#flex PCBAs

Explore tagged Tumblr posts

Text

6 layers flex-rigid printed circuit board, Hitech Circuits from China

Flex-rigid printed circuit board for electronics is crafted using superior quality FR4 Tg170+PI material and boasts countersunk holes for increased efficiency in wiring. Email Cynthia: [email protected] if you are looking for remarkable flexibility flex-rigid printed circuit board.

0 notes

Text

Choosing the Right China PCB Supplier: Key Factors to Consider

In this dynamic world of electronics, Printed circuit boards (PCBs) are the skeleton of every device, from digital clocks to laptops and smartphones. China has become one of the largest hubs of producing PCBs worldwide.

Choosing the right China PCB supplier can be challenging, so make sure to read the factors we will discuss in this article. Let’s get started!

Key Factors to Consider When Choosing a China PCB Supplier

youtube

1. Understanding your PCB Requirments

The first step is to understand what kind of PCBs you need. Do you want single-layer, multilayer PCBs or a specific type? Knowing whether you want standard or customized PCBs will help you shortlist China PCB suppliers. Discuss your project specifications in detail with the supplier for better understanding.

2. Manufacturing Capabilities

While selecting a PCB supplier, check their manufacturing capabilities to ensure they have the right machines and sound technology to meet your specific requirements.

3. Pricing

Every buyer wants to purchase from a supplier that provides the best quality at affordable prices. So, just list suppliers you want to buy from and compare their quality and price. Remember that there may be additional costs like assembly or testing. Buying in bulk can be cost-effective.

4. Quality Control Standards

Ask suppliers for samples and check if they have an in-house inspection team to certify high-quality PCBs. PCBs must pass visual and functional tests to ensure they are durable and reliable. Research if the PCB supplier has globally recognized certifications like ISO 9001 and IPC-A-600.

5. Customization Options

You may have unique requirements for PCBs, so look for a supplier who can customize the boards for you. Whether you are looking for single-layer or multilayer PCBs, make sure the supplier has your desired materials and production techniques for customization.

6. Deadlines & Production Capacity

When working on an urgent project, you may want a supplier with high production capacity to meet your deadlines without compromising quality. Therefore, you should evaluate the supplier’s previous track record to assess their delivery timelines.

7. Communication & Support

Smooth communication and customer support are important to build a relationship between the two parties. Therefore, choose a supplier who gives you updates during the manufacturing process and is pleased to answer your queries in detail.

8. Industry Reputation

A supplier’s reputation is a powerful symbol of their performance and reliability. To check a supplier’s reputation in the industry, read their testimonials, case studies, and customer reviews. This will help you to be confident while selecting a supplier.

Why Choose a China PCB Supplier?

Here are some reasons you should choose a China PCB supplier.

China offers competitive manufacturing costs, making it a perfect choice for buyers seeking quality on a budget. Plus, it is more cost-effective compared to other countries.

China suppliers provide high-quality PCBs using innovative technologies and modern machines.

They have built a solid global reputation, with customers worldwide acknowledging their expertise in shipping PCBs efficiently.

Conclusion

Choosing a China PCB supplier can impact the progress and reliability of your electronic devices. By understanding your requirements and the factors mentioned, you can select a supplier that meets your specific material and production techniques requirements.

#pcb assembly#pcb#pcb manufacturer#pcba manufacturing#flex pcb#pcb fabrication#flexible pcb board#flex circuit pcb#flexible circuit board#Youtube

0 notes

Text

Кроме того, существует технология термоэлектрического разделения PCB на основе меди (также известная как технология прямого касания). Это означает, что толщина меди в нужном месте увеличивается с помощью отверстия для покрытия сварочным материалом и гальванической меди, а тепло передается непосредственно от светодиода или других компонентов к медной базе, в то время как сеть цепей независима от тепловой сети.

Как производитель MCPCB, Hitech Circuits производит различные ПХБ на основе меди для своих клиентов.

Для мощных светодиодных ламп (1000 Вт +) и источников питания.

В области светодиодов существует 4 типа платы на основе меди.

0 notes

Text

Как правило, PCB на основе меди имеет ту же структуру, что и PCB на основе алюминия - однослойная, двухслойная панельная монтажная поверхность, двухслойная двухэлементная монтажная поверхность и четырехслойная двухэлементная монтажная поверхность. Даже если они используют тот же предварительно пропитанный материал для изоляции медного слоя. Однако медная подложка (398W / mK) обладает лучшей теплопроводностью, чем алюминиевая (237W / mK).

#pcb fabrication#pcb manufacturer#pcb assembly#aluminium pcb#pcba manufacturing#pcb#flex pcb#flex circuit pcb#pcb design

0 notes

Text

PCB boards after solder paste printing should enter reflow soldering oven after 30 minutes of solder paste printing to stop solder paste from being exposed to the air for long time with product quality reduced.

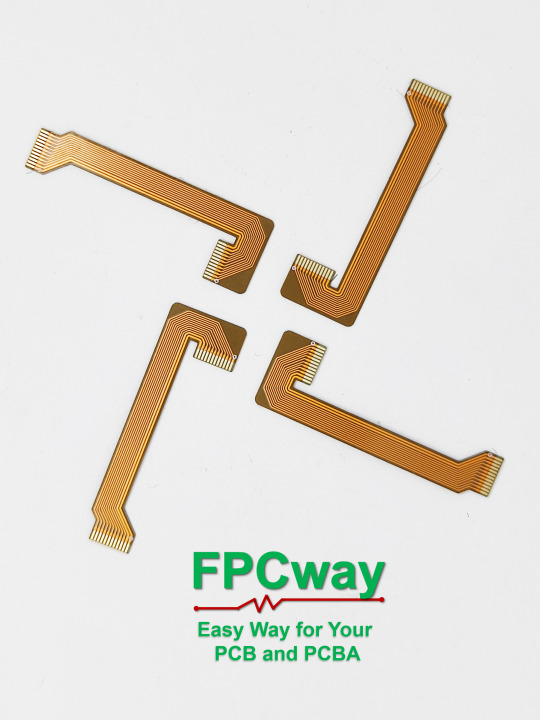

#FPCway #flexPCB#pcb#pcba#fpc# assembly#rigid-flex pcb #fpcway.com

#FPCway#flexPCB#pcb#pcba#fpc#assembly#rigid-flex pcb#fpcway.com#www.fpcway.com#flex pcb#flex circuit pcb#flexible pcb board#flexible circuit board#today on tumblr

0 notes

Text

Decoding PCBA Board Manufacture: A Roadmap to Efficient Production

PCBA (Printed Circuit Board Assembly) board manufacture stands as a pivotal stage in the journey from electronic concept to tangible product. This blog offers a detailed roadmap, guiding both novices and seasoned professionals through the multifaceted process of PCBA board manufacture.

The journey initiates with an elucidation of PCBA board components, ranging from basic resistors to intricate microprocessors. Understanding the role and compatibility of each component is paramount in crafting a functional and efficient board.

Subsequently, the blog navigates through the intricacies of PCB fabrication, encompassing design optimization, material selection, and fabrication techniques. Through insights into surface finishes, layer stackups, and trace routing, readers will grasp the fundamentals necessary for creating robust and reliable PCBs.

The narrative then transitions to the assembly phase, shedding light on component placement, soldering methodologies, and quality assurance protocols. From manual soldering to automated pick-and-place systems, readers will gain insight into the diverse assembly techniques and their respective advantages.

Moreover, the blog addresses the significance of thorough testing and inspection procedures to identify and rectify potential defects before the final product reaches the market. Topics such as in-circuit testing, functional testing, and quality control standards underscore the importance of delivering reliable and high-performance PCBAs.

In conclusion, "Decoding PCBA Board Manufacture" serves as a comprehensive guide for navigating the complexities of PCB assembly manufacturing. By leveraging the insights and best practices shared in this blog, electronics enthusiasts and industry professionals alike can streamline their manufacturing processes, ultimately fostering innovation and excellence in the realm of electronic design and production.

#pcb circuit#fr4 pcb#pcb factory#circuit board#led circuit board#flex pcb#pcb assembly#aluminum pcb#fpc#ems pcba

0 notes

Text

Consumer Electronics Printed Circuit Board Market: Key Growth Drivers in the Global Industry

MARKET INSIGHTS

The global Consumer Electronics Printed Circuit Board Market size was valued at US$ 15.34 billion in 2024 and is projected to reach US$ 24.78 billion by 2032, at a CAGR of 6.9% during the forecast period 2025-2032.

Consumer electronic PCBA (Printed Circuit Board Assembly) boards are integrated circuits used across consumer electronics products to mechanically support and electrically connect components through conductive copper pathways. These boards serve as the backbone of modern electronics, encompassing various types including single-layer, double-layer, and multilayer configurations to accommodate different device complexities.

The market growth is primarily driven by accelerating demand for smart devices, including smartphones, wearables, and IoT-enabled home appliances. While China dominates PCB production with over 50% global market share, emerging 5G infrastructure and AI applications are creating new opportunities across multilayer PCBA segments. Furthermore, leading manufacturers like Jabil and Flex Ltd continue expanding production capacities to meet the growing demand for compact, high-performance electronic assemblies.

MARKET DRIVERS

Proliferation of Smart Devices to Fuel Demand for PCBA Boards

The global consumer electronics market continues to expand at an unprecedented rate, with smart devices driving significant demand for high-quality PCBA boards. Smartphones alone accounted for over 1.4 billion units shipped globally in 2023, each requiring sophisticated multilayer PCBA assemblies. The Internet of Things (IoT) revolution has further accelerated this trend, with projections indicating 30 billion connected devices by 2025. These consumer electronics require increasingly complex PCBA solutions that can handle higher processing speeds while maintaining energy efficiency and compact form factors.

Advancements in 5G Technology Accelerating Market Growth

The global rollout of 5G networks represents a pivotal driver for the PCBA board market, as next-generation devices require completely redesigned circuit architectures. 5G-compatible PCBA boards must accommodate higher frequency ranges (up to 52.6 GHz for mmWave implementations) while minimizing signal loss and electromagnetic interference. Carrier aggregation technologies in modern 5G modems often require up to 40% more complex PCBA designs compared to 4G LTE solutions. This technological shift is prompting manufacturers to invest heavily in advanced production capabilities, particularly for high-frequency laminate materials and precision assembly techniques.

Automotive Electronics Evolution Creating New Demand Streams

The automotive sector’s rapid electrification and digital transformation is generating substantial opportunities for PCBA manufacturers. Modern vehicles now incorporate over 100 electronic control units (ECUs) on average, each containing specialized PCBA solutions. The autonomous vehicle segment particularly demands high-reliability boards capable of withstanding harsh environments while processing massive sensor data streams. Premium electric vehicles may contain PCBA components valued at 3-4 times that of conventional automobiles, creating a high-value growth channel for manufacturers with automotive-grade capabilities.

MARKET RESTRAINTS

Supply Chain Vulnerabilities Constraining Market Expansion

The PCBA industry faces significant challenges from global supply chain disruptions, particularly for critical raw materials. Copper prices have shown 35% volatility year-over-year, directly impacting board production costs. Specialty laminate materials and semiconductor components have experienced lead time extensions up to 52 weeks in some cases, creating production bottlenecks. Geopolitical tensions in key manufacturing regions further exacerbate these challenges, forcing companies to maintain larger inventory buffers that negatively impact working capital efficiency.

Environmental Regulations Increasing Compliance Costs

Stringent environmental regulations, particularly concerning lead-free soldering processes and halogen-free laminates, have significantly increased manufacturing complexity. The Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide now require extensive documentation and testing protocols for each product iteration. Compliance costs for a medium-sized PCBA manufacturer can exceed $500,000 annually, creating substantial barriers to market entry for smaller players. These regulations also necessitate continuous R&D investments to develop alternative materials that meet both performance and environmental requirements.

MARKET CHALLENGES

Miniaturization Demands Outpacing Manufacturing Capabilities

The relentless drive toward smaller, more powerful consumer electronics presents fundamental manufacturing challenges. PCBAs for wearable devices now routinely require trace widths below 50μm and micro-vias under 100μm in diameter, pushing the limits of conventional fabrication techniques. Yield rates for such high-density interconnect (HDI) boards can be 15-20% lower than standard designs, significantly increasing unit costs. This miniaturization trend also demands substantial capital investments in equipment capable of sub-micron precision, with advanced pick-and-place machines often exceeding $500,000 per unit.

Talent Shortage Impacting Technological Advancement

The industry faces a critical shortage of skilled engineers capable of designing and manufacturing next-generation PCBA solutions. Complex RF designs and high-speed digital layouts require specialized expertise that typically takes 5-7 years to develop. The global electronics manufacturing sector currently experiences a 22% vacancy rate for mid-career PCB design engineers, slowing innovation cycles. This skills gap is particularly acute in emerging manufacturing hubs, where educational infrastructure hasn’t kept pace with industry requirements.

MARKET OPPORTUNITIES

AI-Enabled Manufacturing Creating Efficiency Breakthroughs

Artificial intelligence applications in PCBA manufacturing are unlocking unprecedented quality and efficiency improvements. Machine vision systems can now detect assembly defects with 99.98% accuracy, compared to 92% for human inspectors. Predictive maintenance algorithms reduce equipment downtime by 40% in advanced facilities, while AI-optimized panel utilization can decrease material waste by up to 15%. Early adopters of these technologies are gaining significant competitive advantages in both quality consistency and production cost structures.

Emerging Markets Driving Volume Growth

Developing economies represent the next frontier for consumer electronics adoption, creating substantial opportunities for PCBA manufacturers. Smartphone penetration in Southeast Asia and Africa is projected to grow at 8% CAGR through 2030, significantly outpacing mature markets. Local governments are implementing favorable policies to attract electronics manufacturing, including Vietnam’s 10-year tax holidays for high-tech investments. These regions also benefit from younger, tech-savvy populations driving demand for affordable smart devices, creating ideal conditions for volume-focused manufacturing strategies.

CONSUMER ELECTRONIC PCBA BOARD MARKET TRENDS

5G Technology Adoption and High-Density PCBA Demand

The rapid rollout of 5G networks globally is driving significant changes in the consumer electronic PCBA (Printed Circuit Board Assembly) market. As 5G-capable devices require higher frequency and bandwidth performance, manufacturers are shifting toward high-density interconnect (HDI) PCBA boards with advanced materials like low-loss laminates. The global 5G smartphone market is expected to reach over 1.2 billion units by 2025, directly influencing PCBA design requirements. Furthermore, the miniaturization trend in consumer electronics continues to push innovation in multilayer and flexible PCBA solutions, with some manufacturers now offering boards with up to 20+ layers for premium devices.

Other Trends

Automation in PCBA Manufacturing

Consumer electronics manufacturers are increasingly adopting automated surface-mount technology (SMT) lines to improve production efficiency and quality control. This shift is particularly evident in high-volume segments like smartphones and wearables, where precision and consistency are critical. Automated optical inspection (AOI) systems are now being integrated into production lines at a rate exceeding 30% annually, reducing defects by up to 60% compared to manual inspection. As labor costs rise in traditional manufacturing hubs, this automation trend is becoming crucial for maintaining competitiveness.

Sustainability Initiatives Reshaping Materials and Processes

Environmental regulations and consumer preferences are driving significant changes in PCBA materials and manufacturing processes. The European Union’s Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have accelerated the adoption of lead-free soldering and halogen-free laminates. Recent market data shows that over 85% of new PCBA production now complies with RoHS standards, up from just 60% five years ago. Additionally, manufacturers are investing in closed-loop recycling systems for precious metals recovered from PCBA waste, with some achieving recovery rates exceeding 90% for gold and silver.

COMPETITIVE LANDSCAPE

Key Industry Players

Market Leaders Invest in Advanced Manufacturing and Strategic Partnerships

The global Consumer Electronic PCBA Board market features a fragmented yet highly competitive landscape dominated by established manufacturers and emerging regional players. Among these, Jabil and Flex Ltd maintain leading positions, owing to their extensive production capabilities and engagements with multinational electronics brands. These Tier-1 manufacturers collectively held approximately 18% of the global market share in 2024, supported by vertically integrated supply chains and investments in high-mix, low-volume (HMLV) manufacturing.

Meanwhile, Chinese firms like Shennan Circuits Company Limited (SCC) and Avary Holding have expanded aggressively, leveraging cost efficiencies and government-backed semiconductor policies. SCC reported consecutive revenue growth above 12% YoY, capitalizing on domestic smartphone manufacturers’ demand for multilayer PCBAs. The company’s recent acquisition of a German PCB fabricator signifies its ambitions in the European automotive electronics segment.

While major players focus on capacity expansions, mid-sized competitors such as Victory Giant Technology (VGT) differentiate through certified quick-turn prototyping services essential for IoT device makers. Notably, VGT partnered with Xiaomi and Oppo to develop high-frequency PCBA solutions for 5G smartphones, demonstrating innovation-driven competition.

Meanwhile, supply chain disruptions prompted firms like Palpilot International to localize production – establishing plants in Mexico and Vietnam to bypass tariff risks. Such strategic realignments reflect the industry’s shift toward regionalization while sustaining just-in-time delivery models.

List of Key Consumer Electronic PCBA Board Companies Profiled

Jabil Inc. (U.S.)

Flex Ltd. (Singapore)

Shenzhen Fastprint Circuit Tech (China)

Kingbrother Electronics (China)

Shennan Circuits Co. Ltd (China)

Avary Holding (Shenzhen) Co. Ltd. (China)

Victory Giant Technology (China)

Aoshikang Technology (China)

Camelot Electronics Technology (China)

Lensuo Technology Development (China)

Segment Analysis:

By Type

Multilayer PCBA Board Segment Dominates Due to Increasing Demand for High-Density Electronics

The market is segmented based on type into:

Single-layer PCBA Board

Double-layer PCBA Board

Multilayer PCBA Board

By Application

Smartphone Segment Holds Maximum Share Owing to Rising Global Smartphone Adoption

The market is segmented based on application into:

Smart Phone

Tablet

Smart Wear

TV Set

Air Conditioner

Others

By Technology

Surface Mount Technology Leads Due to Higher Efficiency and Compact Design Capabilities

The market is segmented based on technology into:

Through-hole Technology

Surface Mount Technology

Mixed Technology

By Material

FR4 Substrate Maintains Dominance as Industry Standard for Consumer Electronics

The market is segmented based on material into:

FR4 Substrate

Flexible Substrate

High-frequency Substrate

Others

Regional Analysis: Consumer Electronic PCBA Board Market

North America The North American PCBA Board market is characterized by high-value, technology-driven demand, particularly for advanced multilayer boards used in premium consumer electronics. The United States accounts for over 85% of regional demand, fueled by strong R&D investment and the presence of tech giants like Apple and Google. While the market faces cost pressures due to labor and material expenses, manufacturers are increasingly adopting automation to maintain competitiveness. Environmental regulations such as RoHS compliance influence material selection, pushing suppliers toward lead-free and halogen-free solutions. Canada’s market is smaller but growing steadily, supported by telecommunications equipment demand.

Europe European PCBA manufacturers focus on high-quality, precision-engineered boards for automotive, industrial, and consumer applications. Germany leads in production capabilities, housing several global EMS providers. The EU’s circular economy action plan drives innovation in recyclable PCB materials and processes. Though labor costs remain high compared to Asia, European manufacturers differentiate through advanced manufacturing techniques and stringent quality control. The UK and France show particular strength in aerospace and defense applications that require specialized PCBA solutions. Brexit-related supply chain disruptions have prompted some reshoring of PCB production within the EU.

Asia-Pacific As the global manufacturing hub for PCBA boards, Asia-Pacific dominates with over 70% of worldwide production capacity. China’s massive electronics ecosystem drives demand for cost-efficient, high-volume PCBs, with Shenzhen serving as a key production cluster. Japanese and Korean manufacturers lead in advanced HDI and flex PCB technologies for premium devices. Rapid urbanization across Southeast Asia is creating new consumer electronics markets, though infrastructure gaps sometimes hinder supply chain efficiency. The region benefits from vertical integration, with many PCB fabricators also offering assembly services. Intense competition keeps margins thin but fosters continuous process optimization.

South America South America’s PCBA market remains modest but developing, primarily serving domestic consumer electronics manufacturers. Brazil accounts for nearly half of regional demand, though economic instability often delays capital investments in PCB manufacturing. Most complex boards are imported from Asia, while local facilities focus on simpler designs. Currency fluctuations impact material procurement costs, causing pricing volatility. Some countries like Argentina are implementing import substitution policies to boost local PCB production, though technological limitations constrain capabilities. The growing middle class is driving demand for affordable smartphones and appliances, creating opportunities for PCB suppliers.

Middle East & Africa This emerging market shows potential as electronics manufacturing gradually expands beyond oil-dependent economies. Israel stands out for its high-tech PCB applications in defense and telecommunications. UAE and Saudi Arabia are investing in technology parks to attract electronics manufacturers, though most PCBs are still imported. Limited local expertise in complex board design and manufacturing hampers development, leading to reliance on foreign partners. South Africa serves as a regional hub, with some capability for basic PCB production. Infrastructure challenges and fragmented supply chains remain barriers, though government initiatives aim to develop local electronics manufacturing ecosystems.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Consumer Electronic PCBA Board markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global market was valued at USD 12.8 billion in 2024 and is projected to reach USD 18.3 billion by 2032, growing at a CAGR of 4.6%.

Segmentation Analysis: Detailed breakdown by product type (single-layer, double-layer, multilayer), application (smartphones, tablets, wearables, home appliances), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific dominates with 68% market share in 2024, led by China’s manufacturing ecosystem.

Competitive Landscape: Profiles of 15 leading manufacturers including Jabil, Flex Ltd, Shenzhen Fastprint, and Shennan Circuits, analyzing their market share (top 5 companies hold 32% share), capacity expansions, and technological partnerships.

Technology Trends: Assessment of HDI boards, flexible PCBs, embedded components, and IoT integration driving innovation. The multilayer PCB segment accounts for 54% revenue share in 2024.

Market Drivers & Restraints: Evaluation of 5G adoption, smart device proliferation, and supply chain localization benefits versus raw material price volatility and geopolitical trade tensions.

Stakeholder Analysis: Strategic insights for PCB fabricators, EMS providers, OEMs, and investors regarding capacity planning, technology roadmaps, and emerging applications like AR/VR devices.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/global-video-sync-separator-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes_17.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-investments.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/coaxial-panels-market-challenges.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/oled-and-led-automotive-light-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/gas-cell-market-demand-for-ai-chips-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digital-demodulator-ic-market-packaging.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/nano-micro-connector-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/single-mode-laser-diode-market-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/battery-management-system-chip-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/scanning-slit-beam-profiler-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/atomic-oscillator-market-electronics.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/plastic-encapsulated-thermistor-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-policy.html

0 notes

Text

Precision PCBA Solutions by SFXPCB: Global Excellence in Electronics Manufacturing

In today’s fast-paced technological world, PCBA (Printed Circuit Board Assembly) is a fundamental process that powers every modern electronic device—from smartphones and medical instruments to aerospace equipment and industrial control systems. As electronic design becomes more complex, the need for a reliable and precise PCBA partner becomes even more crucial.

At the forefront of innovation and quality in PCBA manufacturing stands SFXPCB, a global provider trusted by industries in Germany, USA, UK, Austria, and Canada. SFXPCB delivers high-quality assembly, superior engineering support, and efficient global logistics—all while maintaining competitive pricing.

What is PCBA?

PCBA (Printed Circuit Board Assembly) refers to the process of assembling electronic components onto a bare PCB (Printed Circuit Board). This process involves:

Applying solder paste to board pads

Placing surface mount or through-hole components

Reflow or wave soldering

Inspection (AOI, X-ray, or visual)

Functional and quality testing

The final product is a fully functional electronic board, ready for integration into a finished device.

SFXPCB – Your Trusted PCBA Manufacturing Partner

With a strong manufacturing base in China and a broad international customer base, SFXPCB provides end-to-end PCBA services tailored to meet the highest industry standards. From prototype assembly to mass production, their process is defined by precision, consistency, and speed.

Why choose SFXPCB for your PCBA needs?

✅ 1. One-Stop PCBA Services

SFXPCB provides a complete PCBA solution, including:

PCB fabrication

Component sourcing (including hard-to-find parts)

SMT & THT assembly

Functional and in-circuit testing

Quality assurance and packaging

This streamlined approach minimizes delays and errors, ensuring your projects run smoothly from start to finish.

✅ 2. Advanced Technology & Capabilities

Equipped with state-of-the-art SMT lines, reflow ovens, AOI systems, and BGA placement equipment, SFXPCB can handle:

Fine-pitch ICs

BGA, QFN, CSP components

High-density interconnects (HDI)

Rigid, Flex, and Rigid-Flex PCBs

Their advanced capabilities make them a top choice for industries demanding high precision and miniaturization.

✅ 3. Unmatched Quality Control

SFXPCB strictly adheres to ISO9001, RoHS, and UL certifications. Each project undergoes:

Automated Optical Inspection (AOI)

X-ray inspection (for BGA and hidden joints)

Manual inspection by experienced technicians

Functionality testing based on customer requirements

You can trust that every assembly meets the highest standards.

Industries That Trust SFXPCB’s PCBA Services

SFXPCB’s ability to handle complex projects and deliver on time has made it the preferred PCBA manufacturer for companies in:

🚗 Automotive Electronics

Reliable and rugged PCBA for engine control units, infotainment, and safety systems.

🏥 Medical Devices

Precision PCBA used in imaging systems, diagnostics, monitoring devices, and wearables.

📡 Telecommunications

High-frequency, high-speed PCBs used in routers, base stations, and IoT gateways.

⚙️ Industrial Automation

Durable assemblies for sensors, controllers, and factory automation systems.

🛰 Aerospace & Defense

High-reliability PCBA for communication, navigation, and surveillance applications.

Global Reach, Local Focus

Though headquartered in China, SFXPCB is a global player, serving clients in:

Germany

United States

United Kingdom

Austria

Canada

Their responsive English-speaking support team and efficient international shipping make it easy to work with them, no matter where you're located.

Fast Turnaround and Competitive Pricing

SFXPCB understands that time-to-market is critical. That’s why they offer:

Rapid prototyping services

Flexible volume production (from 1 to 10,000+ units)

Competitive pricing without sacrificing quality

Through strong relationships with component suppliers and efficient manufacturing practices, SFXPCB delivers high-value PCBA services at a cost-effective rate.

How to Start Your PCBA Project with SFXPCB

Getting started with SFXPCB is simple and fast:

Visit the website: https://sfxpcb.com/

Upload your Gerber files and BOM

Get a fast and accurate quote

Review DFM suggestions from their engineers

Approve and track your order online

You’ll benefit from responsive communication, transparency, and a seamless production process from quote to delivery.

Customer Testimonials

“SFXPCB is our go-to partner for PCBA. They consistently deliver high-quality boards and help us hit tight deadlines.” — CTO, IoT Startup (Germany)

“The team at SFXPCB is incredibly responsive and knowledgeable. We’ve trusted them with multiple projects and never been disappointed.” — Procurement Manager, Medical Device Company (USA)

Contact SFXPCB Today

Have a question or ready to place an order? Reach out directly:

📧 Email: [email protected] 📞 Phone: +86 0755 21012004

In the world of modern electronics, the importance of a reliable PCBA provider cannot be overstated. From prototyping to full-scale production, SFXPCB combines precision, speed, and service excellence to help businesses across the globe bring their products to life.

Whether you're an electronics startup or a global OEM, SFXPCB delivers quality you can trust—on time and on budget.

0 notes

Text

At GreatPCB, our hybrid laminating process integrates FR-4 with high-frequency materials like PTFE and ceramics, ensuring top performance while reducing costs. We also offer rigid-flex structures for complex 3D assembly needs, providing flexibility and reliability.

1 note

·

View note

Text

What is rigid flex PCB board?

Rigid-flex PCB board, it is a circuit board that combines flexible and rigid circuit board technology in the application. Most rigid-flex boards are composed of multiple layers of flexible circuit boards, which are attached to one or more rigid boards from the outside and/or from the inside, depending on the design of the application. The flexible substrate is designed to be in a constant deflection state, and is usually formed as a deflection curve during rigid flex PCB manufacturing or assembly.

Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

0 notes

Text

Rigid Flex PCB PCB or PCBA quotation, please email to [email protected] Learn more: https://lnkd.in/gAhdxTUx

#pcb#pcb assembly#pcb manufacturer#electronic#electrical design#pcb design#assembly#flexible pcb board#flex pcb#hardware#electronic components#components#precision machined components#digikey#mouser

0 notes

Text

Pioneering Excellence in EMS Manufacturing with Absolute Electronics Inc

In the rapidly evolving world of technology, Silicon Valley is where innovation has no bounds, and companies vie with each other to come up with novel products in markets like aerospace, medical devices, high-performance computing, and AI. To shape these innovations, companies require reliable and cutting-edge Electronics Manufacturing Services (EMS). Absolute Electronics Inc. is at the forefront when it comes to this, delivering EMS manufacturing services in Silicon Valley that ensure precision, speed, and quality beating all others.

Setting the Standard for EMS Manufacturing

As one of the leading EMS providers in the region, Absolute Electronics Inc. offers end-to-end EMS manufacturing solutions in Silicon Valley that streamline the entire production process, from concept to end assembly. Their advanced capabilities enable companies to optimize product development without having to sacrifice on industry standards.

Expert PCB Assembly & System Integration

Printed Circuit Board ( assembly (PCBA) is the basis of contemporary electronics manufacturing. Absolute EMS excels in:

Automated Surface Mount Technology (SMT) for scalable, defect-free assembly.

Automated Solder Paste Inspection ((SPI), Automated Optical Inspection (AOI) and X-ray Inspection, eliminating defects before final production.

Conformal Coating For parts intended to withstand harsh conditions.

Unwavering Commitment to Quality with Industry-Leading Certifications

Absolute EMS has a commendable reputation for maintaining the best quality level at all times. With internationally renowned certifications, Absolute EMS ensures its operations not just meet but surpass industry requirements. Some of these significant certifications are:

AS9100D & ISO 9001: These are the central pillars of Absolute EMS's quality management system. They guarantee improved product qulaity as well as strict adherence to industry norms. AS9100D specifically ensures conformity to aerospace and defense-focused projects with utmost quality and reliability standards.

ISO 13485: This certification demonstrates Absolute EMS's emphasis on the medical device industry, in which its manufacturing processes meet rigid regulatory standards for dependability and safety.

J-STD-001: A testimony to the firm's superiority in electronics assembly, this certification of all operators provides assurance that the soldering and assembly operations at Absolute EMS comply with the superior durability and performance requirements.

By holding these elite certifications, Absolute EMS solidifies its commitment to providing top-notch quality across many high-reliability industries.

Innovative Manufacturing Solutions for Diverse Industries

Partnering with Absolute EMS is equivalent to gaining access to the most up-to-date manufacturing solutions tailored for different industries. The firm has multi-industry expertise with precision, reliability, fast time-to-market turnarounds, and performance. Some of the most important industry solutions include:

AI & High-Performance Computing (HPC): As a preeminent Silicon Valley EMS company, Absolute EMS is on the leading edge of facilitating the HPC sector. Absolute EMS is skilled at producing high-speed, advanced assemblies created to exact specifications for enhanced performance and reliability.

Automotive: At the forefront of the evolving automotive sector, Absolute EMS supports next-generation technologies, including Advanced Driver-Assistance Systems (ADAS) and key components like LiDAR and RADAR for autonomous driving.

Aerospace & Satellite Systems: Absolute EMS provides lightweight but highly robust PCB assemblies for aerospace and satellite applications. With its rigid-flex assembly capabilities, Absolute EMS offers solutions for harsh space conditions.

With innovation and quality at its core, Absolute EMS continues to advance technology across industries.

Smart Manufacturing: The Future of EMS

Absolute EMS isn’t just keeping up with the future—it’s building it. Their award-winning Factory 4.0 approach integrates:

End-to-end automation for increased accuracy and production efficiency.

Real-time process monitoring to minimize errors and optimize yield rates.

Predictive maintenance systems to prevent downtime and improve reliability.

Why Choose Absolute Electronics Inc.?

Why choose EMS manufacturing services in Silicon Valley? The area houses a number of the world's most technologically sophisticated businesses, providing:

Access to World-class Engineering Expertise: Work with engineers who are experts in electronic manufacturing.

State-of-the-Art Technology: Utilize the latest computer-aided manufacturing technology.

Shorter Turnaround Times: With less complicated prototyping and manufacturing, you can get to the market sooner with your products.

Companies can tap into the best of Silicon Valley innovation and the finest manufacturing expertise by partnering with Absolute Electronics Inc.

Partner with Absolute EMS for Next-Level Manufacturing

Whether you are a startup looking for rapid prototyping or an existing company looking for high-quality EMS manufacturing services in Silicon Valley, Absolute EMS is your best bet. With a sterling track record of success, stringent quality control measures, and a customer-centric approach, they are dedicated to producing every project that adheres to the industry's highest standards.

Let’s Build the Future Together

Seeking a reliable EMS partner to turn your concepts into realities? Reach out to Absolute Electronics Inc. now and discover how their state-of-the-art electronics manufacturing services can take your next game-changer idea to new heights.

0 notes

Text

Металлический сердечник PCB или MCPCB, включая однослойный металлический сердечник PCB, двухслойный металлический сердечник PCB и многослойный металлический сердечник PCB, широко используется в мощных светодиодных светодиодных приложениях, автомобильной электронике и других областях. HITECHPCB является надежным производителем ПХБ с металлическим сердечником в Китае. Мы предлагаем прототипы PCB с металлическим сердечником, однослойные PCB с медным сердечником, двухсторонние MCPCB и многослойные услуги по производству MCPCB.

0 notes

Text

Медный сердечник PCB - медный фундамент + изоляция + медь

PCB с медным сердечником - это PCB с медной базой + изоляцией + слоем медной схемы, также известный как PCB с медной базой, PCB на медной основе и PCB с медной оболочко��.

ПХБ на основе меди - это металлический сердечник с медной пластиной. Если фундамент гибридного PCB представляет собой медную пластину, встроенную в пластину FR4, то это также PCB на основе меди.

#pcb fabrication#pcb assembly#pcb manufacturer#aluminium pcb#pcba manufacturing#pcb#flex pcb#flex circuit pcb#pcb design#led pcb#Copper core pcb

0 notes

Text

Advantages of SMT Assembly:a High Assembly DensityCompared with traditional through-hole components, chip components call for smaller real estate of board surface.

#FPCway#flexPCB#pcb#pcba#fpc#flexible circuit board#flex PCB and assembly#fpcway.com#rigid-flex pcb#flex pcb#flexible pcb board#flex circuit pcb#today on tumblr#www.fpcway.com

0 notes