#estimating lifecycle cost

Explore tagged Tumblr posts

Text

Meeting Circular Economy Demands Through an Industrial Estimating Service

Introduction As industries evolve to meet sustainability goals and reduce environmental impact, the principles of the circular economy are gaining momentum. A circular economy emphasizes keeping materials in use, minimizing waste, and designing for recyclability. While these values are often discussed at the design and policy level, they also have a direct influence on cost planning and project feasibility. Industrial estimating services are increasingly being called upon to factor circular economy considerations into their cost models, enabling smarter resource use and long-term value recovery.

Understanding the Circular Economy in Industry In contrast to the traditional linear model of "take, make, dispose," the circular economy focuses on extending the life cycle of materials and products. This includes strategies like reuse, remanufacturing, recycling, and designing out waste. For industrial projects, this may involve selecting recyclable materials, designing modular components for easy disassembly, or budgeting for end-of-life recovery processes.

These strategies aren’t free — they come with specific costs and trade-offs that need to be identified early. That’s where an industrial estimating service becomes indispensable.

The Expanding Scope of Estimating Services Traditionally, industrial estimating services focused on materials, labor, and equipment to forecast initial capital expenditures. However, the move toward circular design and sustainability has added new dimensions to the estimating process. Modern estimating services must now account for:

Lifecycle Costing: Estimating not just the upfront costs but also maintenance, repair, and recycling costs.

Material Recovery Value: Including the future resale or salvage value of materials in cost plans.

Sustainability Incentives: Factoring in subsidies, tax credits, and compliance costs for meeting green certification standards.

Modular and Flexible Design: Costing for structures that allow easy upgrades, relocations, or disassembly.

Cost Implications of Circular Economy Design Choices Incorporating circular strategies into industrial projects may increase costs in one phase but reduce them significantly in others. For example, using modular steel components might be more expensive than cast-in-place concrete initially, but the steel can be recovered and resold after the facility’s lifespan ends.

An industrial estimating service evaluates these trade-offs to help clients make informed decisions. These services use sophisticated modeling techniques to compare multiple scenarios — traditional linear construction vs. circular design — to demonstrate the financial and environmental impacts over time.

Leveraging Data for Circular Metrics To support circular economy goals, estimators rely on specialized databases that provide:

Environmental Product Declarations (EPDs): Which offer data on material sustainability.

Recyclability Ratings: For common industrial components and systems.

Deconstruction and Salvage Cost Benchmarks: Allowing precise planning for eventual material recovery.

Carbon Cost Multipliers: Quantifying the cost of embodied carbon emissions for different materials.

These inputs help estimators develop comprehensive cost models that align with both project budgets and sustainability mandates.

Industrial Use Case: Circular Design in a Manufacturing Plant Consider a manufacturing company planning to build a new facility with a 25-year operational life. The client wants to explore circular economy principles to support their ESG (Environmental, Social, and Governance) commitments. The industrial estimating service analyzes options like recycled steel framing, modular wall systems, and demountable interior components. They compare initial costs, lifecycle values, and the estimated salvage worth of components after decommissioning.

Although the circular design has a 12% higher upfront cost, the estimator shows that long-term savings from lower maintenance and higher salvage value reduce the net lifecycle cost by 18%. These insights help the client justify the upfront investment to stakeholders and comply with environmental regulations.

Aligning with Stakeholder Expectations Government bodies, investors, and clients are increasingly favoring businesses that integrate circularity and sustainability into their operations. An industrial estimating service ensures that these objectives are baked into the budget from day one, improving project transparency and attracting eco-conscious investors.

Estimators also help with reporting and documentation required for:

Green building certifications like LEED or BREEAM

Corporate sustainability audits

Government grant applications tied to environmental goals

Challenges and Opportunities Meeting circular economy demands can be complex due to lack of standardized cost data, varying regional regulations, and supply chain uncertainty for recycled materials. However, estimating services that invest in robust data systems and cross-disciplinary collaboration can turn these challenges into competitive advantages.

By being early adopters of circular metrics, these services position themselves as valuable partners for future-focused industrial projects.

Conclusion As industries transition to more sustainable models, the role of an industrial estimating service is expanding beyond cost control to strategic sustainability alignment. By integrating circular economy principles into the estimating process, these services enable better financial planning, resource efficiency, and environmental compliance. They not only help meet today’s project demands but also contribute to building a more responsible and regenerative industrial future.

#circular economy#industrial estimating#sustainable design#lifecycle costing#recycled materials#green construction#cost estimation#modular design#salvage value#ESG goals#deconstruction cost#material reuse#carbon footprint#cost planning#industrial projects#sustainability#estimating service#lifecycle analysis#recycled steel#estimating software#EPD data#long-term savings#green certifications#waste reduction#environmental compliance#circular planning#material efficiency#building reuse#estimating lifecycle cost#eco design

0 notes

Text

Green energy is in its heyday.

Renewable energy sources now account for 22% of the nation’s electricity, and solar has skyrocketed eight times over in the last decade. This spring in California, wind, water, and solar power energy sources exceeded expectations, accounting for an average of 61.5 percent of the state's electricity demand across 52 days.

But green energy has a lithium problem. Lithium batteries control more than 90% of the global grid battery storage market.

That’s not just cell phones, laptops, electric toothbrushes, and tools. Scooters, e-bikes, hybrids, and electric vehicles all rely on rechargeable lithium batteries to get going.

Fortunately, this past week, Natron Energy launched its first-ever commercial-scale production of sodium-ion batteries in the U.S.

“Sodium-ion batteries offer a unique alternative to lithium-ion, with higher power, faster recharge, longer lifecycle and a completely safe and stable chemistry,” said Colin Wessells — Natron Founder and Co-CEO — at the kick-off event in Michigan.

The new sodium-ion batteries charge and discharge at rates 10 times faster than lithium-ion, with an estimated lifespan of 50,000 cycles.

Wessells said that using sodium as a primary mineral alternative eliminates industry-wide issues of worker negligence, geopolitical disruption, and the “questionable environmental impacts” inextricably linked to lithium mining.

“The electrification of our economy is dependent on the development and production of new, innovative energy storage solutions,” Wessells said.

Why are sodium batteries a better alternative to lithium?

The birth and death cycle of lithium is shadowed in environmental destruction. The process of extracting lithium pollutes the water, air, and soil, and when it’s eventually discarded, the flammable batteries are prone to bursting into flames and burning out in landfills.

There’s also a human cost. Lithium-ion materials like cobalt and nickel are not only harder to source and procure, but their supply chains are also overwhelmingly attributed to hazardous working conditions and child labor law violations.

Sodium, on the other hand, is estimated to be 1,000 times more abundant in the earth’s crust than lithium.

“Unlike lithium, sodium can be produced from an abundant material: salt,” engineer Casey Crownhart wrote in the MIT Technology Review. “Because the raw ingredients are cheap and widely available, there’s potential for sodium-ion batteries to be significantly less expensive than their lithium-ion counterparts if more companies start making more of them.”

What will these batteries be used for?

Right now, Natron has its focus set on AI models and data storage centers, which consume hefty amounts of energy. In 2023, the MIT Technology Review reported that one AI model can emit more than 626,00 pounds of carbon dioxide equivalent.

“We expect our battery solutions will be used to power the explosive growth in data centers used for Artificial Intelligence,” said Wendell Brooks, co-CEO of Natron.

“With the start of commercial-scale production here in Michigan, we are well-positioned to capitalize on the growing demand for efficient, safe, and reliable battery energy storage.”

The fast-charging energy alternative also has limitless potential on a consumer level, and Natron is eying telecommunications and EV fast-charging once it begins servicing AI data storage centers in June.

On a larger scale, sodium-ion batteries could radically change the manufacturing and production sectors — from housing energy to lower electricity costs in warehouses, to charging backup stations and powering electric vehicles, trucks, forklifts, and so on.

“I founded Natron because we saw climate change as the defining problem of our time,” Wessells said. “We believe batteries have a role to play.”

-via GoodGoodGood, May 3, 2024

--

Note: I wanted to make sure this was legit (scientifically and in general), and I'm happy to report that it really is! x, x, x, x

#batteries#lithium#lithium ion batteries#lithium battery#sodium#clean energy#energy storage#electrochemistry#lithium mining#pollution#human rights#displacement#forced labor#child labor#mining#good news#hope

3K notes

·

View notes

Text

Green Energy’s Dirty Secret: The Copper Fallacy 🧵

The push for electric vehicles (EVs) and solar power is hailed as a climate solution. But beneath the surface lies a growing crisis: copper dependency.

Each EV requires up to 4x more copper than a gas car. Solar panels, wind turbines, and battery storage also depend heavily on copper. The IEA estimates copper demand could increase 600% by 2050. But reserves are limited, extraction is destructive, and costs are skyrocketing.

🔍 A recent Earth.com study warns: there simply isn’t enough copper to electrify both developed and developing nations.

So what are we really building? A sustainable future—or a green-painted industrial complex?

⚠️ The Problems:

Toxic mining harms ecosystems & pollutes water

Child labor and poor working conditions in DRC, Chile, Peru

EV batteries often aren't recycled

Grid rebuilds are copper-heavy and economically risky

This isn't clean energy—it's outsourced destruction.

🌍 Carbon Colonialism

Rich nations extract copper from the Global South, leaving behind environmental degradation and human rights violations. Amnesty International has reported widespread child labor in EV supply chains.

🚗 The Case for Hydrogen:

Hydrogen fuel cell vehicles use far less copper, offer longer ranges, and refuel in minutes. Infrastructure can piggyback on existing gas networks—unlike EV grids that require total copper-dependent overhauls.

🔋 Other low-impact solutions include:

Graphene batteries

Thorium reactors

Compressed air vehicles

💡 What’s the path forward? ✅ Invest in hydrogen infrastructure

✅ Enforce ethical supply chains

✅ Encourage diversified tech development

✅ Educate the public on lifecycle impacts

🌱 Conclusion:

EVs and solar panels aren’t the endgame—they're a stage in a broader conversation. We must challenge greenwashing and support solutions that work for people, planet, and posterity.

2 notes

·

View notes

Text

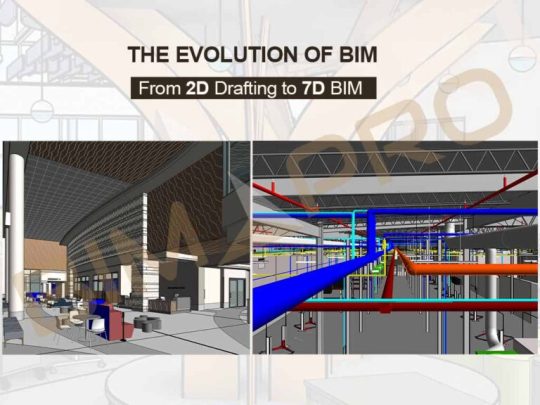

The Evolution of BIM: From 2D Drafting to 7D BIM

The construction industry has witnessed a remarkable transformation over the past few decades, driven by technological advancements. One of the most significant innovations is Building Information Modeling (BIM). What started as simple 2D drafting has evolved into a comprehensive system encompassing multiple dimensions. From design to maintenance, BIM has revolutionized the way we plan, construct, and manage buildings. In this blog, we will explore the journey of BIM from its early days to the highly advanced 7D BIM we see today.

The Era of 2D Drafting: The Beginning

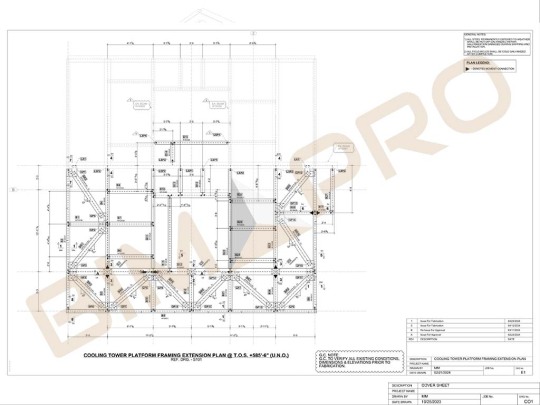

Before the advent of BIM, architects, engineers, and designers relied on 2D drafting techniques. Blueprints and technical drawings were manually created on paper, requiring immense precision and effort. The introduction of computer-aided design (CAD) in the 1960s and 1970s brought a significant shift, allowing professionals to create digital 2D drawings. However, these drawings remained static representations, often leading to errors, miscommunication, and time-consuming revisions. The lack of data integration meant that project information was scattered, leading to inefficiencies in project execution and management.

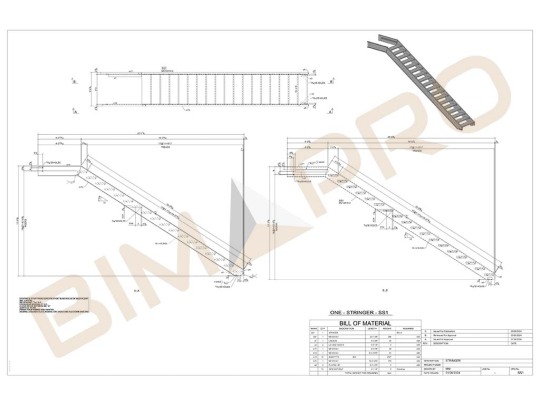

Moreover, 2D drafting required extensive manual labor for each stage of the design process. Any changes in the design had to be redrawn from scratch, consuming valuable time. Coordination between different teams was also challenging, as changes in one discipline often led to inconsistencies in others. Errors were only discovered during construction, resulting in costly rework and delays. Additionally, quantity take-offs and bill of materials (BOM) had to be calculated manually, increasing the risk of miscalculations and cost overruns.

The Transition to 3D Modeling: A Game Changer

The limitations of 2D drafting led to the development of 3D modeling. In the late 20th century, software like AutoCAD, Revit, and ArchiCAD introduced the concept of three-dimensional design. 3D modeling provided a more realistic and detailed representation of structures, improving visualization and coordination among stakeholders. Architects and engineers could now see their designs in a virtual environment before construction began, allowing for better planning and reducing costly errors.

Unlike 2D drawings, 3D models allowed for a more intuitive understanding of spatial relationships. Teams could detect clashes between different systems, such as plumbing and electrical, before construction, leading to a significant reduction in errors. However, despite the added dimension, it still lacked data integration and intelligence, as it mainly focused on geometry rather than project information management. At this stage, Level of Development (LOD) concepts started emerging, enabling different stakeholders to define and refine the details of the BIM model at different stages of the project lifecycle.

4D BIM: Adding the Time Dimension

The next breakthrough in BIM came with the introduction of the fourth dimension: time. 4D BIM integrates project scheduling with 3D models, enabling stakeholders to visualize the construction sequence over time. This advancement improved project planning, reduced delays, and enhanced collaboration among teams. Contractors could simulate different scenarios, identify potential bottlenecks, and optimize construction workflows.

By linking the construction timeline to the 3D model, project managers could anticipate potential issues, allocate resources efficiently, and ensure smoother project execution. 4D BIM allowed teams to see when each component of the project would be constructed, facilitating better coordination between trades and minimizing on-site conflicts. As a result, construction projects became more predictable, reducing downtime and increasing efficiency.

5D BIM: Incorporating Cost Management

Cost estimation has always been a critical aspect of construction projects. 5D BIM brought financial management into the equation by linking cost data with the 3D model and project schedule. This integration provided accurate cost forecasting, real-time budget updates, and improved decision-making. Stakeholders could analyze cost variations, track expenses, and ensure financial control throughout the project lifecycle.

With 5D BIM, cost estimators and project managers could evaluate different design alternatives and their financial impact, ultimately helping in budget optimization and cost-effective decision-making. Cost changes due to material choices, design modifications, or construction sequences could be assessed in real time, preventing budget overruns. Automated quantity take-offs became more efficient and accurate, ensuring that project cost estimates aligned closely with actual construction costs. This real-time tracking of costs made construction more financially transparent, ensuring stakeholders had a clear understanding of budget allocations at every stage.

6D BIM: Enhancing Sustainability and Facility Management

As sustainability became a key focus in the construction industry, 6D BIM emerged to address environmental concerns. This dimension incorporates energy analysis, lifecycle assessment, and sustainability metrics into BIM models. Building owners and facility managers can use 6D BIM to optimize energy efficiency, reduce carbon footprints, and plan for long-term maintenance.

Additionally, it aids in predictive maintenance by providing insights into building performance over time. With real-time data and simulations, sustainability goals such as energy efficiency, material durability, and operational cost reductions can be achieved, ensuring environmentally responsible building designs. Green building certifications such as LEED and BREEAM can be seamlessly integrated into the BIM model, allowing for data-driven decision-making in sustainability planning.

By leveraging 6D BIM, facility managers can track energy consumption, perform preventive maintenance, and monitor the building’s carbon footprint. It enables owners to make data-driven decisions that enhance the building’s efficiency and extend its lifespan, ultimately leading to significant cost savings and environmental benefits. COBie (Construction-Operations Building Information Exchange) standards also play a critical role at this stage, ensuring that asset data is structured and efficiently transferred for use in facility management.

7D BIM: The Future of Building Management

The most advanced stage of BIM, 7D BIM, integrates facility management with real-time data. It allows stakeholders to manage the entire lifecycle of a building, from design to demolition. By incorporating asset management, maintenance scheduling, and IoT integration, 7D BIM enhances operational efficiency and reduces maintenance costs.

Building owners can track the performance of building components, automate maintenance tasks, and ensure long-term sustainability. With the growing adoption of smart buildings and IoT-enabled systems, 7D BIM is paving the way for more connected, efficient, and resilient building management practices. Facility managers can use digital twins of buildings to simulate operational scenarios, predict maintenance needs, and improve asset longevity.

Through integration with IoT, sensors can provide real-time data on occupancy, temperature, and equipment performance, enabling automated responses and predictive maintenance. This not only enhances comfort and safety but also significantly reduces operational costs, making 7D BIM an essential tool for modern building management. Furthermore, as-built BIM models ensure that facility managers have an accurate digital representation of the constructed building, enabling informed decision-making throughout the building’s lifecycle.

Benefits of BIM Evolution:

Here are some expanded benefits of BIM evolution:

Improved Collaboration and Coordination Accurate Quantity Take-Offs and Cost Estimation Reduced Errors, Rework, and Risks Enhanced Time Management and Scheduling Improved Facility Management and Lifecycle Analysis Sustainability and Energy Efficiency Higher Level of Development (LOD) for Better Detailing

Conclusion

The evolution of BIM has transformed the way we design, construct, and manage buildings. From simple 2D drawings to the intelligent and data-driven 7D BIM, the construction industry has embraced a new era of efficiency, sustainability, and innovation. As technology continues to advance, we can expect even more dimensions and capabilities to be integrated into BIM, shaping the future of architecture and engineering. Whether you are an architect, contractor, or building owner, understanding and leveraging BIM is no longer an option but a necessity for success in the modern construction landscape.

1 note

·

View note

Text

Transforming the Health Landscape: The Global Blockchain in Healthcare Market

The integration of blockchain technology into the healthcare sector is revolutionizing the way medical data is managed, shared, and secured. As the demand for transparent, efficient, and secure healthcare services grows, blockchain offers promising solutions to longstanding challenges.

Understanding Blockchain in Healthcare

Blockchain Technology is a decentralized digital ledger that records transactions across multiple computers in a way that ensures the security and transparency of data. In healthcare, blockchain can be used to manage patient records, track pharmaceuticals, ensure the integrity of clinical trials, and streamline administrative processes. The immutable nature of blockchain helps in preventing data breaches, ensuring data accuracy, and enhancing patient privacy.

According to BIS Research, the Global Blockchain in Healthcare Market was estimated to grow to a value of $5.61 billion by 2025, and still the market is showing a steep growth till 2030 witnessing a double-digit CAGR growth rate throughout the forecast period.

Key Market Dynamics

Several factors are driving the growth of the global blockchain in healthcare market:

Data Security and Privacy:

Need for robust data security and privacy solutions.

Healthcare data breaches are a growing concern.

Blockchain's secure, immutable nature protects sensitive patient information.

Interoperability and Data Sharing:

Facilitates seamless data sharing between healthcare providers and systems.

Overcomes current interoperability issues.

Leads to better patient outcomes by providing a comprehensive view of health history.

Supply Chain Transparency:

Tracks the entire lifecycle of drugs in the pharmaceutical industry.

Ensures the authenticity of medications.

Helps combat counterfeit drugs.

Efficient Administrative Processes:

Streamlines various administrative processes, such as billing and claims management.

Reduces fraud and administrative costs.

Support from Regulatory Bodies:

Increasing support from regulatory bodies and governments.

Initiatives by FDA and EMA to explore blockchain for drug traceability and clinical trials boost market growth.

Request for an updated Research Report on Global Blockchain in Healthcare Market Research.

Global Blockchain in Healthcare Industry Segmentation

Segmentation by Application:

Data Exchange and Interoperability

Supply Chain Management

Claims Adjudication and Billing Management

Clinical Trials and Research

Others

Segmentation by End-User:

Healthcare Providers

Pharmaceutical Companies

Payers

Others

Segmentation by Region:

North America

Europe

Asia-Pacific

Latin America and Middle East & Africa

Future Market Prospects

The future of the global blockchain in healthcare market looks promising, with several trends likely to shape its trajectory:

Integration with AI and IoT: The integration of blockchain with artificial intelligence (AI) and the Internet of Things (IoT) will enhance data analytics, predictive healthcare, and real-time monitoring.

Expansion of Use Cases: New use cases for blockchain in digital healthcare will emerge, including patient-centered care models, personalized medicine, and enhanced telemedicine services.

Focus on Patient-Centric Solutions: Blockchain will enable more patient-centric healthcare solutions, empowering patients with greater control over their health data and enhancing patient engagement.

Development of Regulatory Frameworks: The establishment of clear regulatory frameworks and industry standards will facilitate the widespread adoption of blockchain in healthcare.

Conclusion

The Global Blockchain in Healthcare Industry is poised for significant growth, driven by the need for enhanced data security, interoperability, supply chain transparency, and efficient administrative processes. By addressing challenges related to regulatory compliance, implementation costs, standardization, and scalability, and leveraging opportunities in technological advancements, investments, partnerships, and government initiatives, the potential of blockchain in healthcare can be fully realized. This technology promises to revolutionize healthcare delivery, enhancing efficiency, transparency, and patient outcomes, and setting new standards for the future of digital health.

#Blockchain in Healthcare Market#Blockchain in Healthcare Industry#Blockchain in Healthcare Market Report#Blockchain in Healthcare Market Research#Blockchain in Healthcare Market Forecast#Blockchain in Healthcare Market Analysis#Blockchain in Healthcare Market Growth#BIS Research#Healthcare

2 notes

·

View notes

Text

web design company in patna

web design company in patna

In Patna, the capital city of Bihar, India, several website design companies cater to the growing demand for online presence and digital solutions. Choosing the right website design company in Patna involves considering various factors to ensure that your web presence reflects your brand effectively. Here’s an overview of what to look for when selecting a website design company in Patna, encompassed within a 500-word limit:

Local Presence and Reputation: Seek a company with a physical presence in Patna and a positive reputation in the local market. Check their experience working with businesses in the region and their familiarity with the local audience and market trends.

Portfolio and Expertise: Review their portfolio to assess the quality and diversity of their previous work. Look for designs that resonate with your vision and demonstrate creativity, functionality, and responsiveness across various industries.

Client Testimonials and Reviews: Check for client testimonials, reviews, and case studies to understand the experiences of their previous clients. Testimonials can provide insights into the company's reliability, communication, and the ability to deliver on promises.

Technical Expertise and Services: Ensure the company possesses technical expertise in website design, development, and other services you might require, such as SEO, e-commerce solutions, mobile responsiveness, and content management systems (CMS) like WordPress, Joomla, or Drupal.

Customization and Client-Centric Approach: Look for a company that values client input and offers customized solutions tailored to your business needs. A client-centric approach ensures that the website reflects your brand identity and goals effectively.

Communication and Support: Effective communication is crucial for a successful project. Assess their communication channels, responsiveness to queries, and the willingness to provide regular updates throughout the project lifecycle. Also, inquire about post-launch support and maintenance services.

Cost and Value Proposition: Consider the cost of services in relation to the value provided. While cost is important, prioritize value and quality over a low price. Ensure transparency in pricing and clarity on what services are included in the quoted price.

Timeline and Project Management: Discuss the estimated timeline for project completion and their approach to project management. A reliable company should have a structured project plan and a realistic timeline to meet deadlines effectively.

Local Market Understanding: Look for a company that understands the local market dynamics, cultural nuances, and preferences of the audience in Patna. This understanding can help in crafting a website that resonates well with the target audience.

#website designing#online marketing#digital marketing#ott development#website design#ott develop#ott develops#ott#webdevelopment

2 notes

·

View notes

Text

website design company in patna

website design company in patna

In Patna, the capital city of Bihar, India, several website design companies cater to the growing demand for online presence and digital solutions. Choosing the right website design company in Patna involves considering various factors to ensure that your web presence reflects your brand effectively. Here’s an overview of what to look for when selecting a website design company in Patna, encompassed within a 500-word limit:

Local Presence and Reputation: Seek a company with a physical presence in Patna and a positive reputation in the local market. Check their experience working with businesses in the region and their familiarity with the local audience and market trends.

Portfolio and Expertise: Review their portfolio to assess the quality and diversity of their previous work. Look for designs that resonate with your vision and demonstrate creativity, functionality, and responsiveness across various industries.

Client Testimonials and Reviews: Check for client testimonials, reviews, and case studies to understand the experiences of their previous clients. Testimonials can provide insights into the company's reliability, communication, and the ability to deliver on promises.

Technical Expertise and Services: Ensure the company possesses technical expertise in website design, development, and other services you might require, such as SEO, e-commerce solutions, mobile responsiveness, and content management systems (CMS) like WordPress, Joomla, or Drupal.

Customization and Client-Centric Approach: Look for a company that values client input and offers customized solutions tailored to your business needs. A client-centric approach ensures that the website reflects your brand identity and goals effectively.

Communication and Support: Effective communication is crucial for a successful project. Assess their communication channels, responsiveness to queries, and the willingness to provide regular updates throughout the project lifecycle. Also, inquire about post-launch support and maintenance services.

Cost and Value Proposition: Consider the cost of services in relation to the value provided. While cost is important, prioritize value and quality over a low price. Ensure transparency in pricing and clarity on what services are included in the quoted price.

Timeline and Project Management: Discuss the estimated timeline for project completion and their approach to project management. A reliable company should have a structured project plan and a realistic timeline to meet deadlines effectively.

Local Market Understanding: Look for a company that understands the local market dynamics, cultural nuances, and preferences of the audience in Patna. This understanding can help in crafting a website that resonates well with the target audience.

2 notes

·

View notes

Text

Achieving Cost Savings through Supplier Collaboration in Siemens Teamcenter PLM Software

In the dynamic landscape of modern business, collaboration is the cornerstone of success. This holds true not only within an organization but also across the entire supply chain. Suppliers play a pivotal role in the journey from concept to creation, and their collaboration can yield significant cost savings and operational efficiencies. Teamcenter PLM's supplier collaboration features are transforming the way organizations interact with suppliers, leading to negotiated cost savings, improved procurement processes, and enhanced cost control. In this article, we delve into how Teamcenter PLM is fostering this collaborative spirit, backed by real-world examples.

A New Paradigm in Supplier Collaboration

Gone are the days of transactional relationships between organizations and suppliers. The modern approach is based on collaboration, where suppliers are viewed as strategic partners integral to the success of a project. Siemens PLM Software, with its comprehensive suite of supplier collaboration tools, empowers organizations to seamlessly integrate suppliers into their product development processes.

Negotiated Cost Savings: A Win-Win Scenario

Supplier collaboration in Teamcenter PLM opens the door to negotiated cost savings. When suppliers are brought into the design phase, they can offer valuable insights into cost-effective materials, manufacturing processes, and alternative components. By tapping into their expertise, organizations can optimize designs for cost efficiency without compromising on quality. For instance, a manufacturer collaborating with a supplier might identify a more cost-effective yet equally durable material for a component, resulting in substantial cost savings over the product's lifecycle.

Improved Procurement Processes: Streamlining Efficiency

Procurement is a critical component of the supply chain, and any inefficiencies can lead to increased costs. Teamcenter PLM's Cost Management Software supplier collaboration features streamline procurement processes by providing real-time visibility into supplier capabilities, capacities, and lead times. This enables organizations to make informed decisions about sourcing, reducing the risk of delays and costly last-minute changes. For instance, a company collaborating with a supplier can receive updates on raw material availability, helping them plan their production schedule and avoid costly supply shortages.

Enhanced Cost Control: Data-Driven Insights

Effective cost control requires accurate and up-to-date information. Teamcenter PLM's supplier collaboration features enable organizations to access real-time cost data from suppliers. This transparency empowers procurement teams to make strategic decisions based on actual costs rather than estimates. Furthermore, collaboration with suppliers can help organizations identify cost drivers and areas where cost reductions can be implemented. For instance, a company working closely with a supplier might discover opportunities to consolidate shipments, reducing transportation costs.

Real-World Examples of Success

Real-world examples illustrate the power of supplier collaboration in achieving cost savings. Consider a consumer electronics company partnering with a supplier to design a new smartphone. By collaborating closely, they identify a more cost-effective battery design that doesn't compromise on performance. This leads to reduced manufacturing costs and a competitive edge in the market.

In the automotive industry, a car manufacturer collaborates with a supplier of advanced materials. Together, they explore innovative materials that are not only lightweight but also cost-efficient. This collaboration results in cost savings due to reduced material consumption and improved fuel efficiency in the final product.

Conclusion: Empowering Future Success

Supplier collaboration through Teamcenter PLM software transcends traditional boundaries. It's a strategy that fosters innovation, efficiency, and cost savings. By involving suppliers early in the product development process, organizations can tap into their expertise, optimize designs, and make informed decisions that positively impact the bottom line. As the business landscape continues to evolve, organizations that embrace supplier collaboration are not only achieving cost savings but also laying the foundation for future success and growth.

For Free PLM Software trial, download Siemens Teamcenter PLM software trial!

#plmsoftware#costmanagementsoftware#what is plm software#plm software#siemens plm software#cost reduction software#free plm software

2 notes

·

View notes

Text

Floating Wind Turbines Market to Surpass $83.4 Billion by 2034

The floating wind turbines market is undergoing a dramatic transformation as global economies race to decarbonize their energy supply. Valued at US$ 4.9 Bn in 2023, the market is poised to surge at an exceptional CAGR of 29.4% from 2024 to 2034, reaching an estimated US$ 83.4 Bn by the end of the forecast period. Driven by environmental mandates, rapid technological advances, and growing investor confidence, floating wind turbines are gaining traction as a scalable and sustainable solution to meet global energy demands.

A Turning Point in Renewable Energy

One of the key drivers behind the floating wind turbine market growth is the global push to reduce fossil fuel dependency. As countries seek to limit their carbon emissions and increase energy security, investment in renewable energy infrastructure—especially offshore wind—is accelerating. Floating wind turbines offer a solution that overcomes the depth limitations of traditional fixed-bottom offshore turbines, allowing access to high-wind areas in deeper waters.

According to the U.S. Department of Energy (DOE), offshore wind energy production rose 15% in 2023 compared to the previous year, underscoring the growing momentum in this sector.

Funding the Future: Eco-friendly Floating Wind Farms

Governments and international organizations are increasingly backing floating offshore wind projects with dedicated funding. One notable example is the Floatfarm project, launched in January 2024 by a consortium of 17 partners across eight European countries. Funded by the European Commission with nearly EUR 6 million, the project aims to minimize environmental impacts on marine ecosystems and boost public support for offshore developments.

These initiatives reflect a broader shift toward sustainable wind energy systems—not just in power generation, but also in turbine design, material sourcing, and lifecycle management.

Engineering Excellence: Types of Floating Foundations

The success of floating wind turbines largely depends on the type of floating foundation used. The three most common types are:

Improved engineering and a drop in installation costs are enabling larger turbine capacities and the deployment of floating systems in more challenging offshore environments.

Regional Landscape: Europe Takes the Lead

According to the latest market analysis, Europe held the largest market share in 2023, driven by robust public funding, policy support, and infrastructure maturity. Recent initiatives like France’s BATSO project, backed by EUR 2.9 million from ADEME, are focused on improving component replacement methods to cut costs and reduce environmental impacts.

Meanwhile, Asia Pacific is rapidly catching up. In June 2024, Norway-based Equinor received approval to conduct a feasibility study for Australia’s first floating wind development, highlighting the region’s growing interest in floating wind technologies.

Market Dynamics: Key Trends and Opportunities

Several trends are shaping the market trajectory:

Furthermore, the entry of new players is increasing competition and accelerating innovation. Startups and established manufacturers alike are striving to offer low-cost, high-efficiency floating wind solutions.

Competitive Landscape: Industry Leaders in Action

Prominent players in the floating wind turbines industry include:

These companies are investing heavily in R&D, focusing on rotor aerodynamics, advanced mooring systems, and intelligent wind farm control systems to strengthen their market positions.

In June 2024, Skyborn Renewables signed a Master Supply Agreement with Siemens Gamesa for 63 wind turbines for its 945 MW project in the German Baltic Sea. Likewise, Vattenfall and BASF inked a supply and service deal with Vestas for 15 MW turbines in Germany’s Nordlicht project.

Conclusion: Floating Wind’s High-Growth Horizon

With an expected market value of US$ 83.4 Bn by 2034, the floating wind turbines sector presents one of the most dynamic opportunities in the global renewable energy landscape. As technologies mature and investments rise, floating wind turbines are set to become a cornerstone of clean energy strategies worldwide.

Stakeholders who act decisively now—by investing in innovation, forging partnerships, and scaling operations—stand to lead in what is shaping up to be a transformative decade for offshore wind energy.

0 notes

Text

CMP Slurry Monitoring Market, Key Industry Insights, and Forecast to 2032

Global CMP Slurry Monitoring Market size was valued at US$ 183.4 million in 2024 and is projected to reach US$ 326.7 million by 2032, at a CAGR of 8.5% during the forecast period 2025-2032. The U.S. market is estimated at USD 92.4 million in 2024, while China is expected to grow at a faster pace reaching USD 134.6 million by 2032.

CMP (Chemical Mechanical Planarization) slurry monitoring systems are critical quality control solutions used in semiconductor manufacturing to analyze and maintain slurry properties. These systems measure key parameters including Large Particle Counts (LPC), density, viscosity, pH levels, and particle size distribution to ensure optimal polishing performance. The technology plays a vital role in improving wafer yield and reducing defects in advanced node semiconductor production.

Market growth is driven by the semiconductor industry’s transition to smaller process nodes (below 7nm) which requires stricter slurry quality control. The Large Particle Counts (LPC) segment dominates with 38% market share in 2024 due to its direct impact on wafer surface defects. Key players like ENTEGRIS, INC and HORIBA are expanding their monitoring portfolios through acquisitions, with the top five companies holding 62% market share. Recent innovations include real-time monitoring systems that integrate AI for predictive maintenance in fab operations.

Get Full Report : https://semiconductorinsight.com/report/cmp-slurry-monitoring-market/

MARKET DYNAMICS

MARKET DRIVERS

Rising Demand for Advanced Semiconductor Manufacturing to Boost CMP Slurry Monitoring Adoption

The global semiconductor industry is experiencing unprecedented growth, with manufacturing complexity increasing as chip designs shrink below 10nm nodes. This drives the need for precise chemical mechanical planarization (CMP) processes where slurry quality directly impacts yield rates. Leading foundries report that improper slurry monitoring can reduce wafer yields by up to 15-20% due to defects like scratching or incomplete polishing. As a result, semiconductor manufacturers are increasingly adopting automated CMP slurry monitoring systems to maintain optimal particle size distribution, viscosity, and chemical composition throughout the polishing process.

Technology Miniaturization Trends Accelerating Market Growth

The relentless push toward smaller semiconductor nodes below 7nm is creating new challenges in CMP processes that require real-time slurry monitoring. Modern slurry formulations contain engineered abrasives with particle sizes under 100nm, where even minor deviations in particle concentration can cause catastrophic wafer defects. This technological evolution has led to a threefold increase in demand for advanced monitoring solutions capable of detecting sub-100nm particles across multiple CMP process steps. Leading manufacturers now integrate monitoring systems directly into CMP tools to enable closed-loop control, driving market growth as foundries upgrade equipment for next-generation nodes.

Increasing Focus on Predictive Maintenance Creating New Opportunities

Semiconductor manufacturers are shifting from reactive to predictive maintenance strategies, with CMP slurry monitoring playing a pivotal role. Continuous monitoring of slurry parameters allows for early detection of quality degradation before it impacts production. Analysis shows that predictive maintenance enabled by slurry monitoring can reduce unplanned tool downtime by 30-40% while extending consumable lifecycles. Major players now offer AI-powered analytics platforms that correlate slurry data with tool performance, helping fabs optimize polish rates and reduce material waste. This trend is particularly strong in memory chip production, where CMP processes account for over 25% of total manufacturing costs.

MARKET RESTRAINTS

High Implementation Costs Creating Barriers for Smaller Fabs

While CMP slurry monitoring delivers substantial ROI for high-volume manufacturers, the capital expenditure required creates significant barriers for adoption. A complete monitoring system including sensors, analytics software, and integration with CMP tools can cost $500,000-$1 million per toolset. This represents a major investment for smaller foundries or research facilities that may process fewer wafers. Additionally, the need for specialized installation and calibration further increases total cost of ownership, limiting market penetration among cost-sensitive operations.

Technical Complexity of Multi-Parameter Monitoring Presents Challenges

Modern CMP slurries require monitoring of 10+ critical parameters simultaneously, including particle counts, zeta potential, pH, and chemical concentrations. Integrating sensors for all relevant measurements without disrupting slurry flow or introducing measurement artifacts remains an engineering challenge. Many existing monitoring solutions compromise by measuring only 2-3 key parameters, potentially missing critical quality variations. The industry also faces difficulties in developing non-invasive sensors that can withstand the corrosive chemical environment of CMP slurries over extended periods without drift or contamination.

Lack of Standardization Across Slurry Formulations

The CMP slurry market includes hundreds of proprietary formulations from different suppliers, each requiring customized monitoring approaches. This lack of standardization forces equipment vendors to develop numerous sensor configurations and calibration methods. Foundries using multiple slurry types face additional complexity in maintaining separate monitoring protocols for each chemistry. The situation is particularly challenging for advanced materials like ceria-based slurries where oxidation state monitoring becomes critical but lacks established industry standards.

MARKET OPPORTUNITIES

Emerging Advanced Packaging Technologies Creating New Application Areas

The rapid growth of advanced packaging technologies like 3D IC and chiplets is opening new applications for CMP slurry monitoring. These packaging approaches require planarization of multiple material layers including copper, dielectrics, and through-silicon vias (TSVs). Each material combination demands specialized slurry formulations with tight process control. Market analysis indicates the packaging segment will grow at a 12-15% CAGR as next-generation devices increasingly adopt heterogeneous integration. This creates opportunities for monitoring solutions that can handle the diverse material sets used in advanced packaging workflows.

AI-Powered Analytics Transforming Slurry Process Control

The integration of machine learning with CMP slurry monitoring represents a major growth opportunity. Advanced algorithms can now predict slurry degradation patterns and optimize replenishment schedules with 90-95% accuracy. This enables significant reductions in slurry consumption while minimizing quality excursions. Leading manufacturers are developing cloud-based platforms that aggregate data across multiple fabs to identify global optimization opportunities. These AI solutions are particularly valuable for memory manufacturers where small improvements in CMP efficiency can translate to millions in annual savings.

Expansion in Compound Semiconductor Manufacturing

The growing production of compound semiconductors for power electronics, RF devices, and photonics is creating new markets for specialized CMP monitoring solutions. Materials like GaN and SiC present unique planarization challenges due to their hardness and chemical stability. The compound semiconductor market is projected to grow at 18-20% annually as electric vehicle and 5G adoption accelerates. This drives demand for monitoring systems capable of handling the aggressive chemistries and high-pressure conditions required for compound semiconductor CMP processes.

MARKET CHALLENGES

Maintaining Measurement Accuracy in High-Volume Production

Ensuring consistent monitoring accuracy across thousands of wafer polishing cycles remains a significant challenge. Sensor drift, slurry residue buildup, and calibration inconsistencies can degrade measurement precision by 10-15% between maintenance cycles. This variability creates quality control risks as manufacturers push CMP tools to higher throughput levels. The industry is responding with self-calibrating sensors and automated cleaning systems, but achieving six-sigma reliability in production environments continues to challenge equipment developers.

Integration Challenges with Legacy CMP Equipment

Many semiconductor fabs operate CMP tools that are 7-10 years old, lacking modern interfaces for real-time monitoring integration. Retrofitting these systems with advanced slurry monitoring capabilities often requires extensive tool modifications that can cost $200,000+ per tool. The compatibility issues create adoption barriers as manufacturers weigh the benefits against potential production disruptions during installation. Equipment vendors are developing modular solutions to ease integration, but the diverse installed base continues to present technical challenges.

Environmental Regulations Impacting Slurry Formulations

Increasing environmental regulations are forcing changes to CMP slurry chemistries, particularly regarding heavy metal content and wastewater discharge. Each formulation change requires corresponding updates to monitoring protocols and sensor configurations. The EU’s recent restrictions on certain abrasive materials have already impacted 15-20% of traditional slurry formulations. These regulatory shifts create uncertainty as monitoring system providers must continuously adapt to evolving material restrictions while maintaining measurement accuracy across changing chemistries.

CMP SLURRY MONITORING MARKET TRENDS

Increasing Semiconductor Manufacturing Complexity Driving Demand for Advanced CMP Slurry Monitoring

The semiconductor industry’s relentless push toward smaller node sizes below 7nm has significantly increased the importance of precise Chemical Mechanical Planarization (CMP) slurry monitoring. As feature sizes shrink below 5nm, particle contamination becomes exponentially more critical, with even nanometer-scale impurities capable of causing device failures. This technological imperative has driven adoption rates of advanced slurry monitoring systems to over 65% among leading semiconductor foundries. The integration of real-time analytics with IoT-connected monitoring devices allows for immediate corrective actions, reducing wafer scrap rates by approximately 25%. Furthermore, the emergence of artificial intelligence and machine learning applications in slurry monitoring has enabled predictive maintenance capabilities, further enhancing yield optimization.

Other Trends

Transition to Copper Interconnects and New Materials

The industry-wide transition from aluminum to copper interconnects and the adoption of novel low-k dielectric materials have introduced new challenges in CMP processing. Copper slurry monitoring now accounts for nearly 40% of total monitoring system deployments, requiring specialized capabilities to detect electrochemical interactions and maintain optimal oxidation states. Additionally, the introduction of cobalt interconnect technology in advanced nodes has created demand for monitoring solutions capable of tracking multiple slurry parameters simultaneously, including pH levels, oxidation-reduction potential, and abrasive particle distribution.

Expansion of 300mm Wafer Fabs and Emerging 450mm Transition

The continued expansion of 300mm wafer manufacturing facilities worldwide has created substantial demand for slurry monitoring systems. With approximately 130 operational 300mm fabs globally and 20 more under construction, monitoring equipment must handle higher throughput requirements while maintaining precision. Meanwhile, pilot lines for 450mm wafer processing are driving development of next-generation monitoring solutions capable of handling larger slurry volumes and more complex fluid dynamics. This transition presents both challenges and opportunities in slurry monitoring, requiring innovations in sensor technology and data processing capabilities to ensure consistent performance across larger wafer surfaces.

Increasing Regulatory Scrutiny on Environmental Compliance

Stringent environmental regulations governing chemical usage and waste management in semiconductor manufacturing are prompting greater investment in comprehensive slurry monitoring solutions. Facilities are implementing closed-loop systems that reduce chemical consumption by up to 30% while maintaining process quality. Advanced monitoring technologies now track not only slurry composition during use but also degradation byproducts for proper disposal classification. This regulatory pressure, combined with corporate sustainability initiatives, has made environmental monitoring capabilities a key differentiator in slurry monitoring system procurement decisions.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovative Monitoring Solutions Reshape the Competitive Dynamics

The global CMP Slurry Monitoring market exhibits a moderately consolidated structure dominated by specialized technology providers catering to semiconductor fabrication needs. ENTEGRIS, INC leads the competitive landscape with approximately 22% market share in 2024, owing to its comprehensive portfolio of real-time slurry monitoring systems and strong partnerships with leading foundries.

HORIBA and Rheonics collectively account for nearly 30% of the market, leveraging their expertise in precision measurement technologies. These companies gained significant traction through their ability to integrate viscosity monitoring with particle counting capabilities – a critical advancement for 3nm and below process nodes.

Recent developments show competitors accelerating R&D investments to address emerging requirements. Spheryx, Inc. made strategic moves in 2023 with its patented xSight system that offers inline zeta potential measurements alongside traditional LPC detection – a functionality gaining importance in advanced node production.

Meanwhile, Colloidal Dynamics LLC strengthened its position through the 2022 acquisition of Nanolytica’s spectroscopy patents, enhancing its multi-parameter analysis capabilities. The company currently holds about 12% of the global monitoring solutions market.

List of Leading CMP Slurry Monitoring Solution Providers

ENTEGRIS, INC (U.S.)

Rheonics (Switzerland)

Colloidal Dynamics LLC (U.S.)

HORIBA (Japan)

Entegris (U.S.)

Spheryx, Inc. (U.S.)

Applied Analytics, Inc. (U.S.)

Segment Analysis:

By Type

Large Particle Counts (LPC) Segment Dominates Due to Critical Role in Semiconductor Quality Control

The market is segmented based on type into:

Large Particle Counts (LPC)

Subtypes: In-line sensors and off-line analyzers

Density

Viscosity

Others

By Application

Semiconductor Manufacturing Segment Leads Owing to Rising Demand for Advanced Chip Fabrication

The market is segmented based on application into:

Integrated Circuit

Semiconductor Manufacturing

Others

By End User

Foundries Dominate Market Share Due to High-Volume Production Requirements

The market is segmented based on end user into:

Foundries

IDMs (Integrated Device Manufacturers)

Research Institutions

Regional Analysis: CMP Slurry Monitoring Market

North America The North American CMP slurry monitoring market is thriving due to robust semiconductor manufacturing and significant investments in advanced wafer fabrication technologies. The U.S., in particular, holds a dominant position, accounting for over 40% of the regional market share. Key semiconductor hubs such as Silicon Valley and Arizona drive demand for real-time slurry monitoring systems that optimize chemical mechanical planarization (CMP) processes. Strict quality control standards set by semiconductor giants like Intel and Micron intensify the need for high-precision monitoring of slurry properties, including Large Particle Counts (LPC) and viscosity. Rising adoption of Industry 4.0 and IoT-enabled monitoring solutions further accelerates growth in this region. Challenges include high costs of advanced monitoring equipment, though these are offset by strong R&D investments from leading players.

Europe Europe’s market is driven by a combination of environmental regulations and demand for high-performance semiconductor manufacturing. Countries like Germany and Belgium—home to major fabrication plants—are investing in automated slurry-monitoring solutions to enhance production efficiency. EU directives on waste reduction and chemical sustainability push manufacturers toward slurry-monitoring technologies that minimize defects and optimize slurry usage. High labor costs in Europe make automation particularly appealing, fostering growth opportunities for vendors offering AI-driven monitoring systems. However, smaller semiconductor manufacturers in Eastern Europe face cost-related barriers, slowing adoption in those areas. Collaboration between research institutions and industry players is addressing these hurdles while maintaining compliance with stringent regulatory frameworks.

Asia-Pacific Asia-Pacific dominates the global CMP slurry monitoring market, accounting for over 50% of global revenues as of 2024. China, Taiwan, and South Korea lead due to massive semiconductor production capacity—Taiwan’s TSMC alone contributes significantly to regional demand. The rapid expansion of new semiconductor fabs, particularly in China, fuels adoption of density and viscosity monitoring tools. However, cost sensitivity among smaller foundries in Southeast Asia still favors manual monitoring, restricting penetration in some markets. Government initiatives like India’s Semiconductor Mission and Japan’s subsidies for domestic chip production are expected to further accelerate demand. Meanwhile, South Korea’s Samsung and SK Hynix drive innovations in slurry reuse, necessitating highly precise monitoring solutions.

South America The South American market remains nascent, hindered by limited semiconductor manufacturing infrastructure. Brazil shows marginal growth potential due to investments in electronic component production, but overall adoption of CMP slurry monitoring technologies is low. Economic instability and reliance on imported chips discourage capital-intensive slurry monitoring investments. However, multinational companies expanding assembly operations in Mexico and Argentina are gradually introducing basic monitoring tools to improve yield rates. Regulatory frameworks for chemical handling remain underdeveloped, slowing adoption of advanced slurry management systems. Despite these challenges, long-term opportunities exist if local governments prioritize semiconductor industry development.

Middle East & Africa This region represents an emerging market with focused growth in select countries like Israel and the UAE. While semiconductor manufacturing is limited, Israel’s tech-driven economy fosters demand for slurry monitoring in specialized IC production. The UAE’s push for industrial diversification, including semiconductor packaging, presents niche opportunities. However, the lack of large-scale wafer fabs and reliance on imports constrain market expansion. Recent collaborations between Middle Eastern governments and global semiconductor firms hint at future potential, particularly in smart city projects requiring localized chip production. High costs and technical skill gaps remain barriers though, limiting immediate growth.

Get A Sample Report : https://semiconductorinsight.com/download-sample-report/?product_id=97732

Report Scope

This market research report provides a comprehensive analysis of the global and regional CMP Slurry Monitoring markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global CMP Slurry Monitoring market was valued at USD million in 2024 and is projected to reach USD million by 2032, at a CAGR of % during the forecast period.

Segmentation Analysis: Detailed breakdown by product type (Large Particle Counts (LPC), Density, Viscosity, Others), application (Integrated Circuit, Semiconductor Manufacturing, Others), and end-user industry to identify high-growth segments and investment opportunities.

Regional Outlook: Insights into market performance across North America (U.S., Canada, Mexico), Europe (Germany, France, U.K.), Asia-Pacific (China, Japan, South Korea), Latin America, and the Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including ENTEGRIS, INC, Rheonics, Colloidal Dynamics LLC, HORIBA, Entegris, Spheryx, Inc., and Applied Analytics, Inc., covering their product offerings, market share (top five players held approximately % share in 2024), and recent developments.

Technology Trends & Innovation: Assessment of emerging monitoring technologies, integration of AI/IoT in slurry monitoring, and evolving semiconductor fabrication standards.

Market Drivers & Restraints: Evaluation of factors driving market growth along with challenges in semiconductor manufacturing processes, supply chain constraints, and technical barriers.

Stakeholder Analysis: Insights for component suppliers, semiconductor manufacturers, equipment OEMs, investors, and policymakers regarding the evolving ecosystem and strategic opportunities.

Primary and secondary research methods are employed, including interviews with industry experts, data from verified sources, and real-time market intelligence to ensure the accuracy and reliability of the insights presented.

Customisation of the Report

In case of any queries or customisation requirements, please connect with our sales team, who will ensure that your requirements are met.

Related Reports :

Contact us:

+91 8087992013

0 notes

Text

Choosing the right HVAC BIM services partner to optimize building performance

The need for accurate, coordinated and information-rich HVAC BIM models originates from various business needs. These requirements include calculating optimal energy efficiency, realizing sustainable design, and quickly identifying and resolving conflicts with other fields. Furthermore, precise HVAC BIM services support accurate scheduling, cost estimation and enhanced collaboration. It also supports facilities management and maintenance, which realizes operational success for the entire lifecycle.

Understanding the Importance of HVAC BIM Services

HVAC BIM services are critical for stakeholders in construction projects. They foster clear communication, collaboration and visualization based on an information-rich and in-depth 3D model. This allows preemptive identification of conflicts, energy efficiency optimization, and informed decision making for the entire lifecycle. Moreover, selecting HVAC BIM services contributes to effective project delivery, cost savings, and the creation of sustainable buildings with greater occupant comfort.

Navigating HVAC Design with BIM: A Comprehensive Overview

Building HVAC BIM services plays a pivotal role in modern construction by providing a unified, dynamic and data-rich platform for collaboration and decision-making. Based on 3D BIM models, stakeholders can gain an understanding of HVAC system design that enables interference detection, energy optimization, and streamlined coordination. These services use techniques and tools like parametric modeling, Level of Development (LOD 100–LOD 500), and Revit families to create accurate and adaptable representations of HVAC equipment.

Furthermore, automation tools make workflows seamless to ensure precision and efficiency for the entire project lifecycle. By recording important data on performance, material specifications, and maintenance, HVAC BIM services support clients with informed choices that lead to low material waste, accurate fabrication, and expedited facility management.

Essential Factors in Choosing HVAC BIM Service providers

Prioritize Industry experience

Choosing HVAC BIM providers requires prioritising industry experience. Look for firms that have secured a history of handling successful HVAC BIM projects. The complexities within Heating, Ventilation and Air Conditioning (HVAC) are significant, and experience in BIM services for HVAC systems would help clients foster valuable insights to navigate obstacles across various project categories. Familiarity with regulations and industry standards guarantees that projects would adhere to applicable needs, to ensure compliance and high project quality.

Ensure HVAC systems expertise

HVAC components and equipment vary in functionality and complexity, which necessitates specialized knowledge for BIM coordination. The evaluation of compatibility across various building scales and types as well as proficiency across various HVAC systems must be carefully considered when selecting HVAC BIM solutions. An outsourcing partner with competence in HVAC design can grasp technicalities and customize BIM solutions that align with specific needs and overcome project constraints. For optimal performance and coherence, HVAC BIM project planning must synchronize with building designs thanks to this adaptability.

Verify software proficiency

Considering the technical capabilities of BIM, HVAC system modeling requires outsourcing firms with expertise and experience in established BIM tools, such as Revit, Navisworks and other CAD-based platforms. The capacity to seamlessly integrate multiple project tools is critical to achieve coordination and collaboration. Proficiency in these tools ensure HVAC BIM modeling services contribute to streamlined communication and a reduction in potential conflicts.

Foster communication and collaboration

Effective communication and collaboration are important in construction, and HVAC design with BIM should elevate this principle. Analyze the service provider’s communication guidelines to ensure collaboration between multiple stakeholders. From architects and engineers and contractors to facilities managers, choosing HVAC BIM providers can realize accessible and transparent communication channels. Collaboration is improved, project progress is streamlined, and stakeholders are better aligned with project requirements when modern tools and platforms are used.

Seek flexibility and customization

HVAC BIM services transform construction by delivering a dynamic 3D BIM model for informed decision making and collaboration. This model allows for quick interference detection and energy enhancements. The flexibility is observed through its ability to adapt to unique project needs using Level of Development (LOD) for customized detail and parametric modeling for design adaptability. This ensures streamlined integration of HVAC equipment with various building designs, fostering efficient construction and required building performance.

0 notes

Text

Civil Engineer Jobs || Auto Cad Engineer || Diploma Civil Engineer || B.Tech Civil Engineer Jobs || Job in Kolkata || Real Estate Industry || Consultancy Firm || Kolkata || West Bengal || India

Unlock Your Dream Job!

In this Job Post, we dive into the "Ideal Career Zone," revealing the secrets to finding your perfect profession!

Whether you’re hunting for a #job, searching #Naukri, or exploring new #Chakri options, we’ve got you covered with expert tips and career advice. From understanding your passions to mastering job searches and acing interviews, we empower you to navigate the competitive landscape with confidence!

Join us and discover how to elevate your career journey today!

Company Introduction: Several civil design and consulting firms operate in Kolkata, West Bengal, offering expertise in various aspects of civil engineering, including structural, transportation, and water resources. Some prominent firms include various Services. These firms provide services like design, planning, and construction management for a range of projects.

Now the design and development company need some civil Engineers details as:

Job details:

Company Name: Consultancy firm in north Kolkata

Type of Job: Drawing building plan, structural drawing plan, layout plan etc.

Timing: 10am to 6pm.

Salary: As per efficiency.

Qualification: Diploma or B-tech in Civil.

Computer knowledge: Auto-cad in civil drawing.

Required position vacant: 2 to 3 candidates.

Job Role and Responsibilities:

A Civil AutoCAD Designer in a consultancy firm in Kolkata is responsible for creating detailed technical drawings and designs for various civil engineering projects using AutoCAD. This includes developing layouts for site development, roads, drainage, and other infrastructure elements, as well as preparing structural and architectural drawings. The role also involves collaborating with other engineers and professionals, ensuring compliance with relevant codes and standards, and potentially conducting site visits and surveys.

Specific Responsibilities:

Drawing Creation and Modification:

Producing 2D and 3D drawings for civil engineering projects, including site plans, road layouts, drainage systems, and structural elements using AutoCAD.

Collaboration:

Working closely with project managers, architects, and other engineers to ensure accurate and coordinated designs.

Compliance:

Ensuring designs adhere to relevant building codes, industry standards, and client requirements.

Documentation:

Maintaining accurate and up-to-date project documentation, including drawings, specifications, and calculations.

Site Visits:

Conducting site visits to gather data, monitor progress, and ensure the project is executed according to the design.

Technical Support:

Providing technical support to other team members and stakeholders throughout the project lifecycle.

Cost Estimation and BOQ:

Assisting in the preparation of cost estimates and bills of quantities (BOQ) for construction works.

Review and Coordination:

Reviewing vendor drawings and coordinating with other disciplines to resolve any design clashes or issues.

Conceptual Design and Development:

Assisting in the development of conceptual designs and layouts for new projects.

In the context of a consultancy firm in Kolkata, the role may also involve:

Client Interaction:

Communicating with clients to understand their needs and provide technical information.

Project Management:

Assisting in the overall management of projects, including planning, scheduling, and resource allocation.

Business Development:

Contributing to the preparation of technical proposals and man-hour estimations for new projects.

Training and Development:

Participating in training and development activities to enhance technical skills and knowledge.

Interested person can contact HR 9331205133

* Note:- You can find many more job details in various posts in various companies.

You may call us between 9 am to 8 pm

8 7 7 7 2 1 1 zero 1 6

9 3 3 1 2 zero 5 1 3 3

Or you can visit our office.

Ideal Career Zone

128/12A, BidhanSraniShyam Bazaar metro Gate No.1 Gandhi Market Behind Sajjaa Dhaam Bed Sheet Bed cover Show room Kolkata 7 lakh 4

Thank you for watching our channel Please subscribed and like our videos for more jobs opening. Thank You again.

#CivilEngineerJobs, #AutoCadEngineer, #DiplomaCivilEngineer, #BTechCivilEngineerJobs, #JobinKolkata, #SolarPowerIndustry, #Nagpur, #Kolkatajobs, #SodPure, #Kolkata, #WestBengal, #India

0 notes

Text

Chiller Market Size, Trends, Innovations & Key Forces

Global Chiller Market Overview The global chiller market is experiencing steady growth, driven by increasing demand for energy-efficient HVAC systems across industrial, commercial, and residential sectors. As of 2024, the market is estimated to be valued at approximately USD 10.5 billion and is projected to reach around USD 14.8 billion by 2030, growing at a CAGR of 5.8% during the forecast period. Key growth drivers include rapid urbanization, expansion in data centers, and rising temperatures due to climate change. Industries such as pharmaceuticals, food and beverage, chemicals, and plastics heavily rely on chiller systems for precise cooling, further augmenting market demand. The shift toward smart building infrastructure and the emphasis on eco-friendly refrigerants are also shaping the future of the chiller market globally. Global Chiller Market Dynamics Several dynamic factors influence the global chiller market landscape. Among the primary market drivers are stringent energy regulations, the rise in construction activities, and an increasing emphasis on green building certifications like LEED. Government incentives for adopting low-global warming potential (GWP) technologies are also encouraging enterprises to upgrade legacy cooling systems. However, the market faces restraints such as high initial investment costs, complexity in installation, and maintenance requirements. In addition, fluctuating raw material prices for metals and refrigerants pose cost pressures on manufacturers and end-users. Emerging opportunities lie in technological advancements such as IoT-enabled chillers, integration with building management systems (BMS), and the growth of the retrofit market. The push towards sustainability and decarbonization is expected to reshape product offerings, encouraging innovations in magnetic bearing chillers and absorption chillers powered by renewable energy sources. Regulatory frameworks like the Kigali Amendment and F-Gas regulations are prompting a gradual shift toward environment-friendly chiller solutions. Download Full PDF Sample Copy of Global Chiller Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=32840&utm_source=PR-News&utm_medium=387 Global Chiller Market Trends and Innovations Technological transformation is at the core of emerging trends in the chiller industry. Market players are increasingly focusing on smart chillers equipped with real-time monitoring, predictive maintenance, and cloud-based control systems. Variable speed compressors, modular chiller systems, and energy recovery systems are gaining significant traction due to their high efficiency and adaptability. Collaborations between HVAC manufacturers and IoT providers are fostering the development of integrated solutions that offer better lifecycle cost management. Product innovation is evident in the launch of chillers using low-GWP refrigerants such as R-32, R-1234yf, and natural refrigerants like ammonia and CO2. Additionally, hybrid chillers that combine different cooling technologies are being developed to optimize energy usage in varying climatic conditions. Global Chiller Market Challenges and Solutions Despite promising growth, the chiller market faces several challenges. One of the primary issues is the global supply chain disruption impacting the availability of components like compressors and heat exchangers. Manufacturers are addressing this through localized sourcing strategies and investment in digital supply chain management tools. Other challenges include rising manufacturing costs due to material inflation and compliance costs associated with evolving refrigerant regulations. To overcome these, companies are focusing on R&D for cost-effective, eco-friendly refrigerant alternatives and standardizing modular chiller designs to streamline production. The lack of skilled labor in system installation and maintenance also hinders market adoption, especially in emerging economies. Upskilling programs and partnerships with technical institutions are being pursued to bridge this gap.