#freeze drying food without a machine

Explore tagged Tumblr posts

Text

#freeze dried fruits#healthylifestyle#health & fitness#dehydrates#health#best freeze dried food for preppers#how to make freeze dried fruit#best tasting freeze dried survival food#freeze drying food without a machine#healthyeating#healthyfood

0 notes

Note

do you have fresh pasta advice? specifically ravioli. I am finding a recipe now and made tortellini once before with some success but I trust you on all things food

i have advice for almost everything !

generalllyyyyyy speaking 1 cup of flour + 1 egg + 1/2 tsp of salt will get you to pasta dough. the dials you can turn are typically adding More egg yolks.

for ravioli specifically, you need to make sure you develop enough gluten. this can be accomplished in a lot of ways, but the thing to keep in mind is that the more yolks you add, the more difficult it will be to develop gluten. because yolks are primarily fat with some water. and fat inhibits gluten development.

your dough needs to be strong enough so that you can roll it Thin enough that when you lay the dough on top of itself, it has enough structural integrity it won’t rip or tear either thru pressing it together, or during cooking

pasta dough is pretty dry by design, which makes developing gluten harder. so my best advice for the mixing portion is to get your dough combined until it’s not got dry spots but isn’t smooth. cover it, and let it sit for 15-20 minutes. this will hydrate the flour and naturally develop your gluten without much need to Knead

after that time, give it a few kneads to get it smoother. you should at this point wrap it up and refrigerate it for at least an hour, but 3 or 4 is ideal. you can also make a bigger batch, and then divide it and freeze it at this point

when it comes to the rolling part, i’m assuming you’re using a machine although rolling pins will also work with this advice.

with ravioli, you will want to go a step or even two more thin than with a fresh tagliatelle or similar, because again you’re basically going to double the thickness of each raviolo at its seams and edges.

it’s going to get Really Long. so start with a small piece of dough. and run it thru the machine and get it to half of the thickness levels. fold it over a few times onto itself. and start over. here again, this is also kneading the dough, but it’s also elongating the gluten strands which builds strength. (if you bake bread at all and have done stretch and folds, this is a similar principle)

your dough should be really smooth at this point. if it’s sticking at all, you can very lightly dust some flour onto the surface of the dough. but don’t go insane. if it’s cracking or splitting, repeat the previous step. i have done this sometimes two or even three times so if it isn’t Smooth, give it another go

at this point, you’re ready to do the final rolling. on your machine, process it thru each thickness until you’re down to your last 2 (some machines have 6, 7 or even 10 levels of thickness it just depends)

if your dough lets a ton of light thru, you’re probably too thin. you want the level above. if you go to thin, you can reroll it out it will be fine

the Right thickness will be something that when you fold over on itself feels more or less like where you would stop for regular pasta. (usually this is the 2nd or 3rd to last setting depending on your machine) and then fill however you want. egg white thoroughly mixed with a small amount of water makes a good sealant (and you might have an egg white if you added yolk to your base dough.) but also water works well. if you’re dough has been kind of sticky you may not need any water at all.

a lot of this is Feel, and Intuition which is unfortunately hard to convey over a tumblr post. but hopefully this gives you some things to think about as you go forth on your ravioli adventure.

24 notes

·

View notes

Text

WIP Teruki angst incoming. I will probably edit this later and will likely post a final version to ao3. But I wanna share the wip. I don't know why but I jusssst want to get it in the world.

What is he doing?

The rain pelts his skin as he watches Kageyama walk away with the body improvement club. Without their powers they are truly—

No.

He is truly alone.

Teru was defeated. In every sense of the word.

The rain runs down his bare back, tickling the space between his spine. He could not go home like this. He has to find clothes. Something. Anything. The walk to his apartment is not a short one.

He turns towards the fully built school and makes his way towards it, mud squelching between his toes. With each step, a weight pulls down his lungs. His throat tickles with a cough and his eyes start to burn.

He stops at the front door and opens it, the smacking of his bare feet echoing around him as he walks down the tiled hallway.

Not one locker out of place, not a single crack in the foundation. Kageyama rebuilt the entire school down to the tiniest stain on the wall. The smallest spec of dirt.

“And here I thought I could defeat him,” Teru mutters to himself, as he turns a corner to the gym. He snorts, rubbing a hand along the top of his head, the shaved part scraping his palm like sandpaper. “I’m such a fool.”

He opens the gym heading for his locker. He pulls it open, taking out his gym clothes and throws them on. He takes out his spare shoes, slipping them on quickly without socks (as he didn’t have any extras). His dirty toes wiggle uncomfortable in his sneakers.

But he embraces the discomfort. It is what he deserves after all.

Teru closes the locker and walks out of the school. As he exits, the rain starts to pelt him again. He doesn’t have an umbrella. He will be soaked by the time he gets home.

Teru pauses at the gate, eyes hazy as they stare down at the rain running down the sidewalk in little streams.

Home

His apartment. Where he will have to clean his own clothes. His shoes. Wash his hair. Somehow find something to eat. He is dangerously low on food.

Kageyama he… he probably has a family doesn’t he? Teru thinks as he picks up walking again.

A family who will help him get dry. Have dinner ready. Ask where he has been. Be concerned, be available, just be…

There for him.

Teru continues to trudge forward, letting his skin freeze and his ears burn, ignoring the stares. No one asks how he is, if he is okay, if he is hurt—even as his cheeks are stained with dried blood and his hair is leafing off his scalp.

He is but a pebble in a larger stream. He really was not the main character, was he? This is not his story, is it?

He really is..

No one.

The thought shadows into a knife like the one that cut off his hair, dragging into his chest. Seeping anxiety through his heart.

He is no one.

Is that really it then? He just succumbs to being no one, to become just a cog in a machine? Is that really the lesson here that Kageyama wants him to learn?

Why does that feel like the wrong answer?

He makes it to his apartment and he drags himself upstairs. He slides open the door, stepping inside and closes it behind him, cutting off the white noise of rain.

He stands in his genkan, blue eyes tracing the outline of the wood beneath his feet. His apartment is dark and silent. The only sound is the whirring of the fridge in the far corner.

“I’m home…” he whispers to himself as he takes off his gym shoes, now filled with mud.

He takes one step forward when suddenly, the last few hours catch up. Gravity grips him and Teru stumbles backwards, slamming into the front door before his legs give out and he slides to the floor. Lead replaces blood in his veins, weighing down his body into the cold tile.

His hand grips his mouth as acid lurches, his stomach heating up as he feels the bile start to rise. He chokes it down but the emotions remain.

I almost killed him….

A mix of a gasp and a sob rips from Terus throat as his nails dig into his cheeks, as if he can keep his stomach at bay.

He nearly took another’s life. For what? FOR WHAT??

Anger burns in his chest. At himself, at Kageyama for not fighting back, at the gang that left him, at the empty apartment, at the crack in the wall from the last time Claw attacked and and and and and and and and

A scream tears out of this throat, muffled by the hand that stays glued to his mouth. He curls forward into his knees, unable to keep them in—his entire foundation is gone. Flowing out to sea in pieces of broken glass. His fingers bleed as he tries to grab the shards, to pull them back in, to rebuild himself. It is a futile effort.

He gasps for breath, trying desperately to find air, but it catches in his windpipe, unable to properly inflate his lungs. Teru bites his hand, trying to find some semblance of control, of foundation, so he can at least stand back up.

Hyperventilating, he tries to breath through teeth clenched around skin, gasps echoing in his empty world. Gasping, dry heaving around the skin. His teeth draw blood.

And then, slowly, ever so slowly, the tension eases. He removes his hand from his mouth, letting it fall to the floor, a bite mark clear on the meaty side of his thumb. He breathes in deep, shudders, before stumbling to standing as he staggers to the bathroom.

He strips his clothes off, tossing them into the corner of the bedroom. He gets the bath started and starts to clean himself off with the shower. Like clockwork he moves through the motions.

And in the back of his mind he prays that of all the days, today is the day Claw leaves him be. That no one is watching.

Does Kageyama know about Claw? He thinks as he finishes his wash and moves to the bath. He sinks into the tub, hissing as water meets blisters and torn skin.

Did they ever attack him?

He lets himself soak, the tension from the day easing. But the heat (perhaps from the bath?) grows inside him, starting with his chest and moving into his forehead. Pain blossoms behind his eyes.

Would he understand?

He digs through the cabinets. Nothing but some instant ramen. He sighs, pulling it out and moving through the instructions.

Could we fight them together?

He finishes the ramen as the heat intensifies, like someone is pressing a hot rod to his skull. Teru groans as he fumbles his way to his bathroom, reaching under the sink to pull out a small first aid kit.

It’s covered in stickers, ones gathered over the years in a futile attempt to make this box hopeful. Perhaps it could replace the feeling of his mom kissing the scrape on his knee. A flicker of sunlight in a storm.

He scoffs, swearing under his breath as he pops the lid open and digs around it for what he needs.

Cold patch and extra strength tylenol.

He pops the medication, chasing it with a gulp of water, before he peels the patch and sticks it to his forehead. The cooling sensation is familiar. In a terrible sort of way.

Does Kageyama get sick like this…? No, probably not. He is too perfect amazing wonderful powerful to get fevers like I do.

He sinks under the covers, drawing the duvet up to his chin. Heaves in a breath and then…

Stares. Stares at the ceiling above him, tracing the well known cracks and stains. Stares until his eyes dry out and he has to blink to rehydrate them.

Sounds from around the apartment fill his ears. Some are so loud–have they always been this loud? Like the pipes in his walls, the white noise from the fridge, the AC turning on?

Others layer on top of it. The dog barking down the road. The cars running outside.

And in the distance, sounds of chatter from his neighbors. Likely having dinner. It’s a family with two little girls. Teru has said hello a handful of times.

The smell of frying fish and cooked rice wafts into his apartment.

Ah, yes. It is dinner time.

Another shudder of a sigh escapes his lips and Teru turns under his covers, now staring blankly at his wall. He reaches forward, his fingers pressing and patting around until they find it. The last one. The only one he kept.

It’s an old lion plush, once a bright cream color, now dull and orange. The stuffing pools in one leg, making it larger than the rest. The mane is patchy, bald spots dotting the little lion's head. Teru lets out a wet chuckle as his fingers wrap around the stuffed animal pulling it close to his chest. He feels so childish. But as his fingers press into soft fur, worn down through the years, it eases some of the tension inside him.

Unfortunately, they do not keep the flood of fever dreams at bay when he finally falls asleep.

#if you see any typos tho that are glaring let me know#but otherwise this is just to get it out of my system#not gonna do main tags cuz again this is like#so not edited yet#so draft#SO WIP#but I feel like I can't do anything else until I post it SO OKAY#teruki hanazawa

6 notes

·

View notes

Text

How Your Backpacking Meals Are Really Made

By Emily Pennington (excerpted from the July 14, 2024 article in Backpacker)

A faint whiff of cumin and cracked black pepper serenades my nostrils, reminiscent of the Indian spice markets I once visited in my mid-twenties. Only, I’m not in South Asia, or even the back storeroom of a hip Thai restaurant; I’m in my hometown of Boulder, Colorado, touring the massive factory where Backpacker’s Pantry meals are made.

My host for the morning is Soraya Smith, the company’s president and recipe-development chef. Smith, who had always been involved on the recipe side of American Outdoor Products (the parent organization of Backpacker’s Pantry) took over as president after her husband, Rodney, died in a tragic ski accident in 2020. She’s been the face of the family-owned corporation ever since.

“I’m from a foodie family,” explained Smith. “My mom is Spanish-Italian, and my father is from Iran, so we’re very multicultural. I also went to Culinary School of the Rockies before stepping into this role.”

Our first stop was the test kitchen, where Smith pulled different dry ingredients together to experiment with new recipe ideas. To be totally honest, the various plastic bags she grabbed out of a large bin looked more like the Parmesan cheese packets you’d get for free with your pizza delivery than high-quality foodstuffs. But therein contained the secrets to my favorite post-hike meals: proprietary flavorings and mixes, which Backpacker’s Pantry makes with freeze-dried ingredients.

As we entered the factory’s enormous storeroom, I asked Smith for a refresher: What exactly is freeze drying?

Freeze-drying technology was used extensively by NASA during the space boom of the 1960s. Since freeze-dried food retains more than 90 percent of its original nutrients, it’s the best way to keep astronauts stocked with nutritious food. Better yet, the food can last for years without going bad.

When an ingredient is freeze-dried, it’s brought to an inhospitable -60°F, then back above freezing multiple times while inside a vacuum chamber. That way, only the ingredient’s water content is removed. “Some companies make a large sheet of, say, lasagna, cook it, and then dehydrate it,” Smith said. “We, on the other hand, mix each of our freeze-dried ingredients into the bag, so that when you add that boiling water, most of them are getting cooked for the first time. It’s fresher, and I think it has a better texture.”

Once workers grab individual ingredients from the palettes in the store room, they go to the dedicated mixing room, where seasonings and starches are stirred together in large tubs. The room looks like a sterile, high-tech scene out of Willy Wonka.

Here, Smith points out that the brand adheres to a strict allergen separation system. For instance, a recipe with gluten won’t get run through the machines on the same day as a gluten-free recipe to protect customers with gluten intolerances. Ditto for dairy products. (Workers clean the machines thoroughly at the end of each day by passing them through a chrome-covered, bedroom-sized industrial dishwasher.)

After mixing, the meals are mechanically portioned out by category—sauce, starch, meat, and vegetable—then sealed by hand. Workers sample the meals throughout the day, preparing a baggie to taste-test at the beginning, middle, and end of each run. The goal is to ensure the flavors remain consistent throughout. Forks and counter space are set aside in the test kitchen for this specific purpose. If something doesn’t taste right, they ditch the batch and correct it.

The Backpacker’s Pantry factory produces thousands of meals each day. Once the day’s meals get sealed, boxed, and quality checked, they head into a gigantic storeroom, which then ships the products to big retailers, like REI, as well as directly to consumers.

As I closed the huge warehouse doors behind me and concluded my tour, I was surprised to feel tremendously better about all that just-add-water food I’d been eating. The ingredients were both fresher than I’d imagined and more rigorously quality-checked. Ninety percent of their original nutrients, huh? Heck, maybe I’ll toss a couple under my desk to eat in the office.

1 note

·

View note

Text

【The ultimate guide to choosing the perfect Dry Ice Cleaning Machineand dry ice machine for your needs】

UNDERSTANDING YOUR REQUIREMENTS

1. Determine your application area:

Before diving into machine specifications, determine your primary application. Whether it’s industrial cleaning, food preservation, or special effects in the entertainment industry, understanding your specific use case will allow you to more accurately select the machine that’s best for you.Or you can tell us your needs and we will recommend the best solution for you.

2. Dry ice quantity issue:

Consider the amount of dry ice you need. Industrial applications may require high-capacity machines, while smaller equipment can meet smaller-scale needs. Understanding your production requirements is critical.You can refer to 【Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers】and 【How to set up your own dry ice manufacturing factory?】Learn more about dry ice in two articles.

TYPES OF DRY ICE CLEANERS AND DRY ICE PELLETIZERS

1. Dry ice cleaning machine(Dry ice blasting machine):

Compressed air is used to accelerate dry ice pellets to supersonic speeds and spray them onto the surface being cleaned. The high-speed ice particles hit the dirt, and through the freezing and mechanical action of the ice, the dirt is peeled off the surface.It is widely used for cleaning machinery and equipment, production lines, building surfaces, etc. It is especially suitable for the food and pharmaceutical industries because the cleaning process does not require water or chemicals.(Want to learn more about Dry Ice Cleaning?)

· P7X Dry ice cleaning machine: Very suitable for cleaning carbon deposits and oil stains in car engines. It can effectively complete cleaning without damaging engine parts etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· A625i Dry ice cleaning machine: Suitable for cleaning oily molds, motor windings, paint rust cleaning, and printing machine ink residues etc.. (Suitable for rubber factories, shoe factories, factory machine maintenance, etc.)Go to view product details

· P60 Dry ice cleaning machine: Used for car interior renovation and cleaning, car seat cushions, surface glue residue, and oil stain cleaning etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· T6 Dry ice cleaning machine: Used for PCB circuit board renovation and cleaning, soldering residue, surface glue residue, oil stains, PPS material deburring, etc. (Suitable for component factories, component maintenance, factory machine maintenance, etc.)Go to view product details

· B3+ Dry ice cleaning machine: Used for cleaning motor winding dust, printing machine ink, oil sludge, rust stains, heavy oily metal, etc.(Used to clean and maintain a variety of industrial equipment, including engines, pumps, valves, pipes, etc.)Go to view product details

Generally speaking, the dry ice cleaning machine is an efficient, environmentally friendly, and multi-purpose cleaning equipment. Its working principle is based on high-speed spraying of dry ice particles to clean the surface through freezing and mechanical impact. The advantages of this cleaning method include being water-free, leaving no chemical residue, being non-abrasive, suitable for a variety of surfaces and materials, and having a wide range of applications in a variety of industries.

For potential users, when choosing a dry ice cleaning machine suitable for specific needs, factors such as cleaning objectives, working environment, cleaning effect requirements, production capacity and budget need to be considered. Whether in industrial, food, medical or other industries, dry ice cleaning machines have demonstrated their excellent performance in improving cleaning efficiency and protecting equipment surfaces.You can also tell us your needs and our engineers will recommend the most suitable solution for you. Contact an engineer now >>

2. Dry ice pellet machine(Dry Ice Granulator Machine):

Dry ice pelletizer is a piece of equipment specially used to turn liquid carbon dioxide (CO2) into solid carbon dioxide (dry ice) pellets.

Dry ice pelletizers usually deliver liquid CO2 into the machine through a liquid carbon dioxide supply system. Liquid carbon dioxide undergoes a series of cooling and pressurization processes, causing its temperature and pressure to rise. The pressurized liquid carbon dioxide passes through the nozzle or spray head and enters a relatively low-pressure environment. In this environment, liquid CO2 rapidly relaxes and expands, lowering its temperature and turning into a solid state. Because the temperature drops sharply, liquid CO2 turns into a gaseous state and forms tiny CO2 particles, known as dry ice particles.

The Dry ice machine can efficiently convert liquid CO2 into a large number of evenly distributed dry ice pellets. The advanced control system can achieve precise control of parameters such as temperature, pressure and particle size to ensure the production of dry ice that meets requirements. Some Dry Ice Granulator have adjustable mechanisms that allow the user to select different sizes of dry ice pellets. There is no need to add any chemicals during the manufacturing process, and the waste material is CO2 gas, so the dry ice pelletizer is considered a relatively environmentally friendly production method. Most Dry Ice Pelletizer Making Machine are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

3. Dry Ice Block Machine(Dry ice briquetting machine):

A dry ice block press is a piece of equipment specifically designed to compress dry ice pellets or pieces into block form.

Dry ice block presses typically use previously produced dry ice pellets or chips as raw material. These pellets or chips are usually prepared through an overhead dry ice pelletizer or other means. Dry ice raw material is transported to the compression zone and heated to a certain level. The purpose of heating is to cause the dry ice pellets or blocks to begin to soften and melt. After heating, the softened dry ice is placed in a compression zone, where compression machinery or a hydraulic system exerts tremendous pressure to compress the dry ice into blocks. The compressed dry ice blocks pass through the cooling system, where they are quickly cooled and re-solidified to form solid dry ice blocks. The formed dry ice blocks enter the collector through the collection system, and then enter the packaging area through the conveyor system for final packaging.

Go to view product details >>

Main feature:

Efficient production: The dry ice block press can efficiently convert dry ice pellets or fragments into large, solid dry ice.

Uniformity of dry ice blocks: Compression machinery and control systems ensure uniform shape and size of dry ice blocks, suitable for different applications.

Save space: Dry ice in block form is easier to store and transport than in crushed or pellet form, thus saving space.

Energy savings: Previously produced dry ice pellets or crumbs are used as raw material, reducing the need for additional refrigeration and helping to save energy.

Automated operation: Most modern dry ice block presses are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

Application areas:

Food and pharmaceutical transportation: Dry ice blocks are widely used in cold chain transportation to keep food and pharmaceuticals at low temperatures.

Laboratory and scientific research: In laboratories and scientific research fields, dry ice blocks are used to prepare low-temperature environments, such as refrigeration reagents.

Special effects production: Dry ice cubes are often used in film productions and stage performances to create special smoke and cold fog effects.

Environmentally Friendly Cleaning: Dry ice cubes are also used in the cleaning industry for cleaning and removing dirt, especially for electrical equipment cleaning.

Overall, the dry ice block press provides a reliable production method for producing large blocks of dry ice, suitable for the different needs of multiple industries.

RODUCTION CAPACITY

Evaluate the machine's productivity in pounds per hour. Make sure it fits your needs without sacrificing quality. To meet high-volume demand, faster production may be required.

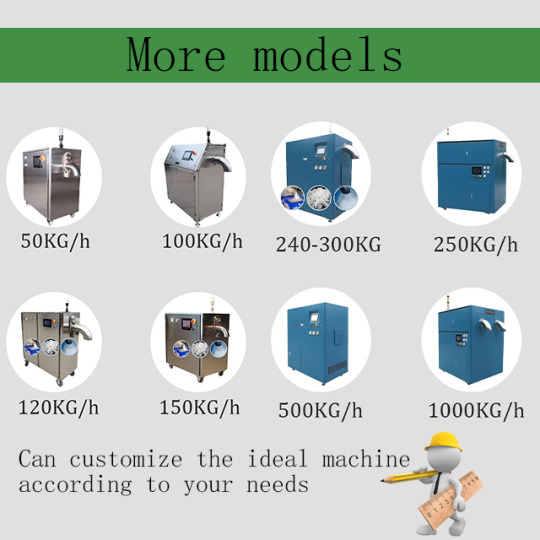

OLLITAL aims to provide customers with more choices in production capacity. Independently developed: 50KG/H (110 lbs/H), 100KG/H (220 lbs/H), 150KG/H (330 lbs/H), 250KG/H (551 lbs/H), 500KG/H (1102 lbs/H), and 1000KG/H (2204 lbs/H) dry ice pellet machine. Or you can tell us your needs and our engineers will customize the most suitable solution for you according to your needs. Contact an engineer immediately for customization >>

TECHNICAL SPECIFICATIONS

1. Size and portability:

Consider the physical size of the machine. A compact, portable unit may be better for versatility and ease of use, especially if you work from different locations or have limited space. If you need to move your cleaning equipment between job sites, choosing a dry ice blaster that is compact and portable may be key. This is important for tasks that require frequent movement or operation in limited spaces.

* Machine size: View the actual dimensions of your dry ice blaster, including length, width, and height. Make sure the machine is sized to fit your workplace and can be easily stored or carried.

* Weight: In addition to size, consider the weight of your dry ice blaster. The lightweight design can improve portability, reduce the burden of transportation, and make the device easier to carry and operate.

* Easy to carry design: Choose a machine with a user-friendly carrying design, such as handles, wheels, or other structures for easy movement. These designs make it easier for operators to move equipment from one location to another.

* Versatility: Some portable dry ice blasters are designed for versatility and can be used in a variety of applications. This flexibility increases the equipment's usefulness and makes it suitable for different types of cleaning tasks.

* Easy to store: Consider the storage needs of the machine when not in use. Some machines may have folding or removable parts to make it easier to store in limited spaces.

* Power and energy requirements: Consider the power and energy requirements of your dry ice blaster. Portable devices are often easier to connect to different types of power sources, such as batteries, generators, or standard electrical outlets.

When selecting a dry ice blaster, considering size and portability can ensure the equipment is better suited to your job requirements, increasing operational flexibility and efficiency.

2. Automation and control:

Automation and control are crucial considerations when selecting a dry ice pelletizer and cleaning machine. Look for user-friendly controls and automation features. An intuitive interface and automation streamline operation, making the machine easier for operators of all skill levels to use.

* Intuitive interface: Choose a dry ice granulator/cleaner with an intuitive interface. An intuitive control panel or touch screen makes it easier for operators to understand and operate the equipment, reducing training time.

* User-friendly controls: Consider choosing a machine with user-friendly controls. Simple buttons, knobs or digital controls allow operators to easily adjust and monitor cleaning parameters.

* Default program: Look for machines with preset cleaning programs. Preset programs improve operational consistency and efficiency, reducing manual setup and adjustments by the operator.

* Automation features: Understand whether the machine has automated functions, such as automatic nozzle adjustment, cleaning trajectory planning, etc. These features simplify the cleaning process and reduce operator intervention.

* Remote control and monitoring: If possible, choose machines that support remote control and monitoring. In this way, operators can monitor and adjust the cleaning process remotely, increasing the operational flexibility of the equipment.

* Fault diagnosis and alarm system: Look for machines with fault diagnosis and alarm systems. These systems can detect and report potential problems in a timely manner, helping to quickly resolve faults and improve equipment reliability.

* Data logging and reporting: Some advanced dry ice cleaning machines have data logging and reporting capabilities that can record key parameters during the cleaning process. This is very useful for quality control and traceability.

* Programmability: If you need to personalize it for a specific application, consider choosing a machine with some programmability to accommodate different cleaning needs.

By choosing a dry ice pelletizer/cleaner with an intuitive interface, automated features, and user-friendly controls, you can increase the ease of use of your equipment, reduce training costs, and ensure consistent cleaning results among operators of different skill levels .

Choosing the perfect dry ice machine requires a thorough understanding of your specific needs, technical specifications, and cost considerations. By carefully evaluating these factors, you will be able to make an informed decision that meets your application requirements and provides long-term value.

Whether you're venturing into a new business or upgrading an existing setup, investing the time in selecting the right dry ice machine is a critical step toward efficiency and success.

If you want to know more about Dry Ice Pellet Manufacturing Machinery or you want to build a dry ice production line, please refer to [Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers].

In this era of cleaning revolution, choose a dry ice cleaning machine to make cleaning easier, more efficient and more environmentally friendly! Thank you for reading our blog, if you have any questions or cooperation intentions, please feel free to contact us. Let us help the cleaning industry together and create a better future!

2 notes

·

View notes

Text

Lyophilizer Machine For Fast And Efficient Freeze Drying

A Lyophilizer Machine moreover referred to as a freeze dryer, is a specialised device used to maintain perishable substances through disposing of moisture through a way referred to as lyophilization or freeze drying. This approach is extensively accomplished in diverse industries alongside prescription drugs, biotechnology, food processing and studies laboratories.

What is a Lyophilizer Machine?

A Lyophilizer Machine in China works with the resource of first freezing the product after which lowering the surrounding strain to permit the frozen water within the cloth to sublimate straight away from the stable segment to the gasoline phase. Unlike traditional drying strategies, freeze drying prevents damage to the product by preserving off excessive warm temperature, maintaining the product’s form, nutritional content, cloth cloth cloth, and bioactivity.

The device typically consists of a freezing chamber, vacuum pump, condenser, and heating cabinets. The product is frozen at very low temperatures, usually beneath -40°C, in advance the vacuum reduces the strain and initiates sublimation. The water vapor is trapped inside the condenser, and the dried product remains in a sturdy, dry United States of America that may be stored for lengthy intervals without refrigeration.

Key Components of a Lyophilizer Machine

Freezing Chamber: Holds the samples and freezes them to preserve fantastic.

Vacuum System: Lowers the pressure to permit sublimation of ice.

Condenser: Captures and freezes the vaporized water.

Heating Shelves: Gently warm the product to accelerate drying.

Control System: Modern lyophilizers have programmable interfaces to show display screens and manipulate temperature, pressure, and drying time.

Applications of Lyophilizer Machines

Pharmaceutical Industry: Lyophilization is extensively used to stabilize vaccines, antibiotics, enzymes, and biologicals which may be touchy to warmth and moisture. Freeze drying extends the shelf life and continues the efficacy of these merchandise without refrigeration.

Food Industry: Freeze drying preserves meals thru removing moisture without damaging taste, texture, or dietary fee. Products like espresso, end result, veggies, and prepared-to-devour food advantage from longer shelf lifestyles and moderate-weight packaging.

Biotechnology and Research: Scientists use lyophilizers to preserve natural samples at the side of micro organisms, viruses, and tissues for a long-time period. It furthermore lets in pattern training for analysis and delivery.

Cosmetics: Freeze drying allows the lively components in beauty products, keeping their overall performance and stability.

Choosing the Right Lyophilizer

When deciding on a Lyophilizer Machine Manufacturer in China, do not forget factors like potential, freezing temperature range, vacuum power, shelf location, and manipulate tool sophistication. Small benchtop fashions in form laboratory art work, on the same time as large commercial machines cope with bulk production.

Conclusion

Lyophilizer Machine Suppliers in China play a crucial function in cutting-edge-day maintenance strategies by using a way of permitting extended-term garage of touchy merchandise without compromising awesomeness. With programs spanning pharmaceuticals, meals, biotech, and cosmetics, freeze drying remains a critical generation in each research and employer manufacturing.

#Lyophilizer Machine#Lyophilizer Machine in China#Lyophilizer Machine Supplier in China#Lyophilizer Machine Manufacturer in China#Services#Machine

0 notes

Text

Dry Ice Market: Key Trends, Industrial Applications, and Growth Forecast Through 2025

The Dry Ice Market is rapidly evolving, driven by increased demand for cold chain logistics, sustainable cleaning methods, and innovative food preservation solutions. With its unique ability to sublimate without leaving a residue, dry ice has become indispensable across industries like pharmaceuticals, food and beverage, and industrial manufacturing. As we look toward 2025, this once-niche segment is poised for substantial growth fueled by new applications and eco-friendly trends.

Major Trends Fueling the Dry Ice Market

1. Expansion of Cold Chain Logistics A significant factor pushing dry ice demand is the rising need for reliable cold chain logistics. E-commerce, online grocery deliveries, and pharmaceutical distribution (especially vaccines and biologics) rely on ultra-low temperature storage during transit. Dry ice provides a dependable, residue-free solution that ensures product safety without electricity, making it a key enabler for global supply chains.

2. Dry Ice Blasting for Industrial Cleaning Traditional cleaning techniques in factories and heavy machinery are being replaced by dry ice blasting—a method that cleans without water or chemicals. This technique uses high-velocity pellets of dry ice to remove contaminants, reducing downtime and leaving no waste. Industries like aerospace, automotive, and food processing have adopted this approach for its efficiency and eco-friendliness.

3. Demand in the Food & Beverage Sector In food production and distribution, dry ice ensures that perishable items remain frozen from factory to fork. It is now standard for meal delivery services, seafood exporters, and gourmet food distributors. The increasing consumer preference for preservative-free foods that require fresh freezing also benefits the dry ice market.

Diverse Industrial Applications Driving Adoption

The Dry Ice Market supports various sectors. In pharmaceuticals, it is essential for preserving sensitive biologics and medications during shipping. Laboratories use it to cool specimens, while event planners use dry ice to create fog effects. Dry ice is also gaining popularity in hospitality and beverage services for its visual appeal in cocktails and specialty dishes.

Furthermore, agriculture uses dry ice to protect grains and produce from pests during storage. Electronics manufacturers have begun using dry ice for short-term component cooling in high-performance computing systems. This versatility is what gives dry ice a solid edge in industrial markets.

Market Forecast and Future Opportunities

Analysts forecast a healthy growth trajectory for the Dry Ice Market through 2025, with a projected CAGR of 7% or more. Growth will stem from both traditional industries and emerging sectors such as pet food delivery, cosmetic transport, and cloud kitchens. Additionally, sustainability efforts are prompting manufacturers to explore carbon capture techniques to produce dry ice from recycled CO₂, making the entire lifecycle more environmentally friendly.

Another innovation in the pipeline is on-demand dry ice vending machines—a concept being piloted in select Asian countries. These kiosks offer small-scale, immediate dry ice access to caterers, florists, and small labs, allowing broader access to this valuable resource.

Startups are also investing in portable dry ice generation units that can be installed in delivery trucks or storage units, helping address last-mile cooling challenges. This development will especially benefit underserved regions and small-scale businesses looking for decentralized refrigeration options.

Conclusion

The Dry Ice Market is becoming a critical component in global logistics, industrial maintenance, and modern food systems. Its diverse applications, zero-waste properties, and alignment with sustainability trends make it a standout performer in today’s market landscape. As innovation continues to unlock new uses—from biotech to beverages—the future of the dry ice industry looks solid, promising, and filled with transformative potential.

0 notes

Text

Top Laboratory Freeze Dryer Suppliers – Why Lyo Group is the Trusted Name in Precision Freeze Drying

In today’s fast-paced research and development environment, laboratories require reliable, high-performance freeze dryers to ensure accuracy, efficiency, and consistency in results. Whether it's for pharmaceuticals, biotechnology, or food analysis, selecting the right laboratory freeze dryer supplier can make all the difference. At Lyo Group, we’ve positioned ourselves as industry leaders in freeze drying systems — offering cutting-edge technology, expert support, and unmatched quality.

Why Laboratory Freeze Dryers are Crucial

Laboratory freeze dryers, also known as lyophilizers, are essential tools used to preserve sensitive materials by removing moisture through sublimation. They help maintain product integrity, prevent degradation, and ensure extended shelf life — all without the use of preservatives or additives.

Freeze drying is particularly vital in:

Pharmaceutical formulation development

Biological sample preservation

Research in chemistry and life sciences

Food texture analysis and quality testing

As demand increases, so does the need for reliable laboratory freeze dryer suppliers that can deliver both quality and innovation.

Meet Lyo Group – Your Expert Partner in Laboratory Freeze Drying Solutions

At Lyo Group, we specialize in designing and manufacturing advanced freeze drying systems tailored for laboratory and R&D applications. With years of engineering experience and a strong commitment to quality, we’ve become a go-to choice for scientists, researchers, and lab professionals across the globe.

What Sets Lyo Group Apart?

Cutting-Edge Technology Our laboratory freeze dryers are equipped with state-of-the-art controls, vacuum systems, and user-friendly interfaces, making complex freeze drying processes seamless and repeatable.

Custom Solutions Every lab is different. We offer customizable options to fit specific applications, sample sizes, and performance needs — ensuring optimal results every time.

Reliable Performance Lyo Group machines are built with high-grade components and undergo rigorous quality checks, ensuring durability and long-term performance.

Technical Support & Training From installation to operation, our expert support team is with you every step of the way. We also provide hands-on training to help you maximize productivity.

Global Reach with Local Focus While we cater to labs worldwide, our customer-first approach ensures you receive personalized service, quick turnaround times, and responsive communication.

Key Features of Our Laboratory Freeze Dryers

Compact, benchtop-friendly designs

Programmable temperature and vacuum profiles

Precise control over shelf temperature and pressure

Wide range of condenser capacities

Easy data logging and reporting for compliance

Whether you're working with pharmaceuticals, tissues, enzymes, or food samples — Lyo Group's laboratory freeze dryers offer the performance and control needed for dependable outcomes.

Choosing the Right Laboratory Freeze Dryer Supplier – What to Look For

When evaluating suppliers, consider the following:

Proven track record and expertise

Availability of after-sales service and spare parts

Technical innovation and compliance standards

Scalability for future needs

Customer reviews and project case studies

Lyo Group checks all the boxes and more — delivering smart freeze drying solutions that adapt to your evolving research needs.

Partner with Lyo Group Today

As one of the most trusted laboratory freeze dryer suppliers, Lyo Group is committed to helping labs achieve accuracy, efficiency, and excellence. Whether you're scaling up research or looking for a reliable replacement, our systems are engineered to perform — and built to last.

📞 Get in touch today to discuss your lab’s requirements, request a quote, or book a product demo.

🔗 Visit our website at Lyo Group

0 notes

Text

Revolutionizing Cooling with Specialized Ice Machines

The Surge in Demand for Tailored Ice Solutions

In a world where precision cooling is paramount, the spotlight has turned to machines that deliver ice in forms suited to specific needs. Businesses, from quaint cafés to sprawling factories, are driving a surge in demand for equipment like those featured in a Commercial small flake ice machine sale. This trend reflects a broader recognition that not all ice is created equal—different industries require different textures and sizes to optimize their operations. Meanwhile, larger-scale operations are turning to robust solutions like the industrial ice cube maker machine, proving that ice-making technology is as diverse as the sectors it serves.

The appeal lies in customization. Where once ice was a one-size-fits-all commodity, today’s advancements allow for targeted applications, enhancing efficiency and quality across the board. Whether it’s preserving delicate seafood or chilling a production line, these machines are stepping up to meet modern challenges with ingenuity and reliability, reshaping how businesses approach temperature control.

Flake Ice: The Versatile Choice for Small Businesses

A Commercial small flake ice machine sale often catches the eye of small to medium-sized enterprises looking for flexibility without overwhelming complexity. Flake ice, with its soft, moldable texture, is a game-changer for industries like food service and retail. Picture a fishmonger arranging a glistening display of fresh catches atop a bed of shimmering flakes, or a bakery using it to cool dough without altering its consistency—this ice type adapts effortlessly to varied needs.

These machines are designed with practicality in mind. Compact yet powerful, they fit snugly into tight spaces, making them ideal for establishments where every square foot counts. The production process involves shaving ice into thin, dry flakes that cool rapidly due to their expansive surface area. This rapid chilling capability, paired with the ice’s gentle nature, ensures products stay fresh without damage, a feature that small business owners value for both quality and cost savings.

Industrial Cube Ice: Powering Large-Scale Operations

On the other end of the spectrum, an industrial ice cube maker machine caters to the heavyweights of industry. These robust units churn out solid, uniform cubes at a scale that suits high-volume demands, from beverage production to concrete cooling. In settings where consistency and durability are non-negotiable, these machines deliver ice that melts slowly, maintaining temperatures over extended periods—a critical factor in logistics or large-scale food processing.

The engineering behind these machines is impressive. Water is frozen in molds under precise conditions, then released as perfectly shaped cubes ready for immediate use or storage. Built to handle continuous operation, they’re the backbone of facilities that can’t afford downtime. For industries like hospitality or manufacturing, where thousands of pounds of ice might be needed daily, this reliability transforms a potential bottleneck into a seamless workflow.

The Mechanics of Modern Ice Production

Behind every Commercial small flake ice machine sale lies a blend of simplicity and sophistication. These units often feature a rotating drum or blade that scrapes ice from a freezing surface, producing flakes at a steady pace. Energy efficiency is a priority, with designs that minimize water waste and optimize cooling cycles. For small businesses, this translates to lower operating costs and a smaller environmental footprint, aligning with today’s push for sustainability.

Conversely, an industrial ice cube maker machine operates on a grander scale, with larger refrigeration systems and automated controls. The process is streamlined for mass production—water fills molds, freezes, and is harvested in a continuous loop. Durability is key, with components crafted from corrosion-resistant materials to withstand harsh conditions. This blend of power and precision ensures that even the most demanding operations run smoothly, day after day.

Applications That Define Their Value

The versatility of a Commercial small flake ice machine sale shines in its real-world uses. Beyond food preservation, these machines support healthcare settings, where flake ice cools without soaking bandages or equipment. In boutique gyms, they provide refreshing hydration stations, enhancing customer experience with minimal effort. Their compact size and adaptability make them a smart investment for entrepreneurs looking to elevate their offerings.

Meanwhile, an industrial ice cube maker machine powers industries that shape our daily lives. In construction, cubes are mixed into concrete to prevent overheating during curing, a practice vital in hot climates. Beverage giants rely on them to fill millions of cups, ensuring every sip stays crisp. Even disaster relief efforts benefit, with portable units supplying ice to keep supplies fresh in remote areas. These machines aren’t just tools—they’re enablers of progress.

The Future of Ice-Making Technology

As industries evolve, so do the machines that support them. A Commercial small flake ice machine sale might soon feature smart technology, adjusting output based on demand or alerting owners to maintenance needs. Such innovations could empower small businesses to operate with the efficiency of larger counterparts. The focus on eco-friendly refrigerants will likely grow, appealing to environmentally conscious buyers.

For an industrial ice cube maker machine, the future holds promise of even greater automation and scalability. Imagine systems that integrate with supply chains, predicting ice needs based on weather or production schedules. Energy-saving designs will continue to advance, reducing costs for industries that rely on massive outputs. This forward momentum ensures that ice-making remains a dynamic field, adapting to tomorrow’s challenges.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Multi-functional: The automatic vacuum sealer can lock moisture and isolate air, it can be continuously sealed without waiting, widely used in Vegetables Eggs, Meat, Snacks, Canned Food, perfect ideal for every family and small restaurant. Step of Using Vaccum Sealer: 【Keep Food Fresh 10X Longer & Save Money】- The vacuum sealer machine is an essential tool in any home kitchen. More and more people prefer vacuum sealer machine to store food, which will make cooking, meal prep easier, reduce food waste. Not only save your time and money, but enhance the taste of your dishes by using our vacuum sealer. 【Professional Vacuum Sealer】- Our food vacuum sealer only takes 5-8 seconds to complete the food vacuum sealing. Keeps food fresh 10X longer than normal storage methods. The perfect solution to keep food fresher and longer. Reduce your food bills and wasted leftovers with our vacuum sealer. Your favorite foods will keep for up to 3 years after sealing and freezing them. 【Easy to Seal】- Our food vacuum sealer adopts fully automatic one-button sealing machine operation, LED indicator light, hands-free design. It has constant temperature to seal dry and wet food. Dry food or for wet food. Suitable for steak, meat, seafood, shrimp, fish, fruits, vegetables, nuts, bread, jars, etc. Meet all your needs. The compact size and lightweight design are ideal for beginners, especially the elderly and children. Become a good partner in your home kitchen. 【Excellent Safety & Multifunctional】- Our food vacuum sealer suitable for maximum 9.5" width vacuum sealer bags any size less will work perfectly as well. Works with any brand sealer bags. You can lift the top cover for easy cleaning. This vacuum sealer meets applicable product safety testing standards and is built to last, keeping you and your family safe is our top priority. 【What You Get】- You will get 1 x Vacuum Sealer Machine, 1 x AC Adapter, 1 x User Manual (Depending on your menu selection). You will love this way of cooking. If you have any question about our Vacuum Sealer Machine, please contact us, we will provide you with a satisfactory solution. [ad_2]

0 notes

Text

How to Make Pasta at Home: Tips, Techniques, and Tools

Old-world excellence meets new-world know-how.

Who would have thought Italy—the country shaped like a dang boot—would conquer the world of favorite foods? Like life-changing pizza, elegant desserts, and slow-cooked braises, Italian pasta's excellence lies in its simplicity.

Simple is a double-edged sword, because there's so much that can go wrong. What kind of flour should you use? Can you make a big batch of ravioli by hand? Do you need a machine to even begin to think about making pasta? Is it even worth making homemade pasta? There are so many questions when it comes to making homemade pasta at home, and we're going to try and answer them, while alleviating your pasta-related fears, and letting you in on some tips and tricks to pasta perfection.

Whether you're a seasoned pasta pro or a total novice, here are some of the best tips, techniques, and tools for how to make pasta at home.

The science of how to make pasta

Pasta is one of the staple foods of Italian cuisine and is beloved the world over because it's tasty, filling, and cheap. While red and white sauces are among the most iconic, really good pasta doesn't require much more than some butter or good olive oil, and maybe a light shredding of parmesan cheese. Its versatility is unmatched, with a myriad of shapes made for specific purposes. Wide noodles are perfect for stacked casseroles like lasagna, while elbow macaroni perfectly soaks up cheese sauce. Homemade pasta is almost an entirely different animal when you compare it to the boxed stuff, and eating it can be a truly ethereal experience.

For most of pasta history, the whole process was done by hand, from mixing dough to kneading and rolling it out into various shapes. Making pasta dough without any mechanical implements is enough to make me swear off the stuff entirely. Even with a good machine, making pasta is one of those arduous cooking activities I would relegate to a lazy Saturday. Could you make your pasta completely by hand? Sure, I'm not going to stop you. But I'm of the firm belief that sweat and heartache don't actually make food taste better. Still, there are plenty of nona's around the world who still do it, and who am I to argue with them?

Even with the best tools and know-how, I wouldn't necessarily call pasta-making a rewarding experience. I cannot stress just how time-consuming it is, from mixing dough to letting it rest, to kneading, shaping, and then cooking. The trouble is, things can go wrong during each of these steps, that could potentially turn your time and labor investment into a wasted weekend and a bowl of slop that's not worth the calories to consume.

My suggestion is to dip your toes into pasta making by making gnocchi. It's easily the most failproof pasta to make, you can make it out of anything from zucchini to butternut squash, and it will help grow your pasta-making callouses. If this experience leaves you cold (and hungry), I'd say to save yourself the heartache and reach for the box of Barilla.

How to store fresh pasta

Like soup, it's easier to make a big batch of pasta than it is to make a handful of ravioli. Some pasta makers store big batches by first drying them out using drying racks. This approach works, but in my opinion, you lose some of that fresh pasta magic in the drying process. But fear not, there's another way to store pasta that doesn't require another step: freezing. For long noodle strands like spaghetti and linguine, lightly dust single servings with flour, coil into nests, then freeze on a parchment-lined sheet until hard. For smaller pieces like macaroni and penne, place pasta on a single layer on a parchment-lined sheet and freeze until hard. Once your pasta is frozen, you can move it to a zip-top bag and keep it in the freezer until you're ready to cook and eat.

You can cook this frozen pasta straight from the freezer without any thawing, just add a couple minutes to the cooking time.

How to make fresh pasta dough

When you look at a list of pasta ingredients, you'll probably find yourself saying, "wow, simple!" This is sheer hubris. The parts list may be simple, but the process will take hours, so don't start mixing up dough around dinner time unless you plan on eating your fettuccine around three a.m. It doesn't actually take that long, mind you, but if it's your first time making pasta, the time it takes to roll out your dough will feel like an eternity. There's another ingredient in the parts list that's absolutely necessary: patience.

Onto the recipe! This is a great catch-all recipe for all kinds of pasta. If you like your pasta soft and tender, make sure you use a special pasta flour. If you like your pasta with a little more chew, and a little more bite, all-purpose flour works fine.

Ingredients:

240g flour

2 whole eggs

2 egg yolks

1 teaspoon kosher salt

Steps

In a large bowl, mix eggs, flour, and sugar. Once it comes together into a ball, cover it with plastic wrap and allow the dough to rest for at least one hour.

Next comes the kneading. You can use good old-fashioned elbow grease, or run it through the thickest part of a pasta roller, folding it in half every time, and repeating this process until the dough is smooth and elastic. If it gets sticky, add a small amount of flour. Divide dough into four pieces.

Run each piece of pasta dough through a pasta roller starting at the thickest setting, and through the thinnest. Then, place the sheets on a floured surface. If you're making ravioli, you can use the dough right away to shape it into dumplings.

To make pasta noodles: If you plan on cutting your sheets into noodles, allow them to dry uncovered for five minutes. Flip, and allow them to dry another five minutes. Flip, and rest another five minutes. Then flip once more, and rest for a final five minutes. Then you can run the sheets through a pasta cutter or slice them into noodles by hand using a knife or pasty cutter. Once you cut your pasta into noodles, lightly toss in flour then carefully lift a stack of noodles and roll it into itself to make small nests. Place these on a baking sheet until ready to cook.

To store fresh pasta: Freeze pasta after placing it on a baking sheet in the step before. Once it's frozen hard, you can move these pasta nests into zip top bags and store for a few months. You can cook this fresh pasta right out of the freezer, just add a couple minutes of cooking time.

To cook fresh pasta: Bring two quarts of salted water to a boil. Place one serving of pasta in the pot and allow to cook for anywhere from three to six minutes, depending on how you like your pasta. Strain the pasta, and toss in your favorite sauce to coat.

How to make gnocchi

Pasta making, even under the best circumstances, can be a daunting experience. For me, it's something that I only do a few times of year, especially around romantic holidays like anniversaries and Valentine's Day. That is unless you count gnocchi. I can make these bad boys in my sleep, and I'm confident you'll be able to as well. Here's a recipe that I use to make butternut squash gnocchi that freeze well so you can make a big batch of them and always have them on hand when you want a stupendous side dish or a rainy day main course.

Ingredients

1 large butternut squash, halved and seeded

3-5 cups flour

1 tsp kosher salt

Nutmeg, grated

Steps

Place butternut squash in a roasting pan. Roast in a 425-degree oven until a knife pierces the flesh easily, 30-45 minutes. Scoop the flesh into a food mill and grind until smooth. Alternatively, you can mash the cooked squash or run it through a food processor. Place the pureed squash into a large bowl.

Add salt and flour to the squash mixture. How much flour you'll need truly depends on how big your squash is. It will take anywhere from 3 to five cups. The dough should be malleable but not sticky. Once it comes together, place the dough on a floured surface.

Divide dough into four equal pieces. Roll into a log and slice off small dumplings. Then, you can roll them on a floured gnocchi paddle or a fork. Place on a parchment-lined sheet. Repeat with the rest of the dough. Once all the dough is rolled out, you can freeze the dumplings hard, then move them to zip-top bags and store them in the freezer for a few months. You can cook them straight out of the freezer when you're ready to eat.

To cook gnocchi: Bring two quarts of water to a rolling boil. Add a handful or so of gnocchi to the pot and cook until they float on top. Then, allow them to cook a minute or two more, fish them out with a slotted spoon.

From there, the service options are endless. You can float them in a bowl of soup, or fry them up in a little brown butter. My favorite way to eat them is to fry up some kielbasa, remove it from the pan, and then fry about four cups of cooked gnocchi in two tablespoons of butter in a non-stick pan. Once the dumplings are toasted on both sides, turn off the heat, and add 1/4 cup of brown sugar and two tablespoons of your favorite hot sauce. Serve hot, after you've grated tons of parmesan cheese on top. It's not Italian by a long shot, but it's easily my favorite way to eat gnocchi.

0 notes

Video

youtube

A new post-NATO Europe? EU has 'lost confidence' and 'no longer trusts' Current Problems Facing Ukraine Ukraine is in the thick of a brutal war with Russia, which kicked off in 2014 with the annexation of Crimea and escalated into a full-scale invasion in 2022. This conflict has unleashed a cascade of problems that are hitting the country from every angle. Here’s a rundown of what Ukraine is dealing with right now: Manpower and Armament Shortages Ukraine’s military is stretched to the breaking point. They’ve been fighting heroically, but they’re running out of soldiers and weapons. The war has turned into a grinding battle of attrition—both sides trying to wear each other down—and Ukraine’s troops are exhausted. They’re short on artillery shells, air defense systems, and advanced gear like fighter jets. Without more people and equipment, holding the front lines or pushing Russia back is a real struggle. Economic Devastation The war is bleeding Ukraine’s economy dry. Fighting costs a fortune, and Russia’s attacks have wrecked factories, farms, and cities. Experts estimate rebuilding could cost over $1 trillion—money Ukraine doesn’t have. They’re relying on foreign aid just to keep the lights on, and the longer this drags on, the worse it gets. Energy and Infrastructure Crisis Russia’s been hammering Ukraine’s power plants and grids, trying to plunge the country into darkness. With winter looming, this could turn into a disaster—imagine millions of people without heat or electricity in freezing temperatures. Roads, bridges, and hospitals have also been smashed, making everyday life and military logistics a nightmare. Reliance on International Support Ukraine depends heavily on the West—especially the U.S. and Europe—for weapons, money, and humanitarian aid. But there’s a catch: this help isn’t guaranteed forever. Elections or political shifts in places like the U.S. could cut the lifeline, and some allies are starting to show signs of “war fatigue.” It’s a shaky foundation to build a war effort on. Russia’s Allies: China, Iran, and North Korea Russia’s not alone in this fight. China’s pumping in economic and tech support, while Iran and North Korea are sending weapons like drones and missiles. This backup keeps Russia’s war machine chugging along, even under heavy sanctions, making Ukraine’s job way tougher. Territorial Occupation Russia controls about 20% of Ukraine, including Crimea and chunks of the Donbas region. These aren’t just strategic losses—they’re home to millions of Ukrainians now living under Russian rule, facing oppression and worse. Taking that land back is a massive challenge. Humanitarian Nightmare Millions of Ukrainians have fled their homes—some to other parts of the country, others abroad. Missile strikes and drone attacks have turned civilian life into a constant gamble. Homes, schools, and hospitals are rubble, and basic needs like food and water are hard to come by in some areas. Psychological Toll This war’s been going on for years, and it’s breaking people down. Soldiers are traumatized from endless fighting, and civilians are living with the stress of air raid sirens and losing loved ones. That mental strain could haunt Ukraine long after the guns fall silent. How Ukraine Can Defeat Russia and Its Allies Militarily Beating Russia—and its buddies China, Iran, and North Korea—is no small feat. You’re talking about taking down a military powerhouse backed by some seriously stubborn allies. But it’s not impossible. Here’s how Ukraine could pull it off militarily, step by step: Boost Military Power with Western Help Ukraine needs more guns, tanks, and troops—fast. They should ramp up their own weapons production, but that alone won’t cut it. The West needs to step up big time with heavy hitters: long-range missiles, air defense systems like Patriots, and F-16 jets. Training and intelligence from allies can also sharpen Ukraine’s edge. They’ve already shown they’re creative with drones—keep that going and scale it up. Hit Russia Where It Hurts: Economic Warfare Sanctions have dented Russia’s economy, but not enough. Ukraine and its allies need to tighten the screws—target oil and gas exports, tech imports, and financial loopholes. Russia’s dodging sanctions through backdoor deals with countries like India or Turkey; shut those down. Oh, and there’s $300 billion in frozen Russian assets sitting in Western banks—use that cash to fund Ukraine’s war and rebuilding. Build a Global Coalition Diplomacy’s a weapon too. Ukraine should keep rallying the world—NATO, the EU, even the UN—to pile pressure on Russia. They need more than just weapons; economic and humanitarian aid will keep the country standing. Reach out beyond the West—think Asia or Africa—to widen the net of support and isolate Russia further. Neutralize Russia’s Allies China, Iran, and North Korea are thorns in Ukraine’s side. Call them out—loudly—for propping up Russia’s war. Push the U.S. and Europe to slap tougher sanctions on Iran and North Korea’s weapons programs. With China, it’s trickier—they’re an economic giant—but exposing their role might make them think twice about how deep they want to wade in. Plan for the Long Haul This isn’t a quick fight. Ukraine needs a game plan to outlast Russia: keep the military strong, but also prep for what comes after. Secure promises now for billions in reconstruction aid so they can rebuild fast when the time comes. And push hard for NATO membership—it’s the ultimate shield against Russia trying this again. Win the Info War Ukraine’s been great at telling its story—keep it up. Show the world Russia’s war crimes, like bombed hospitals or kidnapped kids, to lock in global support. Counter Putin’s propaganda machine so his lies don’t take root. It’s not just about bullets; it’s about hearts and minds. Stay United and Tough Ukraine’s people are its backbone. They’ve held together through hell—keep that fire burning. A united front, from soldiers to civilians, can outlast Russia’s grind. The Best Solutions of All Time You wanted the best solutions ever, so let’s pull from history’s playbook—strategies that have worked in the toughest fights and could help Ukraine crush Russia for good. These are big-picture ideas with a proven track record: Unity and Grit Look at Britain in World War II—they stared down Nazi bombs and kept fighting because everyone pulled together. Ukraine’s already got that spirit; it’s why they’ve lasted this long. Keep the nation united—soldiers, civilians, leaders—and they’ll outlast Putin’s war machine. Outsmart and Innovate Wars turn on breakthroughs. Tanks smashed trench warfare in World War I; radar saved Britain in World War II. Ukraine’s drone game is strong—push it further. Maybe AI-guided weapons or new cyber tricks could tip the scales. Stay one step ahead of Russia’s playbook. Gang Up with Allies The Allies beat Hitler by teaming up—U.S., UK, Soviet Union, you name it. Ukraine’s got the West in its corner; make that team bigger and tighter. More countries, more resources, more pressure on Russia. A global posse can choke Putin out. Starve the Enemy’s Wallet Economic pressure brought the Soviet Union to its knees in the Cold War—sanctions, trade blocks, the works. Hit Russia’s cash flow harder: oil, gas, tech. If they can’t pay for the war, they can’t fight it. Same goes for their allies—squeeze Iran and North Korea dry. Control the Story The Cold War wasn’t just nukes—it was radio broadcasts and pamphlets tearing down Soviet lies. Ukraine’s winning the PR battle; double down. Flood the world with proof of Russia’s atrocities—let Putin’s own people see the monster he is. A war of words can weaken him at home. Fight Dirty When You Have To The Afghan mujahideen bled the Soviets dry in the ‘80s with hit-and-run tactics. Ukraine’s not facing jungles, but they can still play smart—sabotage Russian supply lines, strike deep with drones, disrupt their command. Make every inch of ground a nightmare for Russia. Lock in Security for Good After World War II, NATO stopped Europe from tearing itself apart again. Ukraine needs that kind of ironclad protection—NATO membership or rock-solid deals with the U.S. and Europe. If Russia knows another attack means facing the world, they’ll think twice. Wrapping It Up Ukraine’s in a brutal spot—short on troops, cash, and power, with Russia and its cronies China, Iran, and North Korea throwing everything they’ve got. But there’s a path forward. Militarily, they need more gear, smarter sanctions, and a global posse to back them up. Long-term, it’s about outlasting Russia and locking in security so Putin—or whoever comes next—can’t try this again. History shows unity, innovation, and teamwork win wars, and Ukraine’s got the guts to make it happen. With the world behind them, they can send Russia packing—for good. What do you think? Anything else you’d add to the mix?

0 notes

Text

Rug Cleaning Perth: Secret Techniques Experts Don't Want You to Know!

Rugs are an essential part of home decor, adding comfort, warmth, and style to any space. However, keeping your rugs clean can be challenging, especially with everyday dust, dirt, and spills. While many homeowners rely on regular cleaning methods, professional cleaners in Perth often use hidden tricks to achieve remarkable results. In this guide, we reveal expert rug cleaning techniques that you can try at home for better results.

1. Ice Cube Trick for Dent Removal

Furniture dents can leave unsightly marks on your rug, making it appear worn and uneven. Instead of struggling with brushing or steaming, try this simple trick:

Place ice cubes on the dented area.

Allow the ice to melt naturally.

Once melted, gently fluff the fibers using a spoon or your fingers.

This method allows the fibers to absorb moisture, helping them regain their original shape. This is a popular trick that professionals use to refresh rugs after rearranging furniture.

2. Baking Soda for Odor Elimination

Rugs can trap unpleasant odors over time, especially in busy households. Professionals often use baking soda to neutralize smells effectively:

Sprinkle baking soda generously over the rug's surface.

Let it sit for at least 30 minutes (or overnight for strong odors).

Vacuum the rug thoroughly to remove the baking soda and trapped odors.

This simple method is highly effective in keeping your rug fresh without harsh chemicals.

3. Vinegar Solution for Stubborn Stains

For stubborn stains like coffee spills or pet accidents, vinegar can work wonders. To treat stains effectively:

Mix equal parts white vinegar and water in a spray bottle.

Spray the solution directly on the stain.

Blot the area with a clean cloth, repeating until the stain disappears.

Rinse with a damp cloth and allow the rug to air dry.

Vinegar’s natural acidity helps break down stains without damaging delicate rug fibers.

4. Cornstarch for Grease and Oil Stains

Grease stains are tricky to remove, but cornstarch offers a simple solution:

Sprinkle cornstarch directly onto the stain.

Let it sit for 15-20 minutes to absorb the oil.

Vacuum the area, then blot any remaining residue with a damp cloth.

This technique is particularly effective on kitchen rugs or areas prone to food spills.

5. Freezing Chewing Gum for Easy Removal

Chewing gum stuck in your rug can seem impossible to remove. Try this freezing method:

Place an ice pack directly over the gum.

Leave it for 5-10 minutes until the gum hardens.

Gently scrape off the frozen gum with a butter knife.

This method prevents sticky residues from spreading further into the fibers.

6. Dry Cleaning Powder for Delicate Rugs

For delicate rugs made of wool or silk, dry cleaning powder is a safer alternative to traditional cleaning solutions. To use this method:

Sprinkle a dry cleaning powder on the rug.

Gently brush the powder into the fibers using a soft brush.

After 30 minutes, vacuum the rug thoroughly.

This method effectively removes dirt and odors without over-wetting your delicate rug.

7. Steam Cleaning for Deep Cleaning

While steam cleaning is often seen as a professional technique, you can try it at home for deeper cleaning. Steam cleaning is ideal for removing embedded dirt, allergens, and bacteria.

Rent a steam cleaner from your local hardware store.

Use mild detergent and warm water in the machine.

Clean the rug in sections to ensure even coverage.

Allow the rug to air dry completely before placing it back in your space.

Benefits of Regular Rug Cleaning

Practicing these expert techniques can greatly improve your rug’s appearance and lifespan. Here are some key benefits of regular rug cleaning:

Healthier Living Environment: Clean rugs reduce allergens, dust mites, and bacteria, improving indoor air quality.

Enhanced Appearance: Removing stains, dirt, and odors restores the original color and texture of your rug.

Extended Lifespan: Regular cleaning prevents fiber damage, keeping your rug in top condition for years.

Odor Control: Eliminating odors keeps your home smelling fresh and inviting.

When to Call Professional Rug Cleaners in Perth

While DIY methods are effective for routine maintenance, some situations require expert care. Consider hiring a professional if:

Your rug has deep-set stains that DIY methods cannot remove.

Your rug is made from delicate materials like silk or wool.

You’re dealing with heavy odors or mold growth.

The rug covers a large area and requires thorough deep cleaning.

Expert rug cleaning Perth services use advanced techniques, eco-friendly solutions, and specialized equipment to deliver outstanding results without damaging your rug.

Conclusion

Maintaining your rugs doesn’t have to be challenging. By using these expert techniques, you can keep your rugs fresh, clean, and vibrant. Whether you tackle stains with vinegar or revive fibers with ice cubes, these secrets can save you time and money. However, for deeply embedded dirt or delicate materials, seeking professional rug cleaning Perth services is the best way to ensure your rug receives the care it deserves.

0 notes

Text

When it comes to dry ice supply in the UAE, one name stands out above the rest — Dry Ice Abu Dhabi. Renowned for its unparalleled quality, reliability, and customer-centric approach, Dry Ice Abu Dhabi has established itself as the best dry ice supplier in the UAE, catering to a wide range of industries with precision and expertise. Click to order dry ice in Abu Dhabi or call 0553635753

Why Choose Dry Ice Abu Dhabi?

Dry ice is a critical component in various industries, from food preservation to medical applications, and even entertainment. However, not all dry ice suppliers are created equal. Dry Ice Abu Dhabi has earned its reputation as the top dry ice supplier in UAE by consistently delivering premium-quality dry ice, exceptional service, and tailored solutions to meet the unique needs of its clients.

Here’s why businesses across the UAE trust Dry Ice Abu Dhabi:

Premium-Quality Dry Ice Dry Ice Abu Dhabi is committed to providing only the highest quality dry ice. Their dry ice is dense, long-lasting, and manufactured using state-of-the-art technology to ensure it meets the strictest industry standards. Whether you need dry ice for food preservation, medical storage, or industrial cleaning, you can count on Dry Ice Abu Dhabi to deliver excellence.

Nationwide Dry Ice Supply As one of the leading dry ice suppliers in the UAE, Dry Ice Abu Dhabi offers fast and reliable delivery services across the entire country. No matter where your business is located, you can rely on them to provide timely and efficient dry ice supply to keep your operations running smoothly.

Industry-Specific Solutions Dry Ice Abu Dhabi understands that different industries have unique requirements. That’s why they offer customized dry ice solutions tailored to the specific needs of their clients. From food and beverage to pharmaceuticals, entertainment, and industrial applications, they have the expertise to provide the right dry ice solution for your business.

Competitive Pricing Despite offering top-tier quality and service, Dry Ice Abu Dhabi maintains competitive pricing, making it an affordable choice for businesses of all sizes. Their commitment to value for money has made them a preferred partner for countless companies across the UAE.

Applications of Dry Ice Across Industries

Dry ice is a versatile product with a wide range of applications. As the leading dry ice supplier in UAE, Dry Ice Abu Dhabi serves numerous industries, including:

1. Food and Beverage Industry

In the food and beverage industry, maintaining the freshness and safety of perishable products is crucial. Dry ice is widely used for freezing and transporting food items, ensuring they remain at the optimal temperature throughout the supply chain. Dry Ice Abu Dhabi provides high-quality dry ice that is perfect for food preservation, helping businesses maintain the integrity of their products.

2. Medical and Pharmaceutical Industry