#hardware counting packaging machine

Explore tagged Tumblr posts

Video

youtube

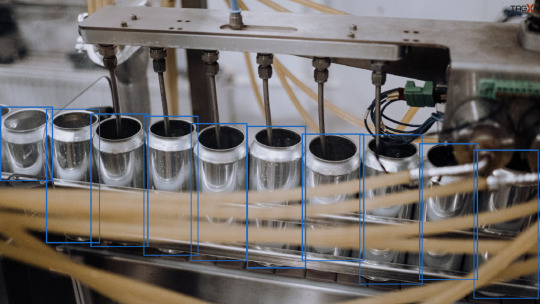

Bathroom Hardware Counting Packing Machine with Noise Insulation Cover

Bestar advanced triple-vibratory bowl counting machine packages mixed bathroom accessories with precision. With custom soundproof enclosure for the vibration bowls and the checkweigher part, to reduce operational noise. The enclosure with door, easy open to feed products and take out finished packages. Perfect for: ✔ Shower hooks ✔ Drain covers ✔ Cabinet knobs ✔ Towel ring screws ✔ Tile spacers Why factories choose this model: ✓ Protected product surfaces ✓ Office-friendly noise levels ✓ One-touch changeovers The discreet powerhouse for premium hardware packaging.

#youtube#packing machine#bathroom hardware#hardware packaging#hardware counting packaging machine#automatic packaging#counting packing machine#bestar packaging#bestar rachel

0 notes

Text

The team learns about Peter's stress baking fairly quickly after he moves into the tower.

"Why does this place smell like cookies?" Tony asks suspiciously, "Pepper put an end to homemade care packages after that Cap incident."

Steve protests from the dining table. "Hey, that fan seemed totally normal. Y'know in my generation you do not mess with baked goods, that's sacred."

Natasha pats his back comfortingly as she joins the conversation.

"They came from the kid. They're actually pretty good, here."

Nat hands a still-warm cookie to Tony, who bites it curiously.

"Damn, it melts in my mouth like buttery ambrosia and still has a perfect crunch around the edges. Is that a nutty aftertaste?"

"Yes!" Peter yells from the other room, a clatter sounding before his head pokes around the wall, oven mitts still attached to his hands.

"I brown the butter, it really deepens the flavour!"

"Good on you kid. What's the occasion?"

Peter stutters, "uhhhh, no occasion. I just like cookies!"

He disappears around the corner again, and Tony sends a confused glance towards his teammates.

Steve shrugs his shoulders, mouth still full of cookie, and Natasha sends him an arched brow. Tony isn't sure what that means, but feels intimidated enough to exit the room anyway.

* * *

The baking lasts the rest of the week, until Peter comes home yelling, "I aced my calculus midterm!!!" running out of the elevator with a stapled set of papers in his hand.

"So no more baking?" Nat asks neutrally.

"Nope! Woohoo!"

Just like that the kid is gone, jumping down the hall towards his bedroom.

Tony looks at Nat quizzically.

"It was midterm week. He baked 3 dozen cookies, 2 types of muffins, and a cheesecake."

"So he stress bakes?"

"He stress bakes."

* * *

It becomes a "thing" in the tower.

Sam eats toast from freshly baked bread one morning while watching Bruce quiz Peter on his upcoming AP history test. Each slice is cut, toasted, and buttered to perfection by Peter while he explains sectionalism in the 20th century.

* * *

Bucky grates carrots while Peter mixes a bowl of dry ingredients furiously, the boy mumbling to himself non-stop.

"Has he gone insane?" Clint asks from the doorway.

"Spanish oral exam," Bucky replies.

"Ay caramba."

"Tal vez pueda sobornar a mi maestra con glaseado de queso crema..." Peter starts mumbling. (Maybe I can bribe my teacher with cream cheese frosting...)

Bucky and Clint share a concerned look.

Clint approaches the boy, "put down the spatula Pete, let's talk about this."

Peter looks up in alarm.

"In English! Just English!"

* * *

"What's up kid? It's spring break, what could you possibly be stressing about."

Today Tony walks into a full kitchen; Wanda, Natasha, and Pepper are occupying the space while Peter pours something creamy into a metal bowl.

"He's asking MJ out tonight, so he's making cookies and cream ice cream in case it goes wrong." Natasha crosses her arms when she replies to him, eyes focused on Peter's mixing.

"Does ice cream even count as stress baking? The very meaning of 'bake' is to put under heat. But I suppose it does feel wrong to call it cooking."

Peter looks up, his brown eyes large and sad like a baby cow, "I still baked the cookies from scratch."

"Yeah he's a real Nara Smith!" Wanda adds enthusiastically.

"Oookay... I'll pretend I know what that means. And since when do we have an ice cream maker?" Tony points to the fancy hardware out on the kitchen counter.

"Oh, I got that for him. We lacked a lot of the tools for basic baking recipes," Pepper informs him.

Tony ponders how ice cream machines count as a basic baking tool, and decides not to argue with three powerful women and their favourite lovesick teenager.

Peter picks up his bowl and moves it into the freezer, clearing away a couple frozen pizzas and a bag of peas.

"Should I even bother with the cones?" Peter asks with a pout.

"Pete she's gonna say yes! Also if you're wallowing in misery with a tub of ice cream we still want our cones so we can emotionally support you with a crunchy treat," Wanda says with a supportive smile.

The others nod along.

"You're right!" Peter agrees before turning around and grabbing an honest-to-god waffle cone maker, with the cone shaping kit to boot.

"Why..." Tony begins to protest, "y'know what, I don't care. Let me know how it goes kid."

The man is ignored as he moves through the kitchen to grab a banana, the women coaching Peter on his manners, flirting, and first date ideas as he exits the room.

* * *

Thor hums around the delicious treat.

"Mmm. You know young Peter, you could have a shop for your creations. Is there a Stark Industries for baked goods?" Thor asks the young lad, crumbs falling from his mouth as he chews the cookie bar.

"I didn't invent the blondie Thor. I was just trying to explain what it is, a cookie brownie! I did decorate them all by myself though," he says with a satisfied grin.

"Ah yes," Thor lifts up another blondie by the pretzel stick Peter put in the squares, attached with a bit of melted chocolate so they're shaped like Mjolnir, "now you are all worthy of the hammer. Ha! This is funny, I'm sure the others will find your talents equally amusing."

Peter picks up his own mini-Mjolnjr and waves it around, "it is I, son of Odin. Don't worry puny Midgardians, I will protect you with my mighty hammer and beautiful hair!"

Thor laughs thunderously at the impression, clapping.

Bruce walks into the room, enticed by the laughter.

"Ah! My friend, Peter has made edible Mjolnirs so you, too, may be worthy. It's delicious and hilarious. Imagine Banner wielding my hammer, ha! Ridiculous," Thor is all too amused by the situation.

Bruce gives Peter an offended look as Thor continues laughing with himself, the younger just shrugging. Bruce takes one of the treats anyways, pointedly not holding it by the pretzel stick.

"Y'know Pete, have you ever considered opening a bakery? You are quite talented. I think the Avengers alone would keep you in business," Bruce asks politely.

"Well I only like to bake when I'm stressed. That wouldn't be a very stable business model," Peter points out.

"True. Although running a business can be quite stressful, so maybe you'd have a continuous supply?"

"Hm. Efficient and unhealthy," Peter nods like it's the perfect plan.

"Wow you really are Stark's intern."

Thor bursts out into another bout of raucous laughter.

"Imagine Stark wielding my dessert hammer," Thor barely gets the words out, "Stark being worthy-AH HAHA."

Bruce and Peter share a look of wide-eyed alarm before joining in on the laughter.

They all share the moment before Bruce straightens up a bit to ask, "what are you even worried about anyways Peter?"

Peter wipes a tear from his eye, "I forgot to call Aunt May this morning like I always do and she only let me move here if I promised I wouldn't neglect her. So now I'm too scared to check my phone."

"I see," Bruce sympathizes.

"Yeah, baking is good for procrastinating. I pretend I'm being productive while also creating comfort food for after my breakdowns."

* * *

Tony steps into the dining room one afternoon to find Peter slicing apples while Steve sits across from him cutting intricate patterns into pie crust. There is an array of leaves and flowers set out on the flour-sprinkled table.

"So is the ornamentation necessary, or is Cap also developing a delicious self-soothing habit," Tony inquires.

"I was just talking to Peter about pie recipes from the 40s and he asked if I could help make his prettier," Steve smiles up at his companions, "it's actually a lot of fun, I can't say I've ever used food to make art before."

"He's a natural talent Mr. Stark!"

Tony agrees with the quirk of an eyebrow and cheeky sideways nod. He observes for a moment before asking something that's been bothering him recently.

"Pete, I gotta ask. Why baking? You inherited your Aunt's terrible cooking skills, and it's not like you're built for other domestic duties. Your room is a mess. What gives? How are you so... refined?"

Peter pauses his chopping to look up incredulously.

"It's science Mr. Stark. Baking is just chemistry! I'm great at chemistry," he says with a grin.

Tony thinks about it.

"Huh. I guess you're right. So, what has you stressed this time? Girl troubles? You get too good a grade in P.E. and Flash is suspicious? Decathlon competition?" Tony lists off some of his previous turmoils.

He hopes it's the decathalon again, those butter tarts were divine.

"Um. Can I finish my apple filling before I tell you? I'll lose motivation if you start yelling at me..." Peter says with a hopeful smile, strain lying underneath it.

Tony's eyes narrow.

"Okay so I maybe blew up your test tubes when trying to develop fire webs and Dum-E may have covered your entire lab in fire supression foam."

Tony's jaw clenches, "I'm gonna let you stew in fear for a bit longer because apple is my favourite - if this was pumpkin you'd already be squashed - but best believe I'm not done with you yet." Tony slowly takes a deep breath before pointing a finger at Peter. "Never change kid, never change."

Tony leaves, distinctly in the opposite direction of his lab, and Peter goes back to slicing apples, now with a genuine smile on his face.

#peter parker#marvel mcu#irondad and spiderson#the avengers#tony stark#spider man#avengers#canon is dead I only know happy found family Stark tower fanfiction#mcu#steve rogers#natasha romanoff#bruce banner#clint barton#thor odinson#pepper potts#wanda maximoff#bucky barnes#sam wilson#peter parker fluff

1K notes

·

View notes

Text

Streamline Your Production with a Parts Collectors Rotary Indexer

In fast-paced manufacturing environments across the USA, managing high volumes of small stamped or machined parts can be challenging. That’s where the Parts Collectors Rotary Indexer comes in—a robust solution designed to automate part collection, reduce manual labor, and improve workflow accuracy.

📦 How It Works

This rotary indexer features a turntable equipped with multiple collection receptacles—typically eight on a standard 36″ diameter platform. You simply set a count mechanism to your desired batch size. Once the target is reached, the table automatically indexes to the next empty bin, ensuring seamless production without manual intervention

🔧 Key Advantages

Accurate Batch Handling: Each batch is consistently counted and sorted, minimizing sorting errors.

Continuous Operation: The rotating carousel allows uninterrupted machine output, even during indexing.

Customizable Configurations: Standard units handle up to 36″ diameters and eight bins—but options extend to larger tables and additional stations .

🏭 Where You’ll Benefit

This equipment finds its value across multiple sectors in the USA, including:

Electronics Assembly: Precise separation of resistors, pins, or connectors.

Automotive: Efficient sorting of clips, washers, and stamped parts.

Fastener Manufacturing: Organizing screws, bolts, and small hardware for packaging or inspection.

🔗 Integrate into Your Production Line

Enhance the efficiency of your rotary indexer by linking it to other key machinery:

Rotary Index Tables: Ideal for machining and component handling between station stops

Conveyor Systems & Ejectors: Automatically deliver parts into rotating receptacles.

Inspection Systems: Conduct quality checks at each indexed position to maintain standards.

Final Word

A Parts Collectors Rotary Indexer significantly optimizes production by automating part collection and sorting, reducing errors, and increasing uptime. It’s an excellent solution for manufacturers aiming to improve efficiency while reducing workforce strain. For more industry-leading solutions, visit the Durant Tool Company homepage today.

0 notes

Text

Vision Sensor Industry Insights Opportunities, Key Applications & Market Dynamics

The vision sensor market was valued at USD 3.3 billion in 2022 and is projected to reach USD 9.12 billion by 2030, growing at a robust CAGR of 13.20%. Rising automation in manufacturing, advancements in image processing technologies, and the integration of vision sensors in industrial robotics are key factors accelerating market expansion worldwide.

Overview

Vision sensors are compact image-processing devices used to capture visual data and make real-time decisions in industrial environments. These sensors combine a camera, processor, and interface in a single housing and are capable of identifying, verifying, measuring, and detecting objects or patterns.

The growing need for quality assurance, increased throughput, and error reduction in manufacturing lines is significantly driving demand for vision sensors. Additionally, the adoption of Industry 4.0, smart factories, and artificial intelligence-powered machine vision has further boosted the relevance of vision sensors across various sectors such as automotive, electronics, packaging, and food and beverage.

With growing emphasis on precision and automation, companies are increasingly investing in smart vision systems that provide real-time analytics, process optimization, and seamless integration with industrial IoT ecosystems.

Market Segmentation

By Type

1D Vision Sensor

2D Vision Sensor

3D Vision Sensor

By Application

Inspection

Gauging

Code Reading

Object Detection

Sorting

Quality Assurance

By Component

Hardware

Cameras

Processors

LED Lighting

Sensors

Software

Image Processing

Detection Algorithms

By End-Use Industry

Automotive

Electronics & Semiconductor

Packaging

Food & Beverage

Pharmaceuticals

Logistics & Warehousing

Metal & Machinery

Key Trends

Rising demand for AI-enabled vision sensors for defect recognition and predictive analysis

Shift from traditional inspection to automated in-line quality control

Integration of 3D vision sensors in collaborative robots (cobots)

Use of cloud-connected vision systems for centralized data management

Deployment of vision sensors in non-industrial applications such as agriculture and smart retail

Segment Insights

Type Insights: 2D vision sensors dominate the market due to widespread use in pattern recognition and barcode reading. However, 3D vision sensors are rapidly growing, especially in robotics and autonomous navigation, where depth perception is crucial.

Application Insights: Inspection and quality assurance are the most common applications, particularly in high-precision industries like electronics and automotive. Object detection and sorting are also witnessing growth in warehousing and logistics sectors.

Component Insights: Hardware accounts for the largest share due to the importance of cameras and sensors in the system's core functionality. However, software innovations are increasingly driving system intelligence and adaptability.

End-User Insights

Automotive: Used for component alignment, welding inspection, and final assembly verification.

Electronics: Ensures precision in PCB inspection, solder joint analysis, and micro-component placement.

Food & Beverage: Applied in label verification, fill-level checks, and packaging integrity.

Pharmaceuticals: Supports counterfeit detection, label authentication, and capsule inspection.

Packaging: Verifies barcode readability, packaging quality, and date/lot code placement.

Logistics: Enables object counting, package sorting, and quality checks in supply chains.

Metal & Machinery: Monitors part dimensions, welding seams, and surface defects.

Regional Analysis

North America: Leads due to strong adoption of industrial automation and smart factories.

Europe: Focuses on sustainable and precision-based manufacturing, boosting sensor integration.

Asia-Pacific: Fastest-growing region driven by massive electronics and automotive production in China, Japan, and South Korea.

Middle East & Africa: Emerging demand from smart infrastructure and industrial safety projects.

Latin America: Increasing adoption in mining, food processing, and consumer goods sectors.

Key Players

Prominent players in the vision sensor market include Cognex Corporation, Keyence Corporation, Omron Corporation, Teledyne Technologies, Balluff GmbH, SICK AG, Basler AG, Banner Engineering, Pepperl+Fuchs, and ifm electronic GmbH. These companies are investing heavily in R&D for AI-powered image processing, multi-sensor integration, and intuitive software interfaces.

Strategic partnerships, acquisitions, and product launches focused on machine learning and deep learning algorithms are enabling these firms to expand their global reach and meet customized industrial requirements.

Future Outlook

The vision sensor market is expected to maintain strong growth momentum due to its critical role in automated quality control, real-time monitoring, and intelligent decision-making. Future developments will focus on miniaturization, higher frame rates, integration with edge computing devices, and deployment in new sectors such as agriculture (crop inspection), smart retail (inventory tracking), and public safety (surveillance and access control).

Trending Report Highlights

Molded Interconnect Device Market

Bioelectronic Sensors Market

FSO VLC Li‑Fi Market

IoT Based Asset Tracking and Monitoring Market

Extreme Ultraviolet EUV Lithography Market

0 notes

Text

Screw Packing Machine

The screw packing machine is a special automatic system designed for accurate counting, sorting and packing of pre-determined quantities. This uses advanced sensors and vibration feeding mechanisms to ensure accurate screw selection and alignment, reduces packing errors and material waste. This machine is ideal for hardware manufacturers, fastener suppliers and assembly kit producers, offering high efficiency, coherent production and low labor costs. Galaxy Packaging Machines is best Screw Packing Machine manufacturers & suppliers in India. We are best source for any packaging machine.

#screw packing machine#packaging machine spare parts#packing machine manufacturer#screw packing machine manufacturer

0 notes

Text

Boundary Scan Hardware Market: Ensuring Testability in an Increasingly Complex Electronics Landscape

The relentless march of technological advancement in the electronics industry is characterized by miniaturization, increasing component density, and the proliferation of complex integrated circuits (ICs). This evolution, while delivering unprecedented performance and functionality, presents significant challenges in terms of testing and validation. Enter Boundary Scan, a standardized on-chip testability feature that has become indispensable for ensuring the quality and reliability of modern electronic assemblies. This blog delves into the Boundary Scan Hardware Market, analyzing its key drivers, segmentation, emerging trends, and promising growth opportunities.

CAGR of 7.6% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

One of the primary drivers is the increasing complexity of printed circuit boards (PCBs). Higher layer counts, finer pitches, and the widespread adoption of Ball Grid Array (BGA) and other surface-mount packages make traditional in-circuit testing (ICT) methods increasingly difficult and, in many cases, impossible. Boundary Scan provides a non-physical access testing mechanism, allowing engineers to control and observe the I/O pins of compliant ICs, effectively bypassing the limitations of physical probes.

Furthermore, the growing demand for high-reliability electronics across industries like aerospace, automotive, and medical devices is a significant catalyst. In these sectors, even minor defects can have critical consequences. Boundary Scan offers a robust and comprehensive testing approach that can detect a wide range of manufacturing defects, including shorts, opens, and incorrect component placement, thereby ensuring the functional integrity and safety of the final product.

The market is segmented based on several criteria. By product type, the market includes:

Boundary Scan Controllers: These are the core hardware units that provide the interface between the test system and the target UUT (Unit Under Test). They generate the test vectors and analyze the responses.

TAP (Test Access Port) Interfaces: These are physical adapters and cables that connect the controller to the JTAG (Joint Test Action Group) connector on the UUT.

Software Integration Tools: While not strictly hardware, these tools are crucial for developing test programs and often bundled with hardware solutions.

By application, the market caters to diverse industries, including:

Telecommunications: Testing complex network equipment and mobile devices.

Aerospace and Defense: Ensuring the reliability of mission-critical avionics and military systems.

Automotive: Validating the intricate electronics within modern vehicles, including ADAS (Advanced Driver-Assistance Systems).

Industrial Automation: Testing control systems and embedded devices used in manufacturing processes.

Consumer Electronics: Ensuring the quality of high-volume electronic goods.

Several emerging trends are shaping the future of the Boundary Scan Hardware Market. Technological advancements are leading to the development of faster controllers with higher channel counts, enabling more efficient testing of increasingly complex boards. The integration of AI and machine learning into test software is also gaining traction, promising intelligent test vector generation and fault diagnosis.

Changing consumer preferences in this market primarily revolve around the demand for more integrated and user-friendly solutions. Engineers are looking for hardware and software combinations that simplify test development, execution, and analysis. There's also a growing emphasis on portability and flexibility, with a demand for compact and adaptable test equipment that can be used in various environments.

Regulatory changes, particularly in high-reliability sectors, are also impacting the market. Stringent quality standards and compliance requirements often mandate the use of comprehensive testing methodologies like Boundary Scan. For instance, aerospace and automotive industries adhere to rigorous testing protocols to ensure product safety and reliability, directly driving the adoption of Boundary Scan hardware.

The growth opportunities within the Boundary Scan Hardware Market are substantial. The continuous increase in electronic content across all industries will necessitate robust testing solutions. The rise of 5G and future communication technologies, with their complex hardware architectures, will further drive demand. Moreover, the increasing focus on functional safety and cybersecurity in connected devices will underscore the importance of thorough testing throughout the product lifecycle.

Furthermore, the integration of Boundary Scan with other test methodologies, such as functional testing and embedded software testing, presents opportunities for more holistic validation strategies. The development of more affordable and accessible Boundary Scan solutions for small and medium-sized enterprises (SMEs) can also unlock new market segments.

In conclusion, the Boundary Scan Hardware Market is a vital and growing segment within the electronics testing landscape. Driven by the increasing complexity of electronics, the demand for high reliability, and continuous technological advancements, Boundary Scan remains a cornerstone for ensuring the quality and functionality of modern electronic assemblies. As technology continues its rapid evolution, the importance and market value of Boundary Scan hardware will only continue to rise, offering significant opportunities for innovation and growth.

0 notes

Text

1 - what was your first distro? Ubuntu 14.10. That my first foray on the family computer into understanding what Linux even was. It lived surprisingly long, I don't really remember what happened to it, and that computer is dead for other reasons anyway.

2 - what was your biggest linux fuckup? All of the times I ran rm -rf on my home directory accidentally. A few of those I managed to cancel before it actually deleted any files. In general just running rm -rf accidentally from searching in history for a file name and pressing enter without looking.

3 - have you ever run rm / on real hardware? Not on the root but on my home dir. Nowadays there is protection against running it on / anyway

4 - do you dual boot or have a secondary machine with windows? Used to have dual boot for a while, but nowadays I have GPU passthrough into a windows virtual machine. I ain't fucking giving windows real hardware, or it will reboot whenever it wants or wake up the computer from sleep to update and reboot (this is a real thing that happens to another computer that is not mine that has windows 11 on it btw btw)

5 - did you change your default shell? Still bash and I do not like any other one, especially zsh because it has different Alt+Backspace and Ctrl+W behaviour than bash that is impossible to change to behave exactly like bash (or at least I was not able to figure it out)

6 - are you afraid of git? No, I am one of the few people I know who actually like git

7 - what was the first machine you installed linux on? Family personal computer. After that it was my own crappy sony vaio laptop that was like 10 years old by then

8 - do you know your way around vim keybinds? I used to be a vim kind of person before emacs, so yes, I do still remember how to use them.

9 - what is your favourite non-os software? Emacs, probably. Kind of crazy how much it can do. QEMU is insane too, surprising how well windows runs in that, almost like it's running on real hardware. The entirety of KDE, I guess, as well. It usually does just work, which I appreciate more and more these days.

10 - biggest linux pet peeve? Dynamic libraries breaking, probably. Not that much of a problem lately because of my current package manager choice, but it used to be something I got very annoyed about when programs stopped working after an update because a dynamic library did not get updated. It still sometimes happens with Qt, but that's about it. Does this even count? Not like anyone will read this post, so it does not matter.

11 - biggest annoyance with the community? The radical free software extremists who do not live in the real word and suggest you use gimp (not even krita) instead of photoshop or LMMS instead of an actual DAW. I'm all for using linux but for some things there is just no good equivalent. There's wine but it is not always perfect and a normal person who is not computer literate will not understand how to set it all up.

12 - do you like your current distro? Yeah. I don't really know that well how to fix any other distro.

13 - Xenia or Tux? I like the design of xenia since it's more of a character than a penguin but tux is pretty funny, i like him too.

14 - what software are you never using again? I will restrict myself to just linux-related software and say nix. I swear I really did try several times to give it a chance and it's just incomprehensible and too much. I do not like their configuration language, and I do not like it canibalizing all package manager, and I do not like it canibalizing all configuration files with half-working solutions that include maybe 20% of the options and then a "... well, you get it, here's also a way to just write the config file as usual but in your system configuration file and we'll append it to the normal file for you", and also it breaking normal unix filesystem pathes so everything has to be installed from nix or patched or ran via the nix shell or it will simply not work.

15 - stock distro or hours of yak shaving? I do prefer to uninstall the things I do not need or want. It used to be worse before, where I would remove things as soon as I no longer needed them. I no longer do this and let the package manager clean them up whenever I clean the system up from unused packages.

16 - have you compiled the kernel? Yes, used to do it for some time, but at some point switched to a binary one because I really do not care that much about the kernel configuration. Things mostly just work nowadays without any custom kernels or anything.

Linux ask game

1 - what was your first distro? 2 - what was your biggest linux fuckup? 3 - have you ever run rm / on real hardware? 4 - do you dual boot or have a secondary machine with windows? 5 - did you change your default shell? 6 - are you afraid of git? 7 - what was the first machine you installed linux on? 8 - do you know your way around vim keybinds? 9 - what is your favourite non-os software? 10- biggest linux pet peeve? 11- biggest annoyance with the community? 12- do you like your current distro? 13- Xenia or Tux? 14- what software are you never using again? 15- stock distro or hours of yak shaving? 16- have you compiled the kernel?

152 notes

·

View notes

Text

Machine Vision Systems Market: A Comprehensive Analysis

The Machine Vision Systems Market has witnessed substantial growth in recent years, driven by the increasing demand for automation across industries, the rise of advanced technologies such as artificial intelligence (AI) and machine learning (ML), and the need for high precision in production and quality control processes. Machine vision systems play a pivotal role in various applications such as inspection, identification, measurement, and visual guidance in industries ranging from manufacturing to healthcare. This blog delves into the current state of the machine vision systems market, highlighting key trends, market segmentation, major players, and future growth prospects.

What is a Machine Vision System?

Machine vision, also known as computer vision, refers to the technology and methods used to provide imaging-based automatic inspection, process control, and robot guidance. A typical machine vision system includes a camera (or multiple cameras), lighting, software, and a computer or processing unit. These components work together to capture, process, and analyze visual data, enabling machines to interpret their environment in ways that resemble human vision. Unlike traditional systems that require human intervention, machine vision systems can automate tasks such as quality inspection, object detection, and pattern recognition with higher speed, accuracy, and consistency.

Market Drivers

Several factors are driving the growth of the machine vision systems market, with the following being the most prominent:

Automation and Industry 4.0: The trend toward automation and the adoption of Industry 4.0 technologies are major catalysts for the machine vision systems market. Manufacturing industries are increasingly using automation to enhance productivity, reduce human error, and ensure consistent quality. Machine vision systems play a critical role in automating tasks such as assembly line inspections, product verification, and robotic guidance.

Quality Control and Inspection: Quality control is a major application area for machine vision systems, particularly in industries like automotive, electronics, pharmaceuticals, and packaging. With consumers demanding higher quality standards and regulations becoming more stringent, manufacturers are turning to machine vision for precise and efficient inspection processes. These systems are capable of detecting even the smallest defects or deviations from standards, thus ensuring product quality and compliance.

AI and Deep Learning Integration: The integration of AI, deep learning, and machine learning algorithms with machine vision systems is revolutionizing the market. These technologies enable systems to learn from data, improve over time, and make more sophisticated decisions. AI-powered machine vision systems can recognize complex patterns, enhance image processing capabilities, and deliver more accurate results in areas such as facial recognition, object classification, and predictive maintenance.

Rising Demand in Healthcare and Pharmaceuticals: The healthcare and pharmaceutical sectors are also increasingly adopting machine vision systems, particularly in areas like drug manufacturing, diagnostic imaging, and medical device inspection. Machine vision is being used for tasks such as counting tablets, inspecting vials, ensuring proper labeling, and detecting anomalies in medical images. As precision and accuracy are critical in healthcare, machine vision systems are proving to be indispensable tools.

Market Segmentation

The machine vision systems market is typically segmented by component, product type, application, and region.

1. By Component:

Hardware: Cameras, frame grabbers, optics, lighting equipment, and processors.

Software: Vision software used for image processing, pattern recognition, and data analysis.

Services: Installation, integration, training, and maintenance services.

2. By Product Type:

PC-based systems: These systems rely on standard personal computers for processing and analyzing images. They offer flexibility and scalability and are used in applications requiring high processing power.

Smart cameras: Smart cameras are all-in-one systems that include a camera, processor, and software in a single device. They are compact, easy to deploy, and ideal for simpler applications.

3. By Application:

Industrial: Machine vision systems are extensively used in manufacturing industries for inspection, identification, quality control, robotic guidance, and measurement tasks.

Healthcare and Medical Devices: In healthcare, machine vision is used for medical imaging, diagnostic procedures, and monitoring applications.

Automotive: The automotive industry uses machine vision for defect detection, assembly verification, and autonomous vehicle navigation.

Consumer Electronics: Machine vision helps in the inspection and testing of electronic components, circuit boards, and displays.

Others: Other applications include food and beverage, packaging, logistics, and transportation.

4. By Region:

North America: The North American market is a leading region in terms of innovation and adoption of machine vision technologies, especially in the U.S. and Canada. The presence of key players and advanced industries fuels the demand for machine vision systems.

Europe: Europe is another major market, with Germany, the UK, and France being prominent contributors. The region's strong manufacturing sector and focus on quality standards drive the adoption of machine vision technologies.

Asia Pacific: The Asia Pacific region is expected to see the highest growth in the machine vision systems market. The rapid industrialization of countries like China, Japan, South Korea, and India, coupled with the growing demand for automation in manufacturing, is driving market expansion in the region.

Rest of the World: Regions like Latin America, the Middle East, and Africa are also witnessing increasing adoption of machine vision systems, particularly in industries such as oil and gas, food processing, and pharmaceuticals.

Key Players

The machine vision systems market is highly competitive, with a mix of established players and new entrants driving innovation. Some of the key players in the market include:

Cognex Corporation: A leading player in machine vision systems, Cognex provides hardware and software solutions for automated inspection, identification, and guidance tasks.

Basler AG: Known for its high-quality cameras and vision components, Basler serves industries such as manufacturing, logistics, and healthcare.

Teledyne Technologies Incorporated: Teledyne offers a wide range of vision systems and components, including cameras, image sensors, and vision processors.

Keyence Corporation: Keyence provides machine vision systems, sensors, and measurement devices for various industrial applications.

OMRON Corporation: A key player in automation and machine vision, OMRON offers solutions for manufacturing, healthcare, and consumer electronics industries.

National Instruments (NI): National Instruments provides vision systems and software for a broad range of industries, including automotive, aerospace, and defense.

Future Outlook and Trends

The machine vision systems market is poised for continued growth, with several trends shaping its future trajectory:

Advancements in AI and Deep Learning: As AI and deep learning technologies become more sophisticated, machine vision systems will continue to improve in terms of accuracy, speed, and decision-making capabilities. AI-driven machine vision will expand into more complex applications such as autonomous vehicles, facial recognition, and predictive maintenance.

Emergence of 3D Vision Systems: 3D machine vision is gaining traction as industries require more detailed and accurate imaging capabilities. 3D vision systems offer enhanced depth perception, enabling applications such as robotic guidance, bin picking, and quality inspection in manufacturing processes.

Miniaturization and Integration: The trend toward smaller, more compact systems is expected to continue. Smart cameras, in particular, are becoming more powerful while maintaining a compact size. This makes them ideal for space-constrained environments and applications requiring easy deployment.

Growth in Non-Industrial Applications: While machine vision has traditionally been associated with manufacturing, non-industrial applications such as healthcare, retail, and agriculture are expected to drive future growth. In healthcare, for example, machine vision can assist in tasks like surgery, diagnostics, and patient monitoring.

Increased Adoption in Emerging Markets: Emerging markets, particularly in Asia Pacific, Latin America, and Africa, are expected to see increased adoption of machine vision technologies as industries in these regions invest in automation and quality control.

Conclusion

The machine vision systems market is evolving rapidly, driven by the growing need for automation, the integration of AI and deep learning, and the demand for high precision across industries. With applications spanning from manufacturing to healthcare, the future of machine vision looks promising, offering new opportunities for innovation and growth. As industries continue to embrace the benefits of machine vision, the market is expected to see robust expansion in the coming years, with a growing focus on smart technologies, 3D vision, and AI-powered systems.

Browse More

Managed Services Market Overview

Medical Device Technologies Market Trends And Growth

Myopia and Presbyopia Treatment Market Size

0 notes

Text

The Best Hardware Packaging Machine Manufacturer in China: Why Choose Xingke for Your Packaging Needs

In the fast-evolving world of packaging, finding reliable and efficient solutions for hardware items can be challenging. Whether you are a manufacturer or distributor, you need a hardware packing machine that delivers precision, durability, and high efficiency. This is where Xingke, a leading hardware packaging machine manufacturer in China, comes in. With years of experience and a strong commitment to quality, Xingke provides innovative packaging solutions that cater to a wide range of hardware products.

Why Choose Xingke for Hardware Packaging Machines?

1. Expertise in Hardware Packaging Xingke is renowned for its specialization in hardware packaging equipment. Our machines are designed to handle various hardware items, including screws, nails, nuts, bolts, and other small parts. We understand the unique challenges of hardware packaging, such as accurate counting, durability, and secure sealing, and we have the expertise to address these requirements effectively.

2. Advanced Technology for Precision and Efficiency Our hardware counting packing machines utilize the latest technology to ensure accurate counting and efficient packaging. Precision is crucial when dealing with hardware components, and our machines are equipped with state-of-the-art systems to minimize errors and maximize productivity. This technology allows businesses to streamline their packaging process, reduce waste, and improve overall operational efficiency.

3. High-Quality Manufacturing Standards As one of the top hardware packaging machine manufacturers in China, we prioritize quality. Our machines are made using durable materials and tested rigorously to ensure long-term performance. Whether you are packaging small hardware components or larger parts, our equipment can handle the task efficiently, reducing downtime and ensuring smooth operations.

4. Customizable Solutions for Diverse Needs Every business has different packaging requirements. Xingke offers customizable solutions to meet the specific needs of our clients. We work closely with businesses to understand their packaging challenges and design solutions that fit their production line seamlessly. This flexibility has made us a preferred choice among companies looking for reliable and adaptable hardware packaging machines.

5. Excellent After-Sales Support We believe that delivering excellent customer service is as important as providing high-quality products. Our team of experts is always ready to assist you with any questions or technical issues you might encounter. With comprehensive after-sales support, we ensure that your hardware packing machine remains operational and efficient throughout its lifespan.

What Makes Xingke the Best Hardware Packaging Machine Manufacturer?

Innovative Technology: Our machines incorporate the latest technology, ensuring precise counting, efficient packaging, and smooth operation.

High Durability: Built with robust materials, our machines can withstand heavy usage and continue to perform at peak levels.

Customization: We tailor our solutions to meet the specific needs of your business, offering versatile and scalable packaging equipment.

Reliable Customer Support: Our dedicated team is committed to providing prompt and effective support whenever you need it.

Competitive Pricing: We offer high-quality machines at competitive prices, ensuring you get the best value for your investment.

Explore Our Range of Hardware Packaging Machines

At Xingke, we offer a comprehensive range of hardware hardware counting packing machine packaging machines to suit different business needs. From automatic counting machines to fully integrated packaging systems, our products are designed to enhance productivity and reduce manual labor. Whether you are looking to package screws, nuts, or other hardware parts, our machines deliver exceptional performance and reliability.

Final Thoughts

Choosing the right hardware packaging machine is crucial for the success of your business. With Xingke, you can be assured of quality, precision, and unmatched service. As a trusted hardware packaging machine manufacturer, we are dedicated to helping businesses improve their packaging processes with reliable and efficient solutions. Contact us today to learn more about our products and how we can help your business grow.

Optimize Your Packaging with Xingke!

Make the right choice for your packaging needs with Xingke, the leading name in hardware packaging equipment. Visit our website to explore our range of products and discover how we can support your business.

0 notes

Text

Professional floor cleaning service in Dhaka -Keep your floors spotless

A clean and well-maintained floor is fundamental for making a clean and outwardly engaging environment, whether it's in your home or office. In a bustling city like Dhaka, where tidy, soil, and stains can effectively gather, keeping up clean floors can be challenging. That's why our professional floor cleaning service in Dhaka is here to assist you achieve flawless floors that upgrade the by and large see and feel of your space.

Our master cleaning group specializes in different sorts of floor surfaces, counting tiles, marble, hardwood, cover, and vinyl. Utilizing state-of-the-art hardware and eco-friendly cleaning arrangements, we guarantee that your floors are deep cleaned, sanitized, and reestablished to their unique sparkle.

Why choose our best floor cleaning service in Dhaka?

Experienced Team: Our trained cleaners have extensive experience in handling different types of flooring, ensuring that no damage occurs during the cleaning process.

Advanced Equipment: We use industry-grade machines to deep clean and remove stubborn stains, grime, and dirt, leaving your floors spotless.

Eco-friendly Products: Our cleaning solutions are safe for your family, pets, and the environment, providing a thorough clean without harmful chemicals.

Tailored Service: Whether you need one-time deep cleaning or regular floor maintenance, we offer customized packages that fit your needs and budget.

Serving All Areas in Dhaka: We provide our floor cleaning services in key areas like Gulshan, Banani, Baridhara, Uttara, Mirpur, Dhanmondi, and more.

Regular floor cleaning not only keeps your space looking fresh but also prolongs the life of your flooring, preventing wear and tear over time. Our best floor cleaning service in Dhaka guarantees high-quality results, ensuring your floors remain in perfect condition, free from stains, dust, and germs.

Contact us today to book your floor cleaning service and experience a cleaner, healthier home or office environment!

#bestfloorcleaningserviceindhaka#floorcleaningserviceindhaka#floorcleaningservicedhaka#floorcleaningservice#floorcleaning

0 notes

Video

youtube

Automatic Counting Packaging Machine with 9 Custom Vibratory Bowls and B...

This heavy-duty packaging system is designed for more than 10 types of hardware components mixing packaging. Machine automated counting for regular-shape products, and worker manual feeding the irregular shape products,. Machine with bucket conveyor to collect all the products which will be packed in the same bag. The complete machine is variety and flexibility application. Machine Advantages: • Nine vibratory counting bowls, each is custom-made according to the products • Matching bucket conveyor for smooth material transfer • Custom-painted on the bowls and buckets for low noise and protect products well • Spacious manual loading station handles non-countable items • Integrated thermal transfer printer for clear bag marking • Big size main packing machine which makes big bag for heavy products packaging

#youtube#packing machine#packaging machine#hardware packaging#hardware packing#counting machine#counting packing machine#automatic counting#automatic packing#automatic machine#Chinesemachine#machinefactory#bestar packaging#bestar rachel

1 note

·

View note

Text

Streamlining Your Move: Assistance and Efficiency with Packers and Movers in India

You will be surprised that it will cost you more effort, time and more money than you expected. It doesn't matter if you are moving locally, but only a few km away or moving locally, the whole speed of moving your whole family or office products is tedious and expensive. With the best packer and India Movers you can do everything you can already be approved and have a quiet step. The following is several focused on how you can help you safely migrate your products Close from the closure:

Register: Packers and Movers Ahmedabad to Kolkata help your transition to propose transitions of your shops, resources, resources, and so that these data that must continuit, what size of the car must move moving products and how your migration is the expected work to complete full movement. As mentioned in these data, your conversion counts and give you a point to talk to the point. With this legitimate preparation, you do not need to emphasize your action.

Save time: Moving Organizations India will help you save a considerable time rule Moving your products with skills skills to move in small skills. If you pack yourself, it can take you many hours, but it can be done by keeping mobilizers and packers in India for a few minutes and maintaining the highest caliber.

Protect Things: India Home Relocation Organizations can protect your home needs by grouping them with special attention and safely assembling and transporting them to give you the best migration management at your home in India. It will destroy your heavy furniture like (bed, sofa, almirah, cabinet, sinks, etc.) and electronic machines (AC, fan, inverter, TV, dishes, lights, water purifier, geese, etc.) with legitimate systems and so on. . op. pack them as indicated on their form and estimate to guarantee total insurance during shipping. They use lightweight printing materials and the latest techniques for safe maintenance and relocation of products, starting in one place and another.

Collection and final condition: India movers will help you make your new home comfortable by unloading your goods after relocation and reassembling all damaged electronic equipment and furniture. . They can help you arrange heavy furniture according to your instructions.

Reasonable grouping and transportation: You have to spend a lot of money on pooling materials, renting a truck, hiring workers to lift heavy products, and extra money if your effects on transportation are compromised. India master packers and packers bring hardware and all the basic binding materials to ensure your family's recordings. The costs of India moving and packaging machines are reasonable and your mobility will be protected and stable.

0 notes

Text

Streamlining Your Move: Assistance and Efficiency with Packers and Movers in India

You will be surprised that it will cost you more effort, time and more money than you expected. It doesn't matter if you are moving locally, but only a few km away or moving locally, the whole speed of moving your whole family or office products is tedious and expensive. With the best packer and India Movers you can do everything you can already be approved and have a quiet step. The following is several focused on how you can help you safely migrate your products Close from the closure:

Register: Packers and Movers Ahmedabad to Kolkata help your transition to propose transitions of your shops, resources, resources, and so that these data that must continuit, what size of the car must move moving products and how your migration is the expected work to complete full movement. As mentioned in these data, your conversion counts and give you a point to talk to the point. With this legitimate preparation, you do not need to emphasize your action.

Save time: Moving Organizations India will help you save a considerable time rule Moving your products with skills skills to move in small skills. If you pack yourself, it can take you many hours, but it can be done by keeping mobilizers and packers in India for a few minutes and maintaining the highest caliber.

Protect Things: India Home Relocation Organizations can protect your home needs by grouping them with special attention and safely assembling and transporting them to give you the best migration management at your home in India. It will destroy your heavy furniture like (bed, sofa, almirah, cabinet, sinks, etc.) and electronic machines (AC, fan, inverter, TV, dishes, lights, water purifier, geese, etc.) with legitimate systems and so on. . op. pack them as indicated on their form and estimate to guarantee total insurance during shipping. They use lightweight printing materials and the latest techniques for safe maintenance and relocation of products, starting in one place and another.

Collection and final condition: India movers will help you make your new home comfortable by unloading your goods after relocation and reassembling all damaged electronic equipment and furniture. . They can help you arrange heavy furniture according to your instructions.

Reasonable grouping and transportation: You have to spend a lot of money on pooling materials, renting a truck, hiring workers to lift heavy products, and extra money if your effects on transportation are compromised. India master packers and packers bring hardware and all the basic binding materials to ensure your family's recordings. The costs of India moving and packaging machines are reasonable and your mobility will be protected and stable.

0 notes

Text

Streamlining Your Move: Assistance and Efficiency with Packers and Movers in India

You will be surprised that it will cost you more effort, time and more money than you expected. It doesn't matter if you are moving locally, but only a few km away or moving locally, the whole speed of moving your whole family or office products is tedious and expensive. With the best packer and India Movers you can do everything you can already be approved and have a quiet step. The following is several focused on how you can help you safely migrate your products Close from the closure:

Register: Packers and Movers Ahmedabad to Kolkata help your transition to propose transitions of your shops, resources, resources, and so that these data that must continuit, what size of the car must move moving products and how your migration is the expected work to complete full movement. As mentioned in these data, your conversion counts and give you a point to talk to the point. With this legitimate preparation, you do not need to emphasize your action.

Save time: Moving Organizations India will help you save a considerable time rule Moving your products with skills skills to move in small skills. If you pack yourself, it can take you many hours, but it can be done by keeping mobilizers and packers in India for a few minutes and maintaining the highest caliber.

Protect Things: India Home Relocation Organizations can protect your home needs by grouping them with special attention and safely assembling and transporting them to give you the best migration management at your home in India. It will destroy your heavy furniture like (bed, sofa, almirah, cabinet, sinks, etc.) and electronic machines (AC, fan, inverter, TV, dishes, lights, water purifier, geese, etc.) with legitimate systems and so on. . op. pack them as indicated on their form and estimate to guarantee total insurance during shipping. They use lightweight printing materials and the latest techniques for safe maintenance and relocation of products, starting in one place and another.

Collection and final condition: India movers will help you make your new home comfortable by unloading your goods after relocation and reassembling all damaged electronic equipment and furniture. . They can help you arrange heavy furniture according to your instructions.

Reasonable grouping and transportation: You have to spend a lot of money on pooling materials, renting a truck, hiring workers to lift heavy products, and extra money if your effects on transportation are compromised. India master packers and packers bring hardware and all the basic binding materials to ensure your family's recordings. The costs of India moving and packaging machines are reasonable and your mobility will be protected and stable.

0 notes

Text

How Computer Vision is accelerating Automation in Manufacturing

Computer Vision has become the most popular and benefited several industries over the past decade, especially in the manufacturing industry. Technology is making a significant impact at every stage of the manufacturing process, from using computer vision in warehouses to modern robotics in R&D labs.

These technological advances in the manufacturing field have helped to reduce production defects, improve product quality, increase flexibility, reduce time and cost, and achieve higher productivity.

In this article, I would like to give you an overview of some of the best uses cases of Computer vision in the manufacturing industry.

Predictive Maintenance

In the worst-case situation, parts or equipment malfunction, and production is halted. Any company that relies on physical components should think about keeping the appropriate machinery or equipment in good working order. Predictive maintenance is described as the process of determining when asset management is required utilizing machine learning and IoT. This allows the manufacturer to optimize the lifetime of the equipment and reduce performance.

By utilizing time-series data, machine learning algorithms fine-tunes the Predictive Maintenance system to analyze failure patterns and predict possible issues. When sensors track such parameters as moisture, temperature, or density, these data are collected and processed by a machine learning algorithm. There are several machine learning models that are able to predict equipment failure.

Reading Text and Barcodes

Recognizing and reading barcodes and text is not an easy task to do each and every day. To solve this problem, future factories will witness the growth of modernized computer vision systems and industrial automation. By implementing a computer vision solution, Printed Circuit Boards (PCB) manufacturers can drive the savings of business.

Industries are incorporating Optical Character Recognition (OCR) technology to make real-time data in the image machine useful and readable. Hardware or Software vendors are implementing advanced text recognition technologies increasingly such as Optical Mark Recognition (OMR), Intelligent Character Recognition (ICR), and Barcode Recognition (OBR), and other image processing technologies to enhance the functionality of existing computer vision systems.

Safety and Security Standards

Employees in the manufacturing business labor in extremely hazardous conditions, putting them at a substantially higher risk of harm. Failure to follow safety and security guidelines can result in serious injury or even death. Even though manufacturing companies have cameras installed to monitor employee movement in the plant to ensure safety standards, it is largely a manual monitoring process where an employee must sit and constantly monitor the video stream. The manual processes are error-prone and this error could result in serious consequences.

An AI-powered computer vision can be an appropriate solution. This application constantly monitors the manufacturing site right from the entry point, into the site, and exit point. Even if there is a minor violation in compliance, the system reports to a respective manager and alerts the employees too. This way, manufacturing companies can ensure their employees adhere to safety and security standards.

Packaging Standards

Counting the number of manufactured components before packaging them in a container is significant in some manufacturing organizations. Manually completing this operation can result in numerous problems. Pharmaceutical and retail products are more prone to this issue. Using a computer vision system to count the number of pieces during the packing process ensures that packaging standards are maintained.

Once the items are properly packed, another use case for computer vision is inspecting any damage on the packaging itself. It’s important that products get to customers safely and in one piece. Damaged packaging risks damage to the product inside. Computer vision systems can proactively divert any damaged packaging before leaving the plant.

Defect Detection

If you are running the production line, you want to produce flawless components or products! Computer vision is the technology that helps businesses acquire this. Productions lines often fail to achieve 100% accuracy while detecting the present or potential defects in the manufacturing processes. These defects can cause a loss to the manufacturers and customers. It can also increase customer dissatisfaction that can prove fatal for the business.

Machine vision is helping manufacturing units to prevent such situations by detecting the macro and micro level defects in the production line. Making investments in computer vision-based defects detection systems can help industries to make their production lines free from any kinds of defects. AI-based computer vision systems can help with cameras and algorithms that can prevent any mishappenings due to defects.

The Way Forward

Manufacturing industries from all over the globe are implementing modern technologies in their processes with an open heart. They all are working to make the manufacturing processes free from risks, unnecessary costs, and energy-efficient. Computer vision is capable of much more than we once thought. At the same time, each of these diverse applications is powered by one powerful technique: Data annotation.

Using professional annotation services can provide Manufacturing AI innovators with a variety of distinct benefits. Professional annotation services, such as TagX, rely on their teams of annotators to ensure that datasets are of high quality. Annotation work can be handled by experienced managers, which relieves AI businesses of this load.

0 notes

Text

The Efficiency and Precision of Screw Packing Machines

The Screw Packing Machine is designed to streamline the packaging of screws and similar small hardware items. These automated systems eliminate the need for manual counting, sorting, and packing, greatly reducing labor costs and increasing overall productivity. With their high-speed capabilities, screw-packing machines can handle large volumes of screws, significantly outpacing manual methods.

0 notes