#electricaldistribution

Explore tagged Tumblr posts

Text

#PowerDistributionUnits, #PDUMarket, #DataCenters, #EnergyEfficiency, #SmartPDU, #Colocation, #ITInfrastructure, #GlobalMarketAnalysis, #ElectricalDistribution, #PowerManagement

#PowerDistributionUnits#PDUMarket#DataCenters#EnergyEfficiency#SmartPDU#Colocation#ITInfrastructure#GlobalMarketAnalysis#ElectricalDistribution#PowerManagement

0 notes

Text

Regional Insights on the Power Distribution Units Market

Global PDU Market: Regional Trends, Innovation, Growth Drivers, and Industry Impact

As the world becomes increasingly digital, data centers are growing rapidly—and with them, the demand for efficient power management solutions. Power Distribution Units (PDUs), essential for managing and distributing power in server racks, are evolving fast due to technological innovation, regional market dynamics, and rising energy concerns. This article explores the key factors shaping the global PDU market: regional adoption differences, cutting-edge technologies, growth projections, sustainability efforts, and potential supply chain disruptions.

Regional Differences Impacting PDU Adoption

PDU adoption rates vary widely across regions. In North America and Europe, where data centers are more advanced, there's strong demand for intelligent PDUs that support remote monitoring, load balancing, and integration with data center infrastructure management (DCIM) systems. These regions are also influenced by strict energy regulations and the rising costs of electricity, pushing organizations to prioritize efficiency.

Meanwhile, Asia-Pacific—especially countries like China and India—is seeing rapid growth in data center construction. Here, the demand is high, but buyers often focus on affordable, scalable PDU solutions rather than premium features. In emerging markets across Latin America and Africa, basic PDUs with essential safety features like surge protection are gaining popularity, especially in areas with unstable power grids. These regional nuances are shaping how manufacturers design and market their PDU offerings worldwide.

Technological Innovations Transforming PDUs

Modern PDUs are no longer just basic power strips. Innovation is pushing PDUs to become intelligent, connected, and more adaptable to data center needs. Key innovations include:

Real-time power monitoring and analytics, allowing operators to detect problems early and optimize performance.

Modular and scalable designs that make it easier to adapt PDUs to different rack setups and future upgrades.

Compact and ruggedized units for edge computing environments that require durable, space-efficient solutions.

PoE (Power-over-Ethernet) capability, which can streamline infrastructure by combining power and data in a single connection.

Support for renewable energy systems, such as solar or wind, allowing data centers to shift toward greener operations.

These features make PDUs not just tools for power delivery but vital components in optimizing overall infrastructure efficiency.

Market Growth Projections and Their Influence

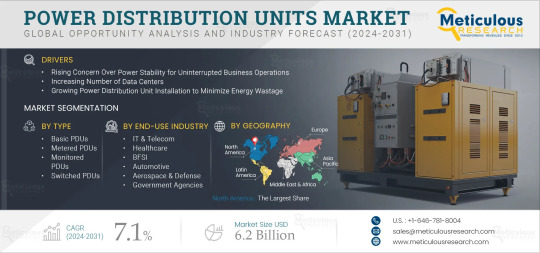

Market projections are a valuable guide for businesses planning their infrastructure investments. According to a recent report by Meticulous Research®, the global PDU market is expected to reach $6.2 billion by 2032, growing at a 7.1% compound annual growth rate (CAGR) from 2025 to 2032. This steady growth reflects the increasing need for reliable, intelligent power solutions in the expanding global data center landscape.

For businesses, this means more focus on planning scalable infrastructure. Data centers must be equipped to handle rising power demands, and procurement teams need to anticipate budget requirements for both new installations and system upgrades. These projections also encourage organizations to evaluate supplier diversity and ensure they have reliable access to PDUs in a growing, competitive market.

The Role of Energy Efficiency in Market Expansion

Energy efficiency has become a top priority in data center operations. As power usage rises, intelligent PDUs play a key role in helping organizations cut costs and meet sustainability goals. Features like outlet-level monitoring, remote rebooting, and load balancing contribute to reducing wasted energy and improving operational performance.

Beyond cost savings, energy-efficient PDUs support carbon reduction initiatives and regulatory compliance. In regions with strict environmental standards, like the EU and parts of Asia, deploying smart PDUs is often a necessity rather than an option. They also help optimize thermal management, ensuring efficient cooling and reducing stress on HVAC systems—ultimately prolonging equipment lifespan.

Supply Chain Risks in the Power Distribution Industry

While demand for PDUs is on the rise, the global electronics industry still faces supply chain disruptions. PDUs rely on key components like sensors, semiconductors, and network chips—all of which have experienced shortages in recent years. These issues can delay manufacturing and product availability, affecting project timelines for data centers.

Geopolitical tensions, export restrictions, and rising transportation costs further complicate the situation. Companies facing long lead times may be tempted to switch to alternative suppliers or lower-grade parts, which increases the risk of system failures. To manage this, many data center operators are now diversifying their supply base, holding backup inventory, and prioritizing partnerships with local manufacturers for critical components.

Leading Companies in the PDU Market

Several major players are driving innovation and reliability in the global PDU space. These companies offer a range of solutions, from basic rack-mounted units to intelligent PDUs with advanced monitoring and automation features. Key players identified in the Meticulous Research® report include:

Eaton Corporation, known for high-performance rack PDUs and energy-efficient technologies; Schneider Electric, a leader in smart infrastructure and modular data center solutions; Vertiv Group, offering advanced PDU systems with real-time monitoring and control features; Tripp Lite (a division of Eaton), which provides a wide range of PDUs for enterprise and small business applications; and Raritan (a brand of Legrand), specializing in intelligent PDUs with outlet-level metering and environmental sensors.

These companies are playing a crucial role in helping businesses transition to smarter, more sustainable, and resilient power distribution infrastructures.

Conclusion

The global PDU market is evolving quickly—driven by regional growth patterns, cutting-edge technology, sustainability pressures, and global economic shifts. With a strong projected growth to $6.2 billion by 2032 and a CAGR of 7.1%, the market is clearly on an upward trajectory.

Organizations planning their data infrastructure strategies must consider not just cost and performance, but also energy efficiency, supply chain resilience, and long-term scalability. And with major players like Eaton, Schneider Electric, Vertiv, Tripp Lite, and Raritan leading the way, the future of power distribution is smarter, greener, and more reliable than ever.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5959

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#PowerDistributionUnits#PDUMarket#DataCenters#EnergyEfficiency#SmartPDU#Colocation#ITInfrastructure#GlobalMarketAnalysis#ElectricalDistribution#PowerManagement

0 notes

Text

What Is a Feeder Pillar? Its Parts, Types, and Benefits

A feeder pillar is an essential component in electrical distribution systems, acting as a central hub for managing and distributing power. Whether used in residential, commercial, or industrial settings, a feeder pillar provides a secure and efficient way to house electrical equipment and ensure the smooth flow of electricity. In this article, we'll explore what a feeder pillar is, break down its parts, explore the different types available, and discuss the many benefits it offers.

Understanding the Feeder Pillar

A feeder pillar is a type of enclosure used to house electrical control and distribution systems. It typically stands outdoors and is used to manage electricity supply from one main source to various subsidiary circuits. These pillars are usually made of durable materials such as stainless steel, galvanized steel, or GRP (Glass Reinforced Plastic) to withstand harsh environmental conditions.

Often referred to as a distribution box or power distribution unit, the feeder pillar plays a critical role in the safe and organized distribution of electricity. It serves as a junction point that connects incoming power from transformers or substations and distributes it to different areas through outgoing cables.

Key Components of a Feeder Pillar

A typical feeder pillar includes several important components, each serving a unique role in electrical distribution:

1. Main Switches and Circuit Breakers

These components help control the power flow into the feeder pillar. They allow operators to isolate circuits during maintenance or emergencies and protect against overloads and faults.

2. Busbars

Busbars are metallic strips or bars made of copper or aluminum. They conduct electricity within the feeder pillar and distribute it efficiently to different outgoing circuits.

3. Outgoing Terminals

These are the connection points where outgoing cables are attached. They direct electricity from the feeder pillar to various areas or devices.

4. Earth Bar and Neutral Link

These provide grounding and neutral points for electrical safety. They help prevent electric shocks and equipment damage by directing fault currents safely to the ground.

5. Enclosure or Cabinet

The outer casing protects the internal components from weather, dust, and unauthorized access. A robust enclosure is vital for long-term durability, especially for outdoor installations.

6. Feeder Pillar Key and Lock System

Security is important in electrical distribution. A feeder pillar key ensures only authorized personnel can access the internal components, reducing the risk of tampering or accidents.

Types of Feeder Pillars

Feeder pillars come in a variety of types, each suited for different applications and environments. Here are the most common types:

1. Standard Feeder Pillars

These are used in general electrical distribution settings such as residential areas, public lighting, or low-voltage networks. They provide basic functionality and protection.

2. Weatherproof Feeder Pillars

Made with IP-rated enclosures, these are suitable for outdoor use. They offer high resistance against dust, moisture, and corrosion, making them ideal for roadside and industrial applications.

3. Stainless Steel Feeder Pillars

Built for strength and longevity, stainless steel units are commonly used in harsh environments like coastal regions or chemical plants. They resist rust and offer a polished look.

4. GRP Feeder Pillars

Constructed from Glass Reinforced Plastic, these pillars are lightweight, non-conductive, and corrosion-resistant. GRP feeder pillars are increasingly popular due to their cost-effectiveness and ease of installation.

5. Customized Feeder Pillars

These are tailored to meet specific requirements, such as additional circuit capacity, integrated smart controls, or aesthetic design. They are often used in commercial buildings and urban infrastructure projects.

Applications of Feeder Pillars

Feeder pillars are used in a wide range of sectors and applications:

Street lighting control

Industrial electrical distribution

Construction sites

Railway and transport infrastructure

Airports and seaports

Shopping centers and commercial complexes

Renewable energy projects

Their flexibility and adaptability make them essential for managing electricity in both temporary and permanent settings.

Benefits of Using Feeder Pillars

Feeder pillars offer numerous advantages that make them a smart investment in any electrical distribution system. Here are the key benefits:

1. Improved Electrical Safety

Feeder pillars are designed with high safety standards. They include circuit protection devices, grounding, and secure enclosures that reduce the risk of fire, electric shock, or equipment failure.

2. Efficient Power Distribution

A well-designed electrical feeder pillar allows electricity to be distributed efficiently across multiple circuits. This helps avoid power loss and ensures stable voltage levels throughout the network.

3. Durability and Weather Resistance

Thanks to materials like stainless steel and GRP, feeder pillars are built to withstand extreme weather and environmental conditions. This durability reduces maintenance costs and extends the service life of the unit.

4. Customizability

Manufacturers offer a range of customization options, from size and color to internal layout and locking mechanisms. Whether you need a basic unit or a complex setup, there’s a solution available.

5. Easy Access and Maintenance

With features like removable doors and secure locking systems, feeder pillars provide easy access for technicians. Regular inspections and repairs can be carried out without hassle.

6. Enhanced Network Control

Modern feeder pillars can be integrated with monitoring and control systems. This allows remote management, fault detection, and load balancing, leading to better network performance.

Selecting the Right Feeder Pillar

When choosing a feeder pillar, several factors must be considered:

Location: Outdoor vs. indoor use

Voltage requirements: Low, medium, or high voltage

Material: Stainless steel, GRP, galvanized steel

Capacity: Number of outgoing circuits and load

Security features: Lock type, tamper resistance, feeder pillar key access

It’s also important to comply with local electrical codes and standards to ensure safety and reliability.

Installation and Maintenance Tips

Proper installation and regular maintenance are essential to maximize the benefits of a feeder pillar. Here are a few tips:

Ensure a stable, level foundation to support the feeder pillar box

Use certified components and follow manufacturer guidelines

Schedule periodic inspections to check for corrosion, wear, or electrical faults

Keep a spare feeder pillar key for emergencies

Label circuits clearly for easy troubleshooting

Trends in Feeder Pillar Technology

With the growing demand for smart infrastructure, feeder pillars are evolving to include modern features:

Smart metering integration

Remote monitoring via IoT

Energy usage analytics

Renewable energy compatibility

Modular design for scalability

These advancements help meet the increasing needs for energy efficiency, sustainability, and digital connectivity in power distribution systems.

Conclusion

A electricity feeder pillar is more than just a metal box—it’s a vital part of any efficient and secure electrical distribution system. From powering street lights to managing complex industrial grids, feeder pillars bring organization, safety, and reliability to electrical networks. Whether you need a robust unit for outdoor use or a customized solution for a high-tech facility, choosing the right feeder pillar can significantly improve your power management strategy.

As technology continues to advance, feeder pillars will remain a key element in the infrastructure that powers our homes, cities, and industries. Their importance in delivering safe, efficient, and scalable energy solutions cannot be overstated.

0 notes

Text

Upgrade Your Power Distribution System! ⚡

Introducing the 32-125A AC23A 690VAC 4-Pole (3P+N) Isolating Switch – Designed for Demanding Outdoor Environments! Featuring an IP65 Metal Enclosure (RAL7035) for superior dust & water resistance and rugged durability.

✅ Safety First: Door interlock handle, padlockable in OFF position, IP20 finger-safe terminals, includes door earthing cable. ✅ Easy Installation: Top/Bottom removable cable entry plates for flexible wiring. ✅ Compliance Assured: Certified to IEC/EN 60947-3, with UKCA & CE marks. ✅ Fuses Included – Ready to Use!

Deliver reliable isolation and protection for your industrial or commercial applications! 🛡️

🔗 Learn more: www.onccy.com 📧 Tech Support: [email protected] | 📱 WhatsApp: +86 17301617015

#IsolatorSwitch#ElectricalDistribution#IndustrialElectric#PowerDistribution#Switchgear#OutdoorEnclosure#IP65#IEC60947#UKCA#CE#ElectricalSafety#HVAC#IndustrialEngineering#CommercialElectric#ONCCY#ElectricalProducts

0 notes

Text

⚡️ Powering Projects Across the Nation with Unmatched Distribution! ⚡️

At Ledes, we're not just about top-quality PVC conduit, fittings, and boxes - we're also dedicated to delivering them seamlessly to YOUR job site, wherever it may be.

Our robust nationwide distribution network ensures:

Reliable Supply: No project delays! We have the inventory and logistics to keep your projects moving.

Fast & Efficient Delivery: Get what you need, when you need it, with our streamlined shipping process.

Coast-to-Coast Coverage: No matter where you are in the US, Ledes has you covered.

Experience the Ledes difference! Visit our website to explore our full range of electrical solutions and find a distributor near you.

➡️ https://www.ledestube.com/

#electricaldistribution#nationwidecoverage#PVCconduit#electricalfittings#junctionboxes#construction#electricalindustry#Ledes

0 notes

Text

0 notes

Text

Exporter of HV & MV Panels in Jordan

Sempra Electric is a Manufacturer and Exporter of HV & MV Panels in Jordan. Sempra Electric, established in 1996, manufactures all its products in accordance with international quality standards. We manufacture Diesel Generators, LV Panels, HV Panels, Transformers, UPS & Battery Banks, Voltage Stabilizers, and other products, all meeting international standards. HV panels are responsible for managing high-voltage systems, whereas MV panels are designed to handle medium-voltage systems in electrical distribution. Our HV & MV Panels function as switches, overseeing normal load current, clearing faults, and regulating power system parameters. And enabling metering functions, thereby ensuring efficient and reliable power distribution. If electricity arrived at home at high voltage, it'd be chaotic. HV and MV panels stabilize voltage, ensuring safe electricity delivery. High Voltage (HV) and Medium Voltage (MV) panels are critical components in the electrical distribution system. Designed to handle and manage high and medium voltage power respectively. Their main purpose is to ensure the safe and efficient distribution and control of electrical power. Here is an expanded overview of their features and functionalities. We use our HV and MV panels to distribute power in industries, commercial buildings, utilities, renewable energy, data centers, hospitals, transportation, mining, oil and gas, telecommunications, water treatment, and military installations. Sempra Electric is a Manufacturer and Exporter of HV & MV Panels in Jordan and places like Zarqa, Irbid, Russeifa, Sahab, Ae Ramtha, Aqaba, Mafraq, Madaba, As-Salt, Al-Jizah, Aydoun, Jerash, Beit Ras, Al Husn, Naour, Karak, Kufranjah. If you have any questions or need more information, feel free to reach out to us. Read the full article

#AeRamtha#AlHusn#Al-Jizah#Aqaba#As-Salt#Aydoun#BatteryBanks#BeitRas#commercialbuildings#DataCenters#DieselGenerators#ElectricalDistribution#Electricalengineering#Electricalequipment#Electricalsafety#Electricalswitches#Energysector#Exporter#ExporterofHV&MVPanelsinJordan#Faultclearing#Flexiblepanels#Highvoltagesystems#Hospitals#HVPanels#Industrialapplications#Internationalqualitystandards#Irbid#Jerash#Jordanexporter#Karak

0 notes

Text

The iPin Spatial Ruler Pro is the ideal optical laser measuring instrument created to simplify life for individuals who require quick and convenient measurements with a smart phone on a regular basis.

For best price of the product, do reach us on 𝐢𝐧𝐟𝐨@𝐦𝐨𝐡𝐧𝐨𝐭𝐢𝐧𝐬𝐭𝐫𝐮𝐦𝐞𝐧𝐭𝐬.𝐜𝐨𝐦

You can also reach us on +91-9821614731

#panelbuilders#panelessolares#processindustry#electricaldistribution#mohnotinstruments#electricalcontractor#measurement#megger#resistance#voltage#kew3552

0 notes

Photo

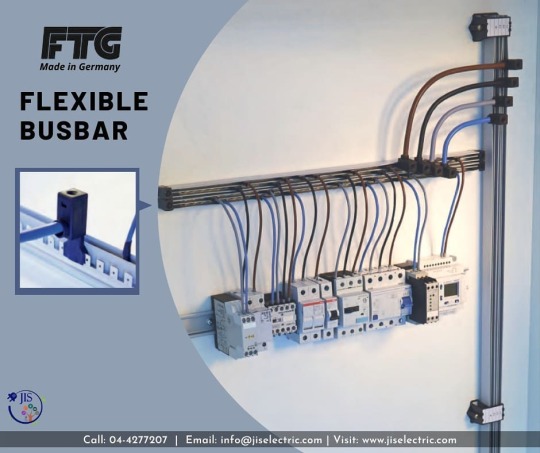

Flexible systems are available in #FTG for power distribution which can be adapted in almost any way from individual requirements by planners to fitters on site. With the Auxigaine #busbar, for example, as many poles as required are possible; it is mounted at switch cabinet height – which all the flexible systems have in common – and in/outfeed can be added or removed extremely easily. To read more, visit www.jiselectric.com #busbars #flexiblesolutions #electricalindustry #electricalengineers #buildingconstruction #buildingmaterials #electricalsupplies #electricaldistribution #switchgears #lowvoltage #jiselectric #dubai #UAE (at JIS Electrical Trading LLC) https://www.instagram.com/p/CSLtMX8Bh7f/?utm_medium=tumblr

#ftg#busbar#busbars#flexiblesolutions#electricalindustry#electricalengineers#buildingconstruction#buildingmaterials#electricalsupplies#electricaldistribution#switchgears#lowvoltage#jiselectric#dubai#uae

0 notes

Video

instagram

(LINK IN BIO) Watch this video to know what is new for electrical industry in budget 2021.. https://t.co/1yGnUjfL7l #wechitraenterprises #budget2021 #electricalpower #powerdistribution #powersector #renewableenergy #seci #ireda #solarsolutions #greenenergy #greenindia #hydrogen #hydrogenenergy #ev #electricvehicle #electricalengineeringstudent #electricalcontractor #electricalengineers #electricalgeneration #electricaldistribution #electricalconsultants #electricalmanufacturing #energyconservation https://www.instagram.com/p/CK5_QX5H7lG/?igshid=hm9a9v97str6

#wechitraenterprises#budget2021#electricalpower#powerdistribution#powersector#renewableenergy#seci#ireda#solarsolutions#greenenergy#greenindia#hydrogen#hydrogenenergy#ev#electricvehicle#electricalengineeringstudent#electricalcontractor#electricalengineers#electricalgeneration#electricaldistribution#electricalconsultants#electricalmanufacturing#energyconservation

0 notes

Photo

Sola KAYDIRINIZ ⬅️ . . . Diğer Çeşitlerimiz İçin www.x24elektri̇k.com Adresimizi Ziyaret Edebilir yada Detaylı Bilgi VE Sipariş İçin WhatsApp NUMARAMIZ (0546) 727 24 24 📞 . . (İSTANBUL İÇİ ÜCRETSİZ TESLİMAT 🚛 ) .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . #electrical #electrician #electricianslife #electricalengineering #electricalengineeringlife #electricalengineeringworld #electricalengineeringfun #electricalacademy #electricallines #electricaldistribution #electricitylines #highvoltagelines #electrictower #electricaltower #funnyscience #funnyengineer #elektrik #elektronik #elektrikelektronikmühendisliği #kablolama #yüksekgerilim #yuksekgerilim #ortagerilim #elektrikçi #mühendislik #elektrikdireği #teknisyen #tekniker #elektrikdagitim #elektrikhatt (Istanbul Province) https://www.instagram.com/p/B9D7Q1rJ62W/?igshid=gx8edpqol3mh

#electrical#electrician#electricianslife#electricalengineering#electricalengineeringlife#electricalengineeringworld#electricalengineeringfun#electricalacademy#electricallines#electricaldistribution#electricitylines#highvoltagelines#electrictower#electricaltower#funnyscience#funnyengineer#elektrik#elektronik#elektrikelektronikmühendisliği#kablolama#yüksekgerilim#yuksekgerilim#ortagerilim#elektrikçi#mühendislik#elektrikdireği#teknisyen#tekniker#elektrikdagitim#elektrikhatt

0 notes

Text

Power Distribution Units Market Opportunities and Challenges

Global PDU Market: Regional Trends, Innovation, Growth Drivers, and Industry Impact

As the world becomes increasingly digital, data centers are growing rapidly—and with them, the demand for efficient power management solutions. Power Distribution Units (PDUs), essential for managing and distributing power in server racks, are evolving fast due to technological innovation, regional market dynamics, and rising energy concerns. This article explores the key factors shaping the global PDU market: regional adoption differences, cutting-edge technologies, growth projections, sustainability efforts, and potential supply chain disruptions.

Regional Differences Impacting PDU Adoption

PDU adoption rates vary widely across regions. In North America and Europe, where data centers are more advanced, there's strong demand for intelligent PDUs that support remote monitoring, load balancing, and integration with data center infrastructure management (DCIM) systems. These regions are also influenced by strict energy regulations and the rising costs of electricity, pushing organizations to prioritize efficiency.

Meanwhile, Asia-Pacific—especially countries like China and India—is seeing rapid growth in data center construction. Here, the demand is high, but buyers often focus on affordable, scalable PDU solutions rather than premium features. In emerging markets across Latin America and Africa, basic PDUs with essential safety features like surge protection are gaining popularity, especially in areas with unstable power grids. These regional nuances are shaping how manufacturers design and market their PDU offerings worldwide.

Technological Innovations Transforming PDUs

Modern PDUs are no longer just basic power strips. Innovation is pushing PDUs to become intelligent, connected, and more adaptable to data center needs. Key innovations include:

Real-time power monitoring and analytics, allowing operators to detect problems early and optimize performance.

Modular and scalable designs that make it easier to adapt PDUs to different rack setups and future upgrades.

Compact and ruggedized units for edge computing environments that require durable, space-efficient solutions.

PoE (Power-over-Ethernet) capability, which can streamline infrastructure by combining power and data in a single connection.

Support for renewable energy systems, such as solar or wind, allowing data centers to shift toward greener operations.

These features make PDUs not just tools for power delivery but vital components in optimizing overall infrastructure efficiency.

Market Growth Projections and Their Influence

Market projections are a valuable guide for businesses planning their infrastructure investments. According to a recent report by Meticulous Research®, the global PDU market is expected to reach $6.2 billion by 2032, growing at a 7.1% compound annual growth rate (CAGR) from 2025 to 2032. This steady growth reflects the increasing need for reliable, intelligent power solutions in the expanding global data center landscape.

For businesses, this means more focus on planning scalable infrastructure. Data centers must be equipped to handle rising power demands, and procurement teams need to anticipate budget requirements for both new installations and system upgrades. These projections also encourage organizations to evaluate supplier diversity and ensure they have reliable access to PDUs in a growing, competitive market.

The Role of Energy Efficiency in Market Expansion

Energy efficiency has become a top priority in data center operations. As power usage rises, intelligent PDUs play a key role in helping organizations cut costs and meet sustainability goals. Features like outlet-level monitoring, remote rebooting, and load balancing contribute to reducing wasted energy and improving operational performance.

Beyond cost savings, energy-efficient PDUs support carbon reduction initiatives and regulatory compliance. In regions with strict environmental standards, like the EU and parts of Asia, deploying smart PDUs is often a necessity rather than an option. They also help optimize thermal management, ensuring efficient cooling and reducing stress on HVAC systems—ultimately prolonging equipment lifespan.

Supply Chain Risks in the Power Distribution Industry

While demand for PDUs is on the rise, the global electronics industry still faces supply chain disruptions. PDUs rely on key components like sensors, semiconductors, and network chips—all of which have experienced shortages in recent years. These issues can delay manufacturing and product availability, affecting project timelines for data centers.

Geopolitical tensions, export restrictions, and rising transportation costs further complicate the situation. Companies facing long lead times may be tempted to switch to alternative suppliers or lower-grade parts, which increases the risk of system failures. To manage this, many data center operators are now diversifying their supply base, holding backup inventory, and prioritizing partnerships with local manufacturers for critical components.

Leading Companies in the PDU Market

Several major players are driving innovation and reliability in the global PDU space. These companies offer a range of solutions, from basic rack-mounted units to intelligent PDUs with advanced monitoring and automation features. Key players identified in the Meticulous Research® report include:

Eaton Corporation, known for high-performance rack PDUs and energy-efficient technologies; Schneider Electric, a leader in smart infrastructure and modular data center solutions; Vertiv Group, offering advanced PDU systems with real-time monitoring and control features; Tripp Lite (a division of Eaton), which provides a wide range of PDUs for enterprise and small business applications; and Raritan (a brand of Legrand), specializing in intelligent PDUs with outlet-level metering and environmental sensors.

These companies are playing a crucial role in helping businesses transition to smarter, more sustainable, and resilient power distribution infrastructures.

Conclusion

The global PDU market is evolving quickly—driven by regional growth patterns, cutting-edge technology, sustainability pressures, and global economic shifts. With a strong projected growth to $6.2 billion by 2032 and a CAGR of 7.1%, the market is clearly on an upward trajectory.

Organizations planning their data infrastructure strategies must consider not just cost and performance, but also energy efficiency, supply chain resilience, and long-term scalability. And with major players like Eaton, Schneider Electric, Vertiv, Tripp Lite, and Raritan leading the way, the future of power distribution is smarter, greener, and more reliable than ever.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5959

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#PowerDistributionUnits#PDUMarket#DataCenters#EnergyEfficiency#SmartPDU#Colocation#ITInfrastructure#GlobalMarketAnalysis#ElectricalDistribution#PowerManagement

0 notes

Text

Voicing for electrical distribution rearrangement in India

Voicing for #electricaldistribution rearrangement in India

News Hour:

Understanding the gravity of the situation where India loses nearly 10000 people to electrocution deaths annually, a civil society group raises voice for total rearrangements of the power supply system in the country.

Endorsed by Gandhian Natwar Thakkar, civil liberties campaigner Dr Gopal Krishna, senior advocate Upamanyu Hazarika, eminent author-journalist Paranjoy Guha Thakurta,…

View On WordPress

0 notes

Text

We sincerely invite you to explore the OCB - UK Metal Distribution Box from ONCCY, your most reliable solution and partner in the electrical field.

The OCB - UK Metal Distribution Box offers numerous significant advantages:

▶Crafted from zinc-iron alloy steel, this material boasts excellent corrosion resistance,

▶The top-hinged door design effectively prevents the distribution box door from remaining open after use, significantly reducing the risk of fire hazards due to an unclosed door.

▶Available in a variety of options suitable for various application scenarios.

▶Equipped with a lockable design for enhanced security, and we offer custom design services to meet your specific needs.

▶Rated with an IP40 protection level.

▶Available in configurations ranging from 2 to 18 ways, accommodating different circuit branching needs from simple to complex.

Get more: www.onccy.com. : [email protected],

WhatsApp at +86 17301617015.

#MetalDistributionBox#ONCCY#ElectricalSolutions#OCBUK#CorrosionResistant#TopHingedDoor#FireSafety#Grounding#CustomDesign#IP40#ElectricalDistribution#ContactUs

0 notes

Text

Exporter of LV Panels in Nigeria

Sempra Electric Pvt. Ltd. is a Manufacturer and Exporter of LV Panels in Nigeria. Sempra Electric Pvt. Ltd., established in 1996, ensures that all our products meet international quality standards at every stage of the manufacturing process. We offer a wide range of products, including diesel generators, LV panels, HV panels, transformers, UPS & battery banks, voltage stabilizers. LV Panels play a crucial role in controlling the flow of electricity from the main power source. To various circuits and equipment within buildings, industrial plants, and other facilities. Our LV Panels often include components such as circuit breakers, fuses, meters, switches, and control systems. They are essential for protecting electrical systems from overloads, short circuits, and other electrical faults. LV panels feature components like circuit breakers, fuses, meters, and switches to distribute electricity safely and efficiently at low voltage levels, safeguarding against overloads and faults in electrical systems. We use our LV panels in buildings, industrial plants, and facilities to distribute electricity safely and efficiently. They control power flow to equipment, lighting, and other electrical loads while protecting against faults. Sempra Electric Pvt. Ltd. is a Manufacturer and Exporter of LV Panels in Nigeria and locations like Lagos, Kano, Ibadan, Benin City, Port Harcourt, Jos, Ilorin, Abuja, Kaduna, Enugu, Zaria, Warri, Maiduguri, Aba, Bauchi, Akure, Abeokuta. If you have any questions or require further information, please feel free to contact us. Read the full article

#Aba#Abeokuta#Abuja#Akure#andvoltagestabilizers#BatteryBanks#Bauchi#BeninCity#circuitbreakers#CircuitProtection#components#ControlSystems#DieselGenerators#Efficiency#ElectricalDistribution#ElectricalInfrastructure#ElectricalLoads#Enugu#EquipmentProtection#Exporter#ExporterofLVPanels#ExporterofLVPanelsinNigeria#fuses#HVPanels#Ibadan#Ilorin#industrialplants#Jos#Kaduna#Kano

0 notes

Text

An device used to measure soil resistant is a ground resistor tester, sometimes known as an earth tester. It is utilized for projecting and sizing conducting grids.

For best price of the product, do reach us on 𝐢𝐧𝐟𝐨@𝐦𝐨𝐡𝐧𝐨𝐭𝐢𝐧𝐬𝐭𝐫𝐮𝐦𝐞𝐧𝐭𝐬.𝐜𝐨𝐦

You can also reach us on +91-9821614731

#mohnotinstruments#rishabhinstruments#digitalmeter#PowerMeter#electricalcontractor#electricaldistribution

0 notes