#engineeringmaterial

Explore tagged Tumblr posts

Text

When comparing alumina tubes, quartz tubes, and silicon carbide tubes, each material offers distinct advantages and drawbacks based on factors like temperature resistance, mechanical strength, chemical resistance, and cost. Here’s a detailed comparison to help you choose the best option for your specific application:

Temperature Resistance

Alumina Tubes:

Withstand temperatures up to 1800°C or more, particularly when made from high-purity alumina (99.7% or higher).

Suitable for extreme high-temperature environments, such as furnaces and kilns.

Quartz Tubes:

Can withstand temperatures up to 1100°C.

Suitable for moderate temperature applications but not ideal for extremely high temperatures.

Silicon Carbide Tubes:

Have the highest temperature resistance of the three, handling temperatures up to 1600–2400°C depending on the grade.

Ideal for applications involving extremely high heat and harsh environments, such as high-temperature furnaces or combustion chambers.

Mechanical Strength

Alumina Tubes:

Excellent mechanical strength and durability, making them resistant to wear and stress at high temperatures.

Can withstand heavy mechanical and thermal loads.

Quartz Tubes:

Fragile compared to alumina and silicon carbide. Quartz is more prone to breaking under mechanical stress or impact, making it less durable.

Silicon Carbide Tubes:

Superior mechanical strength and hardness, making them highly resistant to wear, abrasion, and thermal stress.

Often preferred in environments with high mechanical loads.

Thermal Shock Resistance

Alumina Tubes:

Good thermal shock resistance, but not as high as quartz. Rapid heating and cooling can cause cracking if not managed carefully.

Quartz Tubes:

Excellent thermal shock resistance. Quartz can withstand sudden changes in temperature without cracking, making it useful in applications where rapid heating or cooling occurs.

Silicon Carbide Tubes:

Moderate thermal shock resistance, better than alumina but not as good as quartz. Silicon carbide is tough, but extreme temperature fluctuations can still pose a challenge.

Chemical Resistance

Alumina Tubes:

Highly resistant to chemical attack, especially from most acids and bases. Ideal for processes involving reactive chemicals at high temperatures.

Quartz Tubes:

High resistance to chemical corrosion, particularly in oxidizing environments. However, it can be attacked by strong alkaline substances at high temperatures.

Silicon Carbide Tubes:

Extremely resistant to chemical corrosion from a wide range of chemicals, including strong acids and alkalis. This makes it suitable for highly corrosive environments.

Electrical Insulation

Alumina Tubes:

Excellent electrical insulator at high temperatures, making it ideal for applications where electrical insulation is crucial (e.g., thermocouple protection).

Quartz Tubes:

Also a good electrical insulator, although alumina is generally preferred when higher thermal stability and electrical insulation are needed.

Silicon Carbide Tubes:

Not a good insulator, as silicon carbide has some electrical conductivity, especially at high temperatures. It’s more suitable for applications where electrical conductivity is not a concern.

Cost

Alumina Tubes:

Typically, mid-range in terms of cost. They offer a balance between performance and price, particularly for high-temperature applications requiring strength and durability.

Quartz Tubes:

Generally more affordable than alumina or silicon carbide, especially for moderate temperature applications. However, the fragility may lead to more frequent replacements.

Silicon Carbide Tubes:

More expensive than both alumina and quartz due to their superior properties. However, their durability and high-temperature resistance can justify the cost in demanding applications.

Applications

Alumina Tubes:

Used in furnaces, thermocouple protection, kiln furniture, high-temperature processing, powder processing, and scientific research.

Preferred when both high-temperature resistance and mechanical strength are required.

Quartz Tubes:

Used in optics, semiconductor processing, light sources, and moderate temperature applications where thermal shock resistance is critical.

Suitable for applications with rapid heating/cooling cycles but moderate temperature limits.

Silicon Carbide Tubes:

Used in high-temperature furnaces, combustion systems, heat exchangers, and abrasive environments.

Ideal for extreme temperature applications and environments with high mechanical or chemical stress.

Durability and Longevity

Alumina Tubes:

High durability, especially in high-temperature or chemically aggressive environments, leading to longer life spans compared to quartz.

Quartz Tubes:

Less durable due to their fragility, leading to shorter lifespans in environments with mechanical or thermal stress.

Silicon Carbide Tubes:

Highly durable, with excellent resistance to wear and tear, especially in abrasive or chemically corrosive environments.

#AluminaTubes#QuartzTubes#SiliconCarbideTubes#MaterialScience#HighTemperatureMaterials#IndustrialMaterials#FurnaceTechnology#ThermalResistance#MechanicalStrength#ChemicalResistance#ThermalShockResistance#MaterialComparison#EngineeringMaterials#HighTempApplications#CeramicMaterials#MaterialSelectionGuide#KilnTechnology#IndustrialEngineering#HeatResistantMaterials#AdvancedMaterials#ScientificResearchMaterials#ThermalInsulation#IndustrialFurnaces#MaterialDurability#ElectricalInsulation

2 notes

·

View notes

Text

Are you looking for quality Plastic Mold Steel in India?

When it comes to molding dreams, Virat Special Steels doesn’t just offer steel—it crafts possibilities!

DIN 2738 is the go-to choice for the plastic mold industry, especially when dealing with those big, beefy steel mold components. It’s like the reliable friend who handles high-temperature settings and tough mechanical conditions without breaking a sweat.

And guess what? Virat Special Steels offers Plastic Mold Steel (High Hard) with a hardness range of 410-420 BHN. They also provide Modified 2738 (HH) steel, specifically designed for plastic mold manufacturers. These steels are suitable for applications requiring high hardness and durability, making them ideal for creating molds that withstand significant wear and tear during the molding process.

It’s got better polishability than its cousin, 1.2312 (AISI P20+S). So, whether you’re molding plastic widgets or creating intricate shapes, DIN 2738 has your back like a trusty sidekick.

To get detailed Modified 2738 (HH) steel industrial grade steels, visit the website – www.viratsteels.com

Learn more: https://www.viratsteel.in/materials/premium-quality-high-hardness-plastic-mold-steel-supplier-in-india/

Contact us today to learn more about our products and services! 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#din2738#plasticmouldsteels#plastic mould steel#p20ni#SteelSupplier#SteelIndustry#IndustrialSolutions#EngineeringMaterials

2 notes

·

View notes

Text

Buying GI Blind Flanges: A Step-by-Step Guide

GI Blind Flanges are a critical part of piping systems, used to close off pipe ends securely. Their applications span industries such as oil and gas, water treatment, and chemical processing. This guide breaks down what GI blind flanges are, their advantages, and how to purchase them effectively.

1. Understanding GI Blind Flanges

A GI Blind Flange is a solid disk with no central hole, designed to block the flow in a piping system by sealing off the pipe ends. Made from galvanized iron, these flanges offer enhanced resistance to corrosion, making them perfect for use in harsh conditions.

2. Advantages of GI Blind Flanges

Corrosion-Resistant: The galvanization process helps protect the flange from rust and corrosion, increasing its lifespan.

Cost-Effective: Compared to stainless steel flanges, GI blind flanges are typically more affordable while maintaining reliability.

Easy to Install: These flanges are designed for quick installation, saving both time and labor costs during setup.

Multiple Sizes Available: GI blind flanges come in a wide range of sizes, catering to different piping needs.

Handles High Pressure: GI blind flanges are built to withstand significant pressure, ensuring the piping system’s integrity under stress.

3. Price Range for GI Blind Flanges

Prices vary based on size and supplier, but here’s an approximate breakdown:

Small Sizes (½ inch to 2 inches): ₹60 - ₹180 per piece.

Medium Sizes (3 inches to 8 inches): ₹180 - ₹700 per piece.

Large Sizes (10 inches and above): ₹700 - ₹2,500 or more per piece.

4. Steps to Buy GI Blind Flanges

Identify Your Specifications: Determine the exact size and type of flange you need for your specific application.

Research Trusted Suppliers: Look for suppliers with good reputations for selling GI blind flanges. Reputable platforms include:

Udhhyog: Buy GI Blind Flanges

IndiaMART

TradeIndia

Alibaba

Compare Prices: Gather quotes from multiple suppliers to ensure you’re getting the best deal for your budget.

Check Product Quality: Verify that the flanges comply with industry standards and are manufactured to meet your project’s requirements.

Review Shipping Options: Don’t forget to factor in shipping costs and delivery timelines when finalizing your purchase.

Complete Your Purchase: Once you’ve chosen the right supplier, proceed with the order and monitor the shipping to ensure timely delivery.

#GIBlindFlange#IndustrialFlanges#PipeFlanges#GalvanizedIron#PipingSystems#IndustrialSupply#CorrosionResistance#PipingSolutions#EngineeringMaterials#Infrastructure#Udhhyog#FlangeManufacturers#FlangesAndFittings#IndustrialEquipment#SteelIndustry#OilAndGasIndustry#WaterTreatment#BuyFlanges#ConstructionMaterials#MechanicalEngineering#PipeFittings#UdhhyogSteel#BlindFlange

5 notes

·

View notes

Text

Explore top-quality cold drawn stainless steel pipe, tubing, seamless pipe, carbon steel pipe, and metal pipe by Heavy Metals & Tubes – precision-engineered for industrial excellence.

#StainlessSteelPipe#StainlessSteelTubing#ColdDrawnSteel#SeamlessPipe#MetalPipe#CarbonSteelPipe#IndustrialPipes#SteelManufacturing#HeavyMetalsAndTubes#SteelSolutions#PipingSolutions#PrecisionPipes#SteelIndustry#EngineeringMaterials#MadeInIndia"

0 notes

Text

Monel 400 Fastener Manufacturer, Supplier & Exporter

Introduction to Monel 400 Fasteners

In industries where corrosion resistance and durability are paramount, Monel 400 fasteners have carved out a significant niche. Made predominantly from a nickel-copper alloy, Monel 400 is celebrated for its superior resistance to seawater, acidic media, and caustic substances. As industries like marine, oil & gas, chemical processing, and power generation demand materials that can withstand harsh environments, Monel 400 fasteners have emerged as a top choice.

As a leading Monel 400 Fastener Manufacturer, we understand the technical demands and exact specifications required for critical applications.

What is Monel 400?

Monel 400 is a single-phase alloy predominantly consisting of:

Nickel (63% minimum)

Copper (28-34%)

Trace amounts of iron, manganese, carbon, and silicon

This composition imparts Monel 400 with outstanding strength and corrosion resistance over a broad temperature range, making it particularly resistant to:

Seawater corrosion

Hydrofluoric acid

Sulfuric acid

Alkalis

High-velocity saltwater and steam

Types of Monel 400 Fasteners

As a specialized manufacturer, we offer a comprehensive range of Monel 400 fasteners, including:

1. Bolts

Hex Bolts

Heavy Hex Bolts

Stud Bolts

U-Bolts

J-Bolts

Anchor Bolts

Eye Bolts

Machine Bolts

2. Nuts

Hex Nuts

Heavy Hex Nuts

Lock Nuts

Nylock Nuts

Wing Nuts

Cap Nuts

3. Screws

Hex Head Screws

Socket Head Screws

Self-Tapping Screws

Machine Screws

Wood Screws

4. Washers

Flat Washers

Spring Washers

Lock Washers

Beveled Washers

5. Custom Fasteners

Precision-made according to customer drawing and specification

Applications of Monel 400 Fasteners

Because of their superior corrosion resistance and robust mechanical properties, Monel 400 fasteners find widespread application in:

Marine Engineering

Offshore Oil & Gas Platforms

Shipbuilding

Chemical Processing Plants

Heat Exchangers

Pumps and Valves

Desalination Plants

Nuclear Industry

Aerospace Components

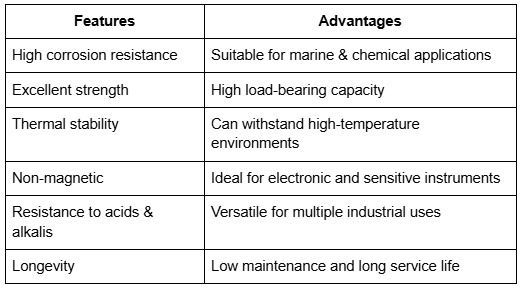

Key Features & Advantages

Chemical Composition of Monel 400

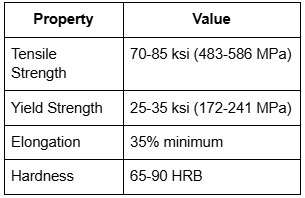

Mechanical Properties of Monel 400

Why Choose Us as Your Monel 400 Fastener Manufacturer?

As a trusted Monel 400 Fastener Manufacturer, Supplier, and Exporter, we provide:

Strict Quality Control: Every batch undergoes thorough inspection and testing.

Customized Solutions: Fasteners manufactured as per ASME, ASTM, DIN, ISO, BS, EN standards.

Global Delivery: Serving clients in the USA, Europe, the Middle East, Asia, and Africa.

Competitive Pricing: Direct manufacturer pricing without compromising on quality.

Quick Turnaround Time: Fast production and delivery to meet urgent project deadlines.

After-Sales Support: Full technical support even after product delivery.

Standards & Specifications We Follow

ASTM B164 / B865 / B366

ASME SB-164 / SB-865 / SB-366

DIN, ISO, EN Standards

Testing & Certifications

Our Monel 400 fasteners are tested as per international standards for:

Tensile strength

Hardness

Impact resistance

Intergranular corrosion test

PMI (Positive Material Identification)

Ultrasonic testing

Third-party inspection (on request)

Certificates provided include:

Mill Test Certificate (EN 10204 3.1/3.2)

Raw material certificate

Third-party inspection reports

NACE Compliance (if required)

Export Destinations

We supply Monel 400 fasteners to several countries, including:

USA

Canada

Germany

UAE

Saudi Arabia

Qatar

Singapore

Malaysia

Australia

South Africa

UK

Europe

Conclusion

Monel 400 fasteners offer an ideal solution for industries requiring exceptional corrosion resistance, high strength, and long-term reliability. As a leading manufacturer, we combine world-class manufacturing practices with stringent quality control to deliver fasteners that meet the highest industry standards. Whether you need standard sizes or custom designs, we can fulfill all your fastener requirements globally.

Frequently Asked Questions (FAQ)

1. What makes Monel 400 fasteners special?

Monel 400 fasteners provide outstanding corrosion resistance in seawater and chemical environments, combined with high strength and durability, making them perfectly suited for harsh and demanding conditions.

2. Can you manufacture custom-size Monel 400 fasteners?

Yes, we offer fully customized manufacturing services based on client drawings, sizes, and specifications.

3. Do you provide third-party inspection reports?

Yes, third-party inspections and certification are available on request.

4. Can Monel 400 fasteners be used in high-temperature environments?

Yes, they perform well at elevated temperatures, maintaining strength and corrosion resistance.

5. What is your delivery time?

We maintain a sufficient stock of standard sizes and offer fast delivery for custom orders, depending on order volume and complexity.

#Monel400#MonelFasteners#HexBolt#HexNut#NickelCopperAlloy#AnankaFasteners#FastenerManufacturer#EngineeringMaterials#PrecisionEngineering#IndustrialSupply#BoltsAndNuts#MetalAlloys#Blog#Articles#Monel400Fasteners#tumblr#blog tumblr

0 notes

Text

Buy Precision 316 Metric Rods Online – USA Delivery Available

Looking for high-quality 316 stainless steel rod products for your industrial, fabrication, or engineering applications? At Alexandria Precision, we specialize in supplying precision ground 316 metric rods that meet the exacting standards of today’s industries. Whether you're machining complex parts or need corrosion-resistant rods for marine environments, our products deliver strength, precision, and performance.

Let’s explore why 316 metric rods are the trusted choice across multiple industries—and how you can conveniently order them online with fast shipping across the USA.

What Makes 316 Stainless Steel Rods Unique?

316 stainless steel is a high-performance austenitic alloy valued for its exceptional resistance to corrosion, particularly in harsh, chloride-heavy settings like marine environments and chemical processing facilities. Its added molybdenum content makes it more resilient than 304 stainless steel, particularly against pitting and crevice corrosion.

Key Properties of 316 Stainless Steel Rods:

Excellent corrosion resistance in saltwater and chemical environments

High tensile strength and durability

Non-magnetic and easy to fabricate or weld

Temperature-resistant for use in both hot and cold applications

Because of these advantages, 316 stainless steel rod is commonly used in:

Marine equipment

Pharmaceutical and food processing equipment

Medical devices

Aerospace components

Industrial machinery

Why Choose Precision Ground 316 Metric Rods?

When tolerances matter, standard rods just won’t cut it. Precision-ground rods offer the dimensional accuracy and surface finish required for high-performance parts.

Our 316 metric rods are:

Centerless ground to h6 tolerances

Available in a wide range of metric diameters

Supplied in custom lengths as per your requirements

Manufactured with strict quality control for consistent results

These rods are ideal for precision machining, CNC applications, and tight-tolerance components.

Alexandria Precision – Your Trusted Source

At Alexandria Precision, we’re more than just a supplier—we’re a reliable partner for engineers, machinists, and business owners who demand precision.

We offer:

A large in-stock inventory of 316 metric rods

Online ordering with secure checkout

Cut-to-length service

USA-wide delivery with fast turnaround times

Friendly, knowledgeable customer support

We provide precision-ground 316 stainless steel rod products that meet the needs of industries ranging from aerospace to manufacturing—all from a single trusted source.

Applications Across Industries

316 metric rods are highly versatile and used in a range of fields:

Medical Equipment: Non-reactive and easy to sterilize

Aerospace: Lightweight, durable, and corrosion-resistant

Food & Beverage: Compliant with sanitation standards

Energy & Power: High resistance to chemical exposure and temperature extremes

Industrial Manufacturing: Ideal for bushings, shafts, and guide rails

No matter your industry, we make it easy to buy 316 metric rods online with confidence.

Need Help Choosing the Right Size?

We know that choosing the right diameter and length is critical. Our website includes a detailed size chart, and our team is always ready to help you select the perfect fit for your application.

FAQs – 316 Stainless Steel Metric Rods

What’s the difference between 316 and 304 stainless steel rods?

The key difference is that 316 stainless steel contains molybdenum, which greatly enhances its resistance to corrosion, particularly in environments with chlorides or strong chemicals. This makes 316 the preferred choice for marine, coastal, and industrial chemical applications, whereas 304 is better suited for general-purpose use.

Can I request custom cut lengths?

Yes! We offer cut-to-length service for all our rods so you receive exactly what you need—no more, no less.

Do you ship across the USA?

Yes, we ship across the USA with quick and dependable service—most orders are packed and shipped within just 1–2 business days.

Are your 316 metric rods centerless ground?

Yes, all our rods are precision-ground to h6 tolerances using the centerless grinding method to ensure a smooth surface finish and accurate dimensions.

Can I use these rods for medical-grade applications?

Yes, 316 stainless is commonly used in medical tools and equipment because of its excellent corrosion resistance and non-reactive properties.

Quick Summary

316 stainless steel rods deliver outstanding strength, excellent corrosion protection, and tight dimensional accuracy—ideal for tough industrial applications. With Alexandria Precision, you can confidently buy 316 metric rods online and get fast delivery across the USA—backed by quality you can trust.

#316StainlessSteel#StainlessSteelRods#MetricRods#PrecisionGround#AlexandriaPrecision#ManufacturingSolutions#IndustrialSupplies#MetalFabrication#EngineeringMaterials#CNCMachining#AerospaceEngineering#MarineGradeSteel#IndustrialComponents#BuyOnlineUSA#MadeInUSA#CustomMetalParts#FastShippingUSA#ShopIndustrial

0 notes

Text

Top 7 Benefits of Stainless Steel 316L Boiler Tubes for High-Performance Industrial Applications

Stainless Steel 316L boiler tubes are a cornerstone in industries like power generation, chemical processing, and oil and gas. Their unique properties make them ideal for high-pressure and high-temperature environments. This article explores the key benefits of using Stainless Steel 316L boiler tubes, highlighting why they are a preferred choice for reliable and efficient systems.

1. Superior Corrosion Resistance

Stainless Steel 316L is renowned for its excellent corrosion resistance, particularly in harsh environments. The addition of molybdenum (2-3%) enhances its ability to withstand pitting and crevice corrosion, especially in chloride-rich settings like marine or chemical processing applications. This makes 316L boiler tubes ideal for industries where exposure to corrosive substances is common, ensuring long-term reliability and reduced maintenance costs.

SEO Keywords: Stainless Steel 316L corrosion resistance, boiler tubes for harsh environments, pitting resistance in boiler systems.

2. Low Carbon Content for Enhanced Weldability

The "L" in 316L stands for low carbon, which minimizes carbide precipitation during welding. This property makes Stainless Steel 316L boiler tubes easier to weld without compromising structural integrity. Welded joints remain strong and corrosion-resistant, making these tubes suitable for complex boiler designs and heat exchanger systems.

SEO Keywords: 316L boiler tubes weldability, low carbon stainless steel, welded boiler tube applications.

3. High-Temperature Strength and Durability

Stainless Steel 316L boiler tubes offer exceptional strength and durability at elevated temperatures. They maintain their mechanical properties in high-heat environments, making them ideal for boilers and heat exchangers operating under extreme conditions. This durability translates to longer service life and fewer replacements, saving costs for industries.

SEO Keywords: High-temperature boiler tubes, durable 316L stainless steel, heat exchanger tubing.

4. Versatility Across Industries

From power plants to pharmaceutical manufacturing, Stainless Steel 316L boiler tubes are versatile enough to meet diverse industry needs. Their ability to handle high-pressure steam, aggressive chemicals, and fluctuating temperatures makes them suitable for applications in:

Power Generation: Efficient heat transfer in boiler systems.

Chemical Processing: Resistance to corrosive chemicals.

Oil and Gas: Durability in high-pressure pipelines.

Pharmaceuticals: Hygienic and non-reactive surfaces for clean systems.

SEO Keywords: Stainless Steel 316L applications, versatile boiler tubes, industry-specific tubing solutions.

5. Cost-Effective Long-Term Investment

While Stainless Steel 316L boiler tubes may have a higher upfront cost compared to other materials, their longevity and low maintenance requirements make them a cost-effective choice. Reduced downtime, fewer repairs, and resistance to corrosion and wear ensure a lower total cost of ownership over time.

SEO Keywords: Cost-effective boiler tubes, 316L stainless steel longevity, low maintenance tubing.

6. Eco-Friendly and Recyclable

Stainless Steel 316L is 100% recyclable, making it an environmentally friendly option for industries aiming to reduce their carbon footprint. Its durability also means fewer replacements, contributing to sustainable operations. Choosing 316L boiler tubes aligns with eco-conscious practices without compromising performance.

SEO Keywords: Eco-friendly boiler tubes, recyclable stainless steel, sustainable industrial tubing.

7. Compliance with Industry Standards

Stainless Steel 316L boiler tubes meet stringent industry standards, such as ASTM A213 and ASME SA213, ensuring quality and safety in critical applications. This compliance gives industries confidence in the reliability and performance of these tubes for their boiler and heat exchanger systems.

SEO Keywords: ASTM A213 316L boiler tubes, ASME SA213 compliant tubing, industry-standard boiler tubes.

Why Choose Stainless Steel 316L Boiler Tubes?

The combination of corrosion resistance, high-temperature strength, weldability, and versatility makes Stainless Steel 316L boiler tubes a top choice for demanding industrial applications. Whether you're operating a power plant, chemical facility, or pharmaceutical production line, these tubes deliver unmatched performance and reliability. Their eco-friendly properties and compliance with industry standards further enhance their appeal, making them a smart investment for long-term operational success.

SEO Keywords: Why choose 316L boiler tubes, high-performance stainless steel tubing, reliable boiler tube solutions.

Conclusion

Stainless Steel 316L boiler tubes offer a perfect balance of durability, corrosion resistance, and cost-effectiveness. Their ability to perform in extreme conditions while meeting industry standards makes them indispensable for modern industrial systems. By choosing 316L boiler tubes, businesses can ensure efficient operations, reduced maintenance, and sustainable practices, all while achieving long-term cost savings.

#industrial#manufacturer#MetalIndustry#SteelManufacturing#CorrosionResistantSteel#SteelSheetsAndPlates#IndustrialMaterials#SteelFabrication#EngineeringMaterials#MetalProcessing#HighPerformanceSteel#StainlessSteelApplications#ChemicalIndustrySteel#MarineGradeSteel#HeavyDutySteel#SteelIndustryNews

0 notes

Text

Carbon Steel API 5L X52 PSL 1 Pipes & Tubes Exporters In India

Metinox Overseas is a leading supplier of Carbon Steel API 5L X52 PSL 1 / API 5L X52 PSL 2 Pipes & Tubes in Mumbai. We specialize in providing high-quality products at the most feasible rates, ensuring customer satisfaction and reliability.

API 5L X52 Pipes are designed for the transportation of corrosive and non-corrosive fluids and gases at high pressures. These pipes are manufactured with a chemical composition including carbon, manganese, potassium phosphorous, molybdenum, chromium, silicon, and sulfur, providing excellent mechanical properties. The API 5L X52 Seamless Pipe exhibits a minimum tensile strength of 60,200 psi and a minimum yield strength of 42,100 psi, making it suitable for various applications.

API 5L X52 PSL1 Welded Pipe is produced by welding pieces of steel together with the help of a filler, offering ease of maintenance and long-lasting durability. X52 ERW Pipe boasts high resistance against corrosion and stress, with wall thickness ranging from 2.11mm to 24.61mm. Additionally, the API 5L Gr X52 HIC Pipeline offers good resistance against pitting induced by hydrogen in various applications.

#highperformancesteel#heavydutysteel#industrialmaterials#engineeringmaterials#corrosionresistantsteel#chemicalindustrysteel#stainlesssteelapplications#metalindustry#marinegradesteel#metalprocessing

0 notes

Text

Discover the Advantages of Silicone Rubber in Industrial Applications 🏭

Silicone rubber offers unparalleled durability and flexibility, making it ideal for custom plastic solutions in industrial settings. Our latest guide delves into its benefits and applications for OEMs and bulk purchasers.

#siliconerubber#industrialmanufacturing#customplastics#oemsolutions#materialinnovation#engineeringmaterials#manufacturingexcellence#product development#industrial design#highperformancematerials

0 notes

Text

Are you looking for Quality #DieSteel in India? Ready to elevate your projects with top-quality die steel? Contact Virat Special Steels Pvt. Limited!

Contact Us Today !

Discover Quality Die Steel with VIRAT SPECIAL STEELS PVT. LIMITED , INDIA. As the leading die steel supplier in Delhi NCR and India, Virat Special Steels takes pride in delivering exceptional quality and reliability. Specializing in DB6 / DIN 2714 / AISI L6, we offer top-notch solutions for your industrial needs.

Why Choose Virat Special Steels?

Premium Quality, our die steel products adhere to the highest industry standards, ensuring durability and performance.

Wide Range, explore our extensive selection of DB6, DIN-1.2714, AISI L6, and more, tailored to meet diverse application requirements.

Reliable supplier, with years of expertise, we've established ourselves as a trustworthy partner for businesses in need of superior die steel.

Partner with Us for Success: Whether you're in manufacturing, engineering, or tooling, Virat Special Steels is dedicated to providing the right die steel solutions for your projects. Our commitment to quality and customer satisfaction sets us apart.

Learn More: https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us : 📩 Email: [email protected] or 📞 Call: +91 98140 21775

#ludhiana#india#viratsteels#viratspecialsteels#toolsteelsupplier#gurugram#iso9001#IndustrialMaterials#ManufacturingExcellence#EngineeringMaterials#MachiningSteel#ToolandDie#SteelAlloys#db6 steel#pune#gurgaon#din 2714#aisil6

2 notes

·

View notes

Text

Jindal MS Seamless Pipe is a high-quality, durable pipe designed for various industrial applications. Known for its strength and corrosion resistance, it is ideal for use in construction, oil and gas, and manufacturing sectors.

#JindalMSSPipe#SeamlessPipe#JindalSteel#MSPipe#IndustrialPipes#SteelPipes#ConstructionMaterials#OilAndGas#PipeFittings#SteelProducts#HeavyDutyPipes#EngineeringMaterials

4 notes

·

View notes

Text

Premium Quality Stainless Steel Heat Exchanger Tubes | SS International

Discover high-quality Heat Exchanger Tubes from leading manufacturers. Our stainless steel and alloy tubes ensure superior heat transfer efficiency and durability for industrial applications. Available in various sizes and materials, our heat exchanger tubes meet international standards for reliability and performance. Ideal for petrochemical, power generation, and HVAC industries. Get precision-engineered tubes for optimal thermal conductivity and corrosion resistance.

Visit Steeltube.co.in today to explore premium-quality Heat Exchanger Tubes designed for superior heat transfer, durability, and industrial performance.

#HeatExchangerTubes#SteelTubes#IndustrialTubes#SSHeatExchangerTubes#CarbonSteelTubes#AlloySteelTubes#PrecisionTubes#SeamlessTubes#WeldedTubes#HeatTransferSolutions#EngineeringMaterials#Manufacturing#IndustrialEquipment#PipingSolutions#MetalIndustry

0 notes

Text

What are the most durable grades of stainless steel?

1. Grade 304 (Austenitic – Most Common & Versatile)

✔ High corrosion resistance, especially in mild environments ✔ Excellent strength and durability ✔ Used in kitchen equipment, building facades, and food processing

2. Grade 316 (Marine-Grade Stainless Steel)

✔ Superior corrosion resistance, especially against chlorides (saltwater) ✔ High durability and strength ✔ Used in marine applications, chemical processing, and medical implants

3. Grade 2205 (Duplex Stainless Steel – High Strength & Corrosion Resistance)

✔ Twice the strength of 304 and 316 ✔ Excellent resistance to stress corrosion cracking ✔ Used in bridges, offshore structures, and chemical plants

4. Grade 430 (Ferritic – Cost-Effective & Durable)

✔ Good corrosion and heat resistance ✔ Magnetic and suitable for decorative applications ✔ Used in kitchen appliances and automotive trims

5. Grade 410 (Martensitic – High Hardness & Wear Resistance)

✔ Good strength and corrosion resistance ✔ Heat-treatable for extra durability ✔ Used in cutlery, surgical instruments, and turbine blades

6. Grade 904L (Super Austenitic – Extreme Corrosion Resistance)

✔ Excellent resistance to acids and harsh environments ✔ Used in chemical and marine industries ✔ High durability but expensive

💡 Which Stainless Steel is Best for You?

For general use → 304

For marine & harsh environments → 316

For high strength & industrial use → 2205

For affordability & decorative use → 430

For wear resistance → 410

For extreme corrosion resistance → 904L

#stainlesssteel#SteelGrades#MetalFabrication#IndustrialMaterials#SteelIndustry#ConstructionMaterials#DurableSteel#CorrosionResistance#StainlessSteelSheets#Metalwork#EngineeringMaterials#MarineGradeSteel#SteelManufacturing#HeavyDutySteel#304StainlessSteel#316StainlessSteel#DuplexSteel#MetalFinishing#ArchitecturalMetal#StrongAndDurable

0 notes

Text

Shop ASTM A582 Stainless 416 Precision Rods for Industrial Use

When your project demands strength, durability, and precise machining, ASTM A582 stainless 416 is the alloy of choice. Known for its excellent machinability and corrosion resistance, this free-machining martensitic stainless steel is widely used in industries ranging from aerospace to manufacturing. At Alexandria Precision, we supply precision-ground 416 stainless steel rods that meet strict ASTM A582 standards—ready to ship across the USA.

What Is ASTM A582 Stainless 416?

ASTM A582 is a specification covering free-machining stainless steel bars designed for parts requiring extensive machining. Under ASTM A582, stainless 416 is a martensitic alloy enhanced with sulfur to improve machinability while maintaining solid strength.

Key features of ASTM A582 Stainless 416 include:

Excellent machinability (best among all stainless grades)

Moderate corrosion resistance

Good mechanical properties after heat treatment

Magnetic in the annealed and hardened condition

It’s commonly used in valves, shafts, fasteners, motor parts, and precision components that require tight tolerances.

Why Choose Stainless 416 for Industrial Applications?

Unlike austenitic stainless steels like 304 or 316, 416 stainless steel offers high sulfur content, improving chip-breaking and surface finish during CNC and lathe operations. It’s ideal for high-volume, precision machining where production efficiency matters.

Here’s why industries prefer it:

Lower tool wear during machining operations

Tighter tolerances for precision parts

Cost-effective for high-production runs

Suitable for heat treatment to increase hardness and strength

Precision Ground Rods Made for Performance

At Alexandria Precision, our stainless 416 rods are:

Precision ground for consistent diameter and tolerance

Cut-to-length per your specifications

ASTM A582-compliant and quality-checked

Available in a range of diameters for various industrial applications

We work closely with industries like aerospace, energy, and defense to provide material that meets demanding performance and compliance needs.

For more insights into the strength and capabilities of this alloy, check out our blog on ASTM A582 Stainless 416.

Applications of ASTM A582 416 Stainless

From small machine shops to large manufacturing plants, 416 stainless finds its way into components such as:

Motor shafts and rotors

Pump parts

Gears and bushings

Threaded rods and screws

Hydraulic fittings

Its excellent machining characteristics allow you to achieve faster turnaround times while maintaining quality.

Trust Alexandria Precision for Your Stainless Needs

We’ve built a reputation as a reliable supplier of precision-ground stainless rods that meet both performance and compliance expectations. Whether you’re prototyping or producing in volume, we’re here to support your project with expert guidance and quick fulfillment.

❓ Frequently Asked Questions (FAQs)

What is ASTM A582 and why is it important?

ASTM A582 is a standard specification for free-machining stainless steel bars used in machined parts. It ensures uniformity in chemical composition, mechanical properties, and quality—critical for industrial manufacturing.

Is stainless 416 corrosion resistant?

Yes, 416 stainless offers moderate corrosion resistance, especially in dry environments. However, it’s not recommended for highly corrosive or marine environments compared to grades like 316.

Can 416 stainless steel be heat treated?

Absolutely. Stainless 416 responds well to heat treatment, which increases hardness and tensile strength—making it suitable for wear-resistant parts.

What industries typically use ASTM A582 416 rods?

Its combination of mechanical strength and ease of machining makes it a top choice in industries like aerospace, defense, manufacturing, and automotive.

Do you offer custom lengths or bulk pricing?

Yes, Alexandria Precision provides custom cut-to-length services and offers volume discounts. Reach out to our sales experts for a custom quote tailored to your needs.

✅ Quick Summary

ASTM A582 stainless 416 rods offer the perfect combination of machinability and mechanical strength for industrial applications. Alexandria Precision supplies precision-ground 416 bars that meet your specifications—ready for fast delivery and reliable performance.

#StainlessSteel#ASTMA582#416Stainless#PrecisionMachining#MetalFabrication#IndustrialSupply#EngineeringMaterials#MachiningSolutions#CNCReady#StainlessSteelRods

0 notes

Text

Stainless Steel 316Ti Plates Exporters in India

At A M Industries, we pride ourselves as one of the major producers and suppliers of high-quality Stainless Steel 316Ti Plates. These plates are well recognized for their outstanding corrosion resistance, high-temperature strength, and durability, hence finding a wide application range in industries involved with chemical processing, marine, architectural, and several others.

The addition of titanium raises the resistance of stainless steel to intergranular corrosion, especially at high temperatures. Therefore, Stainless Steel 316Ti Plates are highly preferred for use when superior performance is desired under very challenging and environmentally sensitive conditions.

The mechanical properties of Stainless Steel 316Ti Plates are excellent, hence their wide applicability. Its resistance to high temperatures, up to 870°C with no marked deformations or loss of strength, is one of its key benefits. Titanium addition in these plates acts as a stabilizer for preventing carbide precipitation during welding and ensures that the plates retain their structural integrity due to such conditions. Hence, this is very ideal for such industries as the petrochemical and oil and gas industries where high-performance materials are required. Stainless Steel Plates Manufacturer 316Ti - A Name Trustable

A M Industries, a leading Stainless Steel 316Ti Plates Manufacturer, ensures that its products reflect the ethos of quality and reliability. An expressive means of producing using high-quality raw materials, coupled with adherence to the latest technology, is necessary for manufacturing the plates. To strongly affect quality control, each lot of plates undergoes detailed testing with regard to mechanical properties, corrosion resistance, and durability. Clients who choose our services can be assured that they are receiving products that will rise above the rest and perform exceptionally well in even the most demanding environments.

#heavy metal#corrosionresistantsteel#Stainless Steel 316Ti Plates Manufacturers#Stainless Steel 316Ti Plates Suppliers#Stainless Steel 316Ti Plates Stockists#Stainless Steel 316Ti Plates Exporters#metalindustry#metal#metalprocessing#industrialmaterials#engineeringmaterials#pipe supplier#highperformancesteel#sheets

0 notes

Text

Enhance your industrial and commercial applications with premium-quality commercial rubber sheets from Ordinem Engitech. Designed for general-purpose sealing, gasketing, flooring, and insulation, these sheets offer flexibility, durability, and resistance to wear and tear. Ideal for automotive, construction, and industrial sectors, our commercial rubber sheets provide a cost-effective solution for various needs.

🔹 Key Features: ✔ Excellent flexibility & durability ✔ Suitable for multiple applications ✔ Good resistance to wear & abrasion ✔ Easy to cut, shape, and install

Get reliable rubber sheet solutions for your business today!

#OrdinemEngitech#CommercialRubberSheet#RubberSolutions#IndustrialRubber#SealingSolutions#DurableMaterials#EngineeringMaterials#RubberIndustry#Gasketing#Flooring

0 notes