolutions#EngineeringSupplies#MadeInIndia#StainlessSteelFlanges#CarbonSteelFlanges#ASMEFlanges#ANSIFlanges#IndustrialSupplier#FlangeExporters#B2BManufacturing#GMBOptimization#TradeIndia#Justdial#IndiaMART

1 note

·

View note

Text

Top Flange Manufacturers in India | Best Quality & Pricing

India is a global leader in flange manufacturing, providing cost-effective and durable solutions for oil & gas, petrochemicals, construction, and power industries. With strict quality standards, Indian manufacturers ensure high-performance flanges for domestic and export markets.

Top Flange Manufacturers in India

1. Bharat Forge Limited

✅ One of India's largest forging companies. ✅ Produces industrial and pipeline flanges. ✅ Supplies to automotive, power, and oil & gas sectors.

2. Rajendra Industrial Corporation

✅ Leading exporter of stainless steel flanges. ✅ Complies with ANSI, ASME, and API standards. ✅ Customizable sizes and finishes available.

3. Riddhi Siddhi Metal Impex

✅ Offers a wide range of carbon steel, alloy steel, and SS flanges. ✅ ISO 9001:2015 certified manufacturer. ✅ Competitive pricing for bulk orders.

4. Kiah Metallurgical India

✅ Specializes in high-pressure industrial flanges. ✅ Provides slip-on, weld neck, and socket weld flanges. ✅ Fast delivery and global distribution.

Types of Flanges & Applications

Flange TypeDescriptionCommon ApplicationsSlip-On FlangeFits over the pipe and welded in place.Low-pressure systemsWeld Neck FlangeDesigned for high-stress applications.Oil & gas, power plantsBlind FlangeUsed to close pipe ends.Pressure vessels, piping systemsThreaded FlangeScrewed onto a pipe without welding.Small-diameter pipingSocket Weld FlangePipe is inserted and welded at one end.High-pressure pipelinesLap Joint FlangeWorks with stub-end fittings.Dismantling pipelinesLong Weld Neck FlangeSimilar to weld neck but with a longer hub.High-temperature applicationsOrifice FlangeUsed with flow meters for measuring fluid.Fluid control systems

Key Factors When Buying Flanges

Material Type – Stainless steel, carbon steel, and alloy steel.

Pressure Ratings – ANSI/ASME Class 150 to 2500.

Industry Compliance – ASME, ANSI, API, DIN, JIS certifications.

Customization – Options for size, coating, and drilling patterns.

Supplier Reliability – ISO certification, reputation, and lead time.

Pricing & Bulk Discounts – Compare suppliers for cost-effective solutions.

Industries That Use Flanges

Oil & Gas – Offshore drilling, refineries, pipelines.

Power Plants – Steam, gas turbines, and cooling systems.

Petrochemicals – Chemical processing and high-pressure piping.

Water Treatment – Wastewater management and desalination.

Shipbuilding – Marine piping and offshore platforms.

Food Processing – Hygienic flanges for sanitary applications.

SEO & Digital Marketing Strategy for Flange Businesses

Google My Business (GMB) Optimization – Keep business information updated.

Backlink Strategy – List products on TradeIndia, Justdial, IndiaMART, ExportHub.

Schema Markup – Implement FAQ & Product Schema for better ranking.

Content Marketing – Publish blogs, case studies, and whitepapers.

LinkedIn & Social Media Engagement – Promote B2B services and new products.

FAQs

Q1: What materials are best for industrial flanges?

A: Stainless steel (SS 304, SS 316) is corrosion-resistant, while carbon steel is cost-effective for general applications.

Q2: How do I choose the right flange type?

A: Consider pressure rating, pipe size, and application needs to determine the best flange type.

Q3: What standards should I check when buying flanges?

A: Look for ASME/ANSI B16.5, API, DIN, and JIS standards for compatibility.

Q4: Can I get custom flanges for my project?

A: Yes, many manufacturers offer customized flange sizes, coatings, and drilling options.

1 note

·

View note

Text

Flow Meters Market: Global Industry Analysis and Forecast 2023 – 2030

Global Flow Meters Market was valued at USD 6.88 Billion in 2021 and is expected to reach USD 10.64 Billion by the year 2028, at a CAGR of 6.43% .

Flowmeters is also known as flow sensors, are electronic devices that primarily measure or manage the flow rate of liquids and gasses within the pipes and tubes. The sensors are normally connected to the gauges to render their measurements; nevertheless, they can also be connected to computers and digital interfaces. In addition, they are also used in HVAC systems, medical devices, chemical factories, and septic systems. These meters can especially measure leaks, blockages, pipe bursts, and switching in the liquid concentration, due to any abomination or pollution. They measure the flow rate of a fluid, liquid, or gas when it passes through a confined transmission system. There are various principles of flow meters, such as orifice meters, venturi meters, rotameters, flow nozzles, and others.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15846

The latest research on the Flow Meters market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Flow Meters industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Flow Meters market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

Leading players involved in the Flow Meters Market include:

ABB Ltd, Siemens AG, Bronkhorst High-Tech BV, Honeywell International Inc., Emerson Electric Co., SICK AG, Omega Engineering Inc. (Spectris PLC), Christian Bürkert GmbH & Co. KG, TSI Incorporated, Keyence Corporation, Sensirion AG, Azbil Corporation, Endress+Hauser AG, KROHNE Messtechnik GmbH and Other major Players.

If You Have Any Query Flow Meters Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15846

Segmentation of Flow Meters Market:

By Technology

Coriolis

Electromagnetic

Differential Pressure

Ultrasonic

Others

By End-User

Oil & Gas

Water & Wastewater

Chemical & Petrochemical

Food & Beverage

Power Generation

Pulp & Paper

Other

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Flow Meters market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Flow Meters market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Flow Meters market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Flow Meters market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Flow Meters Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15846

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Email: [email protected]

#Flow Meters#Flow Meters Market#Flow Meters Market Size#Flow Meters Market Share#Flow Meters Market Growth#Flow Meters Market Trend#Flow Meters Market segment#Flow Meters Market Opportunity#Flow Meters Market Analysis 2023

0 notes

Text

The Hottest Tech Drops At SCA Expo 2019

For the biggest coffee weekend of the year—the 2019 Speciality Coffee Association Expo in Boston—we sent intrepid journalist and Chocolate Barista founder Michelle Johnson onto the showfloor to put her finger on the pulse of what’s new and exciting in the coffee industry today. Last week she told us what was lit; today she’s reporting on the show’s hottest new tech.

Wootz 7 Grinder

From South Korean company, Global CMS, the Wootz 7 Grinder (named after wootz steel) is the new kid on the block officially making its US debut. Ambassador Nick Cho of Wrecking Ball Coffee demoed the grinder, highlighting the simplicity of the plug-and-play machinery inside (a technician’s dream), the digital auto-calibration feature of the burrs to its previous setting, and the rotating wire that evenly distributed the coffee as it entered the portafilter. I’ve been a part of a distribution tool debate and had the opportunity to mess around with this manually. It’s cool to see it automated so seamlessly—especially with a portafilter lock that lets the barista go hands-free. The Wootz 7 Grinder is currently available in Korea and will hopefully begin distributing in the US by the end of the year pending UL and NSF certifications. It will be listed at $2,000 USD.

Mahlkönig E65S

The sleek, slim profile of the Mahlkönig E65S debuted this weekend in Boston, and we’re sure it’ll be an attractive addition to the bar tops of our favorite coffee shops soon. The E65S boasts several new features that promote cleaner and more efficient espresso grinding. One of those features is the digital display with a turn and push selection knob allowing for swift dial-in—six recipes can be programmed as well as any on-the-fly adjustments for those midday rushes. Say goodbye to espresso waste as the adjustable spout is designed to chute four to seven grams of espresso per second (on average) directly into the portafilter. The bean hopper is more durable than Mahlkönig grinders of the past and the whole thing grinds quieter too. The Mahlkönig E65S is listed at $2,200 USD and will begin shipping in May.

Coffunity

Transparency is increasingly a watchword for the coffee industry, up and down the value chain. With increased access to information comes an informed consumer base, better, sustainable pricing for farmers, and increased traceability. Coffunity aims to push this mission further through their app made for consumers, roasters, and producers. Consumers can take a photo of a coffee label and the app will identify and display ratings, reviews, and tasting notes from the coffee community. They can learn more about the coffee’s origin from who produced it to how it was processed (and what that means). Roasters are able to see what others are saying about the coffee. Soon, coffee producers will also be able to see what others are saying about their coffee and how much it sells for, opening up access to information that’s been closed to many for too long. This 2018 SCA Best New Product winning app is available to download on the App Store and Google Play now.

Acaia Pearl Model S

Acaia is back at it again with cutting edge technology to help coffee professionals and home brewers alike up their coffee game. As the Acaia Pearl Model S turns on, it welcomes you with a personalized message you can customize on the accompanying app. This app itself is extremely interactive, allowing for brewers to share their recorded brew recipes to anyone and download them from their friends or the database of recipes uploaded by coffee companies themselves. What’s even more fascinating is that when a recipe is downloaded, it won’t only display on your phone or table but the scale will display each step of the brew process in real-time for brewers to follow along.

The cherry on top is possibly the flow-rate meter that can display by itself or alongside the timer and water weight to indicate the consistency of the pour. On top of all of that, the Pearl Model S still looks so damn good. I don’t know about you but I think I just received the key to being the next World Brewers Cup Champion. The Acaia Pearl Model S is available now online for $185 USD.

MAVAM Mach 2

A disruptor in the undercounter espresso machine game since 2015, Seattle-based MAVAM has officially launched its oncounter espresso machine, the Mach 2. It has the same inner components and temperature stability of its undercounter sibling, and still has a low profile on bar (12.5 in./32 cm. tall) in true MAVAM fashion. The nicest feature of the Mach 2 is the tap button—both on the side for the cool touch steam wand power and on the grouphead. Seeing the machine in action, the tap feature really does promote efficiency for any barista running it, and shows how the espressso machine industry is taking ergonomics and workflow concerns seriously for the next generation of baristas. MAVAM’s Mach 2 is available to order now at $16,000 USD (two-group) and $19,000 USD (three-group).

Michelle Johnson is a news contributor at Sprudge Media Network, and the founder and publisher of The Chocolate Barista. Read more Michelle Johnson on Sprudge.

The post The Hottest Tech Drops At SCA Expo 2019 appeared first on Sprudge.

The Hottest Tech Drops At SCA Expo 2019 published first on https://medium.com/@LinLinCoffee

0 notes