#fpc

Explore tagged Tumblr posts

Text

Dorothy Allison, who died November 6 at 75, wrote with passion, precision and musicality that infused every page with her essence. Her memoir Two or Three Things I Know for Sure is a song of survival. These five sentences, chosen at random, embody her voice:

"When we were small, I could catch my sisters the way they caught butterflies, capture their attention and almost make them believe that all I said was true."

"Mama would touch all the pictures tentatively, as if her memories were more real than the images, as if she did not want to look too hard at the reality of all those people lost and gone."

"She was an actress in the theater of true life, so good that no one suspected what was hidden behind the artfully applied makeup and carefully pinned hairnet."

"My uncles went to jail like other boys go to high school."

"When I make love I take my whole life in my hands, the damage and the pride, the bad memories and the good, all that I am or might be, and I do indeed love myself, can indeed do any damn thing I please."

32 notes

·

View notes

Text

From the journals of the late Prince Absolver:

I can now say with utmost certainty that a firescales's inner blaze gives their scales that blistering brightness. Witnessing Jailbirds physical degradation over the ten years of having her is more than enough proof that the inner blaze is linked to not only appearance but general health and wellbeing: The worse the dragons health and wellbeing is, the weaker their temperature. (And the duller their appearance, and so forth) To corroborate above points refer to smelting records and compare the melting times of ten tons of iron from 4562 PS to 4572 PS. She no longer even turns to look at me

The current location of this firescales is unknown

- Rainwing Emissary Mangosteen

#as i like to call it: the Crimson to Jailbird pipeline#wings of fire#wof#wings of fire design#wings of fire oc#wof oc#skywing#skywing wof#firescales#wof firescales#wings of fire art#fridge draws#crimson#jailbird#fpc#the flying postal company#worldbuilding#wof worldbuilding#wof headcanons

313 notes

·

View notes

Text

she's bringing armageddon//a paramour on high//salvage for the vicious//you're just dying to try

24 notes

·

View notes

Text

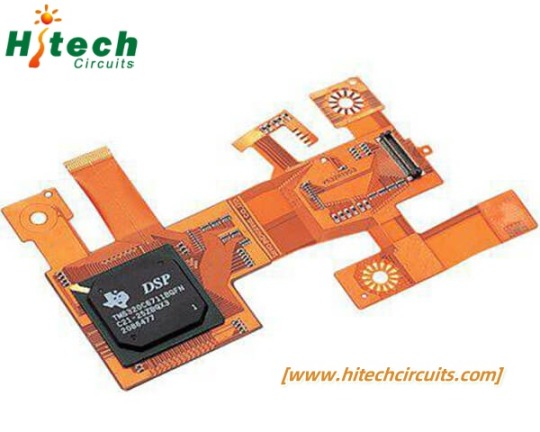

Flexible circuit boards manufacturing (JLCPCB, 2023)

Inkjet print head uses a fiducial camera for registering an FPC panel, and after alignment it prints graphics with UV-cureable epoxy in two passes

#jlcpcb#pcb#fpc#manufacturing#manufacture#factory#electronics#fiducial camera#camera#cv#opencv#computer vision

137 notes

·

View notes

Text

the thing about friday pilots club that i really love is like. they will make a song with the most batshit paranormal lyrics you've ever heard and then you go to their genius page and it's like "this song is about a relationship" no??? this song is about having an alien girlfriend who might also be a murderer. and also you're both probably queer.

#all jokes guys. idc what you interpret your songs as#this post started being about vampire disco and ms supernova#but i think it can also apply to better with and ultraviolet (obsession)#friday pilots club#fpc#fpcposting#mi

17 notes

·

View notes

Video

youtube

FPC flexible circuit board production process #fpc #circuitboard #pcb #technology #factory #customer #icgoodfind

2 notes

·

View notes

Text

LOVE IS JUST TO LACERATE 🫠

#fpc#friday pilots club#nowhere#ultraviolet (obsession)#use me like a weapon is actually insane#this album covers every stage and flavor of 'to be used is to be loved' situationships I'm so serious everyone go listen to it rn

3 notes

·

View notes

Text

teenagers in the tags of my favorite band horny posting I'm SPEECHLESS how does anyone even KNOW them I literally didn't even NOTICE that they're a big deal now omfg

#Friday Pilots Club#i met soooo many people at the show last night and it was extraordinary#THERE WAS A LINE OF PEOPLE WAITING TO TAKE PHOTOS W CALEB#bro last time i saw them ghey played in literally a third of a bar#and we talked to them w literally no one around lmfao we were all DRUNK#WE USED TO GO ON THEIR INSTAGRAM LIVES AND BE THE ONLY PEOPLE ON THERE#love this for them#fpc#by me

2 notes

·

View notes

Text

youtube

Fish Arcade Walkthrough

It is real time game about fish, which is swims through water. Fish needs to avoid black stones. Fish is living in a depth of water. Not very deep and not in the higher level. Game is in genre runner. You – avoid obstacles, Simple game. For relax!

Dima Link is making retro videogames, apps, a little of music, write stories, and some retro more.

WEBSITE: http://www.dimalink.tv-games.ru/home_eng.html ITCHIO: https://dimalink.itch.io/ GAMEJOLT: https://gamejolt.com/@DimaLink/games

BLOGGER: https://dimalinkeng.blogspot.com/ DISCORD: https://discord.com/invite/F24Kw7TaH4 TUMBLR: https://dimalink.tumblr.com/

#retro#retro programming#80s#free pascal#fpc#programming with pascal#game with pascal#water#ocean#fish#sea#avoid obstacles#dive#runner#swin#run#arcade#free time#8 bit#16 bit#ms dos#Youtube

8 notes

·

View notes

Video

youtube

2. Leaving on a Jet Plane - FPC 1970-71 Student Magazine Album

In 1971, some students at Florida Presbyterian College produced a record album. This track features Elizabeth Corrigan, recorded live in the FPC Coffee House. Produced by student Robby Barnes, the album is an assortment of music (and a few comedic moments) performed either by FPC students or musicians who performed on campus. The album was copyrighted 1971 by "Pear/Octophant Inc. Atlanta GA" Various selections are subject to copyright by the composer and/or performers.

#youtube#Rob#Leaving on A Jet Plane#music#singing#songs#1970-71#old friends#Elizabeth Corrigan#Rob Barnes#FPC

7 notes

·

View notes

Text

OC JUMPSCARE !!!

-

In order: Acai 'Berry', Marengo, Extravaganza, Archipelago, (the late) King Blackbird, (a much much younger) Queen Eagle Owl, Pelican and Greeneye

#fridge draws#wings of fire#wof#wings of fire design#wings of fire oc#wof oc#rainwing#icewing#seawing#skywing#the flying postal company#fpc#acai/berry#marengo#extravaganza#archipelago#blackbird#eagle owl#pelican#greeneye

89 notes

·

View notes

Text

DVI output adapter for RP2350 Feather HSTX port 🔌🖥️💡

The RP2350 Feather has an FPC output connector for accessing the HSTX - high-speed transmission - peripheral. This lets us drive DVI displays really easily! Today, we got the prototype PCBs for our HSTX to DVI adapter board; after connecting up a 22-pin FPC cable, we can test out DVI driving via CircuitPython. With HSTX, we don't need to overclock or use PIO, and there's a lot more RAM on the RP2350, so we can easily do 320x240 with 16-bit color and have plenty of SRAM left over. It would be neat if we could do DVI from the PSRAM as a framebuffer at some point for really big displays!

#adafruit#circuitpython#rp2350#feather#fpc#hstx#dvi#hdmi#sram#prototyping#electronics#dviadapter#dviproject#fpgadisplay#displaytech#highspeeddata#techinnovation#diyhardware#featherboard#microcontroller#raspberrypi#displayoutput#circuitdesign#openhardware

7 notes

·

View notes

Text

imnormalimnormalimnormalimnormalimnormalimnorm

5 notes

·

View notes

Text

Flexible PCB Manufacturer & Assembly – One-stop services

Hitech Circuits Co.,Ltd is a professional flexible pcb, FPC printed circuit board manufacturer, supplier from China, due to its features of bendable, reducing product size, good heat dissipation and solderability, easy assembly and low overall cost etc, it is widely used in mobile phones, wearable smart devices, automobiles, medical treatment, and industrial control etc. If you are looking for a reliable flexible PCB board partner in China, please don’t hesitate to contact [email protected]

#pcb#FPC#flexible pcb#pcb assembly#pcb layout#pcb designer#pcb supplier#pcb manufacturing#pcb production

5 notes

·

View notes

Photo

cute i like #beautiful colors

Quick FPC, Rigid-flex PCB prototype and PCB Assembly...

Art by Leah Gardner

74K notes

·

View notes

Text

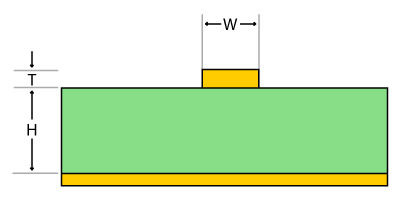

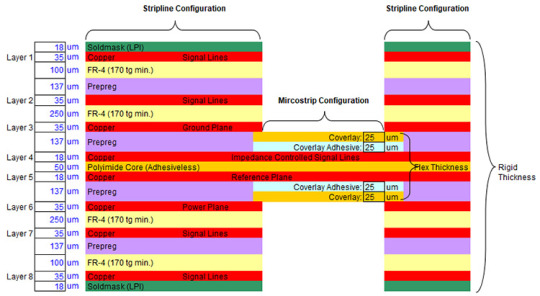

Control Impedance Between Rigid PCB and Flex PCB

As with many of today's high-speed rigid circuit board designs, flex and rigid-flex PCB designs also require controlled impedance signals. The impedance vales are the same, typically ranging from 50 ohm single ended up to 120 ohm differential pairs. However, there are differences in how the impedance values are achieved due to the mechanical bend requirements that a flex or rigid-flex circuit board must meet that a rigid PCB does not.

In this blog post we will cover a range of elements that are impacted by a controlled impedance requirement and strategies that will help lessen the impact on the mechanical bend capabilities of the design.

Flexible PCB Materials

The primary material used for both flex core layers, and the external Coverlay layers is Polyimide. As a material Polyimide is very well suited for achieving controlled impedance signal lines. It is a uniform and homogenous material with an improved DK value in the 3.2 to 3.4 range. The lack of a glass reinforcement eliminates the DK variations created by the glass weave and knuckles in the glass weave as seen in rigid PCB materials. Polyimide is also extremely uniform in its thickness due to its “cast” manufacturing process and that the layers typically range in thickness from ½ to 4 mils.

Polyimide flex cores are available with either Electro-deposited or Rolled Annealed copper. The type used is driven by the min. bend requirement necessary for the design and whether it is a “bend once to fit” or a “dynamic bend” application. The most common copper thickness used is ½ OZ copper. This allows for best combination of the thinnest possible construction with the tightest minimum bend capability and the highest degree of flexibility while still allowing for a reasonable degree of current carrying capability that will meet most design requirements. One potential item, for very high-speed designs, is that as of this time “smooth”surface coppers are not yet available which may create an issue with “skin effect”.

Polyimide cores are also available in two formats that differ in how the copper is attached to the Polyimide. The original material uses a layer of flexible adhesive, either acrylic or epoxy based, to glue the copper to the polyimide. The modern material has the polyimide cast onto the copper without using any adhesive and is referred to as “Adhesiveless”. While impedance controlled designs are possible with either material the preferred is the Adhesiveless. It eliminates the use on an additional material, the adhesive, with a differing DK value and generally allows for thinner more flexible constructions.

Controlled Impedance Configurations

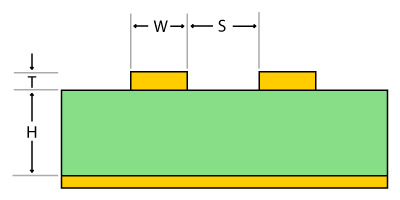

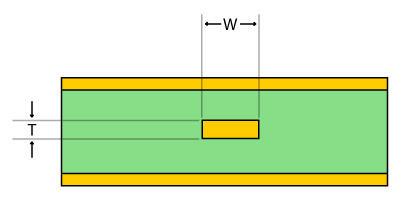

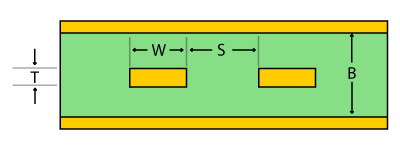

The four primary layer configurations used to achieve controlled impedance in flex circuits are similar to those used in rigid PCB designs:

Embedded Microstrip

Edge Coupled Embedded Microstrip

Symmetrical Stripline

Edge Coupled Stripline

When applied to a flex circuit design the significant difference between the Microstrip and Stripline configurations, beyond the lack of shielding on one side for the Microstrip configurations, is the impact on the flex thickness and in turn the mechanical bend capability and reliability of the circuit.

For maximum bend capability the 2-layer Microstrip is the preferred configuration. When combined with ½ OZ copper, a 0.002” flex core and 0.0005” Coverlays, the finished flex thickness is approximately 0.006” after lamination. This equates to a 0.060” min. bend radius using the general 10X thickness rule.

The Stripline configurations, while provided shielding on both sides of the circuitry, significantly increase the flex thickness and limit the bend capabilities of the part. In addition to the added shield layer and its associated dielectric core layer, both cores need to increase in thickness from 0.002” to 0.003”. For a design utilizing ½ OZ copper the finished flex thickness increases to over 0.011” after lamination. This limits the bend capabilities to over 0.200”.

The key element for both configurations is the use of ½ OZ copper. This allows for the sub 0.005” line widths necessary to achieve the impedance values when combined with the core thicknesses listed above. If 1 OZ copper is used the lines widths need to increase to 0.005” or greater due to etching process limitations. In conjunction the core thicknesses would increase to 0.004”. 1 OZ copper impedance lines increase the Microstrip version to almost 0.009” and the Stripline to almost 0.016”. The need for 1OZ copper is commonly driven by designs that have both impedance and higher currents. We recommend a careful design review to determine the available options which will meet the bend requirements.

Flex To Rigid Impedance Transitions

A unique element of a rigid-flex PCB design with controlled impedance is the need to change the configuration of the impedance lines as the circuits transition from the flex area(s) to the rigid area(s). It’s a common occurrence, in higher layer count designs, to have the flex areas impedance lines configured as a Microstrip but then, due to the need for power and ground planes in the rigid areas, have the configuration change to a Stripline. The preferred scenario is to maintain the same line width / spacing in both the flex and rigid areas by increasing the core thickness in the rigid area to the adjacent plane, but higher layer counts may not allow for the added thickness. The solution is to vary the line width and or spacing as the circuits transition from flex area to rigid area. This situation does not apply to Stripline configurations as the flex area reference planes extend throughout the rigid areas.

Controlled Impedance And Higher Currents

The combination of both impedance control and higher current carrying requirements can create a design challenge. The thicker copper, for the current requirements, compounds with the impedance requirements to create an overlay thick flex construction that may not reliably meet the specified bend requirements. The solution is frequently unique for the specific design and may involve some of the following methods:

1. Divorce current lines to separate flex layers in an Air – Gap multilayer flex construction

2. Increase flex width to allow wider current lines with ½ OZ copper

3. Utilize ganged current lines on multiple flex layers

4. Restrict reference plane(s) to areas only directly above and or below impedance lines and utilize additional free space for ganged current lines

5. Other options, TBD

The goal is always to minimize the flex thickness to the greatest degree possible in order to meet the bend requirements reliably.

Summary

Implementing controlled impedance in a flexible circuit or rigid-flex PCB design has additional considerations due to the mechanical bend requirements of the part. Controlled impedance, by necessity, increase the flex thickness. When combined with higher current carrying requirements it can further increase the flex thickness to the point where the bend requirements cannot be achieved. These challenges can be addressed in most designs with a complete design review and input from an experienced supplier.

0 notes